Moog Videolarm PDW7CN-9, PDW7CS-9, PFD7C12N-3, PFD7C12S-3 User Manual

www.videolarm.com

PDW7CS-9

Explosion-Proof: Purge/ Pressurization Unit

PDW7CN-9 IP Network Ready 7” Explosion-Proof PurgeDome™ Outdoor

PTZ Camera Systems for Hazardous environments UL

approved for Class 1, Division II applications. Includes

Purging System and Lines. With 23x zoom Day/Night

camera, MPEG-4 & MJPEG video compression,

Full D1. Clear dome, with 24VAC input, heater/ blower

PDW7CS-9 Analog 7” Explosion Proof PurgeDome™ Outdoor PTZ Camera

Systems for Hazardous environments UL approved for

Class 1, Division II applications. Includes Purging System

and Lines. With 23x zoom Day/Night camera, MPEG-4 &

MJPEG video compression, Full D1. Clear dome, with

24VAC input, heater/ blower

Before attempting to connect or operate this product, please read these

instructions completely. To be used with the 81-IN5409 Instruction Manual.

81-IN5410

01-30-2009

IMPORTANT SAFEGUARDS SAFETY PRECAUTIONS

UNPACKING

SERVICE

1 Read these instructions.

2 Keep these instructions.

3 Heed all warnings

4 Follow all instructions.

5 Do not use this apparatus near water.

6 Clean only with damp cloth.

7 Do not block any of the ventilation openings. Install in accordance with the

manufacturers instructions.

8 Cable Runs- All cable runs must be within permissible distance.

9 Mounting - This unit must be properly and securely mounted to a supporting

structure capable of sustaining the weight of the unit.

Accordingly:

a. The installation should be made by a qualified installer.

b. The installation should be in compliance with local codes.

c. Care should be exercised to select suitable hardware to install the unit, taking into

account both the composition of the mounting surface and the weight of the

unit.

10 Do not install near any heat sources such as radiators, heat registers, stoves, or other

apparatus ( including amplifiers) that produce heat.

11 Do not defeat the safety purpose of the polarized or grounding-type plug. A

polarized plug has two blades with one wider than the other. A grounding type

plug has two blades and a third grounding prong. The wide blade or the third

prong are provided for your safety. When the provided plug does not fit into your

outlet, consult an electrician for replacement of the obsolete outlet.

12 Protect the power cord from being walked on or pinched particularly at plugs,

convenience receptacles, and the point where they exit from the apparatus.

13 Only use attachment/ accessories specified by the manufacturer.

14 Use only with a cart, stand, tripod, bracket, or table specified by the manufacturer,

or sold with the apparatus. When a cart is used, use caution when moving the cart/

apparatus combination to avoid injury from tip-over.

15 Unplug this apparatus during lighting storms or when unused for long periods of time.

16 Refer all servicing to qualified service personnel. Servicing is required when the

apparatus has been damaged in any way, such as power-supply cord or plug is

damaged, liquid has been spilled of objects have fallen into the apparatus, the

apparatus has been exposed to rain or moisture, does not operate normally, or

has been dropped.

Be sure to periodically examine the unit and the supporting structure to make sure that the

integrity of the installation is intact. Failure to comply with the foregoing could result in the

unit separating from the support structure and falling, with resultant damages or injury to

anyone or anything struck by the falling unit.

Unpack carefully. Electronic components can be

damaged if improperly handled or dropped. If an item

appears to have been damaged in shipment, replace

it properly in its carton and notify the shipper.

Be sure to save:

1 The shipping carton and packaging material.

They are the safest material in which to make

future shipments of the equipment.

2 These Installation and Operating Instructions.

If technical support or service is needed, contact us

at the following number:

The lightning flash with an arrowhead

symbol, within an equilateral triangle, is

intended to alert the user to the presence

of non-insulated “dangerous voltage”

within the product’s enclosure that may be

of sufficient magnitude to constitute a risk

to persons.

Este símbolo se piensa para alertar al usuario a la

presencia del “voltaje peligroso no-aisIado” dentro del

recinto de los productos que puede ser un riesgo de

choque eléctrico.

