Mooney M20r, M20V, M20TN, M20U Service Bulletin

MOONEY INTERNATIONAL

CORPORATION

165 Al Mooney Road North

Kerrville, Texas 78028

THIS BULLETIN DOES NOT CHANGE AIRCRAFT TYPE DESIGN

SUBJECT: Mooney Aircraft Flight Control Balancing After Painting

MODELS/ SN M20R - S/N 29-0520 thru 29-0525

AFFECTED: M20TN - S/N 31-0128 thru 31-0143

M20U - S/N 32-0003

M20V - S/N 33-0004, 33-0006, 33-0007

TIME OF Before Next Flight

COMPLIANCE:

INTRODUCTION: Mooney International Corporation has determined a flight control balance issue may exist after

final paint by outside vendors. Mooney Engineering has determined that the aircraft listed will

need to have the specified control surfaces removed and balanced per Mooney specifications

found in the applicable Service and Maintenance Manual and Mooney Spec 20 Section 35. If

Rudder and/or Elevator Control Surface is found to be out of specification, you will need to use

STEPS 3.0 in this Service Bulletin. A Limitation Placard must be installed prior to flight for Aircraft

requiring flights to a maintenance facility. Compliance with this Service Bulletin will be considered

a one-time inspection and repair, requiring no additional inspections, unless flight control(s) are

repaired, replaced or repainted, which will then need to be rebalanced as required.

INSTRUCTIONS: Read entire procedures before beginning work.

SERVICE BULLETIN

SERVICE BULLETIN M20-335B

Date: January 2, 2019

NOTE:

All work to be done in accordance with FAA AC43.13.

NOTE:

Record ALL Surface Rigging Values before removing components. Run trim wheel up, all the way to the

stop before removing components.

- CAUTION -

DO NOT move control surfaces to extreme angles. Be gentle with tabs and do not bend them.

STEP 1 - LIMITATION Placard (for Aircraft requiring flights to a maintenance facility)

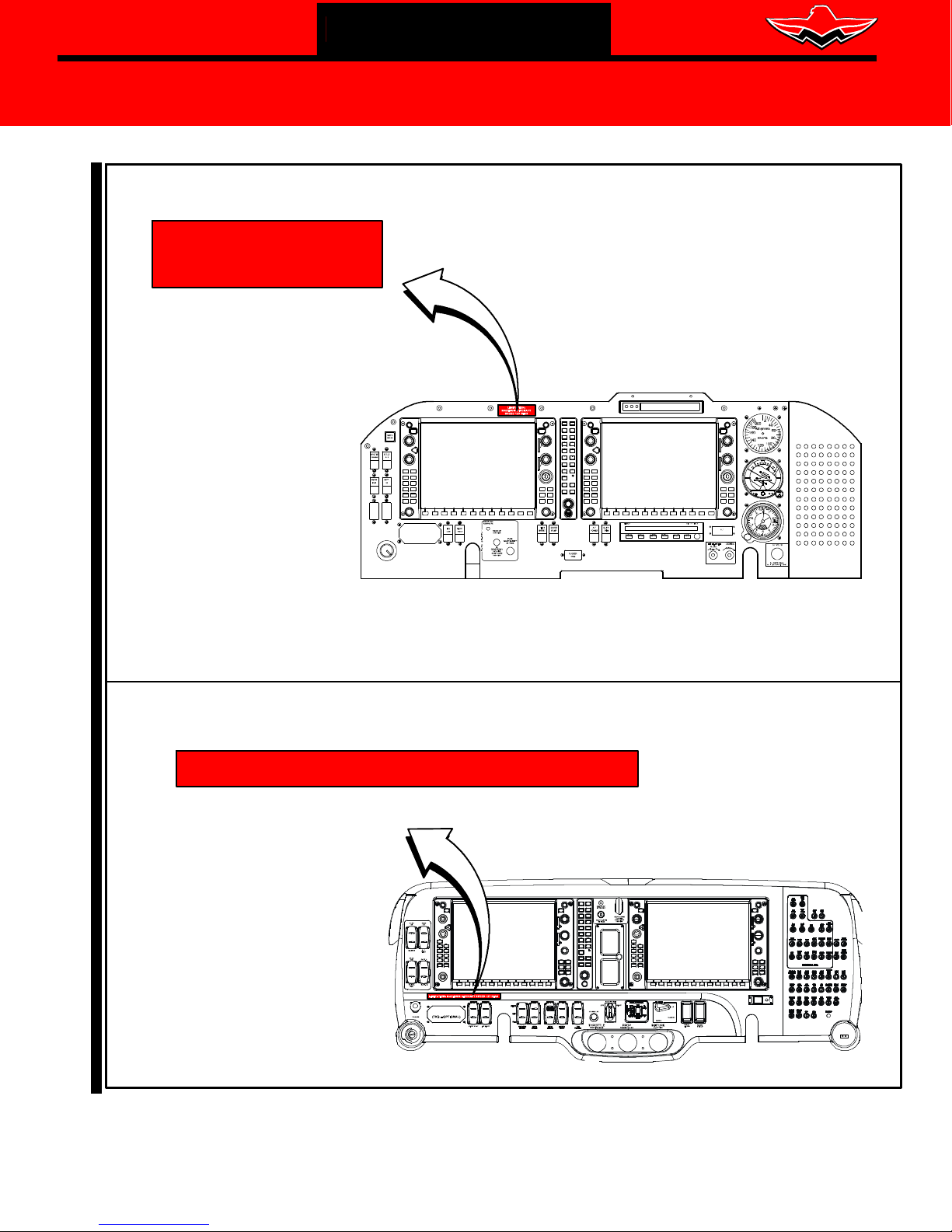

1.0 PLACARD INSTALLATION - Refer to Figure SBM20-335-1

1.1. Install placard P/N M20-335-901 or M20-335-902 on instrument panel, refer to Figure

SBM20-335-1 for effectivity, clean surface area with isopropyl alcohol before applying

placard, this will remove any oils or debris from surface.

