Mooney M20M Service Bulletin

alrg~

SUBJECI:

1

MODEUS/N

AFFECTED:

TIME

OF

COMPLIANCE:

INTRODUCTION:

INSTRUCTIONS:

1.

2

3.

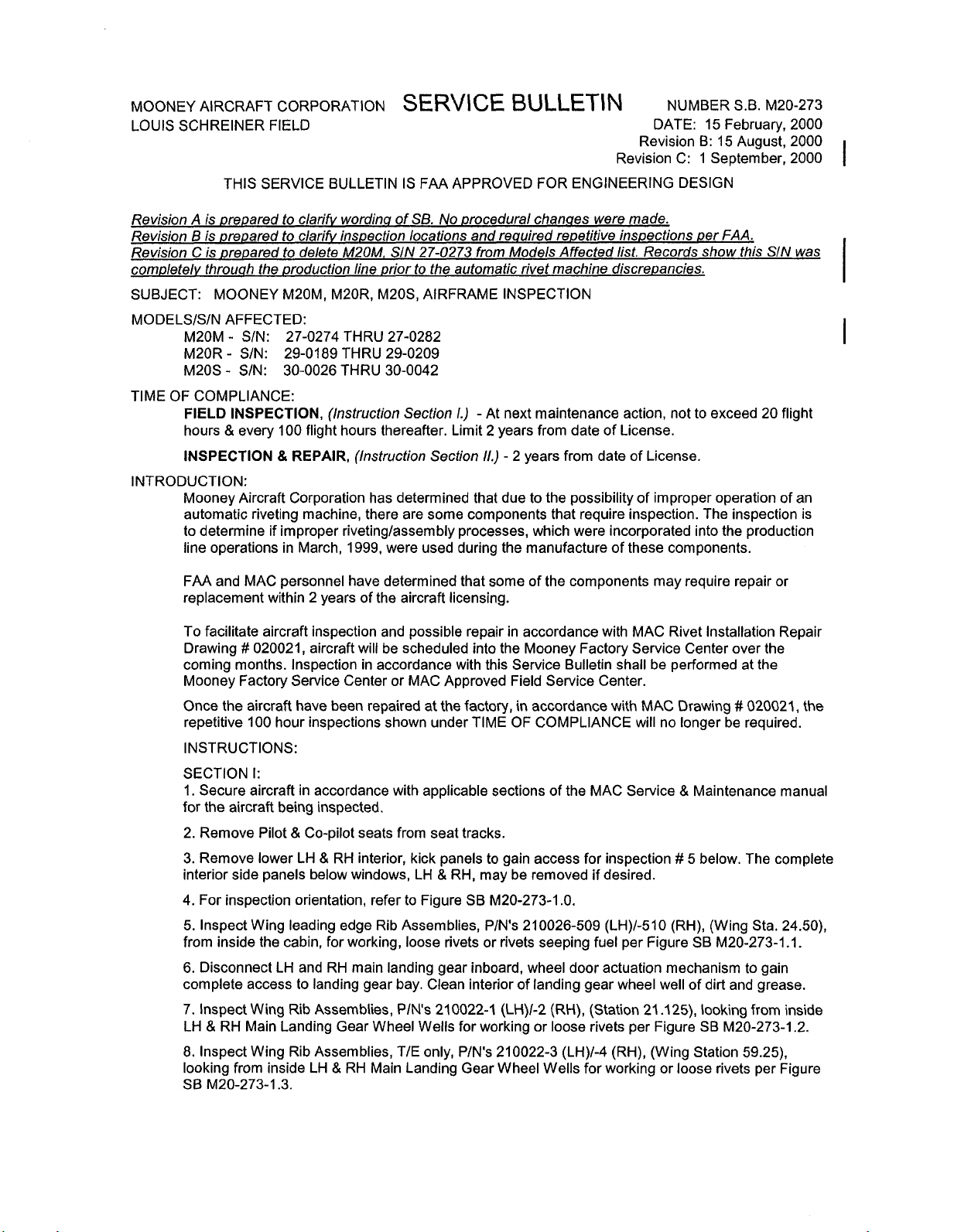

4.

5.

6.

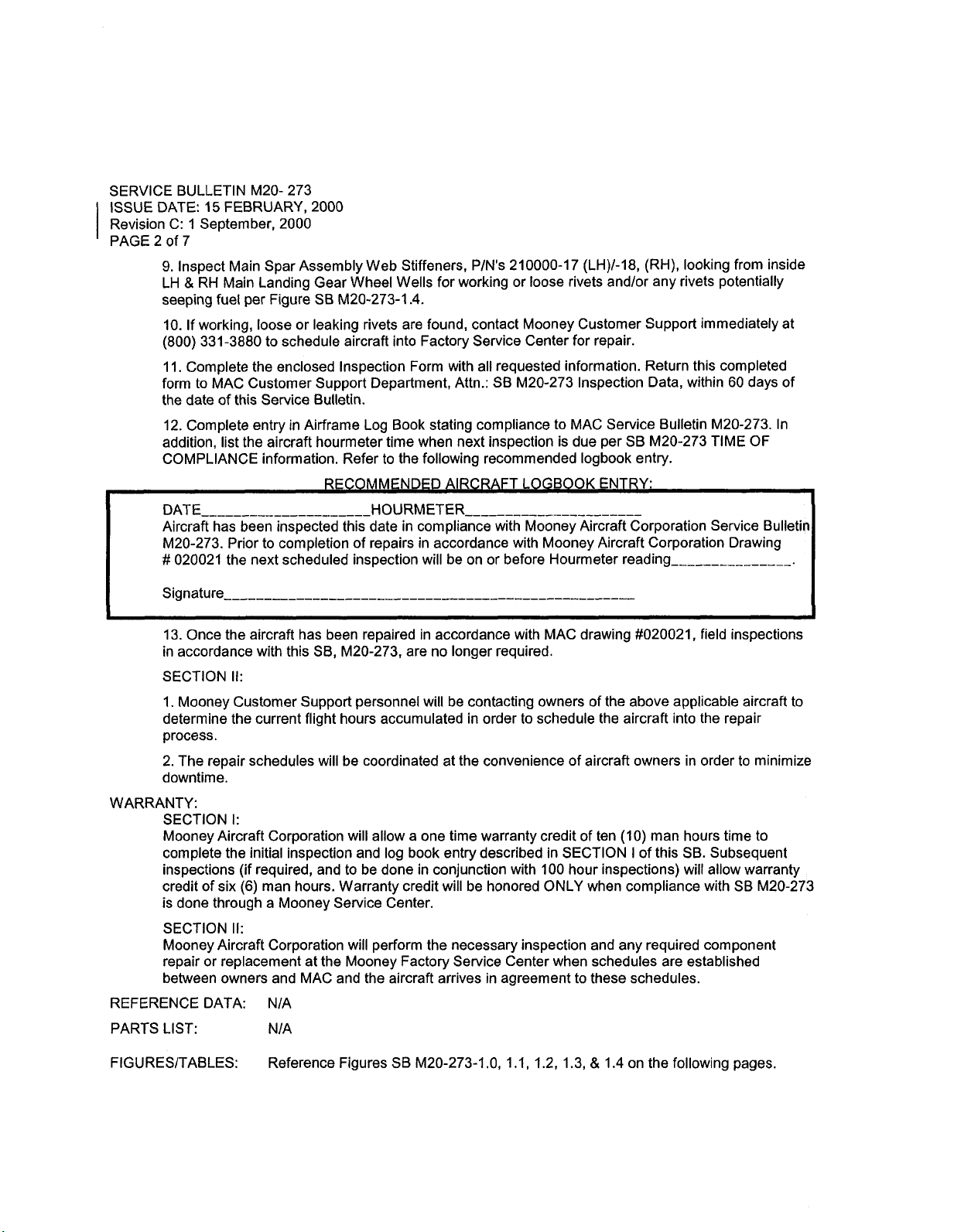

7.

8.

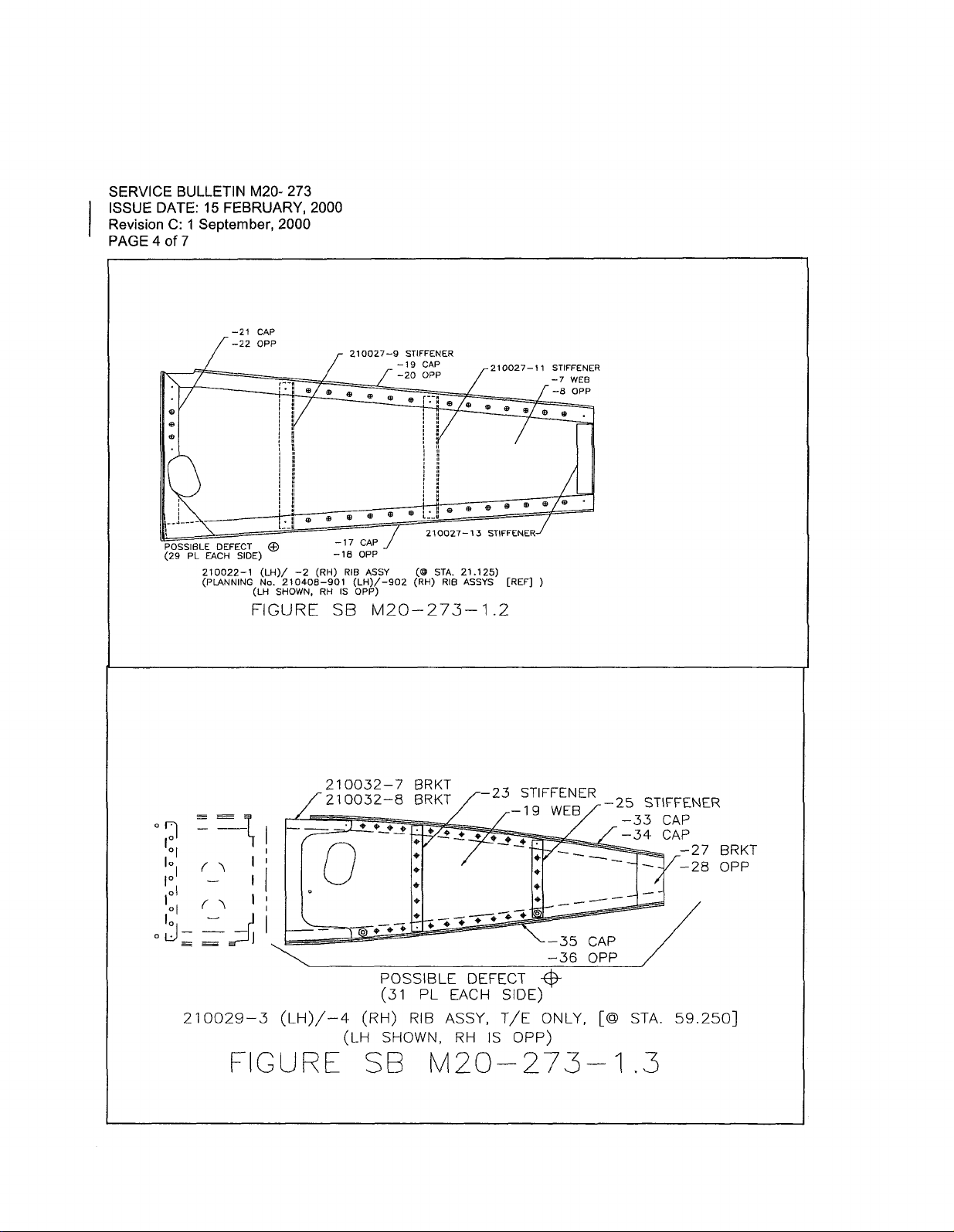

9.

10.

I.

1

12.

MOONEY

(Revision

MOONEY

AT

THE

OVERVOLTAGE

SHOULD

REWIRE

Disconnect

Locate

Cut

Remove

Insert

pin

wire

existino

from

Glareshield

regulator.

wire

Route

Secure

Locate

with

wire

M-V1~02C\20

Use

AMP

M-PA13B18

For

(Steps

switch

Remove

No.

2

1,

on

Functionally

Enter

compliance

24

A

Revision

MODEL:

NDCT

SCHEDULED

VOLT

24

AN

A

PORTION

voltage

wire,

number

number

lacing

regulator

~Mre

M-PA13A18;

M-PA13B18

M-PA13B18

cord

number

wire

320559

wire

nGUREM20-245-1B).

(SEE

Altemator:

2

and

3)

backofArtifical

the

1

amp

check

note

VOLT

AIRCRAFT

is

applicable

B

is

applicable

ELECTRICAL

WARNING

ALTERNATOR

number

per

M-PA13A18;

instructions

or

TyRaps.

M-WT02A20

to

splice

Steps

repeat

M-PA33B18

Horhon

Annunciator

operation

in

aircraft

to

M20J

to

M20M

MAINTENANCE

SYSTEMiSWIRED

LIGHT

OVERVOLTAGE

OF

THE

Altemator

(for

wire

cap

in

(included

along

existing

connected

inches

6

re-connect

1

through

(Step

and

and

C/B

of

altemator(s)

logbook

ELECTRICAL

and

M20M

only--).

27-0001

S/N

IN

THE

CIRCUTT

#1)

wire

push

end

using

the

appropn’ate

-1B

in

wire

to

pin

back

from

wire

with

5

Route

5);

connect

replace

per

and

WIRING

M20K

aircraft

THRU

27-0052

IN

A

ANNUNCIATOR

OCCUR.

ENABLE

TO

iocated

out

AMP

into

kit)

bundletoannunciator

1

of

connector.

number

#2

unconnected

"white"

to

with

POH/AFM,

return

THIS

under

of

pin

324485

S

M

8

pin

annunciator

M-WT02A20

regulator

terminal.

2

the

amp

Section

aircrafttoservice.

MODIFICATION,

stillineffect

and

PANEL

S.

WARNING

instrument

of

#1

wire

cap

voltage

is

THAT

PROVIDES

B.

regulator

(included

Section

regulator

only

MANNER

THIS

the

8

manual,

of

panel

connector,

panel

tile

and

butonwire

endofwire

C/B,

included

Normal

IV,

number

RENDERS

ASSEMBLY

LIGHT.

on

panel

main

in

39-10-01.

receptacle

connector

unconnected

numbers

M-PA33B18

in

-1B

Procedures,

for

those

model

THE

INOPERATIVE

INSTRUCTIONS

the

co-pilot’s

harness

receptacle.

kit).

and

(M-WT103A).

M-WT103A,

end

of

M-PA33A18

kit.

to

Before

side.

reconnect

and

new

vacuum

Takeoff

aircraft.

TO

cut

wire

WARRANIY:

REFERENCE

DATA:

PARTS

FI

LIST:

mM

1.

2

3.

4.

5.

GURESI

TABLES:

This

kit

should

policies

will

accomplish

dateofthis

N/A

KIT

P/N

P~

M-PA~3B18

M-PA33B18

324485

320559

7277-2-2

be

ordered

beinaffect

this

modification

SeM’ce

SB-M20-245-1B

Bulletin.

for

from

this

if

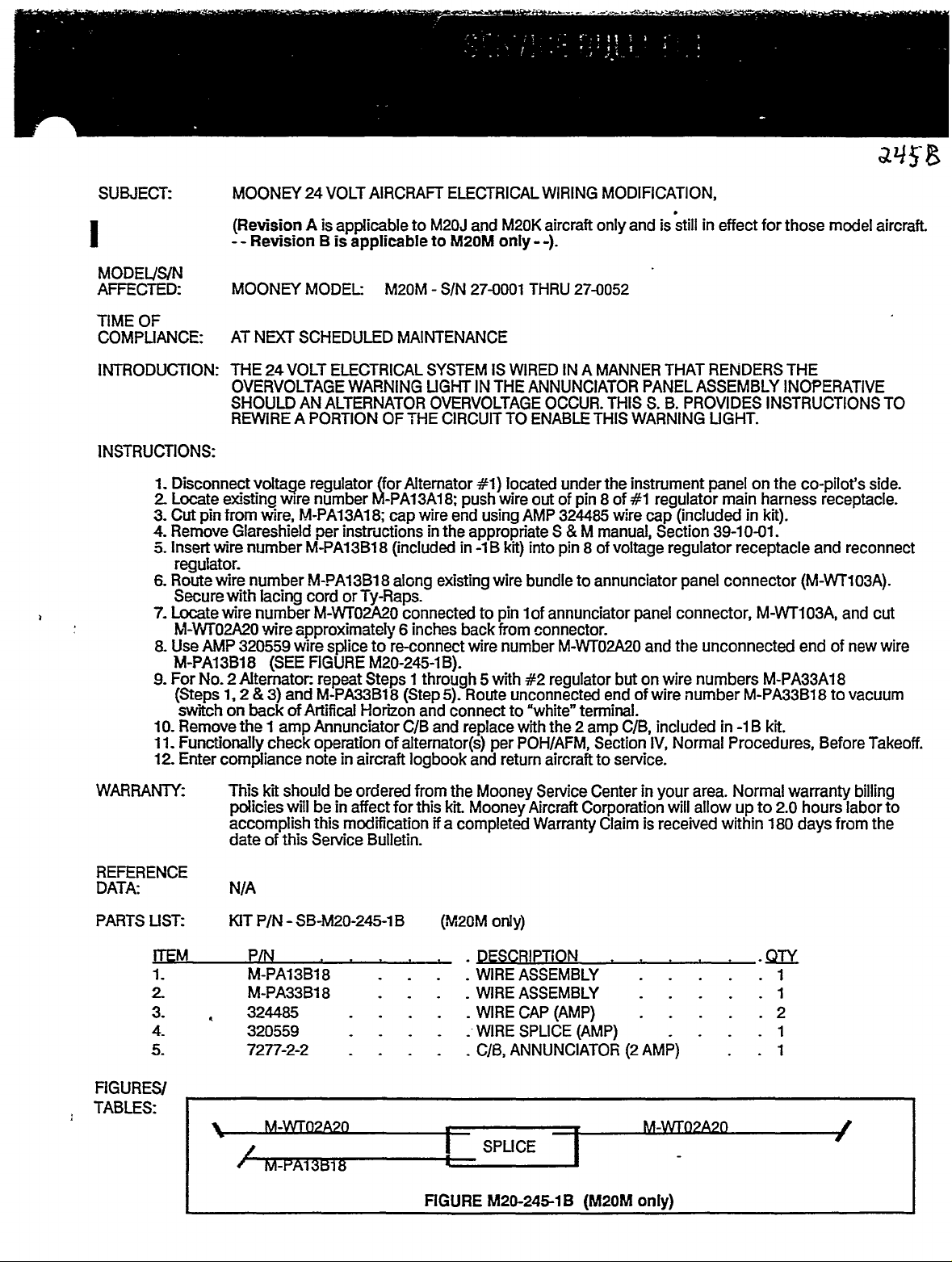

FIGURE

the

Mooney

kit.

