Mooney M20R Service And Maintenance Manual

O

Island Enterprises

SERVICE

END

IC~

~B

T1T

~f

]L

ORIGINAL-

LO

UIS

SCHREINER

JUNE.,

REVISED

10-98

BTRC~AFT

FI

E

LD,

1994

CORPOR

RRVI

E(E

MANUAL

EEE,

NUMBER

ATION

TX

78028

l60

MOONEY

Island Enterprises

AIRCRAFT

CORPORATION

KERRVILLE,

TEXAS

VVARN

harm

public

This

warning

the

Mooney

ING:

health

applies

Aircraft

Manufactured

environment

and

to

placards

Model(s)

manufactured

addressed

with

destroying

by

in

Trichloroethane

1,1,1

at

this

publication.

ozone

Mooney

in

the

Aircraft

substances

upper

Corporation

which

atmosphere.

facility

are

determined

installed

and

to

on

WARNING:

harm

This

warning

Mooney

public

health

applies

Aircraft

and

to

Model(s)

Manufactured

environment

certain

adhesives

addressed

with

destroying

by

procured

this

in

Trichloroethane

1,1,1

publication.

ozone

form

in

the

vendors

substances

atmosphere.

upper

utilized

and

which

on

are

the

determined

applicable

to

MOONEY

Island Enterprises

AIRCRAFT

CORPORATION

M20R

SERVICE

AND

MAINTENANCE

MANUAL

LOG

DATE

REVISION

OCTOBER,

OF

OF

1998

REVISIONS

SECTIONS

AFFECTED

PAGE

TITLE

RR/ISIONS

OF

LOG

INTRODUCTION

CHAPTER

CHAPTER

CHAPTER

CHAPTER

CHAPTER

CHAPTER

CHAPTER

CHAPTER

CHAPTER

CHAPTER

CHAPTER

CHAPTER

CHAPTER

CHAPTER

CHAPTER

CHAPTER

CHAPTER

CHAPTER

CHAPTER

CHAPTER

5

8

21

24

27

28

30

32

33

34

37

39

51

53

57

61

71

77

79

91

Alwavs

destrov

supersededpages

DATE

OF

REVISION

when

you

Insert

revised

SECTIONS

AFFECTED

NCITE:

A

list

each

the

effective

of

pages

will

appear

at

beginning

of

chapter.

MOONEY

Island Enterprises

AIRCRAFT

CORPORATION

M20R

SERVICE

AND

MAINTENANCE

MANUAL

INTRODUCTION

manual

This

the

mation

29-0001

ited

number

The

be

ble

correct

Center.

for

number

of

Part

identified

Model

to

P/N

See

and

applicable

Number’s

can

Section

ponents.

format

The

accordance

ER’S

and

with

ASSOCIATION

Specification

back

Revisions

these

CARD"

Kerrville,

schematics

necessary.

of

the

and

complete

located

to

Mooney

is

manual

that

no

will

require

Technical

department

896-6000,

wiring

planes,as

the

automatically

of

should

send

Notification

other

advises

manual

tional

above

(210)

Correspondence

bers

on

an

airplane

the

side

and

identification

of

number

on

hand

ASSIGNMENT

The

content

of

Group

Chapter

Section

Subject

GROUP

These

broad

Powerplant

tabs.

are

primary

separation

systems.

provides

Mooney

Maintenance

ON.

aircraft

of

the

using

S/N

and

ordered

be

contents

GENERAL

No.

2.

manual

reissues

or

provided

dther

at

Aircraft

78029-0072,

TX.,

sent

is

prepared

more

Publications

ext.

conceming

serial

tailcone

the

OF

this

publication

of

servicing

Model

will

airplanes.

of

replacement

Illustrated

aircraft

of

through

91

for

exceptions

of

this

AVIATION

(GAMA)

The

manual

the

for

These

texts

NOTE

of

to

Mooney

information

the

the

front

Corporation,

Department.

known

to

to

replace

revisions

a

new

subscription

at

Mooney

271.

should

number.

The

placard

below

SUBJECT

(System)

(Sub-system)

(Unit)

divisions

content,

These

and

M20R,

actions

be

designated

or

Parts

being

any

manual

is

various

located

are

pages,

manual

this

manual

Technical

the

of

Attn:

manual

the

be

will

are

desired,

Aircraft

maintenance

contain

serial

located

hon’zontal

the

MATERIAL

is

organized

of

the

Airframe

ie.,

groups

maintenance

Serial

that

Numbers

referto

by

repair

parts

Catalog

worked

Mooney

Electrical

on

are

prepared

MANUFACTUR-

supplemented

model

holders.

on

Title

Service

holders

in

envelopes

are

Publications

"YELLOW

the

Page

P.O.

year

Holders

Box

Parts

when

subscription

The

out.

sent

service.

contact

Corporation

or

part

aircraft

the

number

on

manual

the

aft

at

that

appears

end,

stabilizer.

four

systems

identified

are

infor-

lim-

a

serial

should

applica-

The

on.

Service

Com-

with

air-

not

and

72,

an-

and

new

addi-

If

the

num-

model

left

levels:

enable

VS

at

at

by

CHAPTER

The

various

such

as

are

arranged

number

"Fuel"

sequence

information

The

be

SECTION

major

sub-systems.

second

in

28-20-00.

portion

SUBJECT

individual

The

fled

by

ie.,28-20-01.

and

turer

complexity

APPLICATION

Mooney

all

applicable

GAMA

tion

this

mation

refer

nance

bered

current

models

be

The

vide

format.

concerning

basic

to

oriented

sequentially

sequentially

table

a

Chapter.

(System)

groups

controls,

flight

numerically

assignment,

identified

of

numbers,

the

of

(Sub-System)

systems

These

element

of

the

The

element

fuel

(Unit)

units

element

third

a

This

or

may

the

of

Aircraft

maintenance

When

concerning

the

pages

Mooney

become

numbered

of

contents

of

list

systems

For

example:

28-00

28-10

contain

landing

It

is

with

the

28-00-00,

Fuel

Systems.

of

an

sub-systems

of

the

-20-

system.

within

of

number

not

may

maintenance

NUMBERING

OF

Corporation

effort

this

maintenance

Fuel

the

identified

publication.

each

within

series

more

of

complex

in

the

and/or

General

Storage

(Tanks,

major

gear,

GAMA

per

suggested,

Chapter

refers

aircraft

sequence

a

is

be

within

front

are

indicates

sub-system

the

sequence

assigned

used

action

in

the

is

technical

is

completed

aircraft

of

Any

Distribution

as

,28-20-00,

These

system

aircraft.

the

sub-systems.

each

of

subjects

vents,

systems

etc.

recommended

for

number

to

broken

identified

are

of

numbers,

the

may

by

depending

recommended.

SYSTEM

process

publications

will

person

System

in

pages

breakdown

As

Mooney

page

Chapter

covered

repair,

information

The

systems

example,that

The

"28".

General

the

into

down

the

by

distribution

identi-

be

of

numbers,

manufac-

the

the

upon

of

revising

publica-

any

conform

any

would

mainte-

be

aircraft

will

in

infor-

num-

in

may

pro-

the

the

wishing

will

numbers

ie.,

to

to

etc.)

28-20

Distribution

(Boost

pumps,

fuel

lines,

etc.)

If

there

RIGHT

or

number

28-40-02

panded

28-40

is

reason

a

HAND

would

(Right

information

fuel

be

expanded

Hand).

Indicating

(Sender

gauges,

to

distinguish

quantity

This

throughout

Units,

etc.)

sending

28-40-01

to

concept

the

quantity

between

units

(Left

will

apply

publications.

LEFT

Hand)

to

then

any

HAND

the

and

ex-

REV.

10-98

INTRODUCTION

SERVICE

Island Enterprises

MAINTENANCE

AND

MANUAL

MZOR

MOONEY

AIRCRAFT

CORPORATION

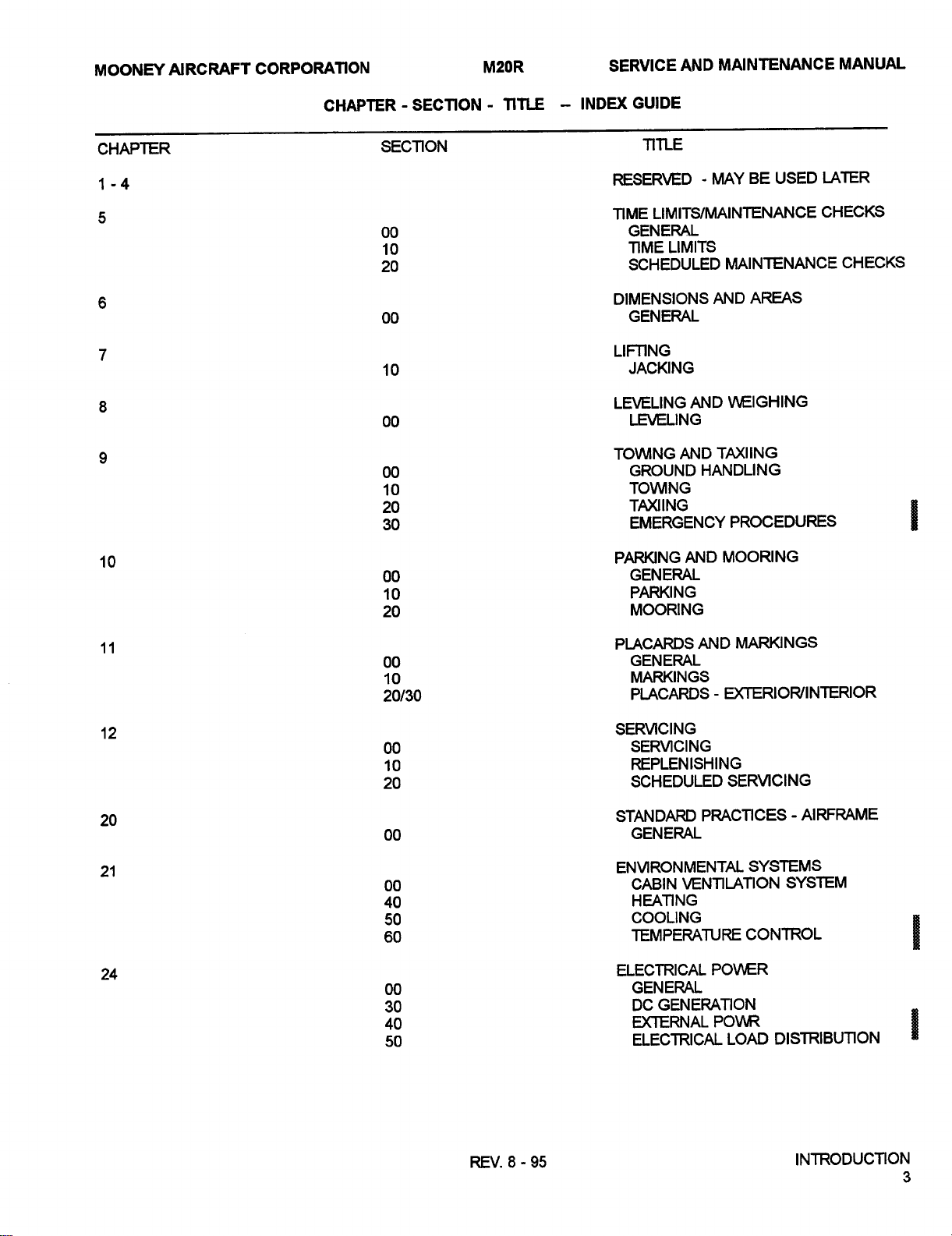

The

following

ponents

configurations

many

avionics

ticular

publications

Any

through

craft

Corporation,

As

publications

ENGINE

The

following

Box

P.O.

