Mooney M20C, M20E, M20F, M20, M22 Service Bulletin

...

SVBJECT:

INSTALLATION

OPERATION

OF

PW\CARO

P/N

/nao-1~7

150010-111

MODELS

TIME

INTRODIICTION:

INSTRL[CTIONS:

EFFECTED:

OF

COMPLIIINCE:

NOTE

M20

(1)

(2)

-1.

Series

M20

On

or

P/N

area

in

full

2.

Location

This

aircraft:

on

Placard

sho~a

this

Locationl

YIILI-V´•II

Locaiions

not

IM22

and

before

150010-111

the

on

view

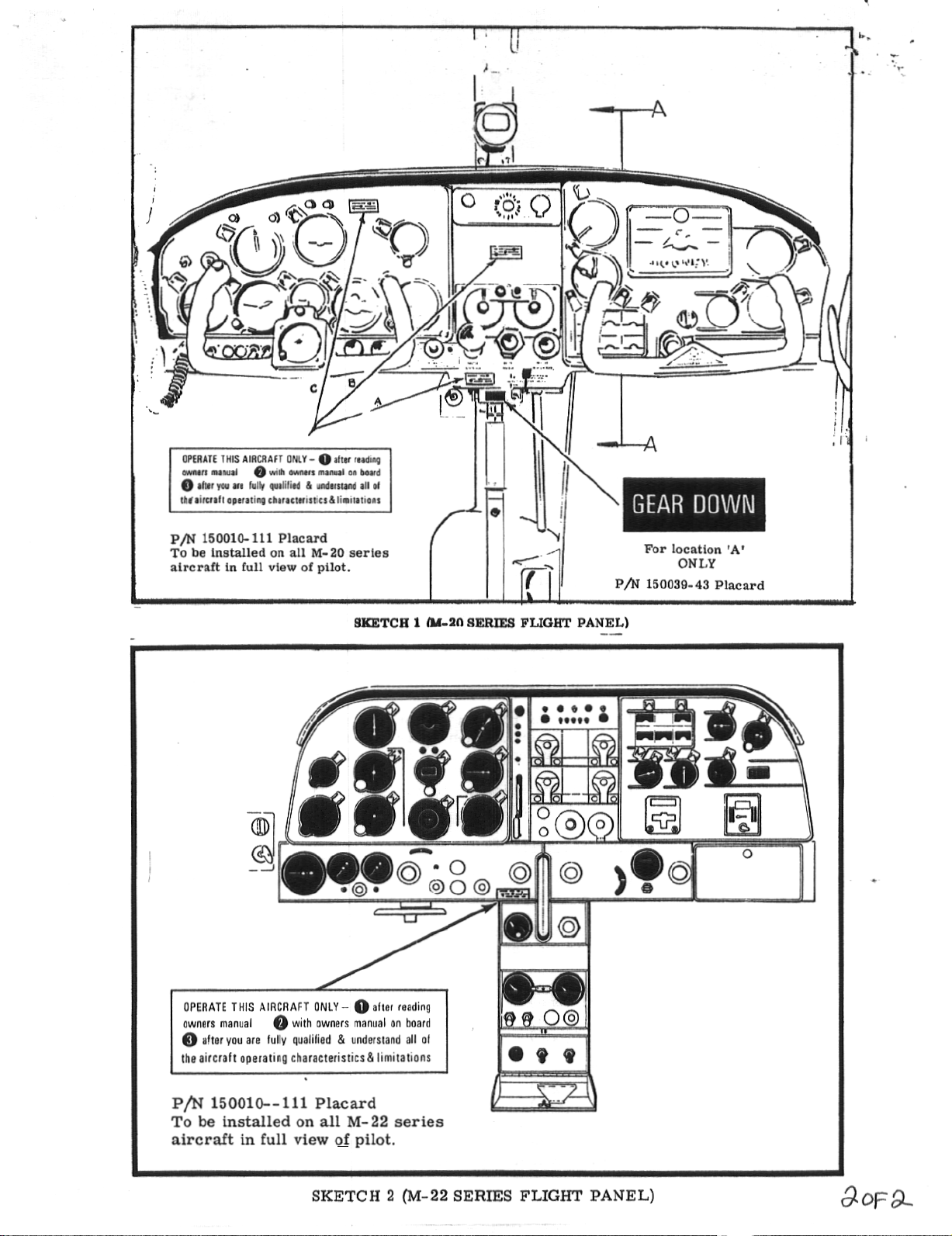

Sketch

Sketch

All

placards

Aircraft

A

the

is

F/I

Sketch

on

recommended

feasible

Series

neX,

flight

of

1-

2

(Shounn

location

1:00:9-b3

B

C

Y

YI

B

and

on

is

the

depicts

depicts

M20C

#200

EZ20E

E70F

1

(Sho~

C

location

Aircraft

100

iiour

a

placard

panel

pilot.

are

self-adhering

on

far

S/Nls

S/N’E

S/M’s

9/N’´•

if

placard

1A’

location.

(optional)

(ret’erence

hlZO

M22

Sketch

adhering

(Gear

on

A.

Inspection

that

series

series

1)

2121

101

i.

101

to

hi´•0002

Ooum)

150010-111

Sketch

are

thru

to

is

shefches

flight

flight

(pressure

order

placard

h?013L

thru

h80001

thru

is

to

1)

for

other

be

panel

panel

Kit

2hO

h70~85

be

is

adhered

shown

sensitive)

No.

150010-111

adhered

adhered

’120

aircraft

1

to

below)

as

per

an

SERVICE

SZRTIICE

BIILLETIN

150010-111

li0019-h3

BlJLLFTIN

,,,,,,.,,I

(L)

M22

Series

(1)

(2)

KIT

Placard

Placard

Stic~eri’(ons

KIT