Ce symbole est prévu pour alerter I’utilisateur à la

presence “de la tension dangereuse” non-isolée dans la

clôture de produits qui peut être un risque de choc

électrique.

Dieses Symbol soll den Benutzer zum Vorhandensein der

nicht-lsolier “Gefährdungsspannung” innerhalb der

Produkteinschließung alarmieren die eine Gefahr des

elektrischen Schlages sein kann.

Este símbolo é pretendido alertar o usuário à presença

“di tensão perigosa non-isolada” dentro do cerco dos

produtos que pode ser um risco de choque elétrico.

Questo simbolo è inteso per avvertire I’utente alla

presenza “di tensione pericolosa” non-isolata all’interno

della recinzione dei prodotti che può essere un rischio di

scossa elettrica

.

The exclamation point within an equilateral

triangle is intended to alert the user to

presence of important operating and

maintenance (servicing) instructions in the

literature accompanying the appliance.

Este símbolo del punto del exclamation se piensa para

alertar al usuario a la presencia de instrucciones

importantes en la literatura que acompaña la

aplicación.

Ce symbole de point d’exclamation est prévu pour

alerter l’utilisateur à la presence des instructions

importantes dans la littérature accompagnant

l’appareil.

Dieses Ausruf Punktsymbol soll den Benutzer zum

Vorhandensein de wichtigen Anweisungen in der

Literatur alarmieren, die das Gerät begleitet.

Este símbolo do ponto do exclamation é pretendido

alertar o usuário à presença de instruções importantes

na literatura que acompanha o dispositivo.

Questo simbolo del punto del exclamaton è inteso per

avvertire l’utente alla presenza delle istruzioni importanti

nella letteratura che accompagna l'apparecchio.

TECHNICAL SUPPORT

AVAILABLE 24 HOURS

1- 800 - 554 -1124

RISK OF ELECTRIC SHOCK

DO NOT OPEN

CAUTION

CAUTION: TO REDUCE THE RISK OF

ELECTRIC SHOCK, DO NOT REMOVE

COVER ( OR BACK). NO USER- SERVICE-

ABLE PARTS INSIDE. REFER SEVICING TO

QUALIFIED SERVICE PERSONNEL.

LIMITEDWARRANTY FOR VIDEOLARM INC. PRODUCTS

VIDEOLARMINC. warrantsthis Productto be freefromdefectsin materialor workmanship,as follows:

PRODUCTCATEGORY PARTS LABOR

All Enclosures and Electronics Five (5) Years Five (5) Years

Pan/Tilts Three (3) Years **6 months if used in autoscan Three (3) Years **6 months if used in autoscan

Poles/PoleEvators Three (3) Years Three (3) Years

Warrior/Q-View/I.R. Illuminators Five (5) Years Five (5) Years

SView Series Five (5) Years

Controllers Five (5) Years Five (5) Years

Power Supplies Five (5) Years Five (5) Years

Accessory Brackets Five (5) Years Five (5) Years

During the labor warranty period, to repair the Product, Purchaser will either return the defective product, freight prepaid, or deliver it to Videolarm Inc.

Decatur GA. The Product to be repaired is to be returned in either its original carton or a similar package

RMA # (Return Materials Authorization number) displayed on the outer box or packing slip. To obtain a RMA# you must contact our Technical Support

Team at 800.554.1124, extension 101.Videolarm will return the repaired Product freight prepaid to Purchaser. Videolarm is not obligated to provide

Purchaser with a substitute unit during the warranty period or at any time. After the applicable warranty period, Purchaser must pay all labor and/or

parts charges.

The limited warranty stated in these product instructions is subject to all of the following terms and conditions:

TERMS AND CONDITIONS

1.NOTIFICATIONOF CLAIMS: WARRANTY SERVICE:If Purchaser believes that the Product is defective in material or workmanship, then written notice

with an explanation of the claim shall be given promptly by Purchaser toVideolarm but all claims for warranty service must be made within the

warranty period. If after investigation Videolarm determines that the reported problem was not covered by the warranty, Purchaser shall p

for the cost of investigating the problem at its then prevailing per incident billable rate. No repair or replacement of any Product or part thereof shall

extend the warranty period as to the entire Product. The

following the repair or replacement of that part or the remaining period of the Product parts warranty, whichever is greater.

