Moog Videolarm FDW7 FusionDome Installation And Operation Instructions Manual

© 2009, Videolarm, Inc. All Rights Reserved

FDW7

FusionDome™ Series

Installation and Operation Instructions for the following models:

FDW7

Before attempting to connect or operate this product,

please read these instructions completely.

www.videolarm.com

CERTIFIED

81-IN5324

02-02-2009

!

1. Read Instructions - All the safety and operating instructions should be read

!

before the unit is operated.

2. Retain Instructions - The safety and operating instructions should be retained

for future reference.

3. Heed Warnings - All warnings on the unit and in the operating instructions

should be adhered to.

4. Follow Instructions - All operating & user instructions should be followed.

5. Electrical Connections - Only a qualified electrician should make electrical

connections.

6. Attachments - Do not use attachments not recommended by the product

manufacturer as they may cause hazards.

7. Cable Runs - All cable runs must be within permissible distance.

8. Mounting - This unit must be properly and securely mounted to a supporting

structure capable of sustaining

a. Installation should be made by a qualified installer.

b. Installation should be in compliance with local codes.

c. Care should be exercised to select suitable hardware to install the unit,

taking into account both the composition of the mounting surface and

the weight of the unit. Be sure to periodically examine the unit and the

supporting structure to make sure that the integrity of the installation

is intact. Failure to comply with the foregoing could result in the unit

separating from the support structure and falling, with resultant damages

or injury to anyone or anything struck by the falling unit.

UNPACKING

Unpack carefully. Electronic components can be damaged if improperly handled

or dropped. If an item appears to

properly in its carton and notify the shipper. Be sure to save:

1. The shipping carton and packaging material. They are the safest material in

which to make future shipments of the equipment.

2. These Installation and Operating Instructions.

the weight of the unit. Accordingly:

have been damaged in shipment, replace it

SAFETY PRECAUTIONSIMPORTANT SAFEGUARDS

CAUTION

RISK OF

ELECTRIC SHOCK!

CAUTION: TO REDUCE THE RISK OF

ELECTRICAL SHOCK, DO NOT EXPOSE

COMPONENTS TO WATER OR MOISTURE.

The lightning flash with an arrowhead symbol, within an

equilateral triangle, is intended to alert the user to the

presence of non-insulated "dangerous voltage" within the

product's enclosure that may be of sufficient magnitude

to constitute a risk of electric shock to persons.

The exclamation point within an equilateral triangle is

intended to alert the user to presence of important operating

and maintenance (servicing) instructions in the literature

accompanying the appliance.

SERVICE

If the unit ever needs repair service, customer should contact Videolarm

(1-800-554-1124) for return authorization & shipping instructions.

TECHNICAL SUPPORT

Videolarm has set-up a 24 hour technical support line for their customers.

24 HOUR TECHNICAL SUPPORT

1-800-554-1124

LIMITED WARRANTY FOR VIDEOLARM INC. PRODUCTS

VIDEOLARM INC. warrants this Product to be free from defects in material or workmanship, as follows:

PRODUCT CATEGORY PARTS LABOR

All Enclosures and Electronics Five (5) Years Five (5) Years

Pan/Tilts Three (3) Years **6 months if used in autoscan Three (3) Years **6 months if used in autoscan

Poles/PoleEvators Three (3) Years Three (3) Years

Warrior/Q-View/I.R. Illuminators Five (5) Years Five (5) Years

SView Series Five (5)Years Five (5) Years

Controllers Five (5) Years Five (5) Years

Power Supplies Five (5) Years Five (5) Years

ry Brackets Five (5) Years Five (5) Years

Accesso

During the labor warranty period, to repair the Product, Purchaser will either return the defective product, freight prepaid, or deliver it to Videolarm Inc. Decatur GA.

The Product to be repaired is to be returned in either its original carton or a similar package affording an equal degree of protection with a RMA # (Return Materials

Authorization number) displayed on the outer box or packing slip. To obtain a RMA# you must contact our Technical Support Team at 800.554.1124, extension 101.