1.2. Fly Aircraft to approved Mooney Repair Station for compliance with this Service Bulletin.

- CAUTION -

DO NOT EXCEED SPEEDS INDICATED ON INSTALLED PLACARD SBM20- 335- 901 OR SBM20-335-902.

STEP 2 - Checking Flight Control Balance - Rudder and Elevator Only

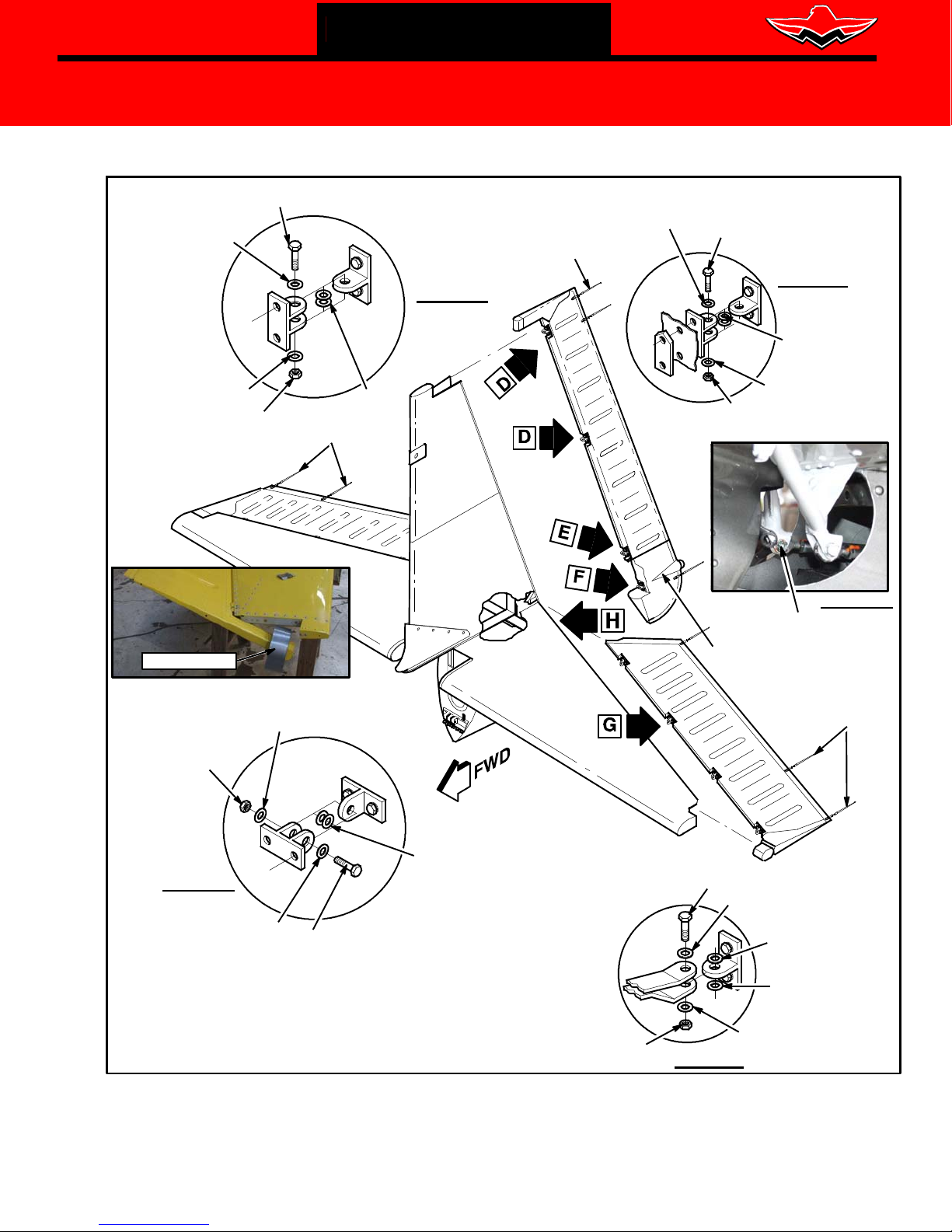

RUDDER REMOVAL/INSTALLATION - Refer to Figure SIM20-335-2

2.1. Disconnect rudder push- pull tube from rudder horn by removing Bolt AN3-10, Washers

NAS1149F0332P, Nut MS17825-3 and Cotter Pin MS24665-151, refer to Figure SIM20-335-2.

