Mooney Ranger M20C 1968 Owner's Manual

--

OWNERS

MANUAL

OPERATE THIS AIRCRAFT

ONLY

-

after reading

owners manual-

@

with owners manual on board

@

after you are fully qualified

&

understand

all of

the aircraft operating characteristics& limitations

OWNERS

MANUAL

SERIAL

NUMBERS

680001

&

ON

Neither

this

document (nor any amendment

hereto)

nor anything contained herein shall be constrild as

an

assilmptisn by Mooney Aircraft Corprat on

+a

Pennsylvania corporation, of any of the

obligations

or liabilities

of

its predecessors. Mooney

Aircraft.

Inc.

or

Moaney Corporation, both Texas corporations, or

as

otherwise imposing on Mooney

Aircraft

Corporation

my

of the obligations

or

liabilities

of

its

predecessor@,

NOVEMBER

1967

ISSUE

MBONEY

A

IRCRAFT,

INC.

KERRVI 6 LE, TEXAS

78028

MANUAL NUMBER 68-20C-OM-B

LIST

OF

REVISED

PAGES

ISSUED

PlNSERT LATEST REVISED PAGES

--

DESTROY SUPEWEDED PAGES.

PAGE

DATE

OF

PAGE DATE

OF

NUMBER LATEST WEVlSlORl NUMBER LATEST

REVlSBON

*THE

ASTERISK INDICATES PAGES REVISED, ADDED, OR

DE-

LETED BY THE CURRENT REVISION.

ADDITIONAL COPIES OR CURRENT REVISIONS OF THIS PUBLICATION

MAY BE PURCHASED FROM YOUR LOCAL MOONEY DISTRIBUTOR

OR

DEALER.

7dIt

a&

GENEME DESCRIPTION

..

:

.......

SECTION

SYSTEMS OPERATIONS

...........

SECTION

NORWL PROCEDURES

...........

SECTION

........

EMERGENCY PROCEDURES SECTI[BN

%mP%ATIONS

..................

SECTION

PERPBRWNCE

................

SECTION

SERVICIONG.

...................

SECTION

This manual

is

issued as your operating guide for the

Moomy Ranger. It is important that you--regardless of

your previous experience--carefully read the handbook

from cover to cover and review it frequently.

IMPORTANT: THIS MANUAL CONTAINS Federal

Aviation Agency-Delegation Option Authority APPROVED LIMITATIONS AND MUST BE CARRIED

IN

THE AIRCRAFT

AT

ALL TIMES.

All information and illustrations in this manual are based

on the latest product information available at the time of

publication approval. The right

is

reserved to make changes

at any time without notice. Every effort has been made to

present the material in a clear and convenient manner to

enable you to use the manual as a ready reference. Your

cooperation in reporting presentation and content recom-

mendations

is

solicited.

eO@BeeBseeeBe@t3

Company warrants each new airplane manufactured by it to

be free from defects in material and workmanship under

normal use and service, provided, however, that this warranty

is

limited to making good at Company's factory any

part or parts thereof which shall within

12

months from

date of original airworthiness certificate be returned to

Company with transportation charges prepaid, and which

upon Company's examination shall disclose to Company's

satisfaction to have been thus defective; this warranty being expressly in lieu of all other warranties expressed

or

implied, and all other obligations or liabilities on the part

of Company, and Company neither assumes or authorizes

any other person to assume for it any other liability in connection with the sale of its airplanes. This warranty shall

not apply to any airplane whichshall have been repaired or

altered outside of Company's factory,

whichin the judgment

of Company affects the airplane's stability or reliability,

norwhich in the opinion of the Company has been subject to

misuse, negligence, or accident. Equipment and accessories not manufactured by seller are guaranteed only to

the extent of the original manufacturer's guarantee.

SECTION

I.

GENERAL

DESCRIPTION

DESBGN

FEATURES

..........................

AIRFRAME. 1-2

........................

POWERPLANT

1-2

FLIGHTCONTROLS

....................

-1-3

LANDING GEAR

.......................

I-

3

SPECIFICATIONS

OUTLINE

POWERPLANT

........................

1-3

...................

PRQPELLER

00smes1-4

MNDmGGEAR

.......................

1-4

..........................

FUEL&OIL 1-5

WEIGHT

&

ILOADmG

....................

1.5

...............

BAGGAGECOMPARTMENT 1.5

DESIGN

FEATURES

The

MOONEY

BANGER

is

a low-wing four-place air-

craft with

a

retractable gear. A four-cylinder engine pow-

ers the aircraft for economical,

high-performance flight.

Licensing under Federal Aviation Agency regulations

as-

sures that your Mooney meets all requirements of Normal

Category aircraft.

AIRFRAME

The airframe has a welded, tubular-steel cabin structure

enclosed in sheet-aluminum skins. Stressed skins rivet to

main and auxiliary spars in the wing, stabilizer, and vertical fin. The laminar- flow wing has full wrap- around skins

with flush riveting

over the forward two thirds of the wing

area.

For pitch trim control, the empennage pivots on the aft

fuselage.

A

torque-tube- driven jack screw, bolted to the

rear tail cone

bulkhead, sets the stabilizer angleof attack.

The forward-opening cabin door provides

access to both

front and rear seats. The baggage compartment door

is

above the wing trailing edge to enable baggage loading from

the ground.

POWER PLANT

The power plant

is

a four-cylinder Lycoming engine that

develops

180

horsepower.

A

50-ampere 12-volt generator

or a

6bampere 12-volt alternator supplies ample electrical power for all standard and optional equipment when the

engine

is

operating

at

flight power settings.

The hydraulic propeller governor, using oil pressure for

increasing blade pitch to control engine speed, regulates

the controllable-pitch constant- speed propeller. Spring

and blade aerodynamic forces decrease blade pitch.

FLIGHT CONTROLS

Conventional dual controls link to the control surfaces

through push-pull tubes.

The Mooney Positive Control

(P.C.)

system

is

standard

equipment,

P,

C.

is

a lateral stability control system that

provides a high degree of roll and yaw stability, thereby

enhancing the inherent wings- level flight charac

teristics

of the aircraft. The system works full time from takeoff

through

lmding but can be easily deactivated or overwwered

for flight maneuvers. P,C. allows you, the pilot,

to devote

more time to navigation, traffic surveillance, and communications,

The tricycle landing gear allows maximum taxi vision and

ground maneuvering.

Hy&aulic disc brakes ad a steer-

able nose wheel aid in positive directional control during

taxiing and crosswind

landings.

The standard gear

is

manually retracted.

A

gear warning

horn along with red

and green position lights help prevent

inadvertent gear-up landings. An electrically operated

gear

is

available at extra cost.

The electric gear system

incoqorates

an

airspeed-achated switch

that

prevents

gear retraction until

a

safe airspeed

is

aeained, Amemer-

gency gear e~ension system

is

installed with the optional

electric gear

system*

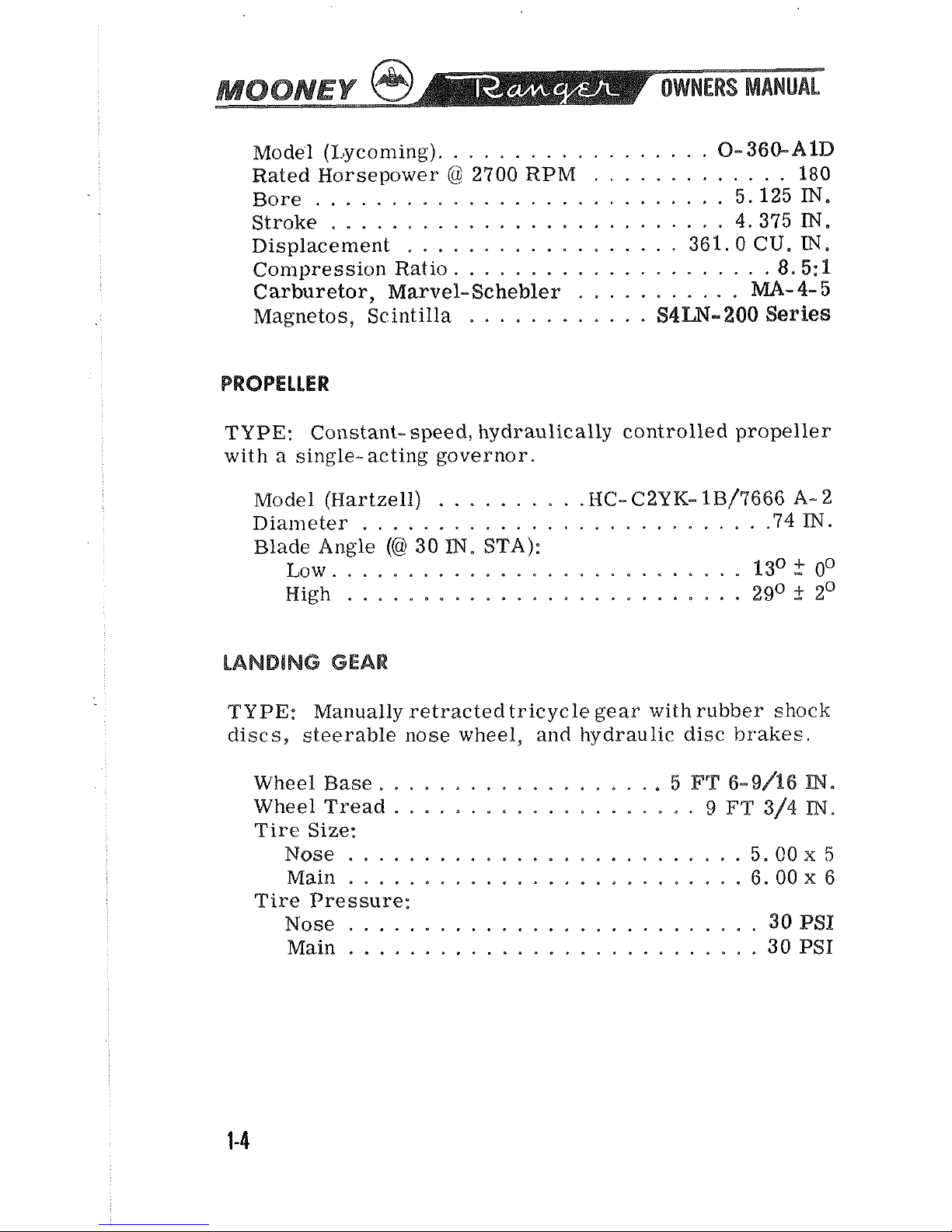

SPECIFICATlONS

OUTLINE

POWER

PUNT

TYPE: Four-cylinder, air-cooled and horizontally opposed

engine

with a wet-sump lubricating system.