Videolarm will return the repaired Product freight prepaid to Purchaser. Videolarm is not obligated to provide Purchaser with a substitute unit during the warranty

period or at any time. After the applicable warranty period, Purchaser must pay all labor and/or parts charges.

ted warranty stated in these product instructions is subject to all of the following terms and conditions:

The limi

1. NOTIFICATION OF CLAIMS: WARRANTY SERVICE: If Purchaser believes that the Product is defective in material or workmanship, then written notice

with an explanation of the claim shall be given promptly by Purchaser to Videolarm but all claims for warranty service must be made within the warranty period.

If after investigation Videolarm determines that the reported problem was not covered by the warranty, Purchaser shall pay Videolarm for the cost of investigating

the problem at its then prevailing per incident billable rate. No repair or replacement of any Product or part thereof shall extend the warranty period as to the entire

Product. The specific warranty on the repaired part only shall be in effect for a period of ninety (90) days following the repair or replacement of that part

remaining period of the Product parts warranty, whichever is greater.

2. EXCLUSIVE REMEDY: ACCEPTANCE: Purchaser’s exclusive remedy and Videolarm’s sole obligation is to supply (or pay for) all labor necessary to repair

any Product found to be defective within the warranty period and to supply, at no extra charge, new or rebuilt replacements for defective parts.

3. EXCEPTIONS TO LIMITED WARRANTY: Videolarm shall have no liability or obligation to Purchaser with respect to any Product requiring service during

the warranty period which is subjected to any of the following: abuse, improper use: negligence, accident, lightning damage or other acts of God (i.e., hurricanes,

earthquakes), modification, failure of the end-user to follow the directions outlined in the product instructions, failure of the end-user to foll

procedures recommended by the International Security Industry Organization, written in product instructions, or recommended in the service manual for the Product.

Furthermore, Videolarm shall have no liability where a schedule is specified for regular replacement or maintenance or cleaning of certain parts (based on usage)

and the end-user has failed to follow such schedule; attempted repair by non-qualified personnel; operation of the Product outside of the published environmental

and electrical parameters, or if such Product’s original identification (trademark, serial number) markings have been defaced, altered, or removed. Videolarm

excludes from warranty coverage Products sold AS IS and/or WITH ALL FAULTS and excludes used Products which have not been sold by Videolarm to the Purchaser.

All software and accompanying documentation furnished with, or as part of the Product

expressly provided otherwise in any documentation or license agreement furnished with the Product.

4. PROOF OF PURCHASE: The Purchaser’s dated bill of sale must be retained as evidence of the date of purchase and to establish warranty eligibility.

DISCLAIMER OF WARRANTY

INCLUDING, BUT NOT LIMITED TO ANY AND/OR ALL IMPLIED WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE AND/OR ANY WARRANTY WITH REGARD TO ANY CLAIM

OF INFRINGEMENT THAT MAY BE PROVIDED IN SECTION 2-312(3) OF THE UNIFORM COMMERCIAL CODE AND/OR IN ANY OTHER COMPARABLE STATE STATUTE. VIDEOLARM HEREBY DISCLAIMS

ANY REPRESENTATIONS OR WARRANTY THAT THE PRODUCT IS COMPATIBLE WITH ANY COMBINATION OF NON-VIDEOLARM PRODUCTS OR NON-VIDEOLARM RECOMMENDED PRODUCTS

PURCHASER CHOOSES TO CONNECT TO PRODUCT.

LIMITATION OF LIABILITY THE LIABILITY OF VIDEOLARM, IF ANY, AND PURCHASER’S SOLE AND EXCLUSIVE REMEDY FOR DAMAGES FOR ANY CLAIM OF ANY KIND WHATSOEVER,

REGARDLESS OF THE LEGAL THEORY AND WHETHER ARISING IN TORT OR CONTRACT, SHALL NOT BE GREATER THAN THE ACTUAL PURCHASE PRICE OF THE PRODUCT WITH RESPECT TO WHICH

SUCH CLAIM IS MADE. IN NO EVENT SHALL VIDEOLARM BE LIABLE TO PURCHASER FOR ANY SPECIAL, INDIRECT, INCIDENTAL, OR CONSEQUENTIAL DAMAGES OF ANY KIND INCLUDING, BUT NOT

LIMITED TO, COMPENSATION, REIMBURSEMENT OR DAMAGES ON ACCOUNT OF THE LOSS OF PRESENT OR PROSPECTIVE PROFITS OR FOR ANY OTHER REASON WHATSOEVER.

