Mooney Executiv 21, M20F Owner's Manual

MODEL

M20F

OWNERS

MANUAL

OPERATE THIS AIRCRAFT

ONLY-

@after reading

owners manual @with owners manual on board

@

after you are fully qualified & understand all of

the aircraft operating characteristics& limitations

MOONEY

AlRCRAF7:

lNC.

YEAR

P

1967

OWNERS

MANUAL

MODEL

SERIAL

NUMBERS

M20F 660003 & 660004

670001

TWRU

670539

Issued

September

1966

Revised

March

1967

aboard your new Executive

21.

Enjoy the greater utility

of the long,

rooiny cabin. The far-ranging fuel capacity

of the Executive

21

now makes possible one-stop trans-

continental flights.

The same high

perforinance and low operating cost which

make its sister ships, the Mark

21

and Super

21,

the

world's leading sellers

in

the retractable-geared class,

are bred into the Executive

21.

Read this manual carefully, it is prepared to help you en-

joy fully the remarkable

perfor~nance and econorn)r charac-

teristics the Executive

2

1

is prepared to deliver.

MBONEY

AIRCRAFT,

INC.

XERRVIL 1 E TEXAS

This manual contains Federal AviationAgency- DelegarionOption

Authority approved li~nitarions and

nus st

be carried in the

Execu-

tive

21

at all times.

EXECUTIVE

21

OWNER'S

MANUAL

TABLEOFCONTENTS

PART

I

DESCRIPTION AND OPERATION

OF

COMPONENTS

Page

General

Propeller

Engine

Power Boost

Engine Ignition

Fuel System

Electrical System

Airframe

Landing

Gear

Flight Controls

Moaney Positive Control Systen.

Trim System

Flaps

Vacuum System

Brakes

Heating and Ventilation Systems

PART

II

FLIGHT

PROCEDURES

General

Weight and Balance

Pre-Flight

Inspection

Entering the Airplane

Starting the Engine

Cold Weather ond Manual Starting

Taxiing and Ground Operation

Pre Take-Off Check

Take-Off and Climb

Power Changes

Cruise Procedures

Indicated Airspeed

Fuel Management

Let-Down Procedures

Land

ing Procedures

Normal Landing

Stopping the Engine

PART I!! SERVICE AND MAINTENANCE

Page

General

Ground Handling

Propeller

Engine

Battery

Care

of

Interior

Care of Exterior

Windows

Landing Gear

Vacuum Operated Step

Required Data

Service Bulletins and Instructions

PART IV PERFORMANCE

DATA

Take-Off and Climb Data

Climb Performance

Cruise and Range (2500')

(5000')

(7500')

(1

0,000')

(1 5,000')

Stall Speed

vs.

Sank Angle

Maximum Range

&

Glide Range

Landing Data

(Fig.

1)

(Fig.

2)

(Fig. 3)

(Fig. 3A)

(Fig.

38)

(Fig. 3C)

(Fig. 3D)

(Fig.

4)

(Fig. 5)

(Fig. 6)

Page

PART V OPERATING

LIMITAT

IONS

FAA/BOAAPPROVED MOONEY

M20F

Page

Power Plant Instruments

Airspeed Limitations

Flight Load Factors

Maximum Weight

&

CG Range

Aircraft Instrumentation Markings and

their Significance

Types of Operation

Power Boost

Placards

Instrument Marking (Except Power Plant)