2.2. Disconnect (un-pin) Strobe Light harness from lower tailcone/rudder area.

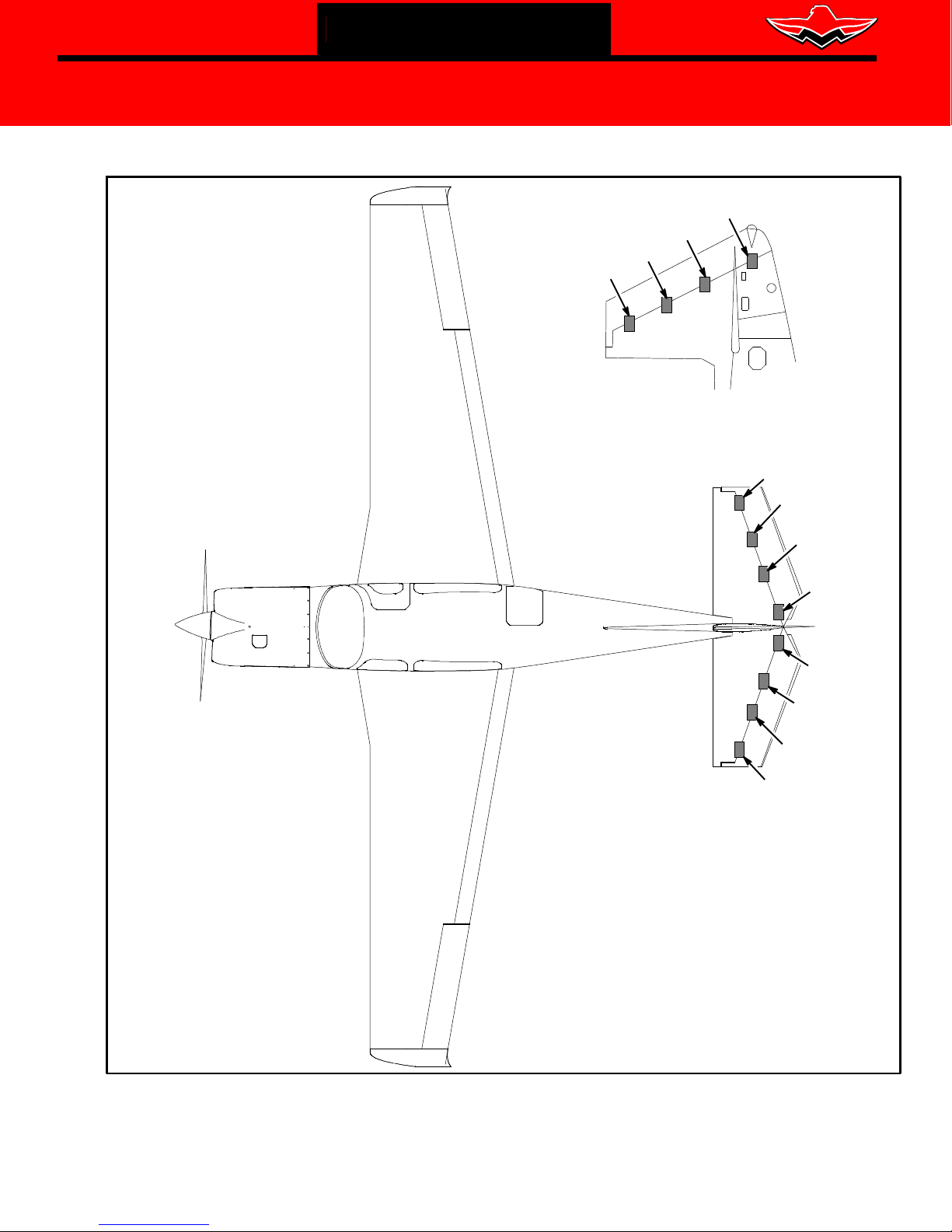

2.3. Remove attaching hardware at rudder hinges, note each hinge hardware on zone chart(s) Figure

SIM20-335-8.

MOONEY INTERNATIONAL CORPORATION 165 Al Mooney Road North, Kerrville, T exas 78028 tel: 830-896-6000 www.mooney.com

SBM20-335B Page 1

MOONEY INTERNATIONAL

CORPORATION

165 Al Mooney Road North

Kerrville, Texas 78028

THIS BULLETIN DOES NOT CHANGE AIRCRAFT TYPE DESIGN

2.4. Secure and stow control rods to prevent damage to painted skins.

2.5. Remove rudder by pulling it straight aft.

2.6. Balance rudder to specifications found in Chapter 27- 91- 00 of the applicable Mooney Service

and Maintenance Manual and Mooney Spec 20 Section 35, be sure to install all static wicks

and Strobe Light (if removed).

2.7. Fill out Flight Control Balance Sheets from Figures SIM20-335-9 and SIM20-335-10 for

balance criteria

SERVICE BULLETIN

SERVICE BULLETIN M20-335B

Date: January 2, 2019

.

2.8.

If Balance is within Specifications, continue to STEP 2.10.

2.9. If Balance is NOT within Specifications, continue to STEP 3 - Adding or Replacing Weight..

2.10. Re- Install IN reverse sequence as removed, refer to Chapter 5 in the applicable Service and

Maintenance Manual for hardware torque values. Refer to

SIM20-335-8 for stack- up of hardware (use new nuts and cotter pins upon reassembly).

ELEVATOR REMOVAL/INSTALLATION - Refer to Figure SIM20-335-2

Rudder Hinge Zone chart Figure

NOTE:

It may be feasible to use a roll of duct tape to hold the Elevator at a slight angle, to aid the removal of

hardware. Damage could occur if extending Elevator at extreme angles.

NOTE:

Keep Control Yoke from moving in/out with a piece of PVC or suitable tube, as

damage could occur if control rod assembly snags on painted skins.

2.11.

2.12. Remove bolts, nuts and washers from the four attaching hinges, note each hinge hardware on

Disconnect elevator push pull tubes, by removing removing Bolt AN3-10, Washers

NAS1149F0332P, Nut MS17825-3 and Cotter Pin MS24665-151, refer to Figure

SIM20-335-2.

zone chart(s) LH Figure SIM20-335-6 and RH Figure SIM20-335-7 as required., refer to

Figure SIM20-335-2.

2.13. Remove both elevators by pulling it straight aft.

2.14. Balance elevators to specifications found in Chapter 27- 91- 00 of the applicable Mooney Service

and Maintenance Manual and Mooney Spec 20 Section 35, be sure to install static wicks

(if removed).

2.15. Fill out Flight Control Balance Sheets from Figures SIM20-335-9 and SIM20-335-10 for

balance criteria.

2.16.

If Balance is within Specifications, continue to STEP 2.18.

2.17. If Balance is NOT within Specifications, continue to STEP 3 - Adding or Replacing Weights.

2.18. Re- Install IN reverse sequence as removed, refer to Chapter 5 in the applicable Service and

Maintenance Manual for hardware torque values. Refer to Elevator

Figure SIM20-335-6 and RH Figure SIM20-335-7

and cotter pins upon reassembly).

