MOONEY

OPERATORS MANUAL

MODEL

M2OC

SERIAL NUMBERS

20-1 147

&

ON

DECEMBER

1974

ISSUE

MOONEY AIRCRAFT CORPORATION

KERRVILLE, TEXAS

78028

m

MANUAL NUMBER

74-20C-O~-~

G#

LOG

OF

PAGES

Page

ONLY

the pages listed herein are applicable

to Model M20

C.

Serial Numbers

Date

..........

Title

12/2/74

............

i

12/2/74

............

ii

12/2/74

............

iii

12/2/74

............

iv

12/2/74

SECTION

I

Page

Date

SECT ION

I

I

Page Date

...........

2-1 12/2/71

...........

2-2 12/2/74

...........

2-3 12/2/74

...........

2.4 12/2/74

...........

2.5 12/2/74

...........

2.6 12/2/74

...........

2-7 12/2/74

...........

2-a 12/2/74

...........

2-9 12/2/74

..........

2- 10 12/2/74

..........

2-11 12/2/74

..........

2-12 12/2/74

..........

2-13 12/2/74

..........

2-14 12/2/74

.......

..

2-15

0,

12/2/74

..........

2-16 12/2/74

..........

2-17 12/2/74

..........

2-18 12/2/74

SECTION

Ill

Page Date

..........

3-1 12/2/74

..........

3-2 12/2/74

3-4

..........

12/2/74

3-5

..........

12/2/74

..........

3-6 12/2/74

3-7

..........

12/2/74

3-8

..........

12/2/74

3-9

..........

12/2/74

..........

3- 10 12/2/74

..........

3-

11

12/2/74

..........

3-12 12/2/74

.

..........

3 13 12/2/74

..........

3-14 12/2/74

..........

3- 15 12/2/74

3-6

..........

12/2/74

..........

3- 16 12/2/74

.

..........

3 17 12/2/74

..........

3-18 12/2/74

..........

3-19 12/2/74

..........

3-20 12/2/74

3-21

..........

12/2/74

..........

3-22 12/2/74

3-23

..........

12/2/74

3.24

..........

12/2/74

3-25

..........

12/2/74

3-26

..........

12/2/74

SECTION

1V

(FAA

APPROVED)

Page Date

4-1

..........

12/2/74

4- 2

..........

12/2/74

4-3

..........

12/2/74

4-4

..........

12/2/74

4-5

..........

12/2/74

4-6

....

.,

.....

12/2/74

.

4 7

..........

12/2/74

4-8

..........

12/2/74

4-9

..........

12/2/74

4-10

.........

12/2/74

LOG

OF

PAGES (CONT.)

SECTION

V

(FAA

APPROVED)

Page

Da

f

e

SECTION

VI

Page

Date

SECTION

VII

/

Page

Date

GENERAL DESCRIPTION

..........

SECTION

SYSTEMS OPERATIONS

...........

SECTION

NORMAL PROCEDURES

...........

SECTION

..................

LIMITATIONS SECTION

........

EMERGENCY PROCEDURES SECTION

................

PERFORMANCE SECTION

.................

SERVICING.

.4

SECTION

This manunl is issued as your operating guide for the

Vooney IIANGEIt. It is important that you--regardless

of

your

previous experience-- carefully read the hand-

boolc

from

cover to cover and review

it

frequently.

IMPORTANT: THIS MANUAL CONTAINS Federal

Aviation Administration APPROVED LIMITATIONS

AND MUST

I'IE CARRIED

IN

THE

AIRCRAFT AT

ALL, TIMES.

All

~~ilormation :incl illustrations in this manual are based

on the latest procluct information available at the time of

1)ut)lic~ttion al)provnl.

'The right is reserved to ~nalce

cliangcs :it any

tillic

without notice.

Every

etfort has been

m:itle 1 o

present the material

in

;L

clc:ir

ancl

convenient

ni:lnllrr to c~iablc you to use the m;i~iii:~l

:is

:I

ready ore-

sent:~tion :incl (*ontent recommenclations is solic.itec1.

Mooney warrants each Aircraft (which includes

its

accessories and equipment) sold hereunder,

to be free from defects in materialand

workmanship under normal use and service when operated

in accordance with Mooneyfs operating instruc-

tions during the period of six

(6)

montlls following

delivery of the Aircraft to

the original retail pur-

chaser or

the first user or during the period of

one

(1)

year follo~ving the date of issue of the original airworthiness certificate for the Aircraft,

whichever

period

fir

st terminates. Mooney does

not

malie ally warranties with respect to equipment

-

and accessories not manufactured by Mooney but

Mooncy assigns

Gny owner of sucll Aircraft (to

the extent same may be assignable) any warra~ities

Mooney has receivecl from the

manufacturers

of

such

ecluipment

ancl

accessories and will,

on

request, provide and execute such instruments as may

be reasonably required to evidence such assignment.

Mooneyfs

obligztion under this warranty

is

limited

to repairing or replacing, at Mooney's option, any

part or parts

which within the applicable warranty

period set forth above, shall be returned, transportation charges prepaid, to Mooney's plant in

Kerrville, Texas or to such other location designated by Mooney, and which upon examination, shall

disclose to Mooney's satisfaction that such part is

defective.

A

new warranty period is not established

for parts replaced hereunder. Parts replaced hereunder are warranted for the remainder of the original

warranty periocl applical~le to Aircraft solcl hereunder.

The

repair or replacement of defective parts under

this warranty shall

be macle by Mooney without charge

for the parts, or

labor for removal, installation and/

or actual

repair of defective parts.

5,

This warranty does not apply to Aircraft, equipment,

accessories, or other parts manufactured or sold by

Mooney which have been subject to misuse, negligence,

accident or improper installation, or

which"1ave been

repaired or altered outside of Mooney's plant in a

way which, in the opinion of Mooney, adversely

affects its performance or reliability. Further, this

warranty does not include

norinal maintenance services (such as engine tune-up, cleaning, control rigging, brake and other mechanical

adjustn~ents,

n~aintenance inspections, etc. ) and the replacelllent

of service items (such as sparlr plugs, brake linings,

filters,

hoses, belts, tires, etc. ) nlade in connection

with such services or required as maintenance,

nor

to normal deterioration of soft trim and appearance

itellis (such as, paint, upholstery, rubber-like items,

etc. ) clue to wear anct exposure.

This warranty shall extend to any owner (hereafter

"Owner") of the Aircraft

making claiill within the

specified warranty period.

THIS WARRANTY BY IdIOONEY IS tIADE EXPRESSLY IN

LIEU OF ANY OTHER P'ARRANTIES EXPRESSED OR

IIIPLIED IN FACT OR BY LAW, INCLUDING ANY IIIPLIED

WARRANTY OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE, AND IS IN LIEU OF ANY

OTHER

OBLIGATION OR LIABILITY CPJ THE PART OF iiOONEY

TCI ANYONE OF ANY NATURE PIHATSOEVER BY REASON OF

THE

IIANUFACTURE

AND/OR

THE

SALE

AND/OR

THE

USE

OF SUCH AIRCRAF1 , 1100NEY SHALL IN NO E'JENT BE

LIABLE TO ANY OWNER OR TO ANY OTHER PARTY OR

PARTIES FOR SPECIAL, INCIDENTAL OR

CONSECUEN-

TIAL LOSS OR DAiiAGES OR FOR

ANY

OTHER LOSS OR

DAMAGE

TO

PROPERTY

AND/OR INJURY

OR

DEATH

TO

PERSONS OTHER THAN FOR THE PROPERTY DAliAGE TO

SUIIJECT AIRCRAF r PROXIMAl-ELY RESULT

I

I'JG

FRO/, ANY

BRtACH BY MOONEY OF THE AFORESTATED l.!ARRANTYt

IIOONEY NEITHER ASSUMES NOR AUTHORIZES BU'IER OF

ANYONL ELSE TO ASSUllE FOR IT ANY OBLIGATION OR

LIABILITY IN CONNECTION WITH THE AIRCRAFT SUBJECT HEREOF, OTHER THAN THOSE EXPRESSLY SET OUT

HEREIN, NO BILL OF SALE OR TRANSFER OF TITLE

TO THIS AIRCRAFT SHALL NULLIFY THE PROVISIONS

HEREOF,

SECTION

I

.

GENERAL

DESCRIPTION

DESIGN

FEATURES

AIRFRAME

...........................

1.

2

POWERPLANT

........................

1-2

FLIGHT CONTROLS

.....................

1.

3

LANDING

GEAR

.......................

1.

3

SPECIFICATIONS OUTLINE

POWERPLANT

........................

1-3

PROPELLER

.........................

1-4

LANDING

GEAR

......................

-1-4

FUEL & OIL

.........................

-1-5

WEIGHT

&

LOADING

...................

-1-5

BAGGAGE

COMPARTMENT

..............

-1-5

MANUAL

DESIGN

FEATURES

The MOONEY RANGER (M20C) is a low-wing four-

place aircraft with a retractable gear.

A

fourcylinder engine powers the aircraft for economical,

high-performance flight. Licensing under Federal

Aviation Administration regulations assures that

your

Mooney meets the requirements of Normal Category

aircraft.

AIRFRAME

The airframe has a welded, tubular-steel cabin structure enclosed in sheet-aluminum skins. Stressed skins

rivet to main and auxiliary spars in the wing, stabilizer,

and vertical fin. The laminar-flow wing has full wraparound skins with flush riveting over the forward top

two thirds of the wing area.

For pitch trim control, the empennage pivots on the aft

fuselage. A torque-tube-driven jack screw, bolted to

the rear

tail con^

bulkhead, sets the stabilizer angle.

The forward-opening cabin door provides access to both

front and rear seats. The baggage compartment door is

above the wing trailing edge to enable baggage loading

from the ground.

POWER PLANT

The

powerplant is a four-cylinder air cooled engine that

develops 180 horsepower.

A

60-ampere 12-volt alterna-

tor supplies ample electrical power for all standard and

optional equipment at all engine speeds

from warmup to

flight power settings.

The hydraulic propeller governor, using oil pressure for

increasing blade pitch to control engine speed, regulates

the controllable-pitch constant-speed propeller. Spring

and blade aerodynamic forces decrease blade pitch.

FLIGHT

CONTROLS

Conventional dual controls link to the control surfaces

through push-pull tubes. The co-pilot's rudder pedals

are removable.

The Mooney Positive Control (P. C.

)

system

is

standard

equipment.

P.

C.

is

a lateral stability augmentation system that provides a high degree of roll and yaw stability,

thereby enhancing the inherent wings-level flight characteristics of the aircraft. The system works full time

from takeoff through landing but can be easily deactivated

or overpowered for flight maneuvers.

P.

C . allows you,

the pilot, to devote more time to navigation, traffic surveillance, and communications.

LANDING

GEAR

The tricycle landing gear allows maximum taxi vision and

ground maneuvering.