Maximum Altitude Loss in Stalls at Gross Weight

Revised

March

1967

PART

I

DESCRIPTION AND OPERATION OF COMPONENTS

GENERAL

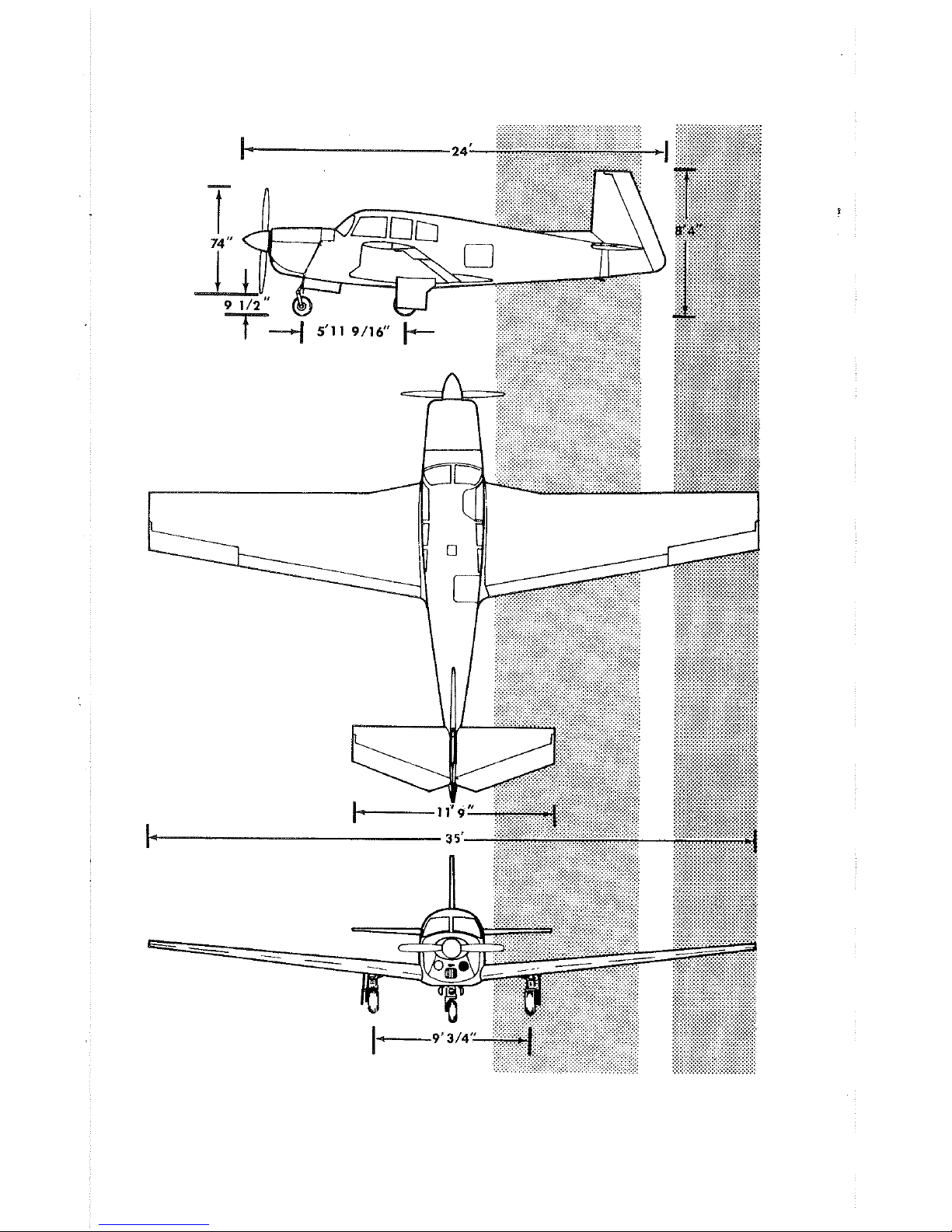

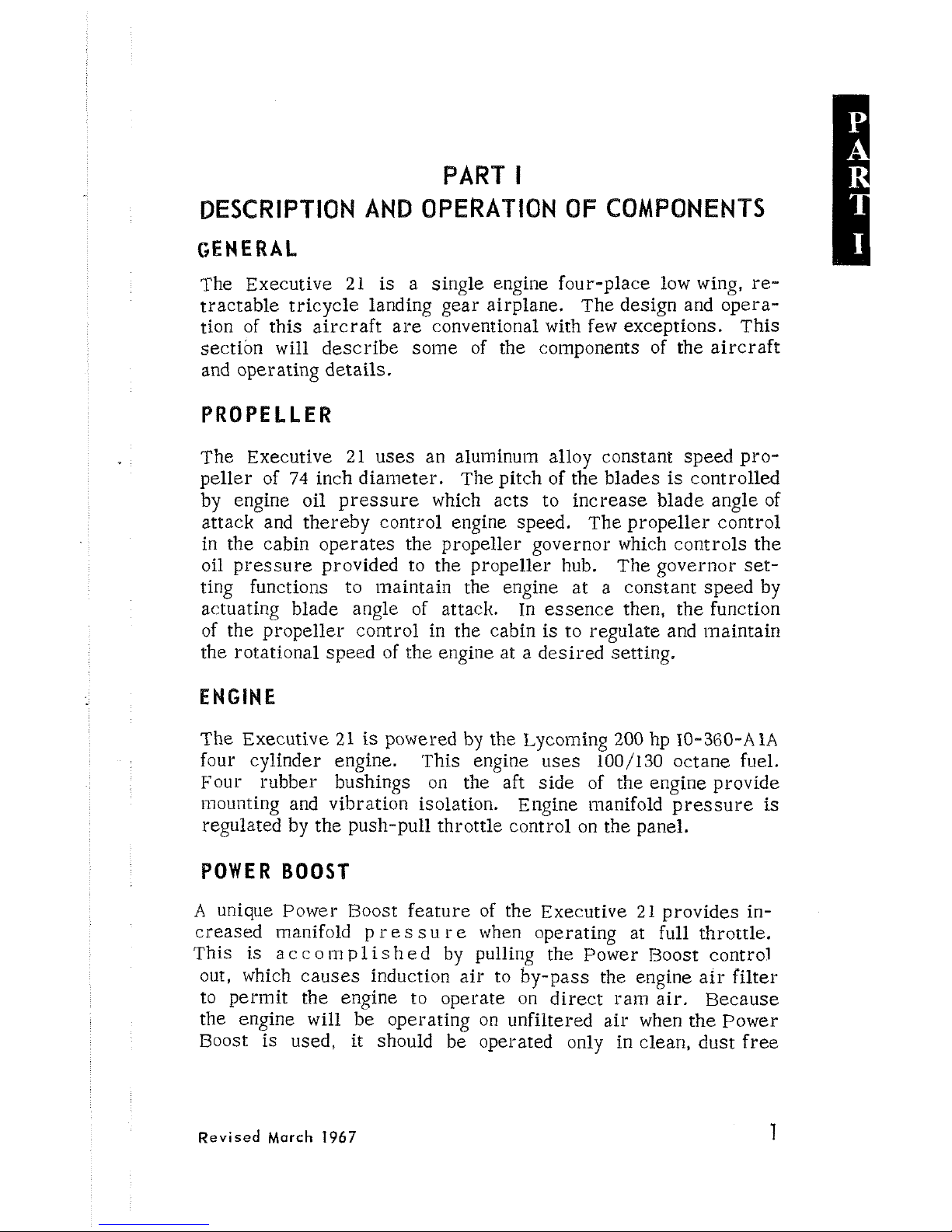

The Executive 21 is

a single engine four-place low wing, re-

tractable tricycle landing gear airplane.

The design and operation of this aircraft are conventional with few exceptions. This

section will describe

some of the components of the aircraft

and operating details.

PROPELLER

The Executive 21 uses an alunlinu~n alloy constant speed pro-

peller of

74

inch diameter. The pitch of the blades is controlled

by engine oil pressure which acts to increase blade angle of

attack and thereby control engine speed. The propeller control

in the cabin operates the propeller governor which controls the

oil pressure provided to the propeller hub. The governor

ser-

ting functions to maintain the engine at a constant speed by

actuating blade angle of attack. In essence then, the function

of the propeller control in the cabin is to regulate and maintain

the rotational speed of the engine at a desired setting.

ENGINE

The Executive 21 is powered by the Lyconling

200

hp

10-360-A

1A

four cylinder engine. This engine uses 100/130 octane fuel.

Four rubber bushings on the aft side of the engine provide

mounting and vibration isolation. Engine

~iianifold pressure

is

regulated by the push-pull throttle control on the panel.

