Mooney M20L Service And Maintenance Manual

O

O

SERVICE

AND

MANUAL

MAINTENANCE

MOONEY

P.O.

BOX

MARCH,

72,

1988

AIRCRAFT

KERRVILTIE,

MANUAL

CORPORATION

TEXAS.

NUMBER

78029-0072

140

MOONEY

SERVICE

AIRCRAFT

M()DEL

AND

CORPORATION

M20L

MAINTENANCE

INTRODUCTION

This

manual

tenance

M20L,

tenance

of

of

The

Serial

aircraft

applicable

format

prepared

AVIATION

TION

manual

the

for

These

sary.

of

back

Revisions

(GAMA)

is

various

the

provides

information

Numbers

actions

will

be

airplanes.

and

in

accordance

MANUFACTURER’S

supplemented

are

manual

reissues

or

automatically

Halders

Publications

on

of

the

the

of

YELLOW

Title

these

should

Page

CorpoMtion,

sent

Attn:

is

manual

and

out.

at

sent

Mooney

780tY-007t,

Notification

when

another

subscription

be

will

new

subscription

Puhlications

cal

department

896-6000.

(512)

Correspondence

numbers

part

aircraft

serial

placard

tailcone

the

ASSIGNMENT

The

content

levels:

four

Group

model

number

located

on

number

below

of

System/Chapter

Subsystem/Section

UniVSubject

GROUP

These

are

primary

enable

Airframe

These

broad

groups

systems

are

for

26-0001

refer

that

designated

contents

Specification

with

model

year

located

texts

pages.

NOTE

of

provided

other

and

complete

CARDS

send

and

Box

P.O.

Service

known

to

is

prepared

advises

The

are

that

new

service.

desired,

Aircraft

concerning

an

airplane

and

appears

the

aft

on

horizontal

the

SUBJECT

OF

this

publication

divisions

separation

VS

identified

servicing

the

Mooncy_Modcl

and

limited

to

a

serial

by

this

of

with

No.

wiring

airplanes,as

in

envelopes

manual

this

manual

to

Mooney

information

the

located

72,

Parts

manual

If

to

Mooney

Kerrville,

manual

no

additional

contact

at

Department.

to

more

will

Corporation

maintenance

should

serial

number.

identification

the

on

left

end,

stabilizer.

MATERIAL

is

of

the

of

content,

Powerplant

tabs.

by

and

main-

Main-

ON,

number

number

manual

GENERAL

ASSOCIA-

2.

schematics

neces-

at

not

are

holders.

Technicnl

front

the

AircraCt

TX.,

holders

replace

revisions

require

Techni-

the

above

contain

hand

side

organized

manual

systems.

are

The

the

the

the

The

that

ie.,

SYSTEM/CHAPTER

The

various

mation

The

systemsare

GAMA

is

suggested,

tified

The

sequence

the

General

groups

such

as

recommended

for

with

the

information

contain

night

major

controls,

arranged

number

e?rample,that

System/Chapter

of

numbers,

of

the

28-00-00,

systems

landing

numerically

assignment,

"Fuel"

number

Fuel

infor-

gear,

iden-

be

refers

Systems.

etc.

per

It

"28".

to

SUB-SYSTEM/SECTION

The

are

of

of

broken

are

the

element

fuel

the

se-

The

major

down

identined

quence

indicates

-20-

systems

into

sub-systems.

by

of

numbers,

the

the

of

an

second

28-20-00.

ie.,

distribution

aircraft

These

element

sub-systems

portion

system.

UNIT/SUBJECT

individual

Th,

identif~ed

numbers,

the

by

used

maintenance

a

by

ie.,28-20-01.

manufacturer

depending

action

APPLICATION

revising

the

GAMA

any

aircraft

the

to

numbered

be

breakdown

complex

table

Aircraft

all

publication

will

Any

the

pages

oriented

As

numbered

of

Mooney

a

of

to

pleted

at

or

of

of

system.

cerning

refer

maintenance

will

tem

aircraft.

more

quentially

at

Th,

tem/Chapter

in

covered

the

28-01)

25-10

within

units

element

third

upon

recommended.

NUMBERING

OF

Corporation

applicable

format.

conform

person

Distribution

Fuel

identined

sequentially

in

the

Mooney

the

page

within

contents

will

provide

Chapter.

a

sub-system

of

the

number

This

and

may

the

complexity

isinthe

technical

this

When

concerning

basic

this

to

wishing

information

as

,28-20-00,

puhlication.

within

current

aircraft

numbers

Mooney

models

sub-systems.

front

in

the

list

a

For

example:

General

Storage

(Tanks,

vents,

sequence

is

or

may

SYSTEM

publications

effort

maintenance

numbering

System

These

may

of

of

sub-systems

repair,

may

assigned

not

the

of

process

is

com-

con-

would

in

any

pages

each

sys-

series

become

be

each

Sys-

be

of

be

of

se-

etc.)

28-20

Distribution

(Boost

pumps,

fuel

lines,

etc.)

Page

1

MOONEY

SERVICE

AIRCRAFT

MODEL

AND

CORPORATION

M20t

MAINTENANCE

28-40__

The

tenance

Manufacturers

aircraft.

and

ENGINE

information

These

Puhlications

available

are

As

Maintenance

Municipal

PROPELLER

McCauley

Aircraft

Company,

following

on

or

publications

be

can

through

publications

Airport,

R.R.

Propellers

3535

Indicating

Manufacturers

of

any

various

on

VENDOR

Units,

etc.)

are

from

Mooney

(Sender

gauges,

list

Components

obtained

available

publications

Box

5

McCauley

quantity

SUPPLEMENTARY

and/or

of

the

Mooney-PFM,

due

listed

from

Mooney

the

to

repair

Aircraft

MarketinglService

components

ADDRESSES

obtained

be

can

118A,

Cialesburg,

Obtain

publications

Vandalia,

Drive,

If

LEFT

sending

-panded

(Right

expanded

tions.

PUBLICATIONS

publications

the

many

stations

Corporation

become

or

through

11.,61401.

from

OH.,45377.

is

there

HAND

units

to

a

28-40-01

Hand).

information

can

MU0L.

Model

configurations

for

a

particular

are

Center.

available,

PUBLICATIONS

they

Porsche

McCauley

reason

RICrHT

or

the

then

(Left-Hand)

This

concept

provide

No

that

avionics

in

listed

willbeadded

Aviation

Accessories

to

distinguish

HAND

number

will

throughout

servicing

avionics

installedinthe

be

can

manufacturer.

the

Parts

Products

Division,

between

fuel

quantity

would

and

2&40-02

apply

the

publica-

main-

and

equipment

List

Price

the

list

to

Inc.,

Cessna

be

to

any

below.

ex-

Page

2

MOONEY

SERVICE

AIRCRAFT

MODEL

AND

CORPORATION

M20L

MAINTENANCE

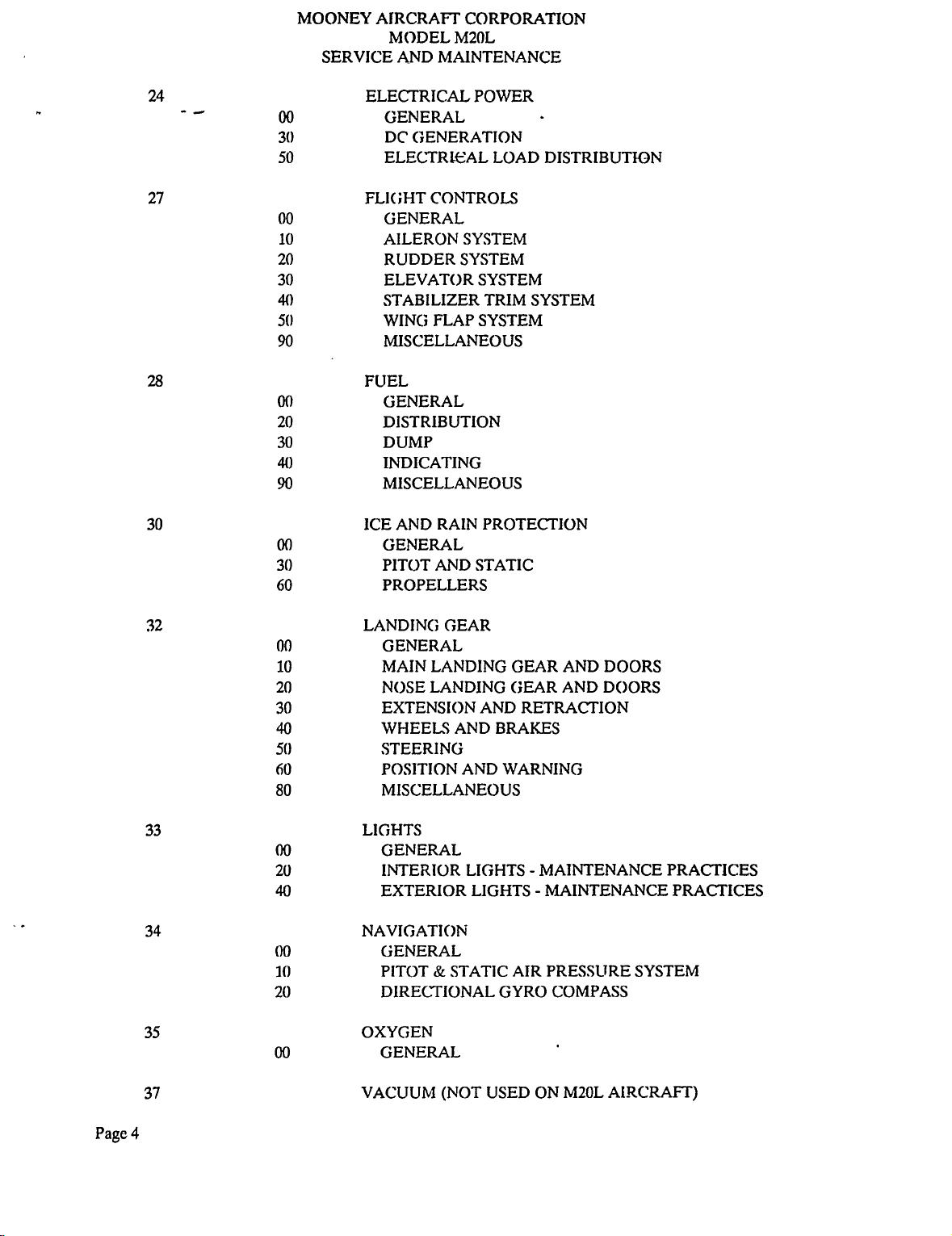

SYSTEM/

CHAPTER

1-4

5

G

7

8

9

SYSTEM/CHAPTER,

SUB-SYSTEM!