.................

Model (I.jyconling).

0-

360-AID

.............

Rated Horsepower @ 2700 RPM

180

...........................

Bore 5.125

IN.

..........................

Stroke

4.375

IN.

..................

Displacement 361.0

CU.

TN.

.....................

Con~pression Ratio

8.5:

1

Carburetor, Marvel- Schebler

...........

MA-

4-

5

............

Magnetos, Scintilla

S4W-

2OQ

Series

PROPELLER

TYPE: Constant- speed, hydraulically controlled propeller

with a single-acting governor.

..........

Model (Hartzell)

HC- C2YK- 1B/7666

A-

2

Diameter

..........................

.74

IN.

Blade Angle

(@

30

IN.

STA):

..........................

Low.

P3O

2

oO

..........................

High 29O

+

2'

LANDlNG

GEAR

TYPE: Manually retracted tricycle gear with rubber shock

discs, steerable nose wheel, and hydraulic disc

brakes.

Wheel Base ...................

5

FT

6-9/16

IN.

Wheel Tread ....................

9

FT

314

IN.

Tire

Size:

Nose

..........................

5.00

x

5

Main

..........................

6.00

x

6

Tire Pressure:

...........................

Nose

30

PSI:

Main

...........................

30

PSI

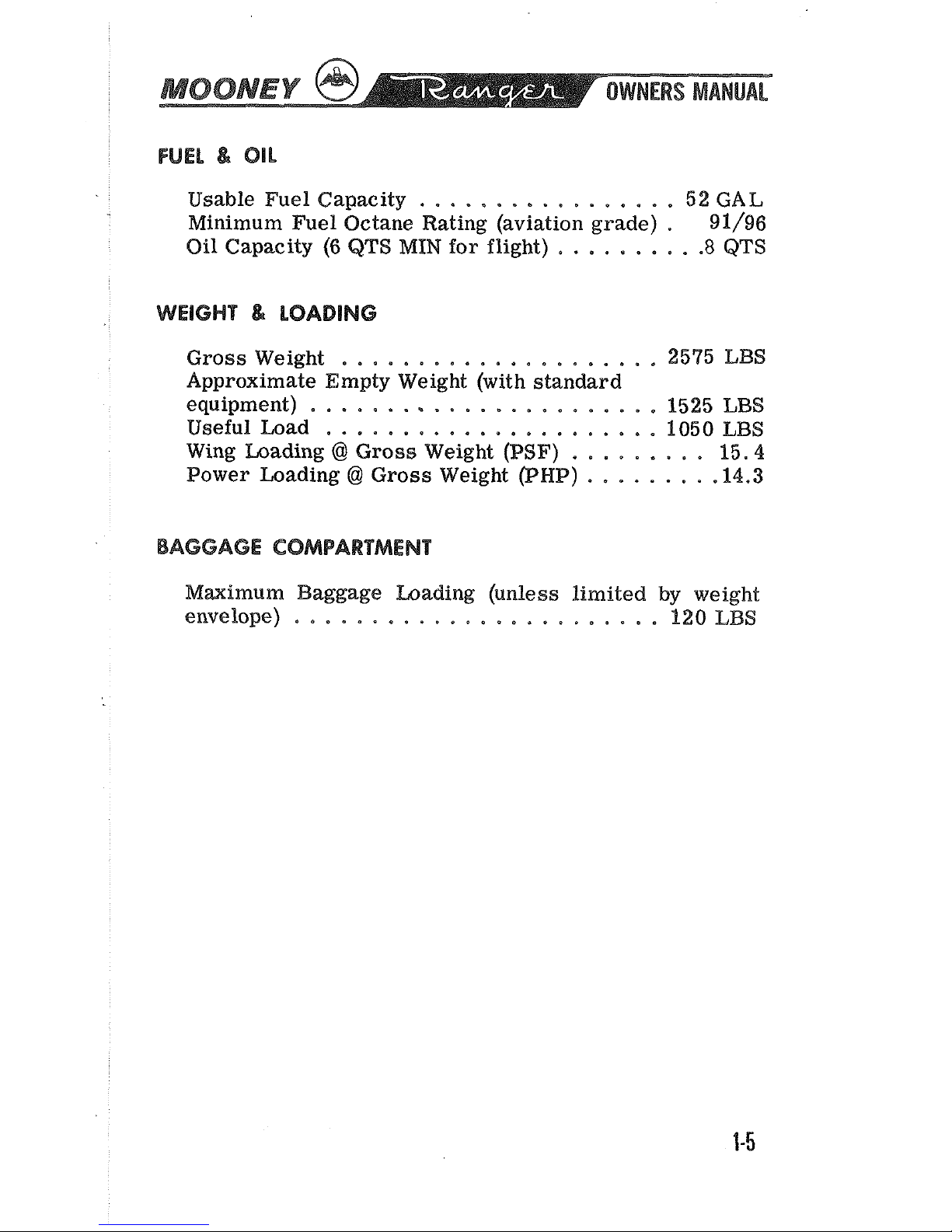

Usable Fuel Capacity

.................

5%

GAL

Minimum Fuel Octane Rating (aviation grade)

.

91/96

Oil Capacity

(6

QTS

MIN

for flight)

.........

.8

QTS

Gross Weight

.....................

2575

IAN

Approximate Empty Weight (with standard

equipment)

.......................

1525

LBS

Useful Load

......................

1050 LBS

Wing Loading

@

Gross Weight

(PSF)

.........

15.4

Power Loading @ Gross Weight (PNP)

........

-14.3

BAGGAGE

COMPARTMENT

Mzimum Baggage bading (unless limited by weight

envelope)

........................

120

LBS

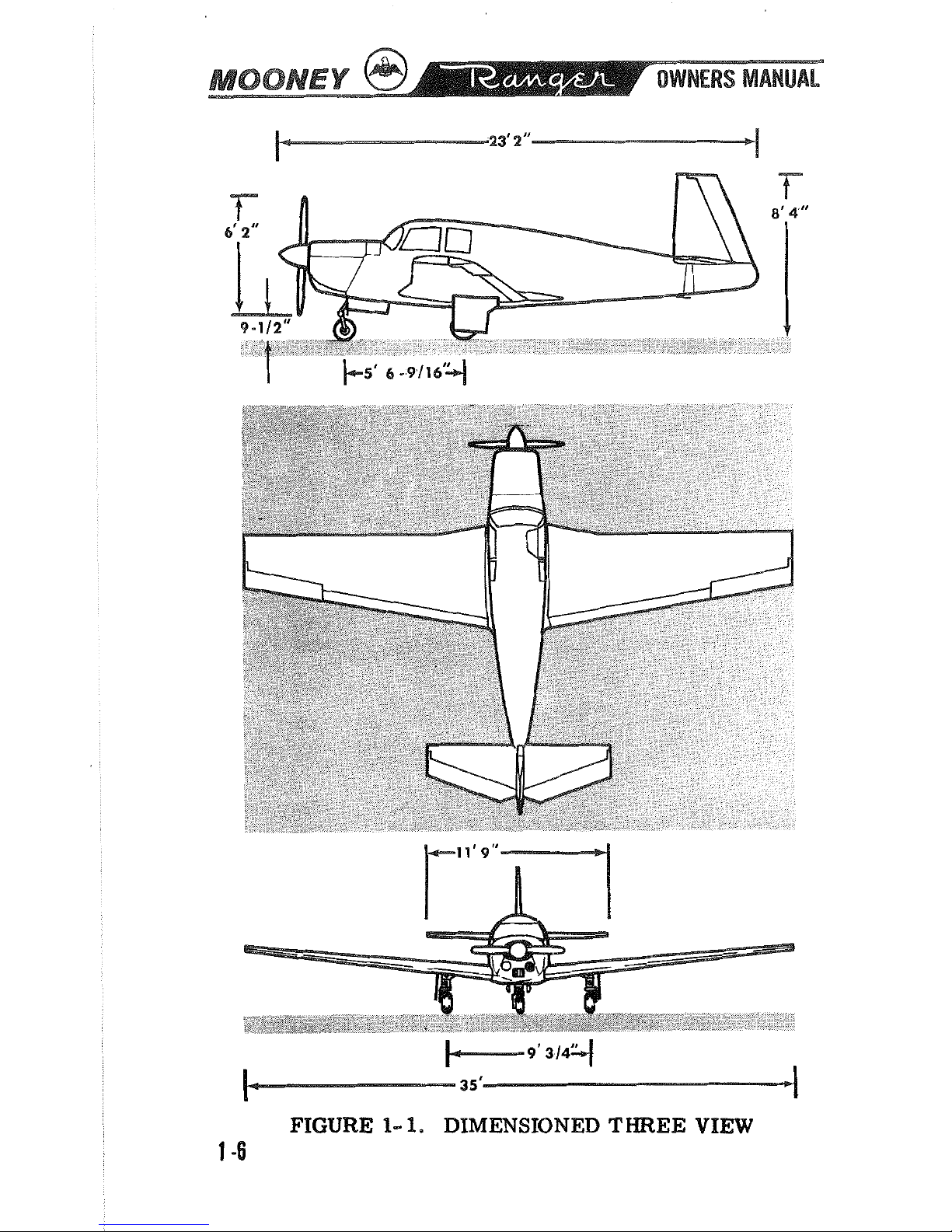

FIGURE

1-

1.