MooneyAircraft

a

completed

(M20M

only)

DESCRIPTION

WIRE

WIRE

WIRE

WIRE

C/B,

SPUCE

M20-24518

Service

Corporation

Warranty

ASSEMBLY

ASSEMBLY

CAP

(AMP)

SPLICE

(AMP)

ANNUNCIATOR

-I

(M20M

Center

in

your

will

Claimisreceived

(2

AMP)

only)

area.

allow

Normal

up

within

to

180

.QK

warranty

hourslabor

2.0

days

1

1

2

1

1

from

I

billing

to

the

THIS

SERVICE

BULLETIN

IS

FAA

APPROVED

FOR

ENGINEERING

DESIGN.

SUBJECT:

MODEL

AFFECTED:

TIME

COMPLIANCE.

S/N

OF

INTRODUCTION:

Some

aircraft

Corporation

will

that

recommended

retrofrt

INSTRUCTIONS:

I.

Remove

Service

stamp

Check

2.

per

3.

Remove

on

screw

fairings

action

S

each

modified

be

and

and

on

for

M

the

outboard

(inboard

will

owners

is

offering

that

will

be

replace

Maintenance

fork

the

proper

No.

150.

ABS

8

side)

be

modified

MOONEY

MOONEY

AT

OWNERS

WEIGHT

have

the

in

order

aircraft

the

co-ordinated

the

center

lover

operation

Section

flap

hinge

fairing.

attaching

pn~or

TLS,

MODEL

DISCRETION

ABOVE

expressed

retrofit

for

the

be

procedures

brought

by

Main

Landing

Manual

link)

and

riggingoflanding

32-30-00.

fairings.

The

two

ABS

re-installation.

to

M20M.

INCREASED

M20M.

POUNDS.

3200

desiretoincrease

a

aircraft

back

Product

the

retraction

M)

(S

and

a

(4

inboard

fairing

SIN

of

be

to

No.

ink

each

on

fairings

to

TAKEOFF

27-0001

MANDATORY

BUT

this

Service

flown

at

to

Mooney

Support

truss

Section

150,

"A-2"

stamp

retraction

gear

wing)bydrilling

have

the

inboard

(See

Step4below)

THRU

27-0052

useful

the

Bulletin

the

increased

Aircraft

Department,

assembly,

32-10-00.

after

paint.

screws

wing

flap

WEIGHT

IF

AIRCRAFT

load

of

to

accomplish

takeoff

Corporation

telephone

520024501

P/N

The

out

after

the

system

attaching

hinge

RETROFIT

IS

M20M

the

weight

for-the

truss

new

replacement

rivets

them

to

aluminum

arm

TO

this.

(512)

(UH)

will

on

the

BE

aircraft.

There

of

3368

retrofit.

896-6000.

be

fairing

fuselage

FLOWN

are

pounds.

Scheduling

and

-502

identified

of

retraction

flanges

fairing.

AT

Mooney

several

(R/H)

and

belly

All

ABS

A

Aircraft

It

by

truss

fairing

TAKEOFF

areas

is

of

the

M20M

per

"A-2"

an

assembly

side

the

and

hinge

flap

metal

rivet

one

1

4.

Remove

from

(2)

(Reference

The

5.

REMOVED.

.250

and

be

After

6.

Trim

7.

(RH)

A

8.

new

(LH)(2

210106,

NOTE:

9.

screw

existing

match

screws

flap

wing

right

Lowerfiaps,

Figure

AVEX

1601-0401

hole

(8

a

magnet

done

between

all

drilled

ABS

flap

each

(2

will

hole

ea)

(L

Outboard

be

can

rivet

tooling

attach

to

seals,

gap

by:

drill

Enlarge

holes

on

to

move

each

rivet

hinge

side)

be

required

074

(RH)(2

R

wing).

holeofmiddle

usedinthe

holes

hole

ABS

P/N

Dn’ll

(1)

out

row

SE

M20-248-1).

rivets

the

existing

each

rivet

rib

residue

fairings.

and

mid,

Reference

in

wing

in

wing

fairings.

210374-001

out

of

being

wing).

residue

bay.

is

P/N

P/N

in

to

ea)

A10-80

skins

flap

the

rivets

drilled

No.

Forcefully

removed.

210398-005

210379-011

outboard

match

Figure

8

rivnut

that

hinge

lower

holding

Remove

30

toward

tooling

inboard

match

arm

(1

pc)

forward

the

out

hole

use

Install

’side

SE

M20-248-3

iairings

to

secure

fairings.

-003

row

aluminum

flap

gap

will

leave

outboard

hand

.250

hole

A10-80

(LH)

-012

wall"

of

in

hole

will

fairing

remaining

Use

pcs),

rivets

from

holding

(2

of

channels,

with

seals

portions

of

each

rubber

or

and

remove

R’Nnutsineach

-006

(RH)

each

the

for

middle

two

basic

side)

middle

(1

each

require

fiange.

in

hole

AVM

flange

1601-0410

left

210375-1

P/N

the

of

the

aft

rib

malletto

all

each

(1

outboard,

ABS

wing

instructions

enlarging

Re-install

of

wing

forward

channels

rivet

inside

rivet

(rib

hit

pieces,

enlarged

side)

fairing,

flap

to.189

each

each

(or

and

P/N

edge

(1

pc)

still

the

line

can

skin

wing

with

magnet,

hole.

inboard,

Figures

per

to

now

hinge

drill

holes.

to

(No.

modified

ABS

hinge

equivalent)

210374-002

of

aluminum

and

-003

attached.

THESE

wing.

be

seen

area

(DO

through

(16

places)

210379-009

P/N

SE

be

identified

aluminum

arm

12

hole)

fairing

fairing

blind

(1

pc)

gap

(2

pcs)

NEED

on

wing

DAMAGE

NOT

M20-248-2A

as

fairings,

M835207-263

so

using

and

and

rivets

-004

seal

on.

each

from

TO

skins)

This

hole.

(LH)

8r

28.

210379-013

P/N

appropriate

hole

new

MS35207-263

(2

pcs),

BE

to

SKINS)

should

-010

P/N

to

wing

a

M20-248

SE

DATE

Page

Use

10.

remaining

Reference

20

of

AVD:

90

4

holes

601-0410

1

holes

Figure

in

wing

SE

rivets

(59

skins

M20-248-1.

each

drilled

row,

out

minus

dun’ng

ABS

removal

fairing

of

gap

attach

seals

holes

and

and

enlarged

channels.

for

rivnuts))

fill

to

3

2

install

1

1.

are

required

12.

Repainting

paint

Remove

13.

included

After

14.

Remove

15.

UNIITAIIONS

Enter

16.

WARRANTY:

MS35207-263

for

of

PIN

color

existing

this

in

airspeed

OPERATING

the

compliance

screws

all

enlarged

the

now

exposed

aircraft

for

airspeed

it

kit;

incoporates

indicator

placard,

P/N

note

Mooney

Aircraft

arrangements

in

holes.)

Sen~al

indicator,

been

has

UMITATIONS

150080-980,

in

AVC

log

Aircraft

owners

all

other

flap

wing

Number.

P/N

new

replaced

book,

Corporation

will

need

for

scheduling

enlarged

gap

820308-527,

airspeed

and

placard

included

insert

to

contact

area

markings

all

AFM

will

aircraft.

holes

to

will

and

lines

from

pilot’s

kit.

in

Supplement

perforn

the

seal

be

required.

replace

for

secured,

side

retrofit

all

Product

up

the

Support

skin

wing

Contact

with

increased

perform

and

panel

into

POH/AFM

actionatthe

area.

CTotal

Mooney

new

airspeed

weight

pitot/static

replace

and

factory

Department,

of

(16)

Service

indicator,

performance.

for

check

with

new

aircraft

return

service

896-6000

(512)

MS35207-263

Parts

Department

P/N

820308-531,

leaks.

OPERATING

service.

to

facility.

to

screws

for

make

REFERENCE

DATA:

PARTS

LIST:

ITEM

i.

2.

3.

4.

5.

6.

7.

8.

FIGURES/

TABLES:

N/A

KITPARTNUMGER

P/N

520024-501

520024-502

820308-531

150080-980

1601-0410

Al

0-80

MS35207-263

NIA

See

Figures

on

(A-2)

(A-2)

next

SE

pages.

M20-248-1

DESCRIPTION

RETRACT

RETRACT

AIRSPEED

PLACARD

RIVET.

RIVNUT

AVEX

SCREWS

AFM

SUPPLEMENT

TRUSS

TRUSS

INDICATOR

ASSY,

ASSY,

SE

LH

RH

M20-248

QT/.

1

1

1

1

240

.16

.16

1

SE

M20-248

DATE3-20-90

Page

4

of

3

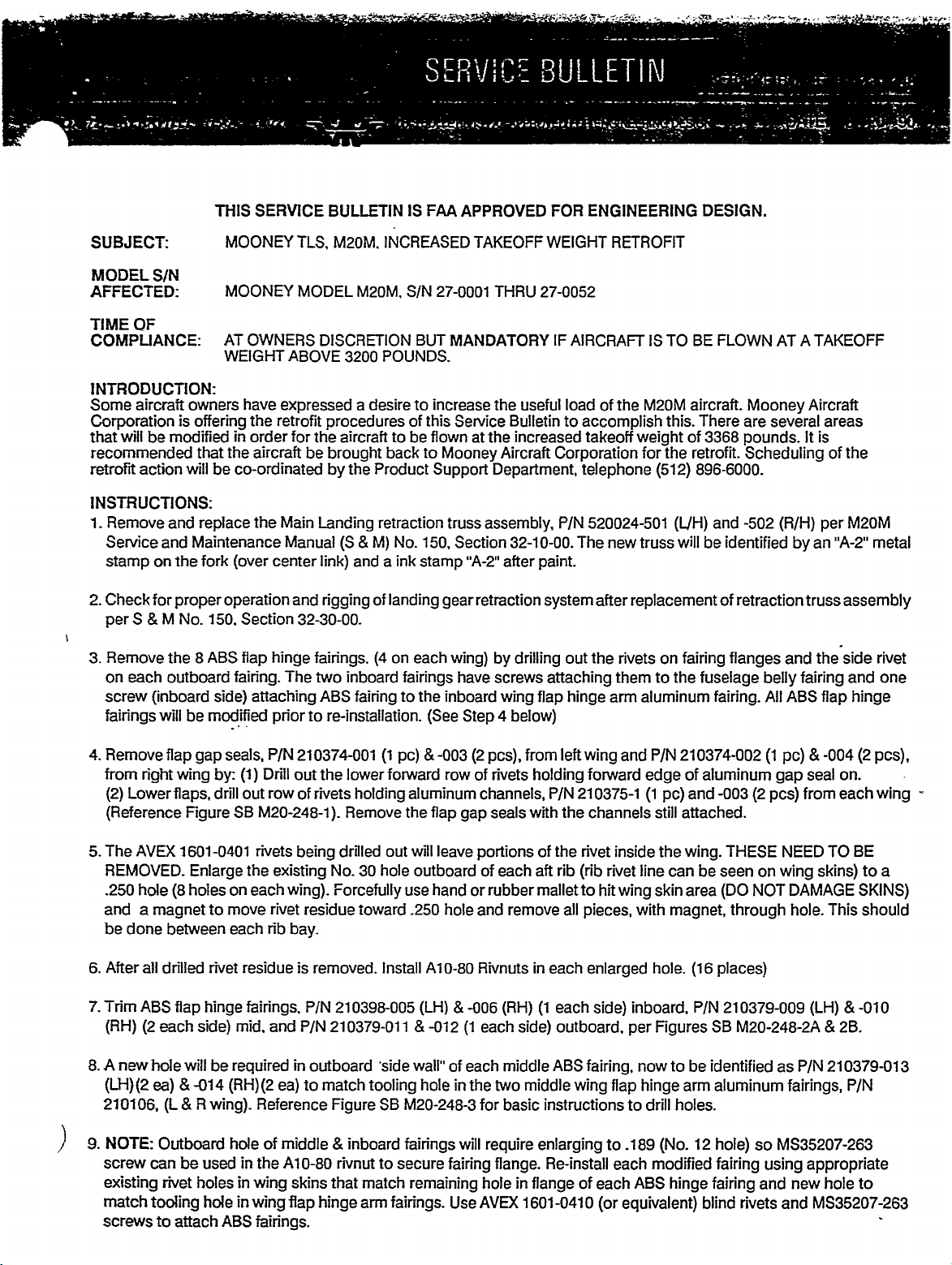

MS20600AD4

(61

REPLACE

DRILL

PLCS)

MIS

WITH

~210374

1601-0410

ROW

FLAP

OF

GAP

AVEX

RIVETS

SEALS

RIVETS

TRIM

DOTrrD

OUT.

EXISTING

DO

EXTEND

LINES

MS20600AD4

REPLACE

DRILL

210375

MS20470AD4

NOT

HOLDING

FIGURE

ABS

INDleArr

WITH

THIS

CHANNELS

(61

DRILL

FLAPS

CHANNELS

SE

FAIRINGS

UNTRIMMED

PLCS)

(67

16019410

ROW

OF

AVEX

RIVETS

RIVETS

PLCS)

THESE

AND

RIVETS

DRILL

OUT.

OUT

ON.

M20-248-1

DIMENSIONS

TO

SHOWN.

CONFIGURAT;IPH

OUT.

UPPER

ROW

OF

240014

RIVETS

FLAP

ASSY

-009

(SHOWN)

-olo

(092)

OFa\n\NC~>

3-CS

CONFKiURATION

NEW

~.Z5

210379

PIK

FIGURE

FAIRINGS

SE

FA\RI~G

M20-248-2A

OPP

’------I

\.2J

I

-011

-012

(SHOWN)

(OPP)

t

SE

DATE

Page

M20-248

3

4

of

90

20

4

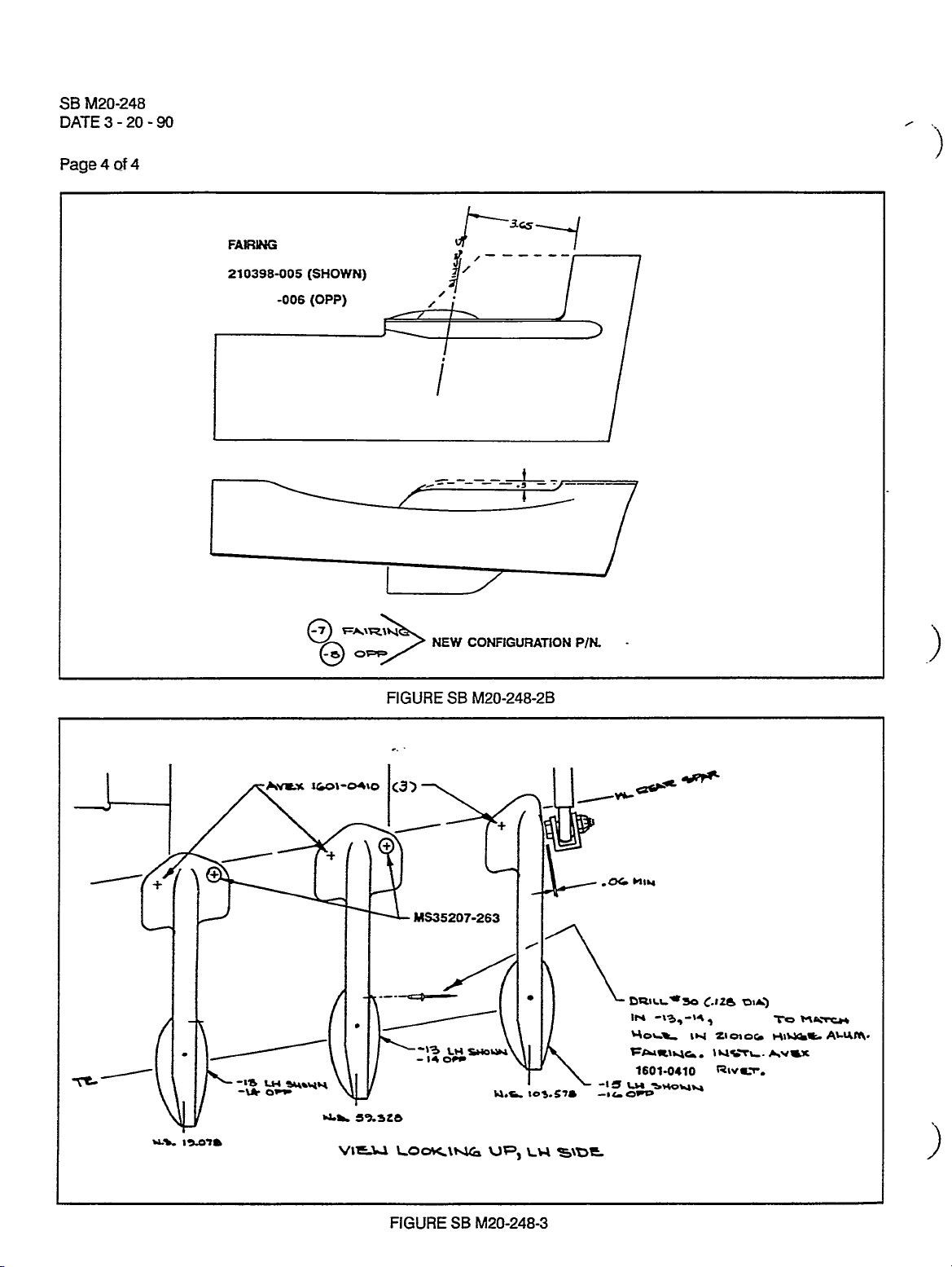

FAIRING

210398-005(SHOWN)

-006

(gpp)

0-~

o~c;