MOONEY INTERNATIONAL CORPORATION 165 Al Mooney Road North, Kerrville, T exas 78028 tel: 830-896-6000 www.mooney.com

Hinge Zone chart(s) LH

for stack- up of hardware (use new nuts

SBM20-335B Page 2

MOONEY INTERNATIONAL

CORPORATION

165 Al Mooney Road North

Kerrville, Texas 78028

THIS BULLETIN DOES NOT CHANGE AIRCRAFT TYPE DESIGN

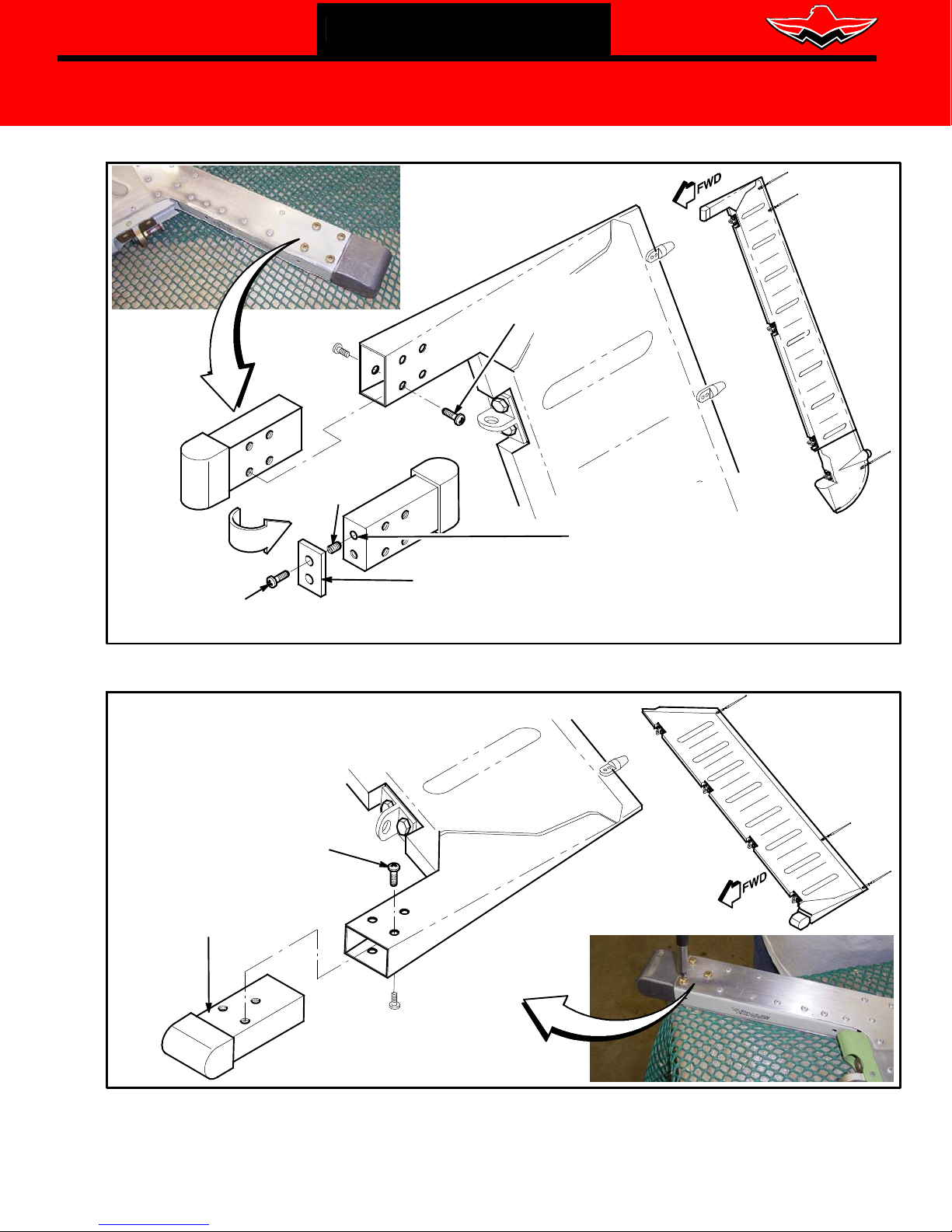

STEP 3 - Adding or Replacing Weights on Rudder and/or Elevator Flight Control

It may be required to slightly file (with rasp) control weight(s) to fit in flight control slot.

Use Proper Handling of Lead Control Weight(s) Personal Protective Equipment (PPE) gloves, non - per-

meable clothing and approved respirators are recommended.

3.1. Contact Mooney Product Support for details on adding weight.

Adding weight to Rudder (Top Weight Only): WEIGHT LIMIT (LBS) MAX = 3.85 AND MIN = 3.20

3.2a. Remove factory counterweight from Rudder by, removing (8) NAS623- 3- 1 screws (keep for

reassembly, refer to

3.2b. Add additional weight(s) 430055-003 as required, based on STEP 2 - Checking Flight

Control Balance, match them to end of factory weight and drill (2) .203” .010” diameter

thru added weights at a depth of .41” into end of factory counterweight as required, refer to

Figure SIM20-335-3. Drill slowly and use care when drilling weight to prevent drill bit

breakage. The use of “Boelube”, “Wax” or “Soap” is recommended on drill bit to prevent

breakage.

3.2c. Install (2) Helicoil inserts R1191-3 to both newly drilled holes in counterweight. Use Loctite

271 on helicoil inserts when installing.

3.2d. Temporarily install added weight(s) 430055-003 with (2) MS35207-XXX to new holes in

factory counter weight and Install counterweight to elevator with (6) NAS623- 3- 1 screws,

hand tighten only and balance per instruction in STEP 2 - Checking Flight Control

3.2e. When balance has been verified and within tolerance as specified in Mooney Service Manual

and Mooney Spec 20 Section 35, Install added weight(s) and correct length screws to holes

in factory counterweight, Using Loctite 222 on screws, hand tighten only. DO NOT OVER

TIGHTEN, doing so will pull helicoil inserts from weight..

3.2f. Install counterweight to Rudder with (8) NAS623- 3- 1 screws, hand tighten only.

DO NOT OVERTIGHTEN, doing so will pull helicoil inserts from weight.