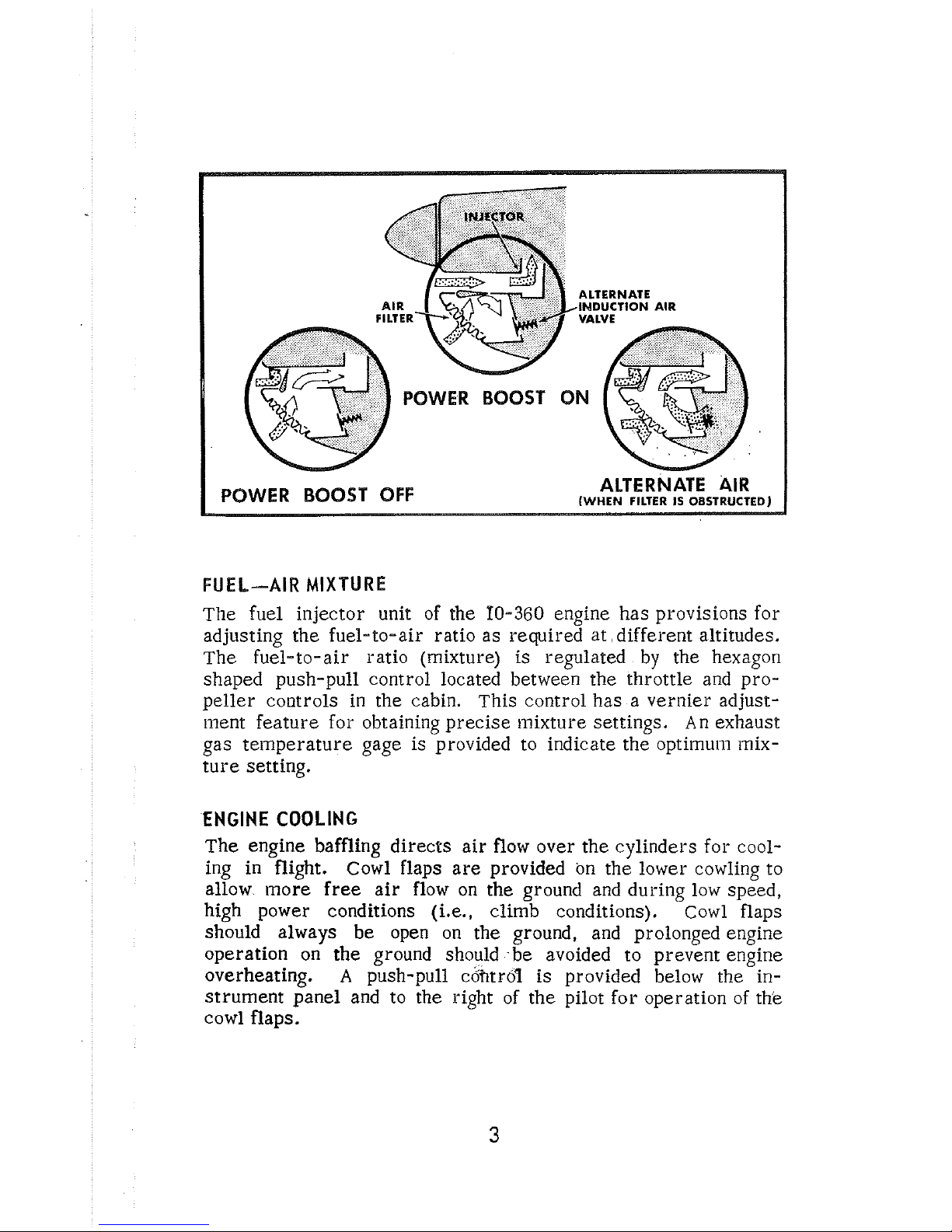

POWER

BOOST

A

unique Power Boost feature of the Executive 21 provides in-

creased

manifold p re

s s

u re when operating at full throttle.

This

is

a

c c o

111

p

1

is

h ed by pulling the Power Roost control

out, which causes induction air to by-pass the engine air filter

to

perinit the engine to operate

on

direct ram air. Because

the engine will be operating on unfiltered air when the Power

Boost is used,

it should be operated only in clean, dust free

Revised

March

1967

air at altitude, and turned off for take-off and landing.

Because

the Power Boost

is effective only when the throttle is in

the

fully opened position, its advantages generally will be realized

at altitudes above

5,000

feet where flight is often with full throt-

tle.

A

light is provided on the panel by the Power Boost control

to remind the pilot to push the control in (to filtered air) before

landing. This light will

come on when the gear

is

lowered

while Power Boost is on.