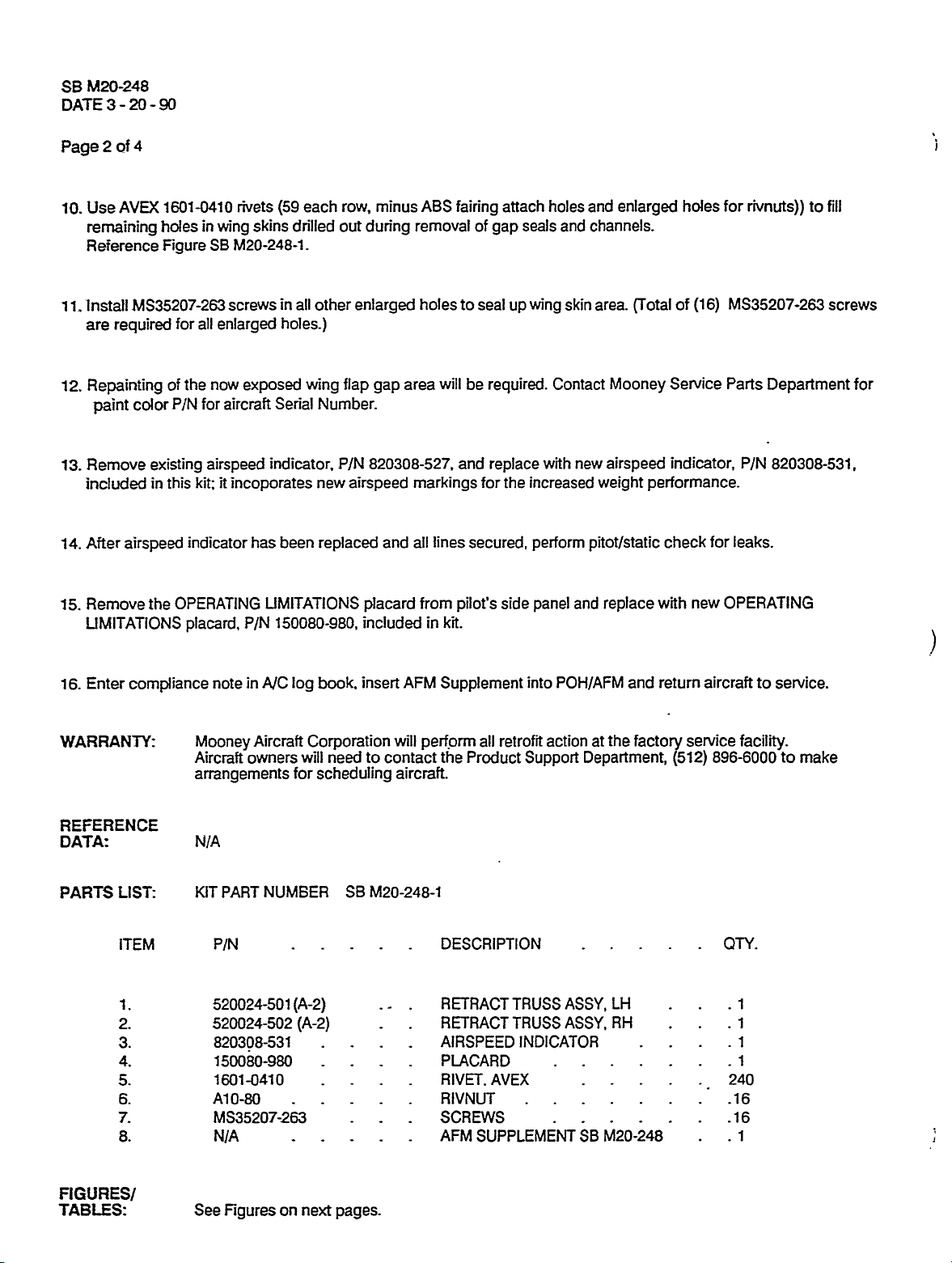

FIGURE

Slu2-I

NEW

CONFIGURATION

SE

M20-248-28

t

PIK

i/

-F

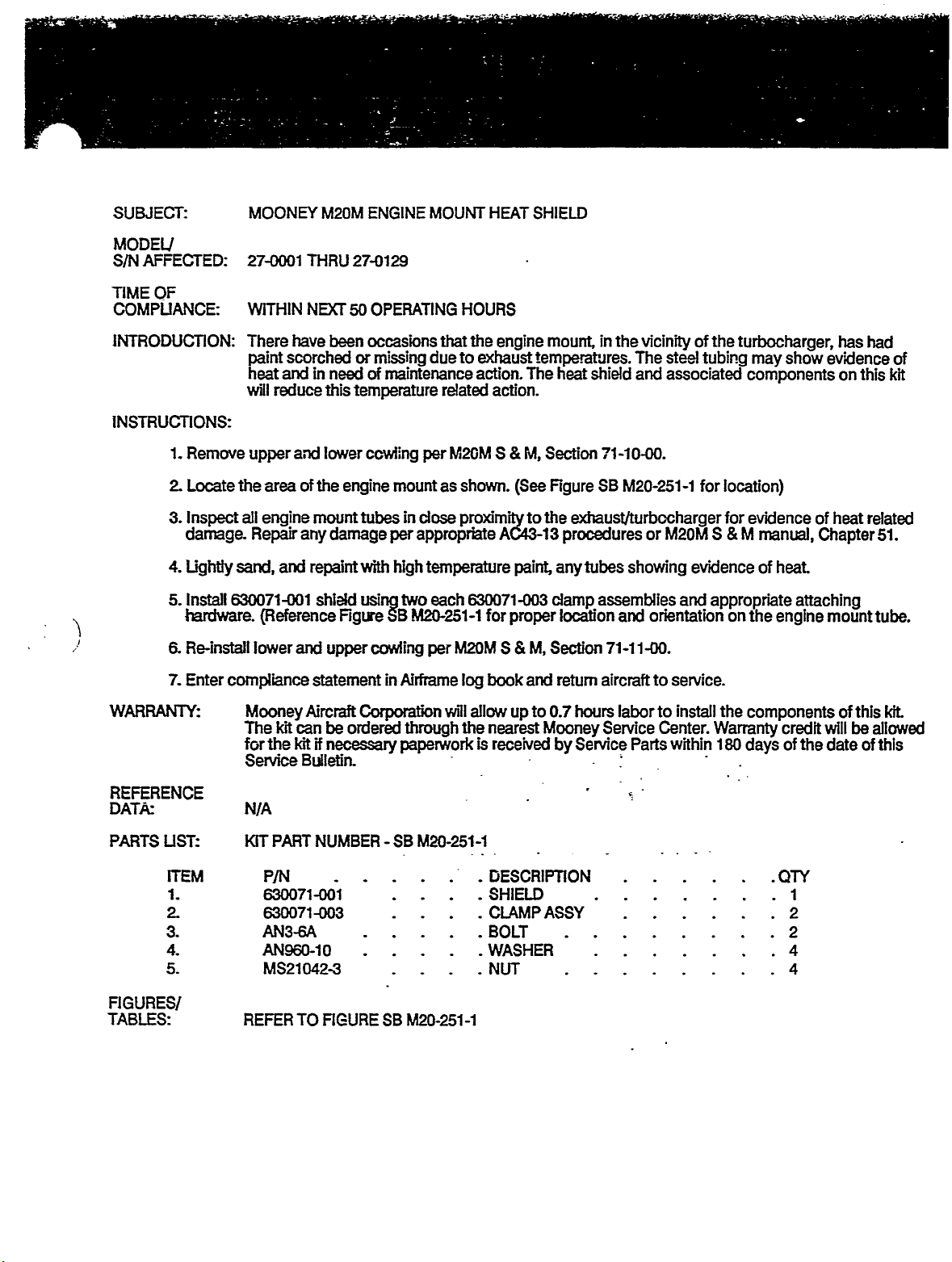

16019410

4P~C

LY

C.12~

Z1010CI

DI~

~o

hv~x

Rtvrr.

~VLX

160~-M\D

I I

I

(J)

V

klS35207-263

,*L~C

I

1´•11

’~b

L~

OCe

SE

Wow

U.L

UP)

M20-248-3

~De

-I~

--IcO~o

w

-14

I

I~-ts

~LI-

Izcn~

-\4´•

orr

*LI

COD~\huo

FIGURE

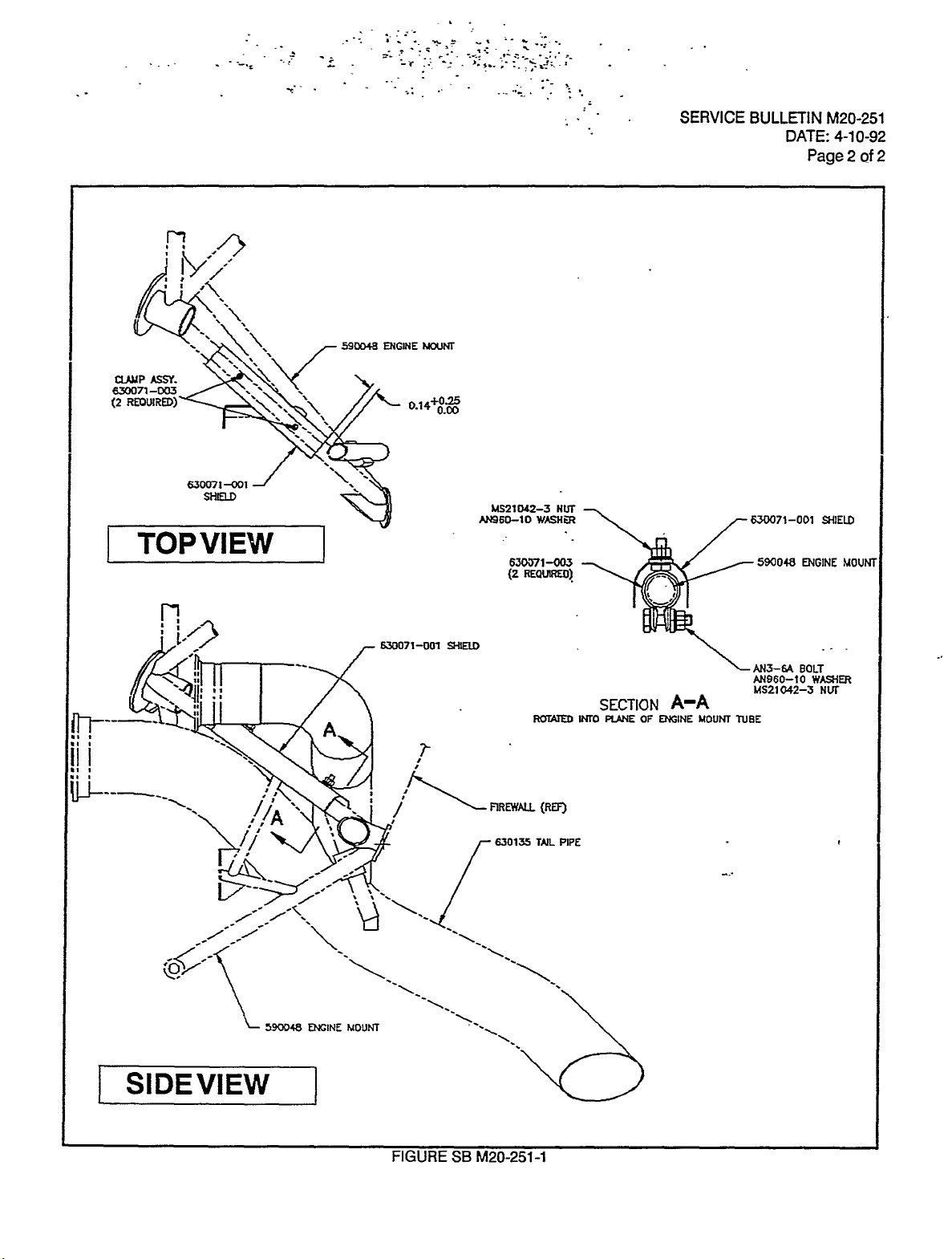

SUBJECT:

MODEU

AFFECTED:

SIN

TIME

OF

COMPLIANCE:

MOONC/

27-0001

WITHIN

M20M

THRU

NMT

ENGINE

27-0129

OPERATING

50

MOUNT

HOURS

HEAT

SHIELD

INTRODUCTION:

INSTRUCTIONS:

1.

Remove

2

Locate

3.

Inspect

damage.

4.

Lightly

5.

Install

hardware.

Re-install

6.

7.

Enter

WARRANP~

REFERENCE

DATA

There

have

scorched

paint

and

heat

will

reduce

upper

the

area

all

engine

Re~iir

and

sand,

630071-001

(Reference

lower

compliance

Mooney

kit

The

forthe

Service

N/A

in

and

of

mount

any

repaint

and

statement

Aircraft

can

kit

Bulletin

been

need

this

lower

the

engine

damage

shield

Figure

upper

be

ordered

if

necessary

occasions

or

missing

maintenance

of

temperature

ccwling

mount

in

tubes

appropriate

per

with

high

two

using

SE

MM251-1

cowling

in

Aimame

Corporation

through

paperwork

the

that

duetoexhaust

action.

related

M20M

per

shown.

as

dose

proximity

temperature

each

630071-003

for

M20M

per

book

log

will

allow

the

nearest

is

engine

The

action.

S

M,

(See

to

AC43-13

paint,

proper

S

and

up

received

mount,

in

temperatures.

heat

shidd

Section

SE

Figure

the

procedures

tubes

any

assemblies

damp

location

Section

M,

aircraft

retum

0.7

to

hours

Mooney

Service

by

the

vicinity

The

steel

and

associated

71-10-00.

M20-251-1

M20M

or

showing

and

orientation

71-11-00.

to

labortoinstall

Service

Center.

Parts

of

evidence

and

service.

within

the

turbocharger,

tubing

may

components

for

location)

for

evidence

S

M

appropriate

the

on

the

components

Warranty

180

days

show

manual,

of

heat.

attaching

engine

credit

of

evidence

of

Chapter

mount

will

dateofthis

the

has

on

heat

of

this

this

be

had

of

kit

related

51.

tube.

kit

allowed

PARTS

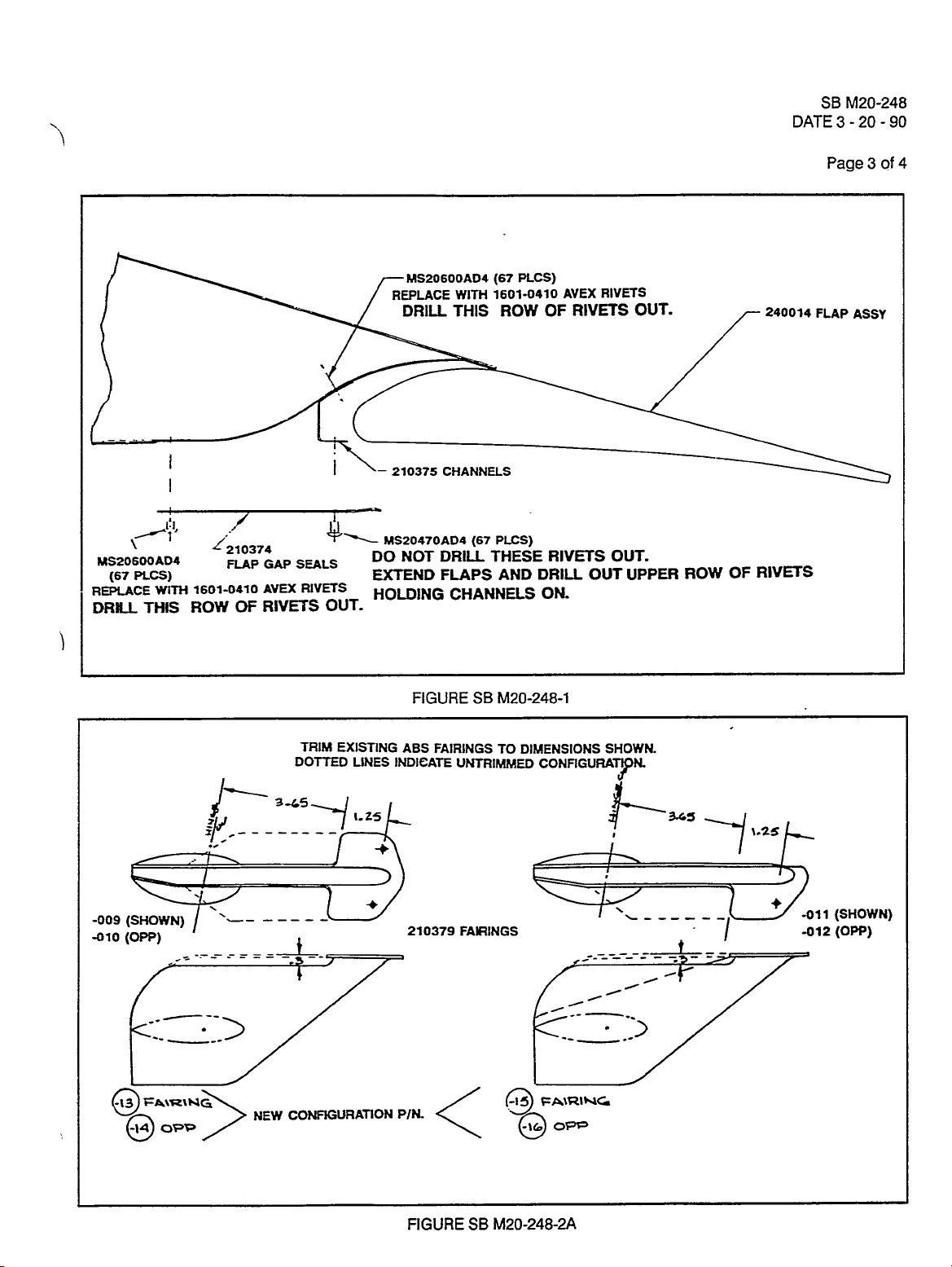

FIGURESI

TABLES:

USTr

ITEM

1.

2

3.

4.

5.

KIT

PART

P/N,,....