EXCEPT FOR THE FOREGOING WARRANTIES, VIDEOLARM HEREBY DISCLAIMS AND EXCLUDES ALL OTHER WARRANTIES, EXPRESS OR IMPLIED,

/ tour operation

**6 months if used in autoscan

/ tour operation

is furnished “AS IS” (i.e., without any warranty of any kind), except where

/ tour operation

**6 months if used in autoscan

/ tour operation

or the

ow the maintenance

DESCRIPTION:

The FDW7 Housing is a Vandal Resistant Housing especially de-

signed for integrated pan/tilt units. The housing top is made of high

impact Lexan

UV stable, polycarbonate plastic. The FDW7 housing measures

10” (w) x 13 (h) and 14.75” (d) with a weight of 8.25 lbs. Flying

leads are provided for all power, control and video connections. The

leads are supplied with a standard BNC and (2) screw down con-

nectors. A 25W heater (25 watts total) with a circulation fan is also

supplied.

®

while the lower dome is made of an optically clear,

ELECTRICAL SPECIFICATIONS (OUTDOOR

ONLY):

Power 24VAC, Class 2 Only

!

26 watts at 24 VAC (accessories)

Heater: 25 watts

Blower: 1 watt

Input Connectors (outdoor units):

BNC

(2) screw-down connectors

NOTE: This unit is designed for operation in an upright

position. Installing the FDW7 upside down may

cause damage to the internal equipment, and

will void the warranty.