3.2g. Touch-up paint as required, per Mooney Service and Maintenance Manual Chapter 20, refer

to Aircraft paint kit for color(s), contact Mooney Service Parts for availability.

3.2h. Install Rudder per STEP 2 - Checking Flight Control

SERVICE BULLETIN

SERVICE BULLETIN M20-335B

Date: January 2, 2019

NOTE:

CAUTION:

Figure SIM20-335-3.

Balance

Balance

Installing new weight to Elevator (LH/RH): WEIGHT LIMIT (LBS) MAX = 4.22 AND MIN = 4.00

3.3a. Remove factory counterweight from Elevator by, removing (6) NAS623- 3- 1 screws (keep

for reassembly, refer to

3.3b.

Temporarily install new weight 430055- 501 to Elevator with (6) NAS623-3-1, hand tighten only.

DO NOT OVERTIGHTEN, doing so will pull helicoil inserts from weight.

3.3c. Balance per STEP 2 - Checking Flight Control Balance, if balancing needs material to be

removed from factory counterweight, continue to

continue to STEP 3.3e.

3.3d.

Clamp the lead weight in a vice and use a rasp to trim the cone end of the weight until it weighs

the specific number from the b

3.3e. Install counterweight to Elevator with (6) NAS623- 3- 1 screws, hand tighten only.

DO NOT OVERTIGHTEN, doing so will pull helicoil inserts from weight.

3.3f. Touch-up paint as required, per Mooney Service and Maintenance Manual Chapter 20, refer

to Aircraft paint kit for color(s), contact Mooney Service Parts for availability..

3.3g. Install elevator(s) per STEP 2 - Checking Flight Control

MOONEY INTERNATIONAL CORPORATION 165 Al Mooney Road North, Kerrville, T exas 78028 tel: 830-896-6000 www.mooney.com

Figure SIM20-335-4.

STEP 3.3d, if balance is within tolerance

alance check per STEP 2 - Checking Flight Control Balance,

Balance

SBM20-335B Page 3

MOONEY INTERNATIONAL

CORPORATION

165 Al Mooney Road North

Kerrville, Texas 78028

THIS BULLETIN DOES NOT CHANGE AIRCRAFT TYPE DESIGN

STEP 4 - Return Aircraft To Service

4.0 RETURN TO SERVICE - Refer to the applicable Service and Maintenance Manual

4.1. Inspect flight controls for full travel, proper rigging, free- play, binding, security of mounting, proper

lubrication and proper direction of control surface movement with relation to control wheel

movement, refer to Chapter 27 of the applicable Service and Maintenance Manual.

SERVICE BULLETIN

SERVICE BULLETIN M20-335B

Date: January 2, 2019

4.2.

Check tail strobe operation.

4.3. Confirm level flight, refer to Chapter 27 of the applicable Service and Maintenance Manual.

4.4. Send all Flight Control Balance Sheets from

to support@mooney.com for aircraft records.

Figures SIM20-335-9 and SIM20-335-10,email

4.4. Remove Placard M20-335-901 or M20-335-902 from Instrument Panel.

NOTE:

Fill out compliance card and send by MAIL or FAX to Mooney International Corporation as

indicated on the attached Compliance Card. (See Figure SBM20-335-11).

4.5. Return aircraft to service.

4.6. Procedure complete.

WARRANTY: Mooney International Corporation will warrant labor 8 hours in accordance with procedures of

this Service Bulletin for aircraft currently covered under the Mooney International Corporation

factory warranty program.

Mooney International Corporation will warrant labor 2 additional hours per Flight Control requiring

balancing in accordance with procedures of this Service Bulletin for aircraft currently covered

under the Mooney International Corporation factory warranty program.

REFERENCE 1. Applicable Mooney Service and Maintenance Manual

DATA: 2. Product Support email: support@mooney.com or phone: 830-792-2919

3. Applicable Mooney Illustrated Parts Catalog

4. Mooney Spec 20 Section 35 (attached)

PARTS LIST: Mooney International Corporation, Service Bulletin Parts Kit(s): Not Ordered As Kit

Order parts as required below:

Item

P/N Description Qty

1. M20-335-901 Placard (for M20R and M20TN) 1

2. M20-335-902 Placard (for M20U and M20V) 1

3. 430055-003 Weight Bar (as required to Balance Rudder Assembly) A/R

4. R1191-3 Helicoil Insert (Mounting Added Rudder Weight) 2

5. MS35207-XXX Screw 10-32 x (XXX=Length determined by # weights) A/R

6. 430055-501 Weight, Elevator (file as required for Balance) 1

7. 222 Loctite, Low Strength (Shop Supplied) AR

8. 271 Loctite, Permanent (Shop Supplied) AR

MOONEY INTERNATIONAL CORPORATION 165 Al Mooney Road North, Kerrville, T exas 78028 tel: 830-896-6000 www.mooney.com

(Shop Supplied Hardware)

SBM20-335B Page 4

MOONEY INTERNATIONAL

CORPORATION

165 Al Mooney Road North

Kerrville, Texas 78028

THIS BULLETIN DOES NOT CHANGE AIRCRAFT TYPE DESIGN

PLACARD M20-335-901

LIMITATION:

MAXIMUM AIRCRAFT

SPEED 127 KIAS

29-0520 THRU 29-0528

31-0128 THRU 31-0143

SERVICE BULLETIN

SERVICE BULLETIN M20-335B

Date: January 2, 2019

NOTE: CLEAN SURFACE

WITH ISOPROPYL ALCOHOL

BEFORE APPLYING PLACARD

PLACARD M20-335-902

LIMITATION: MAXIMUM AIRCRAFT SPEED 127 KIAS

32-0001, 32-0003

33-0004, 33-0006, 33-0007

Figure SBM20-335-1 - PLACARDS, INSTRUMENT PANEL

MOONEY INTERNATIONAL CORPORATION 165 Al Mooney Road North, Kerrville, T exas 78028 tel: 830-896-6000 www.mooney.com

