Moog Videolarm QMRT2-50NA, QMRT3-50NA, QMRT, QMRC Product Instructions

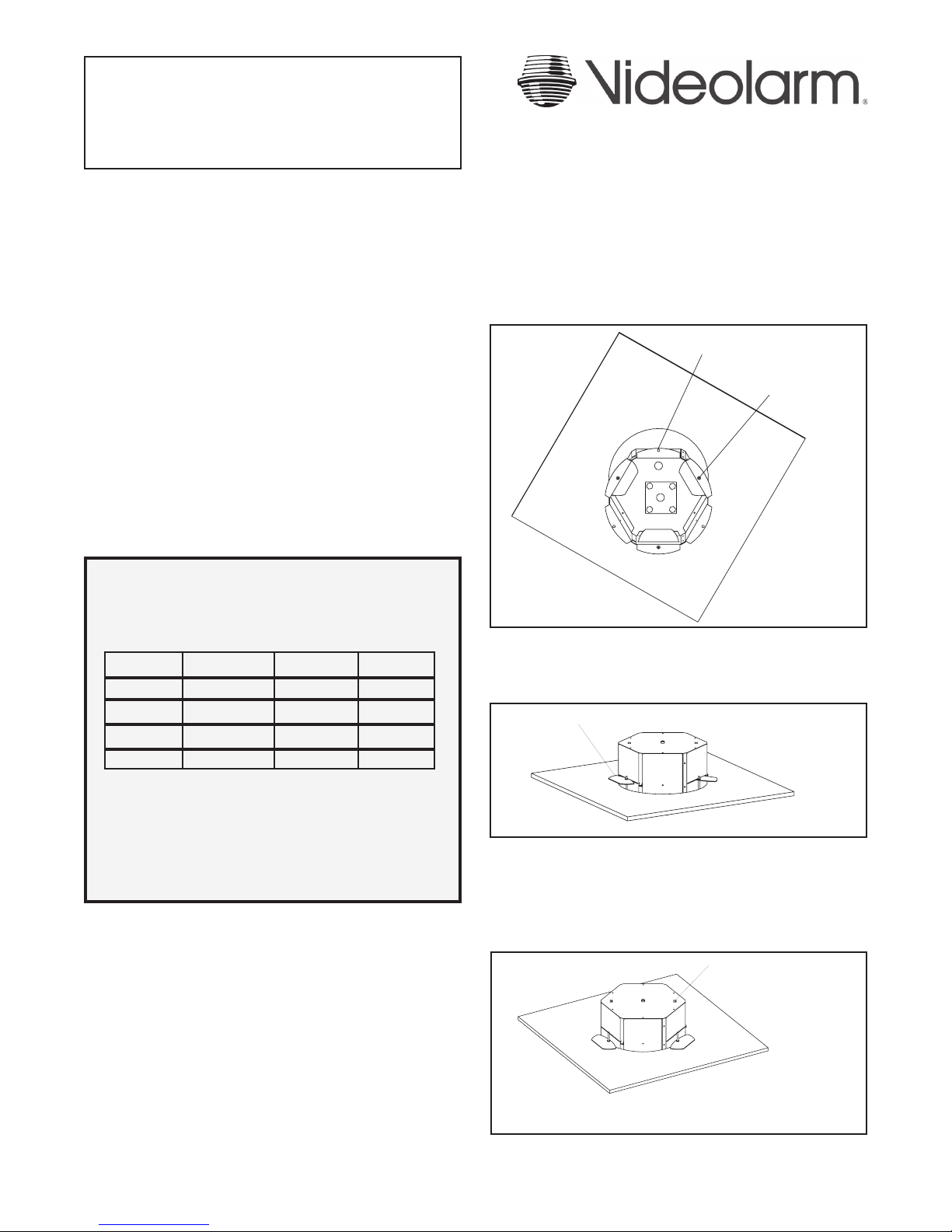

Mounting Holes

Support Arm Holes

Support Arms Rotate Out

Support Wires

81-IN5258-07064

QMR Ceiling Mount Dome

QMR(T/C)X-XXXX

REVISION DATE: July 6, 2004

TABLE OF CONTENTS

Cable and Power Guidelines 1, 11

Electrical Specifications 1

Housing Installation 1

Wiring 2

Camera Adjustment 2

Camera Focusing 2

Camera Settings

Black/White 2

Color 3

Completion of Installation 3

NVT Instructions 3

Exploded View 5

Warranty Information 6

Service and Safeguard Information 7

Troubleshooting 8

PRODUCT INSTRUCTIONS

4. Remove the trim ring/dome assembly by pulling on the outside

of the trim ring. The ring and dome are connected by three flat

springs, which press against the side of the housing and lock into

(3) cutouts.