Hydraulic disc brakes and a

steer-

able nose wheel aid in positive directional control during

taxiing and crosswind landings.

The landing gear is electrically actuated. A gear warning

horn along with red and green position lights

help

prevent

inadvertent gear-up landings.

The retraction

syste11l in-

corporates

a

squat switch that prevents gear retraction un-

til a safe airspeed is attained. An emergency gear extension system is provided.

SPECIFICATIONS OUTLINE

POWER

PLANT

TYPE : Four- cylinder, air cooled, horizontally opposed,

$4

*

x,~~~~~

e-

OPERATORS MANUAL

and carbureted engine with a wet-sump hubricating

system.

.......

Model (Lycoming). 0-360-AID

Rated Horsepower

@

2700 RPM

. .

180 BHP

.............

Bore 5.125 IN.

............

Stroke 4.375 IN.

.......

Displacement 361.0

CU.

IN.

........

Compression Ratio 8. 7:l

...

Carburetor, Marvel-Schebler MA-4-5

...

Magnetos, Scintilla S4LN-200 Serie

PROPELLER

TYPE : Constant-speed, hydraulically controlled

propeller with a single-acting governor.

Model (Hartzell)

...

HC-C~YK-

1B/7666 A-2

............

Diameter. 74 IN.

Blade Angle

(@

30 IN. STA)

:

............

Low 130 + 0°

............

High 2g0+20

-

LANDING GEAR

TYPE:

Electrically retracted tricycle gear with rub-

ber

shock discs, steerable nose wheel, and hydraulic

disc brakes.

.......

WheelBase 5FT6-9/16IN.

........

Wheel Treaci

9

FT 3/4 IN.

Tire Size

:

.............

Nose 5.00~ 5

............

Main. 6.00~ 6

Tire Pressure:

..............

Nose 30 PSI

Ma

..............

30 PSI

*

-~~ONEV

OPERATORS

MANUAL

FUEL

&

OIL

Usable Fuel Capacity

.......

52 GAL

Minimum Fuel Octane Rating

(aviation grade)

........

91/96

Oil Capacity

(6

QTS

MIN

for flight)

.

8

QTS

WEIGHT

&

LOADING

Gross Weight

..........

2575 LBS

Approximate

Einpty Weight

(with standard equipment)

...

1525 LBS

Useful Load

...........

1050 LBS

Wing Loading

@

Gross Weight

.

.

15.1

PSF

Power Loading

@

Gross Weight

. .

14.3

PHP

BAGGAGE COMPARTMENT

Maximum Baggage Loading (unless limited

by

weight envelope)

.........

120 LBS

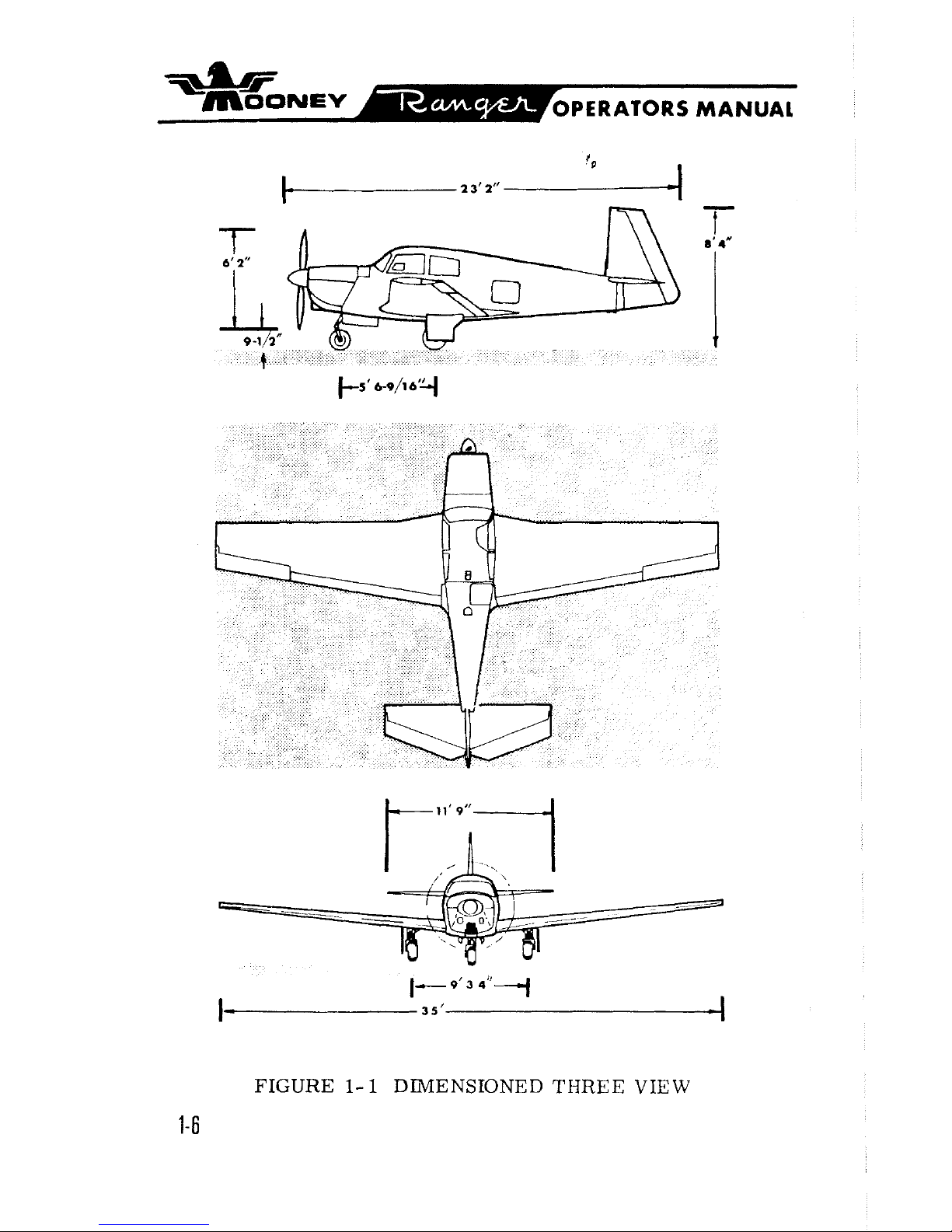

FIGURE

1- 1

DIMENSIONED THREE VIEW

1-6

SECTION

II

.

SYSTEMS

OPERATIONS

POWER

PLANT

.....................

ENGINE CONTROLS 2-4

.....................

IGNITION SYSTEM 2-5

.......................

FUEL SYSTEM 2-5

.........................

OIL

SYSTEM 2-6

ENGINE COOLING

.....................

2-6

.....................

VACUUM SYSTEM 2-6

INSTRUMENTS

.................

FLIGHT INSTRUMENTS 2-7

FLIGHT CONTROLS

............

PRIMARY FLIGHT CONTROLS 2-8

POSITIVE CONTROL

...................

2-9

TRIM CONTROLS

.....................

2-10

WING FLAP CONTROLS

.................

2-10

LANDING GEAR

ELECTRIC GEAR RETRACTION SYSTEM

.....

2-11

EMERGENCY GEAR EXTENSION SYSTEM

.....

2-12

BRAKE

&

STEERING SYSTEMS

............

2-12

ELECTRICAL POWER

ALTERNATOR & BATTERY

...............

2-12

CIRCUIT BREAKERS

...................

2-13

ANNUNCLATOR LIGHTS

.................

2-15

INSTRUMENT

&

PLACARD

LIGHTS

.........

2-16

CABIN LIGHTING

.....................

2-16

CABIN ENVIRONMENT

HEATING & VENTILATING SYSTEMS

........

2-16

WINDSHIELD DEFROSTING SYSTEM

........

2-17

CABIN

SEATS

&

SAFI~Y

BELTS

................

2-18

BAGGAGE

&

CARGO AREAS

..............

2-18

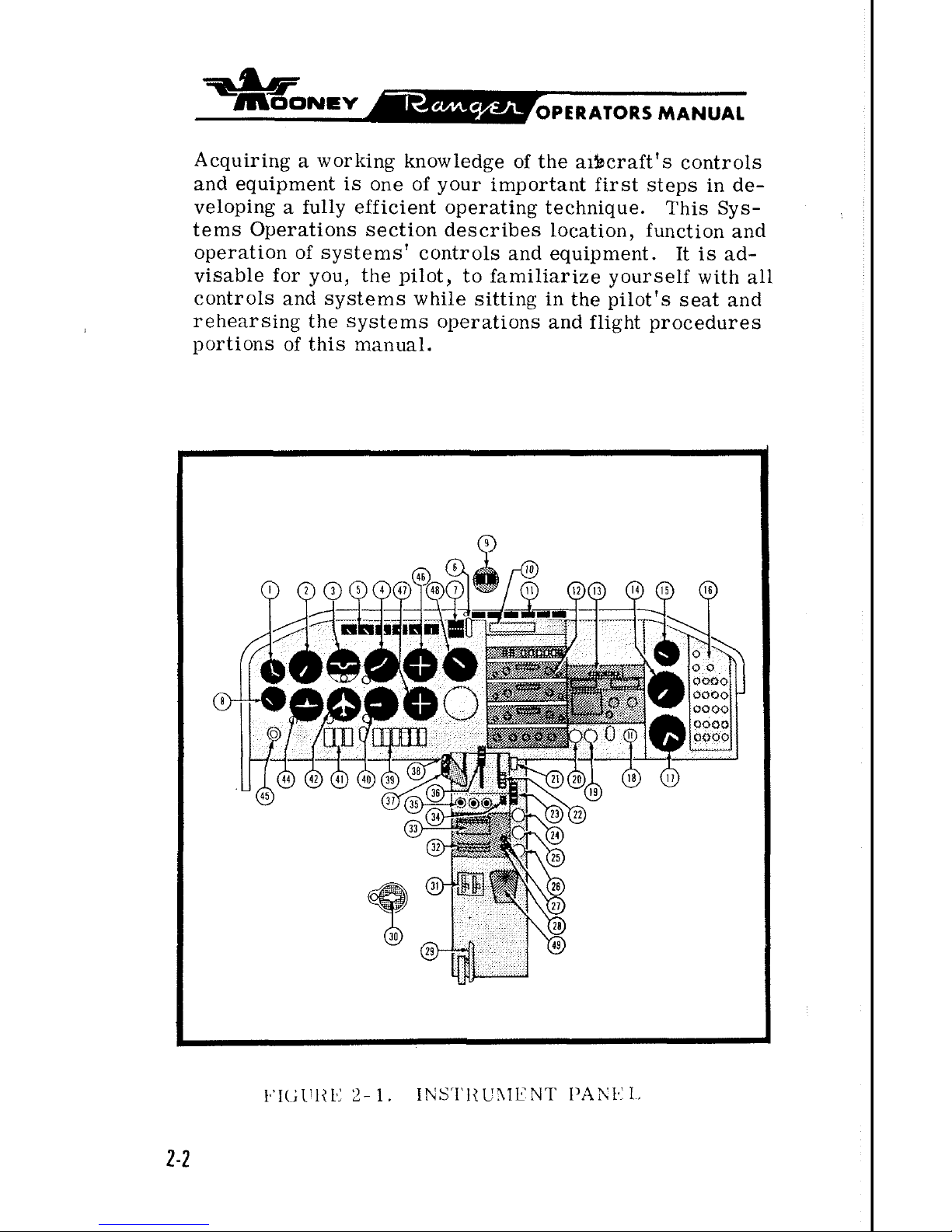

Acquiring a working knowledge of the aibcraft's controls

and equipment is one of your important first steps in developing a fully efficient operating technique. This Sys-

tems Operations section describes location, function and

operation of systems' controls and equipment. It is advisable for you, the pilot, to familiarize yourself with all

controls and systems while sitting in the pilot's seat and

rehearsing the systems operations and flight procedures

portions of this manual.

