Page 1

MOOG

Manual IMI220-145D001

Parison Controller

Page 2

PARISON CONTROLLER

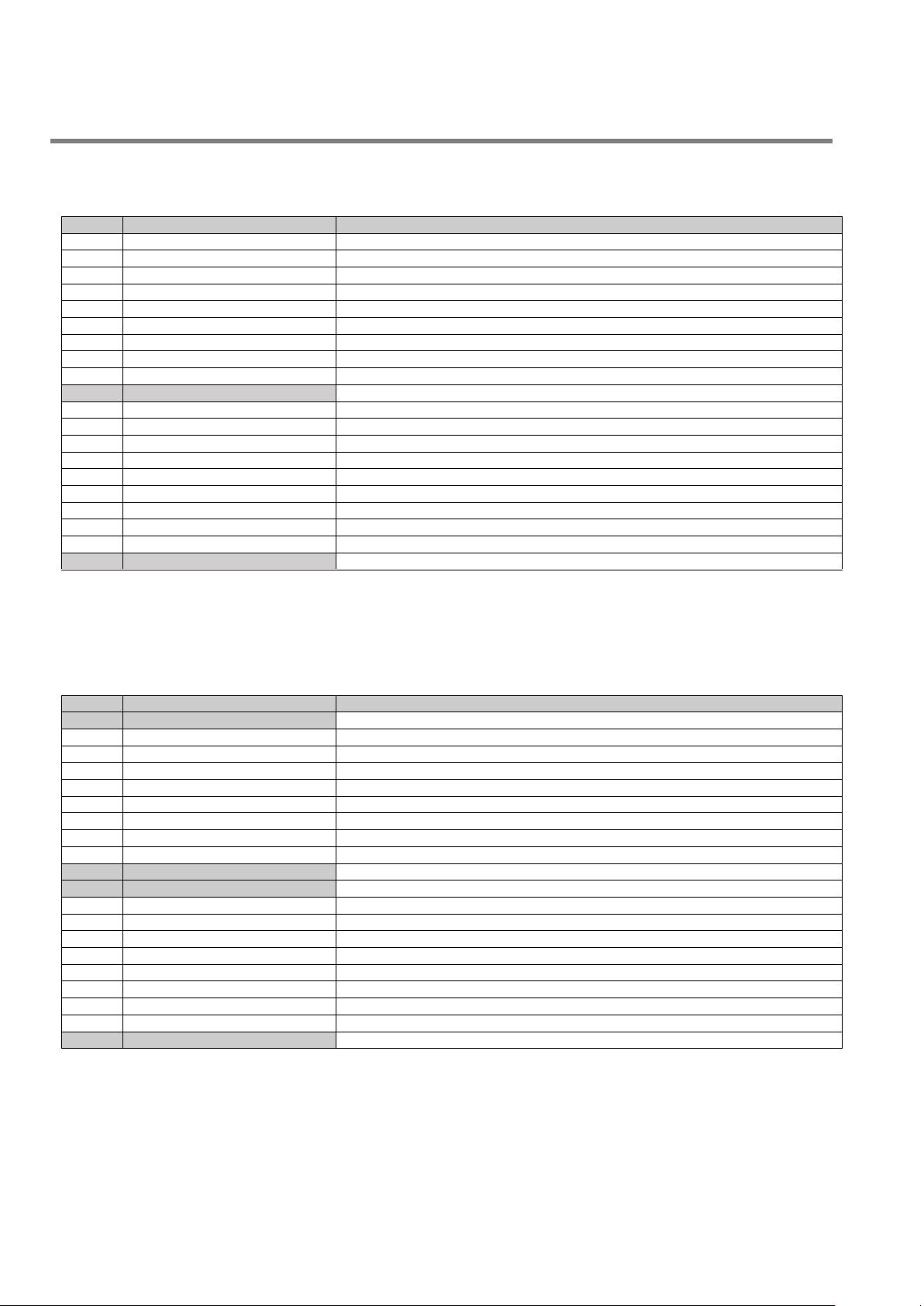

Document Revision

Hardware

Software Rev.

Author

Date

Preliminary

Preliminary

Preliminary

Lstrabla - nfrassine

6th Dec 2004

1.02

1.02

1.02

rfacchi - nfrassine

31st Aug 2005

MAN145-UM-A02A-EN

IMI220-145A002

2.01

rfacchi - nfrassine

5th Oct 2005

MAN145-UM-A03A-EN

IMI220-145A003

3.01

sverga - nfrassine

29th May 2006

MAN145-UM-A03B-EN

IMI220-145A003

3.01 - 3.02

sverga - nfrassine

June 2006

MAN145-UM-B01A-EN

IMI220-145B001

3.04 - 3.05

4.01 - 4.02 - 4.03 - 4.04

– 4.05

sverga - nfrassine

June 2010

MAN145-UM-C01A-EN

IMI220-145C001

5.01

nfrassine

July 2012

MAN145-UM-D01A-EN

IMI220-145D001

6.07

sverga – mamoruso

July 2017

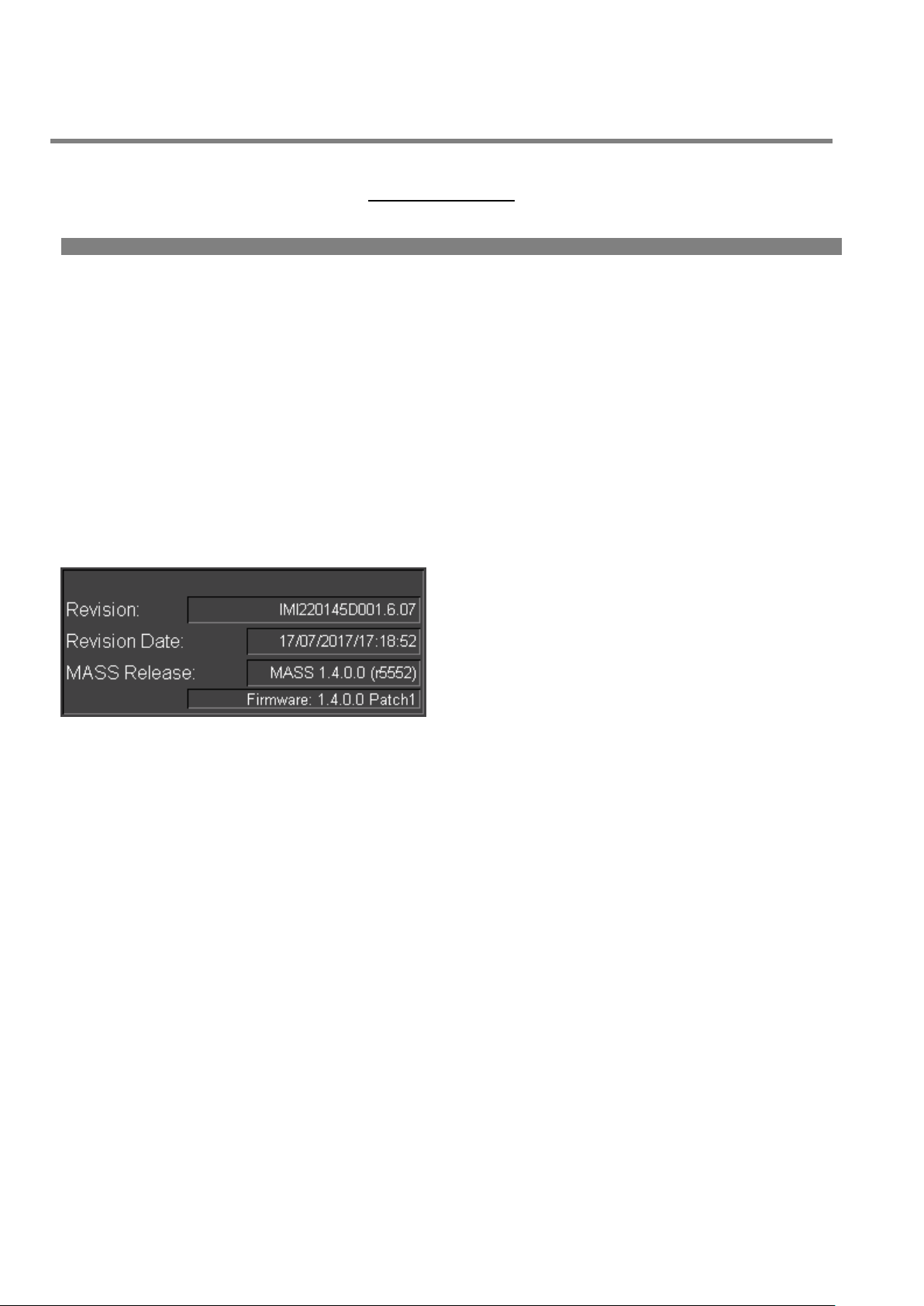

Revision: Number of the current revision application

inside in the PLC.