5. Run electrical cable and video leads into the housing through the

conduit knock-out.

6. With the (3) support arms rotated to the inside, slide the housing

into the pre-cut hole (Figure 1).

CABLE AND POWER GUIDELINES (Detailed info on Page 11)

This chart shows the proper current needed for power supplies for

Q-View™ cameras. Use Class 2 Power only. Input voltage must

be 24 VAC/VDC.

CAMERAS VOLTAGE CURRENT POWER

1 24 VAC/VDC 102mA 2.5W

2 24 VAC/VDC 210mA 5W

3 24 VAC/VDC 331mA 7.9W

4 24 VAC/VDC 487mA 10.9W

Use the formula below to select the correct power supply for

cameras connected in parallel (positive to positive, negative to

negative):

Total current for a 24 VAC system:

TOTAL CURRENT = (202mA x total number of cameras)

Note: 202mA is camera plus power supply

HOUSING INSTALLATION

1. Carefully remove all equipment from the box.

2. Place the 11 1/8" template provided with the unit at the desired

location on the ceiling. Trace around the template, then cut a hole

in the ceiling following the trace lines.

3. Remove the desired conduit knock-out from the top of the QMR

housing.

Figure 1

7. With the bottom flange pressed up against the ceiling, rotate the

support arms to the outside, the arms will fall to the back side of

the ceiling. Tighten the (3) support arm screws (Figure 2).

Figure 2

8. If the housing is going into a ceiling where the support arms will

not work, secure the housing by running bolts into the solid ceiling

through the mounting holes in the bottom flange (Figure 1).

9. For added support, run support wires from a secure structure to

the two slots provided on the top of the housing (Figure 3).

Figure 3

WIRING

1. Make the proper connections to the incoming power. The RED

wire is POSITIVE (+), the BLACK wre is NEGATIVE (-) (For refer-

ence purposes. Polarity is not important in this unit). The GREEN

wire, labeled Ground, is GROUND for VAC or VDC connections.

NOTE: Connect green ground wire to earth ground (metal conduit,

metal stud, etc.)

CAMERA SETTINGS

NOTE: To determine which camera is used in your unit, locate the

serial number on the inside of the housing. Match the two

letter prefix with the corresponding instructions included

here for adjustments.