2.EXCLUSIVE REMEDY: ACCEPTANCE:Purchaser’s exclusive remedy andVideolarm’s sole obligation is to supply (or pay for) all labor necessary to repair

any Product found to be defective within the warranty period and to supply, at no extra charge, new or rebuilt replacements for defective parts.

3.EXCEPTIONSTO LIMITED WARRANTY: Videolarm shall have no liability or obligation to Purchaser with respect to any Product requiring service

during the warranty period which is subjected to any of the following: abuse, improper use: negligence, accident, lightning damage or other acts

of God (i.e., hurricanes, earthquakes),

failure of the end-user to follow the directions outlined in the product instructions, failure of the

end-user to follow the maintenance procedures recommended by the International Security Industry Organization, written in product instructions,

or recommended in the service manual for the Product. Furthermore, Videolarm shall have no liability where a schedule is

replacement or maintenance or cleaning of certain parts (based on usage) and the end-user has failed to follow such schedule; attempted repair by

personnel; operation of the Product outside of the published environmental and electrical parameters, or if such Product’s original

(trademark, serial number) markings have been defaced, altered, or removed. Videolarm excludes from warranty coverage Products sold

AS IS and/or WITH ALL FAULTS and excludes used Products which have not been sold by Videolarm to the Purchaser. All software and accompanying

documentation furnished with, or as part of the Product is furnished “AS IS” (i.e., without any warranty of any kind), except where expressly provided

otherwise in any documentation or license agreement furnished with the Product.

4.PROOF OF PURCHASE: The Purchaser’s dated bill of sale must be retained as evidence of the date of purchase and to establish warranty eligibility.

DISCLAIMEROF WARRANTY

EXCEPT FOR THE FOREGOINGWARRANTIES, VIDEOLARM HEREBY DISCLAIMS AND EXCLUDES ALL OTHER WARRANTIES, EXPRESS OR IMPLIED,

INCLUDING, BUT NOT LIMITEDTO ANY AND/OR ALL IMPLIED WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE AND/OR ANY WARRANTY WITH

REGARD TO ANY CLAIM OF INFRINGEMENTTHAT MAY BE PROVIDED IN SECTION 2-312(3) OF THE UNIFORM COMME

STATE STATUTE. VIDEOLARM HEREBY DISCLAIMS ANY REPRESENTATIONS OR WARRANTY THATTHE PRODUC T IS COMPATIBLE WITH ANY COMBINATION OF NON-VIDEOLARM

PRODUCTS OR NON-VIDEOLARM RECOMMENDED PRODUCTS PURCHASER CHOOSES TO CONNECT TO PRODUCT.

LIMITATION OF LIABILITY

THE LIABILITY OF VIDEOLARM, IF ANY, AND PURCHASER’S SOLE AND EXCLUSIVE REMEDY FOR DAMAGES FOR ANY CLAIM OF ANY KIND

WHATSOEVER, REGARDLESS OFTHE LEGALTHEORY AND WHETHER ARISING IN TORT OR CONTRACT, SHALL NOT BE GREATER THAN THE ACTUAL PURCHASE PRICE OF THE

PRODUCT WITH RESPECT TO WHICH SUCH CLAIM IS MADE. IN NO EVENT SHALL VIDEOLARM BE LIABLE TO PURCHASER FOR ANY SPECIAL, INDIRECT, INCIDENTAL, OR

CONSEQUENTIAL DAMAGES OF ANY KIND INCLUDING, BUT NOT LIMITED TO, COMPENSATION, REIMBURSEMENT OR DAMAGES ON ACCOUNT OF THE LOSS OF PRESENT

OR PROSPECTIVE PROFITS OR FOR ANY OTHER REASON WHATSOEVER.