NOTE: CLEAN SURFACE

WITH ISOPROPYL ALCOHOL

BEFORE APPLYING PLACARD

SBM20-335B Page 5

MOONEY INTERNATIONAL

CORPORATION

165 Al Mooney Road North

Kerrville, Texas 78028

THIS BULLETIN DOES NOT CHANGE AIRCRAFT TYPE DESIGN

BOLT

AN3-11A

WASHER

NAS1149F0332P

SERVICE BULLETIN

STATIC WICKS (3)

SERVICE BULLETIN M20-335B

WASHER

NAS1149F0332P

Date: January 2, 2019

BOLT

AN3-11A

WASHER

NAS1149F0332P

MS21045-L3

ROLL OF TAPE

NUT

STATIC WICKS (3)

WASHER

NAS1149F0332P

SEE

NOTE

DETAIL D

DETAIL E

SEE

NOTE

WASHER

NAS1149F0332P

NUT

MS21045-L3

ELEVATOR PUSH

PULL CONTROL TUBES

TAIL STROBE

HARNESS

STATIC WICKS (3)

DETAIL H

NUT

MS21045-L3

DETAIL G

WASHER

NAS1149F0332P

BOLT

AN3-11A

NOTES:

USE AN960-10 AND/OR AN960-10L BETWEEN HINGE BLOCKS TO

ELIMINATE POSSIBLE GAPS AND END PLAY.

NAS1149F0363P THICK WASHER SAME AS AN960- 10

NAS1149F0332P THIN WASHER SAME AS AN960- 10L

Figure SBM20-335-2 - RUDDER AND ELEVATOR INSTALLATION

MOONEY INTERNATIONAL CORPORATION 165 Al Mooney Road North, Kerrville, T exas 78028 tel: 830-896-6000 www.mooney.com

SEE

NOTE

NUT

MS21045-L3

BOLT

AN3-7A

DETAIL F

WASHER

NAS1149F0332P

WASHER

NAS1149C0332R

WASHER

NAS1149F0363P

WASHER

NAS1149F0332P

SBM20-335B Page 6

MOONEY INTERNATIONAL

CORPORATION

165 Al Mooney Road North

Kerrville, Texas 78028

THIS BULLETIN DOES NOT CHANGE AIRCRAFT TYPE DESIGN

SERVICE BULLETIN

SEE NOTE:

HELICOIL (2)

R1191-3

SCREWS (8)

(REUSE FROM DISASSEMBLY)

NAS623-3-1

DRILL .203” HOLE

TO A DEPTH

OF .41 FOR HELICOIL

IN EXISTING WEIGHT

NOTE:

SERVICE BULLETIN M20-335B

Date: January 2, 2019

SCREW (2)

MS35207-XXX

LENGTH DETERMINED

BY QUANTITY OF WEIGHTS

Figure SBM20-335-3 - RUDDER ADDED WEIGHT INSTALLATION

SCREW (6)

SCREW (6)

NAS623-3-1

(REUSE FROM DISASSEMBLY)

(REUSE FROM DISASSEMBLY)

WEIGHT (IF REQUIRED)

NAS623-3-1

430055-501

WEIGHT (AS REQUIRED)

430055-003

MAXIMUM WEIGHT NOT TO

EXCEED 3.85 LBS

Figure SBM20-335-4 - ELEVATOR ADDED WEIGHT INSTALLATION

MOONEY INTERNATIONAL CORPORATION 165 Al Mooney Road North, Kerrville, T exas 78028 tel: 830-896-6000 www.mooney.com

SBM20-335B Page 7

MOONEY INTERNATIONAL

CORPORATION

165 Al Mooney Road North

Kerrville, Texas 78028

THIS BULLETIN DOES NOT CHANGE AIRCRAFT TYPE DESIGN

SERVICE BULLETIN

SERVICE BULLETIN M20-335B

Date: January 2, 2019

R4

R3

R2

R1

RUDDER HINGE ZONE

RHE1

RH ELEVATOR

LH ELEVATOR

RHE2

RHE3

HINGE ZONE

RHE4

LHE4

LHE3

HINGE ZONE

LHE2

LHE1

Figure SBM20-335-5 - OVERALL LOCATION OF CONTROL SURFACE HINGE ZONES

MOONEY INTERNATIONAL CORPORATION 165 Al Mooney Road North, Kerrville, T exas 78028 tel: 830-896-6000 www.mooney.com

