Mooney M20B Service And Maintenance Manual

~SERVICE

OLDWILLWAYNE

nnD

~ANUAL

$84~AINTENANCE

20B

j

a

tai~ooNEv’

iouls’

KERRVILLE,

AIRCRAFT,

SCHREINER

FIELlj

TEXAS

INC.

:~r´•

OLDWILLWAYNE

~´•´•r

"a

:::~L’\I

-.:1-

u*´•

’L´•’*Lr

:j~´•

~.´•:I

´•::´•i(

1.

2~..-

-Ulr

LtT´•C

1

~r

r´•a´•~

’U

i;-

34´•~-

il´•r´•1P´•1LI

mr

´•O

*~-r

L.´•’

F’

~i

:z´•

Ir~

(L´•L

I’

r‘´•,

~.D

c´•

LiP

t---´•:;?

:,y

6:s~

L

:_;~

+LI´•fl..i´•,,li

i

z

~CF’

=r

’’:Uce

I

L..tt~-?

.u,

’~i’’

)Li:.~CIIL

´•3.

~T.:

;~"J

~i:.

(I

::1:

.d

5::´•::

´•´•´•´•´•i:

~’il´•

N

::I;:´•

~r´•-´•

I

~´•;r

lit

I

f.s.

~’’’r

Y;~C-´•i´•tl:l´•i:

1

i

´•r

;:´•Z~’

l-t

~i´•

~´•´•´•´•it´•

;:u~´•´•.\r

:-i.

I,K

.,.1..

j.

1

r~i

~P:i

i´•:

iF~´•

i.,

I;,::i´•:s´•

(j.I

fr

;´•´•´•:9

-:Y´•:´•:´•

L´•:j

´•."-"~´•9

tc~-i

´•1´•~-´•

c´•.´•‘

~1..´•:

r

B

OLDWILLWAYNE

~NTRODUCTION

I.

A.

B.

t‘.

7A8LE

General

Scope

of

Description

Manual

OF

CONTENTS

Page

1

C.

AND

fl.,´•HA~DLING

General

~4.

Access

Ground

1.

HOISTING

2.

LEVELING

MOORING

4.

TOWING

5.

D.

Servicing

EfUEL

1.

LUBE

2.

BRAICE

3.

Lubrication

E.

III,

POWER

A.

B.

.P

rv.

C.

D.

E.

F.

G.

STRUCTURE

´•A.

B.

PLANT

General

Troubleshooting

Engine

Propeller

Engine

Propeller

Adjustments

1.

2.

General

Removal

1.

2.

3.

Installation

C.

1.

2.

3.

CARBURETOR

ENGINE

REMOVALOFWING

REMOVAL

REMOVALOFAaEROr:

INSTALLATION

INSTALLATION

INSTALLATION

SERVICING

Provfsions

Handling

SYSTEM

On

SYSTEM

Removal

Removal

Installation

Installation

IDLING

Wing

of

of

SYSTEM

IDLE

SPEED

Components

WING

OF

Wing

Conrponents

OF

OF

OF

~MMTURE--

FLAP

WING

FLAP

AnLErlN

Page

Page

Page

6

17

24

j

v.

LANDING

A.

B.

C.

D.

E.

F.

GEAR

General

Removal

MAIN

1.

´•NOSE

2.

Removal

MAIN

I.

NOSE

2.

Reassembly

1.

MAIN

2.

NOSE

I.

2.

a.-,d

BRAKE

~HEn

Brake

Lctzolrng

AND

BRAKE

of

Landing

LANDING

GEAR

ar,t!

Disassembly

GEAR

GEAR

and

GEAR

GEAR

Wheel

LINING

ASSEMBLYINSPECTION

Gear

Rigging

Gears

GEARS

Installation

Maintenance

INSPECIION

S’ISTEM

of

Procedure

Shock

of

AE~0

Discs

Larding

REPLACEMEh"P

Gent

Page’

29

Ys,

OLDWILLWAYNE

VL.

VII.

CONTROL

A.

Removal

B.

C.

D.

FUEL

A.

B.

C.

D.

E..Fietd

--=-2.´•

TABLE

SURFACES

General

and

AnERONS

1.

RUDDER

2.

ELEVATORS

3.

4.

FLAPS

Contro?Swfaces

WINGS

1.

~MPPYNNACE

2.

3.

REMOVABLE

Rigging

1.

2.

3.

4.

5-

and

ILTLERON

TRIM

FLAP

RUDDERRIGGINGAND

ELEVATOR

Adjustment

RICGTNG

RIGGING

SYSTER;Z

General

Troubleshooting

Removal

1.

2.

Removal

1.

2.

and

ELECTRIC

RIECHANICAL

and

RE~IOV.4L

INSTALLATION

Repair

GENERAL

I.

APPAOV~DIMATERIALS

HANDLING

3.

SEALANT

4.

DESCRIPTION

5.

LEAK

LEAK

DETECTON

REPAIR

6.

7.

OF

CONTENTS,

Installation

General

CONTROL

RIGGING

AND

AND

AND

ADJUSTMENT

ADJUSTMENT

Continlted

Specifications

SURFACE

ADJUSTMENT

ADJUSTMENT

RIGCINC

nstcrllation

FUEL’PUMP

FUEL

Installation

Fuel

of

MIXNNG

AND

APPLICATIONINSTRUCTIONS

OF

PROCEDIjRE

END

PUZMP

Cells

LEAKS

ADJUSTMENT

Fuel

of

Fuel

of

SEALANT

Pumps

Selector

V~rlve

36

Page

Page’44

--;-’z;

vnI.

ELECTRICAL

´•B.

IX.

~ZNSTRUMENTS

INSPECTION

X.

SYSTEM

General

A.

T702tbleshootin4

ELECTRICAL

1.

BATTERY

2.

BATTERY

3.

Electrical

C.

1.

EQUIPMENT

DRA\MNG

2.

WnuNe

3.

General

A.

B.

General

A.

B.

Prefiight’-lnspections

Hour

25

C.

D.

E.

F.

G.

Hour

50

Hour

10G

Oz;erLi7nits

Post

Inspection

CHARGING

System

NOTES

TABLE

Inspections

Inspections

Inspections

Inspections

Checks

S~ITCHES

Master

LIST

AND

RATE

Diagram

CIRCUIT

BREAKERS

Page

Page

Page

56

rr´•

68

~74

i’

LIST

OLDWILLWAYNE

OF

ILZIUSTRATIO~S

j

C~

Table

Table

Table

Table

Table

Table

Table

1

Leading

Access

i,

2.

jacking

3.

L~Pveling

4,

Plei~fiing

Attachment

5,

Fuel

6,

B´•ake

7,

Lubrication

8,

Recommended

9,

2

Engine~Troubleshooting.

Aircraft

10,

Aircraft

11.

Aircraft

12

13,

GearRig~ingDiagram.

14.

AiletonControlSystem.

Control

15.

~m

16,

17;

Flap

Ruddez

18.

3

Fuel

Fuel

20,

21.

Typical

22.

FueI

Leaks

23.

Tank

24.

4

Hydrometer

5

Electrical

Electrical

6

26.

.Electrical

27,

Instrument

instrument

7

Three

28.

Particulars

Panels

Arrangement,

the

the

of

Strainer

Cylinder

Wing

Fuselage

Tail

Travel

Contrbl

Control

Control

System

Valve

Leak

Sealant

Which

Leak

Assembly..

Classification,

Detection.

Readings

System

Equipment

System,

Panel,

Troubleshooting.

View

Aircraft.

Aircraft.

Nose

Drain.

Chart.

Skin

Surfaces

System.

System,

Troubleshooting

Constitute

Drawing.

and

Principal

Plates.

and

Wheel

Reservoir.

Steering

LubricatingOils.

Chart.

Skin

Chart,

Skin

Chart.

(SeeFigurel3A,13B,P3c)

Jig.

System.

Application.

a

Flight

vs.

Battery

Troubleshooting.

List,

Master

(Figure26A&26B)

Wiring

Dimensions.

Bat.

Hazard.

Charge

Diagram.

Percent,

Page

Pages

gages

34,

Page

.,page

Page

Page

Page

Page

Page

Page

Page

Page

Page

Page

Page

Page

Page

Page

Page

35,

Page

Page

Page

Page

Page

Page

Page

Page

Page

Page

62

65

Page

Page

Page

1

35B

8r´•

2

7

8

9

10

11

13

14

15

1’6

18

26

27

28

38

39

41

42

43

44

46

49

52.

53

55

57

58

63

66

67

69

78

SECTION

OLDWILLWAYNE

INTRODUCTION

C

OLDWILLWAYNE

A.

GENERAL

20B

tenance,

This

Aircraft

manual

versatile

which

contains

was

aircraft

E

service

designed

for

the

and

and

manufactured

personal

maintenance

and

as

business

information

a

high

aviation

the

for

performance,

field.

MOONEY

low

~H

main-

B.

j.

SCOPE

remaining

clude

tions

corrective

separate

this

mation.

the

OF

Sections

ground

for

section.

manual.

The

desc’;iption

Refer

aircraft.

THIS

two

sections

handling,

each

system

maintenance

to

Tab;e

MANUAL

and

comprise

Only

6f

the

1

ten

servicing,

include

and

the

"Owners

lists

comprise

the

the

maintenance

and

trouble-shooting,

testing;

each

personnel

aircraft

includedP

Operating

the

leading

service

periodic

major

should

Manual"

particula;s

pirt

instructions.

inspections.

removal

system

perform

in

this

and

section

for

this

of

The

and

installation

the

of

the

is

more

a

principal

handbo~k,

service

maintenance

The

aircraft

operations

limited

detailed

dimensions.

whereas

instructions

of

components,

covered

is

described

to

general

description

instruc-

infor-

the

in-

in

a

in

of

’i’’

OLDWILLWAYNE

1

Table

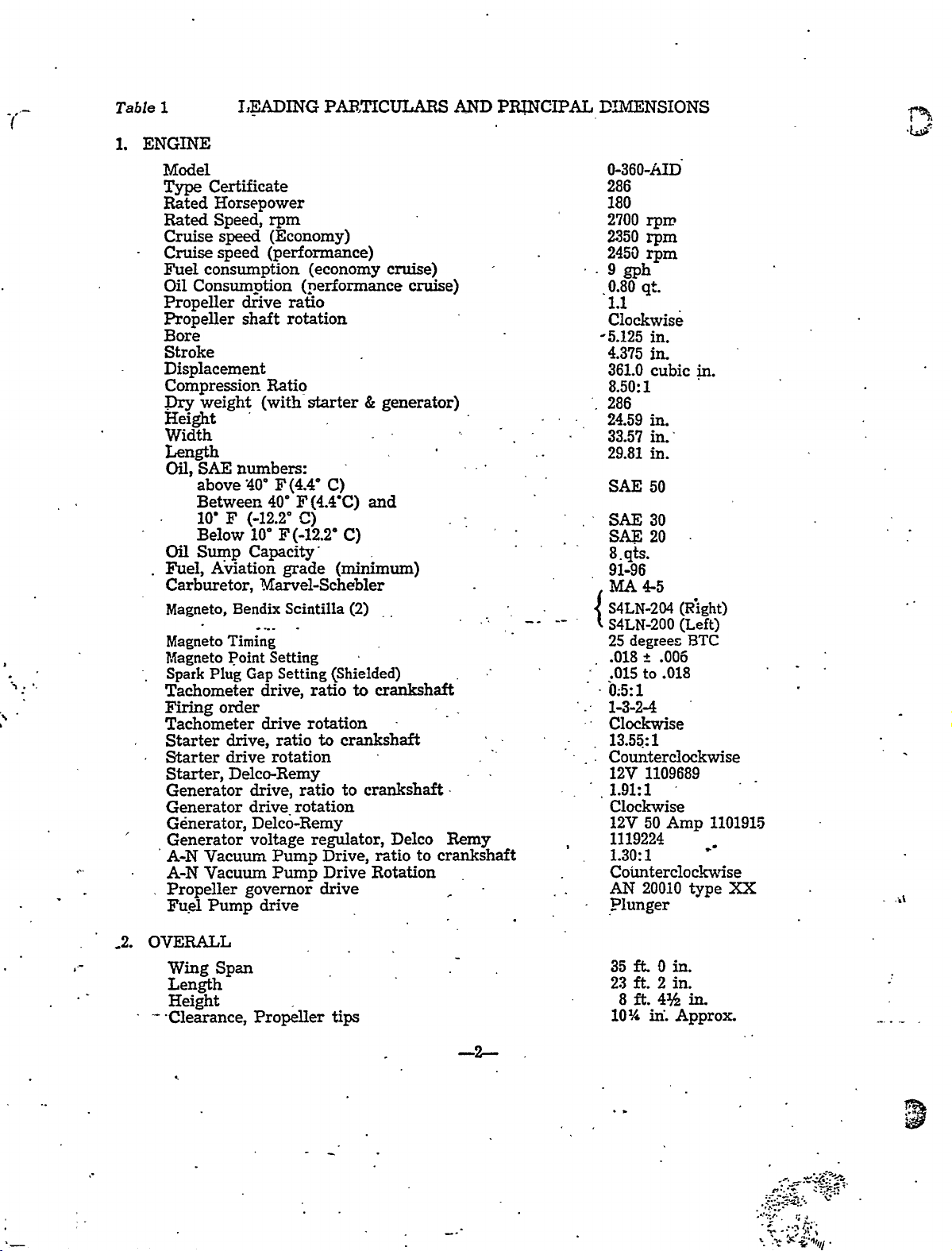

ENGINE

1.