SECTION

00

10

20

00

10

00

00

10

20

SUB-SYSTEM/SECTION

T~TLE

GAMA

RESERVED

DATE

TIME

BY

LIMITS/MAINTENANCE

GENERAL

LIMITS

TIME

SCHEDULED

DIMENSIONS

GENERAL

LIFTING

AND

JACKING

LEVELING

AND

LEVELING

TAXIING

TOWING

GROUND

AND

HANDLING

TOWING

TAXIING

INDEX

MAY

MAINTENANCE

AREAS

WEIGHING

GUIDE

BE

USED

CHECKS

CHECKS

AT

LATER

10

11

12

20

21

MOORING

PARKING

00

10

20

GENERAL

PARKING

MOORING

PLACARDS

00

10

20

GENERAL

MARKINGS

PLACARDS-

AND

MARKINGS

AND

EXTERIOR/INTERIOR

SERVICING

00

10

20

00

00

40

SERVICING

REPLENISHING

SCHEDULED

STANDARD

PRACTICES

GENERAL

ENVIRONMENTAL

CABIN

HEATING;

VENTILATION

SERVICING

AIR~RAME

SYSTEMS

SYSTEM

Page

3

MOONEY

SERVICE

AIRCRAFT

MODEL

AND

CORPORATION

M20L

MAINTENANCE

24

27

28

30

00

20

30

40

90

00

30

60

00

20

30

40

50

90

00

30

50

10

ELECTRICAL

GENERAL

DC

<;ENERATION

ELECTRLt’AL

FLI(;HT

FUEL

CONTROLS

GENERAL

AILERON

RUDDER

ELEVATOR

STABILIZER

WING

MISCELLANEOUS

FLAP

GENERAL

DISTRIBUTION

DUMP

INDICATING

MISCELLANEOUS

AND

ICE

GENERAL

PITOT

PROPELLERS

AND

RAIN

POWER

LOAD

SYSTEM

SYSTEM

SYSTEM

TRIM

SYSTEM

PROTECTION

STATIC

DISTRIBUTION

SYSTEM

37

34

35

32

33

30

50

60

80

00

20

40

00

10

20

00

00

10

20

40

LANDING

GENERAL

MAIN

N()SE

LANDING

EXTENSION

WHEELS

STEERING;

POSITION

MISCELLANEOUS

LIGHTS

GENERAL

INTERIOR

EXTERIOR

NAVIGATI~)N

GENERAL

PITOT

DIRECTIONAL

OXYGEN

GENERAL

VACUUM

GEAR

LANDING

AND

AND

LIGHTS

LIGHTS

Sr

STATIC

(NOT

AND

BRAKES

WARNING

GYRO

USED

GEAR

(iEAR

AIR

AND

AND

RETRACTION

MAINTENANCE

MAINTENANCE

PRESSURE

COMPASS

MZOL

ON

DOORS

DG)ORS

PRACTICES

PRACTICES

SYSTEM

AIRCRAFT)

Pa&e

4

39

MOONEY

00

10

20

SERVICE

AIRCRAFT

MODEL

AND

ELECTRICAL

GENERAL

INSTRUMENT

ELECTRICAL

RACKS

CORPORATION

M20L

MAINTENANCE

PANELS

AND

AND

COMPONENTS

AND

CONTROL

ELECTRONICS

PANELS

EQUIPMENT

51

52

53

55

STRUCTURES

00

10

<;ENERAL

STRUCTURAL

REPAIR

GENERAL

DOORS

00

10

30

GENERAL

CABIN

DOOR

BAGGAGE

MAINTENANCE

MAINTENANCE

COMPARTMENT

PRACTICE

PRACTICE

DOOR

FUSELAGE

00

10

20

30

40

50

GENERAL

MAIN

AUXILIARY

FRAME

STRUCTURE

PLATES/SKIN

ATTACH

FITTINGS

FILLETSIFAIRINC;S

STABILIZERS

00

10

20

30

40

GENERAL

HORIZONTAL

ELEVATOR

VERTICAL

RUDDER

STABILIZER

STABILIZER

56

57

61

00

20

50

00

30

40

50

60

00

10

20

WINDOWS

GENERAL

WINDSHIELD

PLEXIGLASS

WINGS

GENERAL

PLATES/SKINS

ATTACH

FLIGHT

STANDARD

PROPELLERS

GENERAL

PROPELLER

CONTROLLING

gr

DRILLING

FITTINGS

SURFACES

PRA(3TICES

ASSEMBLY

CABIN

WINDOWS

PROPELLERS

Page

5

MOONEY

SERVICE

AIRCRAFT

M()DEL

AND

CORPORATION

M20L

MAINTENANCE

71,_

72

73

74

77

7’)

Qn

10

00

00

10

20

30

00

10

20

on

10

20

00

10

20

30

POWERPLANT

dENERAL

COWLING

ENGINE-

GENERAL

ENGINE

GENERAL

DISTRIBUTION

C’ONTR()LLING

INDICATING;

IGNITION

<iENERAL

POWER

EMERGENCYSHUTDOWN

EN<;INE

GENERAL

POWER

TEMPERATURE

OIL

GENERAL

STORAGiE

DISTRIBUTION

INDICATING;

RECIPROCATING

SYSTEM

FUEL

CONTROL

INDICATING

Page

80

00

10

81

on

10

20

91

00

20

3()

’)5

G

STARTING

GENERAL

CRANKING

TURBINES

<;ENERAL

P()WER

SCHEMATICS

GENERAL

ELECTRICAL

SCHEMATICS

SPECIAL

RECOVERY

SYSTEM

EQUIPhlE~IT

HARDWARE

CHARTS

CHAPTER

_

TINIE

LINIITS/

MAINTENANCE

CH

EC

KS

MOONEY

SERVICE

AIRCRAF~

MODEL

AND

CORPORATION

M20L

MAINTENANCE

CHAPTERS

MANUAL

CHAPTER

SECY~ION

SUBJECT........,

5-(H)-00

5-(H)-01

5-00-02

5-(X)-03

5-00-04

5-0()-05

5-00-06

5-(H)-07

5-10-(H)

5-10-01

5-20-00

5-20-01

5-20-02

5-20-03

5-20-04

5-20-05

5-2()-06

5-20-07

TIME

LIMITS/MAINTENANCE

TABLE

OF

CONTENTS

SUBJECT...........,

General

.,,,,,,.,,,,,5

Landing

Control

Flight

WingFiapSystcms

Electric

Instruments

Cabin

Heating

FuclSystem

Time

Limit

Overhaul

Schedule

Check

Aircraft

Maintenance

Points,

Engine

First

25

50

Hour

Hour

100

Access

Lubrication

CHECKS

Gear

System

Systems

Power

System

,,,.,,,,,,,,,,s

,,,,,,,,,,,,,6

Components

and

Replacement

(Torque

File

Inspection

Functional

Hour

Inspection

Inspection

Inspection

Cover

Identification,

and

Service

,,,,,,,,,,5

Ventilating

Checks

Values)

Check,,,,,,,l2

Guide

Systems

Schedule

,PAGE

,5

.5

.5

.5

.6

.6

.7

.7

12

12

13

13

19

5-CONTENTS

3/4BLANK

Page

MOONEY

SERVICE

TIME

AIRCRAFT

M<)DEL

AND

MAINTENANCE

CORPORATION

M20L

CHAPTERS

LaMTTS/MAINTENANCE

MANUAL

CHECKS

CHAPTER

SECTION

SUBJECYT

5-ETfectivi~y

IConlents........´•

5-00-(K)

5-00-07

5-10-01

5-20-01

L

5-20-0

5-20-01

5-20-01

5-20-02

5-20-05

5-20-06

5-20-06

5-20-(Ki

5-20-06

5-20-06

5-20-07

5-20-07

5-20-07

5-20-07

LIST

EFFECTIVE

<)F

PAGE

1/2BLANK

3/4BLANK

5

6

7

8

9

10

12

.13

.14

15

16

.17

18

19

20

21

22

PAGES

DATE

.3-88

.3-88

.3-88

.3-88

.3-88

.3-88

.3-88

.3-88

.3-88

.3-88

.3-88

.3-88

.3-88

.3-88

.3-88

.3-88

.3-88

.3-88

.3-88

.3-88

5-EFFECTIVITY

U2BLANK

Page

aircraft

airframe

-GENERAL

DESCRIPTION.

are

low-wing

with

nonstructural

5-00-00

AIReRAF~

ol’

single-engine

metal

covered

semi-monocoque

Inminar-now

tural

riveted

wheels

trols.

linked

supply

main

each

der

pedals

tricycle

wheel

retractable.

are

flaps

trim,

about

5-00-01

electric

The

wheel.

nose

brakes

position

indicator

lion

equipment.

retraction

the

position

rigged

electrical

Lion

on

rained.

power

from

panel

electric,

tensicln

which

the

event

5-00-02

Dual

either

from

controls

pushpull

the

control

guide

and

dampen

mechanism

assistincontrol

to

spar

the

to

accompany

The

pilot’s

individual

to

pressure

gear

landing

controlled

electrically

entire

the

its

attaching

LANDING

featured

are

lights,

to

air

pressure

system

tak’eoll

A

gear

lever

while

gear

system

permits

of

an

FLIGHT

Ilight

the

are

tubes

wheels

blocks

links

wing.

construction

are

The

landing

Single

a

on

Bungee

lock

is

approximately

retraction

manual

electrical

control

conventional

maintain

vibration.

f(,ur

place

tubular-steel

has

a

tailcone,

Control

and

spars

the

conventional

rudder

hydraulic

the

to

hydraulic

wheel.

standard

gear,

rudder

by

Removable

having

wide-sgan

operated.

empennage

points.