Revision Date: Date of the current revision application

inside in the PLC.

MASS Release: MASS version related to the actual

application.

Firmware: Firmware release; can differ from MASS

release

Revision History

moog

2 MAN145-UM-D01A-EN Moog Italiana srl - Bergamo

Page 3

PARISON CONTROLLER

moog

1 Installation.

1.1 Installation Overview.

Since there are many makes, models and vintages of blow moulding machines it is impossible to give specific

instructions as to the mounting, wiring and plumbing schemes to use. Different machines have different

requirements that the installer must ascertain before beginning the actual physical installation of the system. A

careful examination of the machine and some thoughtful planning beforehand will usually produce a good,

serviceable installation. There are some suggestions that hopefully will make your installation smooth and provide

many years of trouble free operation.

It is recommended that, if space is available on the machine, the programmer and its various electrical components

be mounted in a separate enclosure. While it might be possible to mount these components in the machine’s main

electrical cabinet, quite a bit of electrical “noise” and heat is usually generated there. While the Parison Controller

was designed with some degree of tolerance for these conditions it must be remembered that it is, in essence, a

computer.

To minimize any detrimental effects on the system that can be sometimes caused in such an environment, it may

be easier and wiser to circumvent any problems before they are created. The old adage “An ounce of prevention…”

can definitely apply here.

If using a separate enclosure or not, thoughtful layout of components is quite important. Remember, for future

troubleshooting it is important to consider accessibility to terminals to allow for voltage readings and the ability to

reach fasteners so components can be removed and replaced. Cable routing should also be considered to prevent

stretching of cables, straining of connections, pinch points and sharp edges that could damage a wire or cable.

Transducer and valve cables should be run through a “Seal-Tite” type of flexible, liquid tight conduit. Although it is

much faster and easier to run them over the machine unprotected, enclosing them in conduit provides protection

against physical damage as well as protection against insulation breakdown due to airborne chemical.

Cabling should also be run away from sources of heat (extruders, accumulators, and heater bands) and strong

electrical fields (motors, transformers, etc.).

The programmer can be mounted anywhere convenient to the operator station but should be located away from

areas where it could be damaged by falling objects or flooded by broken coolant or hydraulic lines.

Cable lengths to valves and transducers should be kept as short as possible to minimize line loss and signal

corruption, but long enough to provide movement of machine members for unrestricted operation and machine

maintenance. When routing cables it is wiser to avoid possible noise sources or areas of potential damage than to

minimize cable lengths.

Moog Italiana srl - Bergamo MAN145-UM-D01A-EN 3

Page 4

PARISON CONTROLLER

moog

1.2 Hydraulic Installation.

Hydraulic installation involves the mounting and plumbing of filters, servo-valve manifolds, cylinders, etc.

If the programmer is being installed as a replacement for another programmer all the necessary components should

already be in place. If not, the following suggestions are offered:

Do not reuse old hose, pipe fittings or tubing. Contamination in old plumbing is almost impossible to

effectively remove and can cause problems in future servo-valve reliability. Old fittings that have been

painted and assembled with old thread sealing compounds will not only introduce contamination, but are

1.3 Hydraulic Filtration.

Clean oil is the key to reliable hydraulic system operation. Dirt, silt and sludge in the system increase operating

temperatures by decreasing heat exchanger efficiency and create excessive wear on pumps, directional and relief

valves and valve seats. Contamination breeds contamination by wearing hoses and other hydraulic components

from the inside.

Moog servo-valves are designed to operate with an ISO code of 14/11. While this may be lower than what you are

accustomed to, the benefits of improved filtration will show up not only in increased servo-valve life but will help to

reduce premature machine wear and the frequency of oil related failures.

Moog offer a full line of filters and filter systems with element ratings starting at 3 microns, flow-rates from 10 to

100 gallons per minute, and operating pressures as high as 3,000 psi. There are a number of good filter systems

available and, even if a Moog filter is not chosen, it is strongly urged you employ one of these other filter systems

on your machine.

High-pressure filter assemblies should be plumbed between the high-pressure hydraulic supply and the “P”

(pressure) port of the servo-valve manifold(s). Plumbing from the filter outlet to the “P” port should be completed

with steel tubing or pipe.

If the machine employs a hydraulic accumulator to maintain stability in the machine’s hydraulic system, the filter

should be installed after the accumulator and before the valve manifold(s).

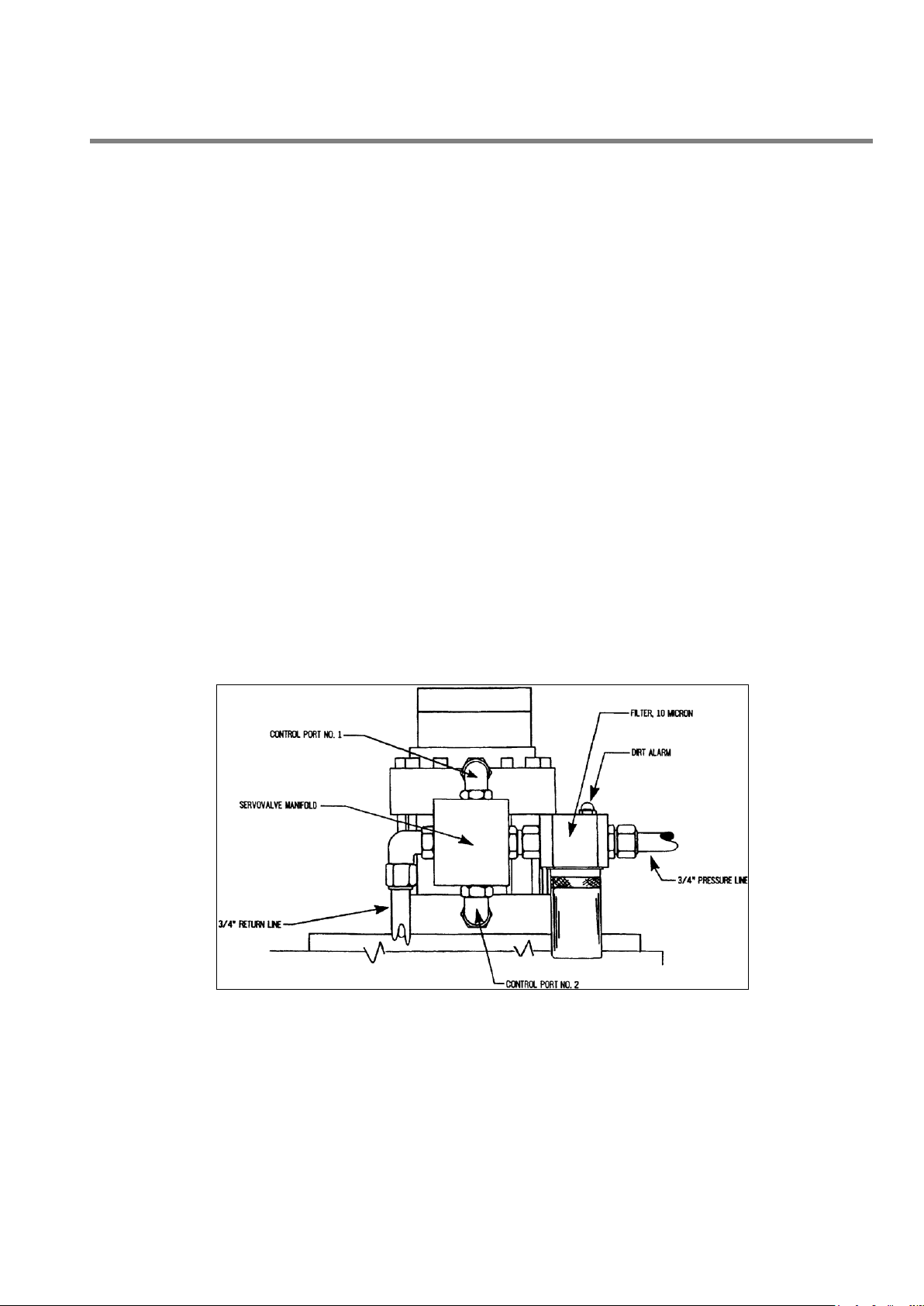

1.4 Servovalve Manifolds.

Servo-valve mounting is accomplished with the use of manifolds for each head. These manifolds allow for easy

removal of the valves to facilitate system flushing or valve replacement in the event of failure.

harder to work with and can contribute to added installation time.

