Moog Videolarm WS5-50NF, WARRIOR 5, WS5 Product Instructions

81-IN5218-06154 WARRIOR 5

WS5-XXXX

REVISION DATE: August 3, 2004

TABLE OF CONTENTS

PRODUCT INSTRUCTIONS

Cable and Power Guidelines 1, 11

Installation Preparation 1

Installation Procedure 1

Wiring 2

Optional Warrior Test Monitor Cable 2

Camera Bracket Setup 2

Camera Focusing 3

Camera Settings 3

Completion of Installation 5

Window Guard™ Replacement 5

NVT Instructions 5

Warranty Information 7

Service and Safeguard Information 8

Troubleshooting 9

CABLE AND POWER GUIDELINES

(Detailed info on Page 11)

This chart shows the proper current needed for power supplies

for Warrior Series cameras. Use Class 2 Power only. Input voltage

must be between 12-28 VDC or 15-28 VAC.

4 3/4"

S

T

U

4 3/4"

Cutout

Figure 1

NOTE: The double-gang box must be fl ush with the drywall.

Two sets of mounting holes are provided on the

sides of the gang box. Use either to ensure that the

box is fl ush with the drywall.

2. Using the security tool provided, loosen the (4) 8-32 security

fasteners and remove the face plate (Figure 2).

D

VOLTAGE CURRENT POWER

12 VDC 350mA 4.2W

24 VAC 202mA 4.8W

Depending on the voltage being used, refer to one of the formulas

below to select the correct power supply for cameras connected in

parallel (positive to positive, negative to negative):

Total current for a 12 VDC system:

TOTAL CURRENT = (350mA x total number of cameras)

Total current for a 24 VAC system:

TOTAL CURRENT = (202mA x total number of cameras)

INSTALLATION PREPARATION

1. Determine the mounting location. Be sure that you’ll be mounting

to a secure wall or ceiling, next to a stud.

2. Complete all wire and conduit runs prior to installation of the

housing.

INSTALLATION PROCEDURE

1. Cut a 4 3/4” x 4 3/4” square hole in the surface with one side

against the stud (Figure 1). If necessary, use the template

provided on the last page of these instructions.

Figure 2

3. Loosen the (2) 8-32 screws holding the top of the camera bracket

and camera in place (Figure 3) and remove.

Figure 3

4. Position the double-gang box in the cutout against the stud and

mark the location of the two mounting holes on the side. Remove

the double-gang box.

5. Determine which side the conduit outlet will be located on: Top,

bottom, left, right, or back. Remove the desired conduit knockout.

CAUTION: TO PREVENT DAMAGE, THE CAMERA AND

BRACKET MUST BE REMOVED BEFORE

TAKING OUT THE CONDUIT KNOCKOUT.