GEAR

gear

dise

on

warning

the

noorboard

springs

mechanism

the

gear

actuated

prevents

untilasafe

warning

Lhe

landing

system

connected

lowering

CONTROL

systems

or

pilot

link

and

aileron

the

coordination.

the

rudder

control

to

MOONEY

SERVICE

The-M2OL

hiph-pcrk,rmance

monoplanes.

cabin

aluminum

full-cantilever

and

a

surfaces

with

stressed

Dual

ribs.

pedals

have

cylinders

dise

co-pilot

equipment.

steerable

a

action,

pedal

trailing-edge

For

pivots

SYSTEM

system

has

self-adjusting

main

the

horn

electric

horn

to

and

assist

in

an

down.

safety

flying

sounds

3/8

gear

has

the

are

in

s\vitch

to

a

gear

of

gear.

a

A

gear

speed

114

is

malfunction.

SYSTEMS

he

can

co-pilolseat.

in

operation,

control

pedals.

tube

interconnect

An

rudder

and

The

AIRCRAFT

MODEL

AND

MAINTENANCE

series

Theall-

frame

skins,

have

slruc-

skins

controi

con-

night

brakes

toe

that

brakes

rud-

The

nose

is

Fully

wing

stabilizer

vertically

steerable

a

hydraulic

Gear

Dosi-

gear

standard

prcloading

over-center

properly

in

the

rctrac-

is

when

the

inch

out

The,

up.

manual

the

ex-

actuatar

gear

operated

All

night

using

surfaces

Formica

alignment

spring

systems

standard

CORPORATION

M20L

MANUAL

co-pilot’s

t’i-m

5-00-03

Wing

controlled

a

switch

5-00-04

1.

trol

two

voltage

on

batteries.

rage

ciator

breaker/switches

and

electrical

landing

lion

system,

starter,

manual

rudder

sets

system

WING

flaps

by

the

on

ELECTRIC

The

master

electrical

the

70

amp,

regulators,

The

protective

light.

equipment

equipment

lights,

interior

lights,

three

electric

an

extension

the

are

a

center

28

alternator

relay

Circuit

two

electric

pedals

stabilizer

FLAP

electrically

spring

console.

switch

power

volt

alternators

and

two

and

protect

from

includes:

100

lights,

fuel

gear

override

are

SYSTEM

loaded

POWER

and

system,

24

system

an

overvoltage

breakers

the

overloads.

watt

gear

Dumps,

retraction

and

removable.

of

angle

actuated

"up-off-down"

SYSTEM

power

comprised

w/

volt

22

has

an

electrical

two

taxi

lights,

and

stall

an

system

electric

an

The

attack.

and

are

con-

relay

integrated

AMP

HR

overvol-

annun-

circuit

or

wiring

Standard

100

watt

naviga-

warning

electric

with

flap

of

System.

5-00-05

All

night

night

pilot’s

pressure

instrument

air

pickup

cone)

at-

in

to

nale

center

come

on.

the

on

type

the

release.

will

5-00-06

VENTILATING

Th,

cabin

the

,,rr,i~,d

temperature.

duct

defros;s

INSTRUMENTS

instruments

panel.

panel.

to

that

static

console.

when

on

Dimming

center

switches;

desired

Push

dim.

CABIN

heater

heal

system

the

Engine

The

operate

static

pressure

tone

ports

to

open

source

the

controled

is

console.

push

illumination

bottom

muff

encasing

source.

with

Air

nozzles

to

windshield.

in

are

instruments

pitot

the

airspeed

on

the

atmosphere.

control

instrument

The

Navigation

They

of

top

of

HEATING

SYSTEMS

Hot

ambient

routed

from

at

the

system

system

each

is

by

switch

is

switch

exhaust

the

air

air

the

provided

shock-mounted

are

provides

indicator.

has

two

side

the

of

An

panel

are

lights

switches

are

momentary

hold

and

obtained,

and

the

system

the

from

controls

main

the

windshield

in

The

static

~ail-

altcr-

on

lights

turned

located

until

then

lights

heater

cabin

healer

base

the

air

the

is

5-(K)-(H)

0-00-07

Fuel

The

in

the

Vents

at

tank

vent

drains

sump

tank.

The

in

the

removing

by

fuel

quantity

in

series

engine

The

Battery

pilot’s

aircraft

dication

fuel

now

The

Master

between

fuel

quantity

Optional

partial

FUEL

svstcm

for;vard,

the

aft,

through

are

three

below

belly

the

transmitters

fuel

to

gauges.

switches

engine;

will

and

Switch,

the

two

indicating

visual

activate

be

power

of

panel,

fueling

SYSTEM

has

scaled,

inboard

outboard

the

the

at

electric

the

fiberglass

quantity

however

activated

meters.

left

Battery

sight

wing

SERVICE

integral

section

top

lower

wing

lowest

fuel

cabin.

belly

in

each

gauges

(L

all

circuity

instrumentation

no

except

sideofthe

Switches,

systems.

gauges

tanks

on

MOONEY

of

corner

surface.

point

pumps

Access

fairing.

tank

(L

R),

available

are

aircraft.

AIRCRAFZT

MODEL

AND

tanks

wing

each

wing.

each

of

Fuel

each

in

located

are

is

gained

Two

wired

are

in

R)

side

left

to

start

tachometer,

panel

pilot’s

turns

on

CORPORATION

M20L

MAINTENANCE

A

tank

below

It

ment

not

for

manufactures

the

of

the

in-

the

for

directives.

The

to

that

without

"ON

MANUAL

fuel

low

is

activated

2

U2

is

recommended

of

components

than

later

that

component

specified

a

component,

the

component

requiring

CONDITION"

replaced

performance

warning

gallons.

TIME

the

service

overhaul

overhauled

or

annunciator

when

usable

Fuel

UMIFCObAPONEN~s

overhaul

that

shoufd

specified

do

not

will

maintenance.

NOTE

Items

reveals

condition.

be

a

periodofoperation

in

data

limits,

constitute

reach

are

when

an

accordance

or

that

to

inspection

unserviceable

or

time

for

light

quantity

or

each

goes

replace-

accomplished

with

airworthiness

if

applicable

a

guarantee

limit

time

be

repaired,

or

5-00-07

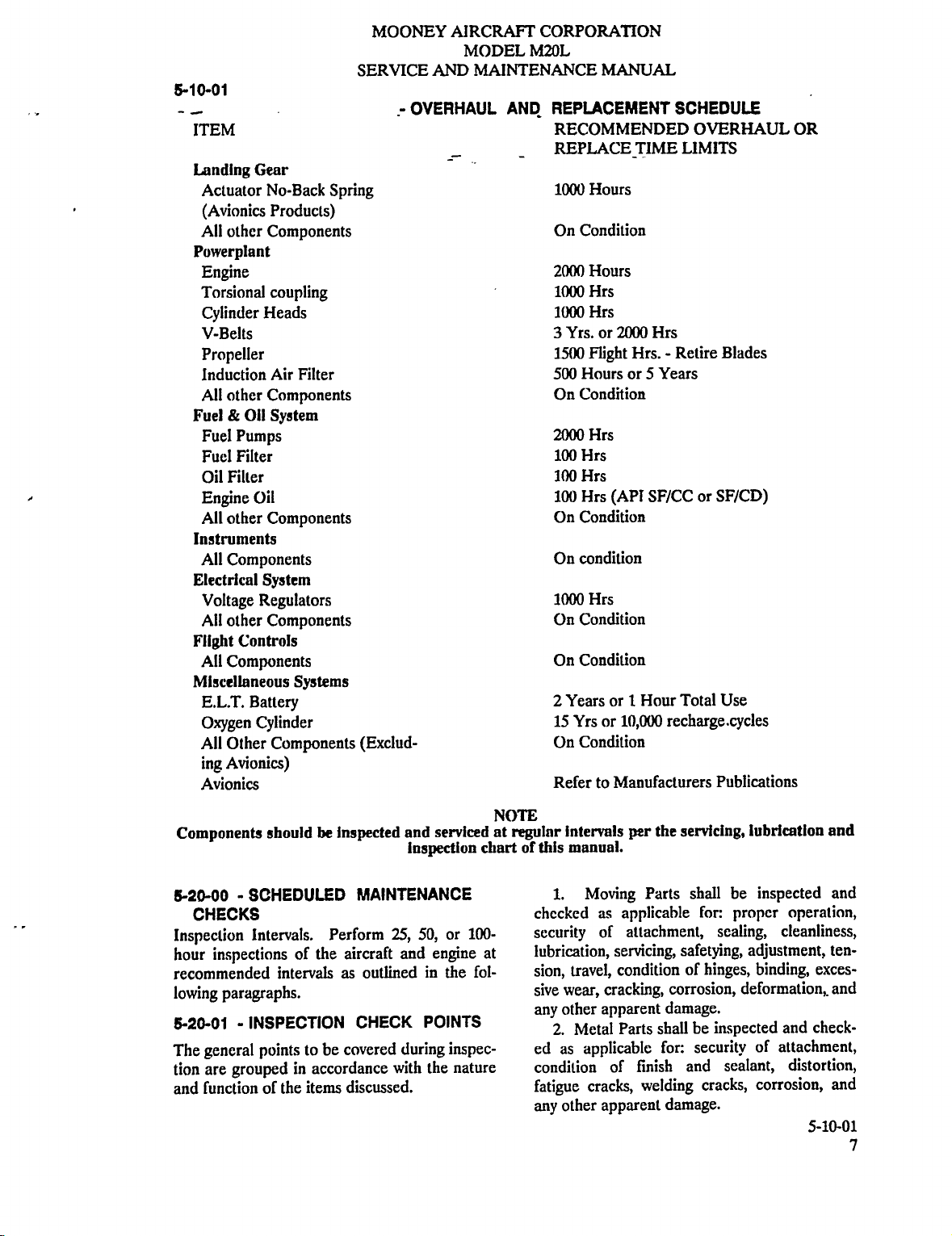

b10-01

ITEM

Landing

Actuator

(Avionics

All

Powerplant

Engine

Torsional

Cylinder

V-Belts

Propeller

Induction

All

Fuel

Fuel

Fuel

Oil

Engine

All

Instruments

All

Electrical

Voltage

All

Flight

All

Miscellaneous

E.L.T.

Oxygen

All

ing

Avionics

Gear

No-Back

Products)

other

Components

coupling

Heads

Filter

Air

other

Components

Oil

System

Pumps

Filter

Filer

Oil

other

Components

Components

System

Regulators

other

Components

Controls

Components

Systems

Battery

Cylinder

Other

Components

Avionics)

SERVICE

Spring

(Exclud-

MOONEY

OVERHAUL

AIRCRAFT

MODEL

AND

CORPORATION

M20L

MAINTENANCE

AN9

MANUAL

REPLACEMENT

RECOMMENDED

Hours

Hours

Hrs

Hrs

Hrs.