Before assembling any new plumbing, inspect it carefully to insure that there are no metal filings or foreign

matter left over from cutting or assembly. Now is the best time to clean it out, before it can get into the

hydraulic system.

Replace the hydraulic oil or have it analyzed by a reputable lab. Depending on your maintenance program,

the oil may not have been checked for some time. Now is a good time to perform any oil-related

maintenance BEFORE the servo-valves are installed.

If you are replacing the oil remember to filter it as you pump it into the machine. New oil right from the

refinery is sometimes the dirtiest oil in the shop.

4 MAN145-UM-D01A-EN Moog Italiana srl - Bergamo

Page 5

PARISON CONTROLLER

moog

Moog servo-valves used in blow moulding Parison control are most often internally piloted devices. This means

that the manifolds used will have 4 ports that connect to the machine’s hydraulic system:

“P” port is the incoming high-pressure supply to the valve.

“T” or “R” port is the servo-valve return to tank.

“A” or “C1” port is one of the controlled ports. This should plumb to one end of the programming cylinder.

“B” or “C2” port is the other controlled port. This should plumb to the other end of the programming cylinder.

Some manifolds may be supplied with an additional fifth port labeled “X”. These manifolds are designed for use

with hydraulic systems capable of supplying an independent source of pilot pressure. If the need for this port is

uncertain, contact Moog Field Engineering for additional information.

There is no specification as to which controlled port should plumb to which end of the programming cylinder. The

following suggestions are offered concerning plumbing:

Try to keep the overall length of the controlled port lines as close to equal as possible.

Keep the servo-valve manifold as close to the programming cylinders as possible. The shorter the length

It is EXTREMELY IMPORTANT that plumbing between the controlled ports of the manifolds and the programming

cylinders be completed with solid tube or pipe. Do Not Use Hoses To Make These Connections! Hydraulic supply

up to the filter and the return lines from the servo-valve manifolds can be done with hose if desired.

In a great number of cases, the solid hydraulic lines that connect the controlled ports to the programming cylinders

will provide enough support for the servo-valve and manifold combination. If the machine is prone to excessive

vibration it would be wise to fabricate some type of bracket to support the servo-valve assembly.

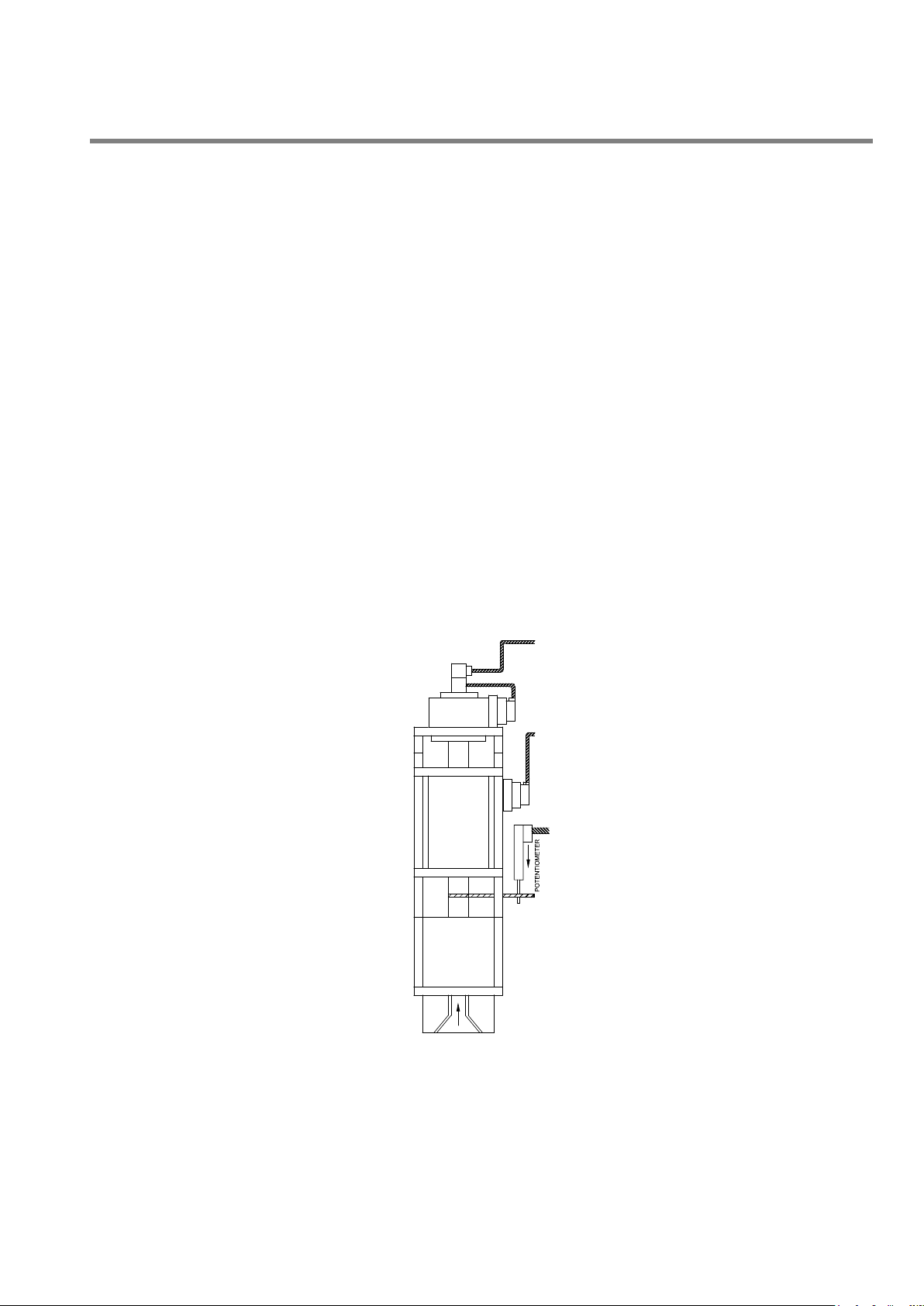

A typical servo-valve and manifold installation is depicted below:

of the control lines, the more accurate position control will be.

Try to plumb all the valves the same way. (All “A” ports to the top of the cylinders or all “B” ports to the top

of the cylinders.) This will reduce confusion and make wiring easier later.

Figure 1

Moog Italiana srl - Bergamo MAN145-UM-D01A-EN 5

Page 6

PARISON CONTROLLER

moog

1.5 Servoactuators.

A servo-actuator is a device, which can be used to take the place of the standard hydraulic cylinder. It combines

the cylinder, DCDT position transducer and servo-valve manifold into one compact, pre-adjusted package. Servoactuators can help reduce hydraulic installation time significantly and make calibration faster and easier.

There are a number of servo-actuators available with different specifications and mounting hardware, therefore no

specific information will be supplied in this document. Please contact Moog if more information is required on a

specific model or type.

Figure 2

1.6 Flushing.

Once all the hydraulic work has been completed you can start the process of flushing the hydraulic system. This

step is recommended to remove as much of the foreign matter left behind in the hydraulic system as possible

before installing the servo-valves.

It is also recommended that the system be flushed every time the reservoir is drained and refilled, a cylinder is

replaced, or a pump or any other major hydraulic component on the machine is replaced.

The first step in flushing is to remove the servo-valves from their manifolds or actuators and replace with the proper

flushing blocks. Install the flushing element in the high-pressure filter assembly and make sure the dirt alarm has

been properly reset. (Flushing elements are identified by a red band printed around the filter element.)

Jog the pumps to insure that there are no major leaks in the hydraulic system. If all looks tight start the pumps and

allow them to run. After a short run time carefully inspect all the hydraulic fittings and lines to insure there are no

leaks.

Periodically check the filter dirt alarm on the high-pressure filter to see if it has tripped. If it has, stop the pumps and

replace the flushing element with a new one. Reset the dirt alarm and restart the pumps. Allow them to run while

periodically inspecting the dirt alarm.