/tour operation

**6 months if used in autoscan

/tour operation

Five (5) Years

/tour operation

**6 months if used in autoscan

/tour operation

an equal degree of protection with a

warranty on the repaired part only shall be in for a period of ninety (90) days

for regular

RCIAL CODE AND/OR IN ANY OTHER COMPARABLE

ay Videolarm

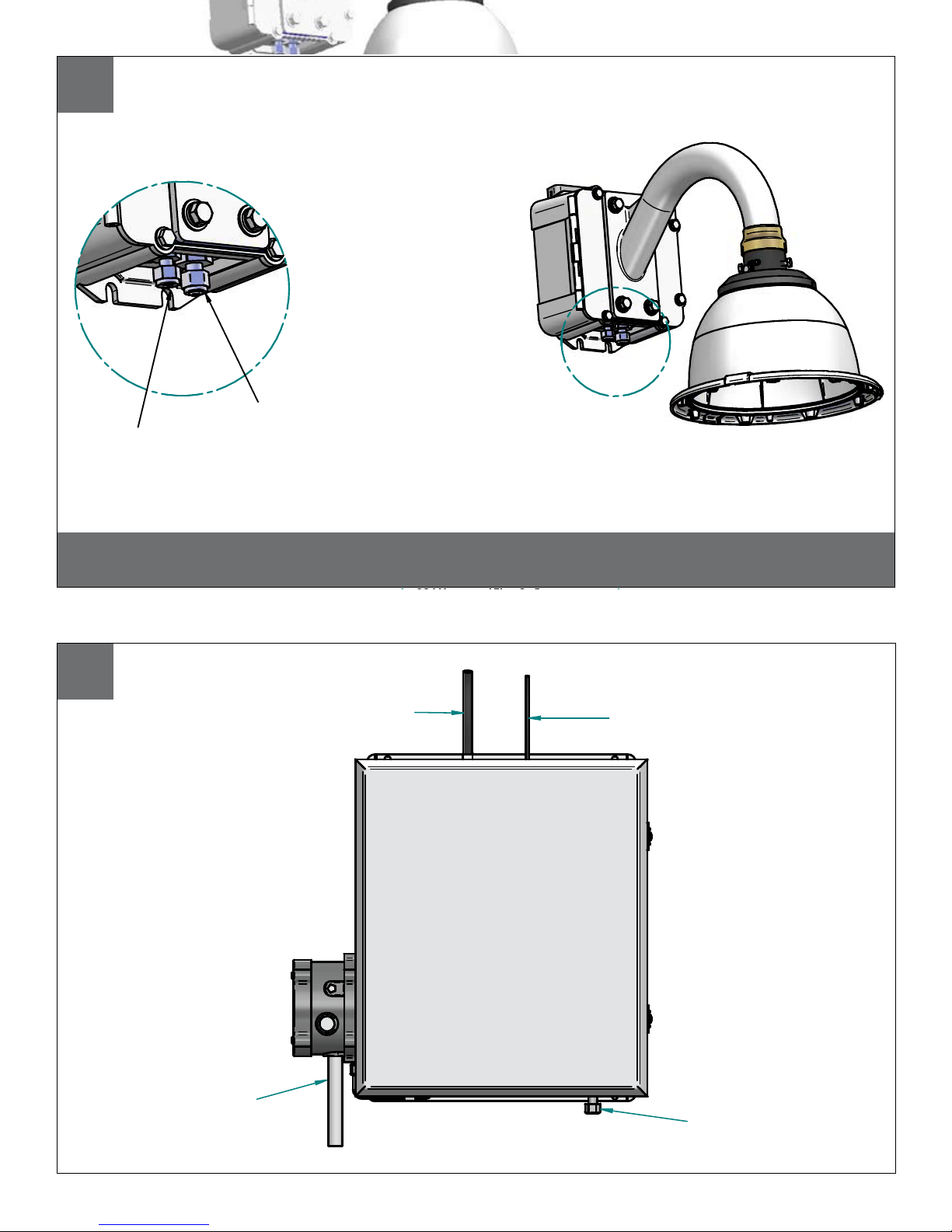