Flight

Hrs

(API

Hrs

1

or

or

10,000

Manufacturers

to

TIME

REPLACE

1000

Condition

On

2000

1000

1000

Yrs.or2000

3

1500

Hoursor5

500

Condition

On

2000

100

Hrs

Hrs

100

Hrs

100

Condition

On

condition

On

1000

Condition

On

Condition

On

2

Years

15

Yrs

Condition

On

Refer

SCHEDULE

OVERHAUL

LIMITS

Hrs

Retire

Years

SF/CC

Hour

or

Total

recharge.cycles

OR

Blades

SF/CD)

Use

Publications

Components

&2M)~

-SCHEDULED

CHECKS

Inspection

hour

inspections

recommended

lowing

paragraphs.

b20-dl

The

tion

and

-INSPECTION

general

are

grouped

function

should

Intervals.

intervals

points

ofthe

be

the

of

be

to

accordance

in

items

Inspected

MAINTENANCE

Perform

aircraft

outlined

as

CHECK

covered

discussed.

and

inspection

25,50,

and

in

POINTS

during

with

the

serviced

or

engine

the

inspec-

nature

100-

fol-

chart

at

NOTE

at

regular

intervals

of

this

1.

checked

security

lubrication,

sion,

sive

wear,

other

any

2.

ed

as

condition

fatigue

other

any

manual.

Moving

as

of

travel,

cracking,

apparent

Metal

applicable

of

cracks,

apparent

the

per

Parts

applicable

attachment,

servicing,

condition

damage.

shall

Parts

for:

f~ish

welding

damage.

servicing,

shall

for:

sealing,

safetying,

of

hinges,

corrosion,

be

inspected

security

and

cracks,

lubrication

be

inspected

proper

adjustment,

binding,

deformation,

of

seLant,

corrosion,

and

and

operation,

cleanliness,

ten-

exces-

and

and

check-

attachment,

aistortion,

and

5-10-01

3.

Fuel,

air,

-shall-be

hoses

cracks,

chaffing,

dents,

improperbendradius,

stallation.

conditions

fuel

and

hydraulic

between

qued

tions

linesshall

systems

25

to

blast

on

be

4.

Pipe

procedures.

Oxygen

Lines

compound

threads

assemblies

oxygen.

sparingly

fitting

of

The

to

only.

oil

inspected

kinks,

Replace

exist.

inch

pounds.

tubes,

torqued

Threads

Lubricate

Use

Tenon

or

valves,

which

thread

first

the

and

hydraulic

deterioration,

correct

or

Hose

clamp

systems

the

and

air

15

to

Tightening

pipe

only

thread

connectors,

might

compound

three

MOONEY

SERVICE

as

between

engine

Hose

ducts,

inch

threads

MIL-T-5542

come

threads

AND

lines

oil

applicable

obstruction,

andinsecure

if

any

installations

systems

shall

clamp

drain

pounds.

and

as

seal

fittings,

in

contact

be

must

of

AIRCRAFT

MODEL

MAINTENANCE

and

for:

of

these

be

tor-

installa-

and

vent

torque

follows:

thread

tape

Darts

with

applied

mail

the

CORPORATION

M20L

MANUAL

the

should

with

lubiicant,

frttings

Threads

istobe

outside

of

oil,

Air,

or

and

Use

threaded

No

compound

sleeves

trcme

in-

on

or

contamination

_

tenon

Fuel,

Thread

only.

threads,

Engine

lubricate

or~on

care

tape

Hydraulic,

Lube*

Apply

sparingly

Fittings

Tapered

used

of

the

be

exercised

the

thread

or

grease

Lines

Oil

equivalent

omitting

carefully.

aircraft

only

directlytoengine.

Tenon

Use

on

tube

to

compound

other

male

on

the

the

coupling

dares.

prevent

lubricant.

"Parker

Use

first

engine

Threadseal

Ex-

the

or

fittings

two

oil

to

Tape.

on

or

correctly

backoff.

full

turn

disconnected

Continue

(1)

positioned

If

(2)

more.

I1

leaks

(3)

and

leaks

to

tighten

but

are

detected,

persist,

rejected;

do

the

until

not

parts

replace

overrun

tighten

should

with

components.

fitting

is

or

one

be

new

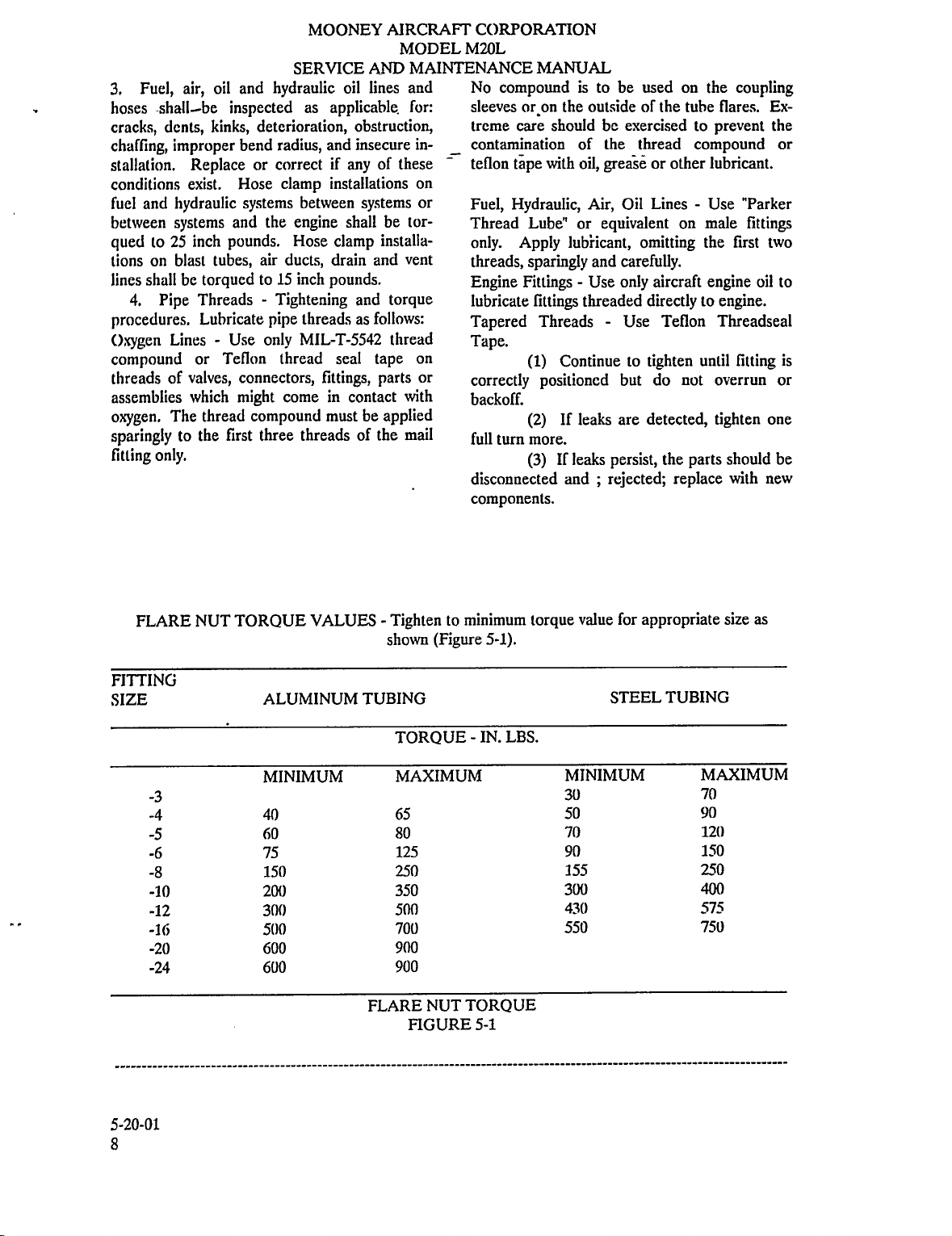

FLARE

FITTINCi

SIZE

-3

-4

-5

-6

-8

-30

-12

-20

-24

NUT

TORQUE

ALUMINUM

MINIMUM

4()

60

75

150

200

300

500

600

600

VALUES

Tighten

shown

TUBING

TORQUE-

500

FLARE

(Figure

MAXIMUM

65

80

125

250

350

700

900

900

NUT

FIGURE

minimum

to

TORQUE

IN.

5-1

5-1).

LBS.

torque

value

MINIMUM

30

50

70

90

155

300

430

550

for

appropriate

STEEL

TUBING

size

MAXIMUM

70

90

120

150

250

400

575

750

as

5-20-01

Electrical

5.

-plicable

minals;

secure

other

Bolts

Ci.

checked

proper

stripping

is

class

thread

The

torque

for:

chaffed,

installation;

apparent

and

for:

torque,

----------------------’---"""""""""""--"""""-""’~""I"""""""""""""""""""

Failure

the

of

intended

stripping

valuetobe

1)

2)

3)

4)

5)

wiring

loose,

broken,

heal

damage.

nuts

fretting,

(Figure

of

threaded

nut

and/or

to

provide

occurring.

Material

Parent

Whether

Whether

The

depth

MOONEY

SERVICE

checked

be

shall

worn

or

insulation;

corroded,

or

deterioration;_and

in

critical

wear,

5-2)

set

of

material

the

the

of

and

fasteners

bolts

an

for

the

screw

screw

the

areas

damage,

safetying.