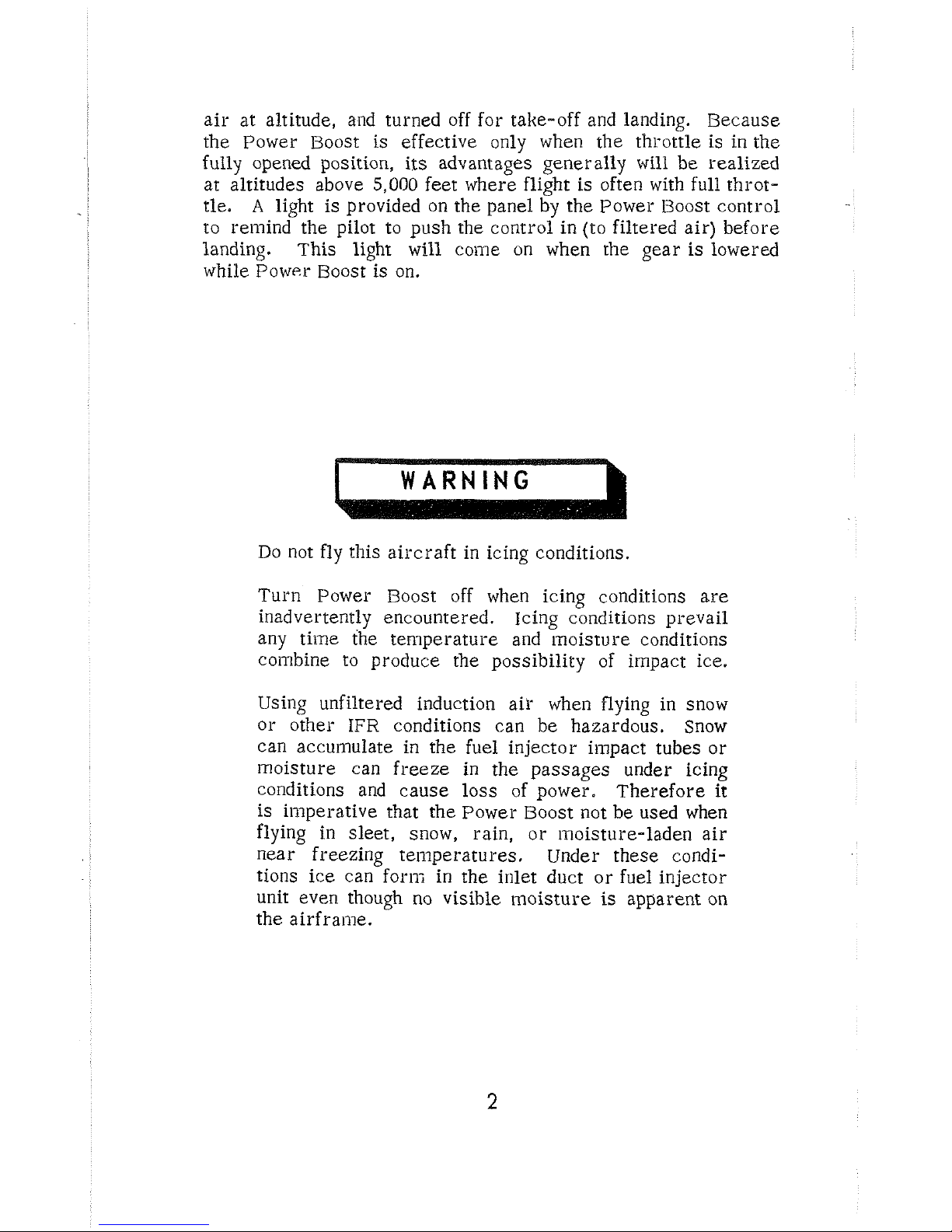

I

WARNING

Do not

fly

this aircraft in icing conditions.

Turn Power Boost off when icing conditions are

inadvertently encountered. Icing conditions prevail

any

time the temperature and inoisture conditions

coixbine to produce the possibility of impact ice.

Using unfiltered induction

air when flying in snow

or other

IFR

conditions can be hazardous. Snow

can accumulate in the fuel injector

impact tubes or

inoisture can freeze in the passages under icing

conditions and cause loss of power. Therefore it

is imperative that the Power Boost not be used when

flying in sleet, snow,

rain, or

i~~oisture-laden air

near freezing

teii~peratures. Under these condi-

tions ice can

for~li in the inlet duct or fuel injector

unit even though no visible moisture

is

apparent on

the

airframe.

POWER

BOOST

ON

FUEL-AIR

MIXTURE

The fuel injector unit of the

10-360

engine has provisions for

adjusting the fuel-to-air ratio as required at, different altitudes.

The fuel-to-air ratio (mixture) is regulated by the hexagon

shaped push-pull control located between the throttle and propeller controls in the cabin. This control has a vernier

adjustnlent feature for obtaining precise mixture settings. An exhaust

gas temperature gage is provided to indicate the

optiinurn mix-

ture setting.

ENGINE

COOLING

The engine baffling directs air flow over the cylinders for cooling in flight. Cowl flaps are provided on the lower cowling to

allow more free air flow on the ground and during low speed,

high power conditions

(i.e., climb conditions). Cowl flaps

should always be open on the ground, and prolonged engine

operation on the ground should be avoided to prevent engine

overheating.

A

push-pull cofitro'i is provided below the instrument panel and to the right of the pilot for operation of th'e

cowl flaps.

.ENGINE LUBRICATION

The engine has a pressure-type wet- sump lubrication system.

It has an eight quart capacity; however, as a general rule, when

the oil level drops below six quarts, one quart

is

added. This

will maintain the oil level between the six and seven quart level.

See Part

111 for type of oil used and time between oil changes.

An oil temperature thermostat, located in the oil reservoir,

is set for

180'

F.

to assure adequate operating engine oil tem-

peratures. The oil cooler is

mounted on the lower left side

of the cowling. An oil filter is available as optional equipment.

ENGINE IGNITION

The ignition system has the following features:

1.

Two Bendix magnetos, the left magneto being equipped with

a set of retard breaker points.

2.

A

starting vibrator, located on the upper firewall, which

furnishes a shower of sparks for starting.

3.

A

switch. which coinbines both ignition and starting functions.

4.

Shielded spark plugs and ignition harness to suppress radio

noises.

When the push-type starter switch is activated in the "start"

position, the starter vibrator sends an interrupted current

through the retard-breaker points while the right magneto

is

grounded out. The left magneto then provides a fixed retard and

a long duration, boosted spark for starting.

FUEL

SYSTEM

Fuel is carried

in

integral. sealed sections in the tront por-

tion of each wing root. Each tank will hold

32

gallons of aviation

gasoline

(100/130

octane\. An internally-mounted fuel quantity

indicator (effective

Dn

S/N

670074 & ON)

can be seen through

each fuel

tank filler neck. considering load and range requireinents. you lxay choose to fill each tank only to its 25-gallon