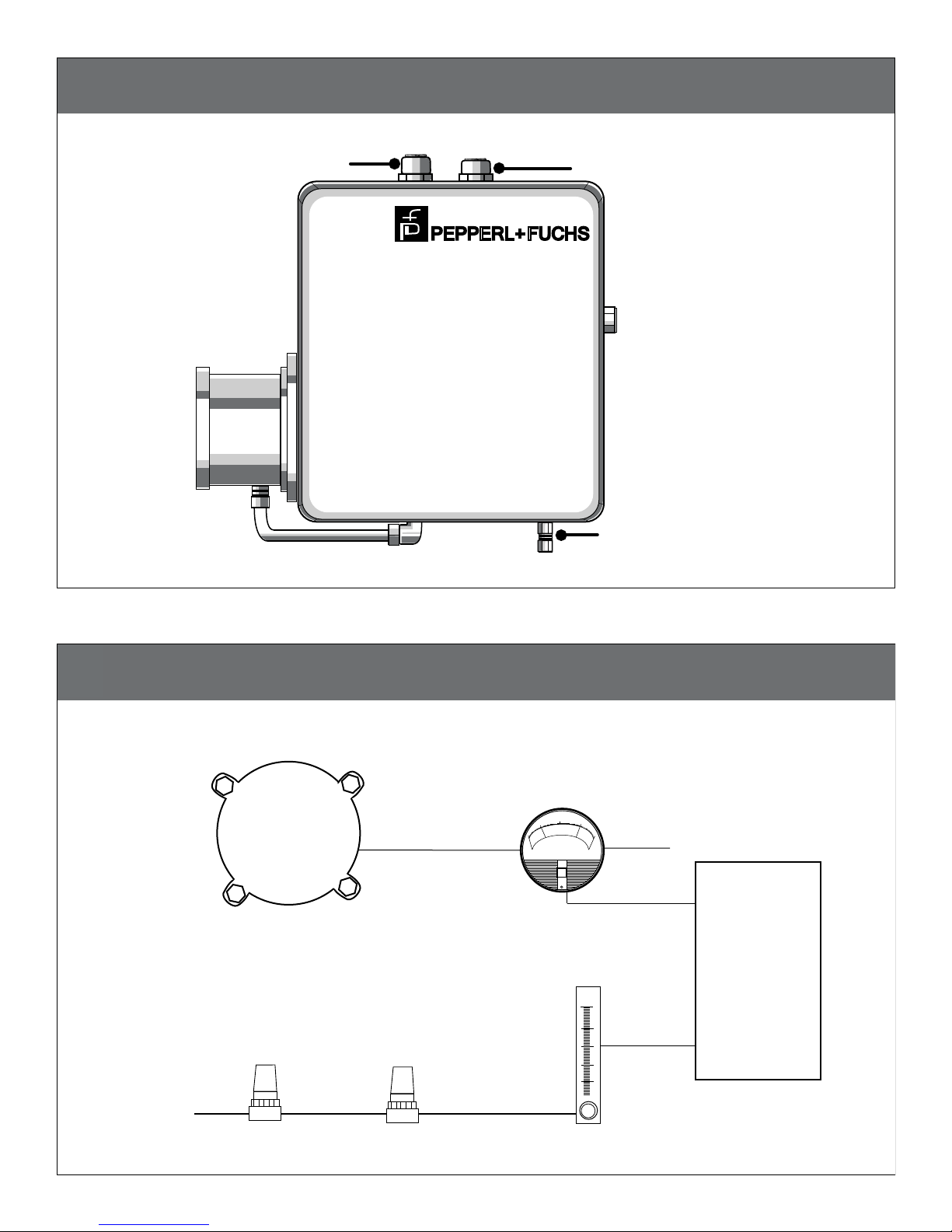

Content of Box

PURGE / PRESSURIZATION UNIT

SUPPLIED 1/4 “ & 3/8 ” POLY TUBING

Content of Box

PROTECTED

CAMERA

ENCLOSURE

PAN / TILT

DOME

HARDWARE

Unit is shipped with 100’ (max) flex tubing (3/8” & 1/4”) to connect enclosure to purge pressurized

unit. 2 fitting are provided as shown in the diagrams.