The system has been satisfactorily flushed when the pumps can run for two complete hours without tripping the

dirt alarm.

6 MAN145-UM-D01A-EN Moog Italiana srl - Bergamo

Page 7

PARISON CONTROLLER

CAUTION

The flushing element is a LOW-PRESSURE element designed to be used in conjunction with the flushing

blocks. Failure to replace it with the correct high-pressure filter element after removing the flushing blocks

will result in the filter element collapsing and possibly damaging the machine.

NOTE

On some machines when the flushing blocks are installed in place of the servo-valves, hydraulically

operated devices may not function. The flushing blocks are configured to direct pressure back to tank

allowing the system to be flushed at low pressure. Because of this, no pressure will be created in the

hydraulic system.

moog

After flushing is complete, stop the pumps and replace the flushing element with a standard high-pressure filter

element. Replace the flushing blocks with the servo-valves. Remember to reconnect the electrical connectors.

1.7 A Word About Hydraulic Pumps.

One of the most common failures seen in parison control valves is a buildup varnish in the valve. This is usually

caused by oil overheating and breaking down. Most standard petroleum based hydraulic fluids begin to reach their

temperature specification somewhere between 130 and 150 degrees Fahrenheit (between 55 and 65 degrees

Celsius). While you may never surpass this temperature while running, it can easily be exceeded when the pumps

are off and the machine heats are on. The stationary oil in the valve absorbs the heat and can quickly surpass the

oil’s breakdown point.

To reduce the possibility of this happening it is suggested that anytime the heats are on, the pumps should continue

to run. The oil moving through the valve will actually act as a coolant and help to prolong servo-valve life.

1.8 Transducers Installation.

The Parison Controller uses DCDT position transducers to feed back programming cylinder position information to

the controller. A separate DCDT is required for each individual head.

If servo-actuators of the type described above are being used, the DCDT is integrated into the actuator package

and has been pre-adjusted at the factory. No further adjustment is required.

If the programmer is used in a position based application there is also a linear position transducer that is needed

to monitor the position of the reciprocating screw or accumulator push-out cylinder.

Moog Italiana srl - Bergamo MAN145-UM-D01A-EN 7

Page 8

PARISON CONTROLLER

moog

1.9 DCDT Position Transducers.

In order to maintain accuracy and repeatability of the programming cylinder motion, care must be taken when

mounting the DCDT tooling position transducer(s).

A DCDT can be mounted with the transducer body as the stationary element and the core as the moving member

or the core can be stationary and the body can move. Whatever method is used, the stationary element must be

rigidly mounted on a non-moving portion of the machine frame to provide a reference for piston movement.

Please note the following precautions when mounting the transducer:

The core must move freely in the body. There should be no side loading of the core nor should the core

A typical DCDT transducer installation using the moving core method is depicted in the drawing below.

rod be bent in order to make it align with the transducer body.

Mountings for both core and transducer body must be rigid. There should be no free play in any of the

brackets and the brackets should be made of a stiff material, which will not bend or give, with normal

machine vibration.

Provision must be made to allow for adjustment of the stationary element of the transducer. The

transducer’s position will need to be adjusted during calibration to bring the programming cylinder’s stroke

into the usable portion of the DCDT’s stroke. The ability to align the body with the core will also make future

DCDT replacement easier, if necessary.

When designing the DCDT mounting brackets allow for some type of anti-rotational device to keep the core

and body properly aligned.

Figure 3

Note the provisions made for the vertical adjustment of the DCDT body and the anti-rotational arrangement

incorporated to keep the core and body aligned.

8 MAN145-UM-D01A-EN Moog Italiana srl - Bergamo

Page 9

PARISON CONTROLLER

moog

1.10 Linear Position Transducer (position based applications ONLY).

Since the profile is synchronized to the position of the push out ram, the Parison Controller requires a means to

track the ram throughout the push-out stroke. In addition, to keep the profile points properly positioned on the

Parison, the Parison Controller must have control over the accumulator or reciprocating screw’s FULL (End of Fill.)

and EMPTY (End of Extr.) points. Both of these tasks are accomplished by the signal provided from the linear

position transducer, also referred to as a linear pot.

The transducer can be mounted so that the shaft EXTENDS FROM the pot body during push-out, or RETRACTS

INTO the body during push-out, whichever makes for a more convenient mounting method.

As with DCDT’s, there are several precautions that should be observed when mounting linear position transducers:

The pot body and shaft must be as parallel to the push out ram as possible. This will prevent side loading

of the transducer shaft and premature failure of the bushings in the transducer body.

The transducer should never be at the full mechanical end of its stroke in either direction. When mounting

be sure that the shaft is at least 0.25” (~5 mm) from its mechanical end stop when the push out cylinder is

at full bottom (empty).

The body should be rigidly mounted to eliminate the possibility of movement caused by machine vibration.

There should be no more than 1/16 inch (~1.5 mm) of end play in the transducer shaft in the direction of

ram movement when the shaft is secured to the ram follower assembly.

The end of the shaft should never be screwed down tightly to the follower assembly. Instead, the ball joint

on the shaft should be allowed to “float” slightly up and down the securing screw. This will reduce any

stresses caused by the slight misalignment between transducer and cylinder that are always present.

Figure 4

Moog Italiana srl - Bergamo MAN145-UM-D01A-EN 9

Page 10

PARISON CONTROLLER

Figure 5

Leds panel

Rotary Knob

SET key

Usb Device

Buttons

Purge Command

Shift key

moog

2 System Architecture.

2.1 Terminal (Front).

The Panel Operator is the place where all the interactions happen between the operator and the Parison

Controller.

The Operative Panel is constituted by a LCD TFT 10.4 inches touch screen and by groups of buttons.

The Parison Controller looks as follows:

10 MAN145-UM-D01A-EN Moog Italiana srl - Bergamo

Page 11

PARISON CONTROLLER

Figure 6

Entry Knob: Used to change the value of various functions.

Rotation in a clockwise sense to increment and anticlockwise

sense to decrement. It is also used as a SET key to confirm a

change.

Del: Delete key. When a field is focused and this button is

pressed the content of the field is erased.

Edit: This button allows to enter the Parison field and edit the

profile. The button LED is ON. Push the Edit button again to end

the Parison editing. The button LED turns OFF.

X10: Increase the sensitivity of the entry knob by a factor of 10.

When X

10

is active the associated led is ON.

Figure 7

Usb device: Allows to save or load the recipes on an external memory.

2.1.1 Fast Access Keys and Knob.

moog

Purge: This button starts the movement of the heads to the purge position; as long as the key “PURGE” is active.

Shift: This button used contemporarily with another button changes the operation of it. This is explained for each

button in the relative pages.

2.1.2 Usb device.

Moog Italiana srl - Bergamo MAN145-UM-D01A-EN 11

Page 12

PARISON CONTROLLER

Figure 8

Start: Lit when the cycle Start (1 or 2) signal is received.

Die gap: Lit when the Die Gap signal is received (only in position accumulator

mode).

Continuous: Lit when the “Continuous Extrusion” machine type is selected.

Accumulator: Lit when “Accumulator” machine type is selected.

Divergent: Lit when “Divergent” die is selected. Normally it is reported to the

head number 1. If the work page visualizes another head this led reports to this

same head.

Convergent: Lit when “Convergent” die is selected. Normally it is reported to

the head number 1. If the work page visualizes another head this led reports to

this same head.

moog

2.1.3 Display Led panel.

End of filling: Lit at the end of the accumulator filling (only in position accumulator mode).

Point out: Lit when each serial marker point is reached.

End of extrusion: Lit at the end of extrusion. (both in continuous extrusion and accumulator mode)

12 MAN145-UM-D01A-EN Moog Italiana srl - Bergamo

Page 13

PARISON CONTROLLER

Green numbers

The fields that can be reached by cursor and can be changed.

Grey numbers

The fields that can’t be reached by cursor and can’t be changed.

Blue bargraphs

Show the value of an analog output.

Yellow numbers

Show actual value.

Yellow bargraphs

Show actual value (feedback e.t.a.).

White

The texts on the screens.

Text left bottom: Shows

the actual recipe that is

working.

Lock: No password inserted.

Acc. Resp: Access Responsible Level on. For changing this password enter in Technical

Level and enter in setup machine.