-

moo~evE

OPERATORS MANUAL

POWER

PUNT

ENGINE CONTROLS

The engine control levers are centrally located, between

the pilot and co-pilot, on the engine control pedestal. The

throttle lever regulates manifold pressure. Pushing the

lever forward increases the setting; pulling the lever aft

decreases the setting.

The propeller control lever, with its crowned

knob, controls engine RPM through the propeller governor. Pushing the lever forward increases engine

RPM:

pulling the

lever aft decreases RPM.

The mixture control lever, with its red hexagon knob, es-

tablishes the fuel-air ratio (mixture). Pushing the lever

full forward sets the mixture to full-rich, pulling the

lever

aft leans the mixture, and pulling the lever to its maximum

aft travel position closes the idle cutoff valve, shutting

down the engine. Precise mixture settings may be established by observing the optional

EGT

gage while adjusting

the mixture control lever.

A

large friction lock on the right side of the engine control

pedestal locks the controls in the desired setting and pre-

vents creeping during flight.

The carburetor heat control knob, mounted in the

subped-

estal to the right of the engine control pedestal, allows the

selection of heated induction air to prevent carburetor

icing

or to melt accumulated ice in the carburetor venturi. The

engine will operate on unfiltered air when the carburetor

heat control

knob

is pulled out, and dirt and foreign sub-

stances can

l-te

taken into the engine causing rapid cylinder

and piston wear. Therefore, the use of

carburetoi heat o13

the ground, except for testing system operation, is not

recommended.

',

-ar

~sJONE~

OPERATORS

MANUAL

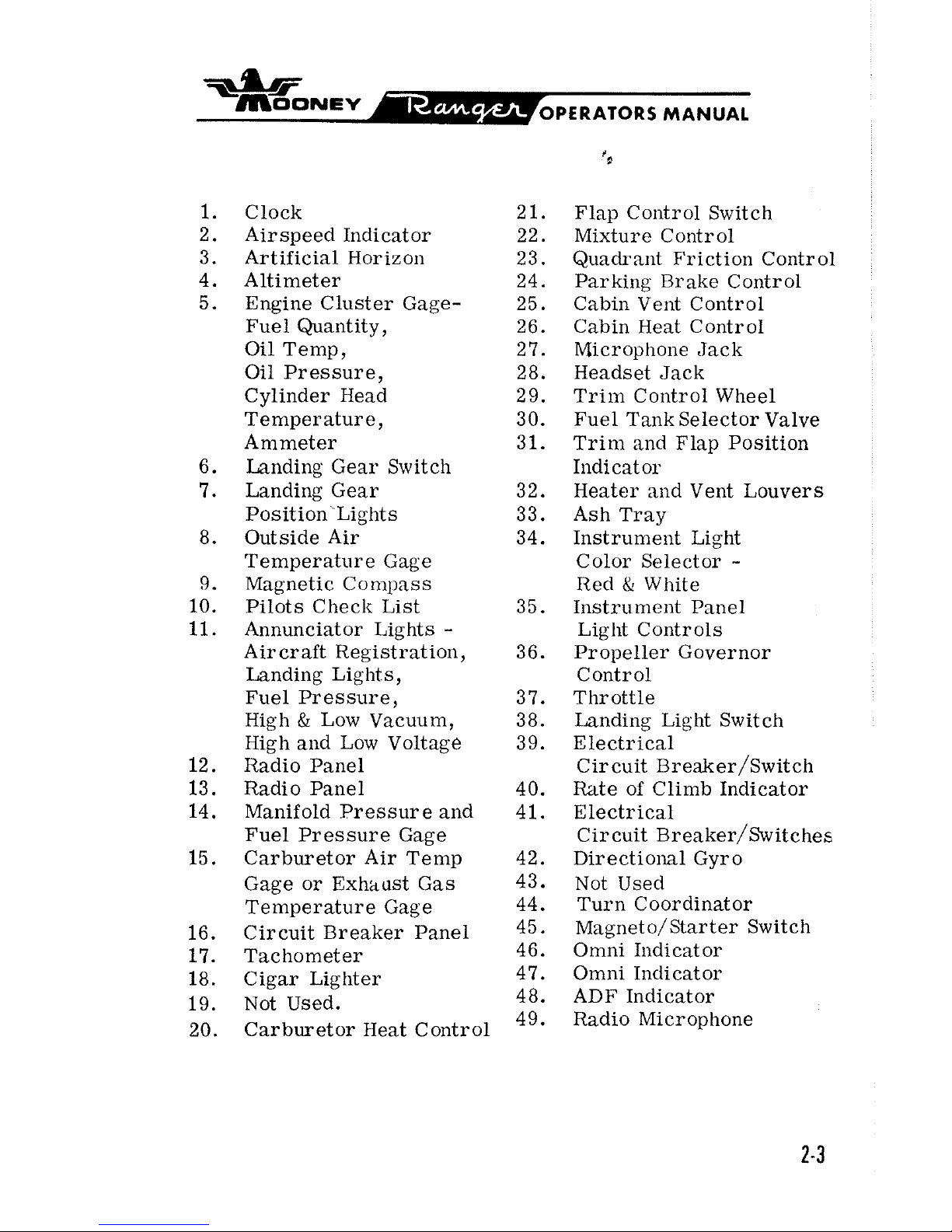

Clock 21.

Airspeed Indicator 22.

Artificial Horizon

23.

Altimeter 24.

Engine Cluster Gage- 25.

Fuel Quantity, 26.

Oil Temp,

2

7.

Oil Pressure, 28.

Cylinder Head

2

9.

Temperature, 30.

Ammeter 31.

Landing Gear Switch

Landing Gear 32.

Position Lights 33.

Outside Air 34.

Temperature Gage

Magnetic

Conlpass

Pilots Checlr List 35.

Annunciator Lights

-

Aircraft Registration, 36.

Landing Lights

,

Fuel Pressure, 3 7.

High

&

Low Vacuum, 38.

High

and Low Voltage 39.

Radio Panel

Radio Panel 40.

Manifold Pressure

and 41.

Fuel Pressure Gage

Carburetor Air Temp 42.

Gage or Exhaust Gas 43.

Temperature Gage 44.

Circuit Breaker Panel

45.

Tachometer 46.

Cigar Lighter 47.

Not Used. 48.

Carburetor Heat Control

49.

Flap

Contr 01 Switch

Mixture Control

Quadrant Friction Control

Parking Brake Control

Cabin Vent Control

Cabin Heat Contr

01

Microphone Jack

Headset Jack

Trim Control Wheel

Fuel

Tank Selector Valve

Trim and Flap Position

Iildicat or

Heater

and Vent Louvers

Ash Tray

Instrument Light

Color Selector

-

Red & White

Instrument Panel

Light Controls

Propeller Governor

Control

Throttle

Landing Light Switch

Electrical

Circuit

~reaker/~witch

Rate of Climb Indicator

Electrical

Circuit

~reaker/~witches

Directional Gyro

Not Used

Turn Coordinator

Magneto/Starter Switch

Omni Indicator

Omni Indicator

ADF Indicator

Radio Microphone

-

~OONEV

OPERATORS MANUAL

All engine instruments except the EGT gage, tachometer and fuel and manifold pressure gages are grouped

in the left instrument panel. Color arcs on instrument

faces mark operating ranges.

Proper interpretation of

engine instrument readings

is

essential for selecting

optimum contr

01 settings and for maintaining maximum

cruise fuel economy.

Engine limitations are given in

Section

IV.

IGNITION SYSTEM

The left magneto has a set of fixed retard breaker points

that aid in smoother, easier starting. A battery-powered

starting vibrator supplies a long-duration, boosted spark.

The starter-ignition switch, mounted on the left of the instrument panel, combines both ignition and starting functions. Turning the ignition key clockwise through

R,

L,

and BOTH to the START MAG position and then pushing for-

ward on the key and receptacle engages the starter. Re-

leasing the key when the engine starts allows the switch to

return by spring action to the BOTH position.

For safety,

the starter-ignition switch must be left at OFF when the

engine is not running.

FUEL

SYSTEM

Two integral sealed sections carry the fuel in the forward

inboard area of the wings.

Full fuel capacity

is

52

gallons.

There are sump drains

at

the lowest point in each tank for

taking fuel samples to check for sediment contamination

and condensed water accumulation.

Section VII discusses

the fuel sampling procedure.

The .recessed three-position fuel selector handle on the

cabin floor sets the selector valve below the floorboard

for LEFT tank, RIGHT tank, or the OFF position. The

fuel selector

va%e assembly contains a valve for draining

condensed water and sediment from the lowest point in the

=.LIF

~OONEV

OPERATORS

MANUAL

fuel lines before the first flight of the da~ and after

each refueling. Section

VII discusses the selector

valve flushing procedure.

Fuel feeds from one tank at

a

time to the selector valve

and through the electric fuel pump

enroute to the enginedriven pump and the carburetor unit. Electric fuellevel transmitters in the tanks operate fuel gages in the

engine cluster. The master switch actuates the fuel

quantity indicator system to maintain an indication of

fuel remaining in each tank.

The fuel pressure gage

registers fuel pressure in the line to the carburetor.

Vents in each fuel tank allow for overflow ventilation.

OIL SYSTEM

The engine has a full-pressure wet-sump oil system with

an

8

quart capacity. The automatic bypass control valve

routes oil flow around the

,oil cooler when operating tem-

peratures are below normal or when the cooling radiator

is

blocked.

The engine oil should be kept at

6

to 8 quarts.

Lycoming

Service Instruction

1014

(latest revision) gives recom

-

mended oil specifications and oil change intervals.

ENGINE COOLING

The down-draft engine cooling system provides ground

and

inflight power plant cooling.

Engine baffling directs

air

over and around the cylinders and out the cowl flap

openings.

Cowl flap doors are fixed in

a

position that

allows proper air flow on the ground and in flight.