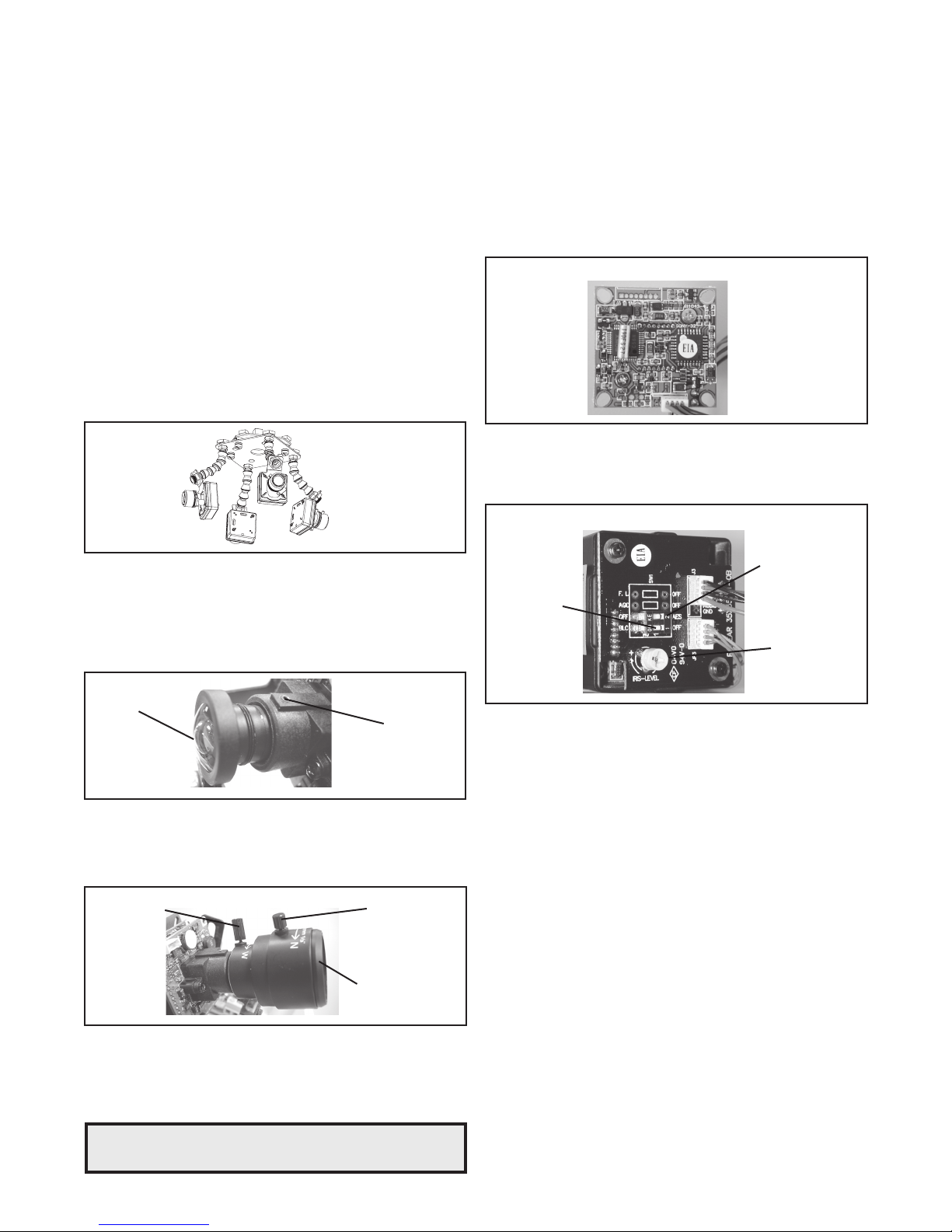

SERIAL NUMBERS BEGINNING WITH YK

2. Attach the BNC connectors to the video in.

CAMERA ADJUSTMENTS

1. After completing installation of the housing, use the segmented

arms to adjust each camera to the desired viewing location

(Figure 4).

2. Once camera adjustments are made, place the dome back into

position to be sure cameras are not touching the inside of the

dome. If any do, adjust until they are clear.

Figure 4

CAMERA FOCUSING

1. Fine focusing:

Fixed Lens: Loosen the set screw in the lens mount and

manually rotate the lens until a clear picture is achieved. Once

the focus is set, retighten the set screw (Figure 5).

Fixed lens

FIXED AND FIXED VARI-FOCAL LENSES. There are no user

adjustable settings on these units (Figure 7).