Overhaul

Illustrated

Maintenance

Service

Fuel

Bulletins

Injector

ACCESSORY

PROPELLER

BAcCauley

OH.,45377.

list

of

the

Mooney,

manufacturer.

Mooney

any

PUBLICATIONS

maintenance

Mobile,

90,

Manual

Parts

Manual,

Propellers

Manufacturers

of

available

on

these

various

Model

that

Service

should

Alabama,

for

Teledyne

Catalog

for

Operators

Specify

Form

PUBLICATIONS

Obtain

M20R

installed

be

can

from

Mooney

Center.

be

components

publications

USA,

Continental

Teledyne

Manual

model

X30593A

publications

SUPPLEM~NTARY

and/or

obtained

for

of

publicatio~ns

avionics

No

in

Aircraft

Most

become

VENDOR

can

36601,

Continental

Teledyne

engine

the

manufa4turer/vendor

from

be

Attn:

Motors

for

from

PUBLICATIONS

can

provide

equipment

airdraft.

Corporation

applicable

the

available,

Manufacturers

These

are

they

ADL~RESSES

obtgined

Motors

Coritinental

which

McCauley

through

Accounts

Aircraft

10-550

maintenance

Receivable

10-550

Motors

Accessories

servicing

obtained

be

can

in

listed

the

publications

ManufacturerNendor.

added

be

will

PUBLICATIONS

Teledyne

Continental

(Prepaid

10-550

data

Models,

aircraft

aircraft

desired

is

Division,

Engine

series

and

maintenance

or

publications

from

Price

Parts

not

are

the

to

only).

Fom~

engines,

engines,

when

3535

the

repair

List

availabel

below.

list

Motors,

X30568A.

Form

ordering.

McCauley

information

are

and

through

X30569A.

Form

listed

stations

are

Aircraft

X30565.

Drive,

due

for

available

Mooney

Products,

Vandalia,

com-

on

the

to

a

par-

Air-

Service

Teledyne

Dept.,

Alternator

bile,

Service

Publications

Teledyne

Master

craft

Precise

I

Manual

MAGNETO

Continental

for

TCM

ALTERNATOR

Service

Alabama,

STARTER

Manual,

Dept

FUEL

PUMP

Continental

IGNITION

Service

Products,

SPEED

BRAKES

Flight,

No.

(Bendix),

Instructions,

36601,

USA,

Teledyne

(Engine

SYSTEM

Manual,

P.O.

63120

Inc.,

761001

Motors,

Type

Motors,

TCM

Box

for

Aircraft

S6RN-25

Form

Attn:

Continental

Driven)

Aircraft

Ignition

Mobile,

90,

Powell

McCauley

Products,

Series

X30531-3,

Publications

Motors,

Products,

Systems

Alabama,

Butte

Rd.,

C400

series

P.b.

magnetos.

Teledyne

Dept.

Aircraft

P.O.

and

USA,

Bend,

constant

Box

Mobile,

90,

Continental

Products,

Box

90,

Mobile,

Components,

36601,

OR

Attn:

97701,

speed

Alabama,

Motors,

Box

P.O.

Alabama,

Form

X40000,

Publications

Telephone:

propellers.

Aircraft

Mobile,

90,

Dept

(503)

36601,

USA,

Products,

Alabama,

36601,

USA,

Teledyne

382-8684

Attn:

P.O.

Attn:

Continental

Publications

Box

36601,

USA,

Publications

Motors,

90,

Mo-

Attn:

Dept

Air-

INTRODUCTION

Rev.

8-95

MOONEY

Island Enterprises

AIRCRAFT

CORPORATION

M20R

SERVICE

MAINTENANCE

AND

MANUAL

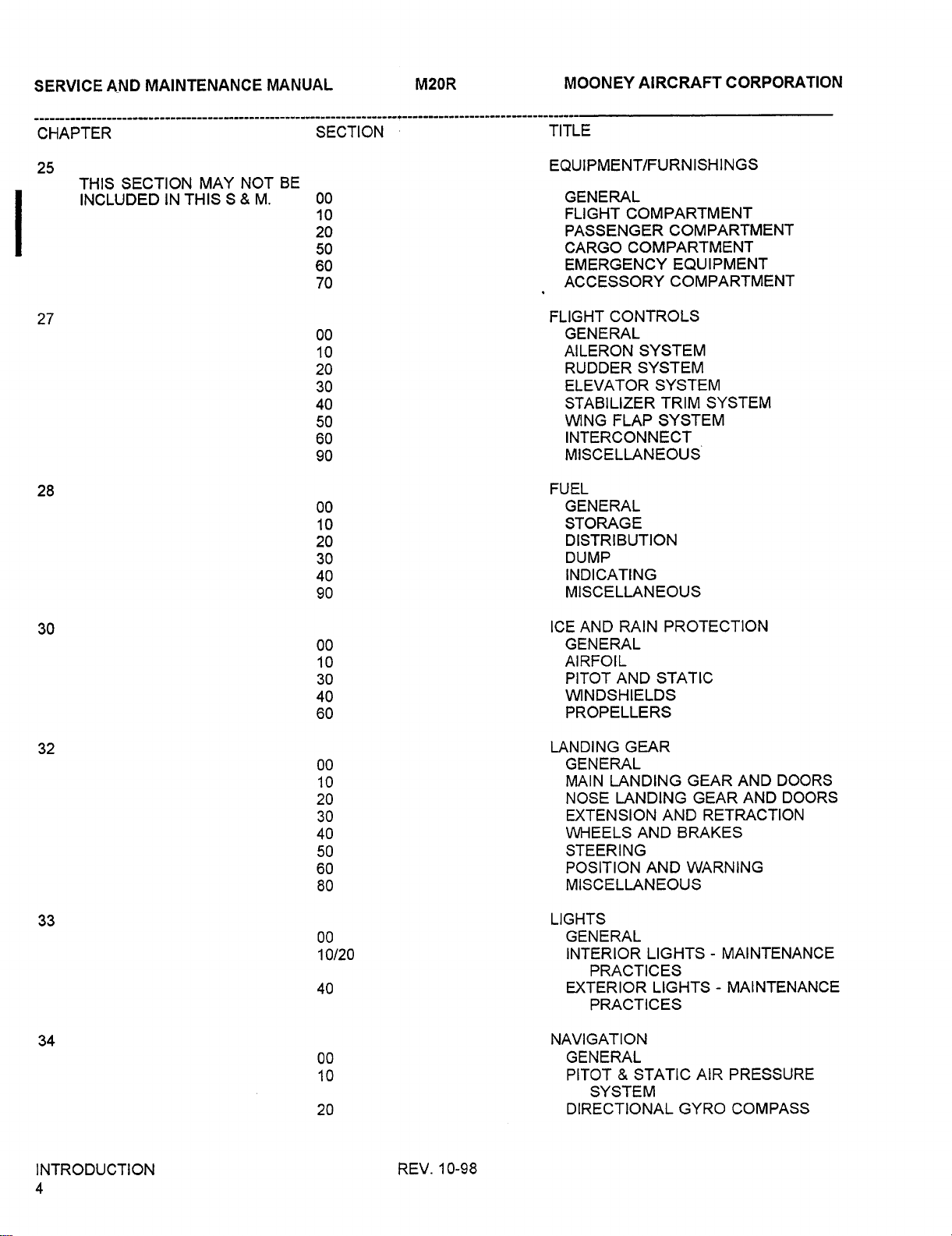

CHAPTER

1

4

5

6

7

8

9

CHAPTER-

SECTION-

SECTION

00

10

20

00

10

00

00

10

20

30

TITLE

INDU(GUIDE

TITLE

RESERVED

TIME

GENERAL

TIME

SCHEDULED

DIMENSIONS

GENERAL

LIFTING

JACKING

LEVELING

LEVELING

TOWING

GROUND

TOV\nNG

TAXIING

EMERGENCY

USED

BE

MAY

LIMITS/MAINTENANCE

LIMITS

MAINTENANCE

AREAS

AND

V~EIGHING

AND

TAXIING

AND

HANDLING

PROCEDURES

LATER

CHECKS

CHECKS

10

11

20

21

12

24

00

10

20

00

10

20/30

00

10

20

00

00

40

50

60

00

30

40

50

PARKING

AND

GENERAL

PARKING

MOORING

PLACARDS

AND

GENERAL

MARKINGS

PLACARDS-

SERVICING

SERVICING

REPLENISHING

SCHEDULED

STANDARD

PRACTICES

GENERAL

ENVIRONMENTAL

CABIN

VENTILATION

HEATING

COOLING

TEMPERATURE

ELECTRICAL

GENERAL

GENERATION

DC

EXTERNAL

ELECTRICAL

MOORING

MARKINGS

UC~ERIOWINTERIOR

SERVICING

-AIRFRAME

SYSTEMS

SYSTEM

CONTROL

POWER

POV~R

LOAD

DISTRIBUTION

REV.8-95

INTRODUCTION

SERVICE

Island Enterprises

AND

MAINTENANCE

MANUAL

M20R

MOONEY

AIRCRAFT

CORPORATION

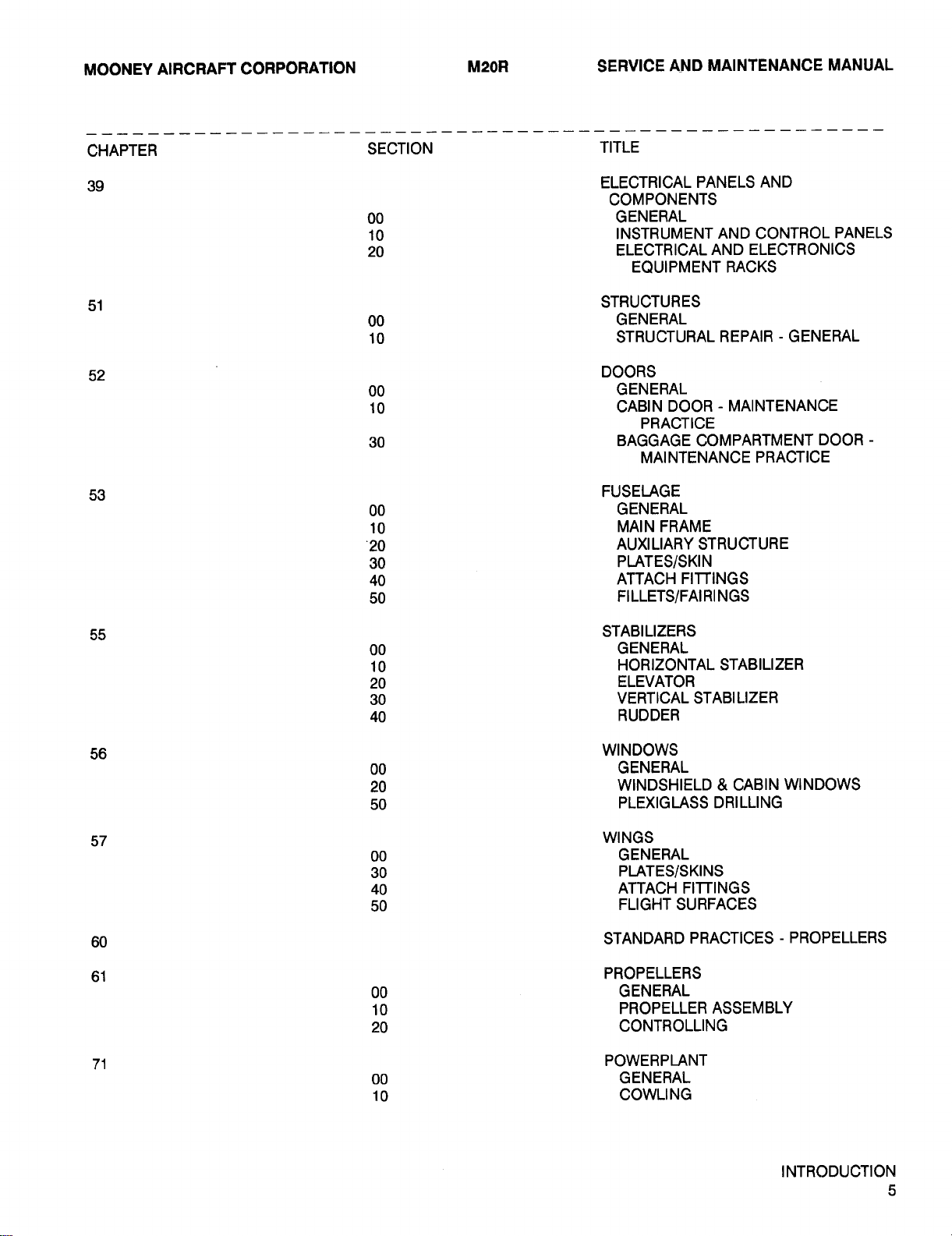

CHAPTER

25

THIS

INCLUDED

27

28

SECTION

1N

THIS

MAY

NOT

S8M.