Model

Type

Rated

Rated

Cruise

Cruise

Fuelconsumption

OilConsumr,tion

Propeller

Propeller

Bore

Stroke

Displacement

Compression

Pry

Height

Width

Length

Oil,

Oil

Fuel,

Carburetor,

Magneto,

Magneto

Magneto

Spark

Tachometer

Firing

Tachometer

Starter

Starter

Starter,

Generator

Generator

Generator,

Generator

A-N

A-N

Propeller

FuelPump

I~EADING

Certificate

Horsepower

Speed,

speed

speed

d~ive

shaft

weight

numbers:

SAE

above’40’

Between

10’

F

Below

Sump

(-12.2"

Capacity~

Aviation

Bendix

Timing

Point

Plug

Gap

order

drive,

drive

Delco-Remy

drive,

drive

voltage

Vacuum

Vacuum

governor

rpm

(Economy)

(performance)

(economy

(!!erformance

ratio

rotation

Ratio

starter

(with

F(4.4’

40’

F14.4’C)

C)

10"

F(-12.2’

grade

Marvel-Schebler

Scintilla(2)

Setting

Setting

ratio

rotation

rotation

ratio

rotation

to

ratio

drive,

drive

Delco-Remy

regulator,

Pump

Pump

drive

PARTICULARS

cruise)

generator)

C)

and

C)

(minimum)

(Shielded)

crankshaft

to

crankshaft

crankshaft

to

I)elco

Drive,

Drive

drive

ratio

Rotation

cruise)

crankshaft

to

AND

Remy

PRfNCIPAL

_

286

180

2700

rpm

2350

rpm

2450

rpm

9

gph

0.80

qt.

1.1

Clockwise

-5.125

4.375

361.0

8.50:1

286

24.59

33.57

29.81

SAE

SAE

SA~

in.

in.

cubic

in.

in.‘

in.

50

30

20

8.qts.

91-96

MA

4-5

S4LN-204

25

.018

_

degrees

(Right)S4LN-200

(Left)

RTC

.006

,015to.018

0;5:1

1-3-2-4

Clockwise

13.55:1

Cour;terclockwise

1109689

12V

Clockwise

12V

50

20010

Amp

type

1119224

1.30:1

Coirntercloc~u´•ise

AN

E~unger

in.

110191.5

XX

´•tio;~

.i\

,2.

OVERALL

’C~ing

Length

Height

´•Clearance,

Span

Propeller

tips

-2-

35

2.3

8

10~

ft.

0

in.

2

ft.

in.

ft.

4~

in:Approx.

in.

Table

OLDWILLWAYNE

A~

1

L~EADIPfG

PARTICULARS

PRINCIPAL

DIMENSIONS

L

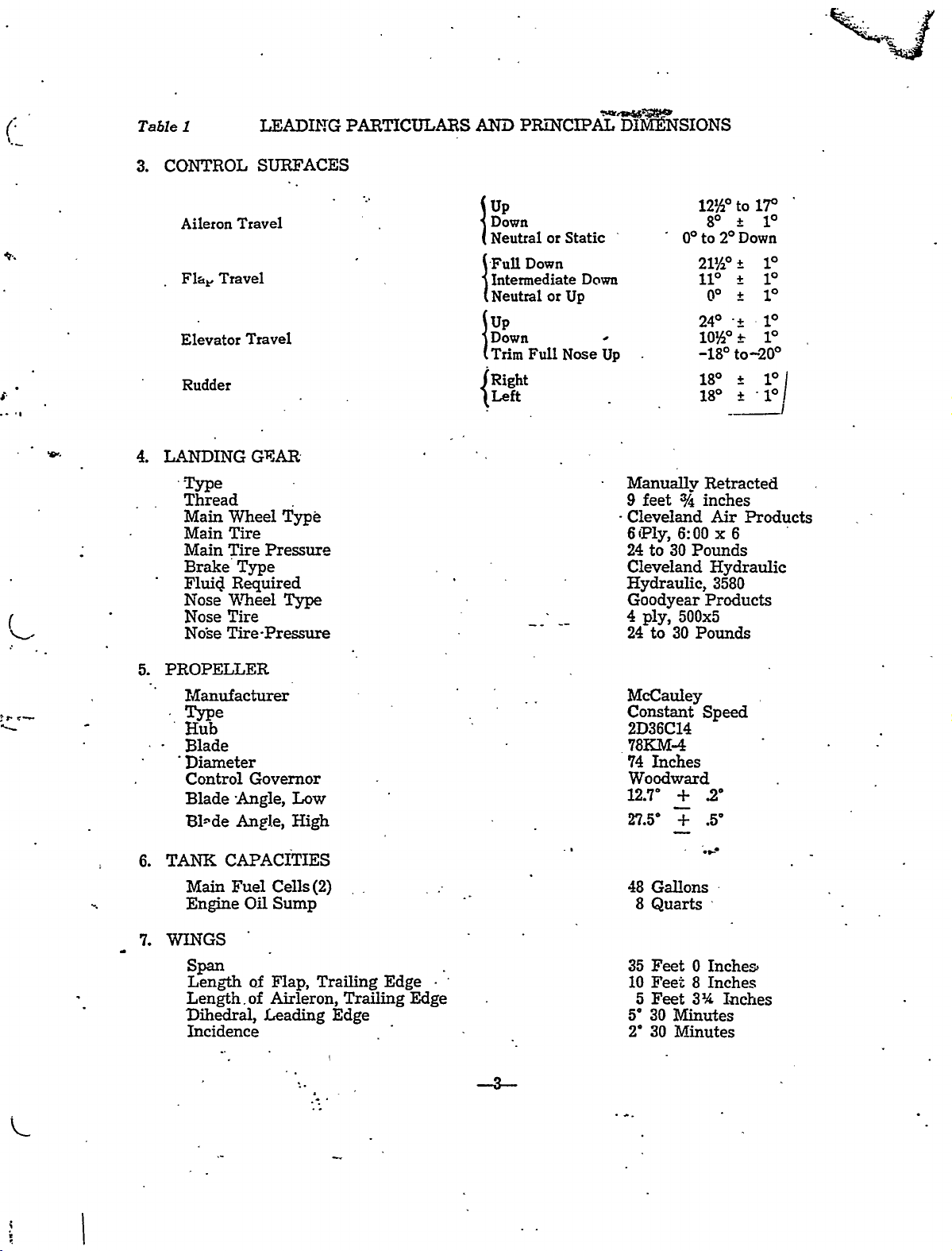

3.

4.

CONTROL

LL4NDING

SURFACES

Aileron

Flb,

Elevator

Travel

Travel

Travel

RudderRight

Type

Thread

Main

FVh,el

Main

Tire

Main

Tire

Brake

Fluid

Nose

Nose

Ndse

Type

Required

~cel

Tire

Tire-Pressure

T;ypi~

Pressure

Type

Up

Down

1

Neutral

´•Full

Intermediate

1

Neutral

Up

Down

Trim

Left

Down

Full

12540

s0

Static

or

00to20Down

213/4

Down

or

Up

Nose

Up

Manually

9

feet

Cleveland

6iPly,

24

to

Cleveland

Hydraulic,

Goodyear

4

ply,

24

to

110

00

240

10’~40

-180

180

1801~

Retracted

3~

inches

6:00

30

Pounds

Products

500x5

30

Pounds

Air

x

Hydraulic

3580

r

t

c

to-200

Products

6

10

i"

i"

10

10

P

1"

170

to

PROPELLER

5.

Manufacturer

tr.s

´•c,

Type

Hub

Blade

’Diameter

6.

7.

Control

Blade

B1´•de

TANK

Main

Engine

mT~INGS

Governor

´•Ang~e,

Ane~e,

CAPACITIES

Fuel

Cells(2)

Oil

Sump

Low

High

Span

Len~th

Length.of

Dihedral,

Incidence

of

Flap,

Airleron,

Leading

Trailing

Edge

Trailing

Edge

Edge

a

McCauley

Constant

2D36C14

78KM-4

Inches

74

Woodward

12.7"t

n.5’

Gallons

48

8

Quarts

35

Feet

10

Fee-i

5

Feet

5’

30

Minutes

2’

30

~Iinutes

Speed

d"

.5’

0

Inches

8

Inches

3’k

Inches

:;:~r´•´•

OLDWILLWAYNE

EMPEi\TNAGE

8.

AND

PRINCIPAL

DIMENSIONS

Vertical

Rudder

Horizontal

Elevator

9.

WING

Wings

Total

Total

DESCRIPTION

tion.

with

provided

through

fold

an

baggage

I.’ENGINE

2.

3.

4.

5.

6.

Fin

Area

Stabilizer

Area

AREAS

(total

Aileron

Area

Flap

M00NEY

The

is

It

powered

all

an

with

the

forward

of

the

rear

compartmenf

The

Lycohing

on~dynafocal

and

to

WING

The

MoontyM2OB

aerodynamic

flight

FUSELAGE

The

fuselage

in

ped

aluminum

stringers

tail

The

formity

IGNITION

This

engine

and

longer

PROPEI~LER

A

14

inch

for

ting

an

engine

Art~a

less

area

Area

by

metal

cabin

to

McCauley

rudder

door

allow

seat

and

engine

the

uses

efficiency

and

stall

tailcone

zinc-chromate

b~kheads

add

longitudinal

empenr~age

and

close

utilizes

ignition

M~Cauley

maximum

mounted

Area

and

naps

M20 8

180

a

pedals

:ocated

passenger

0-360-AID

outside

an

is’

accessible

mounts

transmission

a

laminar;flow

characteristics.

section

primer

is

tolerance

the

life.

all

take-on

governor

ailerons)

isafour

horsepower

constant

and

the

on

entry~to

from

engine

to

standard

over

is

for

to

form

strength

constructed

fit~

latest

metal

constant

power

for

place,

Lycoming

speed

control.

right

the

baggage

the

is

rated

dynamically

of

vibration

wing.

airfoils,

of

monocaque

corrosion

the

tail

to

on

for

all

ignition

speed

and

maximum

7.9

5.01

21.5

12.0

16?,Square

11.2

17.2

low

wing_monoplane

0-360-AID

propeller.

wheels.

side

of

seats.

rear

door

is

seat

rear

180

at

to

This

protection,

cone

the

tail

Conventional

Entrance

the

airplane.

The

located

during

HP

~balance

at

the

cabin

wing

and

yet

construction.

section.

cone.

aft

27d0

the

is

optically’aligned

parts.

system

which

propeller

automatic

efficienc3´•

gives

provides

pitch

at

Square

Square

Square

Square

Square

Square

engine

to

The

baggage

of

the

flight.

RPM

engine

reduces

retains

Aluminum

riveted

Extruded

jigs

quicker,

changing

cruising

Feet

Feet

Feet

Feet

Feet

Feet

Feet

of

metal

and

i;Sipe

the

cabinis

front

compartmen~

cabin

and

during

drag

verv

to

that’~sure

low

a

controlled

speeds.

construc-

is

equipped

controls

seat

door.

is

mounted

flight

improves

docile

ski?,

heat-treated

aluminum

easier

starts

pitch

are

made

backs

is

The

slow-

dip-

uni-

set-

bj´•

--e

6~

OLDWILLWAYNE

7.

MOVABLE

The

built

little

rather

CONT~OL

ailerons,

using

hinges

maintenance,

than

the

e;~vator,

of

and

conven’ion~i

SURFACES

and

machined

provides

rudder

extrusions.

cable

AND

are

superior

system,

FLIGHT

of

all

The

control-feel,

metal

are

CONTROLS

construction.

control

because

used

to

system

actuate

They

requires

torque

the

controls.

are

tubes,

J1g-

very

C

BReLYE

8.

9.

10.

FUEL

INSTRUIMENT

II.