630071-001

630071~03

AN3-6A

AN960-10

MS21

REFER

NUMBER

042-3

TO

FlGURE

-SB

SE

M20-251-1

M20-251-1

DESCRIPTION

SHIELD

CLAMP

BOLT

.WASHER

NUT

ASSY

.QTY

1

2

2

4

4

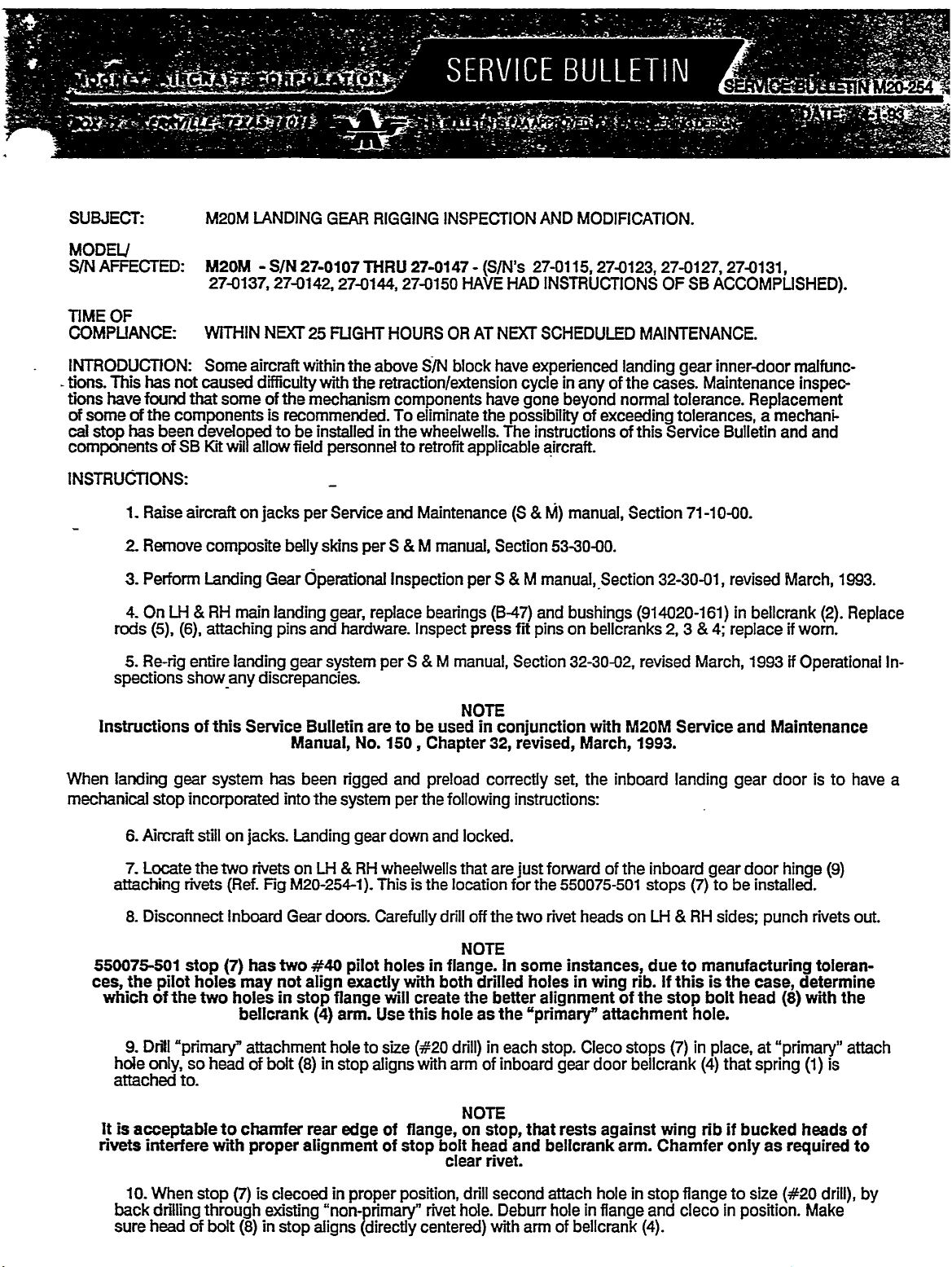

I;

-T

T

~-ci.

CUUP

ASSY.

530071-003

(2

REOWRED)~

TOP

n

i´•/´•l~

SHIELD

VIEW

590048

~t

ENGINE

NOUNT

0.00

MM1M2-3

AN950-10

WASHER

630371-003

~2

REaVatEO)

HUI

Ifi~

SERVICE

BULLETIN

/-530071-001

590048

DATE:

Page

PICINE

M20-251

4-10-92

2

SHIEU)

.UOUNI

2

of

ii

i

ii~----_,

SIDEVIEW

-~3

~Jm

V

sylml-atn

I

~iRREWW.

4lmo

AN3-6A

SECTION

550

ROTATED

1-

(RD)

630135

WL

PUIEIE

PIPE

A-A

OF

~GINE

LIDUNI

TUBE

AN860-10

MS21042-3

BOLT

WASHER

NLIF

-i

d

´•ti

FIGURE

SE

M20-251-1

SUBJECT:

MODEU

AFFECTED:

S/N

TIME

OF

COMPLIANCE:

.tions.

tions

of

cal

some

stop

This

have

has

found

ofthe

has

components

INSTRU~TIONS:

i.

Raise

Remove

2

not

caused

that

components

been

developed

of

SE

aircraft

M20M

LANDING

M20M

27-0137,

WlTHlN

Some

aircraft

difficulty

some

wilt

Kit

allow

on

composite

S/N

27-0107

27-0142,

NMT

within

of

the

is

recommended.

to

be

field

jacks

per

belly

GEAR

27-0144,

FLIGHT

25

the

with

the

mechanism

installed

personnel

Service

skins

RIGG)NG

THRU

HOURS

above

27-0147

27-0150

S/N

INSPECTION

OR

block

retraction/extension

components

To

eliminate

in

the

wheelwells.

retrofit

to

and

Maintenance

M

S

per

manual,

AND

HAD

NDCT

have

27-0115,

INSTRUCTIONS

SCHEDULED

experienced

(S/N’s

HAVE

AT

cycle

have

gone

the

possibilityofexceeding

The

instructions

(S

Section

aircraft.

h;l)

53-30-00.

applicable

MODIFICATION.

27-0123,

landing

in

of

the

any

beyond

manual,

normal

of

Section

27-0127,

OF

SE

ACCOMPLISHED).

MAINTENANCE.

inner-door

gear

cases.

Maintenance

tolerance.

tolerances,

Service

this

71-10-00.

27~131,

Replacement

mechani-

a

Bulletin

malfunc-

inspec-

and

and

rods

spections

Instructions

When

landing

mechanical

attaching

550075501

ces,

which

hole

attached

Perform

3.

4.

On

(5),

5.

Re-n’g

stop

Aircraft

6.

Locate

7.

Disconnect

8.

the

ofthe

Drill

9.

only,

LH

(6),

entire

showany

of

gear

incorporated

still

the

rivets

stop

holes

pilot

two

"primary"

so

to.

Landing

RH

Gear

main

attaching

landing

discrepancies.

this

Service

system

on

jacks.

rivets

two

(Ref.

Fig

Inboard

has

(7)

may

holes

bellcrank

attachment

headofbolt

dperational

landing

and

pins

gear

Bulletin

Manual,

has

been

into

the

Landing

on

M20-254-1).

Gear

two

#40

not

align

in

stop

(4)

(8)

gear,

hardware.

system

system

LH

doors.

fiange

arm.

hole

in

stop

replace

are

No.

n’gged

gear

RH

Carefully

pilot

exactly

to

aligns

Inspection

Inspect

S

3

per

to

be

150

and

the

per

down

whedwells

This

is

holes

with

viill

create

this

Use

size

(i5~20

with

per

bearings

press

M

manual,

NOTE

used

Chapter

preload

following

and

locked.

that

the

location

drill

off

NOTE

in

flange.

both

the

hole

dn’ll)

arm

S

(B-47)

fit

Section

in

conjunction

revised,

32,

correctly

instructions:

are

just

for

the

two

In

some

drilled

better

the

as

in

each

of

inboard

M

manual,~Section

and

bushings

bellcranks

on

pins

32-30-02,

with

March,

the

inboard

of

heads

forward

the

rivet

set,

550075-501

instances,

in

holes

alignment

’primary"

stop.

gear

wing

of

attachment

Cleco

door

32-30-01,

(914020-161)

3

2,

revised

M20M

1993.

March,

Service

landing

the

inboard

stops

LH

on

doe

rib.Ifthisisthe

the

stops

bellcrank

gear

(7)

RH

to

manofacturing

bolt

stop

hole,

in

(7)

(4)

revised

in

4;

replace

and

gear

be

to

sides;

head

place,

that

bellcrank

1993

Maintenance

door

door

installed.

punch

case,

at

"primary"

spring

March,

(2).

if

worn.

if

Operational

istohave

(9)

hinge

rivets

toleran-

determine

with

(8)

is

(1)

1993.

Replace

In-

a

out.

the

attach

It

rivets

back

sure

is

10.

acceptable

interfere

When

drilling

head

of

to

with

stop

through

bolt

chamfer

proper

is

(7)

(8)

alignment

decoed

e>dsting

in

stop

rear

edge

in

proper

"non-primary"

aligns

(directly

of

Range,

of

stop

position,

NOTE

on

bolt

head

clearrivet.

drill

rivet

hole.

centered)

stop,

second

Deburr

with

and

that

arm

rests

bellcrank

attach

hole

of

bellcrank

against

hole

in

Range

arm.

in

wing

Chamfer

stop

and

(4).

rib

Range

cieco

if

bucked

only

size

to

in

position.

as

heads

required

(#20

Make

drill),

of

to

by

SERVICE

BULLETIN

DATE:

M20-254

Page

4-1-93

2of4

lNSTRUCTIONS:

11.

Rivet

rivets

12

Leave

in.

way

Two

mechanics

Retract

13.

door

gear

bellcrank

(2),

(5)

14.

Adjust

rods

(5)gr(6)

head

(8)

15.

Repeat

whedwdl.

16.

Cycle

after

cycles

done

as

M,

17~

Ccmplete

included

has

(3)

(6)

is

(con’t)

stops

in

spring

landing

traveled

center

should

stop

become

in

correct

installation

landing

for

any

in

Step

lag

P/N

(1)

550075-501,

kit.

Re-attach

attached

t/),

this

(personnel)

other

gear

as

line

be

now

bolt

head

loose

position.

of

through

gear

interference,

No.

3.

boole

entry

Inboard

clevis

to

be

safety

it

-(5)

loaded

a

OUT

load

required

the

willgo

will

until

may

inside

using

far

as

of

rod

in

(8)

(no

Tighten

stop

(7)

(Steps

five

complete

bindingorimproper

and

retum

each

of

aircraft

wheelwell

Gear

inboard

for

in

by-pass

during

in

be

a

condition

it

rests

feltoneither

nut

7

thru

aircraft

on

jam

at

the

doors

door

NOTE

the

next

operating

switch

(See

its

retraction

straight

and

feel

bellcrank

on

rod).

bolt

(8)

and

11)

line

location

before

bellcrank

several

the

landing

S

cycle.

(Reference

very

(4)

Bellcrank

against

adjustment

retraction/extension

operation.

to

service.

cycling

(4).

steps.

Section

M,

In

tight.

arm.

(2)

tube

cycles;

Reference

descn’bed

landing

Bolt

head

One

switch.

gear

32-30-01,

this

position,

Figure

Continue

will

on

M20-254-2).

also

become

stop

procedures

inspect

Operational

gear

(8)

under

to

(7).

(Steps

in

steps

for

should

steps

the

adjust

all

components

8

9

following

be

screwed

the

aircraft

5, 6,

pivot

points

Components

bolt

head

loose

when

12

thru

Inspection

above

steps.

7)

14)

and

until

of

OUT

bolt

in

during

in

S

using

all

the

inboard

until

other

the

and

WARRANP~

REFERENCE

DATA:

PARTS

UST:

lTEM

1

2

3

4

5

6

7

8

9

10.

11.

be

FlGUREl

TABLES:

At

some

available

will

Aircraft

be

forms

Mooney

Kit

warranty

N/A

KIT

PART

.P/N

~550075601

.550082-503

.550082-505

.91

4020-1

.8-47

.MS20392-2C7

.MS20392-2C9

.MS20392-2C17

.AN381-2-6

.AN470AD5-13

M20M

later

date

the

field

to

SEE

NDCT

ordered

within

NUMBER

61

S

M

the

complete

and

PAGES

Corporation

through

180

days

SBM20-254-1

S

be

not

may

FOR

FlGURES

will

allow

Mooney

of

M

will

included

hours

3.0

Service

the

issue

DESCRIPTION

STOP

ASSY.

LOWER

ROD,

UPPER

ROD,

BUSHING

BEARING

CLNIS

PIN,

CLNIS

PIN,

CLEVIS

PIN,

COTTER

PIN,

RIVET

Chapter

be

revised

in

this

SBM20-254-1

labor

Centers

dateofthis

(PRESS

(PRESS

kevised

32,

and

Chapter

Service

with

will

Bulletin.

and

to

comply

credit

Service

FIT:BELLCRANK

FIT-BELLCRANK

3-93’

as

32,

Bulletin

AND

kit.

SBM20-254-2

this

be

revised

issued

Service

upon

4)

i&

in

March,

3)

Bulletin.

receipt

QTY

.2

.2

.2

.2

.2

.2

.4

.2

.8

.4

.1

1993,

Parts

of

will

SERVICE

BULLETIN

DATE:

M20-254

Page

4-1-93

3of4

2

--~21

I,I

al

61

spi~P

dp"‘’

3~

5~

II

II

p’’

a

a

SBM20-25

I!

11

O

a

o~

I

~\o

a

o

a,

\~4

0\

L.9

4´•-1

NI7I1CE

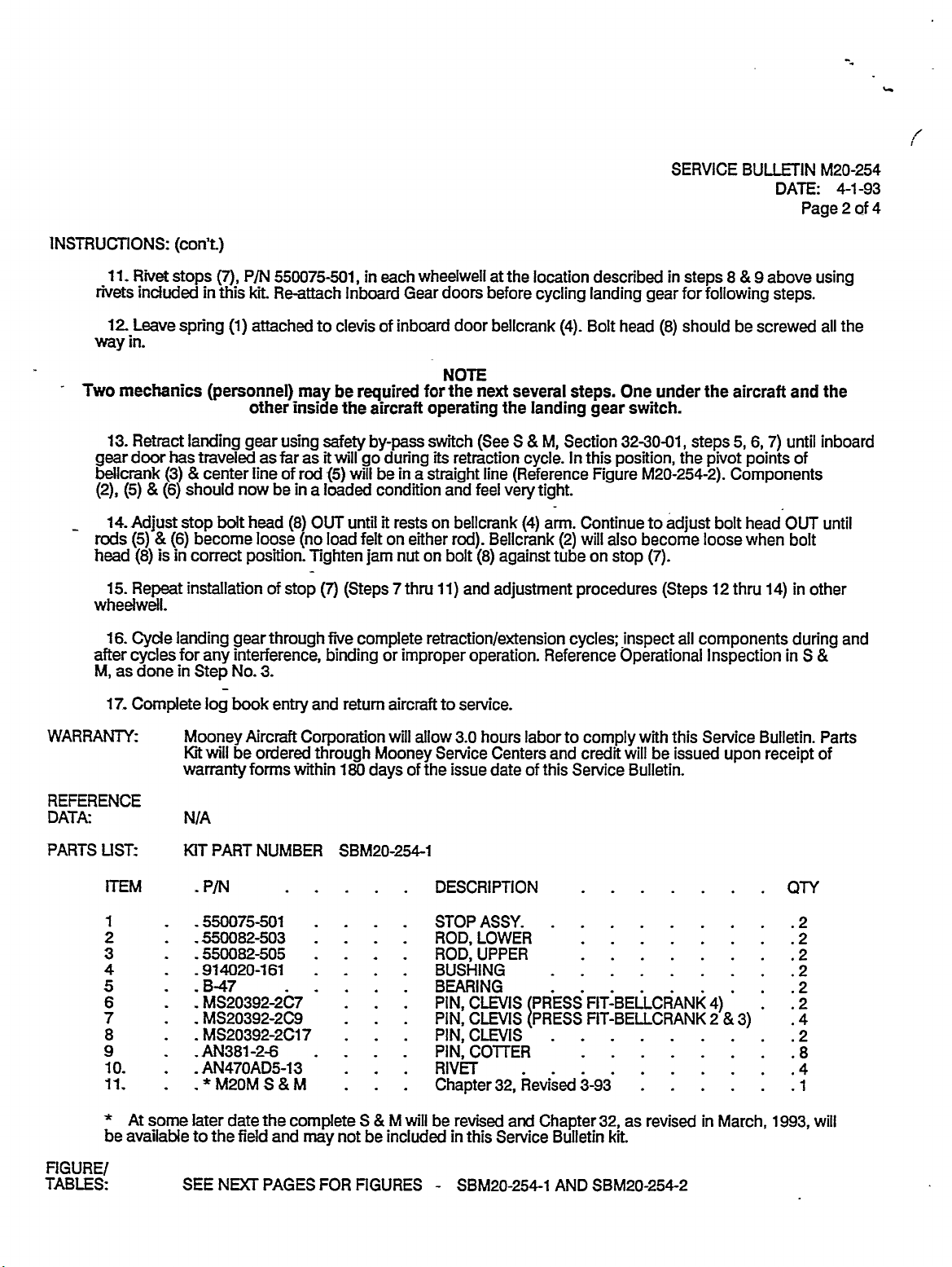

SERVICE

BUU-FTIN

DATE:

M20-254

Page

4-1-93

4

of

4

THESE

THIS

PIVDT

R-EPRESENTS

P[71NTS

THE

CDMP

ARE

M[7ST

ONENTS

ALMOST

IN

EXIREME

SHOULD

i

A

TRAVEL

BE,

STRAIGHT

THAT

LINEI

THESE

o

SBM20-254-2

SERVICE

ISSUEDATE:

BUU~ETIN

Novemberl’l,

M20-255A

1993

I

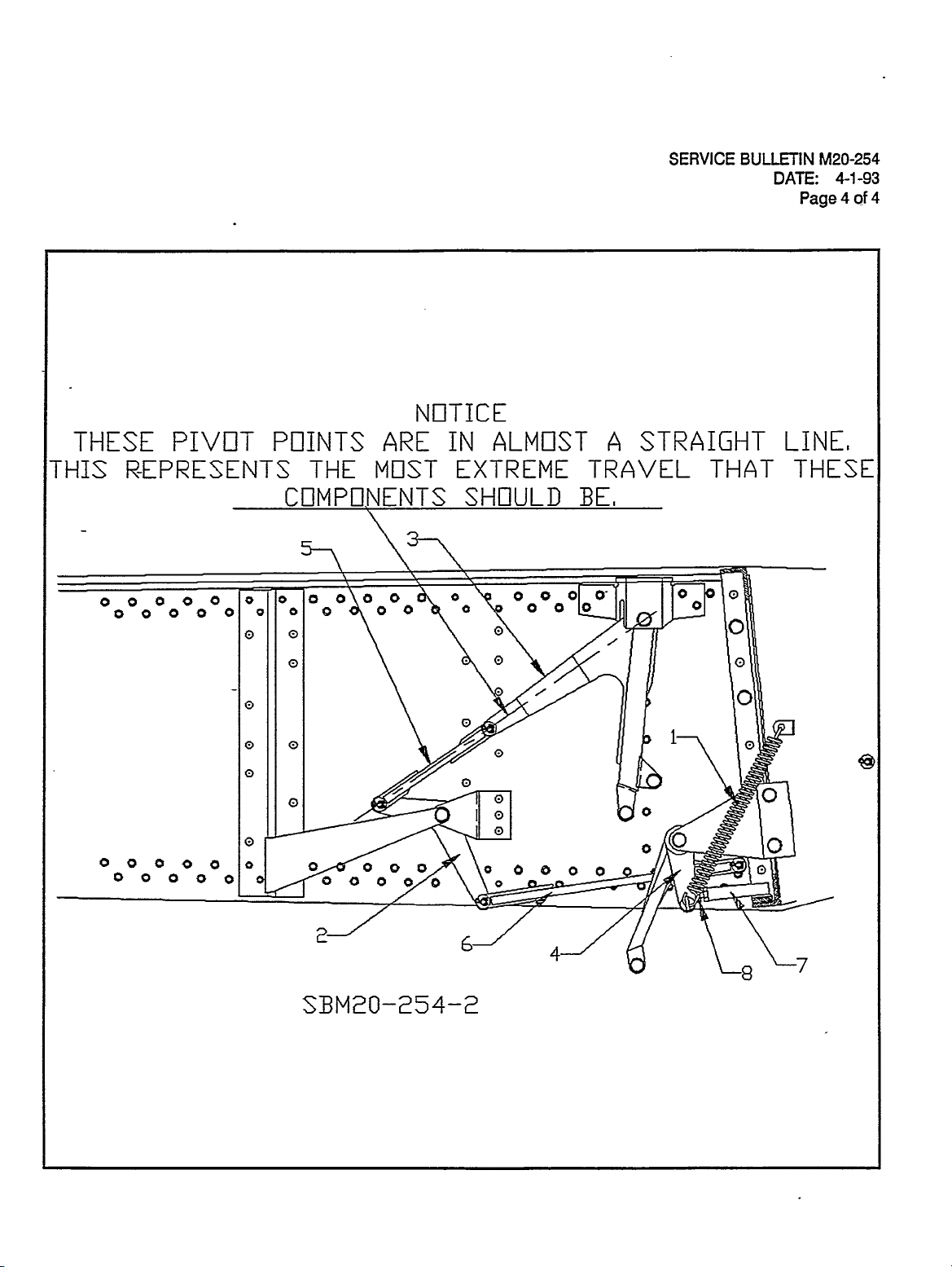

SUB3ECT:

MODELSISIN

AFFECTED:

OF

TlME

COMPLIANCE:

INTAODUCTION:

INSTRUCTIONS:

PART

(S/N

it

1.

sides.

restrained

to

accomplish

Caution

Locate

Z

skin

lap,

of

each

with

vertical

Deburrcut-out

3.