DIMENSIONED THREE VIEW

1

-6

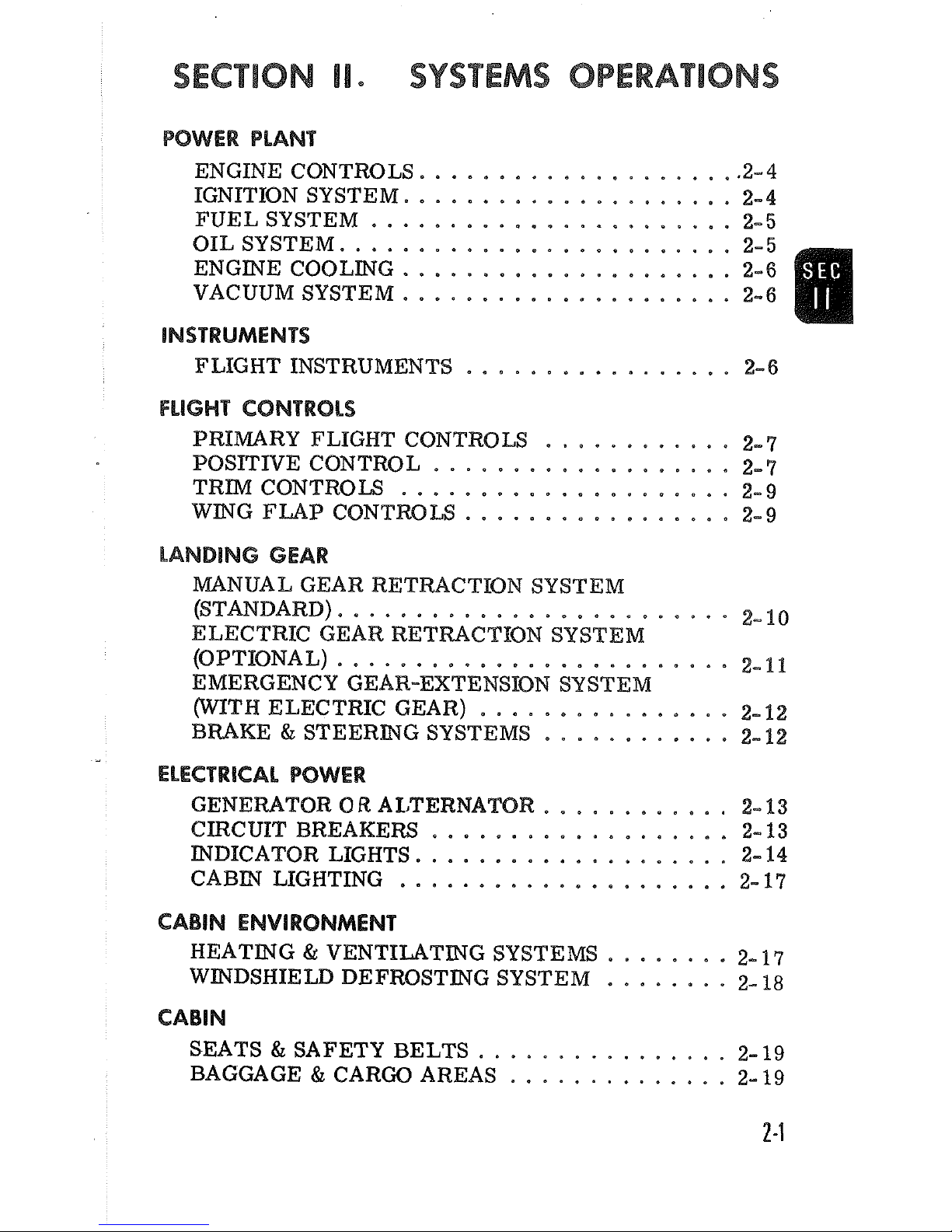

SECTION

SYSTEMS

OPERATIONS

POWER PLANT

....................

ENGINE CONTROLS

-2-4

IGNITION SYSTEM

.....................

2-4

.......................

FUELSYSTEM

2-5

-

OILSYSTEM

.........................

2-5

ENGINE COOLING

.....................

2-6

VACUUMSYSTEM

.....................

2-6

INSTRUMENTS

FLIGHT INSTRUMENTS

.................

2-6

FLlGHP CONTROLS

PRImRY FLIGHT CONTROLS

............

2-7

POSITIVE CONTROL

...................

2-7

TRIM CONTROLS

.....................

2-9

WING

IFUP

GONT128W

.................

2-9

LANDlNG

GEAR

MANUAL GEAR RETMCTICON SYSTEM

.........................

(STANDARD) 2-10

ELECTRIC GEAR

RETMCTION SYSTEM

(OPTIONAL)

.........................

2-11

EMERGENCY GEAR-EXTENSION SYSTEM

(WITH ELECTRIC

GEAR)

................

2-12

BMKE & STEERING SYSTEMS

............

2-12

ELECTRICAL POWER

GENERATOR

O

R

AIjTERMIATOR

............

2-13

CIRCUIT BREAKERS

...................

2-13

INDICATOR LIGHTS

....................

2-14

CABINLIGHTING

.....................

2-17

CABIN ENVIRONMENT

HEATING & VENTILATBNG SYSTEMS

........

2-17

WmDSHIELD DEFROSTING SYSTEM

........

2-18

CABIN

SEATS & SAFETY BELTS

................

2-19

BAGGAGE

&

CARGO AREAS

..............

2- 19

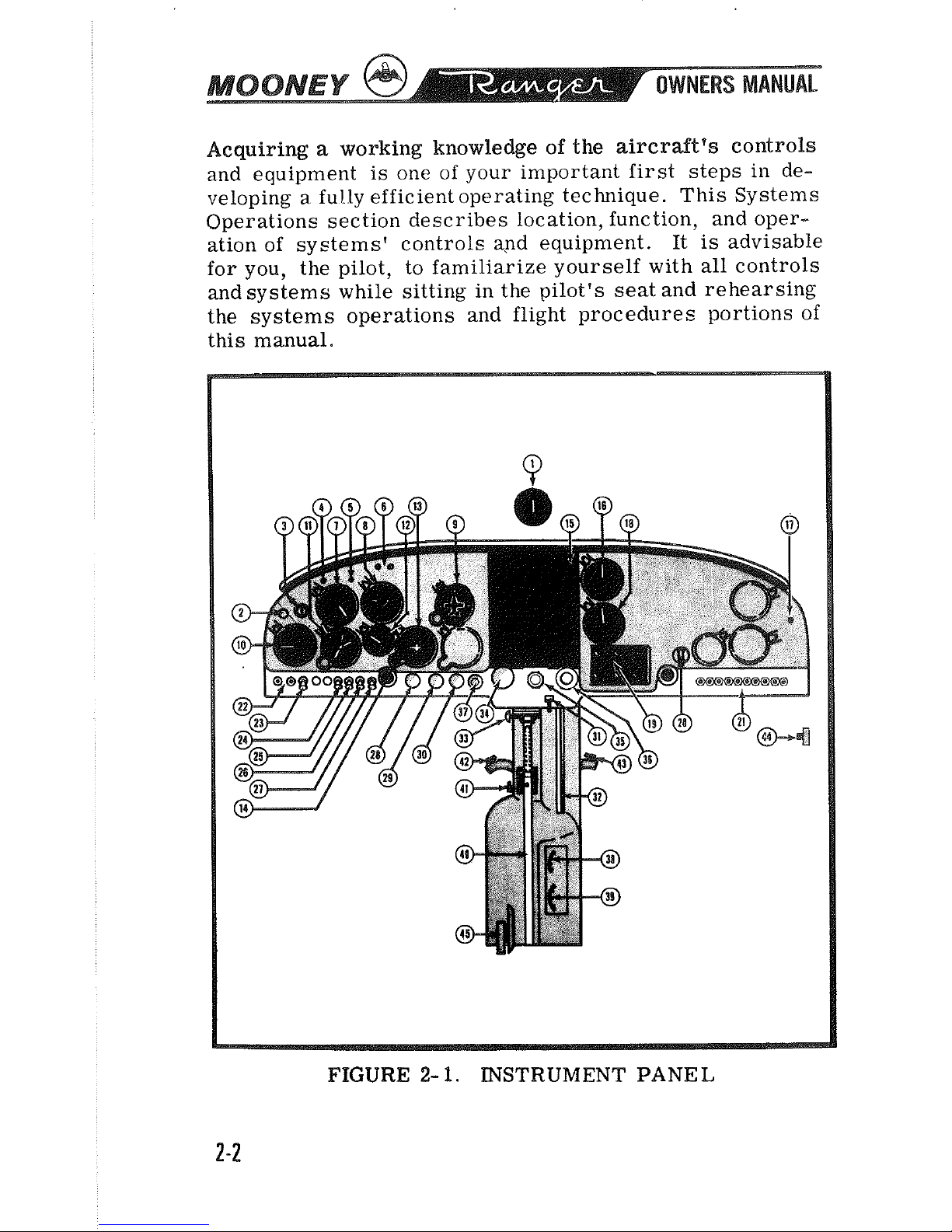

Acquiring a working knowledge

of

the aircraft's controls

and equipment is one of your important first steps in developing

a

fully efficient operating technique. This Systems

Operations section describes location, function, and oper-

ation of systems' controls

and

equipment. It

is

advisable

for you, the pilot, to familiarize yourself with all controls

and systems while sitting in the pilot's seat and rehearsing

the systems operations and flight procedures portions of

this manual.