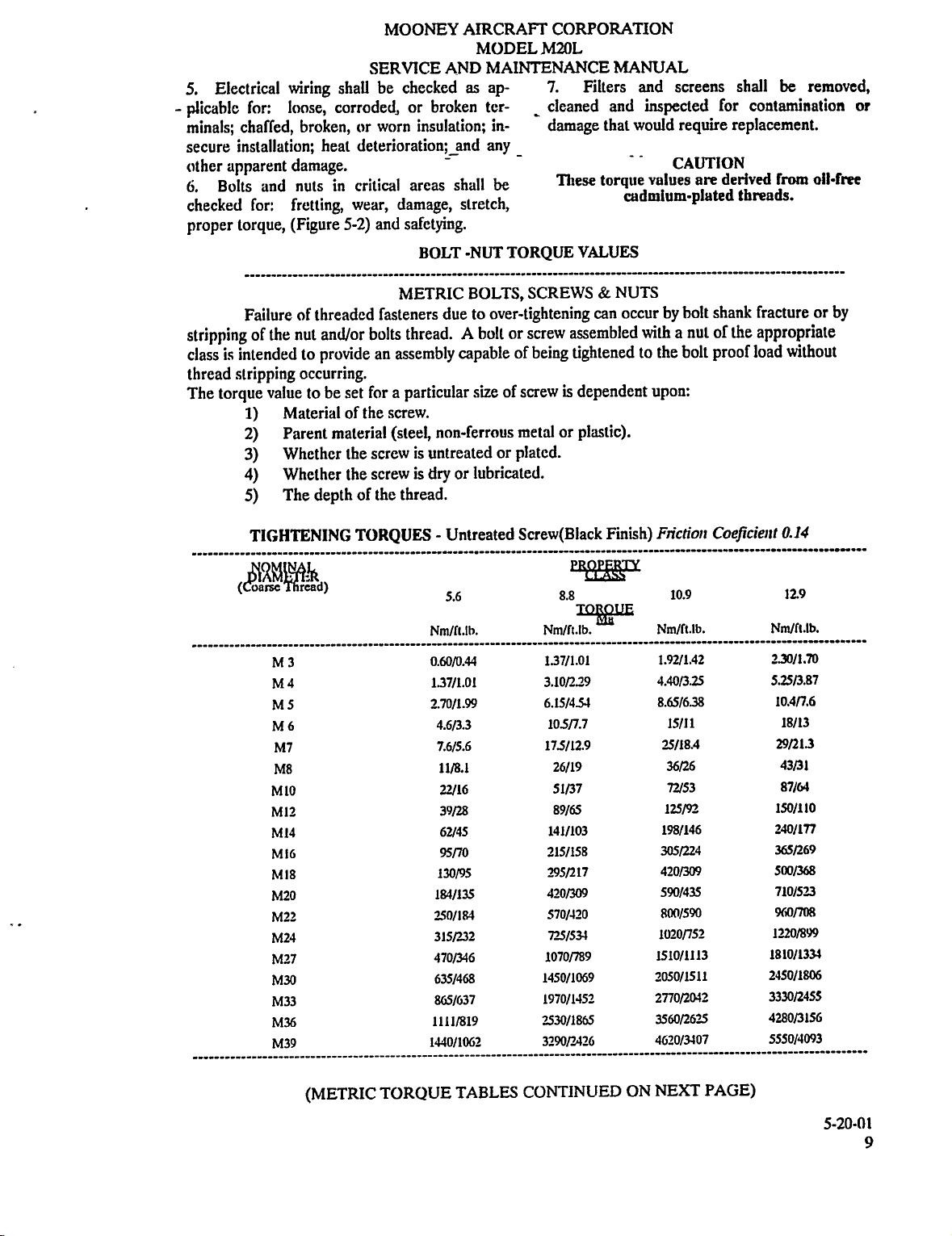

BOLT

METRIC

thread.

assembly

a

particular

screw.

(sleel,

is

is

thread.

AIRCRAFT

AND

as

broken

shall

stretch,

-NUT

BOLTS,

due

to

A

capable

non-ferrous

untreated

or

dry

CORPORATION

MODEL

M20L

MAINTENANCE

ap-

ter-

in-

7.

cleaned

_

damage

any

be

TORQUE

SCREWS

over-tightening

bolt

size

lubricated.

or

of

or

screw

of

being

screw

metal

plated.

Filters

These

VALUES

can

assembled

tightened

is

dependent

or

plastic).

MANUAL

and

and

inspected

would

that

torque

values

cadmium-plated

NUTS

occur

by

with

the

to

upon:

screens

require

CAUTION

are

shank

bolt

of

nut

a

bolt

proof

shall

be

for

contamination

replacement.

derived

Crom

threads.

fracture

the

appropriate

load

removed,

oil´•froe

or

without

or

by

TIGHTENING

MJ

M4

M5

M6

M7

M8

MtO

M12

M14

Mlb

Mts

M20

M22

M24

M27

M30

M33

M36

M39

TORQUES

Untreated

5.6

Nm/h.lh.

0.60/0~44

137/1.01

2.70/1.99

4.6/3.3

7.6/5.6

11/8.1

2/16

39/28

6U45

95n0

130195

184/135

250/184

3151~’J2

470/416

635/468

865/637

1111/819

1440/1062

Screw(Black

eB8e~tPL

8.8

~YE

Nm/Tt.lb.

1J7/1.01

3.10/2~9

6.15/451

10~5/7.7

175/12.9

26/19

51/37

89/65

141/103

3151158

295/217

420/309

570/-120

71J/SU

10701789

1450/1069

1970/165’

7~30/1865

3190PA2~

Finish)

109

Nm/Tt.lb.

1.92/1.42

4.40/335

8.65/638

15/11

25/18.4

36R6

7US3

125/92

198/146

3051225

4201309

590/435

80(1/590

10201752

1510/1113

205011511

2770/2032

3560/2625

4620/5107

O.f4

129

Nm/n.lb.

2~j0/1.70

525/3.87

10.4n.a

18/13

t9/213

43131

87/61

150/110

240/177

3651269

5001368

710/523

9(41/M8

1220/899

1810/1331

2350/1806

33UM2455

4280/3156

5550/4093

(METRIC

TOROUE

TABLES

CONTINUED

ON

NEXT

PAGE)

5-20-Q1

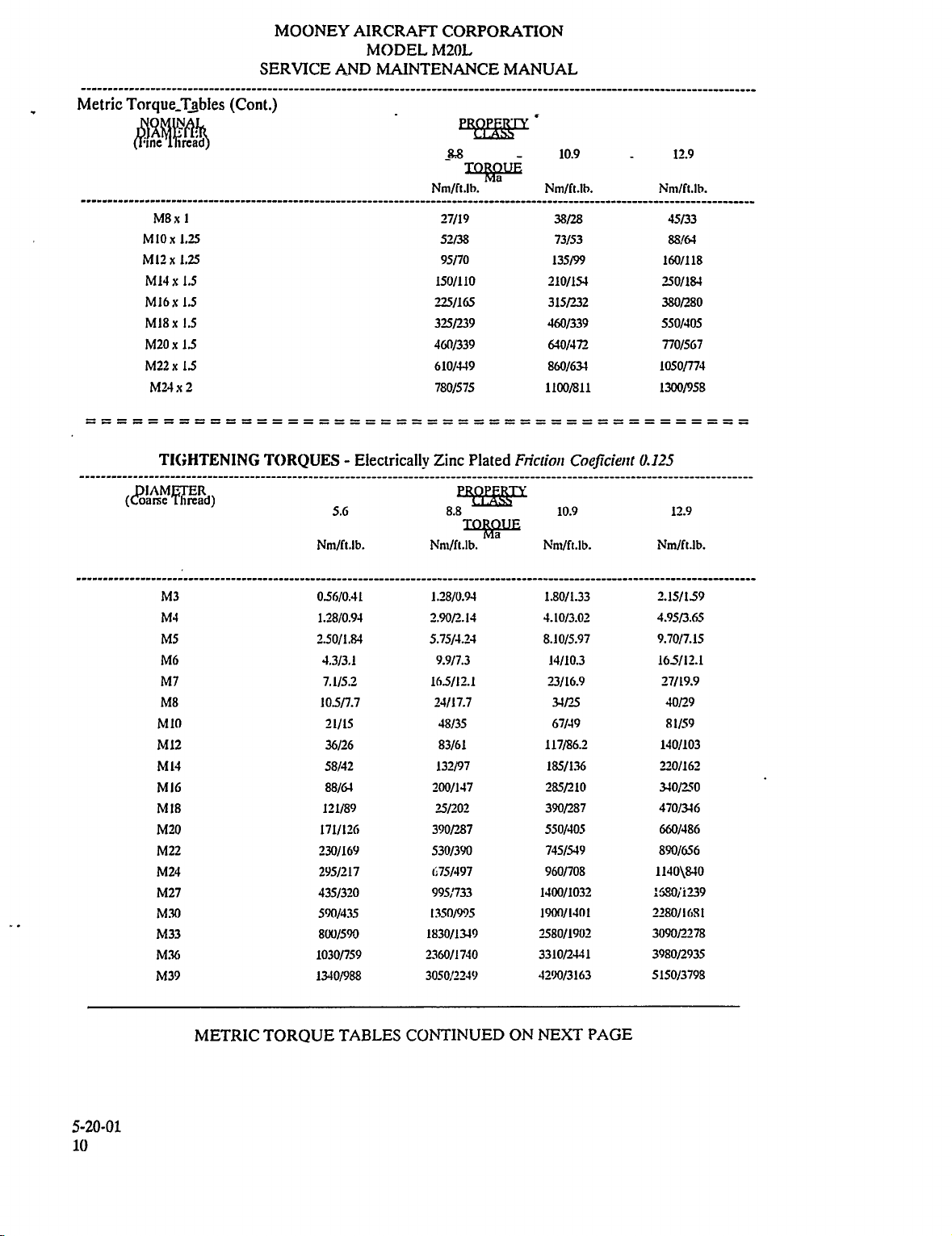

MOONEY

SERVICE

AIRCRA~T

AND

MODEL

MAINTENANCE

CORPORATION

M20L

MANUAL

Metric

Torque_T~bies

1

M8x

10

M

1.25

x

1.25

M1Zx

1.5

M1Jx

1J

M16x

1.5

M18x

1J

M20

x

15

M22

x

M2Jx2

TI(;HTENINC

(Con(.)

T<)RQUES

Nm/lt.lb.

Electrical!v

5.6

8;8

Nm/ft.lh.

27/19

52/38

95/70

150/110

225/165

325P-39

460/339

610/419

780/575

Zinc

Plated

8.8

’Laaf~LUE

10.9

Nm/ft.lh.

38/28

73/53

135/99

210/151

315M2

460M9

~O/J71

860/631

11001811

Fricrion

Coefici~tt

10.9 12.9

n’mlft.lb.

12.9

NmlTt.lh.

