Page 1

Wind Turbine Slip Ring

WP7129

For NEG Micon NM72 / 82 Wind Turbines

Description

Wind turbines require reliable transmission of power and data signals from

the nacelle to the control system for the rotary blades. Moog’s slip rings

provide the performance and quality needed in demanding environments.

Costly downtime is eliminated by using ber brushes and robust mechanical

components in the slip ring design.

Fiber Brush Technology

Over 30 years ago, Moog Components Group developed and patented the

ber brush technology for high reliability slip rings. The patented approach

has led to hundreds of different slip ring designs for challenging applications

which include satellite solar array drive power transfer, helicopter rotor

blade de-icing, radar pedestals, industrial packaging equipment and

now wind turbines—just to name a few. The unique feature of the ber

brush technology is its ability to perform in

environmental and operational extremes. In

addition, the ber brush has the capability

to handle high power while at the same

time transferring data signals. And all this

performance while maintenance free for over

100 million revolutions.

Advantages

• No maintenance required

• Direct attachment to the gearbox

• Sealed for environmental protection

• Rotor junction box for simplied

wiring

• Long wire harness on stationary

side for wiring options

Direct Slip Ring Replacement

Moog Components Group now offers a direct replacement

pitch control slip ring for the *NEG Micon NM72 / 82 wind

turbines. Moog’s unit mounts directly to the gearbox

with a through passage for the hydraulic lines and

wiring. The rotor provides a junction box for lead

connection and a harness on the stationary

side to allow mounting of a lock out or junction

box in the nacelle. Each unit is fully

assembled and sealed for protection

from uids and dust.

Features

• Maintenance free

• Sealed to uid contamination

• Minimal wear debris

• No assembly of frame and brushes required

• High reliability

• No periodic inspections required

*NEG Micon wind turbines are part of Vesta

(www.vestas.com), one of the world’s leading

suppliers of wind turbines

WP7129

Slip Ring

1

Page 2

Wind Turbine Slip Ring

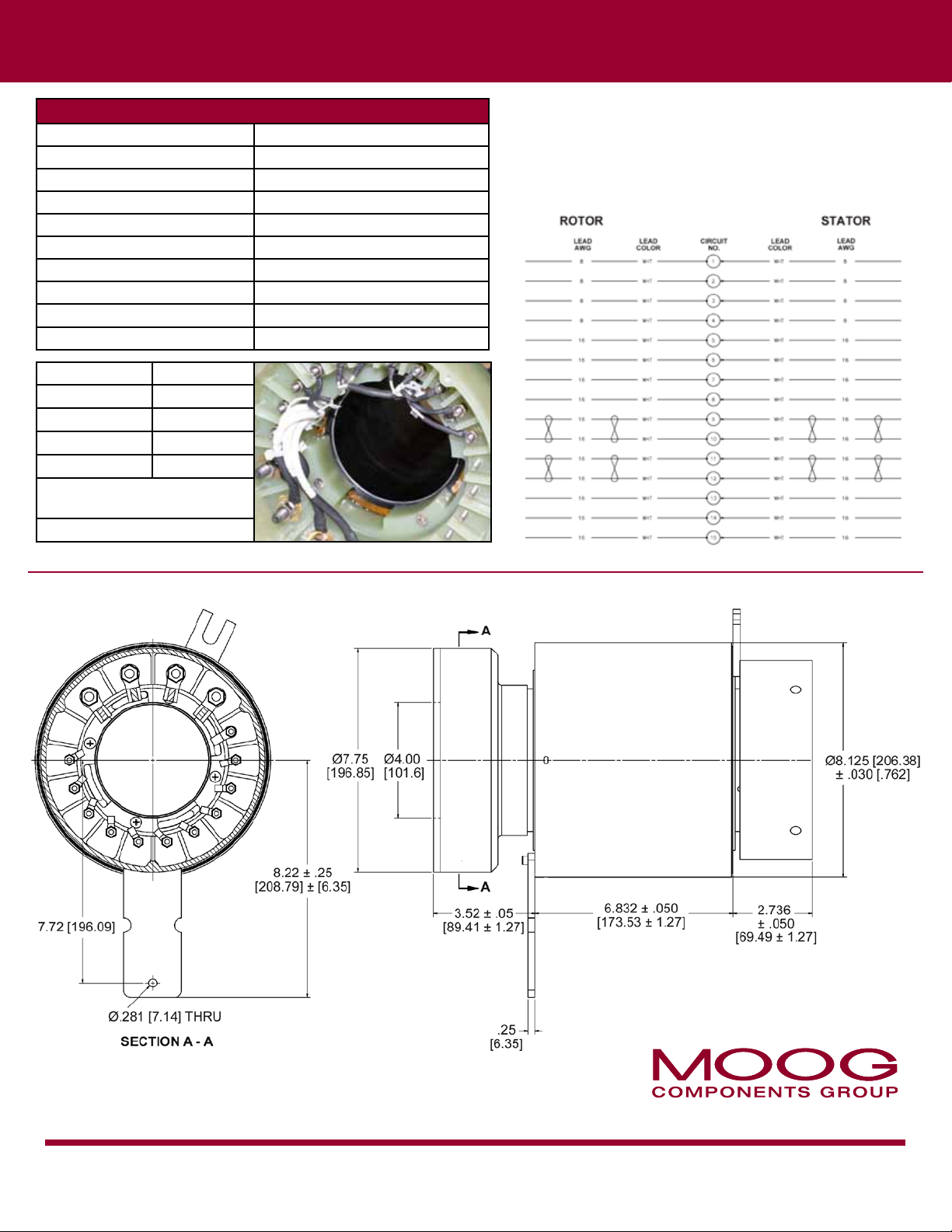

WP7129 Specications

Weight 25 pounds (11.4 kilograms)

Brush Material Silver alloy

Ring Material Silver plate

Brush Life > 100 million revolutions

Ring Life > 100 million revolutions

Lubrication No lubrication required

Cleaning / Maintenance Interval No maintenance required

Power Circuit Rating 30 amps up to 600 volts

Operating Temperature -40°C to +80°C

Sealing IP 54 to prevent uid contamination

Circuits 1 – 4 8 AWG wire

Circuits 5 – 8 16 AWG wire

Circuits 9 – 10 16 AWG TP

Circuits 11 – 12 16 AWG TP

Circuits 13 – 15 16 AWG wire

Stator lead harness 10 feet

long (304.8 centimeters)

Rotor wires to junction box

WP7129 Wiring Diagram

WP7129 Dimensions

Dimensions in inches [mm]

Specications and information are subject to change without prior notice.

© 2011 Moog Inc. MS3057 02/11

Moog Components Group, Blacksburg Operations

1213 North Main Street, Blacksburg, VA 24060 • 800-336-2112 • +1-540-552-3011 • Fax +1-540-557-6400

www.moog.com/components • email: mcg@moog.com

Loading...

Loading...