FIGURE

2-

1.

INSTRUMENT

PANEL

WINDSHIELD CENTER POST

1.

Magnetic Compass

LEFT

PANEL

2. Master Switch

3. Ignition-Starter Switch

4. Gear-Up Signal Light

5. Gear-Down Signal Light

6.

HELO Vacuum Warning

Lights

9.

Airspeed Indicator

8.

Artificial Horizon

(optional)

9. Directional Gyro

(optional)

10. Rate-of- Climb Indicator

(optional)

11.

Altimeter

12. EGT Gage (optional)

13, Turn Coordinator

14,

P.C. Roll-Trim Knob

RADIO

PANEL

15. Radio Equipment

(optional)

RIGHT

PANEL

16. Tachometer

17. Alternator Overvoltage

Warning Light

18. Manifold

Pressure/Fuel

Pressure Gage

19. Engine Cluster Gage:

Fuel Quantity Gage

(L

tank)

Fuel Quantity Gage

@

tank)

Ammeter

Oil Pressure Gage

Oil Temperature Gage

Cylinder Head Temp-

erature Gage

20.

Cigarette Lighter

21. Circuit Breakers

22.

Head Phone & Microphone

Jacks (optional)

23. Electric Fuel Pump Switch

24.

Pitot Heat Switch

25. Anticollision

Light Switch

26. Position Eights Switch

27.

L,anding Light Switch

28. Park Brake Control

29.

Cabin Neat Control

30. Cabin Vent Control

31. Wing Flap Control Knob

32. Wing Flap Pump Handle

33. Gear Lever Safety

Latch

ENGINE CONTrn%.S:

34. Throttle Control

35. Mixture Control

36.

Propeller Control

37. Carburetor Heat Control

d

ENTER

CONSOLE

38. Stabilizer Trim Position

Indicator

39.

Wing Flap Position Pndi-

cator

40. Gear Retracting Lever

41. Main Cabin Heat Inlet

Handle

42. Pilot Heat Inlet Handle

43. Co-pilot Heat Inlet Handle

SIDE PANEL

44. Main-Power Circuit Breake:

Button (Alternator)

CABIN

FLOOR

45. Stabilizer Trim Control

Wheel

46. Fuel Tank Selector Handle

&

Drain (not shown)

PLANT

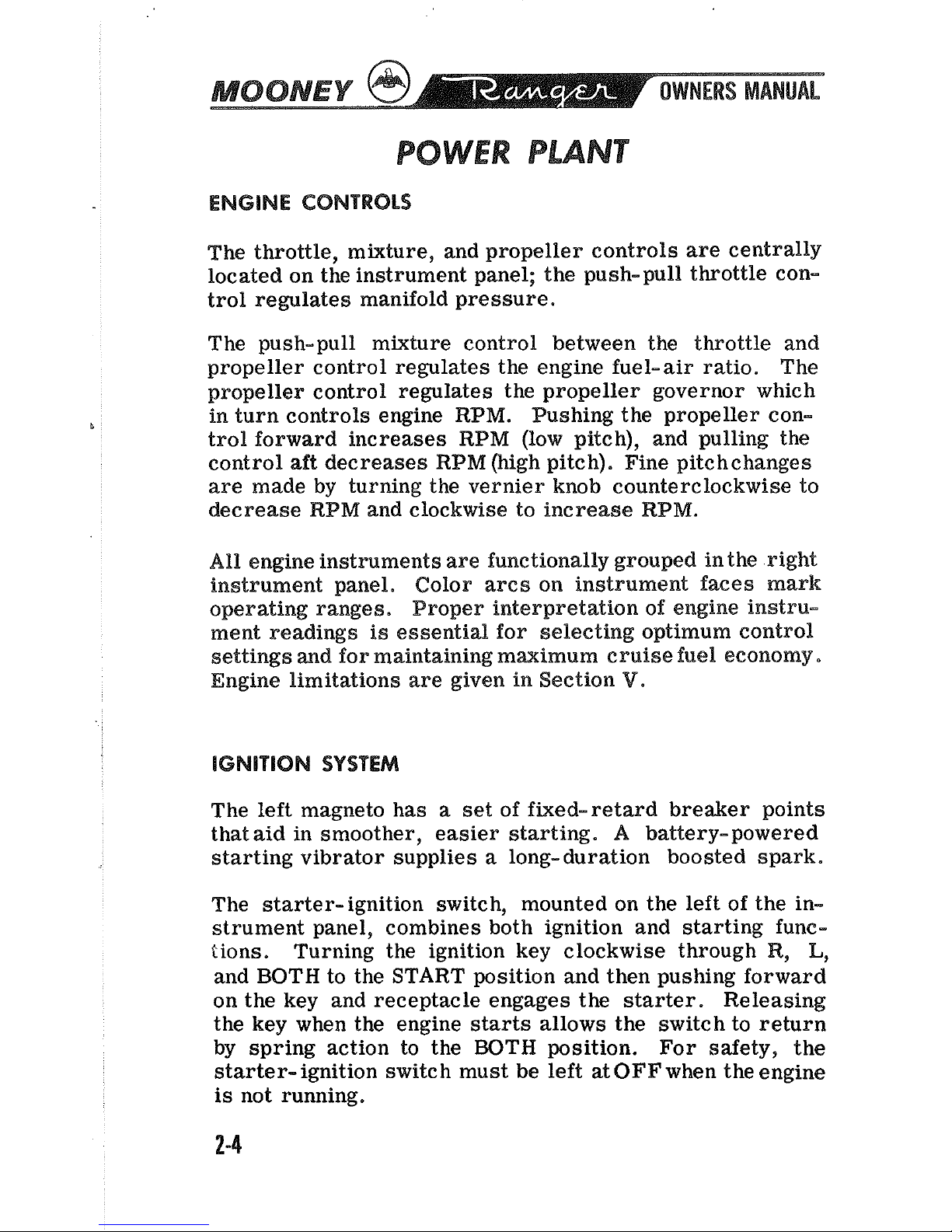

The throttle, mixture, and propeller controls are centrally

located on the instrument panel; the push-pull throttle control regulates manifold pressure.

The push-pull mixture control between the throttle and

propeller control regulates the engine fuel-air ratio. The

propeller control regulates the propeller governor which

in turn controls engine RPM. Pushing the propeller control forward increases RBM (low pitch), and pulling the

control aft decreases RPM (high pitch). Fine pitch changes

are made

by

turning the vernier knob counterclockwise to

decrease

RPM and clockwise to increase RPM.

All engine instruments are functionally grouped in the right

instrument panel. Color arcs on instrument faces mark

operating ranges. Proper interpretation of engine instrument readings is essential for selecting optimum control

settings and for

maintairaing mmimum cruise fuel economy.

Engine limitations are given in Section

V.

IGNITION

SYSTEM

The left magneto has a set of fixed-retard breaker points

that aid in smoother, easier starting.

A

battery-powered

starting vibrator supplies a long- duration boosted spark.

The starter-ignition switch, mounted on the left of the in-

strument panel, combines both ignition and starting functions. Turning the ignition key clockwise through

R,

L,

and BOTH to the START position and then pushing forward

on the key and receptacle engages the starter. Releasing

the key when the engine starts allows the switch to return

by spring action to the

BOTH

position. For safety, the

starter-ignition switch must be left

at

OFFwhen the engine

is

not running.