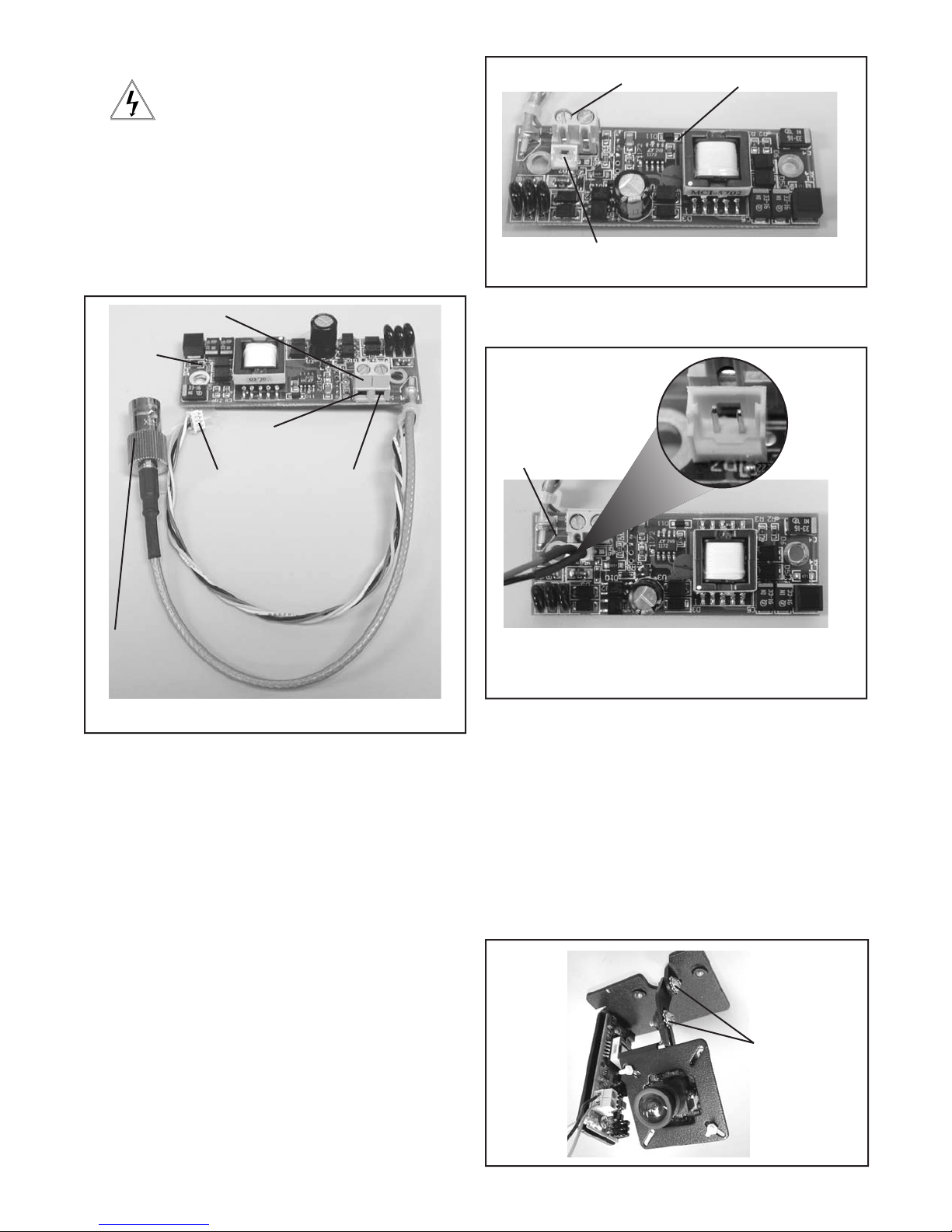

WIRING (Figure 4)

Use Class 2 Power only. Input voltage must be

between 12-28 VDC or 15-28 VAC.

1. Connect the output of your Class 2 Power Supply to the terminal

connectors on the PC Board inside the housing. Refer to the

Troubleshooting section later in this instruction sheet for more

information.

2. Connect the incoming video cable to the BNC connector.

NOTE: For NVT Twisted Pair see Addendum 1.

Te r minal Connector

Test Monitor Cable plug

Figure 5

Power Board

Te r minal Connector

Power

Board

Positive

Connected to

the Camera

Connect to

incoming video

BNC

Figure 4

Negative

OPTIONAL WARRIOR TEST MONITOR CABLE

(Part # - WSTMC)

3. Plug the test monitor cable into the power board (Figure 6).

Attach the BNC connector to your test monitor.

The plug for the Test

Monitor Cable is polarity

protected and can only

be inserted one way.

Test Monitor Cable (NOTE: Your cable may look different)

Figure 6

NOTE: The following instructions are for camera bracket setup,

camera focusing, and camera set-up.

The fi nal steps for installation follow these sections.

DESCRIPTION

The Warrior Test Monitor Cable is a tool that allows users to view

video from cameras via a small on-site monitor. It's quick and

easy to use.

1. Using the security tool provided, loosen the four security

fasteners and remove the housing top. NOTE: The housing

top is held to the base by a lanyard.

2. Locate the power board on the inside of the housing. The Test

Monitor Cable plug is located beside the terminal block where

incoming power is connected (Figure 5).