The

The

assist

manual

the

The

each

sealing

The

location

SY~jTEM

MOONEY

GEAR

landing

spri?gs

gear

in

M

the

20

is

operation

SYSTEM

fuel

system

consists

These

compound,aportion

PANEL

instnunent

of

~ill

panel

flight,

B

unique

wings,

of

celle

radio,

has

uses

the

are

of

Cleveland

in

aided

gear

24

formed

of

been

and

that

it

by

bungee-type

quite’simple.

gallon

by

the

wing.

scientifically-

engine

Disc-Type

is

manUlallv

cells

fuel

sealing

instrument

hydraulic

retracted

springs

located

off,

through

designed

groups.

in

in

to

brakes.

by

the

the

the

proyide

the

pilot.

fuselage,

ftont

of

use

Gear-

make

portion

a

special

functional

i:’

of

_~__

~ta

REATER.AND

12.

VENTILATI3N

13.

BORWARIj

14.

Cabin

duction

Four

cabin

Two

the

for

heat

from

individual

roof

vents

cabin.

DEFROSTER

is

supplied

the

SYSTEM

to

provide

VENT

under

by

engine

airline-type

fresh

SYSTEM:

the

instrument

SYSTEM

heater

a

exhaust

adjustable

air´•for

manifold.

-5-

muff

each

panel

which

vents

passenger.

provide

are

transmits

~located

second

a

air~heated

in

the

source

center

of

by

fresh

con-

of

the

air

n

SECTION

OLDWILLWAYNE

HANDLING

SERVICING

AND

SECTION

OLDWILLWAYNE

ii

r‘

A.

B.

C.

GENERAL

This

ACCESS

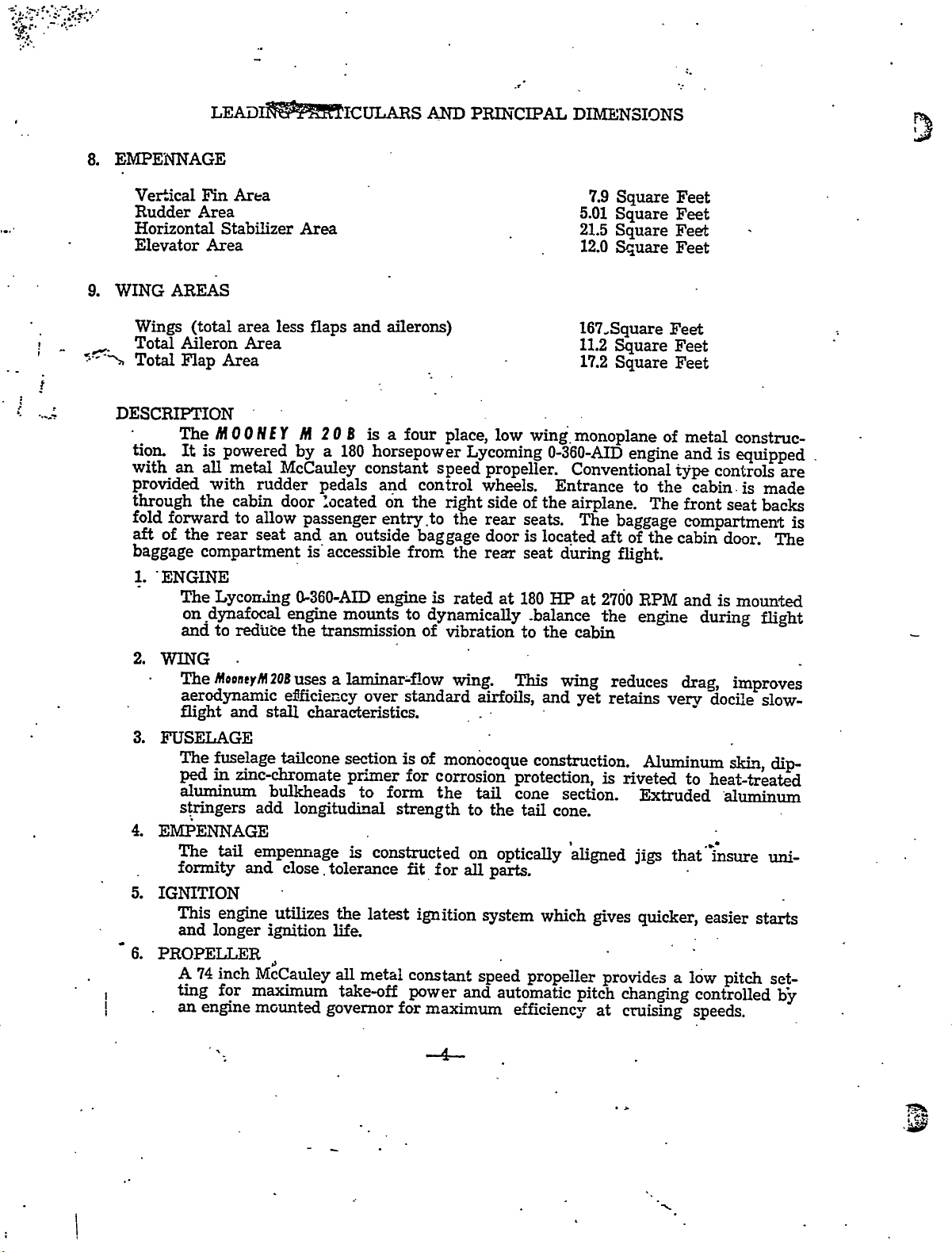

Figure

access

GROUND

The

ground

equipment

uvers.

man

where

and

HOISTING

1.

2.

LEVELING

3.

WEEGGHING

MOORING

4.

5.

section

PROVISIONS

1

shows

for

purposes

HANDLING

following

operations.

may

Brakes

move

may

pushing

the

inboard

When

the

landing

points

jack

aircraft

c!lain

and

the

then

manner,,

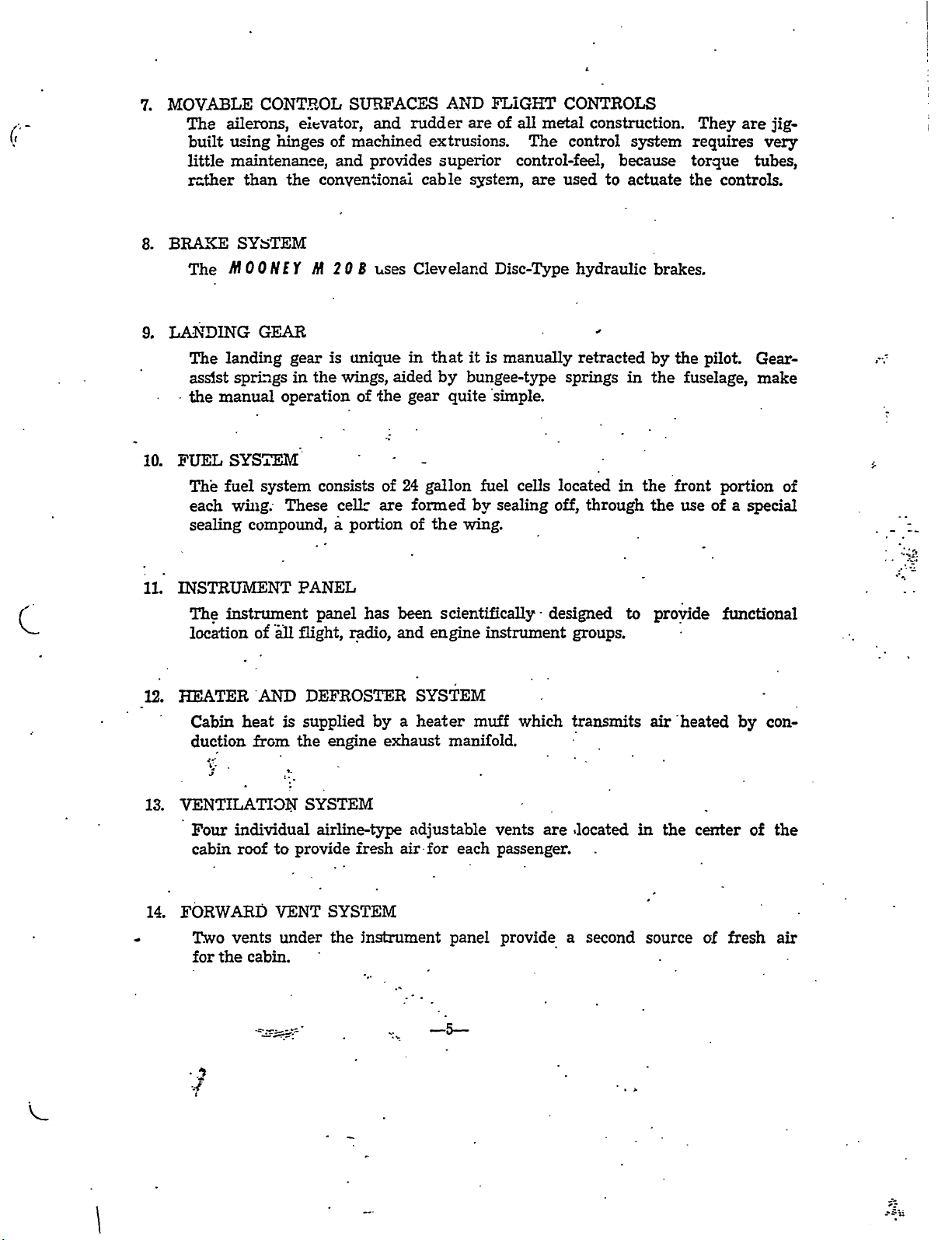

Lo~tigitudinal

parallel

decreasing

ground

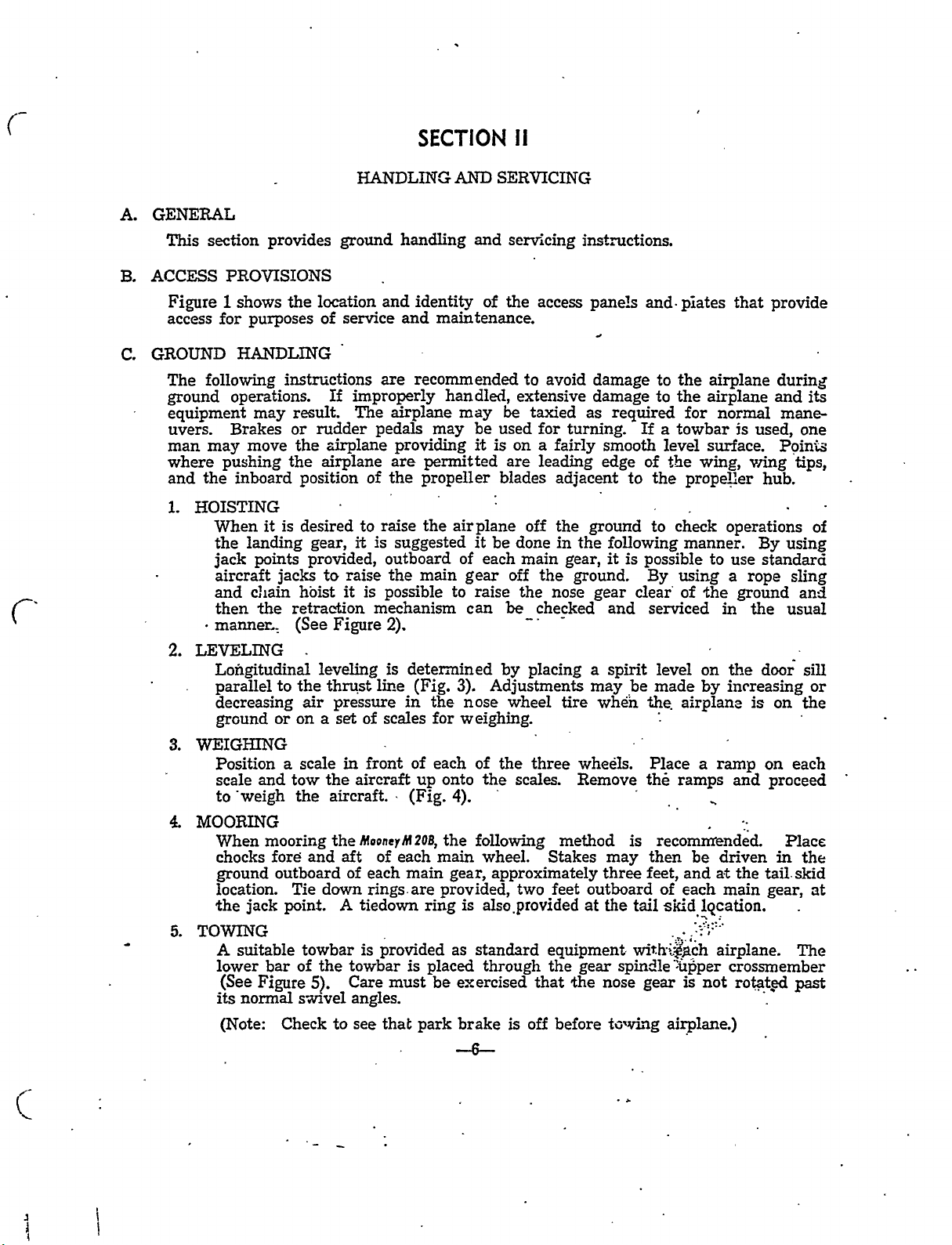

Position

and

scale

to’weigh

When

chocks

ground

location.