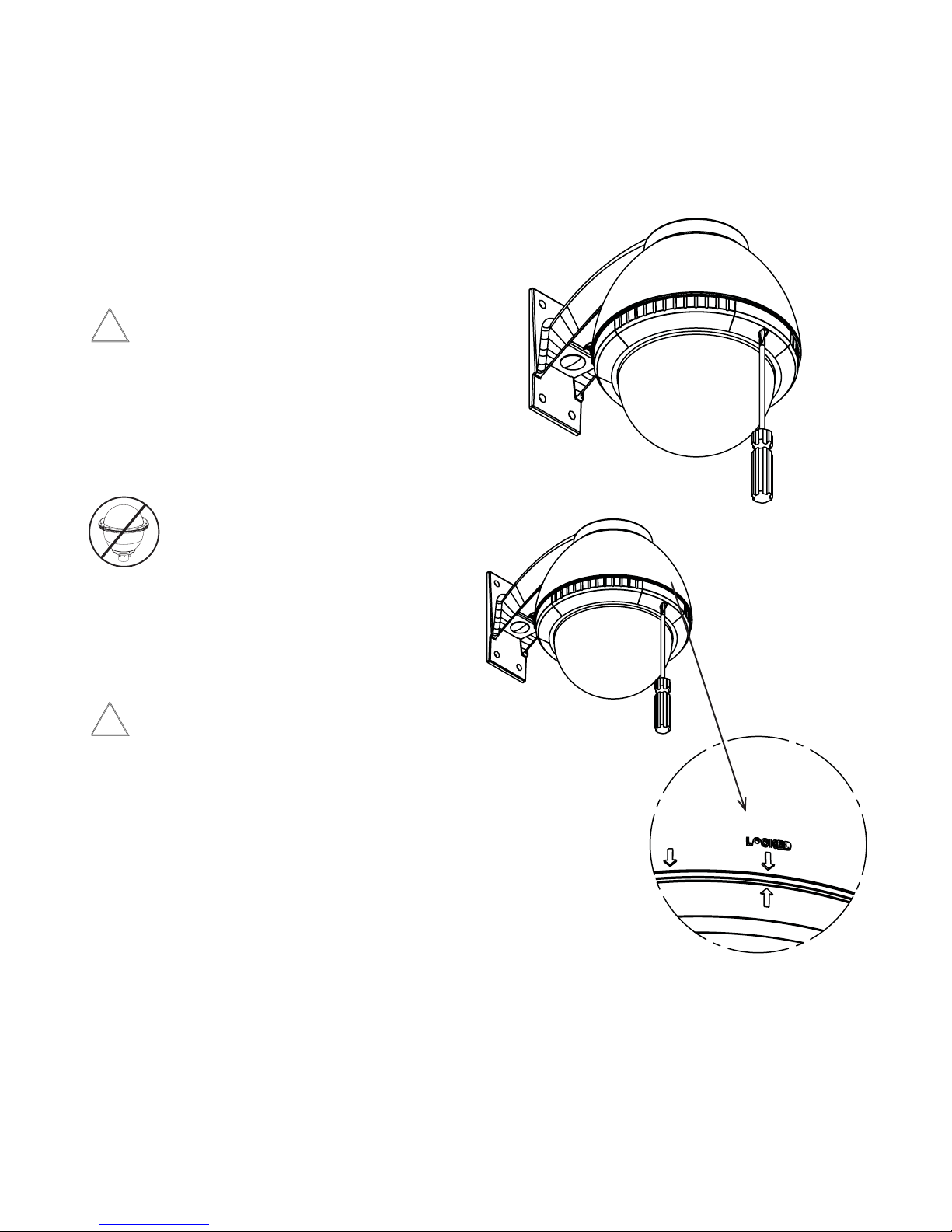

INSTALLING QUICK RELEASE BRACKET AND

PAN/TILT CAMERA ASSEMBLY (ALL MODELS)

1. Open the housing by loosening the screw on the front of the dome

trim ring (Figure 1). Note the arrows and the word "Locked" on the

side of the housing and trim ring. Rotate the trim ring until the

bottom arrow aligns with the second top arrow, then pull the dome

and trim ring off.

GENERAL INSTRUCTIONS:

Tools Required: .100" Flat Head Screwdriver

Phillips Head Screwdriver

Be sure the bracket is properly and securely mounted to a

supporting structure capable of rigidly holding the weight of

!

the entire unit.

Figure 1

2. Install the pan/tilt unit quick-release bracket. It is recommended

that this be done before installing the housing. Instructions for

mounting quick-release brackets from selected manufacturers are

on page 4.

3. Clean the inside of the dome and reattach. Do not overtighten

the screw. Tighten only to the point at which the gap between the

ring and the housing top closes.

-3 -

-3 -

INSTALLING THE HOUSING ASSEMBLY

INSTALLING OPTIONAL PENDANT MOUNT

FOR WALL MOUNT, FDW7

A wall mount bracket comes standard with this unit, and a

template is included to use as a guide for mounting the bracket

to a wall. Choose the desired location for installation and mark

the drill holes using the template. Screw (2) bolts (not

provided) about 3/4 of the way into the (2) top holes. Run

approximately 8" of wiring out of the wall.

NOTE: Be sure the hardware and the mounting surface can sup-

port the weight of the wall mount bracket plus the weight

of the housing and drive unit. The load will be subjected

to vibration from the camera motor and wind.

2. The wall mount bracket provided with the FDW7 includes

a location for conduit entry. If you wish to install conduit to the

bracket remove the conduit hole plug. Install fitting from below the

wall mount and secure with conduit nut from inside the bracket.

3. Open the access door on the bottom of the wall mount by

loosening the screw nearest the mounting plate (Figure 2).