4sm

88/M

160/118

250/1&1

380/280

SS0/J05

nO/567

losom4

1300/958

0.~25

Nm/ft.lb.

M3

MJ

M5

M6

M7

M8

M10

M12

MLJ

M16

Mis

M70

M22

MW

M27

M.30

M33

M36

M39

METRIC

TORQUE

056/0.41

1.28/0.93

2.50/1.&2

4.3/3.1

7.1/5.7

105/7.7

21/15

36/26

58/42

88/W

121/89

171/126

230/169

295/217

435/320

590/435

800/590

1030/759

13´•10/988

TABLES

1.28/0.9´•1

2.90/2.14

5.75/4.24

9.9/7.3

16J/12.1

2´•1/17.7

48/35

83/61

132/97

200/147

25/202

3~0P-87

530/390

(’,75/497

995:733

1.150/9~5

7360/17´•10

3050!1239

CONTINUED

1.80/1.33

4.

ION.O,

8.10/5.97 9.70/7.15

14/10.3

23/16.9

31/15

67/19

117/86.2

185/1.16

285~210

390/287

550/405

745/559

960/708

1400/1031

1900/1401

1580/1902

3310/2541

4290/3163

ON

NEXT

PAGE

2.15/159

4.95/3.65

165/12.1

27/19.9

40r,9

81/59

140/103

220/165

350r-(0

470/316

660/486

890/656

1140\810

:~0ii239

1180/1651

3090/2278

3980~2935

5150/3798

5-20´•01

10

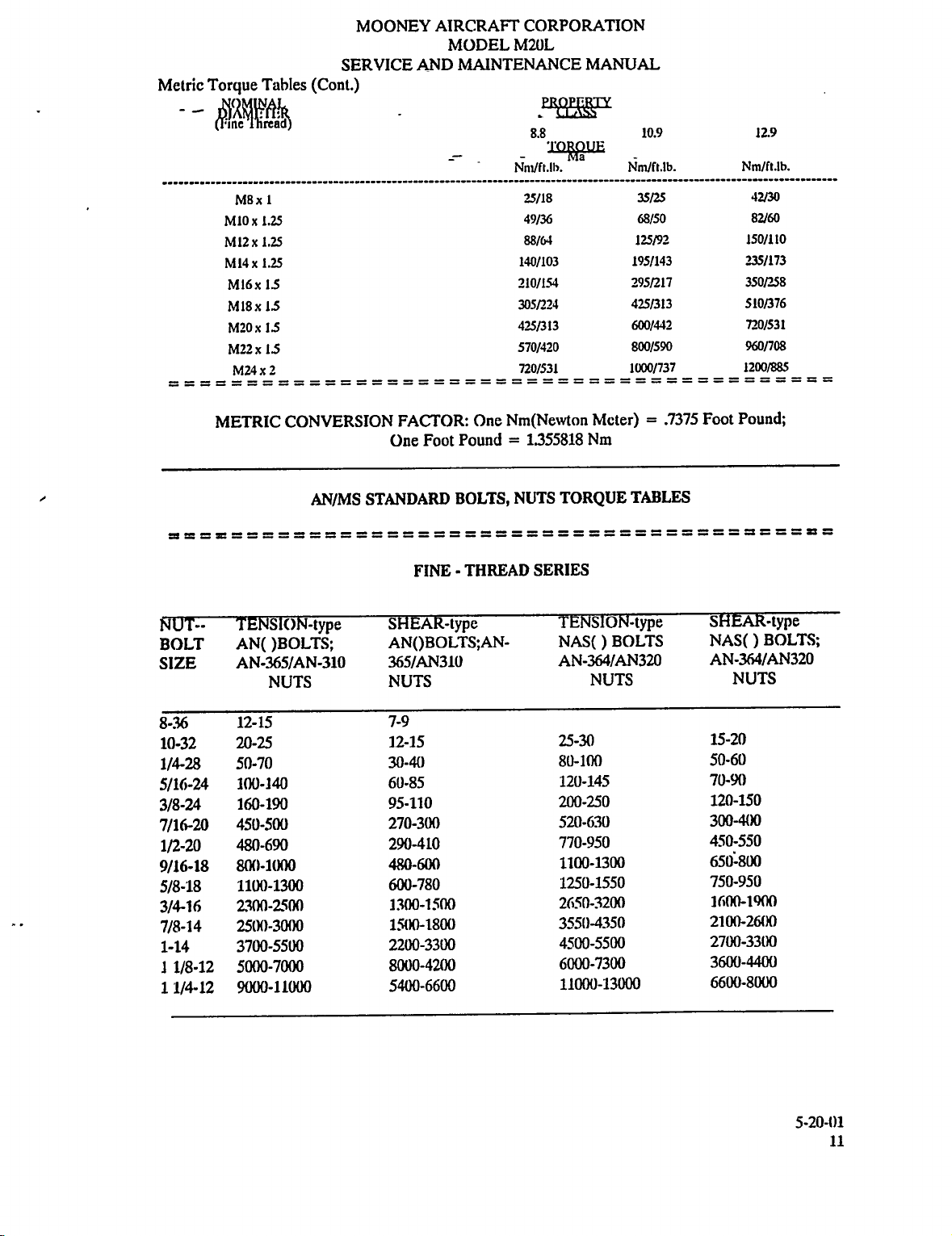

Metric

Torque

Tables

SERVICE

(Conl.)

MOONEY

AIRCRAFI~

AND

MODEL

MAINTENANCE

CORPORATION

MWL

MANUAL

MBx

M10

M12x1.25

M14x

M16x

M1Bx

M20

M22

M2~1x2

METRIC

1

1.25

x

1.25

IJ

15

1J

x

IS

x

CONVERSION

ii--------------------"-------

AN/MS

FACTOR:

One

STANDARD

FINE

Foot

One

Pound

BOLTS,

THREAD

8.8

Nn~fl.lb.

25/18

49/36

881(rl

140/103

3101141

30S~ZJ

42snlJ

570/420

720/531

Nm(Newton

1355818

NUTS

TORQUE

SERIES

Meter)

Nm

10~9

Nmm.lb.

35/25

68/50

125192

195/143

425/313

600/4´•12

800/590

1000/737

TABLES

.7375

Foot

129

Nm/Tt.lb.

42/30

8U60

150/110

2351173

350PS8

510/376

71,0/531

960/708

1200/885

Pound;

NUT--

BOLT

SIZE

8-.76

1032

1/4-28

5/1(,-24

3/8-24

7/16-20

1/2-20

9/16-18

5/8-18

3/4-16

7/8-14

1-14

11/8-12

11/4-12

TENS1()N-type

AN(

)BOLTS;

AN-365/AN-310

NUTS

12-15

20-25

50-70

100-140

160-190

450-500

480-690

80()-1000

1100-1300

2UK)-Zs(K)

250()-3000

3700-5500

5000-7000

L000

9000-1

SMEAR-type

AN()BOLTS;AN-

365/AN310

NUTS

7-9

12-15

30-40

60-85

95-110

270-300

290-410

480-600

600-780

1300-1500

15(8)-1800

2200-3300

8000-4200

5400-6600

TENSION-type

NAS()

AN-364/AN320

25-30

80-100

120-145

200-250

520-630

770-950

1100-1300

1250-1550

2(,503200

35511-4350

4,500-5500

6000-7300

11000-13000

BOLTS

NUTS

SMEAR-type

NAS()

AN-364/AN320

15-20

50-60

70-9(1

120-150

300-4110

4,50-550

BOLTS;

NUTS

650:800

750-950

1600-1900

2100-26(81

2700-3300

3600-4400

6600-8000

5-20-1)1

11

MOONEY

SERVICE

AIRCRAFT

AND

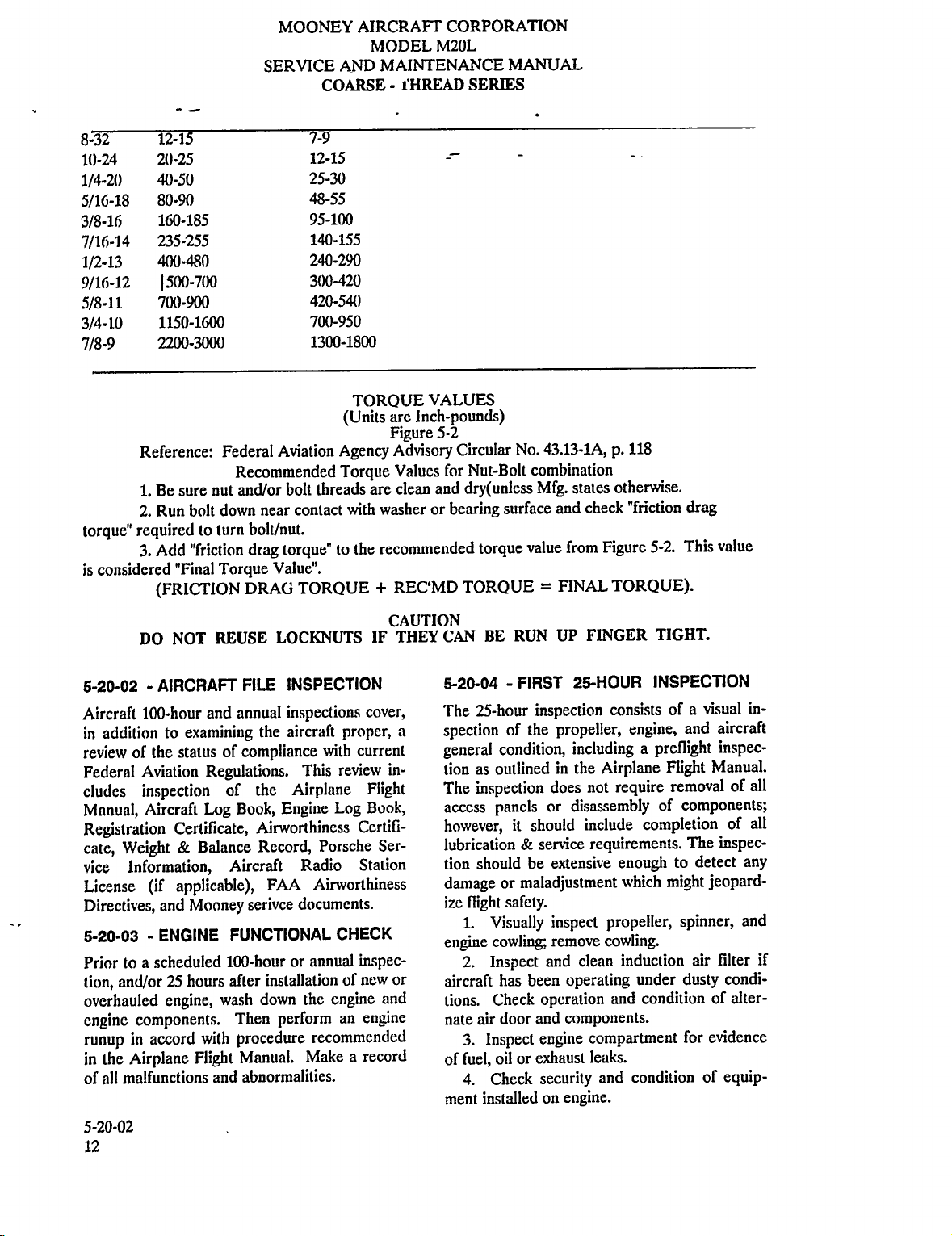

COARSE

MODEL

MAINTENANCE

M20L

~HREAD

CORPORATION

MANUAL

SERIES

8132

10-24

3/4-20

5/16-18

3/8-16

1/2-13

5/8-11

10

3/4-

7/8-9

torque"

considered

is

12-15

20-25

40-50

80-90

160-185

235-255

41)(3-480

1500-700

70(1-900

1150-1600

2200-3000

Reference:

Be

1.

sure

Run

2.

required

Add

3.