´•the

jack

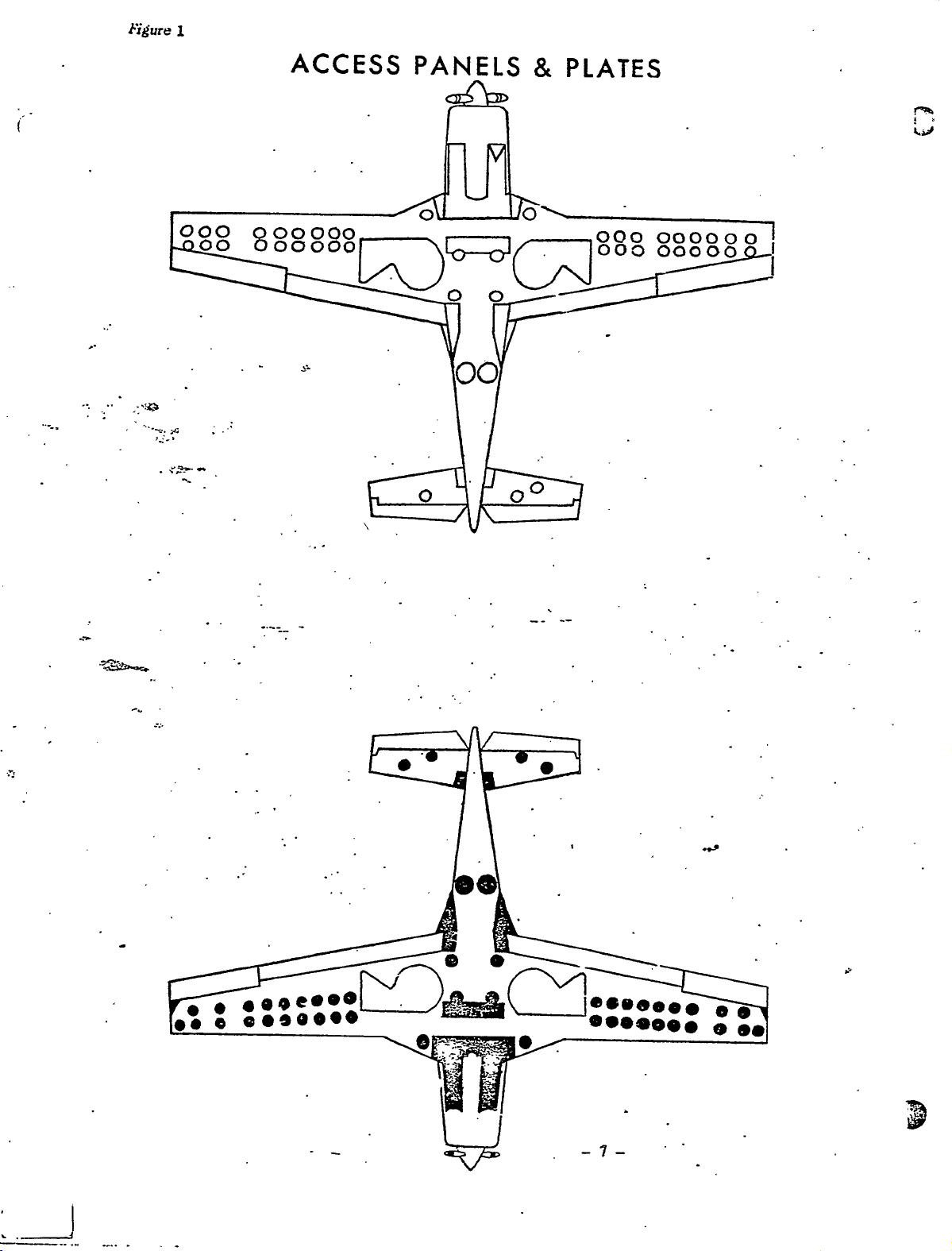

TOWING

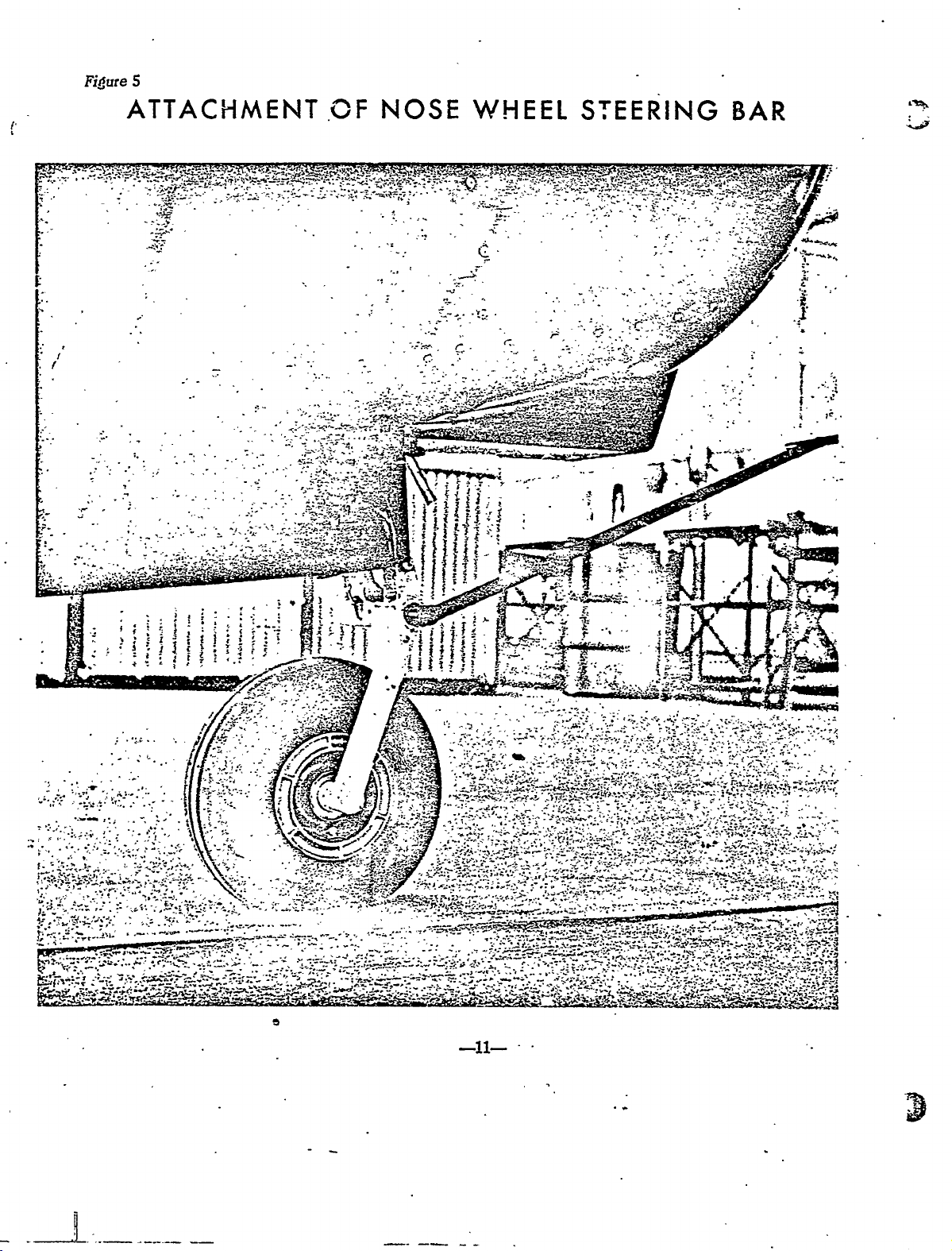

A

suitable

lower

(See

Figure

normal

its

(Note:

provides

the

instructions

result.

or

the

the

position

desired

is

it

jacks

hbist

retraction

(See

the

to

air

or

on

scale

a

tow

the

mooring

fore:

outboard

Tie

point.

towbar

of

bar

s~vel

Check

HANDLING

ground

location

of

If

rudder

and

service

are

improperly

The

pedals

airplane

airplane

of

raise

to

is

it

gear,

provided,

raise

to

it

is

possible

mechanism

Figure

leveling

thrust

a

the

aircraft.´•

and

down

the

5).

line

pressure

set

in

of

front

aircraft

scales

theMooncyMZOB,

of

aft

of

each

rings.are

A

tiedown

is

provided

towbar

Care

angles.

see

that

to

handling

identity

and

recommended

airplane

may

providing

are

permitted

the

propeller

the

suggested

outboard

main

the

2).

determined

is

(Fig.

in

the

for

of

each

up

(Fig.4).

each

main

ring

is

placed

must

be

park

AND

and

of

maintenance.

handled,

may

be

is

it

airplane

it

be

of

each

gear

raise

to

can

3).

Adjustments

nose

weighing.

of

onto

the

the

following

wheel.

main

approximately

gear,

provided,

is

also~provided

standard

as

through

exercised

brake

--6

SERVICING

servicing

the

access

avoid

to

extensive

be

taxied

used

for

on

a

fairly

are

leading

blades

off

done

main

the

off

the

be

by

wheel

the

nose

checked

placing

three

scales.

Stakes

feet

two

equipment~

the

that

off

is

before

instructions.

pane~

damage

damage

as

turning.

adjacent

the

ground

the

in

gear,

ground.

gear

a

may

tire

wh~i´•1

whe~s.

Remove

method

outboard

at

gear

the

required

If

smooth

of

edge

to

following

it

is

possible

clear’

and

spirit

be

is

may

three

the

tail

nose

gear

and

plates

to

the

the

to

for

towbar

a

level

the

the

to

By

serviced

the

Place

the

then

feet,

wing,

propeller

check

manner.

using

of

the

level

on

made

by

airplane

a

ramps

recomnrended.

be

and

of

each

is

not

airplane.)

that

airplane

airplane

normal

is

surface.

vring

operations

to

use

a

rope

ground

the

in

the

increasing

is

ramp

and

driven

the

at

main

airplane.

crossmember

rotat_ed

provide

during

and

mane-

used,

Poin~

hub.

By

standard

door

on

on

proceed

in

tail´•skid

gear,

its

one

tips,

of

using

sling

and

usual

sill

or

the

each

Place

the

at

The

past

~dvre?

OLDWILLWAYNE

I.

.-´•~s

000

00

8

000

00000

ACCESS

PANELS

oU~I--YO

8,

PLATES

000

000000

00000

001_/3Lo--d000

00

r’~

o

oO

CD´•J90~9

8888888

-7-

8

Figure

OLDWILLWAYNE

KING

p~lRANGEMENT

L

3A~1

Z

::i

-´•I´•~:

..I

\‘:2.´•

i,-

´•´•.r

t~

.t~´•:

´•r’:´•-.

.~´•z

I.’

--r

?~t

:r~-;c´•

:j:

-i´•.-

5*

Ing

f

r

t

:~4

~zt

~T

~C

´•,s

~´•le

i-

´•ij´•

’’I

~s

B:

´•I

~ic;.;

5

3;

1

ii;r-

´•_

ir--

´•-´•r´•

’5´•

6i3

~p

~$s1.:

c

?:ic

~Z

´•’~1

t~

.~5

’c’~--

~d

´•-L‘~

C~

5--

f

-J

I

.I’´•r

r:i

-i

j.~

:i´•´•

t~

)5

!~L

--~i´•x

~.-.i

.k

j3

’r

C

’~fr.b

:,j

*~r´•-:

´•´•.t

-,ri~i´•´•´•

ljSP’9

C;

´•r

‘I:

.:6´•

e.r.´•

:-e

´•´•r:

:i

’i

’I

c::

::C;.L

’i~

;I

^-.V

i

:r

p

*j

i

i

,c,

r-

9i’7~-g

r~

:il´•

E

;z-

i

;2;

.´•Y~

pr

r,:s

.i

j~

,Tr;

r’

~iur

-´•.4(..’.´•

,s*

irC

ii´•.

i‘´•~

u´•

~n

::nS+i-~

I

t´•

r

’r

I"’

I

Figute

OLDWILLWAYNE

I

5

3

~1:

LEVELING

;i

s

THE

f

AIRCRAFT

~P

´•1~

:1’

L1;´•t

r

4~

_r

Y

4i~

ic~

BTr

r

a

J

c

~j´•-

Li´•il.