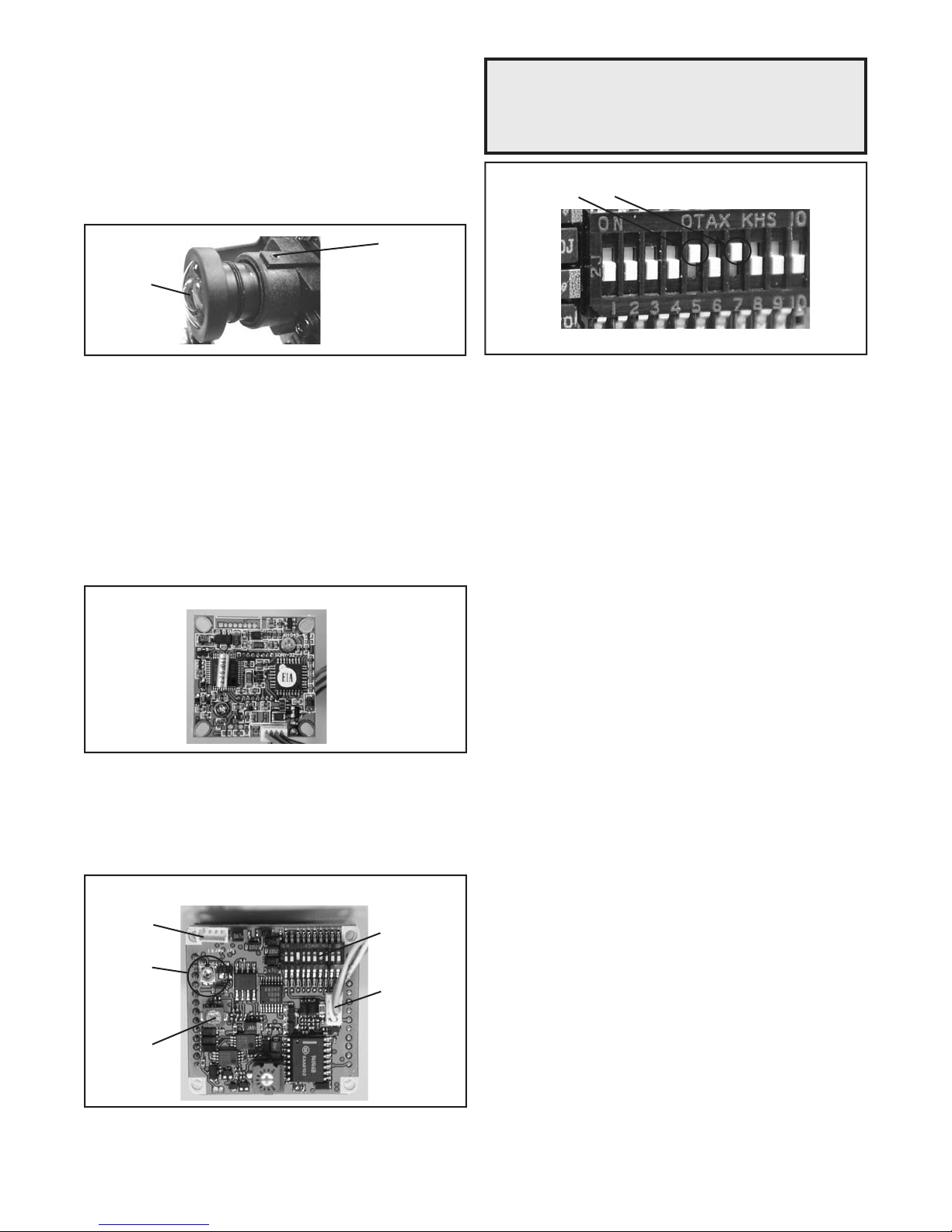

CAMERA BRACKET SETUP

Reattach the camera bracket to the double-gang box using the

(2) 8-32 screws. Check to determine if the position of the camera is

correct. To adjust the bracket, loosen the (2) 8-32 adjustment screws

(Figure 7). Use Loctite™ or an equivalent product to secure the

screws, especially in installations where vibration is a concern.

8-32

Adjustment

Screws

Figure 7

- 2 -

CAMERA FOCUSING (Figure 8)

1. The camera is factory equipped with a 3.6mm fi xed lens. A

2.5mm lens is also provided. To remove the 3.6mm lens, loosen

the set screw and unscrew the lens counter-clockwise.

NOTE: Dip switches are factory pre-set for optimum performance.

In certain specifi c instances it may be necessary to adjust

one or more settings. Consult a qualifi ed technician before

making any adjustments. A Dip Switch settings chart is

available on the next page.

2. Fine focusing of the lens: Loosen the set screw in the lens mount

and manually rotate the lens until a clear picture is achieved. Once

the focus is set, retighten the set screw.

Set screw

Fixed lens

Figure 8

CAMERA SETTINGS

NOTE: To determine which camera is used in your unit, locate the

serial number on the inside of the housing. Match the two

letter prefi x with the corresponding instructions included

here for adjustments.

SERIAL NUMBERS BEGINNING WITH YK

FIXED AND FIXED VARI-FOCAL LENSES. There are no user

adjustable settings on these units (Figure 9).

BW Fixed and Vari-Focal

FACTORY DEFAULT FIXED AND FIXED VARI-FOCAL LENSES:

Dip Switches 5 and 7 on, all others off.

Figure 11

Figure 9

SERIAL NUMBERS BEGINNING WITH MC

The operational settings for the camera are defi ned by ten dip

switches located on the PC Board (Figure 9). Moving the switches to

the on position will activate each setting. Factory defaults are pictured

below (Figure 10).

Hi-Res Color, Fixed and Vari-focal fi xed lenses

Factory

Use Only

Auto Iris

adjustment

screw

DO NOT

ADJUST

Figure 10

Dip Switches

Connection to

Power Board

- 3 -

Loading...

Loading...