ENCLOSURE SUPPLY OUTLET

(3/8 “ Push-in Fitting)

ENCLOSURE REFERENCE INLET

(1/4 “ Push-in Fitting)

PURGED / PRESSURIZATION

UNIT

ELECTRICAL ALARM WIRING

CONDUIT AND SEAL

(Customer Supplied)

SYSTEM SUPPLY INLET

(3/8 “ SS Compression Fitting)

1

2

NOTES

• To ensure adequate protective gas flow to the protected enclosure, all piping and tubing must be

fully reamed.

• Precaution must be taken to prevent crimping and other damage to protective gas piping and

tubing. Caution must be used when opening/closing swing panel to prevent tubing kinks.

• Supplied 1/4” & 3/8” Poly Tubing have ferrule, nut & insert preset. Use that end for connecting to

power box. Cut other end to attain desired length and connect to push-in fittings on

Purge/Pressurization Unit.

• The Tamper-Proof (Primary) Regulator is intended to prevent tampering, while allowing a more

stable setpoint to be achieved in the small, tightly sealed enclosure where the protective gas flow is

critically low and difficult to stabilize. A 5/64” Hex Key or Allen Wrench is required to operate.

• When performing Initial Purge/Pressurization, adjust Primary Regulator to 5 psi. Normal operating

pressure is 2.5 inches of water at Dome Pressure Gauge. Balance Primary and Secondary

Regulators for continuous purge by alternately adjusting Primary (5 psi) and Secondary (2.5 inches

of water).