BE

SECTION

00

10

20

50

60

70

00

10

20

30

40

50

60

90

00

10

20

30

40

90

TITLE

EQUIPMENT/FURNISHING

GENERAL

FLIGHT

PASSENGER

CARGO

EMERGENCY

ACCESSORY

FLIGHT

GENERAL

AILERON

RUDDER

ELEVATOR

STABILIZER

WING

COMPARTMENT

COMPARTMENT

COMPARTMENT

EQUIPMENT

COMPARTMENT

CONTROLS

SYSTEM

SYSTEM

SYSTEM

TRIM

FLAP

SYSTEM

INTERCONNECT

MISCELLANEOUS

FUEL

GENERAL

STORAGE

DISTRIBUTION

DUMP

INDICATING

MISCELLANEOUS

SYSTEM

30

32

33

34

00

10

30

40

60

00

10

20

30

40

50

60

80

00

10/20

40

00

10

20

ICE

AND

RAIN

GENERAL

AIRFOIL

PITOT

AND

WINDSHIELDS

PROPELLERS

LANDING

GENERAL

LANDING

MAIN

NOSE

LANDING

EXTENSION

WHEELS

STEERING

POSITION

MISCELLANEOUS

LIGHTS

GENERAL

INTERIOR

PRACTICES

EXTERIOR

PRACTICES

NAVIGATION

GENERAL

PITOT

DIRECTIONAL

8

SYSTEM

GEAR

AND

AND

LIGHTS

STATIC

PROTECTION

STATIC

GEAR

GEAR

RETRACTION

AND

BRAKES

WARNING

LIGHTS

AIR

GYRO

DOORS

AND

AND

DOORS

MAINTENANCE

MAINTENANCE

PRESSURE

COMPASS

INTRODUCTION

REV.

10-98

MOONEY

Island Enterprises

AIRCRAFT

CORPORATION

M20R

SERVICE

AND

MAINTENANCE

MANUAL

CHAPTER

39

51

52

53

SECTION

00

10

20

00

10

00

10

30

00

10

’20

30

40

50

TITLE

ELECTRICAL

COMPONENTS

GENERAL

INSTRUMENT

ELECTRICAL

EQUIPMENT

STRUCTURES

GENERAL

STRUCTURAL

DOORS

GENERAL

CABIN

DOOR

PRACTICE

BAGGAGE

MAINTENANCE

FUSELAGE

GENERAL

FRAME

MAIN

AUXILIARY

PLATES/SKIN

ATTACH

FITTINGS

FILLETS/FAIRINGS

PANELS

AND

AND

AND

CONTROL

ELECTRONICS

RACKS

REPAIR

MAINTENANCE

COMPARTMENT

PRACTICE

STRUCTURE

PANELS

GENERAL

DOOR

55

56

57

60

61

STABILIZERS

00

10

20

30

40

GENERAL

HORIZONTAL

ELEVATOR

VERTICAL

RUDDER

STABILIZER

STABILIZER

WINDOWS

00

20

50

GENERAL

WINDSHIELD

PLEXIGLASS

CABIN

DRILLING

WINDOWS

WINGS

00

30

40

50

GENERAL

PLATES/SKINS

ATTACH

FLIGHT

STANDARD

FITTINGS

SURFACES

PRACTICES

PROPELLERS

PROPELLERS

00

10

20

71

00

10

GENERAL

PROPELLER

CONTROLLING

POWERPLANT

GENERAL

COWLING

ASSEMBLY

INTRQDUCTIQN

SERVICE

Island Enterprises

AND

MAINTENANCE

MANUAL

M20R

MOONEY

AIRCRAFT

CORPORATION

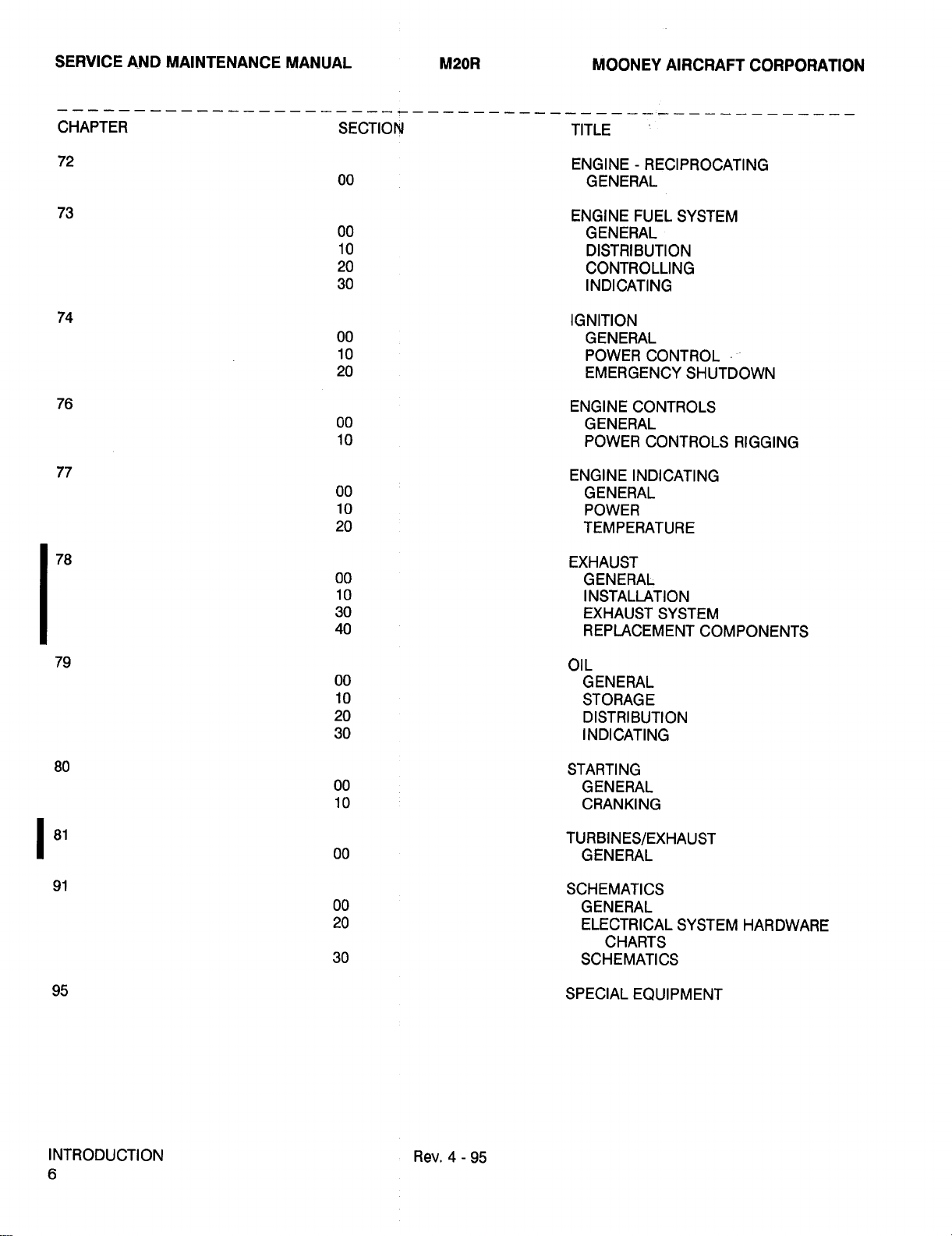

CHAPTER

72

73

74

76

77

SECTION

00

00

10

20

30

00

10

20

00

10

00

10

20

00

10

30

40

TITLE

ENGINE

GENERAL

ENGINE

-RECIPROCATING

FUEL

GENERAL

DISTRIBUTION

CONTROLLING

INDICATING

IGNITION

GENERAL

POWER

EMERGENCY

ENGINE

GENERAL

POWER

ENGINE

GENERAL

POWER

CONTROLS

INDICATING

TEMPERATURE

EXHAUST

GENERAL

INSTALLATION

EXHAUST

REPLACEMENT

SYSTEM

CONTROL

SHUTDOWN

CONTROLS

SYSTEM

COMPONENTS

RIGGING

95

79

00

10

20

30

80

00

10

oo

91

00

20

OIL

GENERAL

STORAGE

DISTRIBUTION

INDICATING

STARTING

GENERAL

CRANKING

TURBINES/EXHAUSTGENERAL

SCHEMATICS

GENERAL

ELECTRICAL

SYSTEM

HARDWARE

CHARTS

30

SCHEMATICS

SPECIAL

EQUIPMENT

INTRODUCTION

Rev.