Cleco

4.

in

baffle

should

sembly.

After

5.

screen

awl.

Repeat

Place

6.

M20-255-1.The

ches

edge

holesinlowered

hole..

install

7.

(insideoffuselage

screen

for

UH

Clean

3.

Paint

9.

Enter

10.

RI

Il.

Mooney

PART

PART

PART

Within

In

needs

ADDCABIN

27-0002

is

recommended,

The

long

UP

to

the

be

area

forward,

cut-out

skin

640296-001

lowered

and

Ident~y

NOTE:

drilling

between

for

640130-000

R/H

distance

lowered

RM

between

side.

area

up

rivets,

compliance

and

out

1:

2:

3:

next

order

to

to

thru

ABS

panels,

provide

retrofit

observed

drill

of

fuselage

9.0

should

lap.

lowered

Be

i4~30

baffle

UH

side

RIH

location

should

plates

skin)

ABS

and

attaching

return

M20M,

Retrofit,

M20M

M20M

M20M

25

Right

provide

be

accomplished

D(HAUSTVENTS

27-0167,

but

not

forward

access

S/N

SM

SRN

hours

a

excluding

essential,

to

during

through

inches

be

Recommended

ABS

plate

sure

matching

skintobe

and

inches

29

baffle

are

plates

that

and

any

dawn

matched.

as

louvers

holes

UH

sub-assembly.

lowered

the

of

lowered

be

maintained

(13

places

plate

(outside

with

install

note

Avex

and

ABS

lowered

in

log

inside

book

baffle

pre-addressed,

cabin

27-0002

27-0053

27-0002

at

or

continual

for

to

the

of

the

inside

out

cut

electrical

cut

16.4

high

radiusonall

lowered

to

a

Drill

RIH

and

will

in

baffle

lowered

in

plate

plate

far

each

of

fuselage

1691-0410-05

surface

interior

plates,

and

stamped

exhaust

next

purge

serial

THRU

THRU

THRU

vents

27-0137

27-0167

27-0052

scheduled

of

the

numbers

on

cabin

listed

(F1G.SBM20-255-1)

S/N

27-0094)

aft

remove

baggage

skin.

hole

of

wiring,

out

by

inches

and

2.26

plate

all

UH

have

and

plate;

position,

does

for

all

plate).

of

panels,

match

to

return

compliance

pilot

during

fasteners.

rivetsand

fuselage

interior

campartment

These

long

and

drilling

ABS

measuring

from

lower

wide.

inches

for

holes

of

UH

this

comers

openings

lowered

punch

matching

RIH

over

have

not

Reference

R/H

skin),

skinasshown

ii

remaved.

exterior

aircrafttoservice.

fuselage

(D(CEPT

(EXCEPT

maintenance

air,

compliance

above.

baggage

panels,

ABS

rivet

of

from

or

the

panels

edge

Keep

cut-out

side

sub-assembly

#30

out

to

procedure.

toward

sandwich

plate,

cut-out

be

to

#30

Pig.

aluminum

paint

card.

exact,

SE

color.

Drill

AN960-6

sideslcabin

S/N

S/N

panels

holes

tubular

baggage

of

ah

vertical

is

.125

holes.

the

aft

holes

hole,

holes

M20-255-1.

screen

washers.

ventilation

27-0094)

27-0094)

action.

of

this

compartment

will

need

be

may

window

inches.

endofthe

through

however,

in

in

Fig.

removed,

in

fuselage

structure.

campartment/cabin

skin

sides

to

verify

Repeat

a

640247-003,

screen

in

accordance

a

fuselage

Repeat

and

640246-002

Sandwich

SE

M20-255-1.

Service

ABS

be

to

clrt-out.

of

cut-out

(Fig.

for

aircraft.

minimum

skin

system

Bulletin

panels,

pulled

if

skin

parallel

SE

M20-255-1)

that

all

side

R/H

aluminum

mesh

with

to

match

for

UH

aluminun

both

UP

desired,

soas

area,

The

size

pilot

sub-as-

with

Fig.

of

.31

#30

cut~ut

ABS

Repeat

modifiction.

and

not

to

vertical

holes

an

SE

inr

baffle

I

I

PART

1,

2.

replace

255-2

3.

4.

5.

2:

REPLACE

27-0053

(S/N

Locate

Access

cabin

J-Box

existing

Re-instaI(ffextubingto

Enter

compliance

Fill

out

and

THRU

ventilation

assembly

640326-505

note

retum

pre-addressed,

27-0167

J-Box

by

butterfly

J-Boxwith

in

ASSEMBLY

excluding

in

loosening

book

log

SIN

forward,

QS100-M40S

assembly

QS100-M40S

and

retum

stamped

1N

CABrN

27-0094)

RH

cabin

with

new

clamp.

aircraft

compliance

VENLlVITION

immediately

J-Box

at

clamp

640326-511

to

service.

card.

J-BOX

behind

and

butterfly

(FIG.

firewall.

flex

tubing

assembly,

SE

M20-255-2)

connection;

SE

Fig.

I

M20-

SERVICE

ISSUE

2

Page

BULLETIN

DATE:

of

4

November

M20-255A

17,

1993

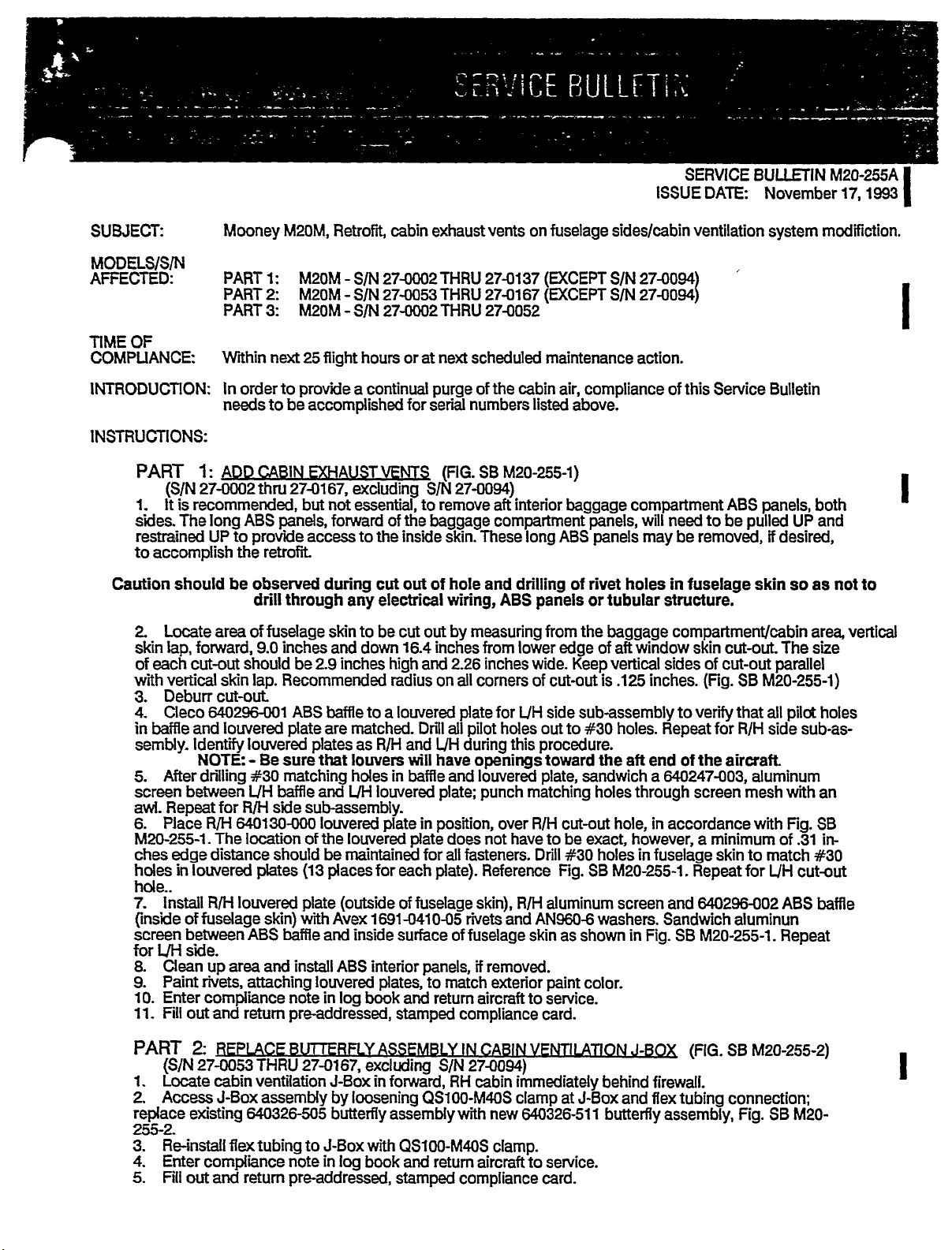

PART

3:

(S/N

1.

2.

connection.

sembly/cable

3.

SE

P/N

4.

and

5.

6.

installation

7.

8.

9.

Applicable

WARRANP~

Mooney

S/N’s

paper

Aircraft

27-0002

work

(September

MODIRCATION

27-0002

Locate

Access

Modify

M20-255-3.

on

Re-install

hardware.

Position

Verify

Re-install

Enter

Fill

kits

cabin

J-Box

Use

640010-000

body

slide

of

compliance

outand

should

Corporation

TH

RU

is

received

29,

1993)

OF

SUDE

THRU

27-0052)

stops

Slide

slide

of

modified

slide

plate

flex

ventilation

slide

needle

from

Plate

plate.

prate

operation

tubing.

plate

nose

slide

slide

must

slide

MS16562-4

so

J-Box

assembly

pliers

plate.

plate

now

plate

is

flextubingtoJ-Boxwith

in

return

be

27-0137

from

of

this

note

pre-addressed,

ordered

will

and

Service

Service

from

allow

1.0

log

4.0

hours

Center

Bulletin.

PLATE

in

forward,

to

remove

Remove

dnlling

by

be

into

J-Box

roll

smooth

QS100-M40S

book

stamped

Mooney

hours

labor

by

Normal

CABIN

ON

loosening

by

e~dsting

two

re-identified

assembly.

can

pin

and

and

retum

Service

labor

on

A/C

Mooney

warranty

VENTILATION

RH

cabin

QS100-M40S

MS16562-4

640010-000

0.50

as

be

inserted

complete

clamp.

aircraft

compliance

Centers.

to

incorporate

S/N’s

Service

immediately

roll

pin

inch

diameter

SE

P/N

Attach

travel

M20-255-501;

cable

into

can

to

service.

card.

applicable

27-01

38

Parts

Department

procedures

J-BOX

clamp

from

slide

hole

be

THRU

on

(FIG.

behind

on

slide

platetrom

in

holes,

assembly

through

obtained

portions

27-0167

and

parts

SE

firewall,

J-Box

plate.

locations

use

with

outlet

in

if

within

kit

M20-2553)

outlet

air

Remove

J-Box.

showninFIG.

as

indelible

existing

air

flex

both

directions,

of

Service

this

compliance

180

days

components

cable

ink

cable

of

flex

to

tube

card

tubing

as-

mark

stops

opening.

prior

Bulletin

and

the

will

to

on

warranty

on’ginal

be

followed.

AIC

date

REFERENCE

DATA:

PARTS

UST:

2

3.

4

5.

6.

7.

8.

NOTE

1.

2

3.

FIGLERES/

TABLES:

Item

1.

Matching

NIA

PART

..Part

.640130-000,..

,640247-003

1691-0410-05

.AN960-6

-64029~-001

.640296-002

Paint

,Compliance

paint

PART

6$0326-511

.MS35206-226

Compliance

See

Figures

1-

Kit

Number

will

be

2

Kit

Part

Card

shipped

Part

Card

SE

M20-255-1,

Number

Number-

with

-SB

kit.

SE

SE

M20-255-1

Descn’ption

Plate,

Screen,

Rivet

Washer

Baffle,

Baffle,

To

To

Provide

M20-255-2

Butterfly

Screw

To

M20-255-2

match

be

aircraft

be

(S/N

Louvered

Aluminum,

(AVD()

ABS,

ABS,

AIC

retumed

S/N

(S/N

assembly

retumed

and

SE

27-0002

(Painted)

LH

RH

color

to

when

27-0053

to

M20-255-3

MRU

(16

mesh)

Service

orden’ng

MRU

Service

27-0137

Parts

27-0167,

Paris

on

following

above

U(CEPT

kit

part

MCEPT

pages.

27-0094)

Quantity

.2

.2

26

26

.1

.1

.1

.1

number.

27-0094)

.1

.2

.1

2.26

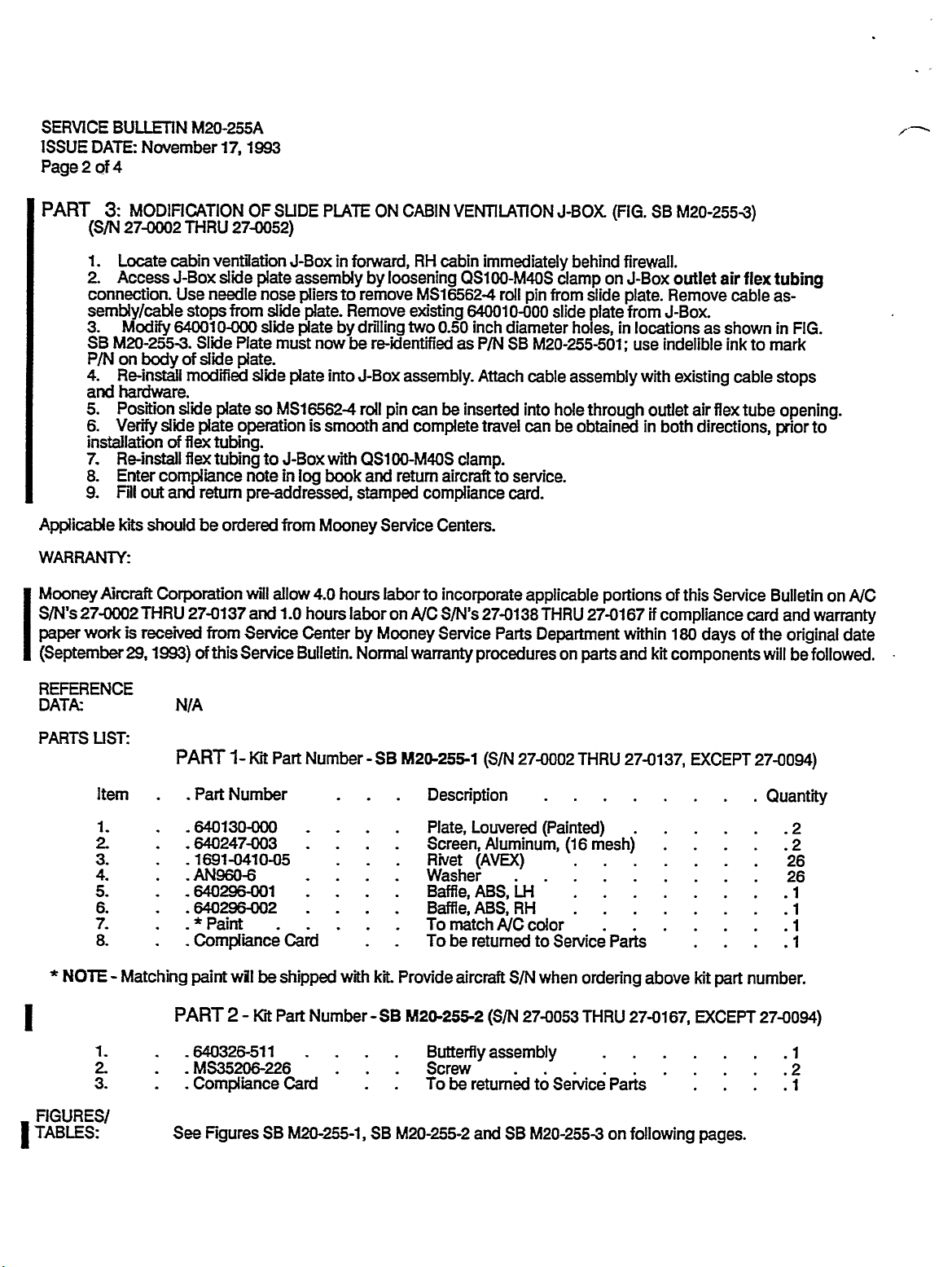

SERVICE

ISSUE

DATE:

BULLETIN

November

M20-255A

17,

Page

3

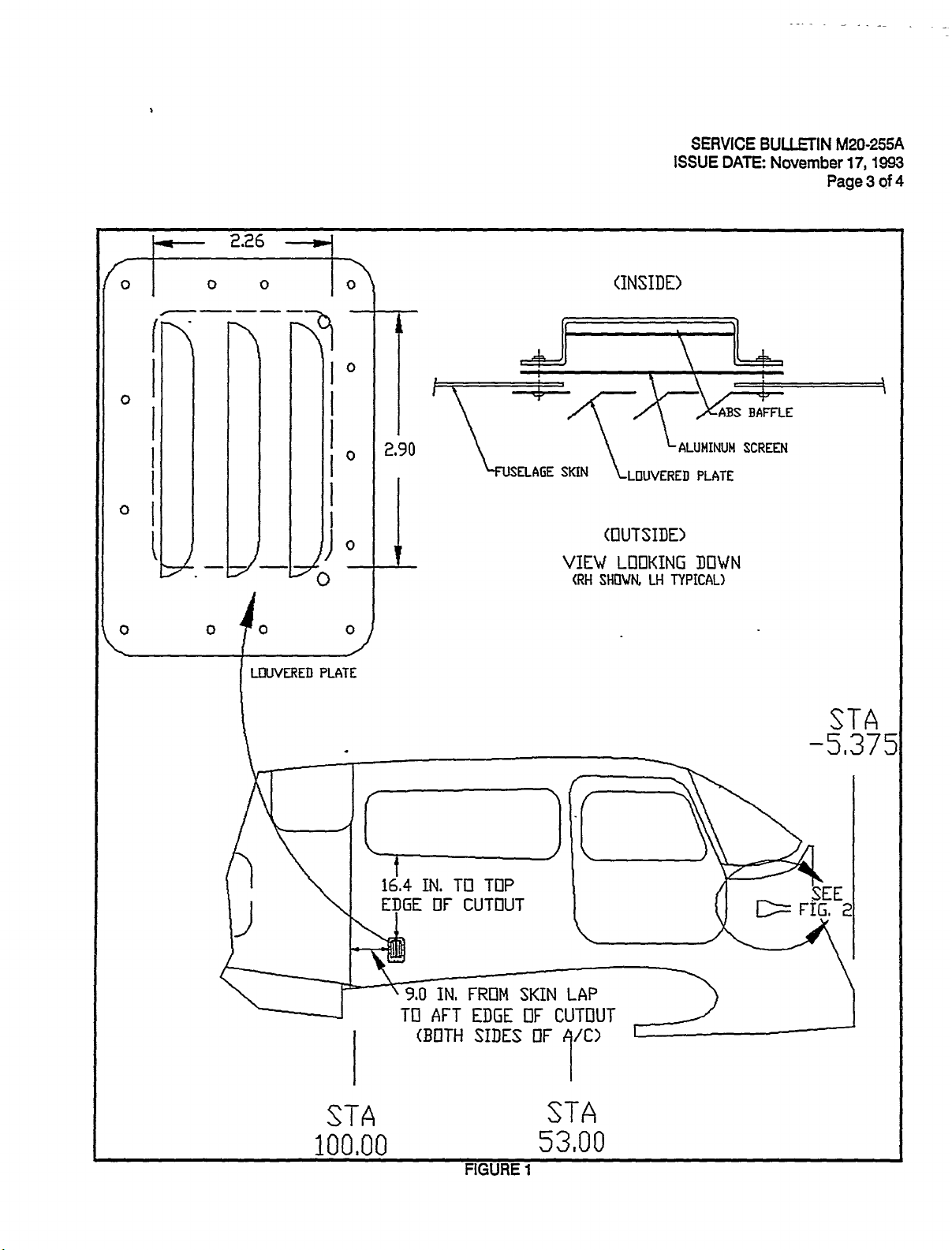

1993

of

4

o

o

lo\

(INSIDE)

~ci

10

BAFFLE

ALUMINUM

10

2,90SKIN

1

~I

I

I

I

III´•

O

O

O

-T~O

LOUVERED

O

PLATE

VIEW

(RH

(CIUTSIDE)

LOOKING

SHOWU

LH

I)OWN

TYPICAL)

SCREEN

PLATE

STA

-5,37

c-1

16.4

IN.

TO

TOP

OF

ET~GE

CUTOUT

\I

j

9,0

IN,

STA

100,00

TO

AFT

(BOTH

FRON

EDGE

SIDES

FIGURE

SKIN

OF

OF

STA

53,00

1

LAP

CUTOUT

SEE

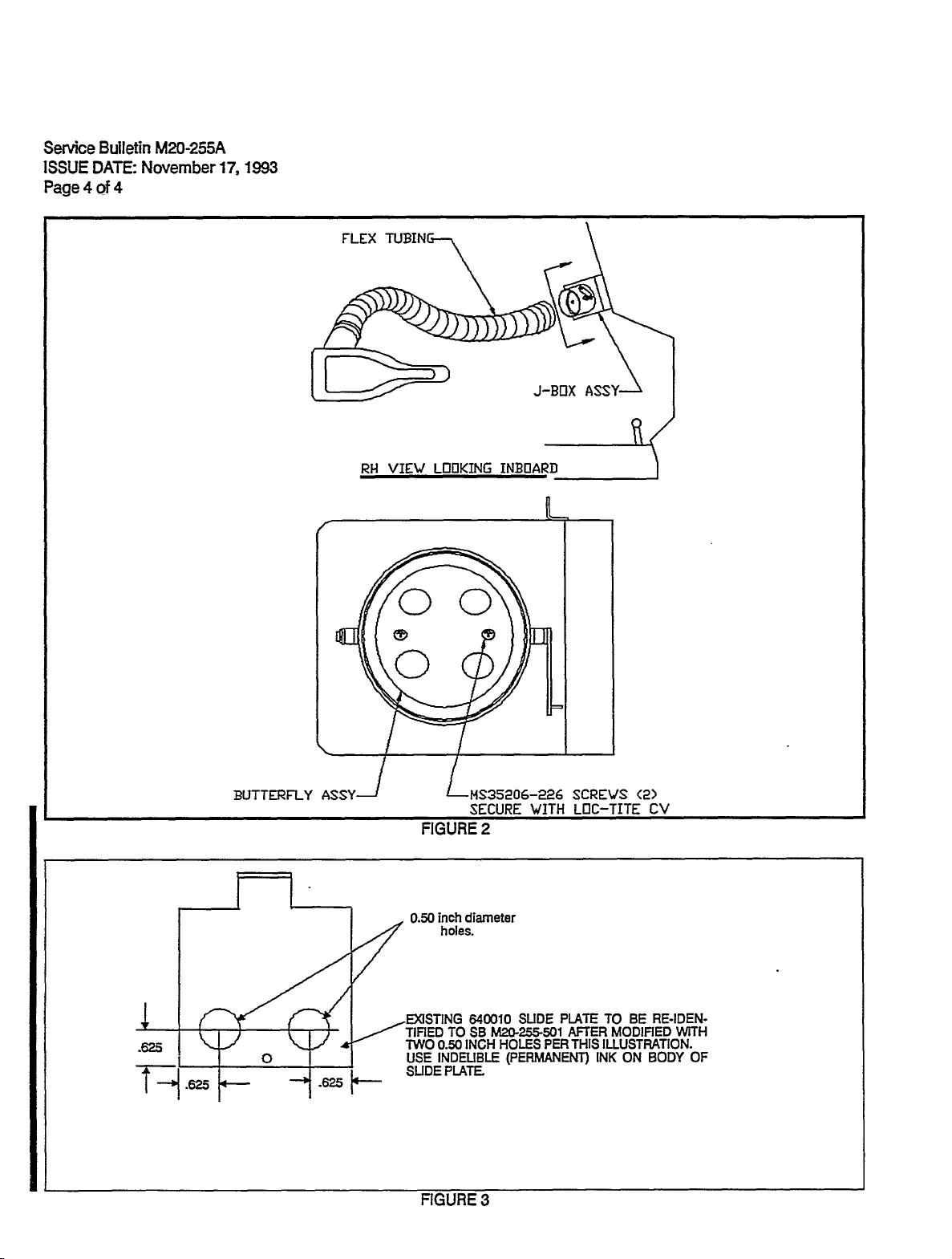

Senrice

ISSUE

Page

Bulletin

DATE:

4of4

M20-255A

November

17,

1993

FLEX

BUTTERFLY

ASSY--,

RH

VIEW

O

O

LDtlKING

LMS35206-226

FIGURE

O

SECURE

2

J-BI7X

INBOARD

WITH

ASS

SCREVS

LOC-TITE

<2>

CV

.625

?-1

.625

inch

0.50

TIRED

TWO

O

USE

SLIDE

diameter

holes.

640010

TOSEM20´•255-501

INCH

0.50

INDEUBLE

PLATE.

SUDE

HOLES

(PERMANENT)

PER

PLATE

AFTER

THIS

RE-IDEN-

BE

TO

MODIRED

ILLUSTRATION.

ON

BODY

INK

WITH

OF

´•u~-

FIGURE

3

THIS

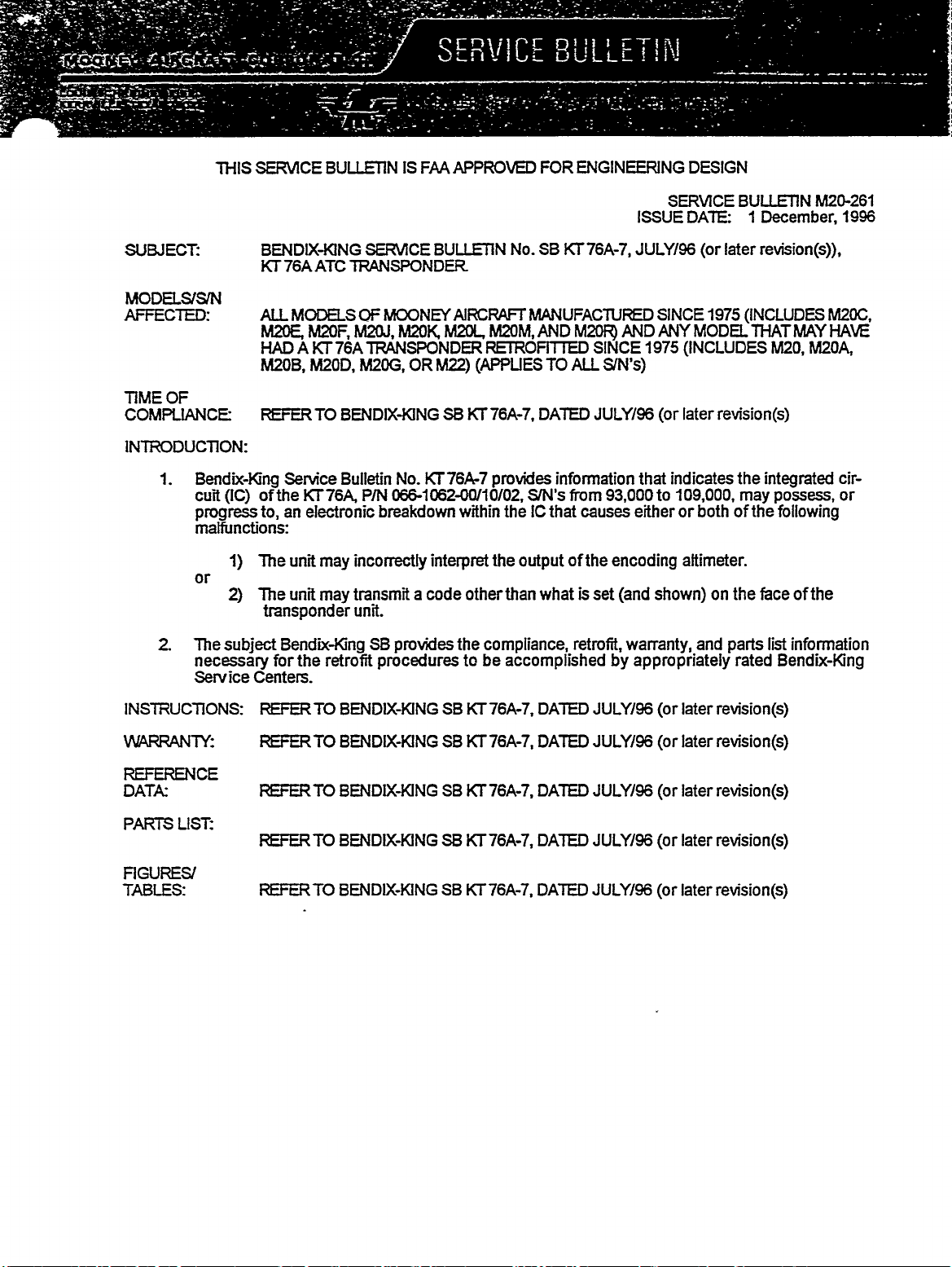

SERVICE

BULLETIN

FAA

APPROVED

IS

FOR

ENGINEERING

DESIGN

SUBJECT:

MODELSISIN

AFFECTED:

TIME

OF

COMPLIANCE:

INTFZODUCTION:

i,

Bendix-King

cuit

progress

malfunctions:

or

2

The

necessary

Seivice

BENDU(-MNG

76A

KT

ALL

M20E,

HADAKT

M20B,

F~EFERTOBENDIX-KING

of

(IC)

to,

The

The

2)

MODELS

Service

the

an

unit

unit

ATC

M20F,

76A

M20D,

KT76A,

electronic

may

may

t~ansponder

subject

Bendix-KingSEprovides

for

Centers.

the

retrofit

SERVICE

TRANSPONDER

MOONC(AIRCRAFT

OF

M20J,

M20K,

TRANSPONDER

M20G,

Bulletin

OR

No.

P/N

066-1062-00/10!02,

breakdown

incorrectly

transmit

unit.

procedures

BULLETIN

M22)

KT76A-7

interpret

code

a

M20L,

KT

SE

within

other

the

to

No.

MANUFACTURED

M20M,

RETROFI~ED

(APPUES

76A-7,

provides

Sn\l’s

IC

the

the

output

than

compliance,

be

accomplished

KT

SE

AND

TO

DATED

information

that

what

76A-7,

M20FP

SINCE

ALL

JULY/96

from

causes

of

the

is

set

retrofit,

ISSUEDATE:

JULY/96

AND

i

S/N’s)

that

93,000

either

encoding

land

warranty,

by

appropriately

SERVICE

SINCE

ANY

975

(INCLUDES

later

(or

indicates

to

109,000,

or

attimeter.

shown)

BULLETIN

later

(or

1975

MODEL

(INCLUDES

revision(s)

the

may

bothofthe

the

on

and

parts

rated

iDecember,

revision(s)),

THAT

MAY

M20,

integrated

possess,

following

faceofthe

list

information

Bendix-King

M20-261

1996

M20C,

HAVE

M20A,

cir-

or

INSTRUCTIONS:

WARRANPI:

REFERENCE

DATA:

PARTS

F1GURES/

TABLES:

LIST:

REFER

I~EFERTO

~EFER

F~EFER

FIEFERTO

TO

BENDU(-KING

BENDIX-KING

TO

BENDD(-KING

TO

BENDU(-KING

BENDIX-MNG

SE

SE

SE

SE

SE

Kr76A-7,

KT

76A-7,

KT

76A-7,

KT

76A-7,

KT

76A-7,

DATED

DATED

DATED

DATED

DATED

JULY/96

JULY/96

JULY/46

JULY/96

JULY/96

(or

(or

(or

(or

(or

later

later

later

later

later

revision(s)

revision(s)

revision(s)

revision(s)

revision(s)

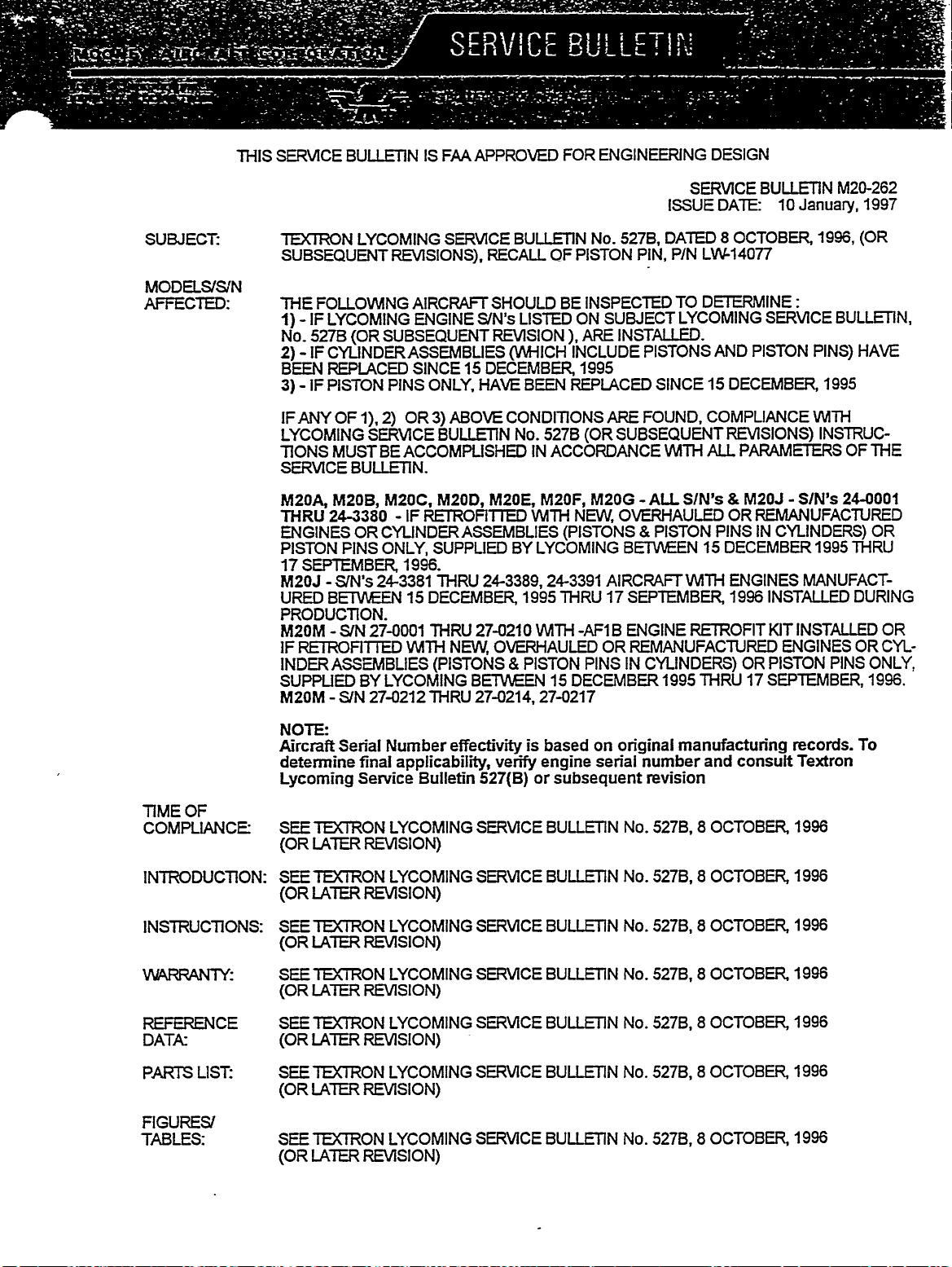

THIS

SERVICE

BULLETIN

ENGINEERING

FAA

APPROVED

IS

FOR

DESIGN

SUBJECT:

MODELS/S/N

AFFECTED:

TEX~RON

SUBSEQUENT

ME

1)

No.