VACUUM

SYSTEM

An engine-driven vacuum pump supplies suction for the

vacuum-operated gyroscopic flight instruments and the

MANUAL

Mooney Positive Control system. Air entering the

vacuum-powered instruments is filtered; hence,

sluggish or erratic operation of vacuum-driven instruments may indicate that a clogged vacuum filter element

is

preventing adequate air intake.

The vacuum an-

nunciator light will illuminate steadily for

Hi

Vac

and flashes for Laow Vac indication.

INSTRUMENTS

FLIGHT INSTRUMENTS

All

primary flight instruments are grouped on the shockmounted flight panel directly in front of the pilot's seat.

Optional gyro instruments may be installed in the standard

T-grouping with the attitude gyro at top center and the

directional gyro immediately below. The standard airspeed

indicator and sensitive altimeter cross the

"T".

The stan-

dard turn coordinator and optional vertical speed indicator

at

left of center complete the flight instrumentation.

The magnetic compass

is

mounted on the windshield post

above the instrument panel. A remote indicating gage is

installed in the left of the flight panel. There

is

space

and lighting for four optional radio indicators on the right

side of the flight panel.

&bF

~OONEV

PERATORS

MANUAL

A

pitot tube, mour~ted on the lower surfaw of the left

wing, picks up airspeed indicator ram air.

A

heated

pitot prevents pitot tube icing when flying in moistureladen air. A drain valve is located on the forward

bottom skin of the left wing just outboard of the wing

fillet. Static ports on each side of the tail cone supply

static air pressure for the altimeter, the airspeed

indicator, and the vertical speed indicator. A drain

valve is located on the fuselage bottom skin below the

tail

cone access door.

An alternate static

pressure

source valve will

be

found under the left side of the

flight panel.

A

stall warning horn, mounted in the cabin head liner

and triggered by a sensing vane on the left wing leading

edge, will sound when airspeed drops to near stall

speed. The sound becomes steady as the aircraft

approaches a complete stall.

There are two landing gear position lights; one is a green

GEAR

DOWN' light and the other is a red IN-TRANSIT light.

No, light shows when the gear is full up. Inadvertent posi-

tioning of the gear switch to the up position while the air-

craft is on the

ground will cause both the red and green

to

be

illuminated and the warning horn to souild if the

throttle is closed.

FLIGHT

CQNTROLS

PRIMARY FLIGHT CONTROLS

Push-pull tubes with self-aligning rod end bearings actuate

the primary flight control surfaces. Beveled aileron trail-

ing edges help reduce pilot control forces required for flight

maneuvering.

A

springloaded interconnect device indirectly joins the

aileron and rudder control systems to assist in

lateral stability during

flight maneuvers. Control

surface gap seals minimize airflow through the

hinge slots and reduce

drag.

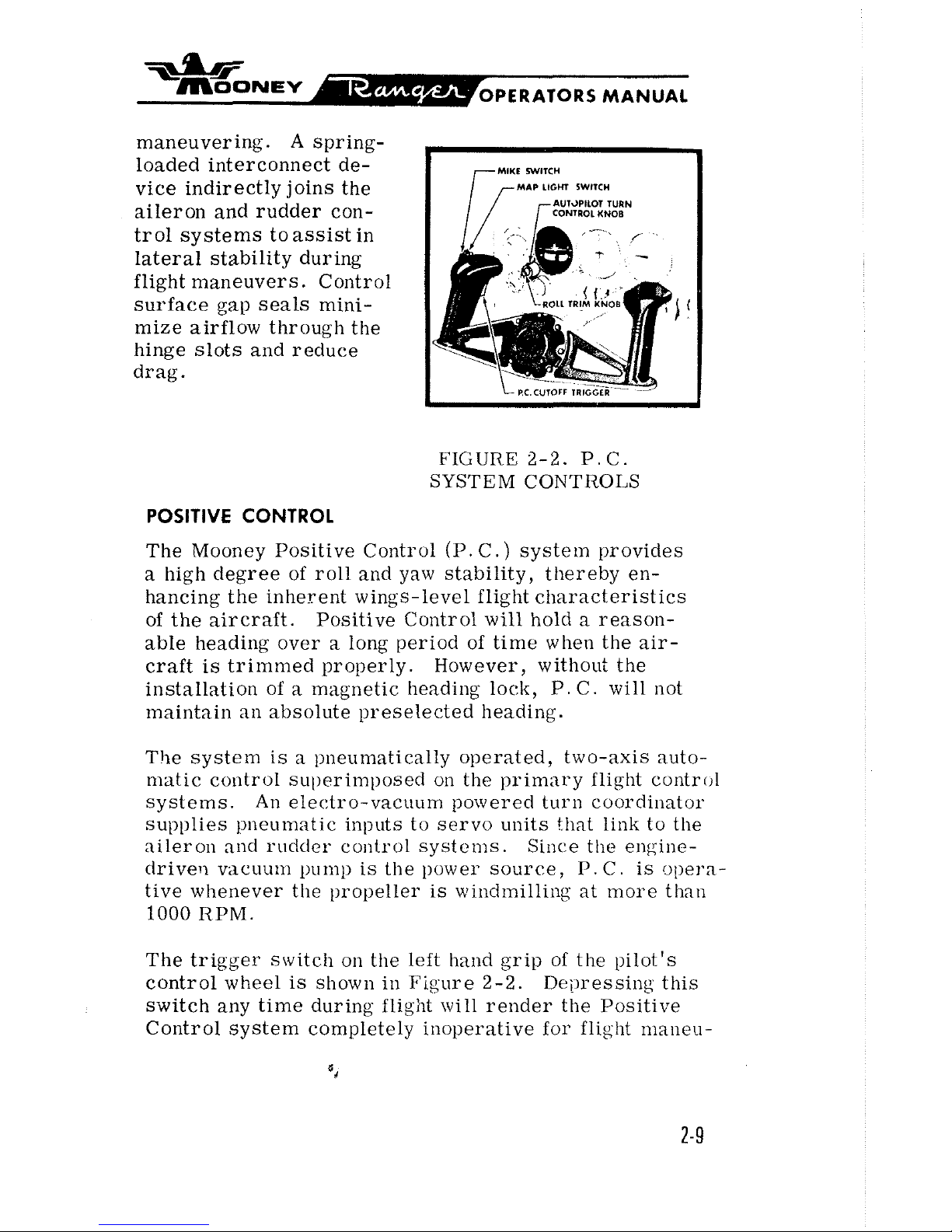

MAP

LIGHT

SWITCH

I'

FIGURE

2-2.

P.C.

SYSTEM CONTROLS

POSITIVE CONTROL

The Mooney Positive Control (P.

C.)

system provides

a high degree of roll and yaw stability, thereby en-

hancing the inherent wings-level flight characteristics

of the aircraft.

Positive Control

will

hold a reason-

able

heading over a long period of time when the air-

craft is trimmed properly.

However, without the

installation of

a

magnetic heading lock, P. C. will not

maintain an absolute preselected heading.

The system

is

a pneumatically operated, two-axis auto-

matic control

sul)erimposecl on the primary flight control

systems.

An

electro-vacuum powered turn coordinator

supplies pneumatic inputs to servo units that link to the

aileron

and rudder control systems. Since tlte engine-

clrivert vacuum

pump

is the power source,

P.

C.

is opera-

tive whenever the propeller

is

windmilling at more than

1000

RPM.

The trigger

switch on the left hand grip of the pilot's

control wheel

is

shown in Figure 2-2. Depressing this

switch any time during

flight will render the Positive

Control system completely inoperative for flight

maneu-

MANUAL

vers or manual flying. When the cutoff gwitch

is

re-

leased, the aircraft will return unassisted to

wings-

].eve1 flight.

P.

C.

can be manually overridden with little

effort if the system should malfunction. Manually

over-powering the system will not damage the aircraft

or the

P.

C

.

components.

The roll-trim knob on the turn coordinator, as shown in

Figure 2-2, provides an aileron trim function through

the

P.

C.

system. Rotating the ltnob trims the aircraft

about its roll axis to compensate for asymmetrical fuel

and passenger loadings.

The

P.

C.

systeim

is

installed to help alleviate pilot

fatigue.

But

lilte any other system in the aircraft,

P.

C

must be monitored for proper functioning.

TRIM CONTROLS

For pitch trim control, the entire empennage pivots on

the tail

cone attachment points to increase or decrease

the horizontal stabilizer angle. This design allows flight

trim establishment with

minimum control surface deflec-

tion.

A

trim indicator located on the console indi-

cates stabilizer trim position.

Forward rotation of

the trim wheel lowers the nose; rearward rotation

nises the nose in flight.

WING FLAP CONTROLS

The flap control on the right

of

the engine control pedestal operates the electrically-actuated wide-span wing

flaps. Moving the control to the

UP

position, retracts

the

flaps. The position of the flaps can be noted from

the flap position indicator.

The control has a

detent

to assist the pilot in detecting the takeoff flap setting.

*

~OONSV

OPERATORS

MANUAL

ELECTRIC GEAR RETRACTION SYSTEM

The two-position electric gear control switch, iden-

tified by

its

wheel-shaped knob, is located at the top

of the instrument panel above the

throttle.

There are three ways to see that the electrically-

actuated gear

is

down-and-locked:

(1)

The green gear -down annunciator light illumi-

nates.

(2)

The indicator marks align as seen on the floorboard visual gear-position indicator.

(3)

The gear warning horn does not sound at

approach power setting of below

12

inches mani-

fold pressure.

A

green GEAR

DN

light, a red IN TRANSIT light,

and a warning horn provide visual and audible gear

position signals. The green light (GEAR DN) shows

continuously when the gear is fully extended. Both

lights are out when the gear is fully retracted.

The illuminated gear-down position indicator in the

floorboard aft of the center console has two

marks

that align when the gear is down.

Retarding the throttle below

12

inches inanifold

pressure causes the gear warning horn to enlit a

regular, intermittent tone unless the gear

is

down-

and- locked.

A mechanically actuated "Squat-Switch" in the re-

traction system prevents

inadvertent landing gear

retraction. The safety switch is not intended to

substitute for the gear switch in keeping the gear

extended while taxiing, taking off, or landing.

EMERGENCY GEAR-EXTENSION SYSTEM

The emergency gear extension handcrank on the left upholstery panel near the pilot's knee

is

for manually driving

the electric gear actuating motor to extend the gear

if

the

electrical system should malfunction. Section

IV

dis-

cusses the emergency gear extension procedure.

BRAKE 8 STEERING SYSTEMS

The main gear wheels incorporate self-adjusting disctype hydraulic brakes. The pilot's rudder pedals have

individual toe-actuated brake cylinders linked to the

rudder pedals. Depressing the toe pedals and pulling out

the parking brake control on the console sets the

brakes

fax

parking. Pushing the parking brake control

forward releases the brakes.