BW Fixed and Vari-Focal

Figure 7

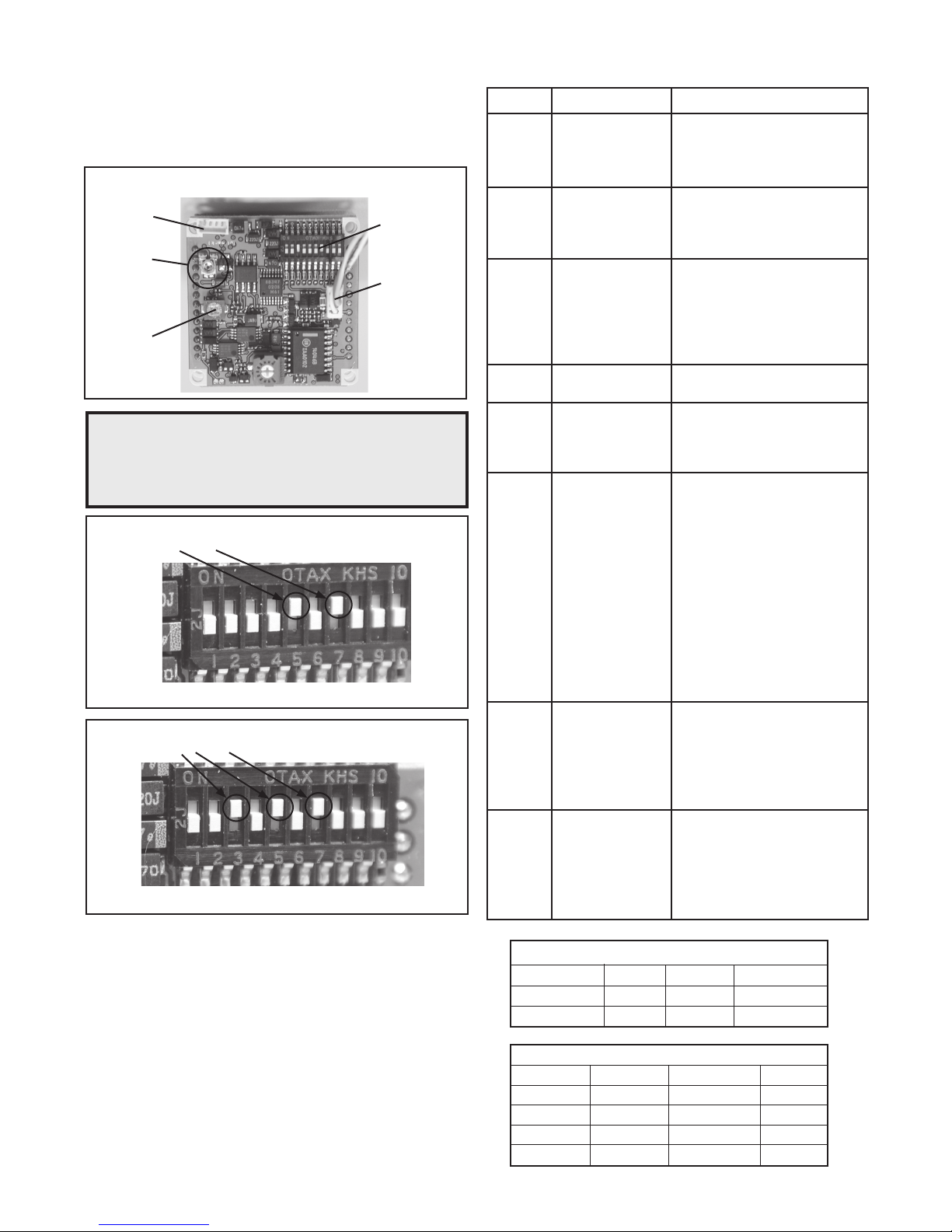

AUTO IRIS LENSES. The dip switches are factory set with AES

off and backlight compensation on (Figure 8). The auto iris is also

set at the factory, but an adjustment screw is included for use if

needed. See page 10 for instructions on adjusting Auto Iris.

BW Auto Iris

AES Default Off

Backlight

Compensation

Default On

Auto Iris

adjustment

screw

Figure 8

Set screw

Figure 5

Vari-Focal Lens: First, adjust the Magnification Lock Screw to the

desired magnification (telephoto to wide angle). Tighten the Lock

Screw. Next, adjust the Focus Lock Screw until a clear picture is

achieved. Tighten the Lock Screw (Figure 6).

Magnification lock screw

Figure 6

Auto Iris Lens:

NOTE: THE AUTO IRIS LENS IS SET AT THE FACTORY.

• IF YOU EXPERIENCE VIDEO TOO LIGHT OR DARK

AUTO IRIS ADJUSTMENT MAY BE NEEDED.

Focus lock screw

Fixed iris varifocal lens

SEE THE TROUBLESHOOTING SECTION FOR

ADJUSTMENT INFORMATION.

- 2 -

SERIAL NUMBERS BEGINNING WITH MC

The operational settings for the camera are defined by ten dip switch-

es located on the PC Board (Figure 9). Moving the switches to the on

position will activate each setting. Factory defaults are pictured below

(Figure 10 and 11).

Hi-Res Color, Fixed and Vari-focal fixed lenses

Factory

Use Only

Auto Iris

adjustment

screw

DO NOT

ADJUST

Figure 9

NOTE: Dip switches are factory pre-set for optimum performance.

In certain specific instances it may be necessary to adjust

one or more settings. Consult a qualified technician before

making any adjustments. A Dip Switch settings chart is

available on the next page.

FACTORY DEFAULT FIXED AND FIXED VARI-FOCAL LENSES:

Dip Switches 5 and 7 on, all others off.