"Final

(FRICTION

nut

bolt

to

"friction

Federal

Recommended

and/or

down

near

bolt/nut.

turn

drag

Torque

DRAG

Aviation

bolt

contact

torque"

Value".

TORQUE

7-9

12-15

25-30

48-55

95-100

140-155

240-290

3(K)-420

420-540

700-950

1300-1800

TORQUE

(Units

Agency

Torque

threads

with

the

to

VALUES

are

inch-pounds)

Figure

Advisory

Values

clean

are

washer

recommended

REC’MD

5-2

for

and

or

bearing

Circular

No.

Nut-Bolt

dry(unless

surface

torque

TORQUE

43.13-1A,

combination

states

Mfg.

and

from

value

FINAL

p.

otherwise.

check

Figure

TORQUE).

118

"friction

5-2.

drag

This

value

DO

6-20-02

addition

of

100-hour

the

Aviation

inspection

Aircraft

Aircraft

in

review

Federal

eludes

Manual,

Registration

Weight

cate,

vice

Information,

License

(if

Directives,

6-20-03

Prior

Lion,

overhauled

engine

runup

the

in

of

all

scheduled

to

a

and/or

components.

accord

in

Airplane

malfunctions

NOT

AIRCRAFT

and

to

examining

status

Regulations.

Log

Certificate,

Balance

applicable),

and

Mooney

ENGINE

hours

25

engine,

with

Flight

REUSE

FILE

annual

the

of

compliance

the

of

Book,

Airworthiness

Record,

Aircraft

serivce

FUNCTIONAL

100-hour

alter

down

wash

Then

procedure

Manual.

abnormalities.

and

LOCKNUTS

INSPECTION

inspections

aircraft

This

Airplane

Engine

Radio

Airworthiness

FAA

documents.

annual

or

installation

the

perform

recommended

Make

proper,

with

review

Log

Porsche

CHECK

of

engine

an

a

CAUTION

1F

cover,

current

in-

Flight

Book,

Certifi-

Ser-

Station

inspec-

new

and

engine

record

THEY

a

or

BE

CAN

5-20-04

25-hour

The

spection

general

lion

as

The

inspection

access

however,

lubrication

should

lion

damage

ize

flight

1.

engine

2.

aircraft

Lions.

air

nate

3.

Inspect

of

fuel,

4.

installed

ment

RUN

FIRST

inspection

of

the

condition,

outlined

panels

or

should

it

service

8r

be

or

maladjustment

safety.

Visually

cowling;

has

door

and

been

operation

and

Inspect

Check

engine

exhaust

oil

or

Check

security

on

FINGER

UP

25´•HOUR

propeller,

including

in

the

Airplane

does

not

disassembly

include

requirements.

extensive

inspect

remove

clean

operating

components.

compartment

leaks.

and

engine.

TIGHT.

INSPECTION

consists

engine,

a

preflight

require

of

completion

enough

which

propeller,

cowling.

induction

under

condition

and

condition

visual

of

a

and

Manual.

Flight

removal

components;

The

detect

to

jeopard-

might

spinner,

air

dusty

olaiter-

for

evidence

of

in-

aircraft

inspec-

of

all

all

of

inspec-

any

and

filter

condi-

equip-

if

5-20-02

5.

Inspect

exttmal

tcntion

6.

Inspect

cracks,

ing,

7.

Check

sive

freeplay,

8.

sible

obstructions.

I).

damage

10.

bolts,

screws,

Check

II.

5-20-05

The

50-hour

mcnts

necessary

or

fairings.

A.

muffler

looseness.

B.

for

nuts

C.

security,

D.

freedom

E.

full

travel,

F.

security

or

damage.

G.

check

operation

paragraph

2.

Propeller.

A.

general

B.

Repair

Cabin.

3.

A.

trol

systems

level.

B.

operation

ly).

C.

damage,

evidence

to

scratches

or

control

or

Check

Inspect

and

security.

Inspect

etc.

and

-80-HOUR

for

the

removal

Inspect

systems

Check

securi~y.

Check

Check

from

Check

freedom

Visually

of

connections

Visually

7L-62-0()).

Check

condition,

Inspect

to

prior

Check

for

Check

and

travel

Check

proper

fuselage,

ofdamage.

or

windshields

scratches.

systems

damage.

and

pilot

Landing

aircraft

service

INSPECTION

inspection

25-hour

of

engine

for

spark

plug

cooling

baffles

cracks.

engine

of

movement,

check

inspect

of

alternate-air

propeller

looseness,

blades

next

night.

brake

proper

trim

system

(Evianually

cabin

operation,

MOONEY

SERVICE

and

wing

dents.

and

windows

for

static

Gear

exterior

battery.

includes

insyection,

inspection

intake,

evidence

elbows

fan

shroud

for

control

fuel

and

and

evidence

induction

and

and

for

nicks

and

parking

operation

and

and

baggage

and

sealing.

empennage

Pay

particular

binding,

systems

Assemblies

for

all

doors,

exhaust

of

leakage

and

and

security

for

and

oil

air

door

spinner

oil

leakage.

and

brake

indicator

clcctrical-

and

AIRCRAFT

MODEL

AND

MAINTENANCE

for

craz-

exces-

for

pos-

security

require-

the

plus

panels,

and

shielding

belts

Tor

and

operation,

security.

lines

for

of

leakage

system;

(refer

for

cracks.

con-

and

nuid

for

doors

for

for

t;

for

at-

of

or

CORPORATION

M20L

MANUAL

D.

Check

ticollision,

and

extension/retraction

E.

Checkfuel

and

proper

4.

areas,

sion

page

5.

and

tion.

damage

pivot

Main,

operation.

F

Check

Landing

A.

Check

and

B.

Check

aircraft

at

Check

C.

and

proper

Wings.

A.

Check

B.

Check

bellcranks

C.

and

D.

Lubricate

points

Boost

proper

Check

Chart/Diagram

6.

Fuselage

A.

Check

rudder

inspection

5-20-08

pivot

7.

for

B.

points

See

damage

Lubricate

ifnecessary.

Section

and

100-HOUR

ANNUAL)

The

10C)-hour

thoroueh,

aircraft.

the

nage

all

at

li""s

fuselage

placement

he

to

Comply

Notes.

vice

aircraft

searching

Preparation

removal

inspection

systems

(inclucfing

mating

and

included

with

and

Bulletins

conlnrmance

applicable

Specification

Recommended

requirements

paragraphs.

cabin.

landing

and

oxygen

Gear.

tires

inflation.

shock

static

hydraulic

installation.

surfaces

ailerons,

for

naps

proper

if

necessary

the

at

and

Empennage.

stabilizer,

and

5-20-07

service

(Refer

(clr

of

the

fuselage,

doors,

attach.

wing

po;nisj.

special

this

at

applicable

dr

No.

Z(H)-hour

outlined

are

instrument,

light

cycle).

selector

Emergency

system

for

discs

weight.

brakes

and

aileron

damage

and

operation.

controls

(refer

end

of

proper

controls

for

components.

INSPECTION

to

Pig,

annual)

inspection

f;lr

the

cover

hinge,

and

~)peraling

testing

inlen~al

FAA

Mooney

ins~ruclions.

to

2A3

(currcnt

and

position,

(Illumination

valve,

fuel

(if

installed).

cuts,

blisters,

for

proper

for

for

tips

attachments,

and

proper

attachments

and

flight

to

Lubrication

this

Section.

elevators,

attachment.

and

night

repetitive

5-3)

inspection

of

the

inspection

and

wing,

and

bearing

empennage

of

components

when

and

applicable.

plates,

Directives,

Vendor

or

Check

FAA

special

in

inspection

the

an-

and

gascolator,

pumps

wear,

for

worn

exten-

war-

damage.

opera-

for

surface

and

fin,

surface

50

hr.

(or

is

entire

includes

empcn-

litirings

loca-

to

limit

re-

is

AD

Ser-

fclr

AircraTt

revision).

followinp

a

5-20-05

ENGINE

i.

spection,

spinner.

remove

Wash

comparlmenl.

with

cord

Porsche

Manual.

and

fight

the

Engine

To

abnormalities,

after

lest

set-up.

A.

Complete

compression

plugs

spark

exceeds

plug

and

lion

needs

Refer

Refer

for

Propeller

Cicntly

backlash.

inches

spection.

side

the

fly

and

ply

oil

fuel

reinslilll

piler

safely.

Lion.

drained)

lily

Manual)

areas

THEN

Lion.

OIL.

connections

fuel

poorboard,

penetrates

5-20-06

gapping,

be

Lo

Porsche

to

Check

B,

Porsche

to

specific

steps

Check

C.

shaft

move

The

the

at

(;ear

D,

Remove

of

the

propeller,

wheel

gear

the

check

separation

E.

Inspect

leakage.

for

hoses

Drain

F.

drains

cartridge;

Check

CI.