It

is

inadvisable to set the parking brake when the brakes

are overheated after heavy braking or when outside temperatures are unusually high. Trapped hydraulic fluid

may expand with heat to damage the system. Wheel chocks

are normally used for long-term parking and mooring.

Rudder pedal action steers the nose wheel. Gear retrac-

tion relieves the rudder control system of its nose wheel

steering and centers the wheel to

permit retraction

irito

the nose wheel well.

ELECTRICAL

POWER

ALTERNATOR 8 BATTERY

A

35-ampere-hour

12

volt negative-ground storage battery

under the left engine cowl and a 60-ampere alternator

$*

supply electrical power for equipment operation. The

ammeter in the engine instrument display indicates

battery charging rate.

A

power loss in the alternator

or voltage regulator will be shown as

a

discharge read-

ing on the ammeter; a discharged battery will be indi-

cated

as

a

high-charge reading.

The voltage regulator adjusts alternator output to current

load while maintaining a constant voltage level.

A11

alter-

nator

warning light illuminat es steadily w hen voltage

regulator output exceeds voltage limits. It flashes when

the voltage

is

low.

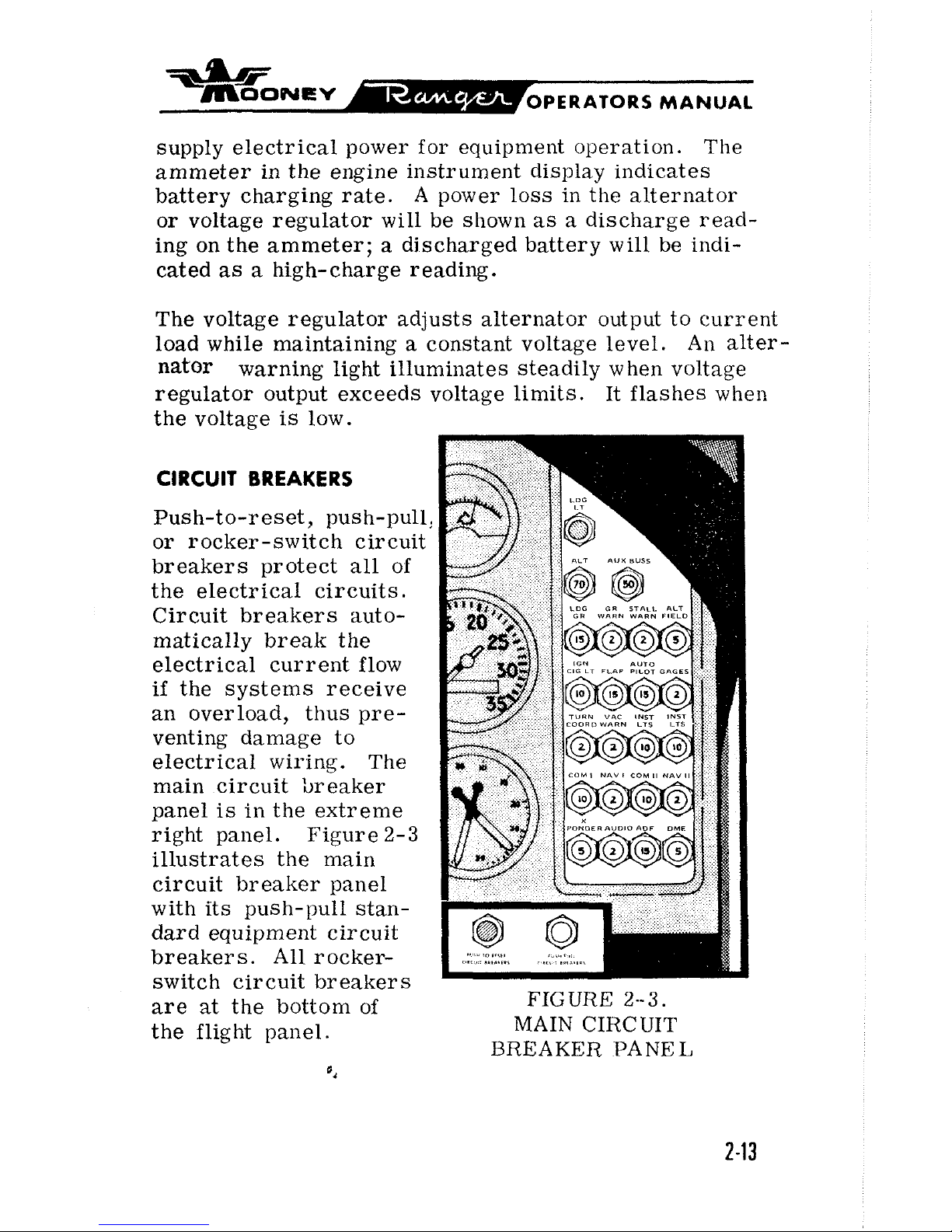

CIRCUIT

BREAKERS

Push-to-reset, push-pull:

or rocker-switch circuit

breakers protect all of

the electrical circuits.

Circuit breakers auto-

matically break the

electrical current flow

if

the systems receive

an overload, thus pre-

venting damage to

electrical wiring. The

main circuit breaker

panel

is

in the extreme

right panel. Figure

2-3

illustrates the main

circuit breaker panel

with its push-pull standard equipment circuit

breakers. All

rocker-

switch circuit breakers

are

at

the bottom of

FIGURE

2--3.

the flight panel. MAIN CIRCUIT

BREAKER

PANEL

ias

~OONEV

OPERATORS MANUAL

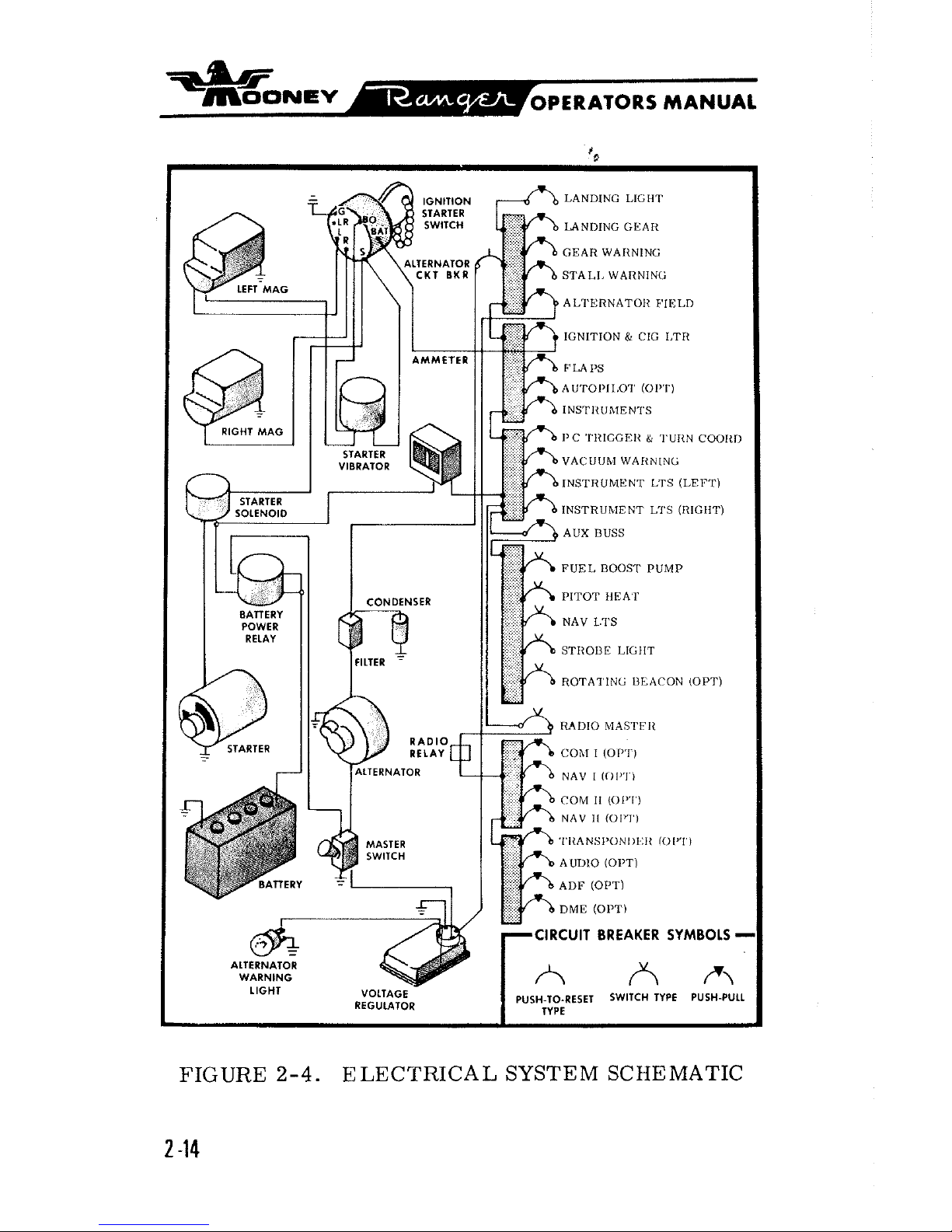

*a

LANIIING GEAR

GEAR WARNING

STALI. WARNING

ALTERNATOIT FIELD

IGNITION

&

CIG LTR

A U'I'O1'11.OT (OW"

INSTl{lJh1EN1'S

I'C TITIGGEIT

8.

'TUIIN COOI~rl

VACUUhl WAftNING

INSTRUMENT LTS (LEFT)

INSTRUMENT LTS (RIGlfT)

FUEL

BOOS'I'

PUMP

PITOT HEAT

STRODE 1,IC;HT

ROTATING BLACON (OPT)

RADIO

MASTFII

NAV I (Ol"1

i

COM

11

(01"I'I

NAV 11 101"1'l

'I'I~ANSl'ONI>I~~II lOl>'l'l

AUDIO (OPT)

FIGURE

2-4.

ELECTRICAL SYSTEM SCHEMATIC

2 -14

idb

~OONEV-

OPERATORS

MANUAL

The alternator push-pull circuit breaker on the main

breaker panel furnishes an emergency overload break

between the alternator and the individual push-pull

circuit breakers. Resetting the alternator circuit

breaker will usually restore an overloaded circuit. If

pressing the button a second time does not reactivate

the circuit, the alternator circuit breaker must re-

main open and the alternator-field circuit breaker must

be pulled out to break the alternator excitation circuit.

Since the alternator is then cut out of the power circuit,

the storage battery supplies electrical power in steadi-

ly diminishing output with the master switch on.

The alternator-field push-pull circuit breaker furnishes

an emergency break in the alternator field excitation

circuit in the event of alternator or voltage regulator

malfunction. If the regulator output voltage exceeds

limits, the red alternator warning light illuminates

steadily. Turning off all radio equipment, and then

turning master switch off and

on, will reset the voltage

regulator. The alternator annunciator

light should

remain out. If the alternator light comes on again,

pulling out the alternator-field circuit breaker cuts the

alternator out of the power circuit.