4-95

CHAPTER

Island Enterprises

TIME

LIMITS/

MAINTENANCE

CH

EC

KS

MOONEY

Island Enterprises

AIRCRAFT

CORPORATION

M20R

SERVICE

MAINTENANCE

AND

MANUAL

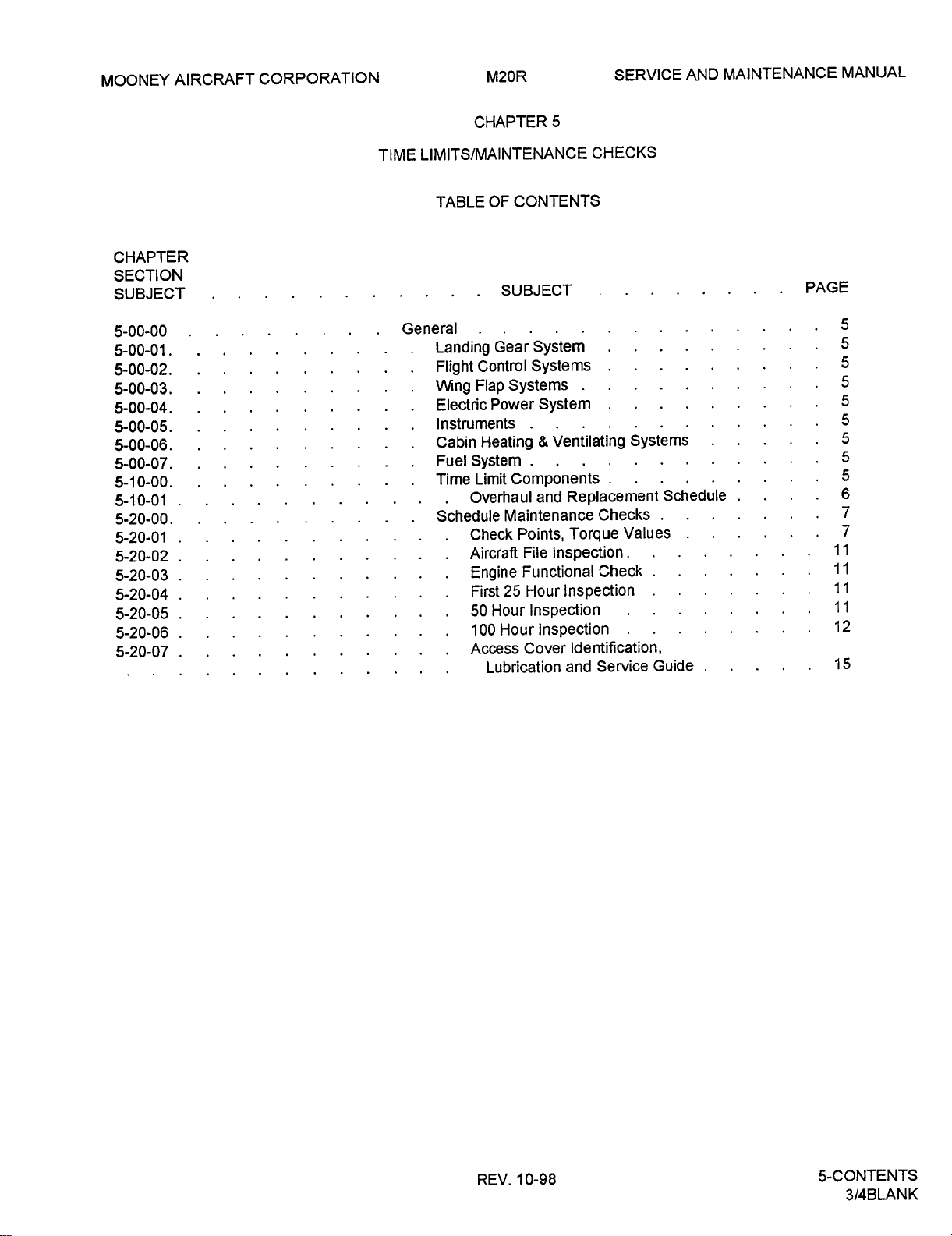

CHAPTER

SECTION

SUBJECT

5-00-00

5-00-01.

5-00-02.

5-00-03.

5-00-04.

5-00-05.

5-00-06.

5-00-07.

5-10-00.

5-10-01

5-20-00.

5-20-01

5-20-02

5-20-03

5-20-04

5-20-05

5-20-06

5-20-07

LIMITS/MAINTENANCE

TIME

TABLE

General

Landing

Flight

W~ng

Electric

Instruments

Cabin

Fuel

Time

Schedule

CHAPTER

CONTENTS

OF

SUBJECT

Gear

System

Control

Systems

FlapSystems

Power

Heating

System

Limit

Components

Overhaul

Check

Aircraff

Engine

First

50

100

Access

Lubrication

and

Maintenance

Points,

File

FunctionalCheck

25

Hour

Hour

Inspection

Hour

Cover

5

System

3

Ventilating

Replacement

Torque

Inspection.

Inspection

Inspection

Identification,

and

CHECKS

Systems

Checks

Values

Service

Schedule

Guide

PAGE

5

5

5

5

5

5

5

5

5

6

7

7

11

11

11

11

12

15

REV.

10-98

5-CONTENTS

3/4BLANK

SERVICE

Island Enterprises

MAINTENANCE

AND

MANUAL

M20R

MOONEY

AIRCRAFT

CORPORATION

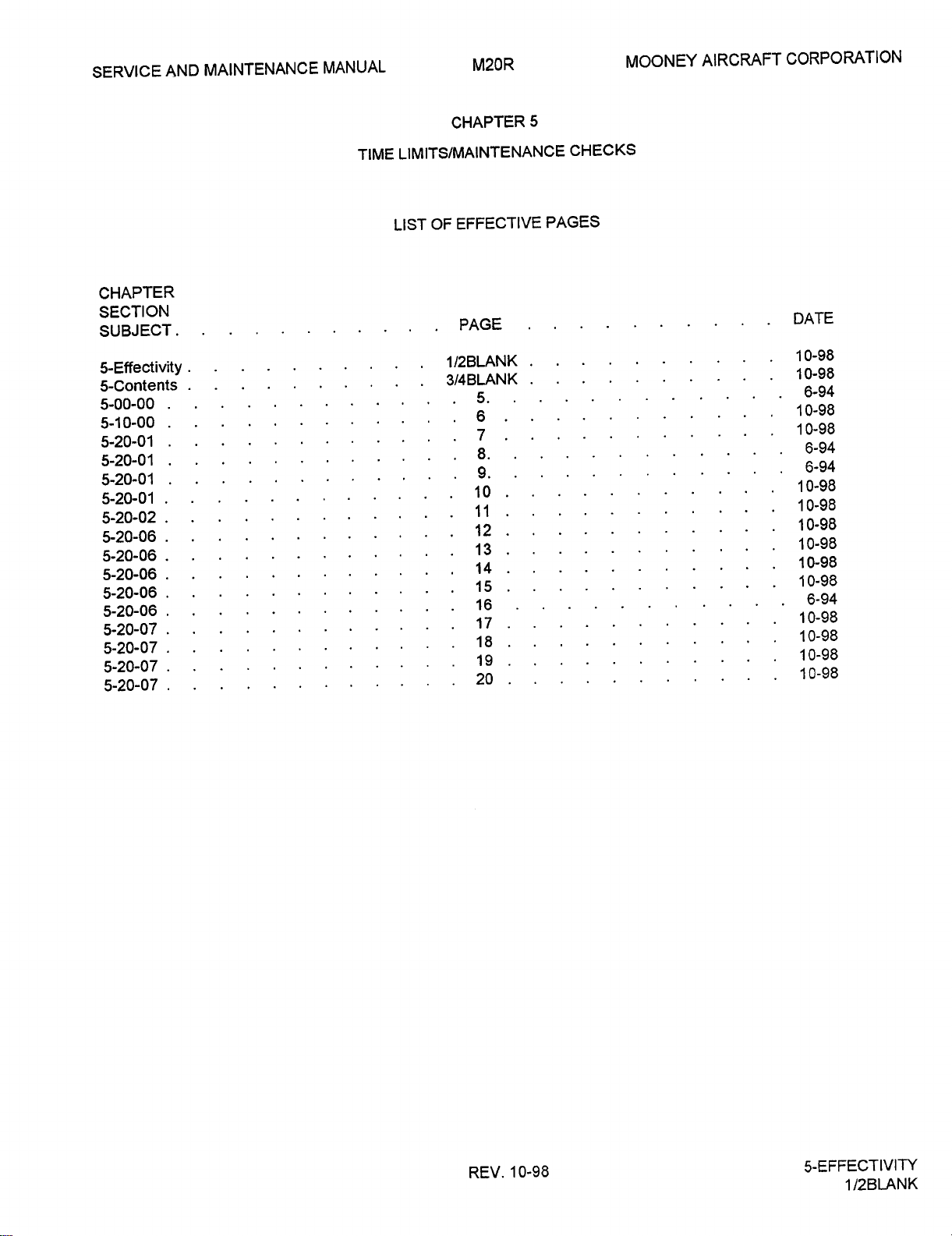

CHAPTER

SECTI

ON

SUBJECT.

ti-Effectivity

5-Contents

5-00-00

5-10-00

5-20-01

5-20-01

5-20-01

5-20-01

5-20-02

5-20-06

5-20-06

5-20-06

5-20-06

5-20-06

5-20-07

5-20-07

5-20-07

5-20-07

CHAPTER

LIMITS/MAINTENANCE

TIME

OF

LIST

1/2BLANK

3/4BLANK

EFFECTIVE

PAGE

5.

6

7

8.

9.

10

?1

12

13

14

15

16

17

18

19

20

5

CHECKS

PAGES

DATE

10-98

10-98

6-94

10-98

10-98

6-94

6-94

10-98

10-98

10-98

10-98

10-98

10-98

6-94

10-98

10-98

10-98

10-98

REV.

10-98

5-EFFECTIVIN

1MBLANK

SERVICE

Island Enterprises

AND

MAINTENANCE

MANUAL

M20R

MOONEY

AIRCRAFT

CORPORATION

5-00-00

AIRCRAFT

aircraft

aspirated,

all-metal

covered

are

single-engine,

airframe

with

semi-monocoque

laminar-flow

construction

spar

and

spars

ribs.

conventional

have

toe

brakes

that

supply

each

pedals

gear,

rudder

main

are

having

pedal

pressure

gear

standard

trailing-edge

stabilizer

about

5-00-01

The

wheel.

featured

warning

floorboard

that

over-center

pressure

prevents

flying

sounds

pre-set

gear

connected

lowering

malfunction.

wheel

its

attaching

electric

Single

horn

preload

actuated

electric

speed

when

value

retraction

wells

trim,

on

are

to

of

landing

position

the

performance.

5-00-02

The

dual

the

control

mechanism

pedals

trim

flaps

spring

flight

pilot

surfaces

Formica

and

in

control

for

system

are

loaded

in

either

conventional

the

pedals.

alignment

spring

assist

to

rudder

is

optional

electric

of

attack.

5-00-03

Wing

a

by

console.

5-00-04

-GENERAL

DESCRIPTION.

four

place,

has

nonstructural

tailcone,

a

the

Control

with

Dual

controls.

linked

wheel.

steerable

is

flaps

entire

wing.

flight

action,

wing

points.

LANDING

gear

disc

self-adjusting

the

main

and

a

standard

the

the

safety

gear

is

attained.

the

manifold

with

the

system

the

gear

gear

Landing

reduce

to

FLIGHT

control

or

co-pilot

operation,

to

guide

dampen

links

coordination.

removable.

are

the

co-pilot’s

sets

WING

FLAP

electrically

"up-off-down"

ELECTRIC

The

high-performance,

low-wing

tubular-steel

a

and

surfaces

stressed

control

wheels

The

individual

to

the

to

hydraulic

Removable,

equipment.

nose

retractable.

fully

are

electrically

empennage

GEAR

system

Gear

gear.

position

gear

equipment.

retraction

lock

the

switch

retraction

A

in

gear

pressure

landing

hasamanual

actuator

in

gear

sound

CONTROL

systems

the

seat.

gear

event

doors

can

using

the

control

blocks

the

vibration.

aileron

A

maintain

The

dual

position.

the

horizontal

SYSTEM

actuated

POWER

M20R

monoplanes.

aluminum

a

skins

pilot’s

hydraulic

The

wheel

SYSTEM

has

a

hydraulic

position

indicator

Bungee

mechanism

gear

the

electrical

takeoff

on

throttle

up.

extension

that

of

fully

levels

SYSTEMS

be

All

flight

pushpull

wheels

An

and

standard

brake

and

switch

SYSTEM

series

normally

cabin

skins,

full-cantilever,

have

structural

riveted

accompany

rudder

cylinders

disc

brakes

cc-pilot

tricycle

controlled

The

wide-span

operated.

pivots

vertically

steerable

brakes

lights,

springs

down.

untilasafe

warning

is

less

The

system

an

enclose

and

manual

electrical

increase

permits

operated

controls

tubes

and

control

interconnect

rudder

systems

co-pilot’s

installation

The

manual

stabilizer

controlled

are

the

on

The

frame

to

the

the

pedals

rudder

landing

For

nose

are

the

on

in

an

An

air

system

horn

than

electric

the

from

are

link

to

rudder

tube

or

angle

center

of

a

on

by

a

a

i.

The

electrical

Volt,

The

relay

breakers

electrical

Standard

la"ding

interior

and

pumpl

retraction/extension

override,

electrical

5-00-05

All

flight

Panel.