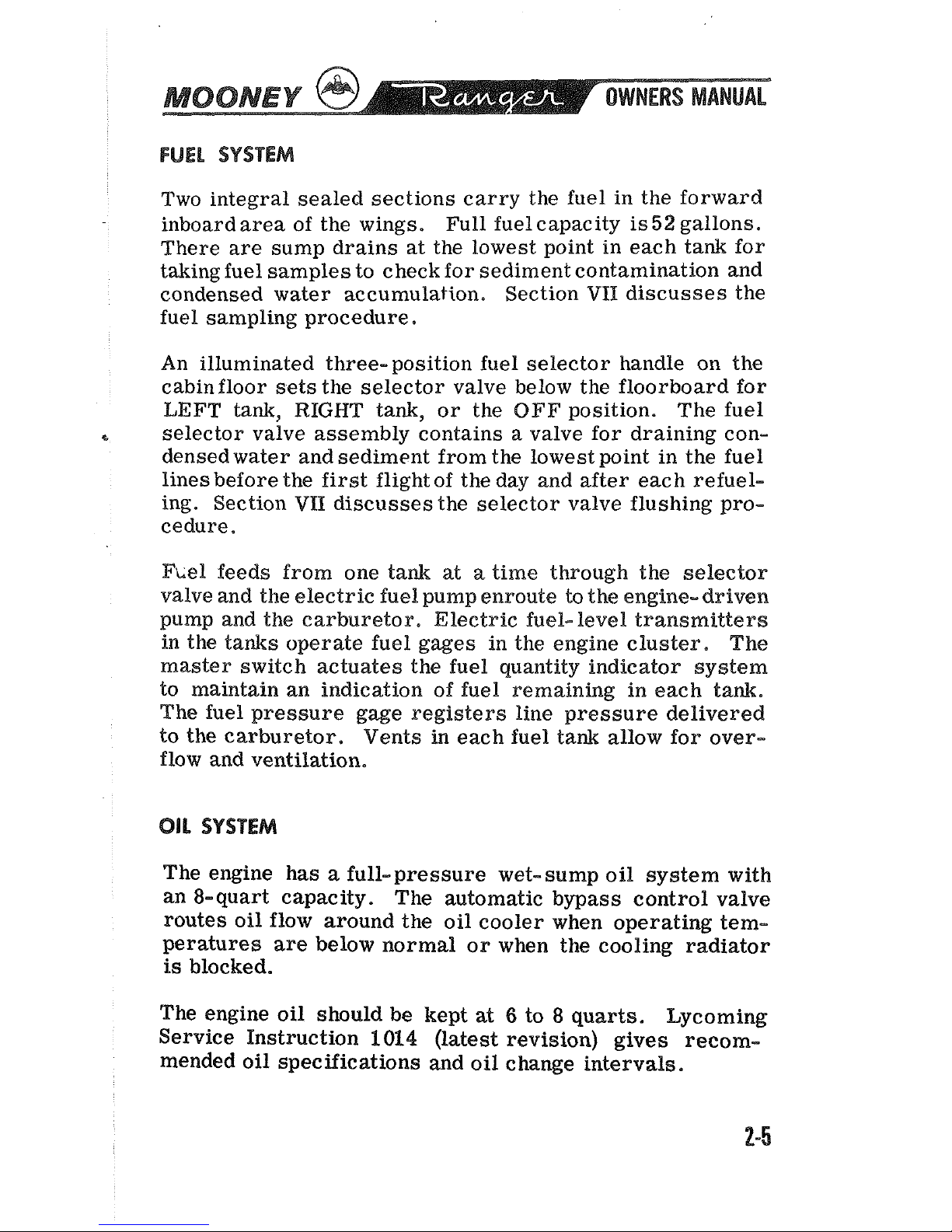

FUEL

SYSTEM

Two integral sealed sections carry the fuel in the forward

inboard area of the wings. Full fuel capacity

is

52

gallons.

There are sump drains at the lowest point in each tank for

taking fuel samples to check for sediment contamination and

condensed water accumulation. Section

VII

discusses the

fuel sampling procedure.

An illuminated three-position fuel selector handle on the

cabinfloor sets the selector valve below the floorboard for

LEFT tank,

RIGHT

tank, or the OFF position. The fuel

selector valve assembly contains a valve for draining

condensedwater and sediment from the lowest point in the fuel

lines before the first flight of the day and after each refueling. Section

VII

discusses the selector valve flushing pro-

cedure.

F~el feeds from one tank at a time through the selector

valve and the electric fuel pump

enroute to the engine- driven

pump and the carburetor. Electric fuel-level transmitters

in the

tanks operate fuel gages in the engine cluster, The

master switch actuates the fuel quantity indicator system

to maintain an indication of fuel

remalnhg in each tank.

The fuel pressure

gage registers line pressure delivered

to the carburetor. Vents in each fuel tank allow for overflow and ventilation,

Olb

SYSTEM

The engine has a full-pressure wet-sump oil system with

an 8-quart capacity. The automatic bypass control valve

routes oil

flow around the oil cooler when operating tem-

peratures are below normal or when the cooling radiator

is

blocked.

The engine oil should be kept at

6

to 8 quarts.

Lycoming

Service Instruction

1014

(latest revision) gives recom-

mended oil spec if'ications and oil change intervals.

The down-draft engine coollng system provides ground and

inflight power plant cooling. Engine baffling directs air over

and

around the cylinders and out the cowl flap openings.

VACUUM

S"SSPEM

An engine- driven vacuum pump supplies suction for the optional gyroscopic flight instruments and the Mooney Positive Control system. Air entering the vacuum-powered

instruments

is

filtered; hence, sluggish or erratic

opera-

tion of vacuum-driven instruments may indicate that

a

clogged vacuum filter element

is

preventing adequate air

intake. The

HI

or

LO

indicator light will glow

if

vacuum

is

above or below limits.

INSTRUMENTS

FLIGHT

INSTRUMENTS

All primary flight instruments are grouped on the floating

shock-mounted flight panel directly in front of the pilot's

seat. Standard flight instrumentation includes the airspeed

indicator, the altimeter, and the turn coordinator. The optional flight instruments are the artificial horizon, the

direction gyro, and the vertical speed indicator. The flapposition indicator

is

in the center console below the instru-

ment panel.

An optional eight-day clock can be mounted in the pilot's

control wheel. The magnetic compass

is

mounted on the

windshield post above the instrument panel. The outside

air temperature gage with probe is installed through the

winds hie ld.

A

pitot tube, mounted on the lower surface of the left wing,

picks up airspeed indicator ram air. An optional heated

pitot prevents pitot tube icing. Static ports on each side

of the tail cone supply static airpressure for the altimeter

and the airspeed indicator. An optional alternate static

pressure source valve may be installed.

A

stall warning horn, triggered by a sensing vane on the

left wing leading edge, will sound when airspeed drops to

near stall speed. Landing gear position lights on the panel

will show red when the gear

is

retracted, Reducing power

below

10

inches manifold pressure when the gear

is

not in

the down- and- locked position will cause the gear warning

horn to sound.

FLIGHT

CONTROLS

PR%MARPI

FLIGHT

CONTROLS

Push-pull tubes withself-aligning rodend bearings actuate

the primary flight eo~tsol surfaces.

Beveled aileron

trailing edges help reduce pilot control forces requiredfor flight

maneuvering. A spring- loaded interconnect device indirectly joins the aileron and rudder control systems to assist in

lateral

aund

directional stability during flight maneuvers.

Control surface gap strips

minimize airflow sooilage at the

hinge

sbts and reduce drag. The co-pilot's rudder pedals

are removable.

POSITIVE

CONTROL

The Mooney Positive Control

(B.C.)

system provides a high

degree of roll and yaw stability, thereby enhancing the inherent wings- level flight characteristics of the aircraft.

Positive Control will hold an average heading over a long

periodof time when the aircraft

is

trimmed properly. However, without the installation of a magnetic heading lock,

P.C. will not maintain an absolute preselected heading.

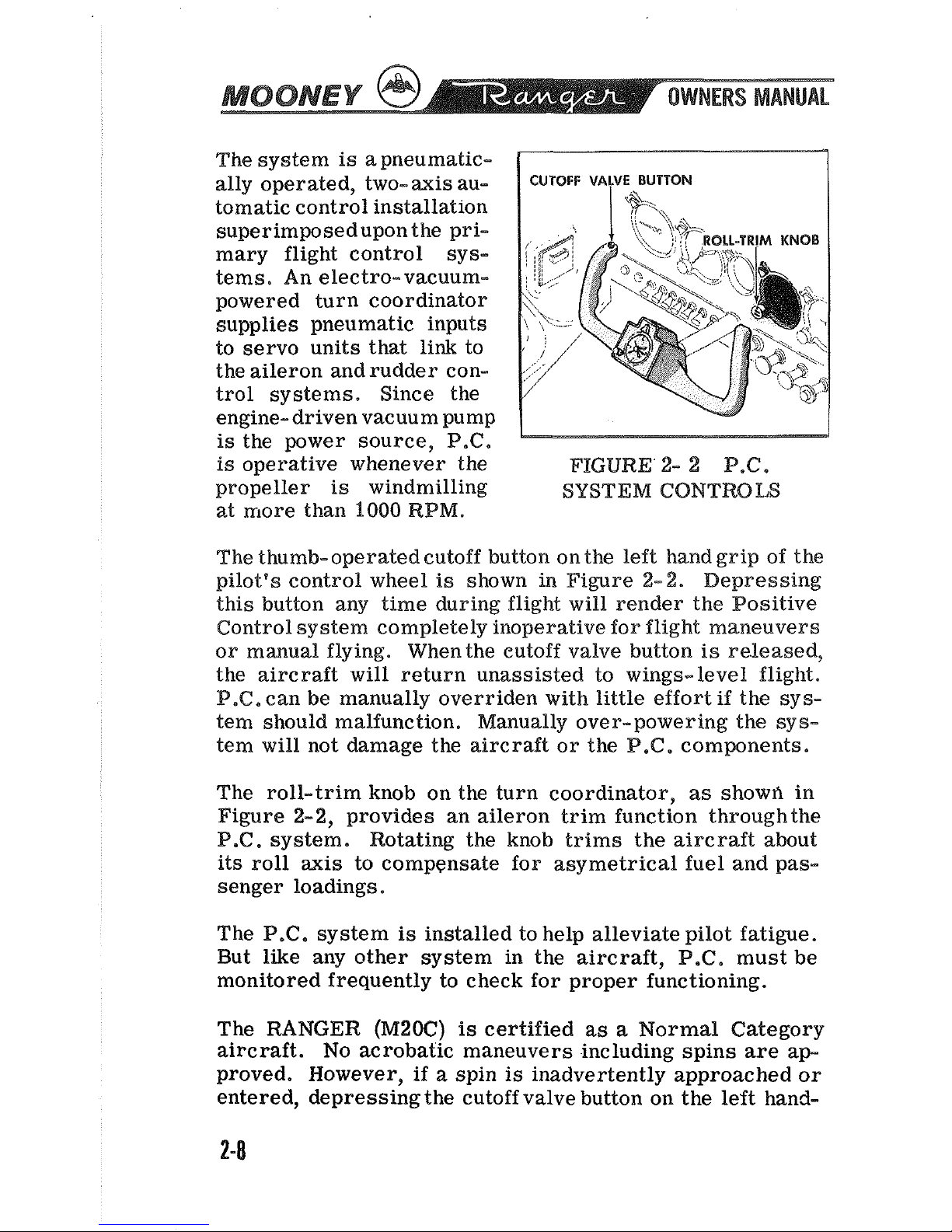

The system

is

a

pneumatic-

ally operated, two- axis au-

tomatic control installation

superimposedupon the primary flight control systems. An electro-vacuumpowered turn coordinator

supplies pneumatic inputs

to servo units that link to

the aileron and rudder control systems. Since the

engine- driven vacuum pump

is

the power source,

B.C.

is

operative whenever the

FIGURE' 2-

2

P.C.

propeller

is

windmilling

SYSTEM

CONTNLS

at more than

1000

RPM.