Once again the bat-

tery is the only source of electrical power; therefore,

all electrical

equipmerlt not essential for flight should

be turned off and the flight terminated as soon as practical to correct the malfunction.

ANNUNCIATOR LIGHTS

The landing gear lights are at the top of the instrument

panel by the landing gear switch. Annunciator lights

for the registration number, landing light, nlternator

,

vacuum, and fuel pressure are in the glare s hielcf.

The purpose and fullction of each of these lights is

discussed elsewhere in this section.

INSTRUMENT

&

PLACARD LIGHTS

All

instrun1e:lt faces 2nd placards are floodlighted by

light bulbs in the glare shield. Rheostat lulobs on the

control quadrants control

the intensity of instru~nent

ancl placard lighting.

Roi

ating the knobs clockwise

tul.11~

011

;III{I

il~(-l.(';\s~s light intcllsity.

CABIN LIGHTING

An

ad~ust~lble eyetx111 dome light illuminates the c.aI,it~

ancl also serves

ns

a bacliup ~i)o!light for illuminating

the

instrume:~t ;)anel; its

OV-OFF-DIM

switch is slight-

ly forward ancl

to

the right of the dsmle light.

CABIN ENVIRONMENT

HEATING

&

VENTILATION SYSTEMS

T\vo ventilating systems l~rovicle cabin environmental con-

trol

suited

to

indivittual pilot ancl passenger prefcre!~.:es.

I.'resh

air healotl i)y the :tn;:ino r:xlt;i?rst. ml~ifler

,

nntl

cool

air I'rol.r1 ail ail-scoop oil

thit

c:o-pilot sicle, can I)e indivicl-

u;\lly controllecl :\ntl tnixed to the clesireil temlicrnture.

The left side fresh-air scoop has an adjustable eyeball

inlet near the pilot's knee.

*

'\-~OONEV

OPERATORS

MANUAL

The cabin overhead vcntilaling systenl worl<s independently of the cabin heating and ventilating systenl.

Rotating the

knob above the pilot seat eXte1lds or re-

tracts the overhead

airscoop t:, control air intake and

to prevent air-buffeting at high cruising speeds.

Small

directional vent deflectors @ith inner knob air volumn

controls, within easy reach of each occupant, distribute

incoming outside

air

as

individi~ally desired.

The cabin heat control is marked CABIN

HEAT.

Opening

the side

;xirscoop control (labeled CABlN VENT) and

setting the cabin heat control turns on cabin heat.

To

lower cabin temperature, the cabin heat control is

pushed toward the

OFF

j~osition. Conlpletely closing the

cabin heat control and fully opening the cabin vent

con-

tr 01, with the overhead :tirscoop extended, supplies

maximum fresh air circulation. In case of engine fire,

the cabin heating

systenl must be turned off.

The right side

airscoop has outlets undel- the

side

panel

for

installatio!~ of radio or autol~ilot ecluil)ment cooling

ducts.

WINDSHIELD DEFROSTING SYSTEM

The defrosting system talces warm air from the cabin

heating system

ductwork and distributes this air over the

windshield interior surfaces. The system works full

time without a separate control.

*

~OONEV

OPERATORS MANUAL

SEATS & SAFETY BELTS

The front seats are individually mounted and may be

adjusted fore and aft to fit individual comfort preferences. Resetting a seat back is accomplished by

pulling the seat back forward, rotating the large cam

selector

lmob at the lower back juncture, and allowing

the back to return to the new position. The rear seat

back can be adjusted by leaning forward in the seat,

pulling the catch lever at the forward end of the side

panel arm rest, and adjusting the seat back to the

desired position.

Safety belts, if

worn properly, keep occupants firmly in

their seats in rough

air and during maneuvers.

These

belts are mechanically simple

nuct conlfortal~le to wear.

They are

attached to the seat so the seat can be moved

without readjusting the belt.

BAGGAGE & CARGO AREAS

The baggage compartnlent has

15

cubic feet

of

baggage

or cargo space and two pair of floor

tiedo\vn straps. The

loose equipment, consisting of

tiedown eyebolts, jack-

points,

tiedown rings, a fuel sampling cup, and a towbar

is stowed in the baggage compartment. The rear seat

backs can be removed for additional cargo space by pulling the

springloacled lock pins at the seat bac.1~ I~ase

a!ld

sliding the seat back rearward.

SECTION

Ill

.

NORMAL

PROCEDURES

GROUND OPERATIONS

PREFLIGHT

.........................

3-2

...................

PREFLIGHTCHECK 3-3

....................

BE

FORE STARTING 3-5

..............

BEFORE-STARTING CHECK 3-5

STARTING

..........................

3-6

.....................

STARTINGCHECK 3-7

...............

Flooded- Engine Clearing 3-8

Cold- Weather Starting

................

3-9

......................

Hand Cranking 3-9

WARMUP & TAXILNG

...................

3-9

BEFORE-TAKEOFF CHECK

..............

3-11

FLIGHT OPERATIONS

TAKEOFF

.........................a.

3-12

.............................

CLmB 3-13

............................

CRUISE 3-15

STALLS

............................

3-17

SPINS

..............................

3-18

POSITIVE CONTROL

..................

-3-20

FUEL MANAGEMENT

...................

3-21

INFLIGHT RESTARTING

................

3-22

LETDOWN

.........................

-3-22

BEFORE- LANDING CHECK

...............

3-23

LANDING

...........................

3-23

AFTER.LANDING

....................

-3-25

SHUTDOWN CHECK

....................

3-25

db

m00hlcv

OPERATORS

MANUAL

Before flying your Mooney, it is necessary that you become thoroughly familiar with all techniques needed to

operate its systems and equipment safely

and efficiently.

This section of the manual provides you with a quick and

easy reference to normal operating procedure recommend-

ations. Checklist procedures are enumerated in steps that

cover cockpit contr

01s and instruments in left-to-right and

top-to-bottom patterns. These procedures are intended to

assist you in developing good flying techniques under average conditions. While close attention to each step is

impor-

tant for safe and efficient operation, sound judgment may

occasionally be called for in making exceptions when circumstances require

a

deviation in operating procedure.

GROUND OPERATIONS

PREFLIGHT

In addition to completing the preflight check, visually in-

spect all of the

airwaft exterior prior to each flight with

particular attention to detection of loose rivets and dents.

When

checking under the aircraft, look for fuel and oil

leaks indicated by oil runs or fuel dye stains.

WARNING: Check the aircraft weight and balance

before proceeding with the flight. Consult the

Weight

&

Balance Record, furnished in the air

-

plane file, for detailed data needed to calculate

load distribution and limitations.

Standard atmospheric

teinperatures are below freezing

above

8000

feet altitude, and it is possible that condensed

water in the fuel lines will freeze to cause fuel starvation.

Therefore, always drain the fuel selector

~~11111

(as de-

scribed in Section

VII) at each preflight inspection.

*

mm

OPERATORS MANUAL

FIGURE 3-1.

PREFLIGHT WALK

AROUNU LIIAGIZAM

PREFLIGHT CHECK

1.

Ignition Switch--OFF.

Master Switch--ON to check outside lights,

then OFF.

Fuel Selector Drain--Selector handle on R; pull

ring and hold for five seconcls.

Repeat pr ocedure

with selector handle on

L.

2.

Instrument Static Port-- UNOBSTRUCTED.

Tail

Tiedown-- RE MOVE.

3. Empennage--CHECK.

Remove all ice, snow, or frost.

4.

Tail Cone Access Door--SECURE?

Instrument Static Port- -UNOBSTRUCTED.

Static System Drain--CHECK.

5.

Wing Skins--CHECK.

Flap and Attach Points--CHECK.

Aileron and Attach Points- -CHECK.

Wing Tip and Navigation Light-

-

CHECK.

Remove all ice, snow, or frost.

6.

Left Wing Leading Edge--CHECK.

Pitot Tube and Stall Switch Vane-- UNOBSTRUCTED.

Fuel Tank--CHECK QUANTITY; SECURE CAP.

Chock and Tiedown--REMOVE.

Left Main Gear Shock Discs and Tire--CHECK.

Fuel Tank Sump Drain--SAMPLE

.

Pitot System Drain--CHECK.

Tank Vent-

-

UNOBSTRUCTED.

Fuel Selector Drain Valve-

-C LOSED.

Windshields--C LEAN.

Left

Side Engine Cowl Fasteners-- SEC URE.

7.

Propeller--CHECK for nicks and cracks.

Forward Engine Components--CHECK starter,

alternator belt, etc.

Induction Air Filter--CHECK clean and sealed.

Landing Light--CHECK.

Nose Gear--CHECK tire; check for towing damage.

Shock Discs--CHECK.

8.

Right Side Engine Cowl Fasteners- -SECURE.

Engine Oil Level--CHECK (full for extended

f

lig it).

Windshield--CLEAN.

*

~OONEV

OPERATORS MANUAL

Fuel Tank Sump Drain--SAMPLE

.

Tank Vent-- UNOBSTRUCTED.

Chock and Tiedown--REMOVE

.

Right Main Gear Shock Discs and Tire- -CHECK

Fuel Tank--CHECK QUANTITY; SECURE CAP.

9.

Right Wing Leading Edge--CHECK.

Wing Skins--CHECK.

Wing Tip and Navigation Light--CHECK.

Aileron and Attach Points--CHECK.

Flap and Attach Points--CHECK.

Remove all ice, snow, or frost.

10.

Baggage Door

-

-

SE C URE

.

BEFORE STARTING

After everyone has entered the aircraft, close and latch

the door.

Be sure all baggage is secure and that all

necessary charts, computers, and other loose items are

aboard and securely stowed so that they will not be

thrown about the cabin if rough air

is

encountered in

flight. See that all safety belts are fastened and that

the seats are adjusted and locked in comfortable positions. With the pilot's seat properly set, you should be

able to fully deflect all flight controls. Be sure

thereis

a flashlight aboard for night flights.

BEFORE STARTING CHECK

1.

Fuel Selector Handle--SET for fuller tank.

2.

Parking Brake Control--PULL ON.

3.

Ignition and Master Switches--OFF.

*

~OONBV~

OPERATORS MANUAL

5.

Landing Gear Switch- - DOWN.

*9

6.

Mixture Control--IDLE CUTOFF

7.

Propeller-- HIGH RPM.

9.

Boost Pump--OFF.

10.

A11 External Light--OFF.

11.

Radios--ALL OFF.

12.

Cabin Heat--OFF.

13.

Main Circuit Breaker Panel--CHECK.

STARTING

Before starting the engine, make sure the surrounding

area

is

clear. It is good practice to call "CLEAR"

before engaging the starter, and to direct the propel-

ler blast to an open area before running up the engine.

To prevent

prcpeller damage, keep engine RPM low

when operating on loose gravel.

The engine will require

some priming for smooth starting.