The

airspeed

system

side

alternate

The

Master

power

altemator

alternator

and

or

wiring

electrical

lights,

lights,instrument

stall

warning

an

an

flap

instruments

Engine

pitot

system

indicator.

has

of

the

static

instrument

manualdimming

5-00-06

The

heater

cabin

heat

ambient

the

blower

fuel

on

lowest

the

firewall.

tank

pilot’s

fueling

fuel"

source.

main

base

system

inboard

top

the

bottom

crankcase.

are

cluster

The

when

with

from

windshield

defrost

5-00-07

The

fonuard,

outboard

scoop

the

at

is

in

of

the

the

engine

each

the

engine

of

the

systems.

partial

A

110w

activated

gallons.

5-10-00

It

is

recommended

components

specified

accordance

airworthiness

period

Switch

system,

and

two

system

an

overvoltage

circuit

and

equipment

equipment

2-100

watt

system,

electric

system,

electric

system.

-INSTRUMENTS

are

instruments

provides

The

static

two

tailcone)

that

source

panel/g]areshield

mechanisms.

CABIN

SYSTEMS

muff

encasing

Hot

controls

air,

heater

defrosts

motor

system

FU

EL

SYSTEM

has

sealed,

section

wing

in

left

The

engine-driven

wired

gauge.

activates

of

each

forward

in

corner

lower

point

panel,

optional

of

warning

should

with

directives.

wing

usable

TIME

of

tanks..

annunciator

LIMIT

that

be

operation

manufactures

and

power

comprised

10

AMP

an

annunciator

taxi

HR,

overvoltage

switches

from

lights,

has

breaker

panel/glareshield

an

starter,

trim

air

is

with

system

in

the

are

air

pressure

instrument

pickup

to

open

provided

shock-mounted

in

lighting

HEATING

the

from

the

system

windshield.

is

available.

exhaust

the

temperature.

air

cabin

duct

integral

of

each

each

surface.

Two

sen’es

visual

fuel

overhaul

wing.

tank

vent

tank.

The

section

fuel

fuel

quantity

fuel

to

The

Master

the

fuel

sight

quantity

COMPONENTS

accomplished

for

that

relay

100

of

a

24

Volt,

overloads.

includes:.

nawgation

electrical

electric

an

manual

(optional)

the

co-pilot’s

to

static

ports

tone

the

atmosphere.

center

on

systems

VENTILATING

system

heater

to

nozzles

wing

Vents

through

Fuel

sump

electn’e

of

the

pump

transmitters

quantity

Switch,

quantity

gauges

for

light

goes

or

replacement

later

not

component

service

control

AMP,

batteries.

protective

light.

protect

2-100

lights,

fuel

extension

and

operate

pressure

on

console.

muff,

Air

An

optional

tanks

the

at

a

drains

fuel

fuselage,

mounts

gauges

left

indicating

are

each

tank

below

than

data

Circuit

watt

lights,

gear

boost

gear

Flight

panel.

each

have

is

the

mixed

routed

the

at

in

the

aft,

NACA

are

pump

side

2

1/2

the

or

the

28

the

an

the

An

aft

on

in

in

for

is

of

in

or

REV.

10-98

5-00-00

MOONEY

Island Enterprises

AIRCRAFT

CORPORATION

M20R

SERVICE

MAINTENANCE

AND

MANUAL

The

component,

component

maintenance.

0-01

5-1

ITEM

Actuator

other

All

I

Engine

Propeller

Magnetos

I

induction

All

other

Fuel

Flexible

other

All

specified

will

No-Back

Components

Air

Components

Selector

Hoses

Components

overhaul

constitute

not

do

reach

OVERHAUL,

Landing

Spring

Avionics

Plessey-(GEC)

Powerplant

-iCEjl

Filter

IL

Fuel

Valve

(Airight

except

(All,

if

limits,

a

guarantee

limit

MAINTENANCE

RECOMMENDED

that

time

time

Gear

Prddcts(Eaton)

Oil

System

or

Christopher

5

TeRon

(in~cludes

as

Teflon

applicable

without

Tool)

below).

hoses)

a

tO

that

the

requi~ng

REPLACEMENT

AND

OVERHAUL,

CONDITION"

"ON

replaced

or

performance

SCHEDULE

MAINTENANCE

Hours

1000

See

See

On

2000

2000

or

500

SI

SI

Condition

Hours

Hours

6

years

Hours

M20-52A

M20-92A

data)

500

Hours

Condition

On

Condition

On

7

On

years

Condition

or

overhauled

(refer

(refer

or

Annually

Engine

NOTE

items

reveals

condition.

REPLACE

OR

to

mfg’s.

TCM

to

(recommended)

whichever

O/H,

are

when

unserviceable

an

repair

repaired,

inspection

TIME

data)

be

to

repair/inspection

occurs

or

LIMITS

first.

Vacuum

Filters-

Filters

Other

I

All

All

Vacuum

Stand-by

E.L.T.

I

Oxygen

I

Air

All

Avionics

Regulator

Vacuum

Gyro

Components

Components

Components

Pump,

Vacuum

Battery

Cylinders

*Lt.

VI1t.

Composite

Scott

Oxygen

Conditioning

Other

Components

Instruments

Garter

Pump

Instruments

Electrical

Flight

Miscellaneous

Primary.

Pump/Clutch

Steel

Cylinders

C_ylinders

Regulator

Components.

Hydrostatic

Filter

System

Controls

(Excluding

Test

Systems

Avionics)

Required

SeeSedion

Condition

Oni

Condition

On;

5

y;rs.(O/H)/

3

y;rs.(O/H)/

ii

3

yepr

-5800

intervals.

Hours

100

Hours

500

Hours

500

Condition

On

Condition

On

Hours

200

2

Years

24

yeaw

5

i

years

6

years-overhaul;

for

specific

On

Condition

Referto

(CV1J4

or

(Insped

1

or

or

10,000

or

10,000

maintenance

Manufacturers

Filter-

Annually

500

or

Total

Hour

recharge

recharge

3

(See

On

6

Hrs.

Drive

Coupling)

Use

cycles

cycles

years-test

and

NOTE

seNicing

above)

Publications

Condition)

Engine

gB

O/H

Replace

Replace

times.

Components

5-1

0-00

should

be

inspected

and

and

serviced

inspection

REV.

NOTE

at

chart

regular

10-98

intervals

manual.

this

of

per

the

servicing,

lubrication

SERVICE

Island Enterprises

AND

MAINTENANCE

MANUAL

M20R

MOONEY

AIRCRAFT

CORPORATION

5-2060

Inspection

inspection

recommended

paragraphs,

Aircraft

considered

should

5-20-01

The

general

items

in

discussed.

grouped

the

Moving

applicable

sealing,

cleanliness,

adjustment,

binding,

deformation,

Metal

2.

security

sealant,

of

distortion,

corrosion,

tubular

each

frame

annual

damage.

3.

Fuel,

be

inspected

deterioration,

radius,

any

installations

systems

and

of

or

torqued

installations

drain

lines,

inch

pounds.

-SCHEDULED

CHECKS

Intervals.

the

of

operated

high

cleaned

be

intervals.

-INSPECTION

points

accordance

Parts

for:

proper

tension,

excessive

and

Parts

attachment,

and

structure

inspection

oil

air,

as

obstruction,

insecure

these

on

between

to

on

and

aircraft,

intervals

risk

to

shall

any

shall

fatigue

any

and

applicable

conditions

fuel

25

blast

vent

Perform

components

as

NOTE

inasalt

for

corrosion

and

Refer

covered

be

with

be

inspected

operation,

lubrication,

travel,

wear,

other

apparent

be

inspected,

condition

other

should

for

hydraulic

installation.

and

hydraulic

systems

inch

tubes,

lines

MAINTENANCE

a

25,

outlined

air

environment

inspected

43-4.

AC

to

CHECK

during

the

nature

security

servicing,

condition

cracking,

damage.

as

cracks,

apparent

be

signs

any

oil

lines

foc

cracks,

chaffing,

Replace

exist.

systems

and

the

pounds.

air

shall

be

or

50,

and

the

in

damage,

at

frequent

POINTS

inspection

and

and

checked

of

attachment,

of

applicable,

finish

of

welding

damage.

inspeded

corrosion

of

hoses

and

dents,

improper

or

Hose

engine

Hose

ducts,

torqued

100-hour

engine

following

are

and

function

safetying,

hinges,

corrosion,

and/or

cracks,

during

shall

kinks,

bend

correct

clamp

between

shall

clamp

vacuum

to

are

for:

The

as

be

15

at

of

or

if

4.

Pipe

Lubricate

Oxygen

compound

valves,

might

connectors,

come

compound

on

flares.

tape

Fuel,

of

the

the

or

threads

used

tube

prevent

teflon

Lube"

lubricant,

carefully.

Engine

lubricate

manufacturers

fittings

Vacuum

components.

procedures

Tapered

(1)

p0sitioned

If

(2)

(3)

disconnected

components.

Bolts

5.

for:

fretting,

6.

5-2)

Electrical

loose,

and

(Figure

fO’:

broken,

deterioration;

Filters

7.

inspected

require

replacement.

Threads

threads

pipe

Lines

Teflon

or

in

be

must

the

male

coupling

Extreme

contamination

with

oil,

Hydraulic,

equivalent

omitting

Fittings

threaded

Lines

Refer

on

vacuum

Threads

Continue

but

do

leaks

are

If

leaks

and

nuts

and

wear,

and

safetying.

wiring

corroded,

wom

and

and

screens

contamination

for

Tightening

as

Use

thread

fittings,

contact

applied

fitting

sleeves

care

grease

Air,

on

the

first

Use

lubn’cation

No

instructions

to

system.

Use

to

tighten

not

overrun

detected,

persist,

rejected;

in

critical

damage,

shall

and

insulation;

other

any

shall

follows:

with

only.

of

or

Lines

Oil

male

two

directly

Section

Teflon

replace

be

broken

and

only

seal

or

parts

oxygen.

sparingly

No

or

on

should

thread

the

other

fittings

threads,

aircraft

only

to

is

37

Threadseal

until

backoff.

or

tighten

the

areas

stretch,

inspected

insecure

apparent

be

removed,

or

damage

torque

MlL-T-5542

on

tape

assemblies

the

to

compound

outside

the

exercised

be

compound

lubricant.

"Parker

Use

sparingly

engine

engine.

be

to

when

for

maintenance

fitting

full

one

parts

with

new

be

shall

proper

as

terminals;

installation;

damage.

procedures.

thread

threads

which

thread

The

first

three

istobe

of

Thread

Apply

only.

oil

Check

used.

installing

Tape.

is

correctly

tum

more.

should

inspected

torque,

applicable

chaffed,

heat

cleaned

that

would

of

the

to

or

and

to

be

and

TORQUE

See

Following

REV.

10-98

VALUES

Tables.

5-20-00

MOONEY

Island Enterprises

FLARE

AIRCRAFT

TORQUE

NUT

CORPORATION

VALUES-

These

torque

T~ghten

values

are

to

deri)/ed

min’imum

MZOR

torque

CAUTION

from

oil-free

value

for

cadmium-plated

SERVICE

appropriate

AND

size

threads.

MAINTENANCE

shown

as

(Figure

MANUAL

51).

FITTING

SIZE

-3

-4

-5

-6

-8

-10

-12

-16

-20

-24

Failure

and/or

bly

The

1)

2)

3)

4)

5)

of

bolts

capable

torque

Material

Parent

V~hether

V~hether

The

NOMINAL

DIAMETER

(Coarre

threaded

thread.

of

value

of

material

depth

Thread)

Ms

M4

Ms

Ms

M7

Ms

M10

M12

M14

Mis

Mis

M20

Mn

M24

M27

M30

M33

M36

M39

fasteners

being

be

to

the

screw.