it

Sticker

P/N

as

If

thi´•

A,

R,

(shorn~

AdilerP

Oxners

Adhere

shorn~

as

Adhere

Ouiner;

1

NO.

lane)

(or,p)

NO.

2

is

150010-111

or

iiircraSt

made

placard

C,

Sketch

on

rticker’’

Manual.

P/I

an

sticker"

Manual.

then

150010-111

Sketch

of

paper

placard.

cannot

it

1)

to

to

is

an

outside

2.

outside

and

be

to

the

placard

has

installed

be

flieht

of

of

same

adhered

front

on

front

panel--;r

M22

size,

recommended

on

to

coier

S/hi’s

cover

desian,

;te

left

full

of

C.70001

of

?I?O

~22

and

locations

of

view

Series

and

Series

wording

line

of

Aircraft

~70002

A-A

pilot.

Aircraf~

I

oFa

~k,

i

09

o

a

onaet

IN´•

M

hr~un

o

Ihllil~lll´•l´•l´•li´•(

150010-111

PJN

Lnsta~led

be

To

drcralt

‘B

´•I(´•01*1.):

oh

:-I

lilt

Il´•Ulrl

ONLI-O´•II´•

II~

~I´•

*lh

Lull

in

rlili´•

Il´•l´•LI´•lllillb

Plpep~

1I1

an

vie.

L

alpllot.

Ua~

M-20

I´•

li´•il´•li´•l.

esrisa

I´•UI´•l

U1

III*

BYLTCB

~ar

locPLLon

ONI.Y

150038-45

P/N

1

nm

aERIE8

PLI(IIP~

PANEL)

’A’

PLpeard

oPrlnrs

awara

8

P/N

To

aircraft

THS

manull

ear

vau

150010--111

installed

be

in

all

I1RCRl\lr

8

st

v

full

s

BO

ONLY-

with

awnsr

a

Placard

all

on

of

view

SKETCH

Oall,~

manuai

und,l.,nl

M-22

pilot.

an

series

2

6’

raaling

bpard

all

(M-22

ol

90~

O

SERIES

´•00

FLIGRI~

o

Q

Q

O

PANEL)

of

a

SUBJECT:

ALTIMETER

INSPECTION

MODELSPI~EC1TED:

~E

INTRODUCTION=

II~STfLUCTIONS:

COMPLIANCE:

OF

~zoc,

~20E,

~20F,

P122,

This

S/N

S/N

S/N

S/N

Bulletin

airpla3le

aftimeter

August

2,

Immedia’;ely,

Evidence

some

to

22-374

to

necessary,

determine

operating

Weston-Garwin

in

malfunction

li~ely

Model

issued

if

To

are

670001-670135

1177,

1283,

1295

660001

670001

for

was

1199,

1286

thru

ihru

and

will

which

purchased

1967.

this

been

has

of

the

exist

in

altimeters,

require

several

on

if

the

properly,

1217,

thru

1308,

660004,

670002

also

apply

Trleston-Garwin

a

between

Service

found

Model

instrument.

all

airplanes

that

testing

Weston-Gar~Jin

accomplish

1288,

670001

Bulletin

this

of

models

1268,

670001

to

an

22-374

Service

the

1273,

thru

any

Model

is

altimeters

Mooney

Model

the

1292,

670062

thru

other

i,

mandatory.

this

Bulletin

1290,

July

accumulation

Since

which

altimeter

of

1277,1281,

1293,

670446

Mooney

22-374

and

1966

of

can

condition

are

equipped

and

airplanes.

22-374

following:

tolerances

cause

is

with

is

being

replacement,

altimeters

a

1)

2)

3)

4)

barometric

Set

field.

agree

plus

Set

(1013.3

Turn

the

pressure

it

pressure

with

or

barometric

the

low

is

possible

minus

mi77;hars)

end

disen,oa,Ped.

pointer

Turn

the

pressure

watch

hand

the

high

for

field

bare

forward

knob

end

by

needle

scale

and

elevation

100

scale

mechanism

stop.

and

to

The

disengagement

fails

for

bare

stop.

alternately

slippage.

check

feet.

and

During

cause

to

During

or"

of

aft

rotate

altimeter

altimeter

altimeter

observe

this

alternately

the

scale

this

pushing

allowing

the

so

movement,

internal

will

as

soas

to

reading.

to

altimeter

to

as

the

to

motion,

and

coincide

for

a

29.92

move

in

order

mechanism

be

obvious

knob

move

again

pulling

tolerance

inches

the

exert

is

turned.

the

slightly

with

It

should

reading.

scale

slight

to

see

to

if

scale

exert

appropriate

of

of

hg

to

if

become

the

to

and

INSTRUCTIONS:

5)

Turn

(1013,3

with

should

move

reading

if

or

then

be

replaced

with

contact

or

repaired.

The

check

formed

the

the

be

in

direct

of

the

the

defective

with

by

barometric

reading

the

same.

Step

reading

altimeter

or

the

required

the

pilot.

and

obtained

relation

2

does

in

is

repaired

altimeters

ground

by

scale

If

Step

this

compare

the

with

not

not

at

until

back

in

Step

pointers

the

agree

1

is

working

an

approved

shall

the

Service

to

this

not

fly

24.42

altimet;er

2.

do

bare

with

within

properly,

VFR

altimeter

Bulletin

inches

The

not,

scale,

the

facility.

only

of

reading

readings

at

all

if

or

final

reading,

tolerances,

ii;

and

in

visual

is

replaced

be

may

hg

times,

the

should

Aircraft

per-

~ZI´•

OON

R~C;SA

-9

i"

dOX

´•1.

I

Zlrz

SUB;IECT:

MODUS/

AFFECTED:

S/N

OF

TIME

COMPLIANCE:

INTRODUCTION:

INSTRUCTIONS:

36

Filler

Fuel

S/N

MZ0C

M22

and

Within

next

Exposure

effect

on

assembly

oftime

period

procedures

Fuel

filler

serviced

be

Refer

to

Caps

2623

Aircraft

25

to

weather.