Acc. Tech: Access Technical Level on. This password is fixed by Moog.

Bottom page: soft

key to change the

page

Alarm line: If there are one or more

alarms on the alarms page, the alarms

are displayed at the bottom of each

page.

Min and Max: Minimum and maximum are displayed in the status line.

In the example on the left the minimum valid value is 0, while the

maximum is 5000.

moog

2.2 General page description.

2.2.1 Colours assignment for all pages:

2.2.2 Page Header:

Center: Shows the page title.

Date and time of day: Show the actual day, date and hour of the system. For adjustment go to the Technical level

or a Resp. level password.

Text right bottom: (yellow) Shows the current level state:

The other one shows the current number page.

2.2.3 Page Bottom:

This line shows the last alarm and changes the back colour depending on the priority. On the left of the text the

number shows the code of the alarm displayed at the moment.

Moog Italiana srl - Bergamo MAN145-UM-D01A-EN 13

Page 14

PARISON CONTROLLER

Figure 9

Figure 10

Figure 11

Figure 12

moog

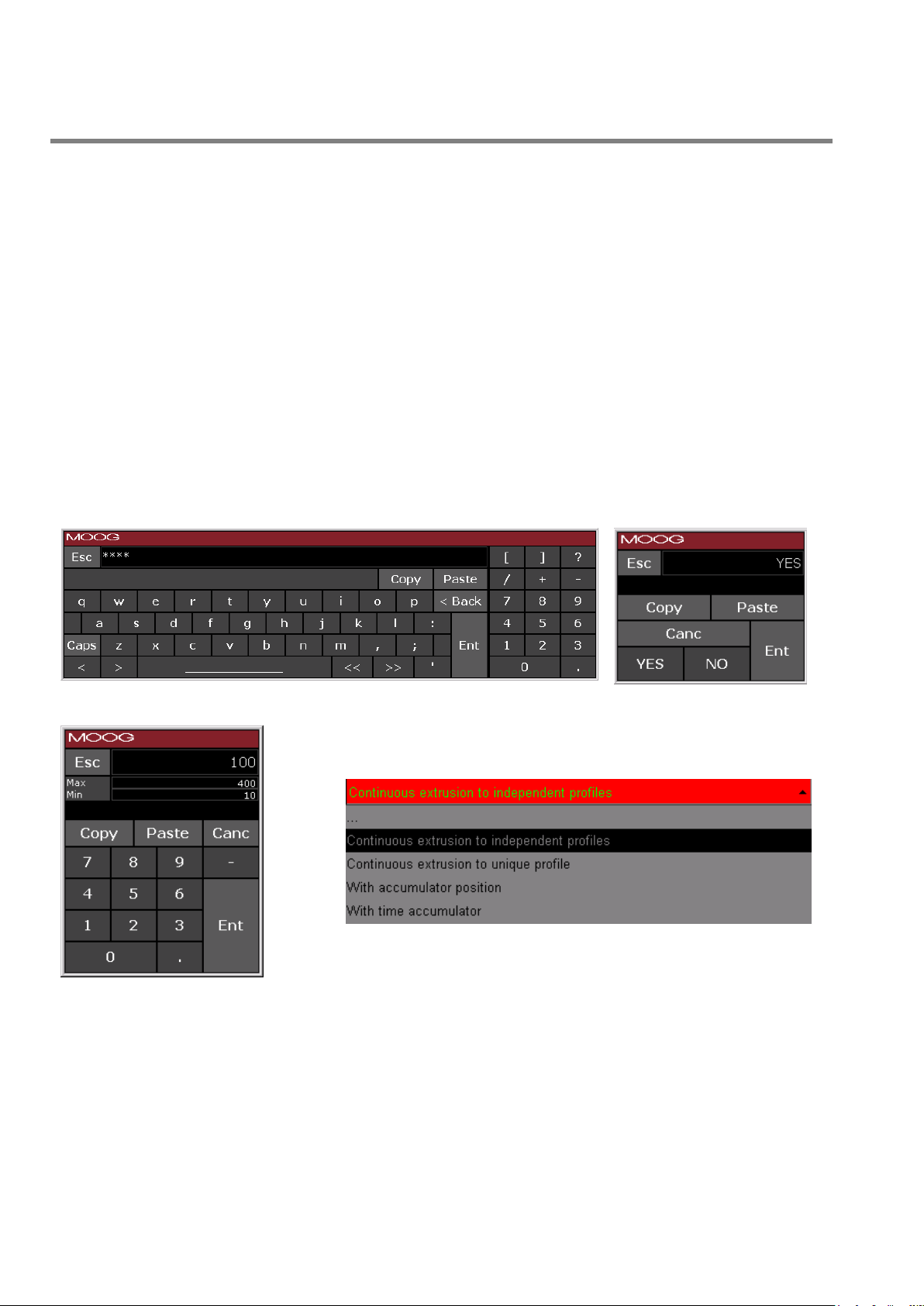

2.3 Change of Setpoints.

If the cursor is on a numeric, Boolean, multi text list, alphanumeric field (green), the value can be changed.

Numeric fields: insert the desired number with the rotation of the Entry Knob. In clockwise the numbers increase.

It is possible to insert the decimal value only rotating the Knob and it is possible to insert the value left of the dot

with X10 multiplication factor and entry knob. Confirm by Set key.

Boolean fields: switch to YES/NO with rotate Entry Knob. In clockwise it is YES selection. Confirm by Set key.

Multi text list fields: rotate Entry Knob (one or more times) to scroll forward or (one or more times) to scroll

backward until desired text is displayed. Press Set key to accept the change.

Alphanumeric fields: Insert the first character alphanumeric with the rotation of the Entry Knob, move to the right

using the shift key + entry knob, using again the entry knob insert the following character. When the string is

completed confirm by Set key.

If a field need not to be changed (i.e. after typing a wrong number or changing the intention) move the cursor

away.

When a field is in variation with the insertion of a new data the led near Set Key is lit and the field changes colour.

It is also possible to modify all the existing fields using the relative keyboard (double click on the field):