The standard fuel system does not incorporate a separate

priming system;

priming is accomplished by pumping the

throttle with the electric fuel pump turned on and the mixture control lever in the FULL RICH position. For

nornlal

starts, pump the throttle twice. A cold engine will require

three or more "priming shots" depending upon the ambient

temperature.

'rhe

sc'lrti

heckli list

is recnmmendr el~xl

starti, edures; however, unde~

,lit-

climatic,

conditicli' dter the starting procetl~ A to accommod:;

existing 8 iiditions. If the engi11~. does not start aftel

10

or

15

~jrlds of cranking, discontinue cranking and

al-

1

t

t$<

rtzr to cool for approximately five minutes

t)efox I-ranklllg adgain.

A11

\$

1,1!:

the

sf

nrter to cr!ol in-

terrnltt ~ntly will

p~olcnlv

*

-

tar

life.

The engine

is

air-r2r r:ooled and depel

3

on the

forward speed of

if

tincraft

to maintain

j3,

$per cooling.

Particular

egre

is

necessary, therefore,

:

hen operating

the engine

oil

the ground. To help prei

s

overheating,

always

!IC;;~

the aircraft into the wind tl~d avoid pro-

longed

engitle ground operation.

STARTING

CHECK

1.

Master Switch--ON

2.

Fuel Quantity Indicators riECK for conformity

to observed quantity.

3.

Annu~~ciator 1,ights- IyRESS to TEST.

5.

Electric Fuei Pump--ON.

6.

Mlxture Control- --Open to FULL RICH.

7.

Throttle--PUMP 'I'WICE to prime engine; then

OPEN

approximai ely one-quarter.

8.

Ignition Starter hitch--turn to "START" and PUSH

forward. When engine starts, release to "BOTH".

*

~OONEV

OPERATORS MANUAL

1.

Oil Pressure Gage--25 PSI MIN (If there

is

no

pressure indication within

30

seconJs, PULL

mixture control to IDLE CUTOFF and check oil

system.

)

12.

Carburetor Heat--ON momentarily to check operation. (RPM should drop.

)

CAUTION: Limit the use of carburetor heat

during ground operation to the time required

to make sure the system

is

functioning prop-

erly.

Heated carburetor air does not pass

through the air filter; consequently, dust,

dirt, and foreign substances can be drawn into

the engine to cause accelerated cylinder and

piston ring wear.

13.

Fuel Pressure Gage--GREEN ARC

14.

Lights--As required.

15.

External lights- -ON as required.

16.

Pitot Heater--CHECK and note ammeter de-

flection.

17.

Radios--QN and CHECK.

18.

Stabilizer Trim Indicator--TAKEOFF.

19.

Fuel Selector I-Iandle- - CHECK right and left.

Flooded- Engine Clearing

1.

Throttle--FULL OPEN.

2.

Mixture Control--IDLE CUTOFF.

*

-~OONEV

--

OPERATORS MANUAL

3.

Electric Fuel Pump--OFF

4.

Ignition Starter Switch--turn to "START" and

PUSH

forward.

5.

Throttle--RETARD when engine starts.

6.

Mixture Control--Open slowly to FULL

RICH.

Cold- Wea ther Starting

The starting procedure for a cold engine is the same as

the normal starting procedure, except that additional

priming (mixture control set at FULL RICH) may be

necessary. During extremely cold weather it

is

advisa-

ble to preheat the oil and engine compartment with

ground heaters

.

Hand Cranking

Hand cranking is not recommended.

WARMUP

&

TAXIING

Allow the engine to warmup at

1000

to

1200

RPM; normally,

taxiing will sufficiently warm the engine. The engine is

warm enough for takeoff when it will develop full RPM and

when the throttle can be opened without backfiring, skipping,

or

a

reduction in oil pressure.

Release the parking brake,

and as the aircraft moves forward apply the toe brakes

lightly to check brake effectiveness.

Nose wheel steering,

through rudder pedal action,

is

ordinarily sufficient for

ground maneuvering. But, when necessary, make tighter

turns by applying inside braking.

CAUTION: Never rely on the retraction safety

switch to keep the electric gear extended while taxiing, taking off, or landing. Always check the elec-

tric gear switch position.

Taxi with the mixture

FULL

RICH and the propeller

at

HIGH RPM to prevent engine overheating. Avoid prolonged ground

operation.at low RPM that will tend to

foul the spark plugs.

WARNING:

While taxiing before takeoff, make sure

that the Positive Control system

is

functioning normally and that the gyro instruments have erected

properly

.

The control wheel will tend to move in the opposite direction from the taxi turn when

P.

C.

is

working properly.

The absence of flight control movement, or extreme control movement in either direction without prompt return

to neutral, indicates a P. C. malfunction that should be

corrected before flight. Taxi turns also present an

opportunity to check the directional gyro for proper indi-

cation. The turn coordinator should indicate a bank in

the direction of the turn.

Before

runup, head the aircraft into the wind and center

the nose wheel. It is always a good practice to stop the

airplane with the nose wheel centered, since running up

the engine or starting to taxi with the nose wheel in a

cocked position imposes high side loads on the nose gear

Minimize engine ground operation to prevent overheating.

Monitor cylinder head and oil temperatures. Check the

propeller governing system by advancing the throttle to

1700 RPM; then, pull the propeller control full aft (de-

crease RPM). As soon as a 100

RPM

drop is noted,

return the propeller control to

FULL

INCREASE

RPM.

In cold weather, repeat the cycle two

or three times to

flush the system

with fresh, warm oil. Then, check

R

and L magnetos, returning the switch to BOTH between

checks. Neither magneto should drop off more than 125

RPM when operated individually nor should the

difference between the two exceed 50 RPM. With this check

completed, slowly close the throttle to 1000-1200 RPM

and complete the before-takeoff check.

*

~OONEV

OPERATORS

MANUAL

BEFORE-TAKEOFF CHECK

1.

Flight Controls--CHECK for unrestricted travel.

2.

Fuel Selector Handle--SET for fuller tank.

3.

Altimeter--SET to field elevation. (Obtain tower

or weather station barometric pressure; check

altimeter barometric pressure to determine deviation.

)

4.

Directional Gyro-- SET to magnetic compass.

5.

Flight Instruments--CHECK.

6.

Engine Instruments--CHECK.

7.

Clock--SET and wind

as

needed.

8.

Stabilizer Trim--SET for TAKEOFF

9.

Propeller--CYCLE and CHECK

at

1700 RPM

10.

Magnetos--CHECK at 1700

RPM.

11.

Wing Flaps--SET for TAKEOFF or as desired.

12. Electric Fuel Pump--ON. (Check rise in fuel

pressure.

)

14. Seat Belts--FASTENED.

15. Door and Pilot

Window-- LATCHED closed.

Before applying power for takeoff, quickly recheck for:

1.

~ropeller-j4?~L~ INCREASE.

2.

Trim Indicator--TAKEOFF.

fg

3.

Flap Indicator--TAKEOFF or as desired.

4.

Fuel Selector Handle--FULLER TANK.

WARNING: Do not change fuel tanks imme-

diately before takeoff.

5.

Carburetor Heat--OFF.

Proceed with takeoff as soon as the above checklist is

complete. If

it

is

necessary to hold for clearance in-

structions, run the engine at 1400- 1500

RPM

to insure

proper cooling and to minimize spark plug fouling.

NOTE:

During takeoff from high elevation airports

or during climb, engine roughness or loss of power

may result from over-richness. In such a case ad-

just mixture control only enough to obtain smooth

operation--not for economy. Observe instruments

for temperature rise.

FLIGHT

OPERATIONS

TAKEOFF

When ready for takeoff, apply power slowly to avoid

picking up loose stones, etc.

,

with the propeller.

(On short fields you may prefer to hold the brakes un-

til gaining full power.) As the aircraft accelerates

continue increasing power until reaching full throttle.

Have the control friction lock tight enough to prevent

throttle creep.

As

speed increases during the takeoff roll, apply back

pressure on the control wheel at about 65-75 MPH (56

to 66 Knots).

The aircraft will tend to rock into a nose-high attitude

as

it breaks ground. To compensate for this tendency,

slowly relax some of the elevator back pressure as the

nose wheel leaves the runway. Keep the nose on the

horizon just after the aircraft breaks ground to allow

smooth flight from the runway without an abrupt change

in pitch attitude.

When making a cross-wind takeoff, hold the nose wheel

on the runway longer and accelerate to a higher speed

than normal.

PulI up abruptly to avoid contact with the

runway while drifting. When clear of the ground,

make

a coordinated turn into the wind to correct for drift.

Retract the landing gear only when safely airborne and

in good control. Retract the flaps when the aircraft has

cleared all obstacles and has gained an indicated airspeed of about 80 to 90

MPH

(70 to

78

Knots).

After takeoff:

(1)

Apply the brakes to stop wheel rotation.

(2)

Retract the gear.

(3)

Retract the flaps.

(4)

Establish climb- out attitude.

(5)

Turn off the electric fuel pump at a safe altitude

and check the fuel pressure indication to insure

that the engine-driven fuel pump is nlaintaining

fuel pressure.

CLIMB

An enroute climb speed of 115-120

MPH

(100-104 Knots)

IAS is

recommended for improved engine cooling and

forward visibility.

The speed for maximum rate of

climb

i~ a straight-line variation froill 100

MPH

\

(

87

Knots) IAS at s,ea Ievel (decreasing approximately one

MPH per 1000 feet increase in a1titude)'ko 91 MPH (79

Knots)

IAS

at 10,000 feet.

The speed for maximum

angie of climb (for obstacle clearance at full power,

gear and flaps up)

is

about 80 MPH (70 Knots)

IAS

at

full power. The recommended power setting for nor-

mal climb

is

2600 RPM and 26 inches manifold pres-

sure

.

Manifold pressure will drop with increasing altitude

at

any throttle setting. Power can be restored by gradually opening the throttle until reaching full throttle.

WARNING: Do not fly this aircraft into known

icing conditions.

Under certain moist atmospheric conditions, it

is

pos-

sible for ice to

form in the induction system, even in

summer weather. The formation of ice in the induction system will be reflected by a drop in manifold

pressure. When an unaccountable loss of manifold

pressure is noted, apply full carburetor heat and open

the throttle to the limit of manifold pressure. The use

of carburetor heat

inay cause the engine to run rough;

if so, lean the mixture until the engine smooths.

WARNING: Do not use partial carburetor heat

unless the aircraft is equipped with a carburetor

air temperature gage. Moisture in crystnlform

that would ordinarily pass through the induction

system as crystals can be

melted withapplication

of partial carburetor heat. This moisture in turn

can form carburetor ice due to the temperature

drop as the air passes through the carburetor

venturi. Therefore, when applying carburetor heat,

always pull the control FULL ON. When turning

carburetor heat OFF, move the control to the

FULL OFF position.

*

~OONEV

PERATORS

MANUAL

After establishing climb power and trimming the aircraft

for climb, check to insure that all controls, switches,

and instruments are set and functioning properly.