l~lark on the indicator. Tank vents allow ventilation as fuel is

depleted

and overflow when fuel expands in hot weather. The

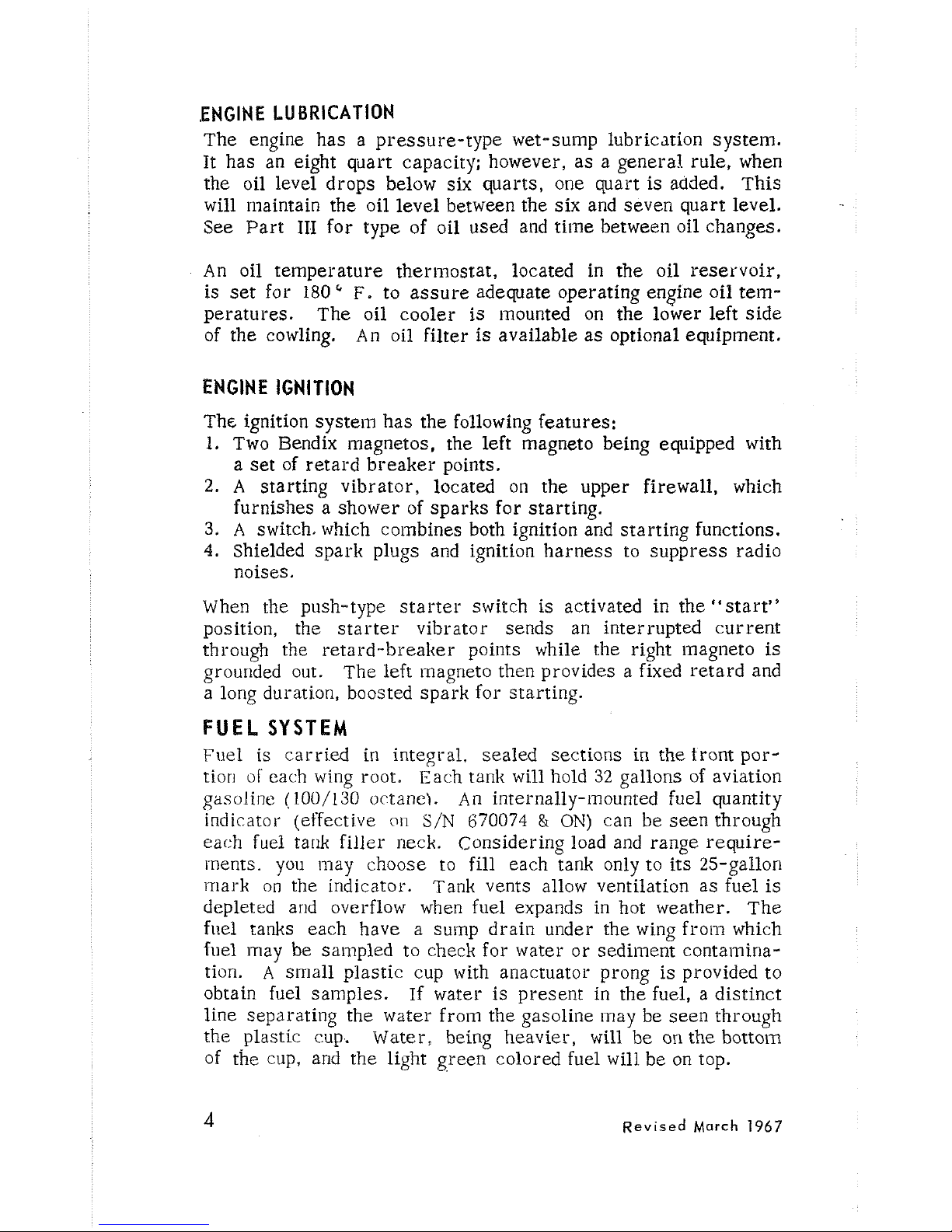

fnel tanks each have a suinp drain under the wing from which

fuel

]nay be saillpled to check for water or sediment contamina-

tion.

A

small plastic cup with anactuator prong is provided to

obtain fuel

sa~nples.

If

water is present in the fuel, a distinct

line separating the

water from the gasoline may be seen through

the plastic cup. Water. being heavier, will be

on

the bottom

of the cup, and the light green colored fuel will be on top.