O’ring

have

when

for

port

cap

occasionally

Figure

(Shaw

and

night

packings

been

this

assemblies

S.B.

Aero),

M20D

ON,

hours,

fuel

fumes,

and

reported

exposed

deterioration.

to

M20-229-1

Inspection

S/N

and

every

seals.

lose

to

these

to

shouldbechecked

prevent

andthe

201

fuel

elements.

hard

gr

100

and

The

their

to

following

and

Adjustment

ON,

hour/annual

possibly

two

resilience

This

open

ALL

M20E,

other

O’rings

and

S.B.

periodically

close

or

procedures

M20F,

inspection

elements

the

on

sealing

intended

is

for

conditions.

M20G,

Shaw

characteristics

to

proper

for

these

thereafter.

have

a

Aero

describe

sealing

inspections

M20K

M20J,

deteriorating

fuel

filler

after

inspection

should

and

cap

a

and

adjustments:

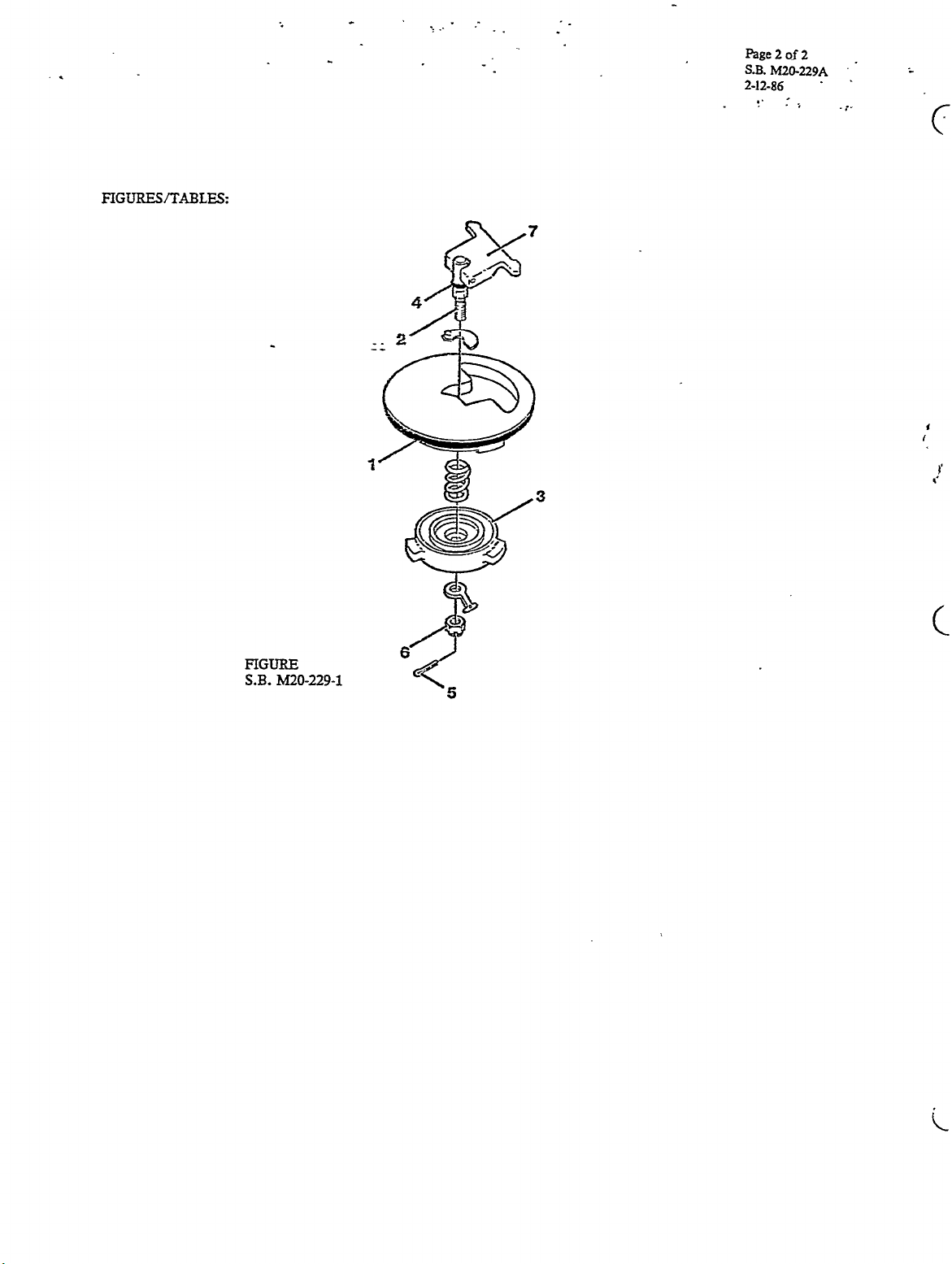

of

i.

TheO’ring

that

petroleum

2.

The

lock

I

binding

;(4)

might

shaft

plate

that

real

(1)

abrasive

cause

or

jelly

(2)

running

shouldbelubricated

(3)

while

opening

this

seals

amur.d

Tri-Flow

through

shaft.

or

the

action

will

closing

cap

the

the

assembb

on

keep

center

seal

or

the

O’ring

of

occasionally

assembly.

cap

should

mating

the

with

cap

be

nange.

soft

housing,

Tri-Flow,

This

kept

and

should

clean

Occasional

pliable.

that

or

also

and

actuated

equivalent,

lubricate

free

lubrication

dirt

the

rotating

to

prevent

the

orgrit

with

O’ring

The

3.

sealing

accomplished

A.

Remove

brittleness.

B.

Adjust

nut

be

cap

C.

Fuel

D.

Connect

pressure.

and

the

capability

the

per

assembly

cap

Remove

tension