(steel,

the

screw

the

screw

the

of

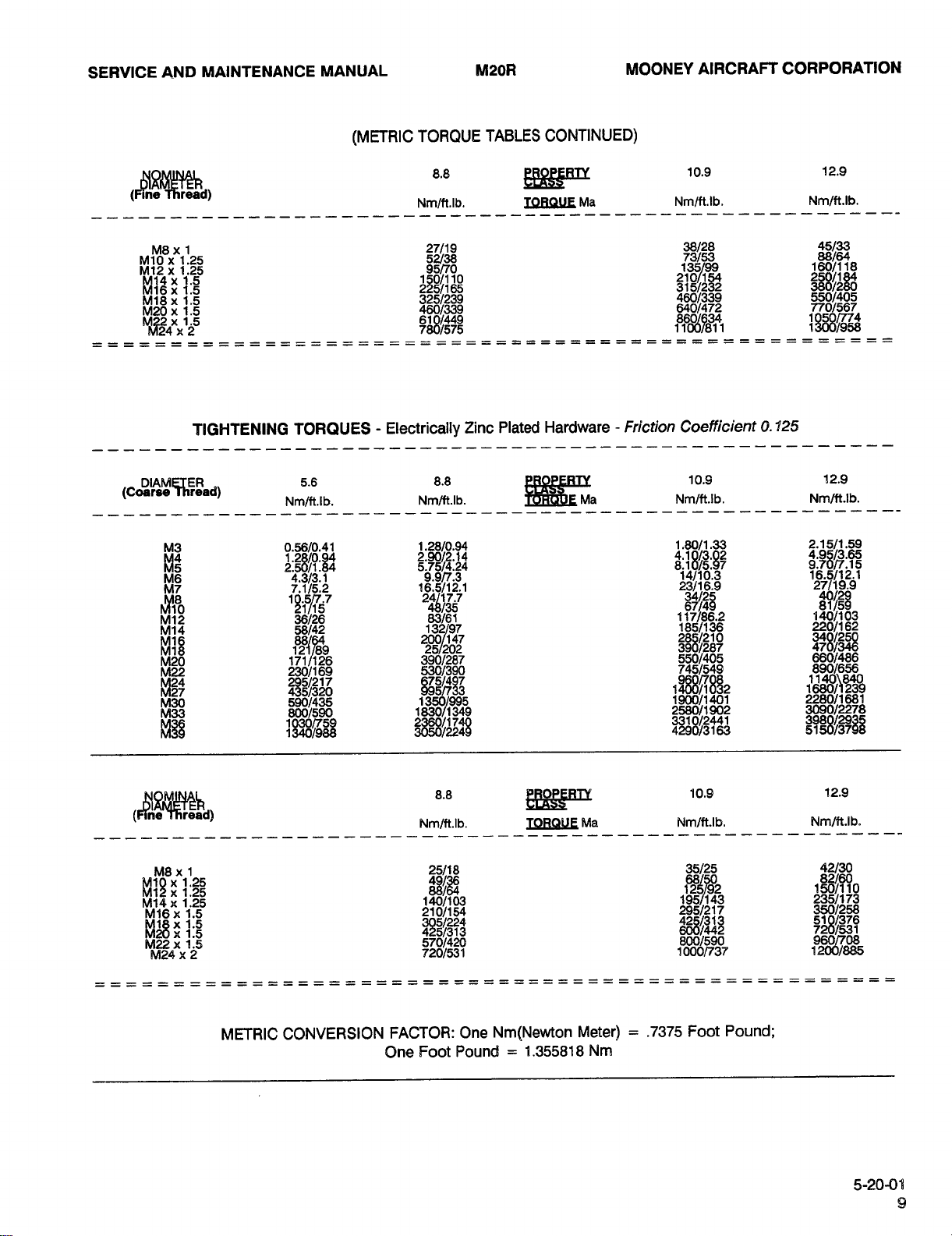

TIGHTENING

A

bolt

or

tightened

for

set

non-ferrous

is

untreated

is

dry

thread.

Nmlff.lb.

0.60/0.44

1.37/1.01

2.70/1

11111819

1440/1062

due

screw

to

a

particular

lubricated.

or

TORQUES

5.6

.99

4.6/3.3

7.6/5.6

1118.1

22/16

39/28

62/45

95/70

130/95

184/135

250/1

84

5/232

31

470/346

635/468

865/637

MINIMUM

4b

60

75

150

200

300

500

600

600

METRIC

to

over-tightening

assembled

the

bolt

proof

size

metal

or

plated.

Untreated

ALUMINUM

TORQUE

MAXIMUM

i

i

1

FLAPENUTMWUE

FIGURE

BPLTS.

occur

can

nut

a

with

without

load

of

or

plastic).

8.8

Nmlff~lb.

1.37/11.01

3.1

0121.29

6.15/4.54

10.5/7.7

17.5/112.9

2~1B

51

89/65

i

41

5/1158

21

295/217

570/

1070/789

1450/1/069

19701i452

2530/11865

3290/a426

54rew

Hardware

137

1~103

is

TUBING

POUNDS

INCH

,j

80

125

250

350

500

700

900

900

51

SCREWS

by

of

the

thread

dependent

(Black

PROPERPI

CLASS

TORQUE

8

NUTS

shank

bolt

appropriate

stripping

upon:

Finish)

Ma

STEEL

MINIMUM

30

50

70

90

155

300

430

550

fracture

class

occurring.

Fiicfion

TUBING

or

intended

is

Coefficienf

10.9

Nmlff.lb.

1.92/1.42

4.40/3.25

8.65/6.38

15/11

25/18.4

36/26

72/53

125/92

198/146

305/224

420/309

590/435

800/590

1020/752

1510/1113

2050/1511

27/0/2042

3560/2625

4620/5407

stripping

by

MAXIMUM

to

provide

0.

70

90

120

150

250

400

575

750

of

14

the

nut

an

12.9

Nmlff.lb.

2.30/1.70

5.25/3.87

19.4n.6

18/13

29/21.3

43/31

87/64

150/110

240/in

365/269

500/368

71

0/523

960/708

1220/899

1810/1334

2450/i

3330/2455

4280/31

5550/4093

assem-

806

56

5-20-01

SERVICE

Island Enterprises

AND

MAINTENANCE

MANUAL

M20R

MOONEY

AIRCRAFT

CORPORATION

MFn08xXlhS

M12x1.25

1.5

M14

x

M16x1.5

M18

1.5

x

M20x1.5

115

M24x2

TIGHTENING

Me

M12

M14

M20

M22

(METRIC

TORQUES

5.6

Nm/ft.lb.

0.56/0.41

4.3/3.1

10.5/7.7

7.2!1!1/5.25

36126

58/42

1

1

230/169

TORQUE

Nm/ft.lb.

95/70

150/110

225/165

325/239

460/339

Electrically

Nmm.lb.

1.28/0.94

2.90/2.14

5.75/4.24

9.9/7.3

66.5/12.1

2~7

83/61

390/287

530/390

8.8

8.8

147

Zinc

TABILES

~PSBIY

TORQUE

Plated

CONTINUED)

Ma

Hardware

Friction

10.9

Nm/ft.lb.

38/28

73/53

135/99

210/154

315/232

460/339

640/472

)316~dfja3;bl1

125

Coefficient

10.9

Nm/ft.ib.

1.80/1.33

4.10/3.02

8.10/5.97

14/10.3

8.

2~ij16.9

117/86.2

185/a36

550/405

745/549

12.9

Nm/ft.lb.

45/33

88/64

160/118

550/405

62.9

Nmm.lb.

2.15/1.59

Ic,rJ

4

16.5/12.1

140/103

220/1

660/486

890/656

62

M30

RA33

Ma

M14x1.25

M16

BIA241x

x

x1.25

x

x

1

1.25

1.5

1.8

2

METRIC

590/435

8001590

CONVERSION

Nm/ft.lb.

FACTOR:

Foot

One

s.e

25/18

140/103

210/154

570/420

720/531

One

Pound

TORQUE

Nm(Newton

1.355818

Rna

Meter~

Nna

.7375

1900/1401

2580/1902

fO.D

Plm/ft.lb.

35/25

295/217

Foot

Pound;

2280/1681

3090/2278

62.9

Nm~t.lb.

42/30

235/173

350/258

5-2069

MOONEY

Island Enterprises

AIRCRAFT

CORPORATION

M20R

SERVICE

AND

MAINTENANCE

MANUAL

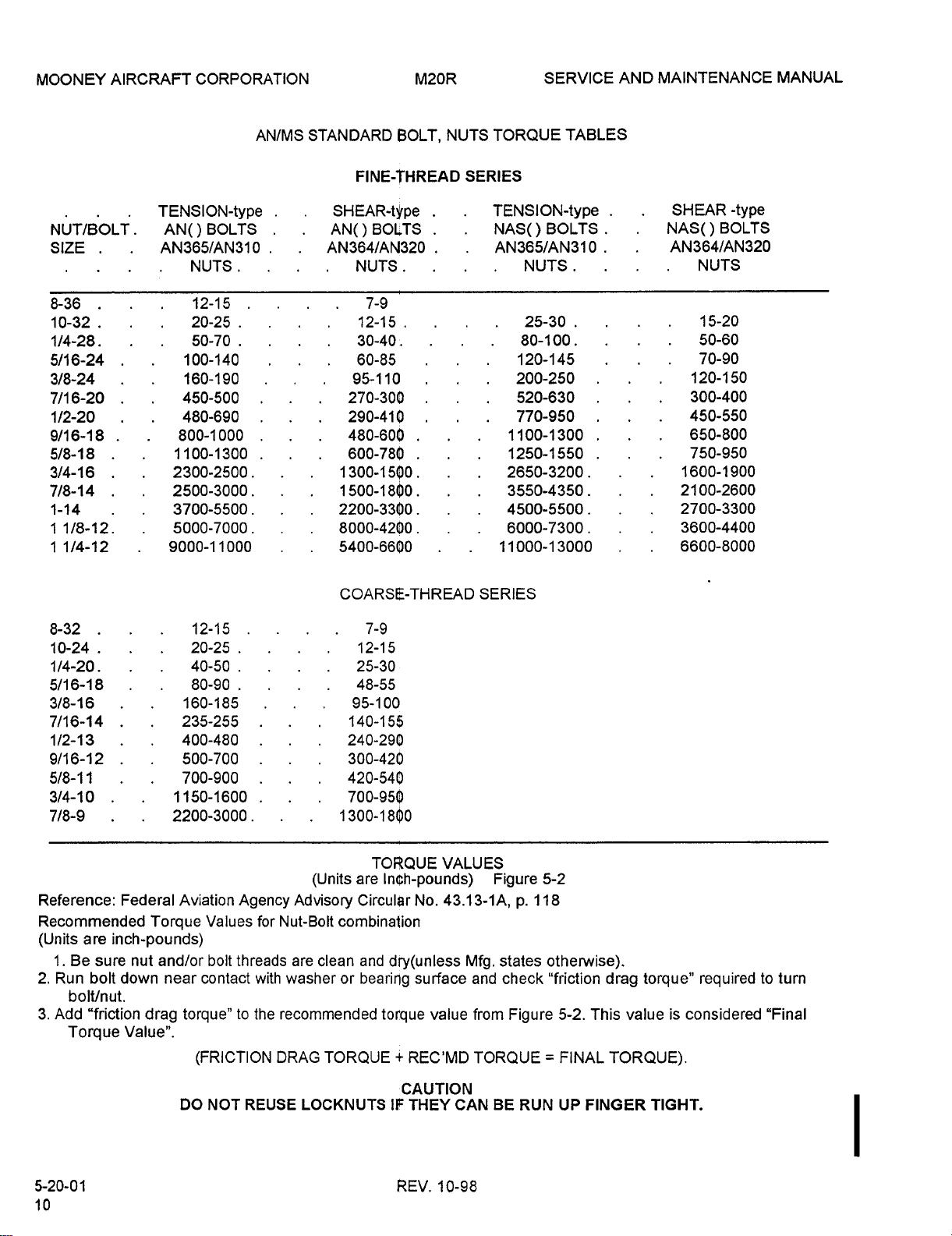

NUT/BOLT

SIZE

8-36

10-32

1/4-28.