CUTOFF

VALVE

BUTTON

The

thumb-operated cutoff button on the left hand grip of the

pilot's control wheel

is

shown in Figure

2-2.

Depressing

this button any time during flight will render the Positive

Control system completely inoperative for flight maneuvers

or manual flying. When the

eutoff valve button is re.leased,

the aircraft will return unassisted to wings-level flight.

P.C.

can be manually overriden with little effort

if

the sys-

tem should malfunction. Manually over- powering the sy

s-

tem will not damage the aircraft or the

Be@.

components.

The roll-trim knob on the turn coordinator,

as

showrl in

Figure 2-2, provides an aileron trim function through the

P.C.

system. Rotating the knob trims the aircraft about

its roll axis to compensate for asymetrical fuel and passenger loadings.

The

P.C.

system

is

installed to help alleviate pilot fatigue.

But like any other system in the aircraft,

P.C.

must be

monitored frequently to check for proper functioning.

The RANGER

(M20C)

is

certified as a Normal Category

aircraft. No acrobatic maneuvers including spins are approved. However, if a spin is inadvertently approached or

entered, depressing the cutoff valve button on the left hand-

grip of the pilot's control wheel will de-energize the

P.C.

system while using normal spin recovery techniques. Spin

recovery can be executed from the

co- pilot's side

by

over-

powering the

P.G.

system.

TRIM CONTROLS

For pitch trim control, the entire empennage pivots on the

tail cone

attachmentpoints to increase or decrease the hori-

zontal stabilizer angle of attack. This design allows flight

trim establishment with minimum control surface deflection.

A

pointer in a slot located in the center console below the

instrument panel indicates stabilizer trim position. Forward rotation of the trim wheel lowers the nose; rearward

rotation raises the nose in flight.

WING

FMP

CONTROLS

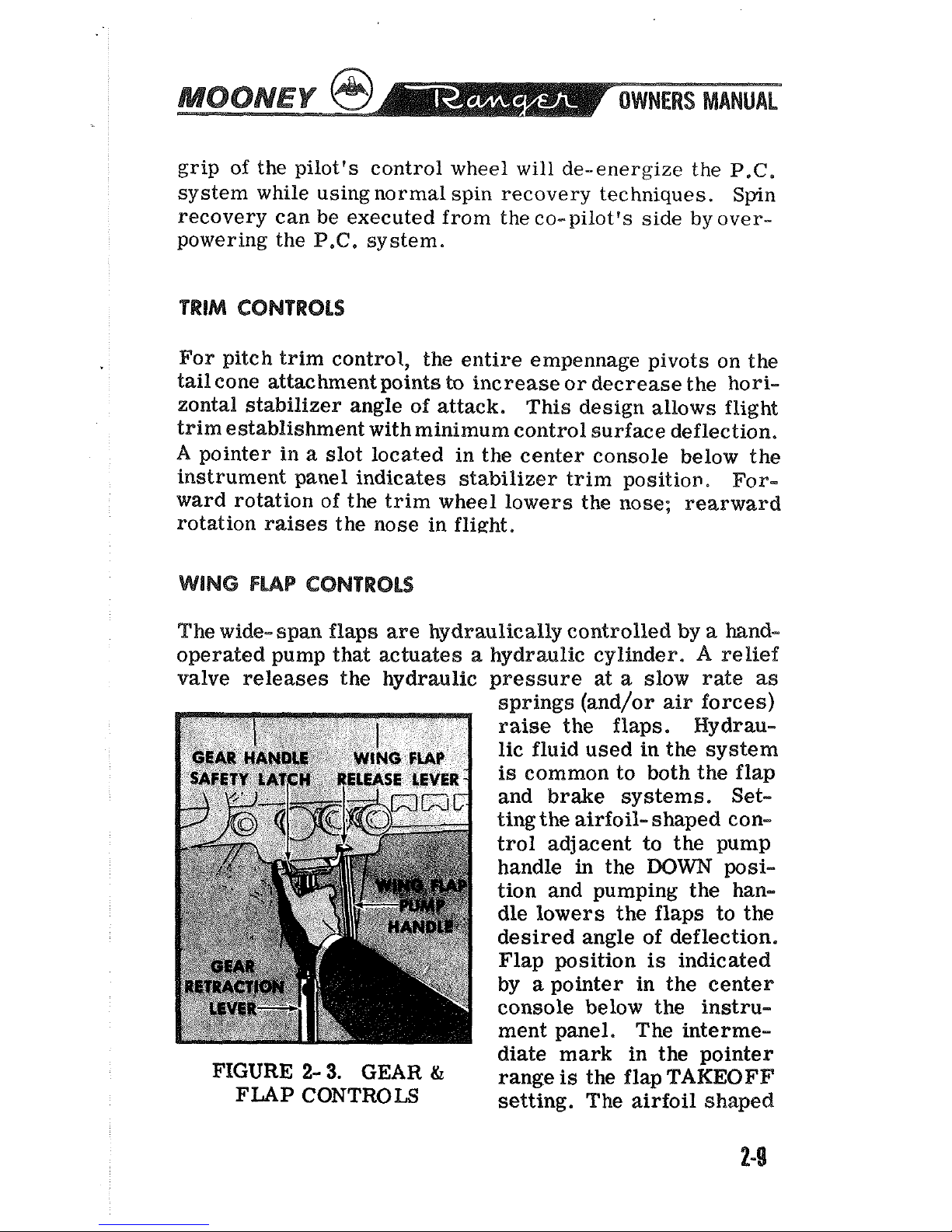

The wide- span flaps are hydraulically controlled

by

a

hand-

operated pump that actuates

a

hydraulic cylinder. A relief

valve releases the hydraulic pressure

at

a

slow rate

as

FIGURE

2-

3.

GEAR

&

FLAP

CONTROLS

springs (and/or air forces)

raise the flaps. Hydraulic fluid used in the system

is

common to both the flap

and brake systems. Set-

ting the

airfoil- shaped con-

trol adjacent to the pump

handle in the

DOWN

position and pumping the handle lowers the flaps to the

desired angle of deflection.

Flap

position

is

indicated

by

a

pointer in the center

console below the instrument panel. The intermediate mark in the pointer

range

is

the flap

TAKEOFF

setting. The airfoil shaped

control

is

placed in the

UP

position to retract the flaps.

To stop the flaps at

an

intermediate setting during retrac-

tion, the flap- shaped control

is

simply placed in the

DOW

position,

A

horn emitting a steady tone (different from the lower

pitch, intermittent tone of the gear-warning horn) warns

of approaching

stall,

Both warning horns are inoperative

when the master switch

is

off.

LANDlNG

GEAR

MANUAL

GEAR

RETRACTION

SYSTEM

(STANDARD)

The standard tricycle landing gear

is

unique in that it

is

manually retracted.

The system operates by direct mec-

hanical linkage. Manual retraction of the gear

is

aided by

bungee-type springs in the fuselage and assist springs in

the wing

thatbalance the weight of the gear. Rubber shock

discs in the welded tubular

steel gear structure absorb the

shock of landing and rough terrain taxiing, Red and

green

lights on the instrument panel indicate gear position, Press-

ing forward the indicator lens housing test- illuminates

the

lights.

Depressing the safety latch button, sliding the gear handle

from the down socket, and moving the lever rapidly to the

floor between the seats retracts the gear. Sliding the handle

into the

uplock socket completes the operation.

The more

rapid the movement of thelever, the easier

it

is

to retract

the gear. The gear will retract easiest

at

low airspeeds.

Sliding the gear handle from the

uplock socket and moving

the lever forward to the instrument panel lowers the gear.

Sliding the handle into the

downlock socket and checking

the green indicator light and safety latch for

a

down-and-

locked indication completes the gear lowering operation.

There are three ways to see that the manually retracted

gear is down- and- locked:

(1)

The gear- down indicator light illuminates.

(2)

The safety latch on the retraction lever handle socket

is

engaged.

(3) The gear warning horndoes not sound at approach pow-

er settings of below

10

inches manifold pressure.

.

The red indicator light (marked GEAR-mEOCK)

is

on

when the handle on the retraction lever

is

not fully engaged

in the down-and-locked position, thereby warning of an unsafe- to- land condition. The green light (marked

GEAR-

LOCK

DN)

indicates that the handle is properly engaged in

the down position and the gear

is

in the landing configuration.

The thumb-operated safety latch on the down socket helps

prevent accidental gear unlocking. When the throttle

is

re-

tarded below

10

inches manifold pressure, a horn emitting

a

low pitch, intermittent tone (different from the steady tone

of the

stall

warning horn) warns of an unlocked gear. Both

warning horns are inoperative when the master switch

is

off.