CRUISE

Careful and detailed flight planning for each trip will increase operating efficiency. The weather, route, load

and starting and arrival time will affect altitude selec-

tion and over-all flight efficiency.

The performance tables in Section

VI

will aid in selection

of optimum cruise power settings. Cruise power

is

that

portion of the power spectrum where the mixture may be

leaned.

Leaning is limited to

75

percent power or less

for aircraft not equipped with an EGT gage.

Leaning a-

bove

75

percent power may cause detonation and engine

damage unless exhaust gas temperature

is

maintained

200°F below peak EGT on the rich side. Monitor cylinder head temperature when leaning. (Ref. Service Instruc-

tion Lycoming No.

1094B).

Upon reaching cruise altitude, allow acceleration to

cruise

airspeed,

then trim the aircraft for level flight,

reduce manifold pressure and

RPM

to desired cruise

power. When cruising at

75

percent power or less,

lean the mixture once cruise power is established.

For

best economy, slowly pull the mixture control lever toward the lean position, continue leaning until the engine

runs rough. Then, enrich the mixture until the engine

runs smooth. For increased power, enrich the mixture,

increase

RPM,

advance the throttle, and repeat the

leaning procedure.

CAUTION: Do not lean the mixture l?eyond 2000F

below peak EGT on the rich side at power settings

above 75 percent rated power. In selecting a cruise

RPM, the engine must not be continuously operated

within the range of 2000 to 2250 RPM. Recommended

cylinder head temperature

for

continuous cruise

operation

is

4000F or less.

Very exacting fuel-air mixtures can be selected by observing the optional exhaust gas temperature gage (EGT) while

adjusting the mixture control. Operate the mixture control

slowly to allow for the slight lag in the EGT indicator.

For best economy below 75 percent rated power, lean the

mixture by pulling the mixture control lever aft until the

EGT indicator shows a

peak (maximum) temperature and

starts to decrease. Then, enrich the mixture by pushing

the

control lever forward until

the

temperature drops

25'F

(one mark on the gage) froin peak temperature.

For best power (maximum airspeed) below 75 percent power,

lean the mixture by pulling the mixture control lever aft until the

EGT indicator shows a peak (maximum) temperature,

and then enrich the

mixture by pushing the control lever

forward until the EGT shows a drop of

100~~ (four marks on

the gage) below the peak temperature.

When making power changes it is advisable to always

increase RPM before increasing

ma~lifold pressure,

and to decrease manifold pressure before reducing

RPM. Always stay within the established operating

limits, and always operate the controls slowly

and

smoothly.

Aerodynamic efficiency is optimum

in the normal indi-

cated cruise

ranqcs.

'I'he airsl~eed indicator

is

nlarlted

with a green arc from

64

to 175

MI'H

(56

to 152 Knots)

and a yellow arc from 175 to

200

MPH

(152 to 174 Knots).

The yellow arc indicates the range of airspeeds in which

you must exercise caution when flying in rough

air

or

gusts.

(Rough

air

is

defined

as

flight in turbulence of

a

degree that is uncomfortable to the pilot and passengers.

)

Reduce speed when encountering rough air or gusts, and

operate in the airspeed indicator green arc range.

WARNING: Operate this aircraft as

a

Normal

Category airplane in compliance with the opera-

ting limitations stated in the form of placards,

markings, and manuals. Do not attempt maneu-

ver

s

involving full application of rudder, elevators,

or ailerons above

132

MPH (115 Knots) CAS. No

aerobatic maneuvers including spins are approved.

STALLS

The

stall

characteristics of the airplane are conventional

and rapid recovery from a stall is affected by releasing

elevator back pressure and applying power

.

Power - off

stall speeds

at

various bank angles are presented in Sec-

tion VI.

It is

important to remember that while stalls are a permis-

sible maneuver; they should not be practiced to learn how

to stall the airplane but, rather, to learn how to recognize

an incipient stall and to take prompt corrective action before the aircraft completely stalls.

Turn on the electric fuel pump prior to practicing stall

recovery and apply full carburetor heat before reducing

power.

For power-on stalls, the FAA

recolntnends about

65

percent power.

Enter stalls only

from coordinated

flight, regardless of the method of entry or airplane configuration.

Flight controls will remain effective t

hrou~l~out all nor ma1

stall maneuvers. Approach the stall slowly, but positively,

idb

~OONEV

PERATORS

MANUAL

by reducing airspeed with about one mildoan hour decrease

per second, until detecting the first evidence of the ap-

proaching stall. The stall warning horn will give the first

indication of the approaching stall and this may be followed

by downward pitching, aerodynamic buffeting, rapid decay

of control effectiveness, and/or a rapid loss of altitude with

the control wheel aft.

Upon recognizing the approaching

stall, recover by releasing elevator back pressure and

applying power.

WARNING:

Do not deactivate the stall wa.rning

horn when practicing stalls; the stall warning

horn is required aircraft equipment.

If stall recovery

is

not initiated during the approach to the

stall, the airplane will stall and the nose will pitch down-

ward. Recovery from the complete stall is conventional,

with release of elevator back pressure and the addition of

power.

Holding the aircraft in a stall with the control wheel fully

aft

may result in a roll to one side or the other, unless

precise control coordination is maintained. The rudder

may

prove inore effective than the ailerons in preventing

the roll; however,

recovery from the conlylete stall and

possible roll

is

again achieved with normxl

use

of the

controls. Delay the

al)l)licatioli

of

power, to prevent

k~uilcl-up

of

excessive airspeed,

if

the aircraft assumes a

steep nose-down attitude.

SPINS

intentional

spins are not permitted in this airplane;

I~owever, if stall recovery is delayed or

if

the air-

plane is

lleld in the stall, in an uncoordinated manner,

the airplane will likely go into

a

spin.

A

spin is a

stall

coillbinecl with rotation, with the airplane rotating

downward in

a

descending corliscrew-like path. The

outside wing in the rotation

moves fastest and produces

some effective lift, while the wing toward the inside of

the spin moves slower and produces little or no effective

lift.

A

spin

is

generally caused by an uncoordinated

yawing of the aircraft while in a stalled condition.

Should

a

spin occur employ the following recovery pro-

cedures immediately:

1.

Neutralize the ailerons and close the throttle.

2.

Briskly apply full rudder against the spin.

3.

Follow with rapid forward movement of the con-

trol wheel to pitch the nose down.

4.

Hold the rudder in full antispin configuration until

rotation stops.

5.

Recover from resulting dive.

NOTE:

If spin recovery is delayed until the

aircraft has made one complete turn in the spin,

rotation may continue up to one additional turn

after

antispin controls are fully applied.

WARNING:

Up to

2000

feet of altitude may be lost

in a one-turn spin and recovery; therefore stalls

at low altitude are extremely critical.

On

entering a spin, the aircraft will roll, very much like

a

barrel roll. The wings will be ~lear vertical at about

the first

quarter turn of the spin.

At about the half turn

point, the wings are

approachiny level but,

now, the nose

will be very

low--approacl~ing vertical. After one fill1

turn llas been con~l~letect, the nose will come

up

somewhat,

but will

remain well below the horizon.

The rate of ro-

tation during the

first

portion of the spin is quite rapici and

occupants of the aircraft will likely become disoriented.

On subseq~ient turns, the wings may be near level or

slightly lower

tBward the clirection of the spin. The nose

*

~OONEV

OPERATORS MANUAL

will continue to be pointing more nearlyr#oward the ground

than the horizon, as the ;~irplane revolves and descends.

As

tlie spin progresses, it may enter into what is re-

ferred to

as

a flat spin. When the spin becollies flat, the

aircraft nose comes

up

and relliains more on the horizon,

with possibly

some shallow up and down oscillation. The

rate of descent and rate

of

rotation both become slower.

An aircraft in a flat spin

becomes stabilized into autoro-

tation and once in this condition, the co~itrols beconle

ineffective

and

recovery is very difficult or nlay not be

possible.

I11 complying with the

FAA

Regulation for Nor ma1 Category

aircraft, it has been demonstrated that the airplane will

recover after delayed stall recovery

up

to and including

one

-

t

ur

11

spins.

Tiiis one-turn "margin of safety" is designed to provide

adequate controllability when

recovery from a stall is

tlelayecl.

The one-tiu-n "margin of safety"

1s

~col)arclized

if

tlie airplane is not recovered when the lirst evlclence

of

a

stall is detected.

POSITIVE

CONTROL

Positive Control will hold an approximate heading over a

period

of

time: however, it will not hold an esact heading

without the installation of a magnetic

Ileacling locl~ To

checlc for a

P.

C. m~~lfuiiction while in flight, first esta-

blish

a

inoderate I~anlr; then, release the controls to see

if the aircraft will

return to straight wings-level flight as

indicatecl by tlie artificial horizon, Repeat the ~~rocedure

with a turn in the opposite direction. Slu:;<isl~, erratic,

or incomplete

banli recovery warns of a ~nalfunction in

the

1'.

C . systeni.

WA

FINING:

rI'horougl~ly familiarize yourself with

the flight

char;lcterislics

of

the aircraft with Positive

Control

i~iol)t?rative. 7':iis

can

be

clone 1)y simply

scjucezin?

the tLiltoff trigscr while 1n:iliing turns

and i~~aneuvei-s. Check the

P.

C.

system fre-

quently during

each flight to insure that it is

functioning properly, particularly when

IFR

or

marginal weather inay be encountered.

In the event of a complete engine power loss,

P.

C.

will

continue to operate as long

as

the propeller is wincl-

milling at

1000

RPM

or more.

Loss of

vacuum (indi-

cated by a

LO

vacuum annunciator light) will automatical-

ly make the

P.

C. system inoperative.

However, the

turn coordinator will continue to operate on electrical

power. The turn coordinator can be used

as

a flight refer-

ence

if

other gyro instruments become inoperative.

FUEL MANAGEMENT

Proper fuel n~nnagement during flight will help maintain

lateral trim and

ill

also serve

as

a fuel cluantity check.

After takeoff with both

tailks full, use fuel from one tanlr

for one hour: then, switch to the other tank and note the

time.

Use all the fuel from the second tank.

The

relnainillg fuel endurance in the first tank can be calculatecl from

the time it took to deplete the secolld tank, less one hour.

You must

rememher , however, that this eudurance cnl-

culating ~)roceclure can be relied upon only if power and

mixture renlain the same aild

an

allowallce is lnade for the

extra fuel

used during clinlb.

For estimation purposes,

coilsider fuel consu111l)tion tluriilg a full-power climb to

be

40

percent higher than that of best-power cruise, and

50

percent higher than that of best-erol:omy cruise.

CAUTION:

Do not allow the engine to lose l)onler

or quit before switcliin~:

fuel

talllis.

A

red "I'acl

I1rcss"

:xnnunci:xtor will il1uinitl;ile wllen prcssurc