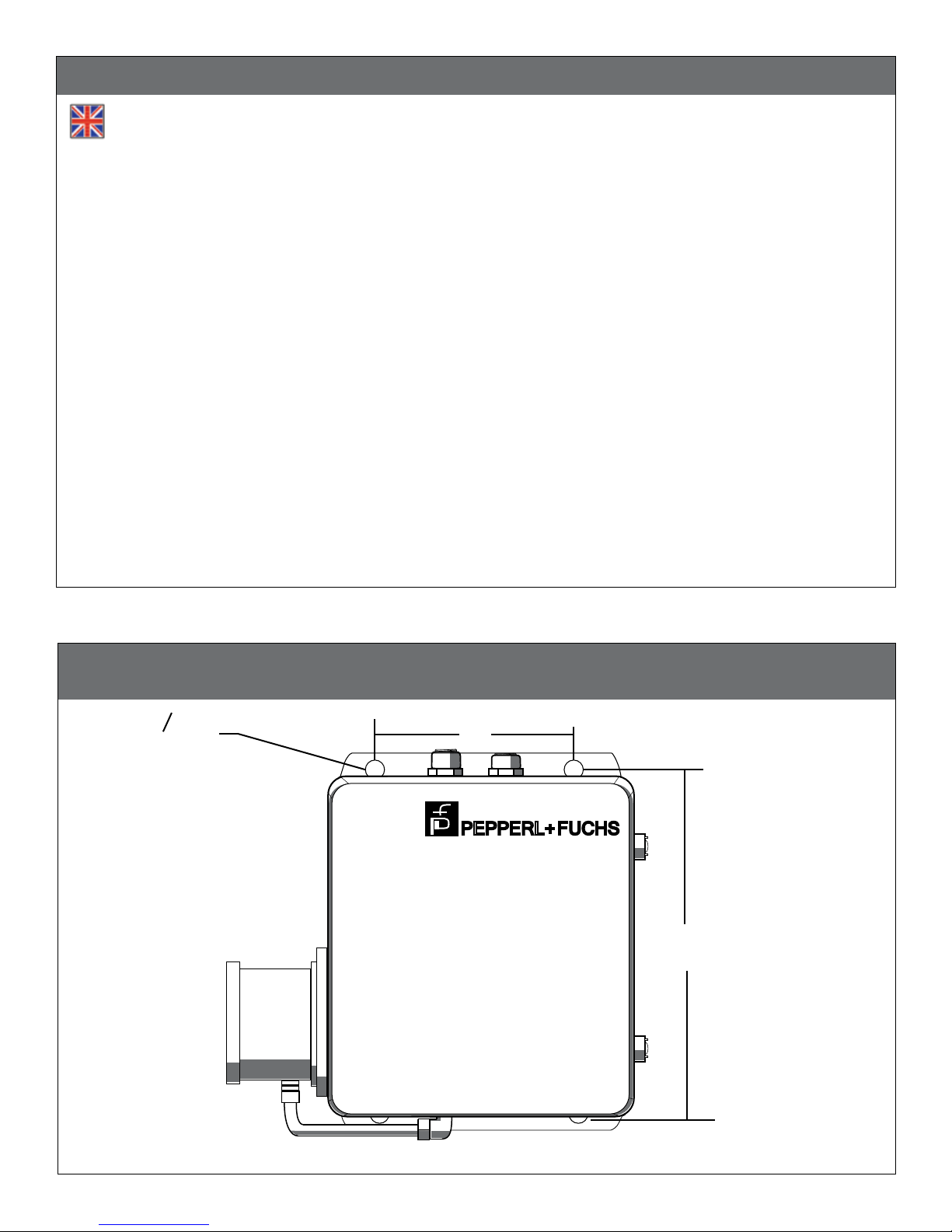

English

SYSTEM MOUNTING

14.7

O 0.32

4 places

PEPPERL FUCHS

+

10.0

3

4

LOW

SAFE

HIGH

0

.1

.2

.3

.4

.5

ENCLOSURE PRESSURE

SDOEN OF WOSTOE

5

4

3

2

1

500

400

300

20

10

OFF ON

METER

TUBING CONNECTION DIAGRAMS

DOME

PRESURE GAUGE

[ENCLOSURE]