14 MAN145-UM-D01A-EN Moog Italiana srl - Bergamo

Page 15

PARISON CONTROLLER

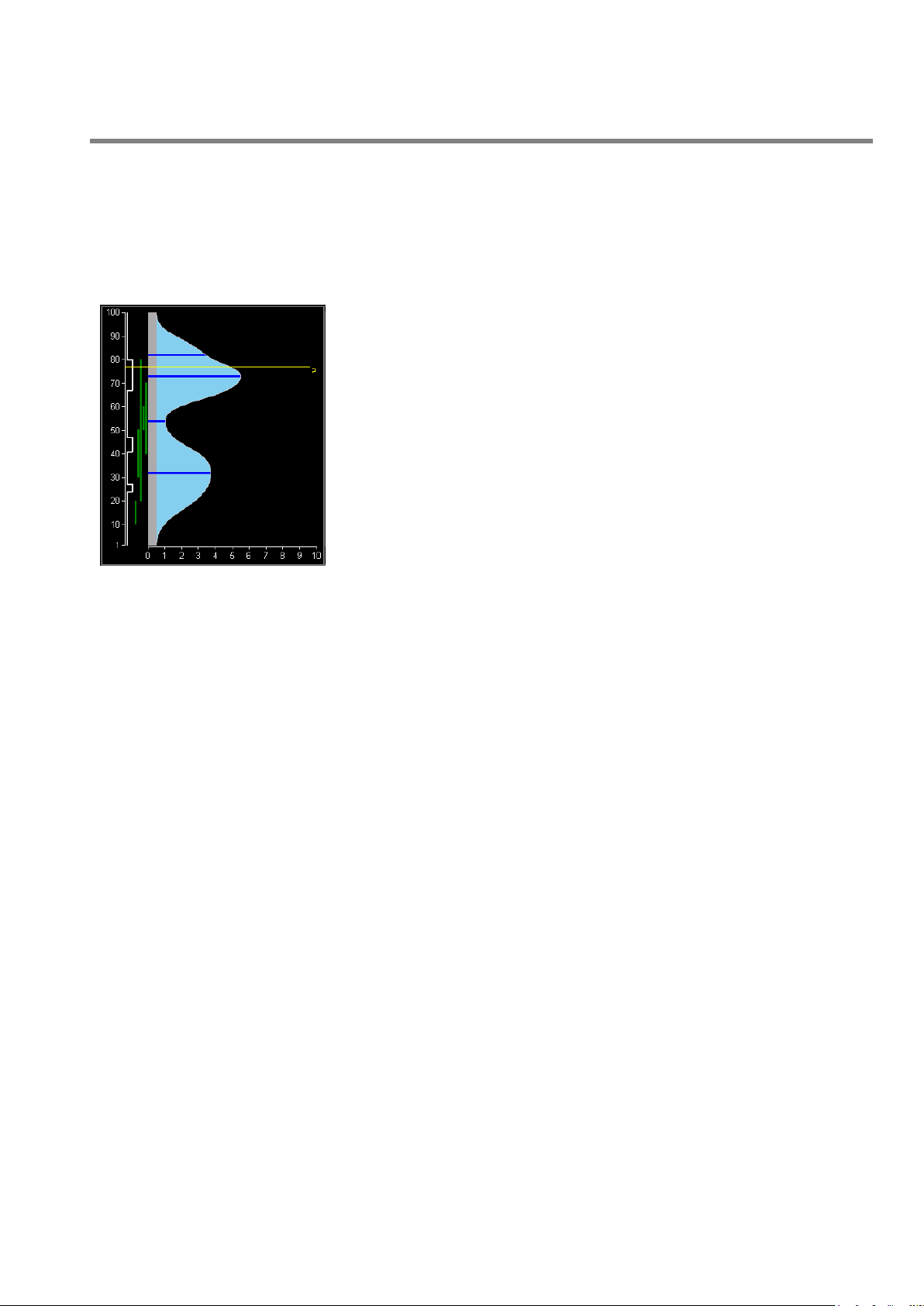

Figure 13

Working point panel: vertical histogram showing current working point

(for selected head).

Serial markers panel: (visible if select ON in Setup Machine Page)

vertical panel containing a logic status diagram of serial marker status

along the profile. The left position is OFF, the right position is ON.

Synchronism panel: (visible if set 1 or plus at number synchronism on

Setup Machine Page) vertical panel containing from 0 to max 5 vertical

lines as programmed synchronization points; each synchronism signals is

defined through start and stop points (which define synchronism line

width) and through type.(with accumulator machine).

Profile panel: area where the profile appears (maximum 400 points).

Each point can get a value from 0 through 10000 (100.00%); the profile is

drawn making an interpolation among some basic points (masters),

highlighted by horizontal line. Interpolation can be of various types: Bezier

curves, linear, flat, parabolic 1 (parabola with tangent 0 on end point) or

parabolic 2 (parabola with tangent 0 on start point); an interpolation can

be selected in a different way for each area available between a master

and the next one. The parison field, besides showing current profile, can

display the offset between programmed profile and the feedback profile

actually present on the head. On a profile it is possible to place some

markers allowing to physically detect a parison point.

2.4 The Parison field.

2.4.1 Field appearance.

When parison field is displayed by browser, it's sub-divided into 4 parts:

Starting from left you can see:

moog

2.4.2 Editing profile.

The cursor can be moved on a parison field using UP, DOWN arrow keys. The cursor position is drawn by a dashed

line; when the field is focused, the cursor is drawn by a continuous line. In this phase any operation involving a

change in current profile invokes field editing (background colour becomes orange); the field shows both original

profile and that being edited (changing page is possible going back to original profile).

When focus is on parison field, these operations are allowed:

2.4.3 Normal functioning:

- Arrows

- by pressing UP/DOWN arrow keys it's possible to move the cursor by a point upwards or downwards.

- by pressing +/- keys it's possible to change the amplitude of the current cursor point; the value changes

according to the amount contained in Increase; the changed point is setup as a master.

- Entry knob

- by the rotation it's possible to change the amplitude of the current cursor point; the value changes according

to the amount contained in Increment; the changed point is setup as a master.

- by pressing SHIFT + Rotation it's possible to move the cursor upwards or downwards.

Moog Italiana srl - Bergamo MAN145-UM-D01A-EN 15

Page 16

PARISON CONTROLLER

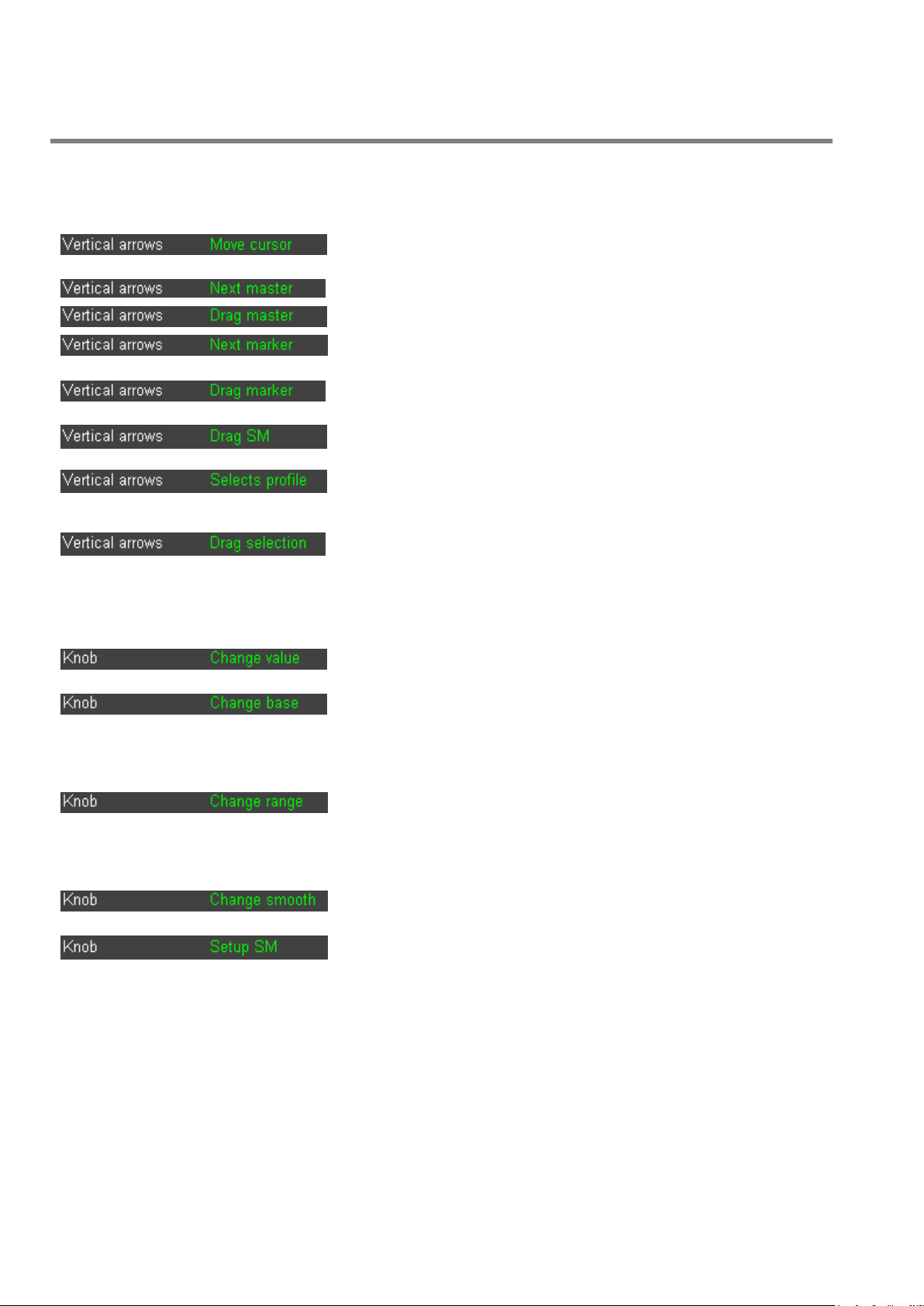

Move cursor: move the cursor up and down (default

functioning)

Next master: move the cursor among the masters

Drag master: drag the master up and down

Next marker: move the cursor among the markers

(visible if select ON in Setup Machine Page)

Drag marker: drag the marker up and down. (visible if

select ON in Setup Machine Page)

Drag SM: drag the Serial Marker up and down. (visible

if select ON in Setup Machine Page)

Selects profile: select a part of the profile. It is possible

to select an area of points (reverse mode): selection is

active from previous master to next master

Drag selection: drag the selection up and down. If an

area is selected, it is possible to move it: if the motion

meets a master, it will be cancelled

Rotate the knob to change the Value (default

functioning)

Rotate the knob to change the Base. To increase the

minimum value (base) of the whole profile: all points are

translated in such a way that the profile keeps the same

look. The base can be changed up to that the maximum

value of the profile is 100

Rotate the knob to change the Range. To increase/

decrease the whole profile range: all points are

proportionally changed in such a way that the profile

keeps the same look. The range can be changed up to

that the maximum value of the profile is 100

Rotate the knob to change the Smooth. The value can

be from 0.5 up to 2 and it is only for Bezier interpolation

Rotate the knob to setup the Serial Marker (if selected

ON in Setup Machine Page)

2.4.4 Other possibilities.

It is possible to select (F5) how the vertical arrows have to work.

moog

It is possible to select (F6) how the Knob has to work.