Figure 10

FACTORY DEFAULT AUTO IRIS LENSES:

Dip Switches 3, 5 and 7 on, all others off.

Figure 11

Dip Switches

Connection to

Power Board

MC CAMERA DIP SWITCH SETTINGS CHART

SWITCH SETTING DEFINITION

1 Setting this switch to "On" and

2

3

4

5

6

7

8

9

10

Flickerless Mode

BLC (Back Light

Compensation)

MIRIS (Manual/

Electronic Iris

GAMMA

AGCMAX

(auto/gain control)

(Automatic White

Balance Control)

AW1

AW2

AW3

AEREF

AEME

switch 3 (MIRIS) to "Off" will

help to reduce the flicker in

fluorescent lights

Helps prevent an object from

being washed out when the

object is directly in front of a

light source.

When the switch is in the

on position the auto iris lens

controls the amount of light on

the chip. If in the off position

the light level is controlled

electronically.

Helps balance the contrast in

the picture.

Allows day/night cameras to

switch to b/w in low light conditions,

also helps with low light conditions

in standard and hi-res cameras

Used to help improve the

color quality of the camera

picture under different lighting conditions. The Factory Default is Switch 7 "ON",

switches 6 and 8 "OFF".

NOTE: ANY ADJUSTMENTS

TO THESE SETTINGS

SHOULD ONLY BE MADE

BY A QUALIFIED CCTV

TECHNICIAN

See examples below to help

with any adjustments.

This sets the electronic

convergence level. In the "off"

position the level is set to 100

IRE; in the "on" position the

user can set the level. Not

used with auto Iris

With this switch in the "On"

position users can manually

adjust the shutter speed and

gain using other switches See

the tables below for specific

settings

SHUTTER SPEED

Flickerless (1) BLC (2) MIRIS (3) Shutter Speed

On Off Off 1/100 Sec.

Off On Off 1/60 Sec.

GAIN

MIRIS (3) AEREF (9) AGCMAX (5) Gain

On Off Off 0dB

On On Off 6dB

On Off On 12dB

On On On 18dB

SERIAL NUMBERS BEGINNING WITH CB

NOTE: This hi-res color camera uses a 1/4" chip and a 3-6mm

auto iris lens. It is comparable to a 1/3" chip using a

4-9mm auto iris lens.

The operational settings are defined by four dip switches located on

the side of the PC Board (Figure 12 and 13). Moving the switches

to the UP position will activate specific settings. Refer to the chart

below.