on

(6)

opened,

of

threaded

turned

assemblytokeep

rubber

Check

does

should

hose

bubbles.

not

Use

in

tank.

MZOI<

filler

selector

observing

nut

Water

fitting

of

following

shaft

portion

and

for

stop

only

port

can

corrected

each

form

and

(2)

shut

water

beinthe

each

to

fuel

cap

Replace

the

one-half

Higher

aircraft

propped

enter

or

damaged

cap

procedures:

wing

replace

and

rotating

of

shaft

with

from

tank’s

leaks

leak.

pressure

must

WARNING

the

fuel

soon

as

assembly

filler

if

needed.

t2).

hand

pressure

entering

OFF

position

vent

by

O’rings

’’CAUTION"

nd

pou

"NOTE"

have

during

open

tank

through

should

This

cap.

as

possible.

shouldbechecked

and

plate

fuel

inspect

(3)

nut

and

tank.

port

lock

Tighten

priortopressurizing

line.

Apply

if

bubbles

(0.5

psi)

damage

anti-siphon

this

circumference

of

pressure

soaping

ma~

the

(6)

still

only

are

air

the

valve

loose

a

be

O’ring

by

removing

so

cap

provide

observed

pressure

fuel

testing.

periodically.

(1)

assembly

the

one-half

of

tank.

inside

for

cotter

necessary

the

pound

ftlIer

and

This

damage

any

(5)

pin

handle

tanks.

fuel

(1/2

assembly

cap

adjustment

can

(7)

seal

psi)

be

or

from

can

of

air

of

REFERENCE

PARTS

DATA:

LIST:

N/A

NOT

(Parts

Number

Part

MS29513-010

MS29513-338

included

in

kit

order

Description

O’Ring

O’Ring

531-001

if

tcenter)

touter)

cap)

needed).

(for

431-9R

and

Qty.

Required

1

1

FIGURES/TABLES:

Page

SE.

2-12-86

2

of

2

M20-229A

FIGURE

S.B.

M20-229-1

I’

I

Loading...

Loading...