5/16-24

3/8-24

7/16-20

1/2-20

9/16-18

5/8-18

3/4-16

7/8-14

1-14

11/8-12.

11/4-12

TENSION-type

AN()BOLTS

AN365/AN310

NUTS

12-15

20-25

50-70

100-140

160-190

450-500

480-690

800-1

000

1100-1300

2300-2500

2500-3000

3700-5500

5000-7000

9000-11000

AN/MS

STANDARD

FINE-fHREAD

SMEAR-type

AN()BOLTS

AN364/AN320

NUTS

12-15

30-40

60-85

95-110

270-300

290-410

480-600

600-780

1300-1500

1500-1800.

2200-3300.

8000-4200

5400-6600

7-9

BOLT,

NUTS

SERIES

TORQUE

TABLES

TENS1ON-type

NAS()

AN365/AN310

BOLTS

NUTS

25-30

00

80-1

120-145

200-250

520-630

770-950

1100-1300

1250-1550

2650-3200

3550-4350

4500-5500

6000-7300

11000-13000

SMEAR

NAS()

AN364/AN320

BOLTS

NUTS

15-20

50-60

70-90

120-150

300-400

450-550

650-800

750-950

1600-1900

2100-2600

2700-3300

3600-4400

6600-8000

-type

8-32

10-24

1/4-20.

6-18

5/1

3/8-16

7/16-14

1/2-13

9/16-12

518-11

314-10

7/8-9

Reference:

Recommended

are

(Units

1.

Be

sure

Run

Add

bolt

bolt/nut.

"friction

2.

3.

Torque

1150-1600

2200-3000

Federal

Aviation

Torque

inch-pounds)

and/or

nut

down

near

drag

Value".

COARSE-THREAD

12-15

20-25

40-50 25-30

80-90

160-185

235-255

400-480

500-700

700-900

95-1

140-155

240-290

300-420

420-540

700-959

1300-1800

(Units

Values

bolt

contact

torque"

(FRICTION

Agency

threads

to

for

Nut-Bolt

with

washer

the

recommended

DRAG

Advisory

clean

are

TORQUE

combination

or

7-9

12-15

48-55

00

TOFPQUE

are

In$h-pounds)

Circular

and

dry(unless

bearing

torque

i

No.

surface

value

REC’MD

SERIES

VALUES

43.13-1A,

Mfg,

and

from

TORQUE

Figure

p.

states

check

Figure

5-2

118

otherwise).

"friction

5-2.

FINAL

drag

This

value

TORQUE).

torque"

is

required

considered

to

"Final

turn

5-20-01

10

DO

NOT

REUSE

LOCKNUTS

CAUTION

IF

THEY

REV.

CAN

10-98

BE

RUN

UP

FINGER

TIGHT.

SERVICE

Island Enterprises

MAINTENANCE

AND

MANUAL

M20R

MOONP/

AIRCRAFT

CORPORATION

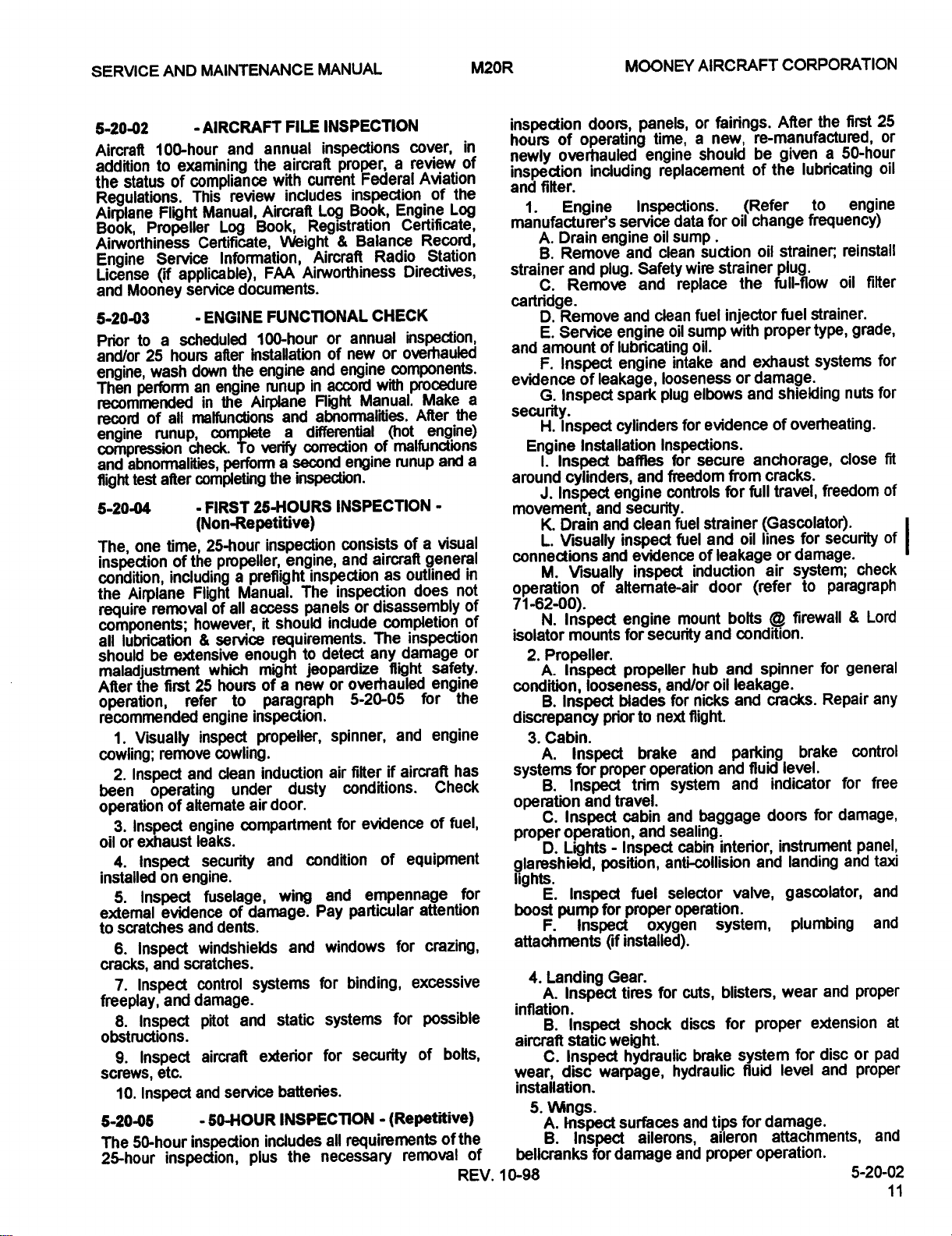

8-20-02

status

100-hour

to

of

Aircraft

addition

the

Regulations.

Airplane

Book,

Airworthiness

Engine

License

and

5-201)3

Prior

and/or

engine,

Then

recommended

record

engine

Flight

Propeller

Service

(if

Mooney

to

a

25

wash

perform

of

runup,

hours

all

compression

and

abnormalities,

after

test

Right

530-04

one

The,

inspedion

condition,

the

require

time,

of

including

Airplane

removal

components;

lubrication

all

should

be

maladjustment

Zrst

the

After

operation,

recommended

1.

Visually

2.

Inspect

3.

inspect

exhaust

or

4.

Inspect

5.

Insped

scratches

6.

Inspect

7.

Inspect

8.

Inspect

9.

Inspect

10.

Inspect

S0-hour

remove

operating

of

on

evidence

and

and

etc.

inspection,

cowling;

been

operation

oil

installed

extemal

to

cracks,

freeplay,

obstructions.

screws,

5-20QI

The

25-hour

-AIRCRAFT

and

examining

the

compliance

review

This

Manual,

Log

Certificate,

Information,

applicable),

service

scheduled

check.

documents.

ENGINE

after

the

down

an

engine

the

in

malfunctions

comdete

to

installation

Airplane

perform

completing

FIRST

25-HOURS

(Non-Repetitive)

25-hour

the

propeller,

a

preflight

Manual.

Flight

all

of

access

however,

service

8

extensive

25

refer

and

alternate

engine

leaks.

engine.

and

windshields

scratches.

control

damage.

and

inspection

which

hours

to

engine

inspect

cowling.

clean

under

security

fuselage,

of

dents.

pitot

aircraft

service

80+10UR

enough

inspection.

air

compartment

damage.

systems

and

plus

FILE

annual

aircraft

current

with

includes

Aircraft

Book,

Log

Registration

Weight

Aircraft

Airworthiness

FAA

FUNCTIONAL

100-hour

runup

and

in

engine

Flight

abnormalities.

and

differential

a

conedion

verify

second

a

the

inspection.

inspection

engine,

inspection

The

panels

should

1

requirements.

to

jeopardize

might

of

a

new

paragraph

propeller,

induction

dusty

door.

condition

and

wing

Pay

and

for

static

e>derior

batteries.

INSPECTIOPI

includes

the

INSPECTION

inspections

proper,

Federal

inspection

Book,

Balance

5

Radio

CHECK

annual

or

of

new

engine

accord

with

Manual.

of

engine

INSPECTION

consists

aircraft

and

as

inspection

or

disassembly

include

ovemauled

or

5-20-05

The

any

detect

spinner,

filter

air

conditions.

evidence

for

of

and

empennage

particular

windows

binding,

systems

for

security

-(Repetitive)

all

requirements

necessary

cover,

review

a

Aviation

of

Engine

Certificate,

Record,

Station

Directives,

inspedion,

overhauled

or

components.

procedure

Make

After

engine)

(hot

malfunctions

and

runup

visual

of

a

general

outlined

does

completion

inspection

damage

safety.

Right

engine

for

and

engine

aircraff

a

Check

of

equipment

attention

for

crazing,

excessive

for

possible

of

bolts,

of

removal

the

Log

the

not

the

has

fuel,

for

the

REV.

the

or

inspection

hours

in

of

newly

1.

manufacturer’s

A.

B.

strainer

C.

doors,

of

operating

overhauled

including

Engine

Drain

Remove

and

Remove

service

engine

and

plug.

panels,

time,

engine

replacement

Inspections.

oil

clean

Safety

and

a

should

data

sump.

suction

wire

replace

fairings.

new,

for

strainer

cartridge.

fuel

clean

oil

sump

oil.

intake

looseness

elbows

plug

for

inspections.

for

secure

Freedom

controls

fuel

fuel

of

induction

mount

security

hub

and/or

nicks

for

ne~d

Right

and

operation

system

and

baggage

sealing.

cabin

injector

with

and

evidence

from

for

strainer

and

leakage

door

bolts

and

and

oil

and

interior,

a

a

in

of

of

or

Remove

D.

Service

E.

amount

a"d

F.

G.

Inspect

inspect

evidence

security.

H.

Inspect

Engine

I.

inspect

around

cylinders,

J.

Inspect

movement,

Drain

K.

L.

M.

Visually

Wsually

connections

opention

71-62-00).

N.

Inspect

2.

Propeller.

A.

mounts

Inspect

isolator

condition,

B.

Inspect

discrepancy

Cabin.

3.

A.

systems

B.

inspect

operation

C.

Inspect

proper

operation,

D.