2)

BEEN

3)

ANY

IF

LYCOMING

TIONS

SERVICE

M20A,

THRU

ENGINES

PISTON

17

SEPTEMBER,

M20J

URED

PRODUCTION.

M20M

IF

LYCOMING

FOLLOWING

IF

LYCOMING

5278

CYUNDERASSEMBUES

IF

REPIJ\CED

if

PISTON

MUST

M20B,

243380

SIN’s

BETWEEN

SUBSEQUENT

(OR

OF

2)

1),

SERVICE

BE

BULLETIN.

M20C,

CYUNDERASSEMBLIES

OR

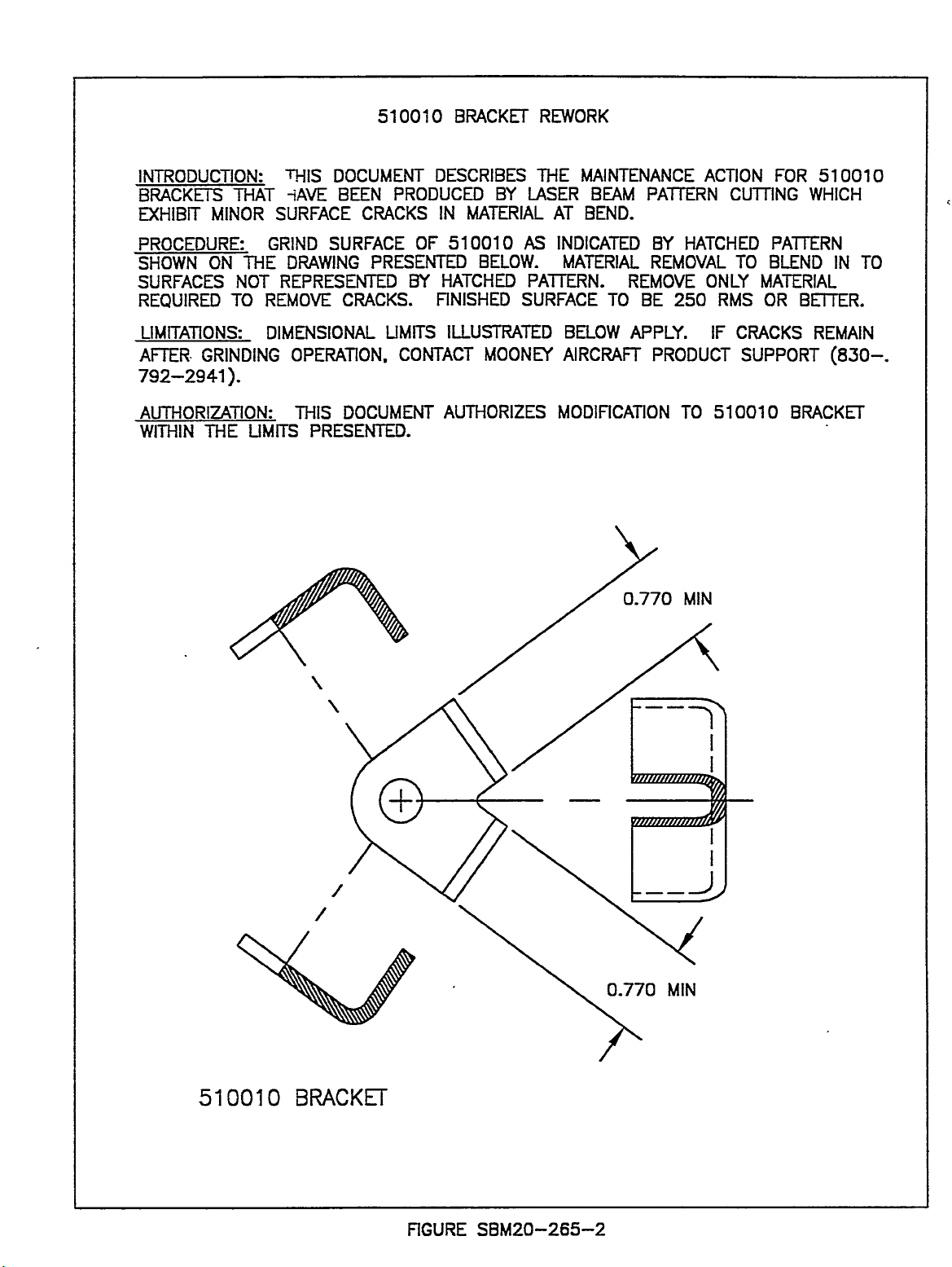

FINS

ONLY,

24-3381

SIN

27-0001

INDERASSEMBLIES

SUPPLIED

M20M

SIN

LYCOMING

BY

27-0212

SERVICE

REVISIONS),

AIRCRAFT

ENGINE

SINCE

PINS

ONLY,

ABOVE

OR

3)

BULLETIN

ACCOMPLISHED

M20D,

IF

RETROFITTED

SUPPLIED

1996.

MRU

15

DECEMBER,

THRU

v\nTH

NEW,

(PISTONS

MRU

BULLETIN

RECALL

SHOULD

S/N’s

REVISION

OM-IICH

15

DECEMBER,

HAVE

CONDITIONS

M20E,

BY

24-3389,

27-0210

OVERHAULED

8

BETVMW

27-0214,

OF

LISTED

BEEN

No.

5278

ACCORDANCE

IN

M20F,

WITH

LYCOMING

24-3391

1995

WITH

PISTON

15

27-0217

No.

PISTON

INSPECTED

BE

SUBJECT

ON

ARE

INCLUDE

1995

REPLACED

ARE

(OR

M20G

NEW,

(PISTONS

AIRCRAFT

THRU

17

-AF1B

OR

PINS

DECEMBER

SERVICE

ISSUEDATE:

DATED

5278,

PIN,

LW14077

P/N

DETERMINE

TO

LYCOMING

INSTALLED.

PISTONS

SINCE

FOUND,

15

COMPLIANCE

SUBSEQUENT

ALL

WITH

SIN’s

AL,

OVERHAULED

PISTON

8

BET~

15

WITH

SEPTEMBER,

ENGINE

REMANUFACTURED

IN

RETROFIT

CYLINDERS)

1995

THRU

BULLETIN

8

OCTOBER,

SERVICE

AND

PISTON

DECEMBER,

REVISIONS)

PARAMETERS

M20J

8

REMANUFACTURED

OR

PINS

IN

ENGINES

INSTALLED

1996

KIT

PISTON

OR

17

SEPTEMBER,

CYLINDERS)

DECEMBER

10January,

1996,

BULLETIN,

PINS)

1995

WITH

INSTRUC-

S/N’s

1995

MANUFACT-

INSTALLED

ENGINES

PINS

M20-262

1997

(OR

HAVE

OF

THE

24-0001

OR

THRU

DURING

OR

ONLY,

1996.

OR

Cn-

OF

TIME

COMPLIANCE

INTF~ODUCTION:

INSTRUCTIONS:

VWRRANTY:

REFERENCE

DATA:

PARTS

FIGURESI

TABLES:

LIST:

NOTE:

Aircraft

determine

Serial

Lycoming

SEETDCTRON

LATER

(OR

SEETMTRON

LATER

(OR

SEETDCTRON

LATER

(OR

SEETDCTRON

LATER

(OR

SEE

TEXTRON

LATER

(OR

TDCTRON

SEE

LATER

(OR

SEE

TECTRON

LATER

(OR

Number

final

applicability,

Service

Bulletin

LYCOMING

REVISION)

LYCOMING

REVISION)

LYCOMING

REVISION)

LYCOMING

REVISION)

LYCOMING

REVISION)

LYCOMING

REVISION)

LYCOMING

REVISION)

effectivity

verify

527(8)

SERVICE

SERVICE

SERVICE

SERVICE

SERVICE

SERVICE

SERVICE

is

based

engine

or

subsequent

BULLETIN

BULLETIN

BULLETIN

BULLETIN

BULLETIN

BULLETIN

BULLETIN

on

sen~al

original

No.

No.

No.

No.

No.

No.

No.

manufactun‘ng

number

revision

8

5278,

5278,8OCTOBER,

8

5278,

8

5278,

8

5278,

8

5278,

8

5278,

consult

and

OCTOBER,

OCTOBER,

OCTOBER

OCTOBER,

OCTOBER,

OCTOBER,

records.

Textron

1996

1996

1996

1996

1996

1996

1996

To

THIS

SERVICE

BULLET1N

IS

FAA

APPROVED

FOR

ENGINEERING

DESIGN

SUBJECT

MODEYS/N

AFFECTED.

AM-Safe

tie

down

OF

TIME

COMPLIANCE:

INTRODUCTION:

from

shoulder

have

position

is

to

that

been

or

provide

may

found.

have

Seat

M20

M20J

M20K-

M20L-

M20M

M20R-

M20J

Seat

if

may

Brand

system

missing

hamess

may

information

failed.

Belt

Series

26-0001

27-0001

29-0001

S/N’s

8elt

replacement

any

have

shoulder

Within

Ramp

The

create

retainer

ALL

24-0001

24r1686

25-0001

25-1225

and/or

the

for

or

the

inspections

retainer

Ty-rap’s

difficuit~s

for

bushings

SIN’s

thru

thru

thru

thru

thru

26-0041

thru

thru

24-1150

Shoulder

retainer

restraint~s

the

rear

defective

next

bushings

locking

inspection

with

24-1685

24-TEA

25-1224

25-TEA

27-iBA

29-TBA-

thru

has

been

bushing,

seats.

nylon

25

operational

at

in

releasing

nylon

Non-lnertial

-With

With

With

Wrth

Wrth

\Nnh

With

24-1417

Restraint

accomplished,

incorporate

These

grommets

some

several

on

tab

may

and

correctly

grommet

Non-lnertial

Rear

Non-inertial

Rear

Rear

Rear

Rear

Assemblies

nylon

NOTE

hours

airports

prevent

the

restraint

failure.

Reel

Seat

Seat

Seat

Seat

Seat

M20K

grommet

retainer

a

retainer

used

or

have

model

the

repain~ng

Shoulder

Reel

Should

Reel

Shoulder

Shoulder

Shoulder

Shoulder

S/N’s

instail~d

the

replacement

configuration.

bushing’s

in

at

next

found

aircraff.

restraint

buckle

any

Shoulder

er

Shoulder

Restraint

Restraint

Restraint

25-0560

bushing

the

original

maintenance

the

Unauthon’zed

buckle

in

an

defective

Restraints

Restraint

Restraint

thru

during

should

nylon

emergency.

SERVICE

ISSUE

installed

Restraint

Assemblies

Restraint

Assemblies

Assemblies

Assemblies

Assemblies

250780

production,

Seat

Belt/Restraint

used

for

also

configuration.

action.

grommets

repairs

from

properly

retainer

DATE:

Assemblies

Assemblies

had

the

be

The

bushing

BULLmN

15

August,

Indiana

however,

Assembly

cargo

inspected

missing

using

ty-raps

snapping

intent

of

grommet

M20

Mills

restraint

for

broken

or

into

this

-263

1997

SE

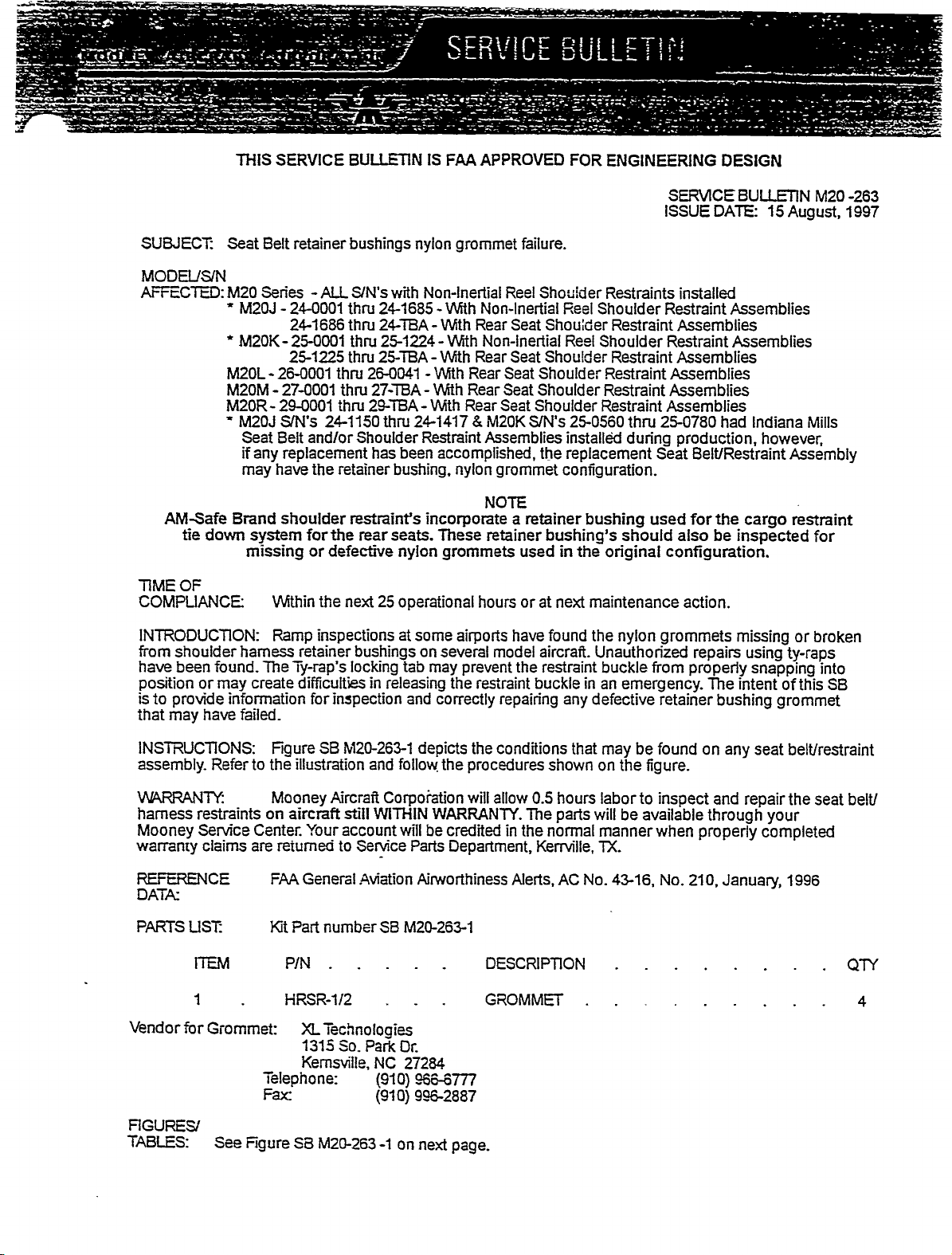

INSTRUCTIONS:

assembly.

VWRRANTY:

harness

restraints

Mooney

warranty

REFERENCE

DATA:

PARTS

Vendor

FIGURES/

TABLES:

UST~

lTEM

1

for

Refer

Service

claims

Grommet:

See

Figure

the

to

Mooney

aircraft

on

Center.

reiumed

are

FAA

Kit

Part

P/N

HRSR-1/2

Telephone:

Fax:

Figure

SE

hi120-263-1

illustration

Aircraft

still

k~our

account

to

General

number

XL

Technologies

1315

So.

Kernsvitle,

SE

M20-263

and

Corpoiation

WITHIN

Service

Aviation

SE

Park

NC

(910)

(910)

-1

on

depicts

follow

WARRANTY.

will

be

Parts

Airworthiness

M20-263-1

Dr.

27284

966-6777

9~6-2887

next

the

the

credited

conditions

procedures

will

allow

Department,

DESCRIPTION

GROMMET

page.

in

the

Alerts,

shown

0.5

The

normal

Kenviile.

that

hours

parts

AC

No.

may

on

laborto

will

manner

TX.

43-16,

the

be

be

found

figure.

inspect

available

when

No,

on

and

through

properly

210,

seat

any

repair

completed

January,

belt/restraint

the

your

1996

seat

beltl

QT/

4

t,

~I

I

II(

--EXISTING

I-_11

IJNSAFE--NILON

tlRSR-I/P

c

o,

2.