4

Revised

March

1967

SAMPLING

FUEL

FROM MAIN TANKS

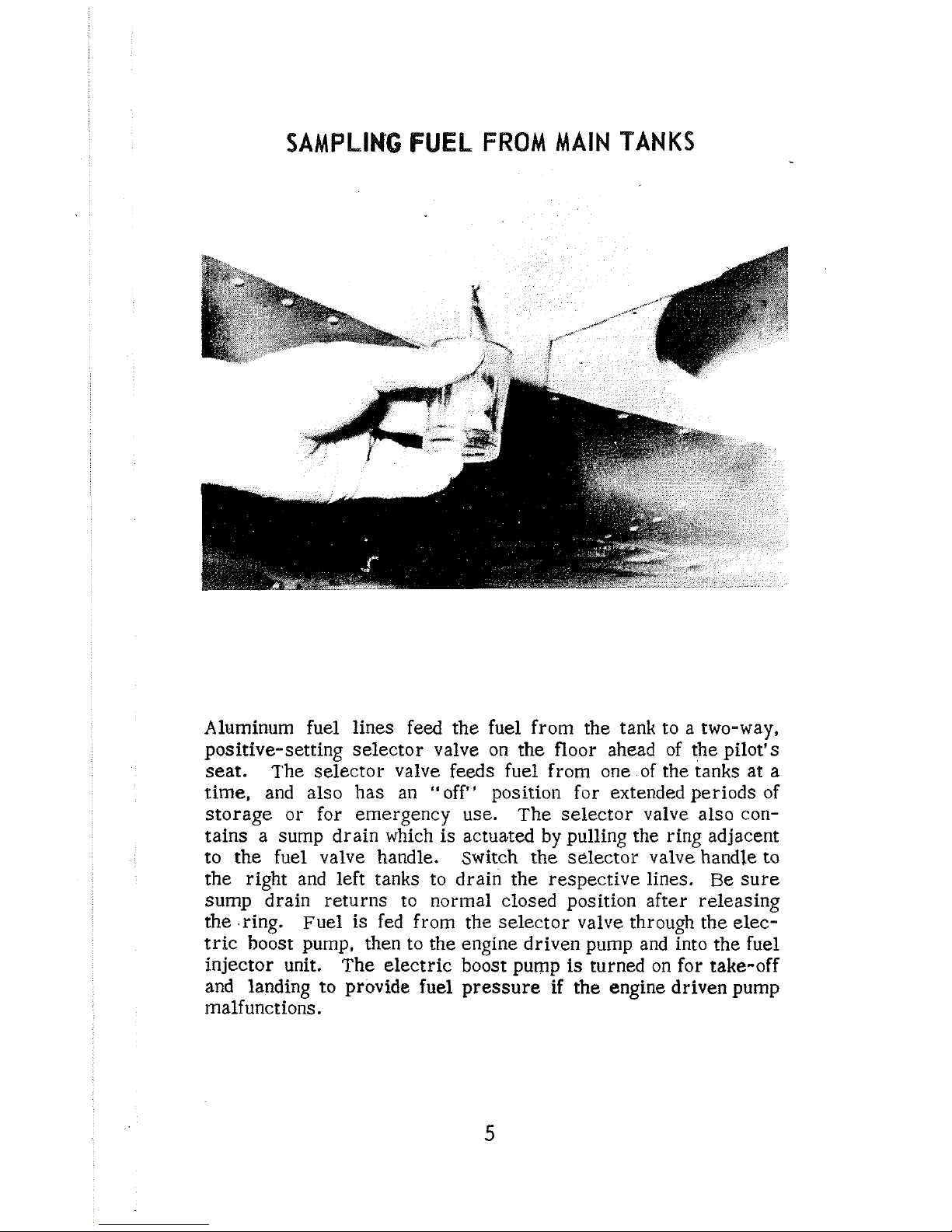

Aluminum fuel lines feed the fuel from the tank to a two-way,

positive-setting selector valve on the floor ahead of the pilot's

seat. The selector valve feeds fuel from one of the tanks at a

time, and also has an "off" position for extended periods of

storage or for emergency use. The selector valve also con-

tains a sump drain which

is

actuated by pulling the ring adjacent

to the fuel valve handle. Switch the selector valve handle to

the right and left tanks to drain the respective lines. Be sure

sump drain returns to normal closed position after releasing

the

.ring. Fuel is fed from the selector valve through the electric boost pump, then to the engine driven pump and into the fuel

injector unit. The electric boost pump

is

turned on for take-off

and landing to provide fuel pressure if the engine driven pump

inalfunctions.

SELECTOR DRAIN VALVE

1

WARNING

Under no circutnstances should aviation fuel of a

lower grade than

100/130 octane be used. Aviation

fuels

1xay be distinguished by their color:

80

octane

is

red,

91

octane is blue, and 100 octane

is

green.

ELECTRICAL

SYSTEM

The electrical syscenl is provided with a 50-amp.,

12-volt

gen-

erator and a

35

amp - hour battery which is located aft of the

baggage compartment. All electrical systems can be turned

off by the

master switch which actuates a relay located at the

battery.

The inaster switch for the electrical system is located

at the left-hand side of the flight panel. The electrical system

operates all the electrical accessories listed below:

1.

Radios

2.

Engine starter

3.

Starter vibrator

4. Navigation lights and interior lights

5.

Landing light

6.

Rotatirig beacon (if installed)

7.

Heated pitot

(if

installed)

8.

Turn coordinator

9.

Cigarette lighter

10.

Electric landing gear (if installed)

1

1.

Fuel gages

12.

Electric fuel puinp

13.

Stall warning horn

14. Landing gear warning horn and warning lights

NOTE: The engine has its own separate electrical

systelil

and will continue to run, even though the ~naster

switch has been turned off. or even though the accessory electrical

system should malfunction.

Interior Lights

Panel

illu~nination is provided by two adjustable spot lights

mounted on the headliner and individual post lights for the instrument panel. These lights are controlled by a rheostat. The

fuel selector valve is

illuillinated by a small light lnounted under

the panel on the left side.

The intensity of this light is con-

trolled

by

rotating the lens housing.