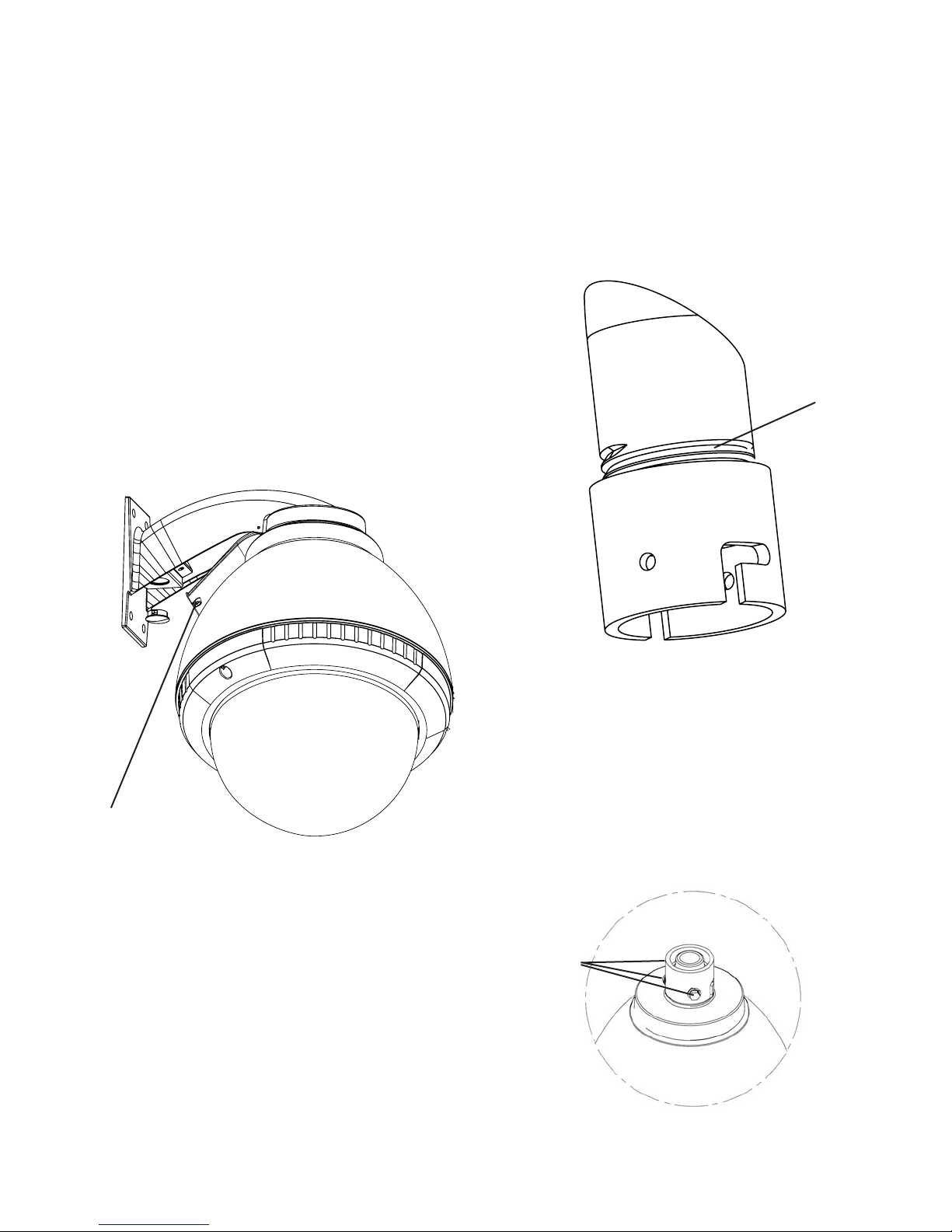

1. This unit includes a 1 1/2" NPT housing for a standard 1 1/2"

NPT pipe. The FD7 can be used with other brackets

designed with 1 1/2" male pipe threads, such as the Videolarm

WM20G and WM20 wall mount brackets.

2. Attach the housing coupling (Figure 3).

NOTE: Pipe threads should be clean and rust free.

Use a sealer (such as Teflon™ tape or silicone

sealer) on the threads.

Add thread

Figure 3

sealing tape

Access panel

Figure 2

4. Attach the wires from the wall to the connector provided, using the

wiring color code chart as a guide.

5. Once all wiring connections are made, place the wires inside the

wall mount bracket and close the access door. Secure with the

screw removed earlier.

6. Clean the outside of the dome.

1. Mount the housing assembly to the mounting bracket and

housing coupling. A safety cable is included with the housing to

temporarily hold it while making wiring connections. Loop the

safety cable over one of the set screws on the housing coupling

and make the appropriate connections using the (2) screw-down

connectors supplied.

2. Undo the safety cable and twist the housing onto the housing

coupling. Secure all (3) setscrews provided on the housing

coupling (Figure 4).

Set screws

Figure 4

3. Clean the outside of the dome.

-4 -

Loading...

Loading...