ELECTRIC

GEAR

WETRACTION

SYSTEM

(OPTIONAL)

The two-position electric gear control switch, identified by

its wheel- shaped knob,

is

located near center of the instru-

ment panel.

There are three ways to see

that

the electrically actuated

gear is down- and- locked:

(I)

The gear-down indicator light illuminates.

(2)

The indicator marks align on the gear position indieator in the floorboard.

(3) The gear warning horn does not sound at approach power

settings of below

10

inches manifold pressure.

Position indicator lights and a warning horn provide visual

and audible gear position signals.

A

red signal light (marked

GEAR-UNLOCK) will show continuously when the gear is

fully retracted. A green signal light (marked GEAR-LOCK

DN)

to the left of the actuating switch shows continuously

when the gear

is

fully extended. Both lights are out

as

the

gear changes position.

The illuminated gear- down position indicator in the floorboard aft of the center console

has

two marks that align

when the gear

is

down. Retarding the throttle below

10

2-11

---

MANUAL

inches manifold pressure causes the gear warning horn to

sound unless the gear

is

down- and- locked.

An airspeed- actuated safety switch in the

pitot system pre-

vents landing gear retraction until attaining

a

safe takeoff

airspeed. The safety switch

is

not designed to substitute

for the gear switch

in

keeping the gear extended while taxi-

ing, taking off, or landing.

When the throttle

is

retarded below 10inches manifold pres-

sure, a horn emitting

a

low pitch, intermittent tone (differ-

ent from the steady tone of the stall warning horn) warns of

anunlocked gear. Both warning horns are inoperative when

the master switch

is

off.

EMERGENCY GEAR-EXTENSiON

SYSTEM

(WITH

ELECTRIC

GEAR)

The emergency gear- extension handcrank on the left uphol-

stery panel near the pilot's knee

is

for manually driving

the electric gear actuating motor if the electrical system

should malfunction. Section

IeFT

discusses the emergency

gear-extension procedure.

BRAKE & STEERING

S"BTEMS

The main gear wheels incorporate self- adjusting disc-type

hydraulic brakes. The pilot's rudder pedals have individual

toe-actuated brake cylinders linked to the rudder pedals.

Depressing the toe pedals

and pulling out the parking brake

control on the instrument panel sets the brakes for parking.

Pushing the parking brake control forward releases the

brakes.

It is inadvisable to set the parking brake control when the

brakes are overheated after heavy braking or when outside

temperatures are unusually high. Trapped hydraulic fluid

may expand with heat to damage the system. Wheel chocks

are normally used for long-time parking

and

mooring.

Rudder pedal action steers the nose wheel. Gear retraction

relieves the rudder control system of

its

nose wheel steering loads and centers the wheel to permit aligned retraction

into the nose wheel well.

ELECTRICAL

POWER

GENERATOR

OR ALTERNAmBR

A

35-ampere-hour negative-ground storage battery in the

engine

cornpaktment supplies direct-current electricalpow-

er. Either a 50-ampere direct-current generator or a

60

ampere self- rectifying alternator provides current for battery charging and electrical equipment operation. The am-

meter in the engine cluster gage indicates battery charging

or discharging rate.

A

power loss in the generator (alternator) or voltage regulator will be shown as a discharge

reading on the ammeter; a discharged battery will be indicated as

a

high charge reading.

The master switch turns on the entire electrical power sup-

ply system. While electrical equipment

is

operating in

flight, the master switch must not be flipped off and on.

The voltage regulator adjusts generator (alternator) output

to current load while maintaining a constant voltage level.

Aircraft with alternator power systems have an overvoltage

warning light on the instrument panel that illuminates when

voltage regulator output exceeds voltage limits.

CIRCUIT

BREAKERS

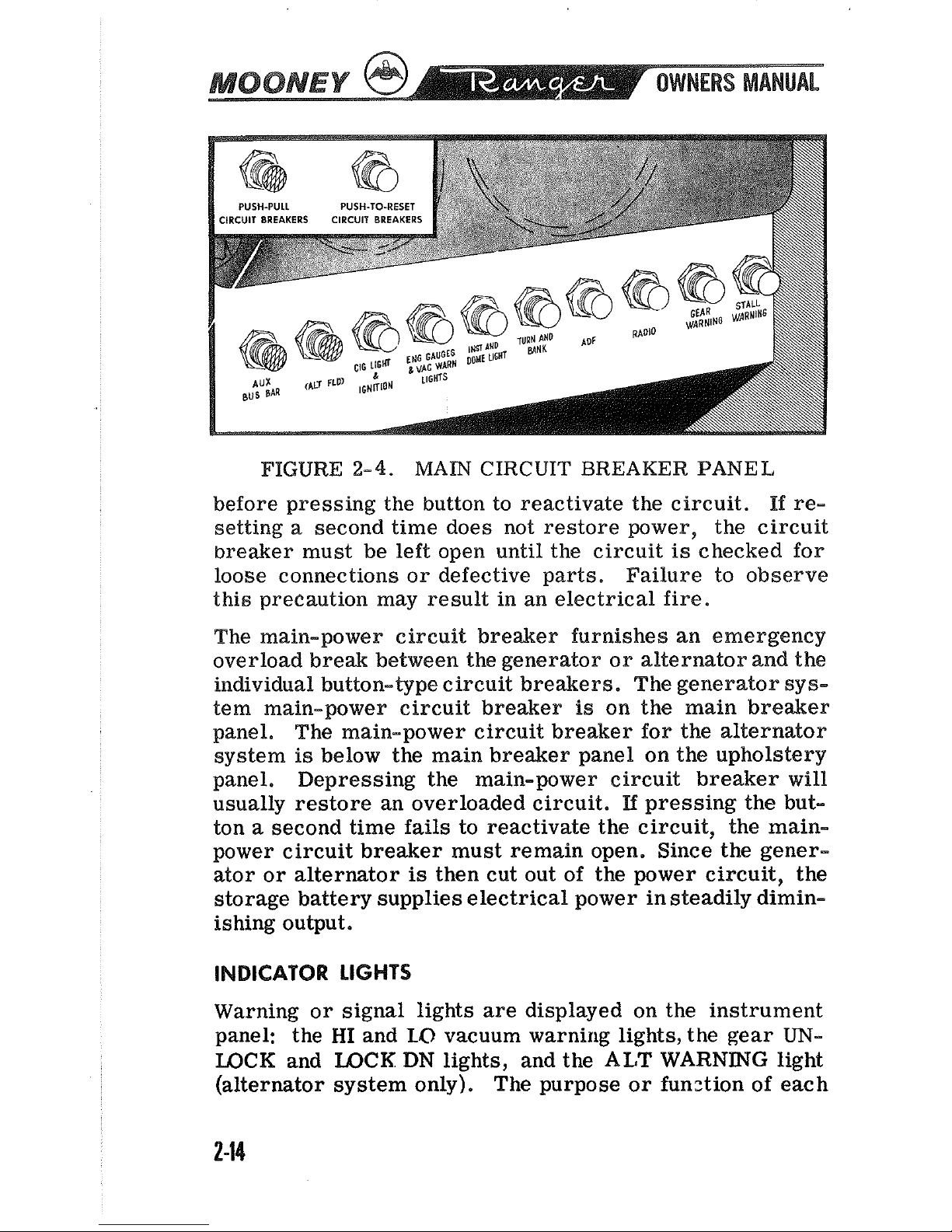

Push- to- reset or toggle- switc hcircuit breakers protect all

of the circuits in the electrical power systems. Circuit

breakers automatically break

the electrical current flow if

the systems receive an overload, thus preventing damage

to electrical wiring. The main circuit breaker panel is in

the right subpanel.

Figure

2-4

illustrates the main circuit breaker panel with its push-to-reset button-type standard equipment circuit breakers. All switch-type circuit

breakers are on the lower left side of the

pilot's instrument

panel.

If

an electrical circuit is found inoperative and its circuit

breaker button

is

in

the out position, it

is

advisable to wait

two or three minutes to permit the breaker contacts

to

cool

FIGURE

2-4.

MAIN

CIRCUIT

BREAKER PANEL

before pressing the button to reactivate the circuit. If re-

setting a second time does not restore power, the circuit

breaker must be left open until the circuit

is

checked for

loose connections or defective parts. Failure to observe

this precaution may result in an electrical fire.

The main-power circuit breaker furnishes an emergency

overload break between the generator or alternator and the

individual button-type circuit breakers. The generator sys-

tem main-power circuit breaker

is

on the main breaker

panel. The main-power circuit breaker for the alternator

system

is

below the main breaker panel on the upholstery

panel. Depressing the main-power circuit breaker will

usually restore an overloaded circuit.

If

pressing the but-

ton a second time

fails

to reactivate the circuit, the mainpower circuit breaker must remain open. Since the generator or alternator

is

then cut out of the power circuit, the

storage battery supplies electrical power in steadily diminishing output.