Lights

of

of

leakage,

Installation

and

and

and

of

looseness,

prior

Inspect

for

proper

and

and

engine

lubricating

engine

spark

cylinders

baffles

and

engine

security.

clean

inspect

evidence

inspect

alternate-air

engine

for

propeller

blades

to

brake

trim

travel.

cabin

and

Inspect

position,antLcollision

of

"E:

boost

pump

F.

attachments

4.

Landing

B.

aircraft

C.

installation.

5.

~Hngs.

A.

B.

bellcranks

disc

wear,

Inspect

Inspect

Inspect

static

inspect

inspect

Inspect

for

for

(ifinstalled).

Gear.

tires

weight.

warpage,

surfaces

damage

selector

fuel

proper

oxygen

for

shock

hydraulic

ailerons,

operation.

system,

blisters,

cuts,

discs

brake

hydraulic

and

tips

aileron

and

proper

for

After

re-manufactured,

be

given

of

the

(Refer

oil

change

oil

strainer;

plug.

full-flow

the

fuel

proper

exhaust

or

damage.

and

shielding

of

ovemeating.

anchorage,

cracks.

full

travel,

(Gascolator)

for

lines

oil

or

damage.

air

system;

(refer

firewall

condition.

spinner

leakage.

cmcks.

and

parking

fluid

and

valve,

level.

indicator

doors

instrument

and

gascolator,

brake

landing

plumbing

wear

proper

system

fluid

for

for

level

damage.

attachments,

operation.

a

lubricating

to

frequency)

strainer.

type,

systems

freedom

security

to

paragraph

for

Repair

for

and

e>dension

disc

and

10-98

25

first

50-hour

oil

engine

reinstall

oil

filter

grade,

for

for

nuts

close

check

5

Lord

general

any

control

free

for

damage,

panel,

taxi

and

and

and

proper

or

pad

proper

and

5-20-02

or

fit

of

of

I

at

MOONEY

Island Enterprises

AIRCRAFT

CORPORATION

M20R

SERVICE

MAINTENANCE

AND

MANUAL

C.

Inspect

D.

6.

Fuselage

A.

a.

C.

See

7.

operation.

of

Lubricate

Inspect

proper

Lubricate

Check

Section

proper

evidence

damage,

inspections

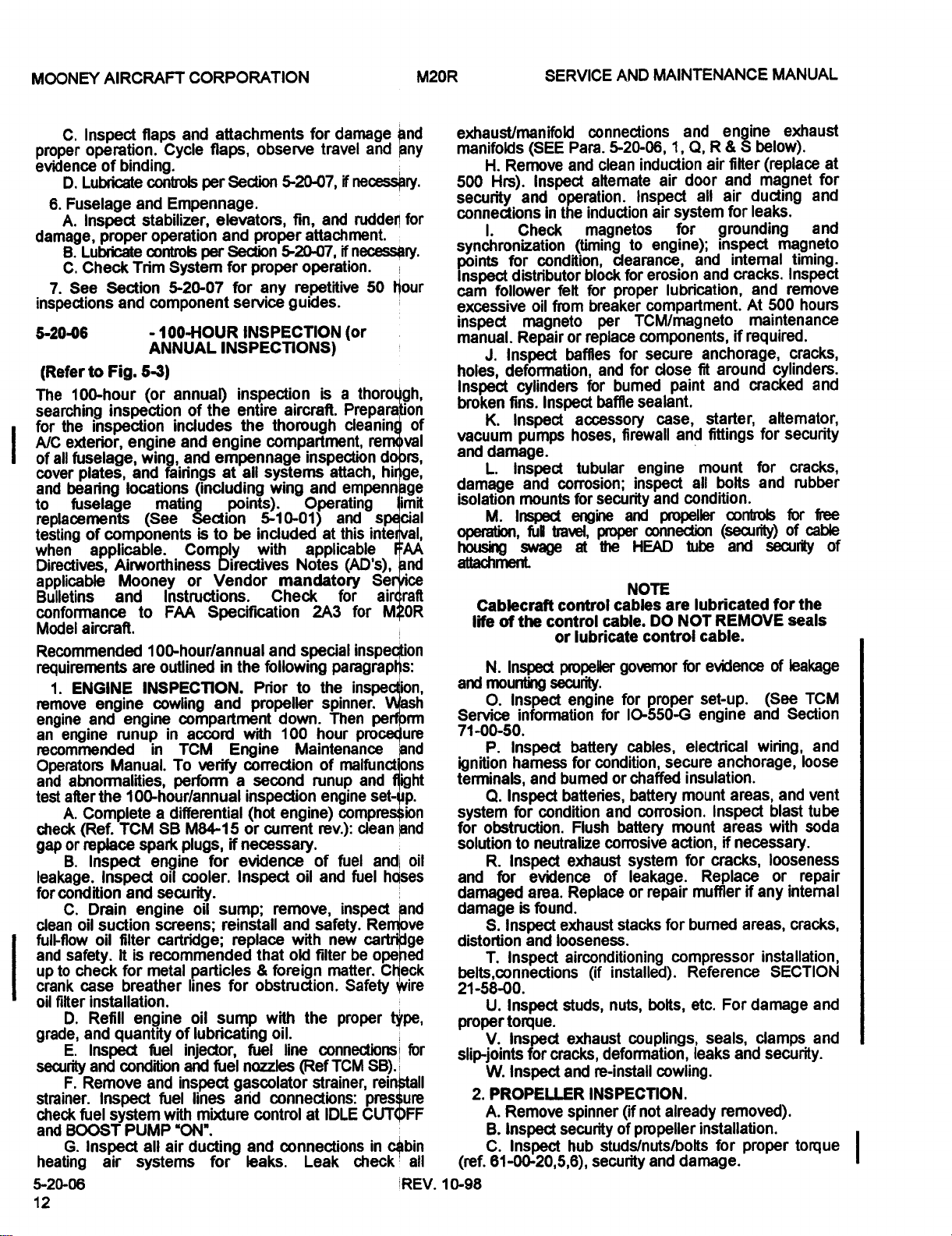

5-20-06

to

100-hour

the

inspedion

e~cterior,

fuselage,

plates,

bearing

fuselage

Pig.

inspection

The

searching

for

AIC

I

to

(Refer

all

of

cover

and

replacements

of

testing

when

components

applicable.

Directives,

applicable

Bulletins

conformance

aircraft.

Model

Recommended

requirements

ENGINE

i.

remove

engine

engine

and

anengine

recommended

Operators

and

abnormalities,

after

A.

Complete

(Ref.

or

~place

B.

Inspect

condition

Drain

oil

safety.

check

to

case

filter

D.

Refill

and

E.

Inspect

F.

Remove

fuel

BOOST

G.

Inspect

the

Inspect

suction

oil

installation.

and

Inspect

system

air

test

check

gap

leakage.

for

clean

full-flow

and

up

crank

oil

grade,

security

strainer.

check

and

heating

5-20-06

12

and

flaps

Cycle

binding.

contrds

and

Empennage.

stabilizer,

operation

controls

Trim

System

and

5-20-07

component

100-HOUR

ANNUAL

53)

annual)

(or

of

includes

wing,

mating

(See

and

and

fairings

(including

Section

engine

and

locations

Comply

Airworthinessess

Mooney

and

to

are

or

Instructions.

FAA

100-hour/annual

outlined

INSPECTION.

cowling

engine

runup

Manual.

compartment

accord

in

in

TCM

To

perform

100-hour/annual

differential

a

TCM

SE

M84-15

plugs,

spark

engine

oil

cooler.

and

security,

engine

filter

Itisrecommended

for

breather

engine

quantity

condition

PUMP

all

systems

oil

screens;

cartridge;

metal

particles8foreign

lines

oil

of

lubricating

fuel

injedor,

and

and

inspect

fuel

lines

with

’ON".

air

ducting

attachments

observe

flaps,

Section

per

elevators,

and

proper

section

per

for

proper

for

any

service

INSPECTION

INSPECTIONS)

inspection

entire

the

the

engine

empennage

all

at

systems

points).

5-10-01)

istobe

included

with

biieclives

Vendor

Specification

the

in

following

Prior

and

propeller

with

Engine

corection

verify

a

second

inspedion

(hot

current

or

if

necessary.

evidence

for

Inspect

sump;

reinstall

replace

that

for

obstruction.

sump

fuel

fuel

naules

gascolator

arid

for

control

and

leaks.

mi>dure

for

damage

travel

5´•20-07,

fin,

~20´•07,

if

and

attachment.

if

operation,

repetitive

guides,

is

aircraft,

a

thorough

compartment,

inspection

attach,

and

wing

Operating

and

this

at

applicable

Notes

mandatory

Check

and

for

2A3

special

paragraphs:

the

to

spinner.

down.

100

Then

hour

Maintenance

of

malfun

runup

engine

engine)

compres$ion

rev.):

fuel

of

and

oil

remove,

safety.C.

and

with

new

old

filter

matter.

with

the

oil.

line

proper

connedionsjfor

TCM

(Ref

strainer,

connections:

IDLE

at

connections

Leak

~nd

and

~ny

necess~iry.

50

tiour

i

and

set-~p.

~nd

andi

hoises

opehed

Check

ivire

t~pe,

SE).

rein~tall

pres$ure

CUTOFF

in

c~bin

:REV.

for

of

AA

oil

all

Ndde~

necessery.

for

(AD’s),

for

inspe~ion

i

clean

fuel

be

Safety

check

exhaust/manifold

manifolds

H.

Remove

500

Hrs).

security

connections

check

i.

Sy"ch""ization

points

Inspect

cam

excessive

for

distributor

follower

inspect

manual.

J.

Inspect

holes,

Inspect

broken

vacuum

and

deformation,

cylinders

fins.

K.

Insped

damage.

L.

inspect

damage

isolation

M.

Inspect

operation,

housing

attachment

Cablecraft

of

life

N.

and

Service

71-00-50.

ignition

Inspect

mounting

O.

Inspect

P.

Inspect

harness

terminals,

Q.

Inspect

system

for

solution

and

for

obstrction.

to

R.

Inspect

for

damaged

damage

S.

T.

Inspect

Inspect

distortion

belts,connections

21-58-00.

U.

Inspect

propertorque.

V.

Inspect

slipjoints

W.

Inspect

2´•

PROPELLER

A.

Remove

B.

Inspect

C.

Inspect

81-00-20,5,6),

(ref.

10-98

(SEE

Inspect

and

operation.

in

the

condition,

felt

oil

from

magneto

Repair

baffles

Inspect

pumps

and

corrosion;

mounts

full

travel,

swage

control

the

central

or

propeller

security.

information

bumed

and

batteries,

condition

neutralize

evidence

area.

is

found.

exhaust

and

looseness.

studs,

for

cracks,

and

security

connections

Pare.

5-20-06,

induction

clean

and

altemate

Inspect

induction

magnetos

clearance,

block

for

proper

breaker

per

replace

for

and

bumed

for

baffle

to

erosion

for

compartment.

TCM/magneto

components,

secure

for

sealant.

firewall

engine

(timing

or

accessory

hoses,

tubular

inspect

for

security

engine

at

lubricate

engine

battery

for

and

proper

HEAD

the

NOTE

cables

cable.

control

govemor

for

IO-550-G

for

cables,

condition,

chaffed

or

connection

battery

corrosion.

and

Flush

battery

conosive

exhaust

Replace

of

stacks

system

leakage.

or

airconditioning

installed).

(if

nuts,

exhaust

couplings,

deformation,

re-install

INSPECTION.

spinner

hub

not

(if

of

propeller

studs/nuts/bolts

security

air

air

system

for

engine);

lubrication,

dose

paint

case,

and

and

pmpeller

are

NOT

DO

for

proper

secure

mount

mount

action,

repair

for

compressor

bolts,

cowling.

already

and