Y~:

a

Ld~s´•

f~ri

5´•~1

E~ij

I

i

r

,~s

ri

~1

i

CIIC

7..

41

´•-~´•t-..2

b,c~

t

´•-~s,

4

i:

i´•

J

;,´•v

~r´•

I

r

´•i:

-.-´•´•;-:1

s´•

.1.I.

C

i

I’

L;-:´•

r

C

i

t~i

".Zp

,.I-.

7.

A

e´•~

´•C&i’~

~r:,

´•r´•~.

M

I--

L1

-´•C~

´•:´•I

L’:

~iS:

-i~-

3

El-

r~

res

´•r

r~´•´•L:

Mr

v´•,

r´•´•r

-:T~Z

’~Mz:

´•r~.

re

-~r

i;

.7’

T~

c;fi:

1´•´•

L-´•-

,a

Figure

OLDWILLWAYNE

4

L~EIGHING

IHE

AIRCRAFT

´•ii

:Jr-~

ir..

,t

-.e

1:

c

´•´•I

.f

-I

il´•.´•

´•F:´•

ra

ii.-

B´•-

´•~N

I--

-J~’´•.

-i´•-

:´•r´•

~sl

i.

p~a

Y

s´•i~

-‘---n

g

i

’i’i

21~

-dv

L´•

--L-

E~

;~f-

~L´•

i~i-.

a

.I

it

s~

-~--.´•--I

-~P-

ti

7~-

´•;--´•~s.W

´•---~Y

;.1

iR3

f4

d

3

I.:-

.I

f?_~

-ii´•..l´•

i--

TI

~t

’t’

´•i-´•.Y

c~

d

.:;iiii

i

´•-L´•i

L’´•.i

2~

-2

-i~1´•

r

t

--1"

5

OLDWILLWAYNE

Fi~ure

ATTACHMEr\aT

NOSE

i

MII1EEL

4.

SIEERING

~t´•r’E

r

BAR

~h

ii_

E

I

,k´•-‘-

´•-I

I

~-i-

:1-

.C

z

.’r;C

-ca--´•

-rF;7

i:

51

’r

i

ft5i

I.t~

I

c

4j

r

f

C1..

-t

s

r

3

Xe’

C-

!3~1r

i

If~

f

tiI

t1

~t

7

I

i

´•ii

i

i~

i

i-ri

t’t´•

’i;

i

f

Ij

i-~

c

r"-

~a

I

I

r

f’

:--1

ii

i´•

~6,,´•;i

1"

i

´•´•p:

.r:

B

a

f

t

,z

f

i

.I

t´•-~;

.L:;´•’

~r

i-;

’I

2.;,?´•

7-´•’

-1

i

~7

i

i.:

-ii.

Tf

t

_´•.-

::I:.~

;´•’.’r´•~´•´•

Z;

´•´•´•´•~C;i’

Z~a

i

Z"

´•´•’1.

i~-4‘t-.

.-´•.´•---I~

C

J~z

?i:

’.´•i´•

r

C-

´•´•´•Elh

´•-J

´•´•~.r

15

.I:

.n.

´•r´•

li´•

sc

-s";

,,,r

L~

f

i

´•z

r:’

;1

Z-

-----1~--

D.

OLDWILLWAYNE

SERVICMG

1.

FUEL

f~.

I~UBE

a.

b.

c.´•

a.

SYSTEM

Filling

Each

sible

pansion

gasoline

located

each

of

Fuel

The

equipped

dirt

Draining

Drain

bottom

turned

OIL

Filling’

Fill

The

Fuel

wing

for

filling

type

spilled

on

fuel

Strainer.

fuelstrainer

rrith

accumulations

Fuel

the

of

on

SYSTEM

Engine

’the

engine

intragal

gas

the

cell.

System.

fuel

the

the

Sump.

Cells.

by

cap.

outside

intoard

(r’igure6)

an

from

fuel

tank

sump

fuel

lifting

easy

and

the

selector

being

with

cell

A

scupper

the

corner

drain

drained

system

has

a

dzus

a

filler

under

is

located

regularly,

by

valve.

drained).

the

lubricating

capacity

fastened

box

neck

each

and

removing

(Note:

of

drain

opening.

wing.

in

should

the

oil

24

Il.

door

is

provided

The

This

the

nosewheel

be

the

fuel

spectfied.in

S.

gallons

and

checked

flush

selector

removmg

to

fuel

is

the

drain

valve

Table

and

drain

cell

lowest

well.

for

is

drain

water

from

must

i.

the

off

acces-

point

It

ex-

any

is

is

or

the

be

b.

r

3.

BI~AKE

b.

E.

LUBRICA’I~ION

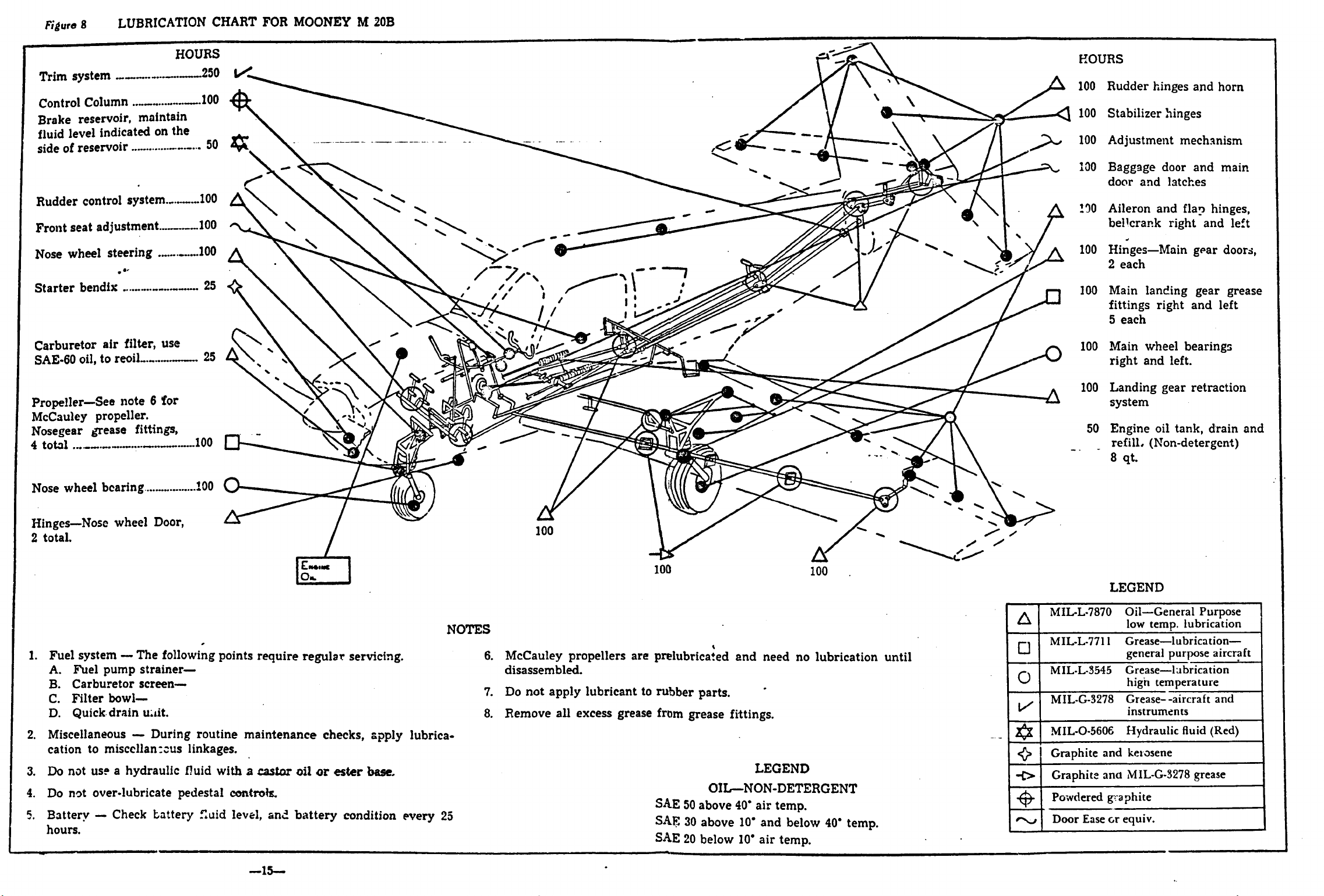

Refer

time

intervals,

and

gear

of

the

lubricants.

_.of

and

grit,

Where

a.

sealed

The

SYSTEM

Filling

The

fluid

tion

land

of

is

Draining

Tb

discs

system

to

the

type

and

a

Draining

engine

is

brake

and

Disc

the

set.)

drain

the

and

main

Excess

may

reservoir

Engine

installed

Brake

cylinder

specified

replenished

Brakes

brake

the

the

and

slowly

can

Lubrication

Srpe~

gear.

and

do

lubricant

lead

is

Sump.

sump

Cylinder

in

lining.

Brake

brake

be

cleaned.

of

Bearings

not

to

malfunction

not

can

each

in

reservoir

Table

when

require

System.

system,

pump

Chart

lubricants

require

on

provided

easily

be

MooneyMiO~i

Rsservoir.

iFigure

It

1.

necessary.

no

~pen

the

brakes

by

flushing

(Figure

used.

used

per’iodic

of

around

adjustment

in

(Caution:

exterior

-drained

should

Do

´•t~4e’brake

8)

Grease

´•bell

lubrication.

surfaces

the

unit.

a

airplane

7)

be

After

not

until

out

with

instructions

for

cranks,

bearing,

means

by

as

must

checked

initial

whatever,

fill

reservoir

bleeder

all

the

denatured

fittings

hinge

Avoid

of

bearings

apply

of

standard

be

filled

at

every

installation,

during

fluid

regarding

are

points,

the

the

equipment.

while

va13e

runs

alcohol.

provided

and

excessive

tends

lubricant

oil

with

100

the

parking

on

out.

to

quick

the

hour

inspec-

the

Cleve-

service

the

The

the

location,

the

on

rod-ends

application

attract

sparingly

drain

brake

life

brake

brake

brake

nose

are

dirt

-12-

FigureB

OLDWILLWAYNE

FUCL

L

STRAINER

DRAI~I

~s

´•Lia~

-´•i´•’

r´•.

P

I

3jC

r-

t~L.

S

Y´•

-´•r

~C’

~L1?I1-C

).f

"I~S

’i´•

u.

B;i

c,i

1~

5~

,Ir.13;p~´•

1

..,2´•

s

r

´•C

’CQ

-13-

-e

Figme

OLDWILLWAYNE

7

BKAKE

CYLINDER

RE´•SERVOIR

::?’´•~t

k

t´•,´•´•.l´•

ii

;’r

1

c

r

I"

´•I_

~T’

:~L_.

z

~LTI2´•1

d

T´•1´•

~s´•

~J

ib

i,

I

s

-\j´•~

:sl::

f

P:.

cI-;´•

i-.

":i

u

t

f~

"~’.QF

-i-

)i;

r´•F.i;

8~

L

i-.

.~i

:3:

.-´•a:2;.

r;

-;s~

.j.

"35.1~

.5

..,i

.~m;´•r´•

´•c~:

:n

i~72;r

1

T

i5~7;

--r-1

i~

L´•.~x.,r

´•c~a

2~;

;´•S

?1

~1

--I

Figure

OLDWILLWAYNE

8

LUBRICATION

CHART

FOR

MOONEY

20B

M

Trim

system

Control

Brake

fluid

side

Rudder

Frontseat

Nose

Starter

Carburetor

SAE80

Propeller--See

McCauley

NoseSear

tot31...11´•L.

4

Column

reservoir,

level

indicated

maintain

oireservoir..´•--´•´•´•.´•´•´•´•´•´•---´•´•´•

control

system.,.c.,.,100

adjustment...l.--10D

wheel

bendfx

air

to

oil,

propeller.

grease

steering

iilter,

reoil,.,...~.

note

fittinbs,

I-´•´•-´•´•´•-´•-´•´•CI1´•´•-´•--100

HOURS

the

on

....~.--.100

use

6

Tot

V’,

50

~c\‘

25.´•´•

25

//’e

KOURS

Rudder

100

e-

I

1/

100

Stabiiizer~inges

100

Adjustment

:00

Baggage

door

!30

Aileron

bei!crar?k

100

Hinges-Main

2

100

Main

fittings

5

~I

100

Main

right

100

Landing

hinges

and

and

each

landing

right

each

wheel

and

mechlnism

door

latches

right

left.

gear

and

and

hinges,

fla?

and

gear

gear

and

bearings

horn

main

left

doors.

grease

left

retractionsystem

50

Engine

refill.