3

APPLY

HRSR-1/2

NEAT

i

4

VERIFY

SIIOULDCR

NYLON

(1I\ISPECT

T~RDMMES

FROW

~ROMMET

BUSI-IING

FOR

BUSIIING

SLIPPED

I´•IEAT

SWRUNK

RES7laAINT

I

I

IN

DEFECTS)

MISSING

RETPOFIT

OVER

GUN

Tn

IN

PLACE

S~-IRINK

PLACE

SNAPS

PROCEDUPES

STUD

GROMMET

OVER

GRUMMET

I I I

’Y

SECURELY

´•´•t,\ri´•\,

rnm

;OIC!

o

5m

oo

F

co

II

´•\,r,~

i.

i

\i’

I(´•´•i

1~

\t\

ii:

THIS

SERVICE

BULLETIN

ENGINEERING

IS

FAA

APPROVED

FOR

DESIGN

SUBJECT:

MODELSIS~

AFFECTED:

TIME

INTRODUCTION:

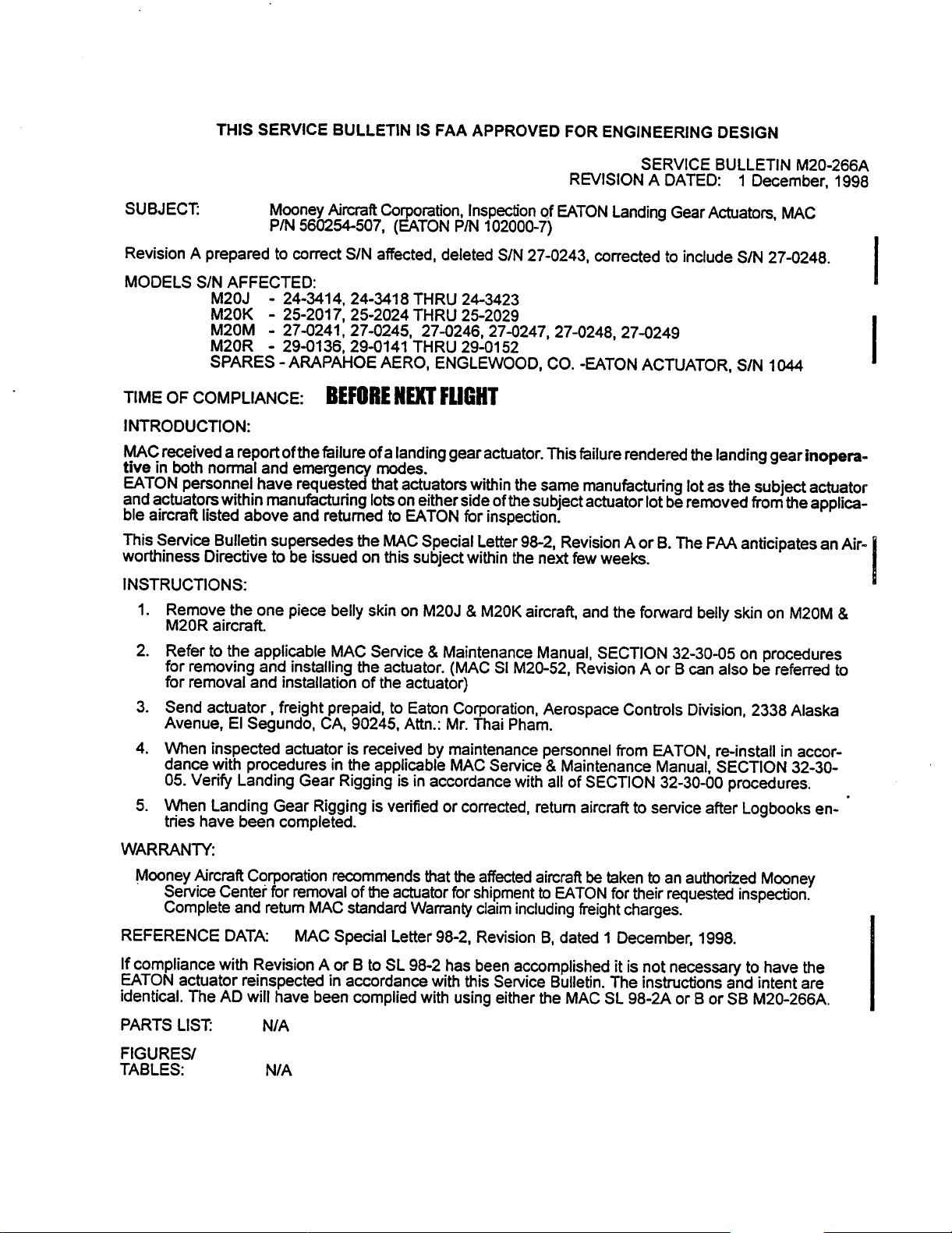

There

have

730005-1.

links

The

M20B,

M20L,

INSTRUCTIONS:

Remove

I.

Since

be

completed

numbers

part

M20C,M20D,

M20M

Iower

Aileron,

been

the

Aluminum

Smooth

Center,

M20B,

M20J

M20K

N120L

M20M

M20R

wn~in

reports

LH

in

accordance

be

to

M20E,

belly

fiberglass

Control

M20C,

S/N

S/N

ALL

S/N

S/N

nex~

of

a

RH

6

inspected

skin

to

Belly

24-0001

25-0001

SERIAL

27-0001

29-0001

25

crack

are

M20F,

gain

Skin

belly

Links

M20D,

hours

adjacent

very

with

are

M20G,

access

aircraft

aircraft

M20E,

THRU

THRU

NUMBERS

MRU

THRU

of

operation

similar,

instrudions

the

follows:

as

M20J,

to

Inspection

M20F,

24-3359

25-1999

27-0197

29-0042

to

the

weld

is

a

requested

M20K

underside

lst

skin

Forward

M20G

and

in

area

shown

of

of

aff

fiberglass

accordance

of

that

below.

aircraft:

nose

ALL

SERIAL

the

LH

an

inspection

730005-1

730051-501

wheel

skin

SERVICE

ISSUEDATE:

wil~

NOTE

aileron,

(LH)

well

NUMBERS

2

center

of

both

6

730006-000

6

(LH)

BULLETIN

1

February,

below.

control

of

these

730052-501

M20-264

link,

control

(RH)

1998

P/N

(RH)

ff

during

at

the

required

If

2.

a

ter,

from

3.

When

joint

angle

4.

Carefully

the

at

If

5,

no

Reinstallthe

6.

7.

If

discrepancies

6.

Connect

Maintenance

Visual

a

2nd

900angIe

for

visual

inspection

control

the

paint

(2nd

links.

area

and/or

from

joint.

inspect

weld

area,

discrepancies

e>dsting

If

existing

cordance

attaching

that

Note

be

to

Helm

the

good

with

are

Manual

inspection

joint

control

determines

location

inspected.

foreign

any

bean’ng),

resultsofthe

in

either

exist,

good

control

this

found,

bolts,

instructions.

from

the

dean

control

SE,

proceed

spacer,

is

determined

it

Helm

link.Wboth

proceed

that

there

of

spacer

maten~al

conduct

Magnetic

weld

or

area,

prime

links.

links

are

are

required

to

and

nuts

Lubn’cate

bearing,

links

between

have

a

Magnetic

in

the

not

PARTS

washers

NOTEQ

that

(link

have

to

step

are

no

been

Particle

adjacent

and

repaint

NOTEZ

replaced

at

each

LIST

Helm

either

has

been

9

thru

reinforcing

LH

RH

removed

Particle

Inspection

tube

area

at

this

annual

below.

in

accordance

bearings

control

been

replaced),

replaced,

11.

gussets,

control

from

the

Inspection

to

material.

(epoxy

time,

100

or

withTeffon

link

has

reassemble

remove

linksatattach

weld

area

of

each

determine

paint

recommended).

repetitive

hour

inspection

with

AC43-13

spray

a

reinforcing

further

no

LH

6

bolt.

of

the

link

on

if

any

inspections,

or

lubricant

inspection

skin

belly

RH

aileron,

Remove

900

2nd

that

2nd

discrepancy

in

thereafter.

per

Service

S

Mooney

gusset

is

and

cen-

paint

angle

90"

e~a’sts

ac-

3

M.

9.

10.

Verify

When

aiieron

rigging

rigging

verified

is

accordance

in

to

be

with

correct,

the

reinstall

proper

aircraft

section

aluminum

of

the

applicable

belly

skin

model’s

or

fiberglass

S

6

M

manual.

skin.

SERVICE

ISSUEDATE:

2of

Page

BULLETIN

2

1

February,

M20-264

1998

11.

Complete

WARRANP~

REFERENCE

DATA:

PARTS

MODEL’s

M20B,

M20E,

M20J,

LIST:

M20C,

M20F,

M20K

Logbook

KIT

Pi~

M20D,

M20G,

KlT

P/N

and

entry

2.0

hours

to

Up

Service

cordance

claimisreceived

Labor

Aircraff

ment

N/A

Center

with

and/or

Corporation

M20-264-1

DESCRIPTION

LINK,

LINK,

M20-26P2

return

labor

for

inspection

instructions

the

within

replacement

AILERON

AILERON

aircraft

and

cost

180

warranty

CONTROL,

CONTROL,

to

and

days

parts

policy

service.

of

replacement

replacement

of

this

SE

of

dateofthis

(if

needed)

for

LH

RH

aircraft

a

will

affected

will

parts

of

subject

in

still

SE.

be

not

aircraft

730005-1

730006-000

be

aileron

under

covered

are

PM

credited

warranty

under

beyond

to

control

warranty

the

Mooney

links

and

warranty

Mooney

in

agree-

QT/

1

1

ac-

M20L,

M20R

FIGURES/

TABLES:

M20M,

N/A

LINK,

LINK,

AILERON

AILERON

CONTROL,

CONTROL,

LH

RH

730051-501

730052-501

1

1

SERVICE

ISSUE

BULLETIN

DATE:

April

P~I20-265

1998

13,

SUB~ECT:

MODEU

AFFECTED:

TIME

MAIN

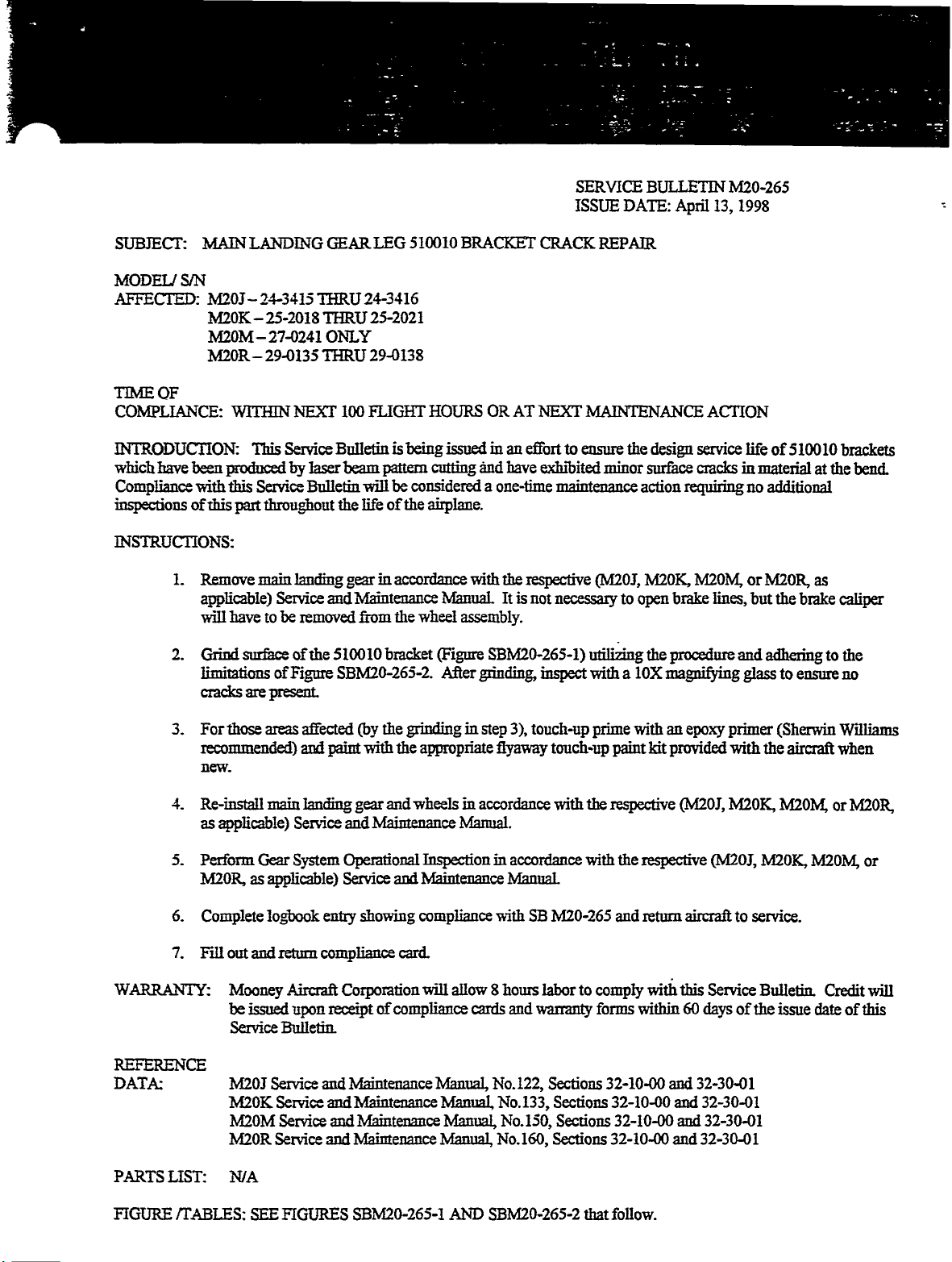

SM

OF

COMPLIANCE:

FNTRODUCTION:

which

have

been

Compliance

inspections

with

of

INSTRUC~IONS:

I.

Remove

applicable)

will

2.

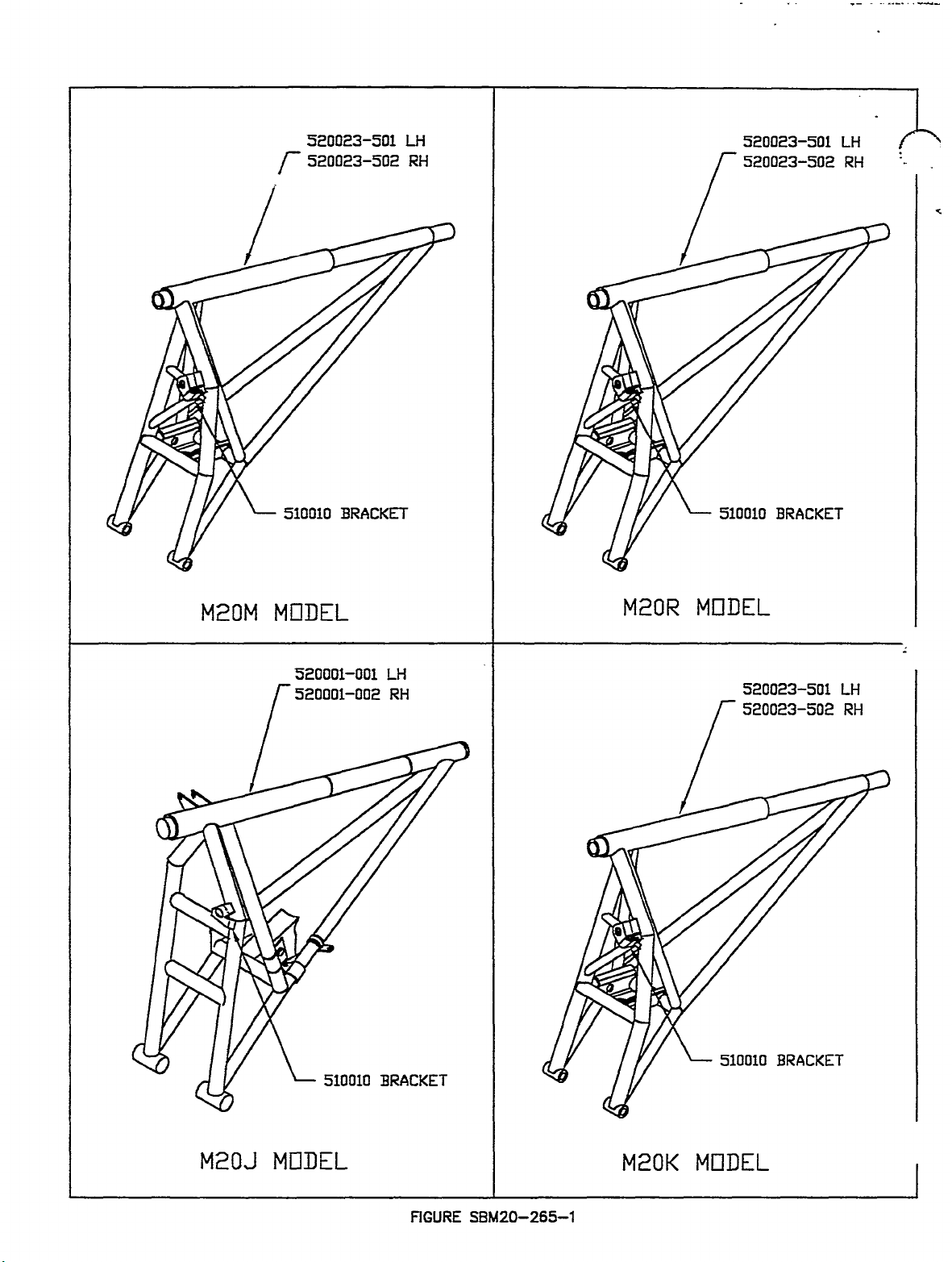

Grind

limitations

cracks

lu120K

M20M

~1120R-

WITHIN

produced

this

this

part

have

LANDING

25-2018

27-0241

29-0135

This

Service

throughout

main

Service

be

to

s~inface

of

are

present.

THRU24-3416

NEXT

Service

laser

by

Bnlletin

landing

removed

the

of

Figure

CiEARLEG

25-2021

THRU

ONLY

29-0138

THRU

100

FLIGHT

gear

will

Iife

from

is

pattern

be

of

in

bracket

Bnlletin

beam

the

andMaintenance

510010

SB~u120-263-2.

510010

HOURS

being

cutting

considered

the

airplane.

accordance

XlanuaL

the

wheel

CEEgure

Alter

BRACI~

OR

in

issued

~nd

a

with

assembly.

SBrv120-265-1)

grinding

AT

effort

an

have

one-time

the

respective

is

It

not

CRACK

NEXT

to

exhibited

maintenance

necessary

inspect

REPAIR

MAINTENANCE

the

ensure

minor

design

smface

action

~20J,

to

open

Imlin’ne

witha10X

the

AC?ION

service

cracks

requiring

brake

Iines,

procedure

magnifying

life

in

no

or

but

and

glass

material

of

510010

additional

~1120R,

the

brake

adhering

to

ensure

at

as

to

brackets

the

bend

caliper

the

no

3.

1.

5.

6.

7,

WARRANTY:

REFERENCE

DATA:

PARTS

LIST:

those

For

areas

recommended)

new.

Re-install

as

Perform

Ivl20R

main

applicable)

Gear

as

applicable)

Complete

Mooney

issued

be

Service

M20T

Service

Service

~UII20M

~EV120R

N/A

Service

Service

affected

and

landing

Service

System

Airaaft

upon

Bulletin

the

(by

with

andwheels

gear

Maintenance

the

paint

and

Operational

Service

entry

and

showing

Corporation

of

receipt

and

andMaintenance

and

and

compliance

Maintenance

Maintenance

Maintenance

grinding

appropriate

Tnspection

Maintenance

compliance

card

will

Manual

Manual