SBM20-335B Page 8

MOONEY INTERNATIONAL

CORPORATION

165 Al Mooney Road North

Kerrville, Texas 78028

THIS BULLETIN DOES NOT CHANGE AIRCRAFT TYPE DESIGN

SERVICE BULLETIN

SERVICE BULLETIN M20-335B

Date: January 2, 2019

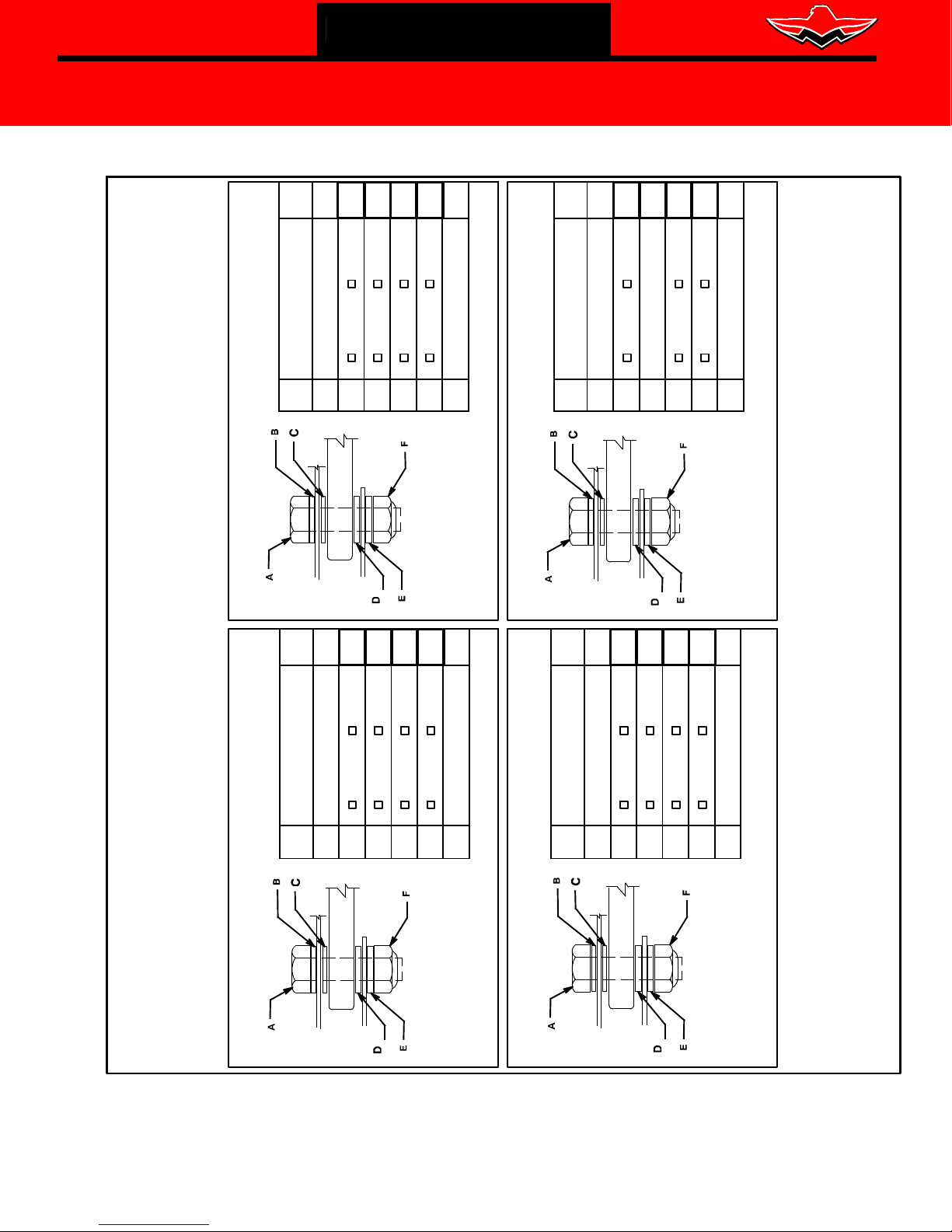

LHE2

1

QTY

Description

Part Number

Item

QTY

Thick Thin

Thick Thin

Thick Thin

AN3-11A BOLT

A

B

C

D

1

1

Thick Thin

MS210N44-N3 NUT

F

E

1

LHE4

1

QTY

Description

Part Number

Item

QTY

Thick Thin

Thick Thin

Thick Thin

AN3-11A BOLT

A

B

C

D

1

1

Thick Thin

MS210N44-N3 NUT

F

E

1

LH ELEVATOR HINGE ZONES

Description

Part Number

*Note - Denote "Thick" and/or "Thin" washer shim and quantity

LHE1

AN3-11A BOLT

A

Item

Thick Thin

Thick Thin

Thick Thin

B

C

Thick Thin

MS210N44-N3 NUT

D

F

E

LHE3

Description

Part Number

AN3-11A BOLT

A

Item

Thick Thin

Thick Thin

B

Thick Thin

Thick Thin

MS210N44-N3 NUT

C

D

F

E

NAS1149F0363P SAME AS AN960-10 (.063 Thick)

NAS1149F0332P SAME AS AN960-10L (.032 Thin)

NOTE:

Figure SBM20-335-6 - LH ELEVATOR HINGE ZONE CHART

MOONEY INTERNATIONAL CORPORATION 165 Al Mooney Road North, Kerrville, T exas 78028 tel: 830-896-6000 www.mooney.com

SBM20-335B Page 9

MOONEY INTERNATIONAL

CORPORATION

165 Al Mooney Road North

Kerrville, Texas 78028

THIS BULLETIN DOES NOT CHANGE AIRCRAFT TYPE DESIGN

SERVICE BULLETIN

SERVICE BULLETIN M20-335B

Date: January 2, 2019

RHE2

1

QTY

Description

Part Number

Item

QTY

Thick Thin

Thick Thin

Thick Thin

AN3-11A BOLT

A

B

C

D

1

1

Thick Thin

MS210N44-N3 NUT

F

E

1

1

QTY

Description

Part Number

Item

QTY

Thick Thin

Thick Thin

Thick Thin

AN3-11A BOLT

A

B

C

D

1

1

Thick Thin

MS210N44-N3 NUT

F

E

1

RH ELEVATOR HINGE ZONES

Description

Part Number

*Note - Denote "Thick" and/or "Thin" washer shim and quantity

RHE1

MOONEY INTERNATIONAL CORPORATION 165 Al Mooney Road North, Kerrville, T exas 78028 tel: 830-896-6000 www.mooney.com

Item

Figure SBM20-335-7 - RH ELEVATOR HINGE ZONE CHART

Description

RHE3 RHE4

Part Number

Item

Thick Thin

AN3-11A BOLT

A

B

Thick Thin

Thick Thin

C

Thick Thin

MS210N44-N3 NUT

D

F

E

NAS1149F0363P SAME AS AN960-10 (.063 Thick)

NAS1149F0332P SAME AS AN960-10L (.032 Thin)

NOTE:

Thick Thin

AN3-11A BOLT

A

B

Thick Thin

Thick Thin

C

Thick Thin

MS210N44-N3 NUT

D

F

E

SBM20-335B Page 10

MOONEY INTERNATIONAL

CORPORATION

165 Al Mooney Road North

Kerrville, Texas 78028

THIS BULLETIN DOES NOT CHANGE AIRCRAFT TYPE DESIGN

SERVICE BULLETIN

SERVICE BULLETIN M20-335B

Date: January 2, 2019

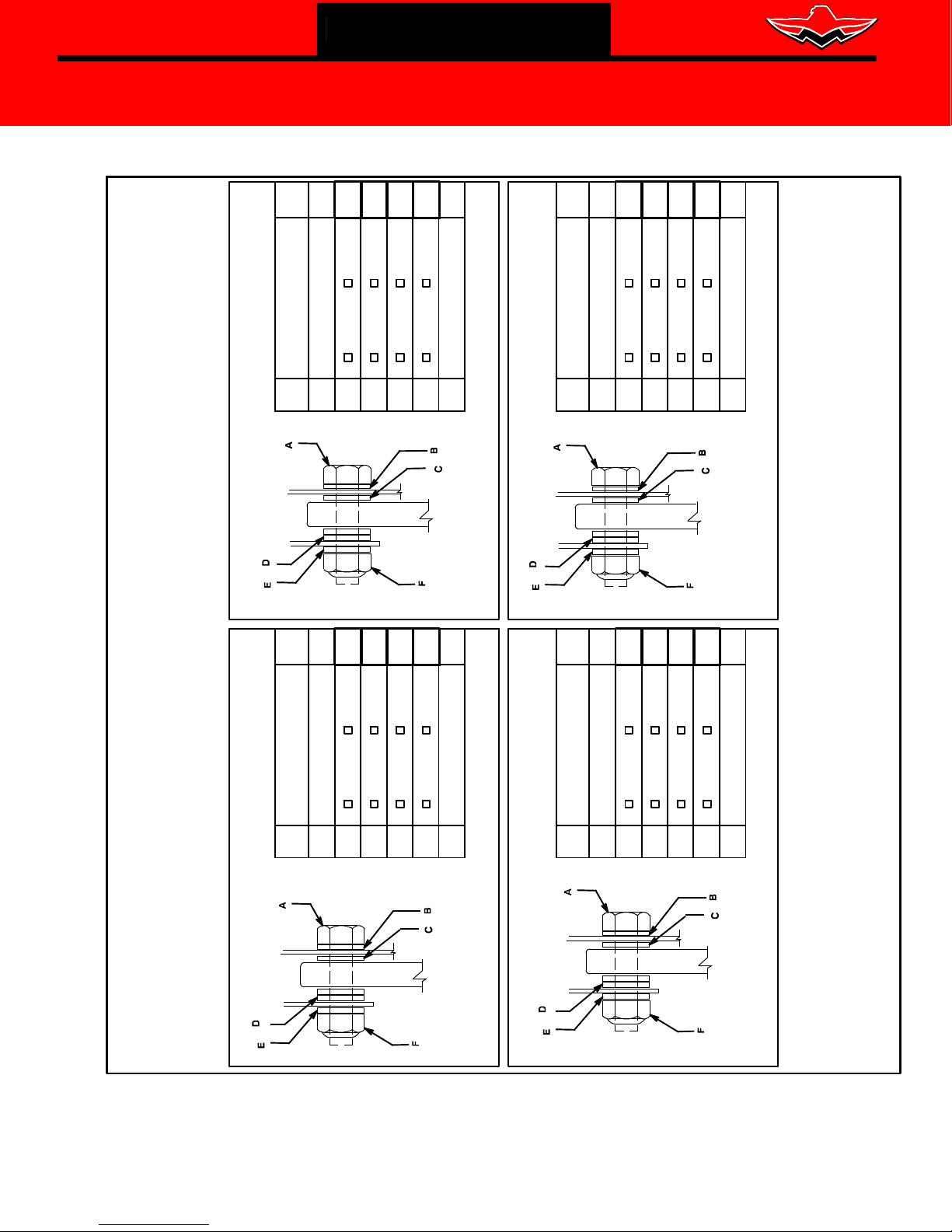

R2

UP

1

QTY

Description

Part Number

Item

Thick Thin

AN3-11A BOLT

A

B

Thick Thin

Thick Thin

C

D

1

Thick Thin

MS210N45-L3 NUT

F

E

1

QTY

Description

Part Number

AN3-7A BOLT

A

Item

1

Thick Thin

B

Thick Thin

NAS1149C0332R WASHER

C

D

1

Thick Thin

MS210N45-L3 NUT

F

E

UP

DOWN

1

QTY

1

1

QTY

DOWN

1

RUDDER HINGE ZONES

Description

Part Number

AN3-11A BOLT

*Note - Denote "Thick" and/or "Thin" washer shim and quantity

R1

A

Item

Thick Thin

Thick Thin

Thick Thin

B

C

Thick Thin

MS210N45-L3 NUT

D

F

E

R3 R4

UP

DOWN

UP

Description

Part Number

AN3-11A BOLT

A

Item

Thick Thin

Thick Thin

Thick Thin

B

C

Thick Thin

MS210N45-L3 NUT

D

F

E

DOWN

NAS1149F0363P SAME AS AN960-10 (.063 Thick)

NAS1149F0332P SAME AS AN960-10L (.032 Thin)

NOTE:

Figure SBM20-335-8 - RUDDER HINGE ZONE CHART

MOONEY INTERNATIONAL CORPORATION 165 Al Mooney Road North, Kerrville, T exas 78028 tel: 830-896-6000 www.mooney.com

SBM20-335B Page 11

MOONEY INTERNATIONAL

CORPORATION

165 Al Mooney Road North

Kerrville, Texas 78028

THIS BULLETIN DOES NOT CHANGE AIRCRAFT TYPE DESIGN

SERVICE BULLETIN

SERVICE BULLETIN M20-335B

Date: January 2, 2019

Figure SBM20-335-9 - FLIGHT CONTROL BALANCE SHEET

MOONEY INTERNATIONAL CORPORATION 165 Al Mooney Road North, Kerrville, T exas 78028 tel: 830-896-6000 www.mooney.com

SBM20-335B Page 12

Loading...

Loading...