8

qt.

oil

tank,

(n’on-detergcn~)

drain

and

wheel

Nose

Hinges--Nose

total.

2

i.

Fuel

,yslcm

Fuel

A.

B.

Carburetor

Filterbowl--

C.

D.

Buick´•drain

Miscellaneous

2.

cation

not

Do

3.

Do

4.

not

~fg

bcaring..................100

wheel

pump

Door,

The

strainer--

screen--

u;dt.

following

During

misccllan~=us

to

a

use

hydraulic

over-lubricate

Check

t~ltery

routine

linkages.

nuid

pedestal

T,uid

points

with

cbnCtala

level,

require

maintenance

a

casbt

an~

Ewlr

OL

regular

oil

or

battery

serviciag.

checks,

ester

condition

apply

base,

lubrica-

every

NOTES

29

6.

McCauley

disassernbled.

Do

7.

8.

Remove

not

100

apply

all

propelle,p

lubricant

excess

are

grease

100

prelubriealed

to

rubber

from

SeE

SAB

SAE

parts.

grease

OlGNON-DETERCENT

50

above

3(1

above

20

below

end

need

fi~ttings.

LEGEND

40’

air

10.

and

air

10’

temp

below

temp.

no

100

lubrication

40.

temp.

until

LEGEND

MILL-7870

a

MILL-7711

MIL-LS545

O

M1L-G-3´•278

I/

-C,

MIL-O-5666

i

Graphite

Graphite

Powdered

X~

I

__

I

Oil--GeneralPurpose

low

temp.

Grease--lubrication--

general

Grease--lubrication

hign

Grease--aircraft

instruments

purpose

temperature

HydraulicRuid(Ked)

kel~sene

and

MlL-G-S278

ana

g~aphite

lubrication

aircraft

and

grease

DoorE.seorequiv.

-13-

rollers

OLDWILLWAYNE

for

following

wheel

When

and

lubrication

bearings

repacking

the

retainer

precautions:

from

with

of

mechanisms

ring.

the

grease,

wheel

Do

hub

be

sure

not

pack

requiring

and

the

lubricant

the

lubrication

clean

grease

wine

the

the

off

any

wti~

space

wheel

available,

c~cgss.

suitable

a

bet~een

hub.

specific

observe

r

and

thorou~ly

enters

into

Whenever

not

are

Remove

solvent.

the

instructions

the

C

it

oils.

has

The

i.

2.

been

The

Apply

Squeeze

appears

oil.

during

engine

quality

ubserved

proper

ail

the

on

Be

careful

operation

manufacturer

brand

grades

sparingly,

ma,aneto

the

fingers,

not

Aviation

the

that

of

and

oil

to

never

add

will

does

best

are

cam

do

Grade

morc

foiler

not

too

cause

not

overall

listed

than

felts

add

oil.

much

oil,

pitting

recommend

of

results

below.

the

Oil

enough

at

regular

If

the

because

and

proper

are

to

-felt

burning

oils

obtained

the

coat

~inspection

is

dry,

the

excess

of

brand

by

seasonal

bearing

periods.

moisten

will

the

magneto

names.

viscosity!

from

surfaces.

If

with

be

light

thrown

points.

Use

However,

non-detergent

oil

off

a

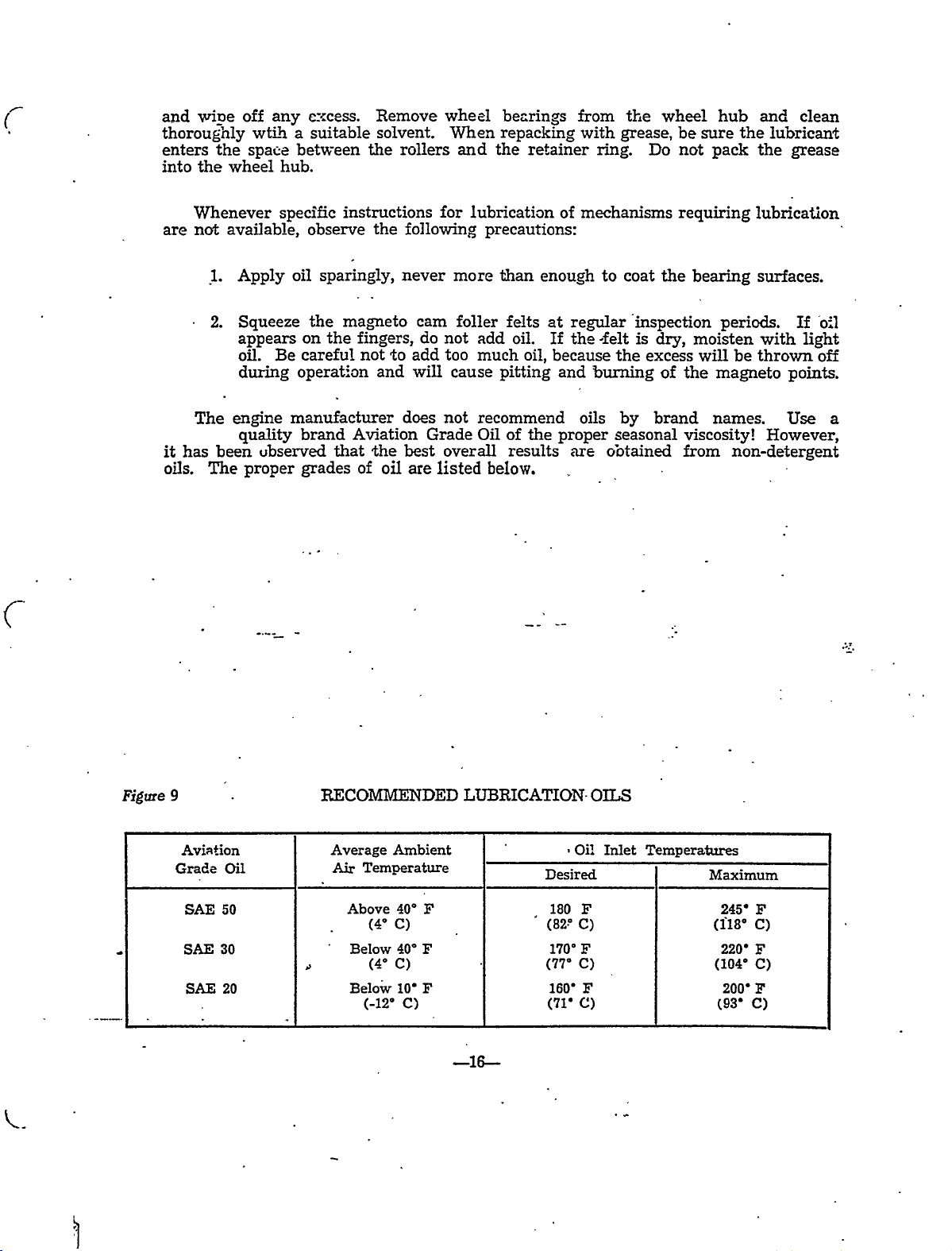

Figure

9

Aviation

Grade

SAE

SAE

SAE

F

F

F

LUBRICATION

--ZC

Desired

180

(82’

170"

(17"

160’

(71’

Oil

F

C)

F

C)

c,

F

OILS

Inlet

Temperatures

Maximum

245’

(i18’

220’

(104"

200’

(93’

F

C)

F

C)

F

C)

RECOMMENDED

Temperature

Above

(4"

Below

(4"

Below

(-12’

Ambient

40"

C)

40"

C)

10’

C)

Average

Oil

50

30

20

Air

SECTION

OLDWILLWAYNE

POVVER

PLANT

r:

OLDWILLWAYNE

SECTICN

)II

C

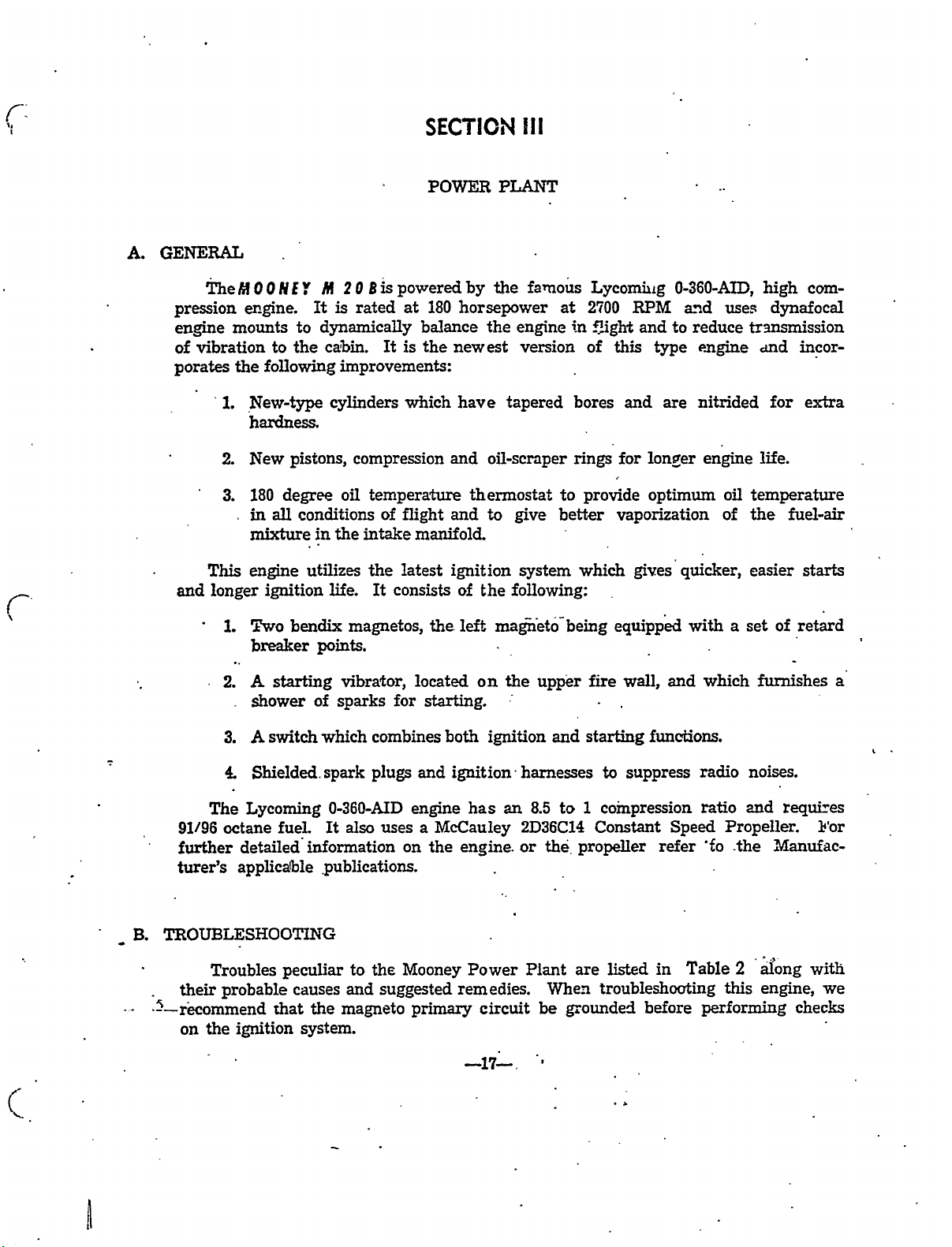

A.

GENERAL

Thel#00NEr

pression

engine

vibration

of

porates

This

and

mounts

the

1.

2.

3.

longer

1.

engine.

to

the

to

following

New-type

hardness.