Service

with

of

lubricating

Run

of

engine

refill

DO

H.

Inspect

pump

the

INSPECTION.

engine

down

Perform

procedure

Maintenance

verify

perform

the

check.

if

necessary.

.047

in.,

the

checked

Engine

Valve

Engine

to

backlash

bolts

propeller

backlash

tip.

Box

propeller

use

a

surface

torsional

undue

or

engine

Inspect

condition

oil

and

replace

oil

tank

engine

the

proper

oil.(REF.

engine

tank

oil

USE

NOT

fuel

Tor

security

connections

fuel

and

prewall.

MOONEY

SERVICE

cowling

the

engine

an

engine

recommended

correction

second

a

100-hour

a

Clean

since

differential

and

II

Cap

last

inspection

associated

for

proper

Maintenance

clearance.

Maintenane

accomplish.

on

Propshaft.

are

torqued

blade

should

Torsional

and

gear

duct

hox.

cooling

flashlight

for

wear

coupler

wear.

evidence

for

cooler.

oil

gr

security.

tank

from

with

breather

oil

Remove

new

tank

safely.

type,

Porsche

fc,r

3.0

and

gear

to

proper

AVIATION

injector

condition.

and

inside

supply

Prior

and

and

of

gap

on

200

ignition

check

to

not

from

While

to

visually

and/or

for

Inspect

line

grade,

minutes

box(if

level

and

shroud,

line

AIRCRAFT

M()DEL

AND

the

Lo

propeller

and

engine

in

runup

in

Operators

malfunctions

runup

engine

(hol

engine)

or

replace

most

worn

hr.

inspec-

system

operation.

Manual.

Manual

Verify

in.lbs.

800

to

for

exceed

Coupling

the

rotating

inspect

damage

signs

any

of

fuel

oil

and

engine:

full-pow

cartridge

for

ot,struc-

box(if

lear

and

quan-

Operators

lilt

to

drained).

k,r

opel´•a-

C;RADE

fuel

all

Inspect

under

where

M20L

MAINTENANCE

in-

from

ter.

ac-

the

and

remove

filtings

Be

Balterv

and

Check

strainer,

replace

Inspect

check

ON,engin;OFF.

suction

Use

blow

filter

years

gear

.311

in-

right

of

and

cP(

oil

and

all

line

the

Remove

5

haust/maniroid

manifold

fan

belt

die

The

be

belts

above

pnger

C’heck

more

Refer

hrs).

deiclrmalion,

Check

p’ope’

attachment.

check

it

CORPORATION

MANUAL

Remove

I.

end

each

Release

from

new

on

Install

new

to

sure

Switch

that

verify

fuel

lines

Remove

J.

clean

micron

2

fuel

fuel

system

Remove

K.

opening

compressed

out

cartridge

cartridge;

51H)

or

L.

Inspect

and

M.

damage,

the

belt

in

pairs

lest.

N.

to

to

than

to

and

or

and

Examine

bcit

deviation

Alternator

gently

see

.080

Porsche

Check

heating

Yrs.

for

tension

of

between

Repair

Check

ballle

Check

O.

lubrication.

R.

Inspect

bolts

all

condition.

and

Fuel

of

filter:

retaining

aircraft.

filter.

biter

observe

and

fuel

and

reinstallstrainer.

gr

fuel

lines

with

for

air(no

replace

Hours.

air

induction

induction

clean

500

Hrs).

connections,

muffler

cutst

bv

pushing

span

and

.31

if

either

move

if

the

in.

Engine

distributors

or

replace

barnes

and

sealant.

engine

and

Filter.

remove

ring

new

Using

and

secure

flow

the

Main/Boost

pressure

for

filter

and

inspect

strainers

and

conneclions:pressure

Main/Boost

Filler

Air

and

dirt

more

from

inside/out.

with

ducting

air

Leak

areas.

V-Belts

breaks

the

on

a

using

static

from

inches.

.30

one

backlash

alternator

the

Can

at

play

exceeds

If

it

Maintenance

components.ir

fclr

security,

pt

for

conlrclls

full

travel,

enrrine

rubber

mount

mounts

Remove

Gttings

from

gaskets,

retaining

direction.

fuel

light

leaks.

any

Remove

the

on

fuel

cartridge,

clean

than

filter

new

connections

and

systems

air

filter(replace

check

engine

ea.)

(2

and

wear.

belts

0122.5

force

position

Replace

does

not

inspection:

blade

this

condition

for

cracks,

around

for

and

fuel

lines

from

and

611er

install

ring.

Turn

ON

Dump

out.

goes

gascolator

and

firewall.

pump

check

if

needed.

60

PSI)

Re-install

after

leaks.

for

all

exhaust

on

cooling

Check

mid-

the

in

Lhs.

should

meet

Use

blade.

Tan

is

rip

tolerance

Manual.

(500

required..

holes,

cylinders.

clperalion,

security

cracks:

C~lr

for

security

nl-

to

5

in

at

ex-

the

the

no

of

Check

S.

aad,i~nition

loose

terminals,

harness

tion.

Check

T.

sures.

Manual

conditicln

obstruction.

Lery

neutralize

proper

nators,

for

With

observe

ing

within

an

interact

(Sce

information

U.

Inspect

and

Flush

if

cases

necessary

corrosive

charge

V.

Inspect

dislribu~ors,

securityordamage.

W.

ENGINE

the

cowline.

the

following:

Oil

(1)

and

(2)

the

seconds.

5

Both

pressue

low

output,

Power

(3)

properly.

Both

(4)

pendently.

All

fuel

engine.

Fuel

pressure

Slowly

verify

234;7

Shut

nltings,

Inspect

Remove

fuel

power

exceed

not

leaks,

2.

(5)

the

to

(6)

(7)

and

(8)

loose

X.

PROPELLER

A.

removed).

Check

B.

tion.

Check

C.

damage,

D.

Inspect

and

Check

F.

to

appropriate

angles.

G.

and

nicks.

Inspect

condition.

cracks

Refer

blade

cracks

battery

and

fuel

Porsche

and

batteries

corrosion.

battery

action.

status.

accessory

hoses,

OPERATIONAL

removed

gauge

oil

pressure

alternators

lever

ignition

Dumps

increase

that

RPM.

down

etc.

and

INSPECTION.

security

hub

huh

Repair

high

spinner

cables,

for

burned

pumps

Engine

Section

Check

with

and

systems

is

within

the

propeller

engine

reinstall

spinner

of

bolts

parts

priclr

and

POH/AFM

MOONEY

SERVICE

electrical

condition,

chaffed

or

operation

71-00-50).

and

vent

blast

mount

soda

Check

case,

Brewall

the

start

should

light

should

propeller

Function

operate

limits.

power

check

and

cow)ing.

(if

propeller

for

and

to

low

and

AIRCRAFI~

AND

wiring,

security,

insula-

&--~res-

Maintenance

systems

tubes

and

area

solution

batteries

starter,

and

OLlings

CHECK

engine

a

go

producing

governor

and

supply

to

speed

for

not

already

installa-

blades

flight.

angles.

for

correct

read-

show

should

be

lever

security

next

blade

bulkhead

MODEL

MAINTENANCE

for

for

bat-

to

for

alter-

and

on

inde-

full

does

any

and

for

for

CORPORATION

M20L

MANUAL

Check

H.

interlercnce

obtain

to

TLape

LANDING

3.

-SYSTEM

blisters,

with

AI\Yays

Cycle

A.

new

and/or

B.

INSPECTION.

Check

slippage,

approved

run

checks

replaced

Check

misalignment,

condition

bearings

corrosion.

fluid

f,,

at

Check

C.

Check

D.

level.

Check

E.

leakage,

at

of

250

tit

felt

dents,

spinner

with

correct

tires

least

after

wheels

corrosion,

hour

brakes

hydraulic

hydraulic

securityofanchorage.

Check

F.

engagement

G.

paragraph

H.

damage.

for

Maximum

assembly

Heat

on

1.

adjustment,

J.

sheared

gees

for

lubrication.

Jack

7-10-00.

Check

Check

is

Trented

Check

Check

parking

release.

and

nose

or

ullowable

1/3t

nose

aircraft

nose

inch

main

damage.

Check

K.

bcllcranks,

damage,

cleanliness,

L.

security

of

check

of

overheating

M.

per

landing

pivof~

d~torlion,

lubrication.

and

Check

mounting,

or

Perform

Section

the

damage.

32-30-01.

bulkhead

cylinder.

prop

pt.)

for

excessive

if

S

Landing

tire

and

intervals.

cracks

brake

gear

gear

NOTE

and

proper

necessary.

nying

for

bolt

for

reservoir

brake

as

roil

GEAR

or

Lire

CAUTION

any

before

seals

broken

towing

dent.

Landing

wheel

alignment,

gear

gear

and

bearings

misalignmcnt,

landing

cleanliness,

landing

RETRACTION

inflation,

wear.

Gear

has

been

the

cracks,

failure.

bearings;

warying,

lines

chalin&

system

recommended

cleanliness

for

retraction

pins.

damage

Na

repair

Gear

components.

steering

corrosion,

cleanliness

for

retraction

gear

and

gear

for

correct

(Use~Tenon

cuts,

Replace

Retraction

removed

alrc~an.

distortion,

Check

repack

or

wear

for

proper

hoses

and

and

kinks,

for

proper

in

and

tube

bun-

on

Iq

allt,wed

mechanism

and

or

linkage,

for

wear,

corrosion,

actuator

operational

klr

indication

5-20-06

FUEL

4.

A.

-hhspcct

evidence

when

of

B.

seepage

C.

sediment,

Check

D.

E.

lank

selectic,n,

~)k’F

position.

~Chcck

F.

mounting,

and

lion,

neclions.

pumps.

(i.

mitters

wiring

ness,

for

and

H.

cap

placards,

Check

I.

and

tion´•

replace

01),

5.

A.

corrosion,

dents,

and

cracks,

and

cans(slretched

deteriorated

B.

crazing,

security

C.

corrosion,

scratches,

dents,

points,

play,

lubrication,

travel,

D.

damage,

scratches,

dents,

of

lion

weights,

for

security,

lubrication

lion

comparlmcnl

hinge

hinge

and

E.

damage,

and

F.

Inspect

I-(K)

52-1

security,

SYSTEM

fuel

seepage

Drain

is

Check

water

or

Check