Dip Switches

Auto Iris

Adjustment

Screw

Figure 12

Figure 13

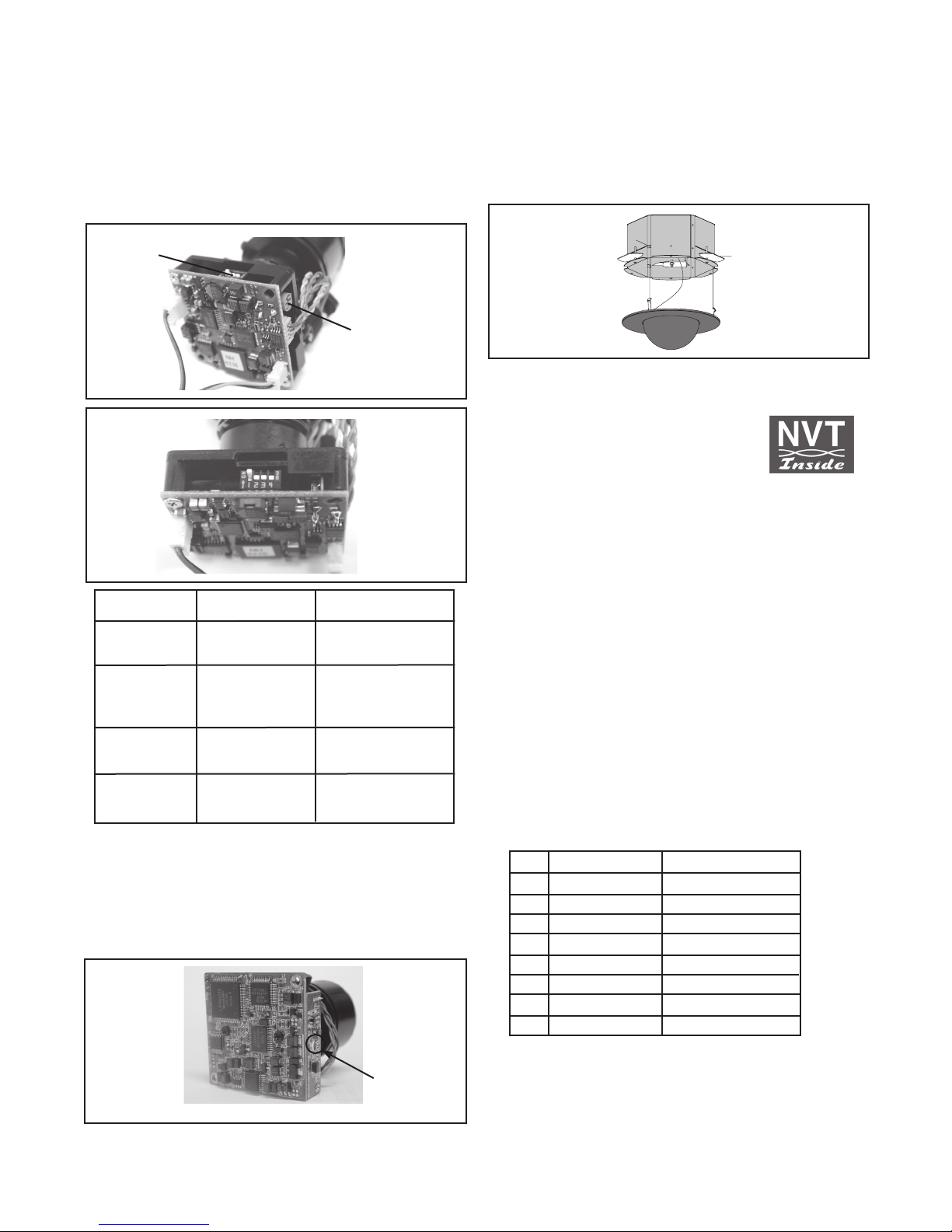

COMPLETION OF INSTALLATION

Once all connections and adjustments have been made reattach the

trim ring/dome assembly by pressing in and sliding the three flat

springs into the housing (Figure 15). Make sure the springs are

aligned with the three spring slots. You will feel all three springs snap

into place when the dome is correctly secured into place. Rotate the

dome for final proper positioning of the liner and camera.

Figure 15

NVT INSTRUCTIONS

UNSHIELDED TWISTED PAIR

VIDEO WIRING

NOTE: The customer must purchase the Video Transceiver from

NVT. Part numbers are:

• NV-212A (500 ft.)

* NV-213A or NV-213A-M (1000 ft.)

• NV-652R, NV-862R, or NV-1662R (3000 ft.)

Dip Switch UP DOWN

1

(Iris) Auto Iris On Position for Fixed Lens

2

(Flickerless) Shutter speed Normal

fixed at 1/100 sec.

3 (Back Light ON Normal

Compensation

4

(Synch Mode) Internal Synch Line Lock Mode

SERIAL NUMBERS BEGINNING WITH CT

FIXED AND FIXED VARI-FOCAL LENSES. There are no user adjustable settings on these units (Figure 14)

AUTO IRIS LENSES: The auto iris can be adjusted if needed. See

the Troubleshooting section for instructions.

Auto Iris

adjustment

screw

Figure 14

The cameras included in the Q-View™ series have the option of

transmitting video signals to NVT receivers via unshielded twisted

pair cable. You must purchase the receiver separately. Instructions for

connecting the receiver end of the the unshielded twisted pair cable

will be included with the NVT receiver. Following are instructions for

connecting the unshielded twisted pair cables to the RJ45 (Cat. 5)

cable running outside your housing.

1. Video for all four cameras is contained in the one RJ45 (Cat. 5)

cable. An RJ45 female coupling is provided so that all connections

can be made with an RJ45 connector. The following is the wiring

diagram for the four twisted pair wires that are included with the

Cat. 5 cable.

PIN WIRE COLOR CAMERA NUMBER

1 White/Green Camera 1 +

2 Green Camera 1 -

3 White/Orange Camera 2 +

6 Orange Camera 2 -

5 White/Blue Camera 3 +

4 Blue Camera 3 -

7 White/Brown Camera 4 +

8 Brown Camera 4 -

Loading...

Loading...