New

pistons,

180

degree

all

in

mixture

engine

ignition

bendix

Two

breaker

M

203ispoweredby

rated

It

is

dynamically

cabin.

improvements:

cylinders

compression

oil

conditions

the

in

utilizes

life.

magnetos,

points.

at

balance

It

is

which

temperature

of

flight

intake

the

It

manifold

latest

consists

POWER

180

the

and

and

ignition

theleft

newest

PLANT

the

famous

horsepower

the

engine

version

have

tapered

oil-scraper

thermostat

to

give

system

of

the

following:

magn’eto-being

at

in

bores

rings

to

better

which

Lycomiug

2’i00

Zigh´•t

of

this

and

for

provide

vaporization

equipped

0-360-AID,

RPM

and

to

type

are

longer

optimum

a?d

reduce

engine

nitrided

engine

uses

oil

of

gi\res.quicker,

with

a

high

dynafocal

tr3nsmission

c~ind

incor-

for

extra

life.

temperature

the

fuel-air

easier

set

starts

retard

of

com-

The

91/96

further

turer’s

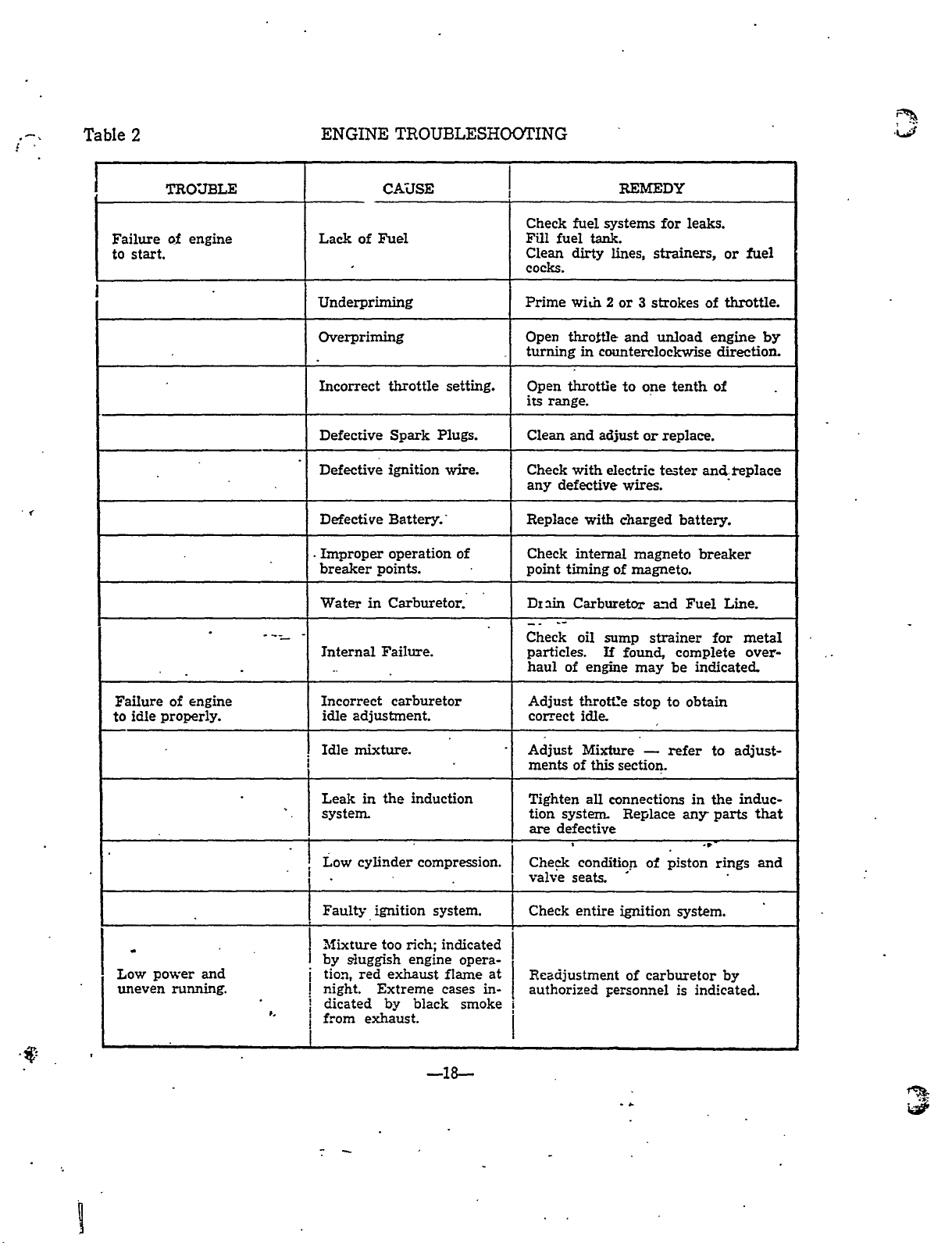

TROUBLESHOOTING

B.

Troubles

their

´•’t--rktommend

the

on

A

2.

3.

starting

shower

switchwhich

A

4

Shieided.spark

of

Lycoming

octane

fuel.

detailed~information

applica~ble

~publications.

peculiar

that

causes

the

system.

probable

ignition

vibrator,

sparks

0-360-AID

It

also

to

and

magneto

located

for

combines

and

plugs

engine

uses

a

on

the

Mooney

suggested

primary

starting.

both

ignition

has

McCauley

the

engine.

Power

remedies.

-17-.

on

ignition

circuit

the

harnesses

8.5

an

2D36C14

or

Plant

uplier

and

to

the_

When

be

fire

wall,

starting

to

suppress

1

compression

Constant

propeller

listed

are

troubleshooting

grounded

and

functions.

Speed

refer’fo.the

in

before

which

radio

ratio

Propeller.

Table

this

performing

and

2

furnishes

noises.

engine,

a

requires

B’or

witli

we

checks

Table

OLDWILLWAYNE

r~zh

2

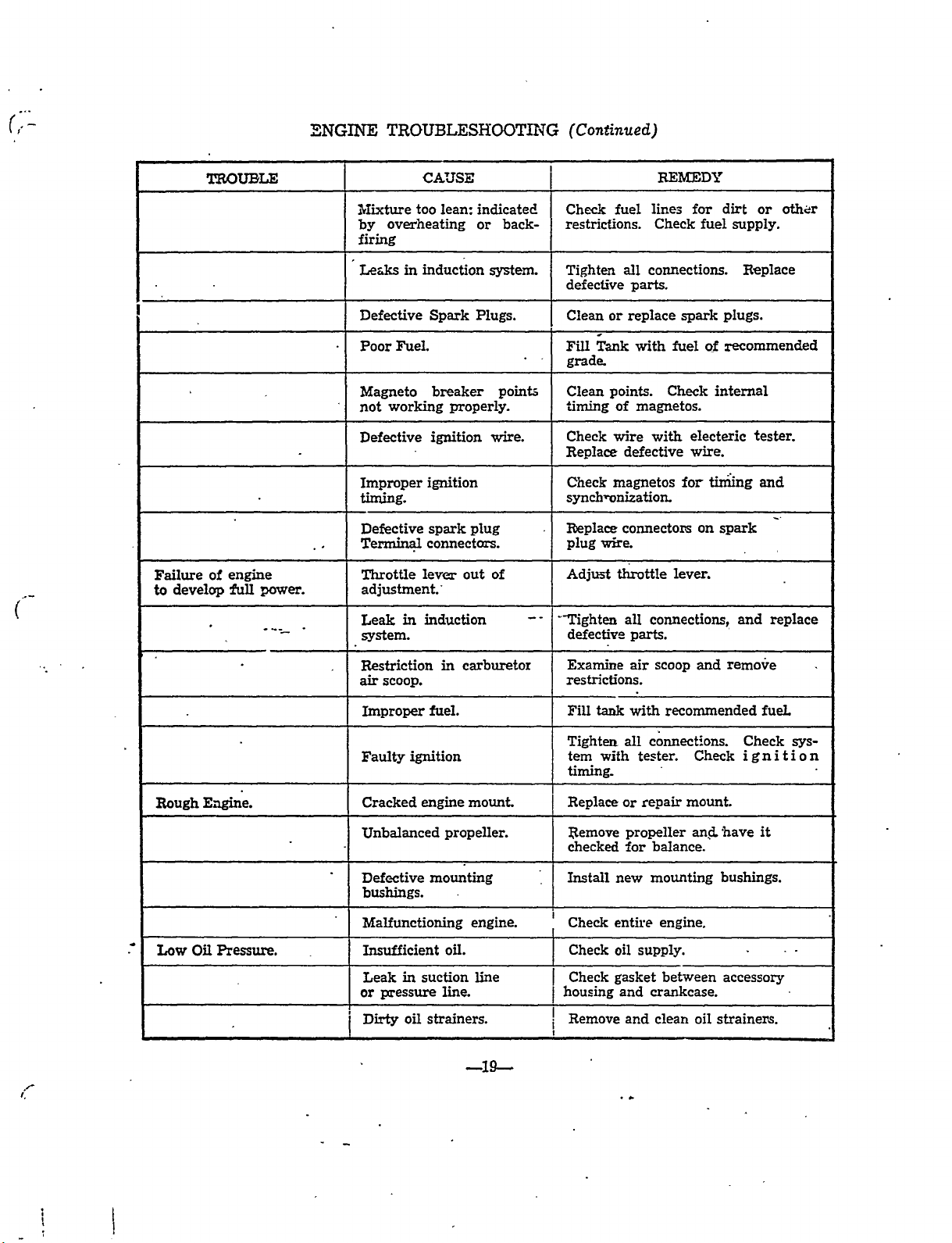

ENGINE

TROUBLESHO~TING

Failure

to

start.

TRO’JBLE

of

engine

Lack

Underpriming

Overpriming

Incorrect

Defective

Defective

Defective

.~proper

breaker

Water

~I

InternalFailure.

of

in

CA’JSE

Fuel

throttle

Spark

ignition

Battery.’

operation

points.

Carburetor.

setting.

Plugs.

wire.

of

Check

Fill

Clean

cocks.

Prime

Open

turning

Open

its

Clean

Check

any

Replace

Check

point

I

DIlin

Check

particles.

haul

fuel

range.

defective

timingof

of

fuel

systems

tank.

dirty

wi;n

throttle

in

counterclockwise

throttle

and

adjust

with

with

internal

Carburetor

oil

sump

If

engine

REMEDY

lines,

2

or

and

to

electric

wires.

charged

found,

for

strainers,

3

strokes

unload

one

or

replace.

tester

magneto

magneto.

a?d

strainer

may

leaks,

tenth

and.~eplace

battery.

breaker

Fuel

complete

indicated

be

or

throttle.

of

engine

directioa

of

Line.

for

fuel

by

metal

over-

Failure

idle

to

Low

uneven

of

properly.

power

running.

engine

and

Incorrect

idle

Idle

Leak

system

Low

Fault~

Mixture

by

i

night.

I

i

1

from

sluggish

tion,

dicated

carburetor

adjustment.

mixture.

the

in

cylinder

ignition

too

red

exhaust

Extreme

by

exhaust.

induction

compression

system.

indicated

rich;

engine

flame

cases

black

opera-

smoke

Adjust

correct

Adjust

ments

Tighten

tion

are

Check

I

valve

Check

at

in-

Rfadjustment

authorized

i

thrott’e

idle.

Mixture

of

all

system

defective

condition

seats.

entire

this

connections

personnel

section.

ignition

stop

Replace

of

of

carburetor

to

obtain

refer

any

piston

system.

is

to

in

the

parts

rings

indicated.

adjust-

induc-

that

and

by

~e

~NGINE

OLDWILLWAYNE

(Con~inued)

I

Failure

to

develop

of

engine

~Pull

power.

Mixture

ove~heating

by

firing

Leaks

Defective

Poor

Magneto

not

working

Defective

Improper

timing.

Defective

Terminal

Throttle

adjustment.~

Leak

I

system.

Fuel

in

too

in

C~JSE

lean:

induction

Spark

breaker

properly.

ignition

ignition

spark

connectors.

lever

induction

indicated

or

Plugs.

plug

out

back-

system.

point;

wire.

of

Check

restrictions.

Tighten

defective

Clean

or

ihnk

Fill

grade

Cleanpoints.

’riming

Check

Replace

Check

synch~onization

Replace

I

plug

wire.

Adjust

I~"righten

defective

lines

fuel

Check

connections.

all

parts.

replace

with

of

magnetos.

with

wire

defective

magnetos

connectors

tI;rottle

all

connections,

parts.

REMEDT

far

fuel

spark

fuel

Checkinternal

electeric

wire.

for

on

lever.

dirt

supply.

Replace

plugs.

of

recommended

tiniing

spark

and

or

tester.

and

replace

oth~

Rough

Low

E;lgine.

Oil

Pressure.

Restriction

air

scoop.

Improper

Faulty

Cracked

Unbalanced

Defective

bushings.

Malfunctioning

Insufficient

I

in

Leak

or

pressure

Dirty

ignition

engine

suction

oil

strainers.

carburetor

in

fuel.

propeller.

mounting

oil.

line.

-19-

mount.

engine.

line

Examine

restrictions.

Fill

Tighten

tem

timing.