Amineter

The ammeter in the engine instrument clustgr will indicate if

the battery is charging or

discWt-ging.

A

inalfunction in the

generator or voltage regulator will be shown

a3 an ammeter

discharge at flight power settings.

A

low battery will cause a

high charge indication.

Revised

March

1967

Electrical Panel

The electrical panel is divided into two parts:

a. The electrical toggle switches, on the lower left side of the

pilot's panel, act in combination both as on-off switches and

as breaker switches. Should any of these circuits be overloaded, the switch

auto~~~atically turns to the "ofP' position.

These switches are,

froin left to right:

1.

The electrical fuel puinp

2.

An optional equipment switch (Marker beacon)

3.

An optional equipment switch (Glide slope)

4.

An optional equipment switch (Pitot heat)

5. An optional equipment switch (Rotating beacon)

6.

The navigation lights

7.

The landing light

b. The breaker switches which are located on the lower right

side of the copilot's panel, are covered by a special breaker

switch cover. These switches are of the push-to-reset

type*

AIRFRAME

The structure of the Executive

21

is of conventional all-metal

design. The cabin section consists of tubular steel structure

covered with

alu~ninunl sheet metal. The center windshield

post and the

firewall are stainless steel.

'The wing, stabilizer, and fin have

a

11iain spar design and an

auxiliary spar with stressed skin to carry torsional loads.

?'he

tail cone is a conventional semi-monocoque design,

The seat

design features contoured construction. The front seats are

adjustable fore and aft and have adjustable three-position backs.

The rear seat back may be

retnoved for additional cargo space.

The entire empennage pivots around two attachment points to

the tail cone to provide stabilizer trim.

A

screw

mechanism

actuates the empennage movement at the rear bulkhead when

the

trim control wheel is operated.

Revised

March

1967

LANDING

GEAR

Manual Systern

The landing gear is unique in that it is manually retracted by

the pilot by

means of a lever in the cabin.

The systein is op-

erated by direct mechanical linkage and has proven to be one

of the

most reliable and maintenance-free retraction systeins

available. An electrically powered landing gear retractipn systen1 is also available at extra cost and is described in the following section.

The

inanual system is aided

by

bungee type springs in the fuselage and assist springs in the wing, which balance the weight of

the gear.

~ubber discs are used for shock absorption in the

welded steel tube gear structure. Grease fittings are provided

at certain

iinportant lubrication points on the landing gear.

The position of the gear is indicated by lights on the panel which

will warn of an unlocked condition. These lights

may be dinllned

by rotating the lens housing to prevent glare at night. Press the

lens housing in to test the bulbs. The red indicator light will

coine

on if the handle on the retraction lever is not sufficiently engaged in the down and locked position, thereby indicating

an unsafe-to-land condition. The green light indicates that the

handle is

properly engaged in the down position, and the gear

is in the landing configuration.

A

thumb operated latch

is

provided on the down socket to prevent unlocking of the gear when

it is down unless it is deliberately released.

To retract the gear, depress the safety latch button and slide

the gear handle

fro111 the down-lock socket.

Move the handle

rapidly to the

floor between the seats.

Slide the gear handle

into the up-lock socket, and the operation is complete. The

more rapid the lnovernent of the handle, the easier it is to re-

tract the gear. The gear retracts easiest at low airspeeds.

To lower the gear, slide the gear handle

from the up-lock socket

and

move the handle forward to the instrument panel. Slide the

gear handle into the down-lock socket and check the gear warning

light for a gear-down indication (a green light).

Electrical Gear Systein (optional)

The optional electrical landing gear retraction

systetn is operated by the wheel-shaped switch on the upper portion of the

flight panel. To raise the gear, the knob is pulled out and the

switch moved up to its upper detent. An "airspeed switch" is

incorporated in the electrical circuit which prevents landing

gear retraction until a safe airspeed is attained.

Never rely on the airspeed safety switch to keep

the gear extended while taxiing, taking off or landing.

Always check the gear switch for the down position.

A

litilit switch will stop the gear in its retracted position; the

gear-up light will coine on, and the gear switch will require no

further attention until landing. To lower the landing gear, the

knob is pulled out,

~noved down, and placed in the lower detent.

A

liinit switch will stop the gear system when the proper locking force has been exerted to hold the gear down, and the green

gear-down-light will come on.

A

discharged storage battery lnay prevent the land-

ing gear

fro111 fully extending.

There are three ways to check that the gear is completely down

and locked:

1.

The green "safe-to-land" indicator light (on the left panel)

will

coine on.

2.

The black indicator marks, as seen through the glass in the

floorboard, will be aligned.

3.

Retard throttle fully, and if no warning horn is heard the

gear should be down and locked. The gear warning horn

eniits an interrupted sound of a different pitch than the stall

warning horn.

When these conditions are fulfilled, the aircraft inay be landed

with no further attention to the landing gear

syste~i~.

Loading...

Loading...