INDICATOR

LIGHTS

Warning or signal lights are displayed on the instrument

panel: the

HI

and

LO

vacuum warning lights, the gear

UN-

LOCK

and

LOCK

DN

lights, and the

ALT

WARNING

light

(alternator system only). The purpose or

funztion of each

TURN COORDINATOR

INST & WME LIGHTS

CLUSTER GAGE

IGNITION

-

STARTER SWITCH

ALTERNATOR

FIELD

LAXDING UGHT SWITCH

POSITION LIGHT SWITCH

ANTICOL. LIGHT SWITCH (OPT)

HEATED

PITOT SWITCH (OPT)

GLIDE SLOPE SWITCH (OPT)

MARKER BEACON SWITCH (OPT)

FUEL PUMP SWITCH

CIRCUIT

BREAKER

SYMBOLS

PUSH-TO-RESET NPE PUSH-PULL TYPE

SWITCH NPE

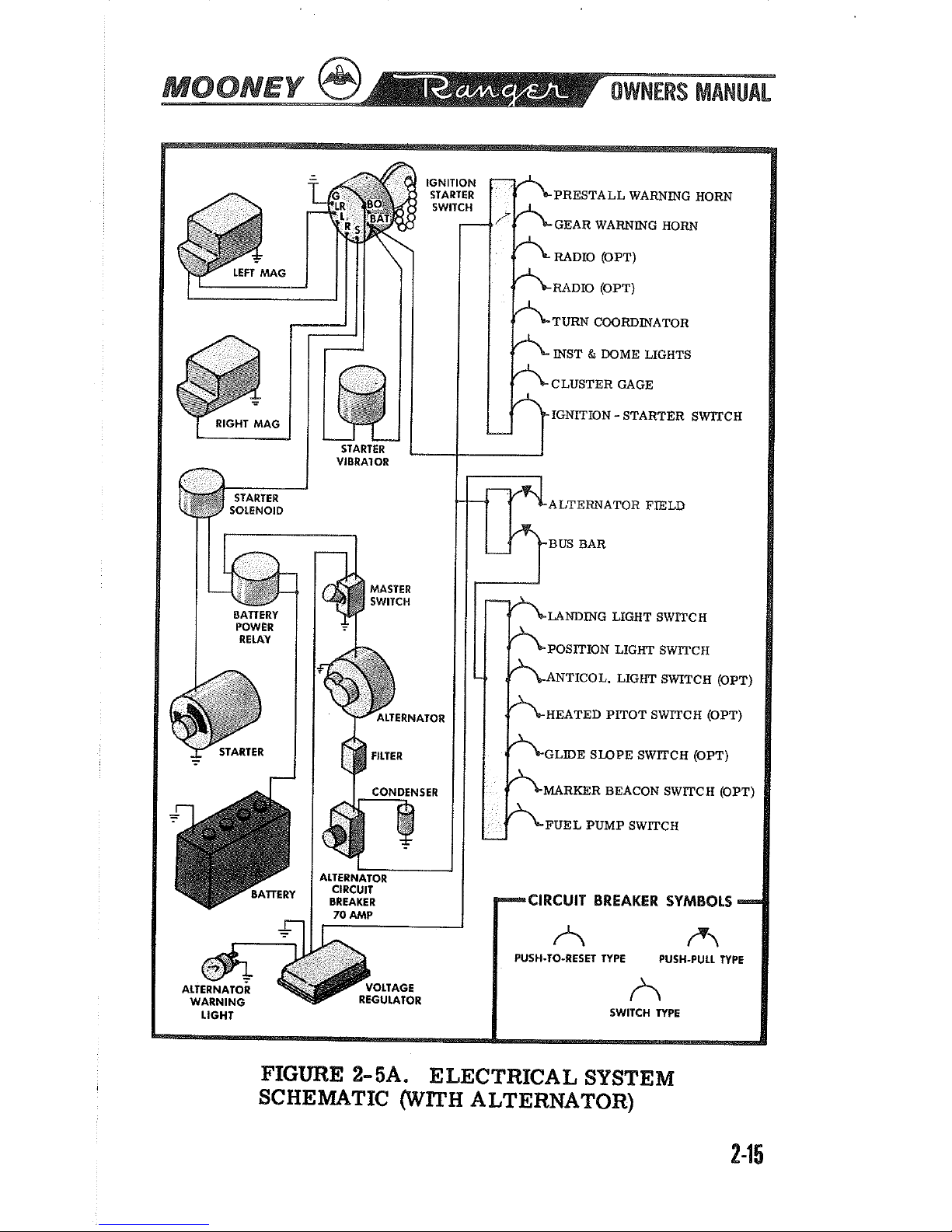

FIGURE

2-

5A. ELECTRICAL SYSTEM

SCHEMATIC (WITH ALTERNATOR)

INST & DOME LIGHTS

CLUSTER GAGE

IGNITION

-

STARTER SWITCH

LANDING LIGHT SWITCH

POSITION LIGHT SWITCH

ANTICOL. LIGHT SWITCH (OPT)

HEATED

PITOT SWITCH (OPT)

GLIDE SLOPE SWITCH (OPT)

FUEL PUMP SWITCH

CIRCUIT BREAKER SYMBOLS

SWITCH

TYPE

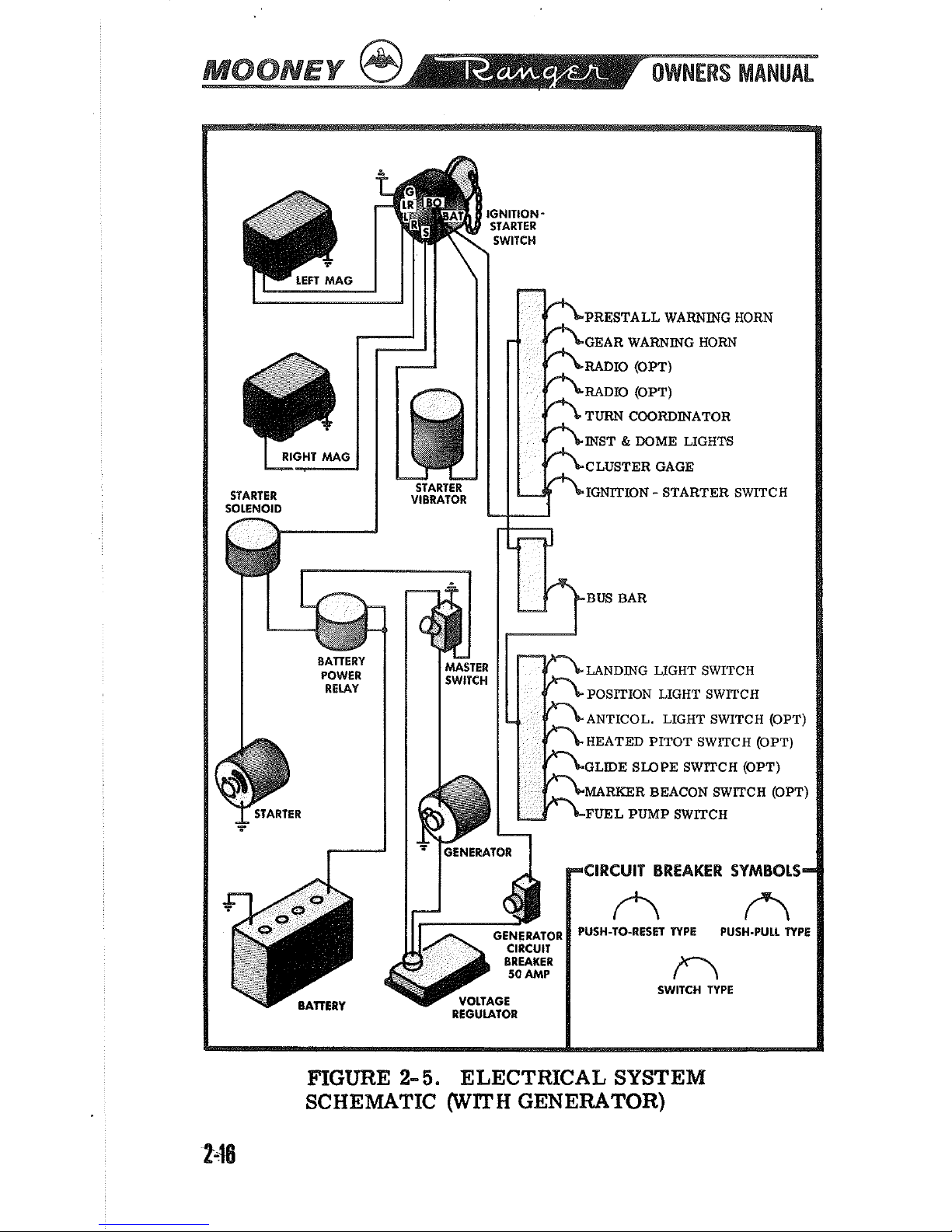

FIGURE

2-

5.

ELECTRICAL SYSTEM

SCHEMATIC (WITH

GENERATOR)

of these lights

is

discussed elsewhere in this chapter, All

but the alternator warning light may be dimmed for night

flight. Pressing forward on the lens housings tests the

warning lights; turning the lens housings dims the warning

lights. The

ALT WAWING light does not have a press-to-

test circuit

-

CABlN

LIGHTING

The rheostat knobs in the headliner control instrument

lights, overhead spot lights, and the compass light. Rota-

ting the knob clockwise turns on and increases light intensity. An overhead dome light illuminates the cabin.

CABIN

ENVIRONMENT

HEATING

8

VENTiUTiNG

SYSTEMS

Two

ventilating systems provide cabin environmental con-

trol suited

to

individual pilot and passenger preferences.

Fresh

air

heated

by

the engine exhaust muffler and

COOP

air

from an airscoop on the co-pilot side can be individually controlled and mixed to the desired temperature. The

louvered inlet in the center console

and the left and right

inlets forward of the center console under the instrument

panel control airflow. All three console inlets have adjacent control handles.

The cabin overhead ventilating system works independently

of the cabin heating and ventilating system. Rotating the

knob above the pilot seat extends or retracts the overhead

airscoop to control

air

intake.

Small directional vent deflectors with inner knob volume controls, within easy reach

of each occupant, distribute incoming outside air as individually desired.

The cabin heat control

is

marked

CABIN

NEAT. Opening

Loading...

Loading...