Replace

Remove

checked

Install

Check

Check

Check

hou´•ing

I

Remove

j

tank

with

air

with

connections.

all

tester

or

repair

propeller

balance.

for

new

mounting

entire

oil

supply.

gasket

crankcase.

and

and

and

scoop

recommended

Check

mount.

and

engine.

between

oil

clean

remove

Check

ignition

have

bushings.

accessory

strainers.

fuel

sys-

it

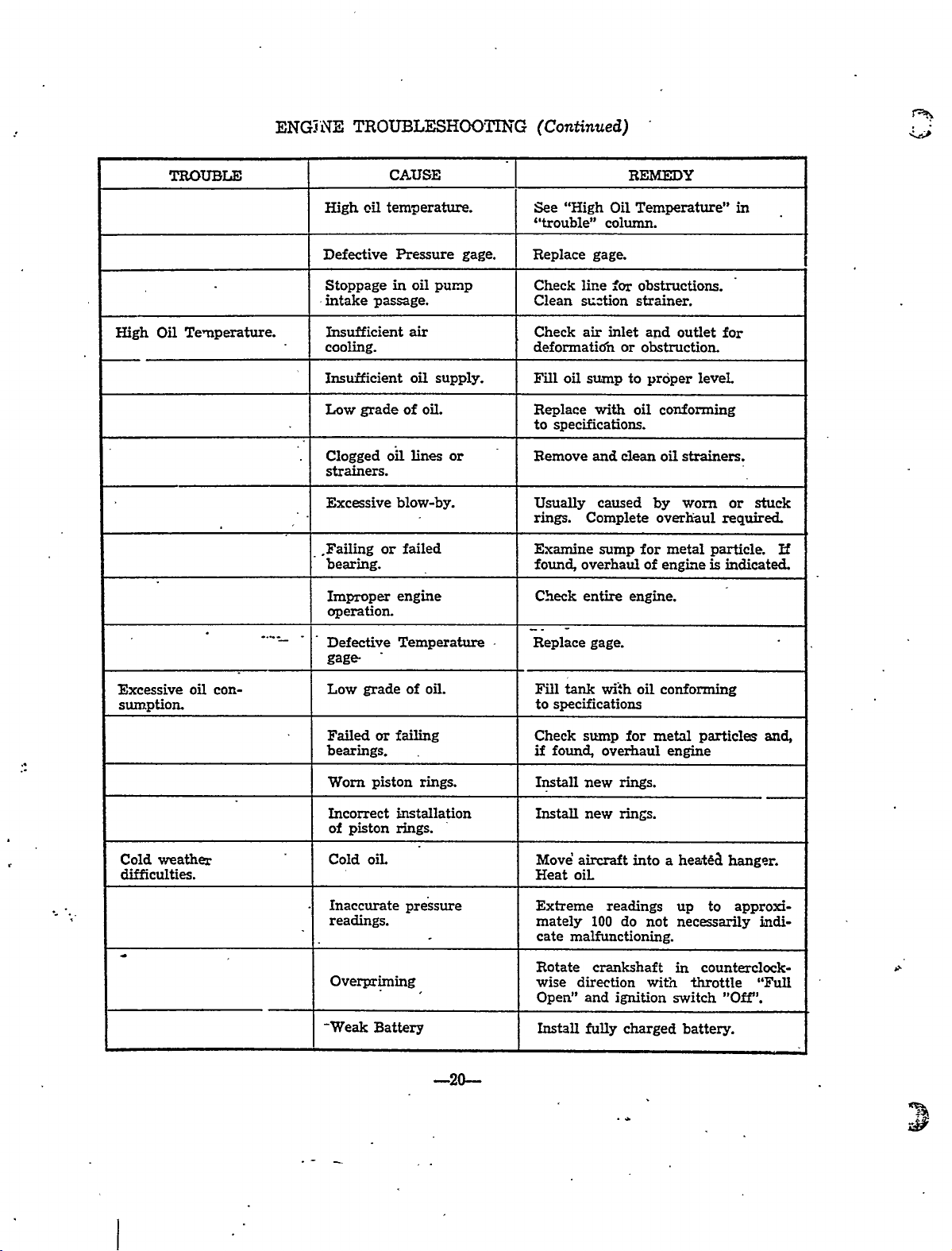

TROUBLESHOO’TI~U’G

OLDWILLWAYNE

(Continued)

High

TROU&I;E

Oil

Temperature.

oil

High

I)efective

Stoppage

intake

Insufficient

cooling.

Insufficient

Low

grade

Clogged

strainers.

Excessive

.Failing

bearing.

Improper

operation.

CAUSE

temperature.

Pressure

in

oil

passage.

air

oil

of

oil

Lines

blow-by.

failed

or

engine

pump

supply.

oil.

or

gage.

See

’’trouble"

Replace

Check

Clean

Check

deformatidn

Fill

Replace

to

Remove

I

Usually

rings.

Examine

found,

Check

On

"High

column.

gage.

lir?e;cor

s~r=tion

inlet

air

or

oil

sump

with

specifications.

andcleanoilstrainers.

caused

Complete

sump

overhaul

entire

REMEDY

Temperature"

obstructions.

strainer.

and

outlet

obstruction

to

prdper

oil

conforming

worn

by

overhaul

for

metal

of

engi?e

engine.

level

particle

is

in

for

stuck

or

required.

indicated.

Ef

Excessive

sumption.

Cold

difficulties.

weather

Defective

gage

oil

con-

Low

Failed

bearings.

Worn

Incorrect

of

piston

Cold

I

I

Inaccurate

readings.

Overpriming

-Weak

grade

or

piston

oil

Batterg

Temperature

of

oil.

failing

rings.

instailation

rings.

pressure

Replace

I

I

Fill

to

Check

if

Install

Install

Move’

Heat

Extreme

mately

cate

Rotate

wise

Open"

install

gage.

tank

wi~h

specifications

sump

found,

overhaul

new

new

aircraft

oil

readings

100

malfunctioning.

crankshaft

direction

and

fully

oil

for

rings.

rings.

into

do

ignition

charged

conforming

metal

engine

a

up

not

necessarily

in

with

switch

particles

to

counterclock-

throttle

battery.

and,

hanger

approxi-

indi-

"Full

"Ofir’.

-2e

C

OLDWILLWAYNE

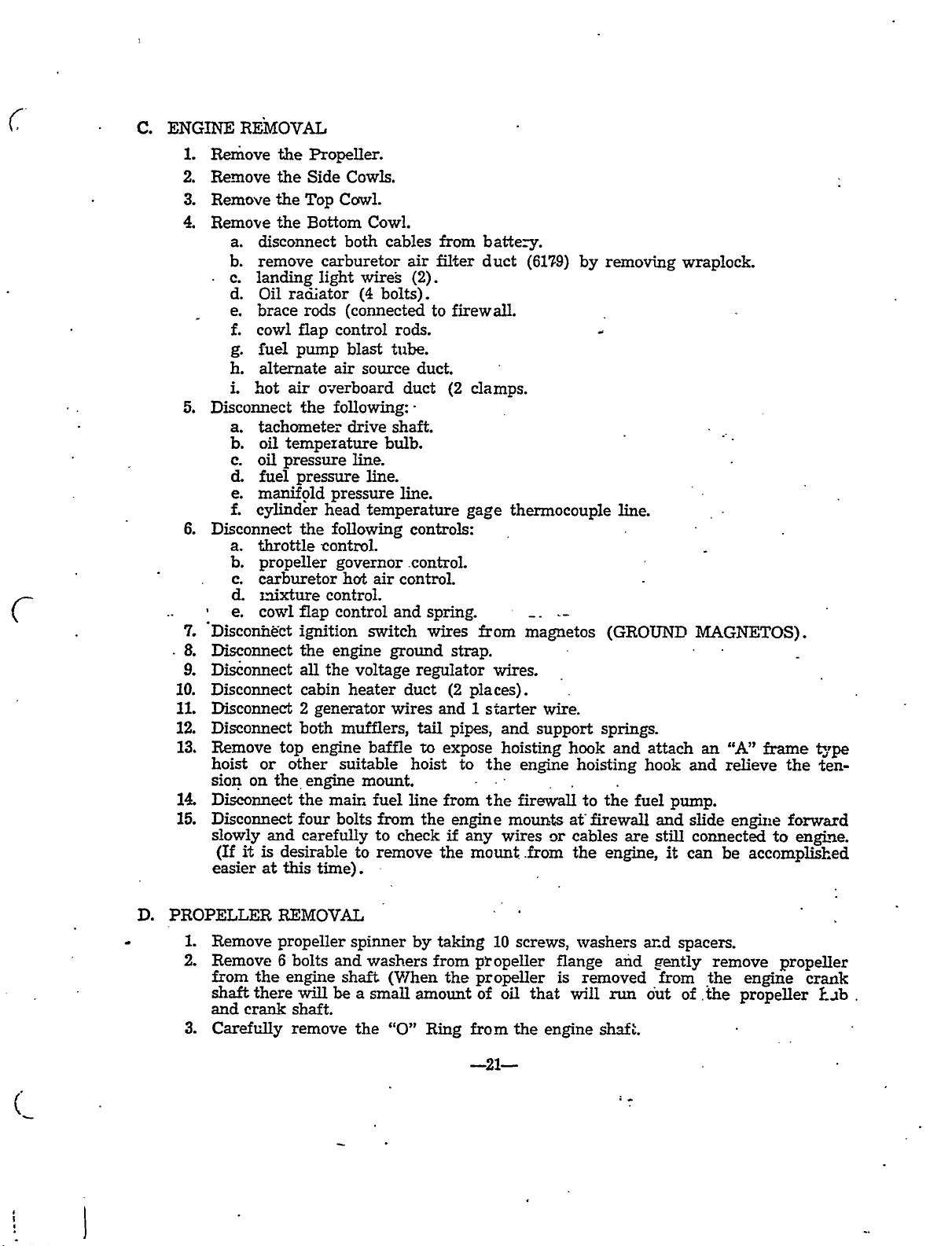

ENGINE

c.

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14;

15.

REMOVAL

RemovethePropeller.

the

the

radiator

flap

pump

air

the

temperature

pressure

pressure

the

tnixture

flap

ignition

the

all

cabin

2

both

top

other

or

the~

the

four

and

carefllUv

is

desirable

this

at

Side

Cowl.

Bottom

carburetor

rods

control

air

overboard

following:´•

pressure

head

following

rontrol.

governor.control.

control.

control

engine

the

generator

engine

suitable

engine

main

bolts

time).

Remove

RemovetheTop

Remove

disconnect

a.

b.

remove

c.

landinglight

d.

Oil

brace

e.

cowl

f.

fuel

g.

h.

alternate

hot

i.

Disconnect

tachometer

a.

b.

oil

oil

c.

d.

fuel

manifold

e.

f.

cylind~

Disconnect

throttle

a.

b.

propeller

carburetor

c.

d.

co~l

e.

Disconi~ct

Disconnect

Dis~onnect

Disconnect

Disconnect

Disconnect

Remove

hoist

sion

on

Disconnect

Disconnect

slowly

it

(If

easier

Cowls.

Cowi.

both

cables

wireg

bolts).

(4

(connected

rods.

blast

source

drive

shaft.

bulb.

line.

line.

temperature

hot

air

and

switch

ground

voltage

heater

wires

mufflers,

baffle

mount.

fuel

from

to

check

to

remove

air

(2).

to

duct.

duct

line.

controls:

control.

sprin~

wires

regulator

duct

tail

to

hoist

line

the

from

filter

firewall.

(2

strap.

(2

and

pipes,

expose

from

engine

if

the

battery.

duct

clamps.

gage

~from

wires.

places).

1

starter

and

hoisting

the

to

the

wires

any

mount.from

(61~9)

by

thermocouple

magnetos

wire.

support

hook

engine

firewall

mounts

or

hoisting

to

at’firewall

cables

the

removing

line.

(GROUND

springs.

and

attach

hook

fuel

the

are

engine,

wraplock.

MAGNETOS).

and

pump.

slide

and

still

connected

it

can

an

"A"

frame

relieve

engine

to

be

accomplished

the

forward

engi~e.

t~pe

´•ten-

D.

PROPELLER

I.

Remove

2.

Remove

from

shaft

and

3.

Carefully

the

there

crank

RF~MOVAL

propeller

6

bolts

andwashers

engine

be

will

shaft.

remove

spinner

shaft

a

the

small

"0"

by

from

amount

Ring

taking

the

10

p~opeller

propeller

of

oil

from

the

screws,

that

washers

flange

is

will

engine

removed

run

shaft.

and

and

dut

from

spacers.

the

of.’the

remove

propeller

engine

propeller

crank

Elb.

Loading...

Loading...