16 MAN145-UM-D01A-EN Moog Italiana srl - Bergamo

Page 17

PARISON CONTROLLER

moog

2.4.5 Other function keys possibilities.

by pressing the key DEL it's possible to remove a master on the profile, in correspondence to the cursor

point.

by pressing the function key programmed as Toggle marker (F2) it's possible to add or remove a marker

on the profile in correspondence with the cursor point. By the function key DEL it's possible to remove a

marker.

If a master and a marker are both on the same point, press the key DEL to remove the marker as first.

by pressing the function key programmed as Select interpolation (F4) it's possible to change the type of

the interpolation area between two masters, the choice selection is made among Bezier curves, linear, flat,

parabolic 1, parabolic 2.

by the function key programmed as Clear (F3) it's possible to completely delete the current profile. The

When the serial marker panel is visible (set the parameter to ON in Setup Machine Page), the following operations

are possible:

PLC profile will be updated only when the operation is confirmed by pressing the Set Key.

modify the serial marker using F5 to set Vertical arrows to Drag SM and F6 to select Knob as Setup SM.

The SM can be dragged using the arrows.

the status of the serial marker can be switched ON and OFF using the knob or

2.5 Functionality.

2.5.1 Safe Condition.

Necessary conditions to start issuing a new profile are:

Temperature Ok ON

Emergencies ON

Alarm OFF

machine in automatic ON

Purge OFF

Tooling OFF

The digital input “machine in automatic” has to be ON during the normal work and has to be OFF

during the machine configuration. (Machine type selection, number of heads selection, number of

point selection, number of extruder selection, output command type selection, heads and

accumulator calibration and die type selection)

2.5.2 Language packages.

PARISON CONTROLLER is supplied with a language package (application rev. IMI220145D001.X.XX). It is

possible to choose among the following languages:

English, Italian, German, French, Spanish, Portuguese, Danish, Russian, Turkish, Greek, Chinese and Japanese.

and - keys.