ATMOSPHERIC

REFERENCE

EXP

PRESURE

SWITCH

PROTECTED

CAMERA

ENCLOSURE

REFERENCE

SYSTEM

SUPPLY

INLET

SUPPLY

PRIMARY

REGULATOR

SECONDARY

REGULATOR

FLOWMETER

TUBING CONNECTION DIAGRAMS

ENCLOSURE SUPPLY OUTLET

ENCLOSURE REFERENCE INLET

SYSTEM SUPPLY INLET

PEPPERL FUCHS

+

PURGE/PRESSURIZATION UNIT

5

6

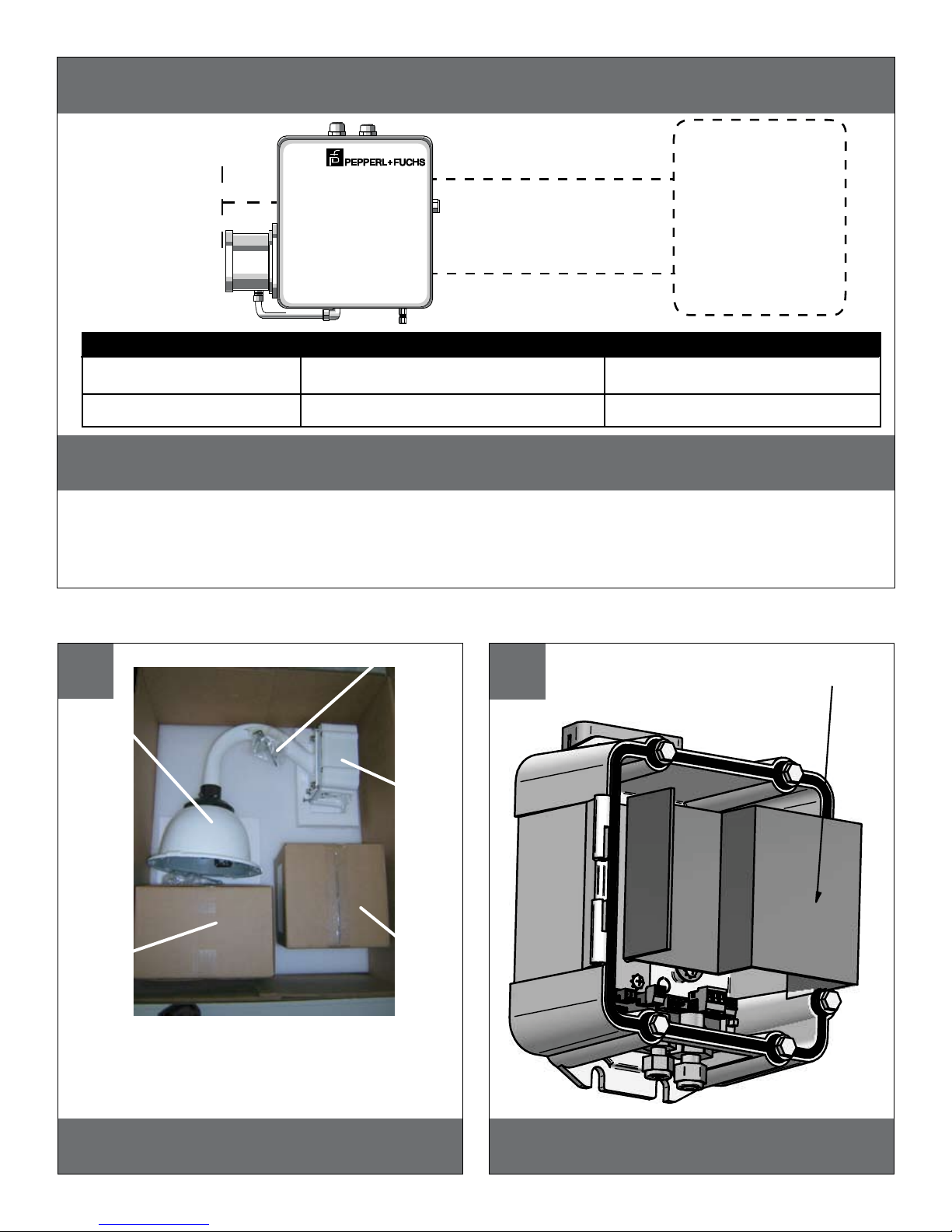

Open the metal power supply box on the camera

enclosure and remove cardboard packing

materials.

REMOVE INSERT

Carefully unpack both boxes and compare

with parts list.

POLE MOUNT CLIPS

POWER

SUPPLY

BOX

PAN

TILT

UNIT

DOME

TRIM

RING

CAMERA

ENCLOSURE

SET-UP PROCEDURE

• See supplied Model 1001A Installation and Operation Manual for Class I Purging Set-up.

The use of a temporary SCFH flowmeter is unnecessary. Use the permanently installed flowmeter on the swing

panel in the Purge/Pressurization Unit.

• See supplied Model 1001A Installation and Operation Manual for additional installation and operation information.

CONNECTION SIZES, LENGTHS & BENDS

System Supply Camera Supply Camera Reference

3/8” OD SS Tubing SUPPLIED SUPPLIED

Fully Reamed 3/8” Poly Tubing 1/4” Poly Tubing

MAXIMUM:

100 ft MAX

100 ft MAX

20 ft / 10 bends

GAS SUPPLY

(System Supply)

CAMERA

REFERENCE

CAMERA

SUPPLY

PROTECTED

CAMERA

ENCLOSURE

PEPPERL FUCHS

+

PURGE/PRESSURIZATION UNIT

7

8

9

220-240VAC INPUT

110-120VAC INPUT

INPUT: (120VAC 1A

240VAC .5A)

The box is designed for either 120 or 240 VAC input

single phase. Line (L) and Neutral (N) wires should

be connected as marked on the board and

plugged into the corresponding voltage for the

input single phase.

Attach unit securely to the wall mount using (4) 3/8”

or 8mm hardware (not supplied).

WALL MOUNT:

The power box may be pole mounted with the

pole support clips. (Stainless steel straps not

provided).

10

120Vac

Input

240Vac

Input

Main

Switch

Connect incoming ground to ground post as

shown.

11

12

13

Loading...

Loading...