+

Moog Italiana srl - Bergamo MAN145-UM-D01A-EN 17

Page 18

PARISON CONTROLLER

moog

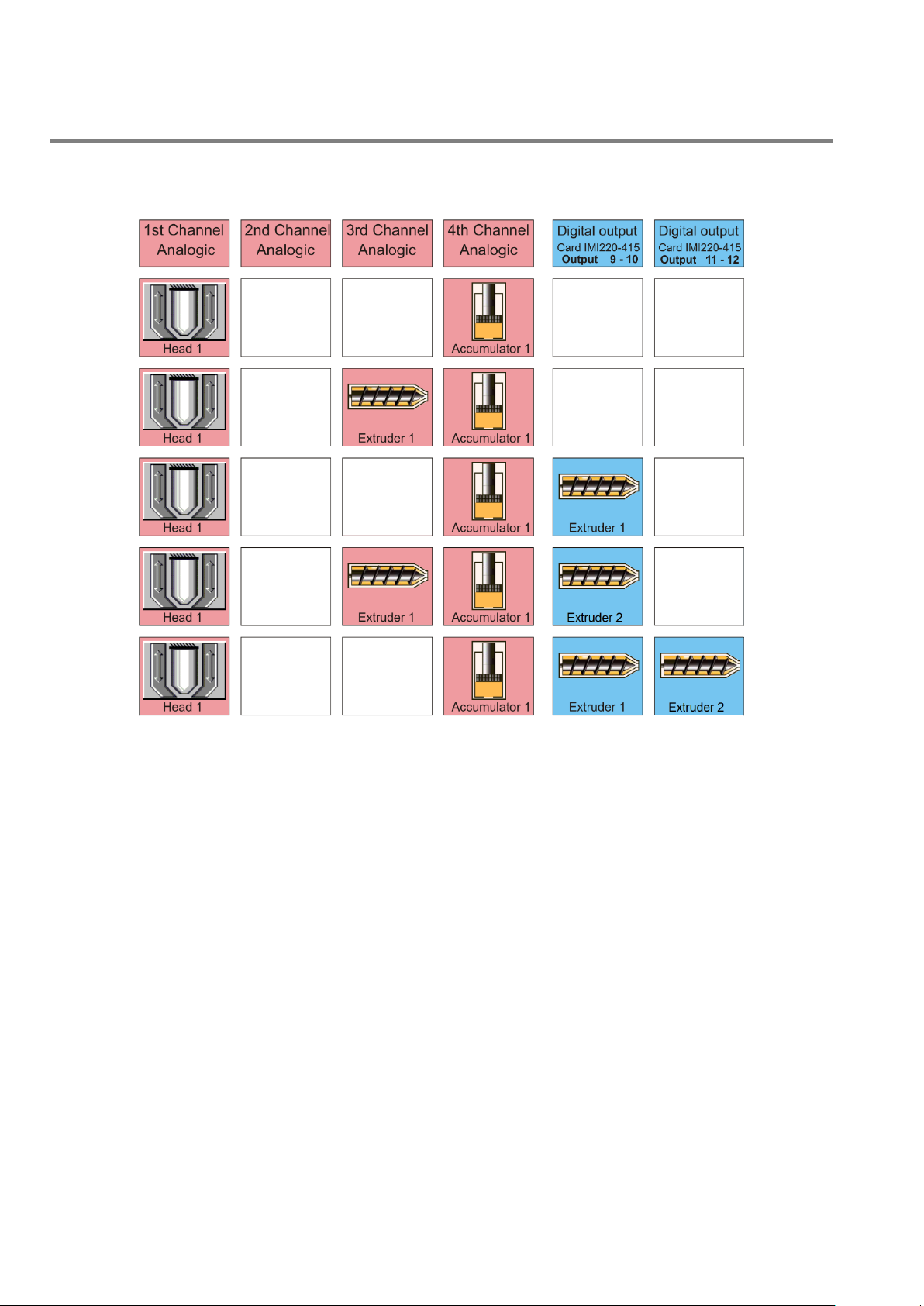

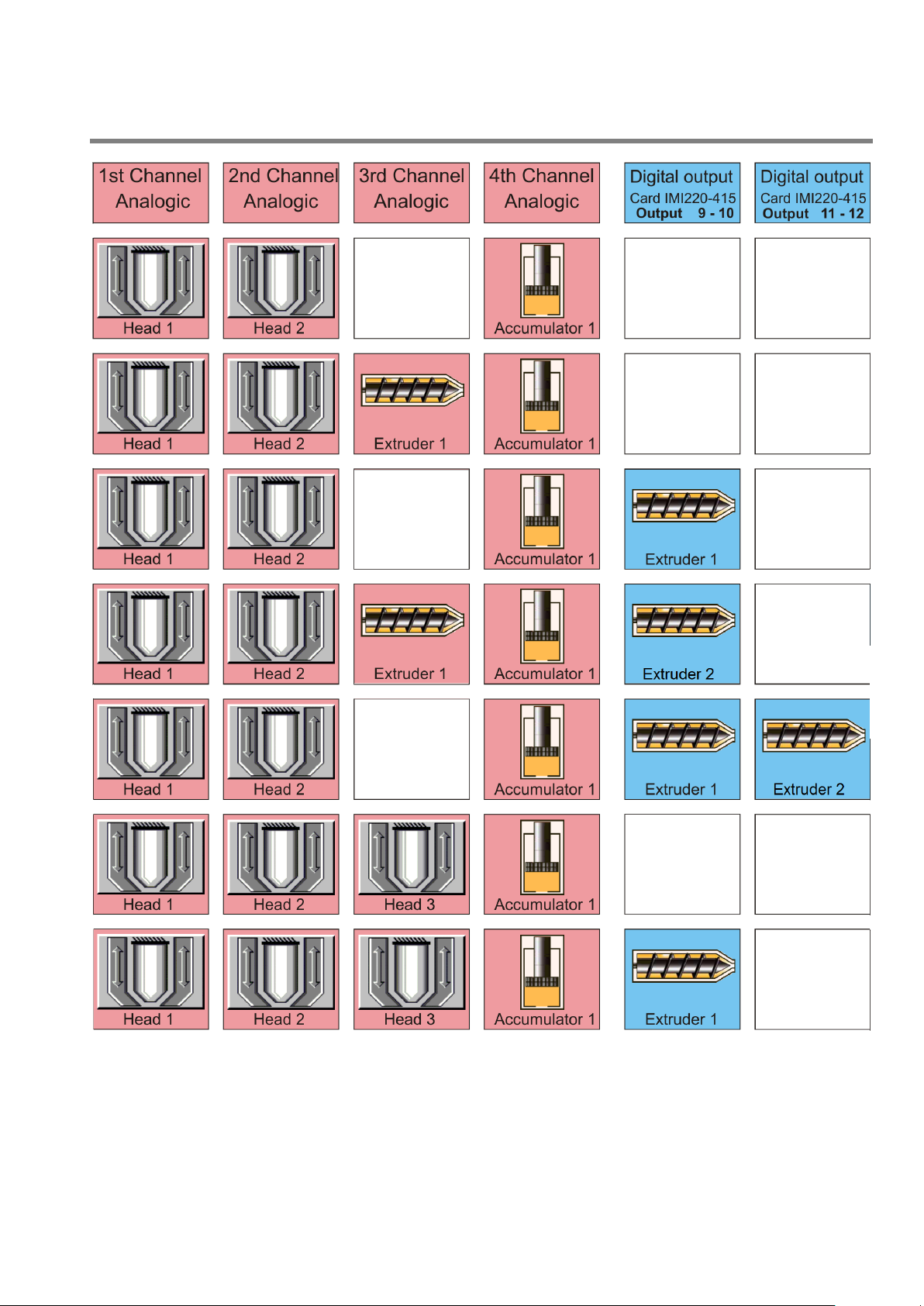

2.5.3 Elements.

PARISON CONTROLLER can be configured to manage up to 4 heads.

Each regulator uses an analog input to acquire the mandrel opening and an analog output to drive the mandrel

positioning actuator.

The regulator can operate in closed loop (with no-intelligent actuators) or in open loop (with intelligent actuators

that operate in closed loop stand alone).

The input value is calibrated in range 0% - 100.00% through definition of upper extreme voltage and lower extreme

voltage. In case of intelligent actuators the calibration points are set to 0 mV and 10000 mV if it is not necessary to

make the calibration.

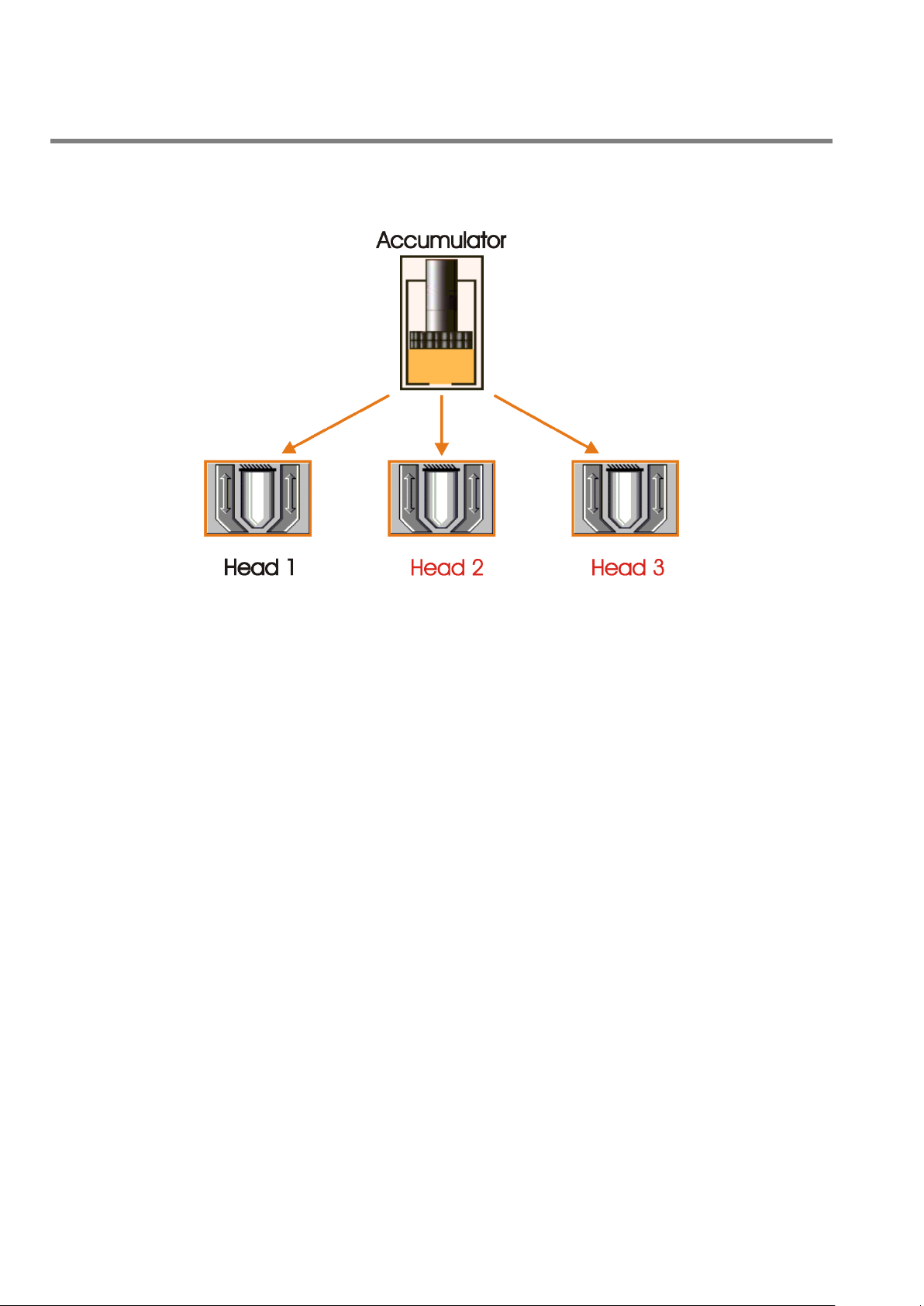

PARISON CONTROLLER can be configured to manage 1 accumulator.

A regulator in position in accumulation mode requires that the accumulator management is setup on fourth channel.

The setpoint generated by thickness regulator depends on the accumulator position in injection stroke relating to

the total injection stroke.

Input value is calibrated in range 0% - 100.00% through definition of full accumulator voltage (100% and input

higher than empty position) and empty accumulator voltage (0% and input lower than full position). It is possible to

exchange the analog output polarity to ignore the actuator connection polarity. The default polarity value waits for

increasing voltage values to bring the accumulator to empty position.

The input calibration should be made in this way:

It is possible to indicate a voltage to be applied on extrusion control output and activate empty accumulator

calibration procedure. The system automatically detects mechanical end-of-stroke, stores this value and interrupts

extrusion control. Using manual methods, the accumulator should be brought to empty and full position and it is

possible to manually confirm the positions.

PARISON CONTROLLER can be configured to manage up to 2 extruders.

It is possible to decide whether to use the extruder or not and which channel it should be associated to. It can be

associated to:

A thickness regulator in continuous extrusion.

A thickness regulator in time accumulation.

Accumulator.

It is possible to decide whether the extruder is driven by an analog or digital command. In case of analog command

the output voltage of a channel is the speed setpoint. In case of a digital command two digital outputs allow increase

or decrease of speed.

Extruder with analog command:

o It is possible to calibrate the input with: 0 speed voltage, maximum voltage, and maximum speed.

The speed is expressed in RPM.

o It is possible to calibrate the output with: maximum speed, voltage to reach maximum speed.

o These setpoints can be setup: speed to be reached, rising ramp in RMP/sec., falling ramp in

RPM/sec., minimum speed, maximum speed.

Extruder with digital command:

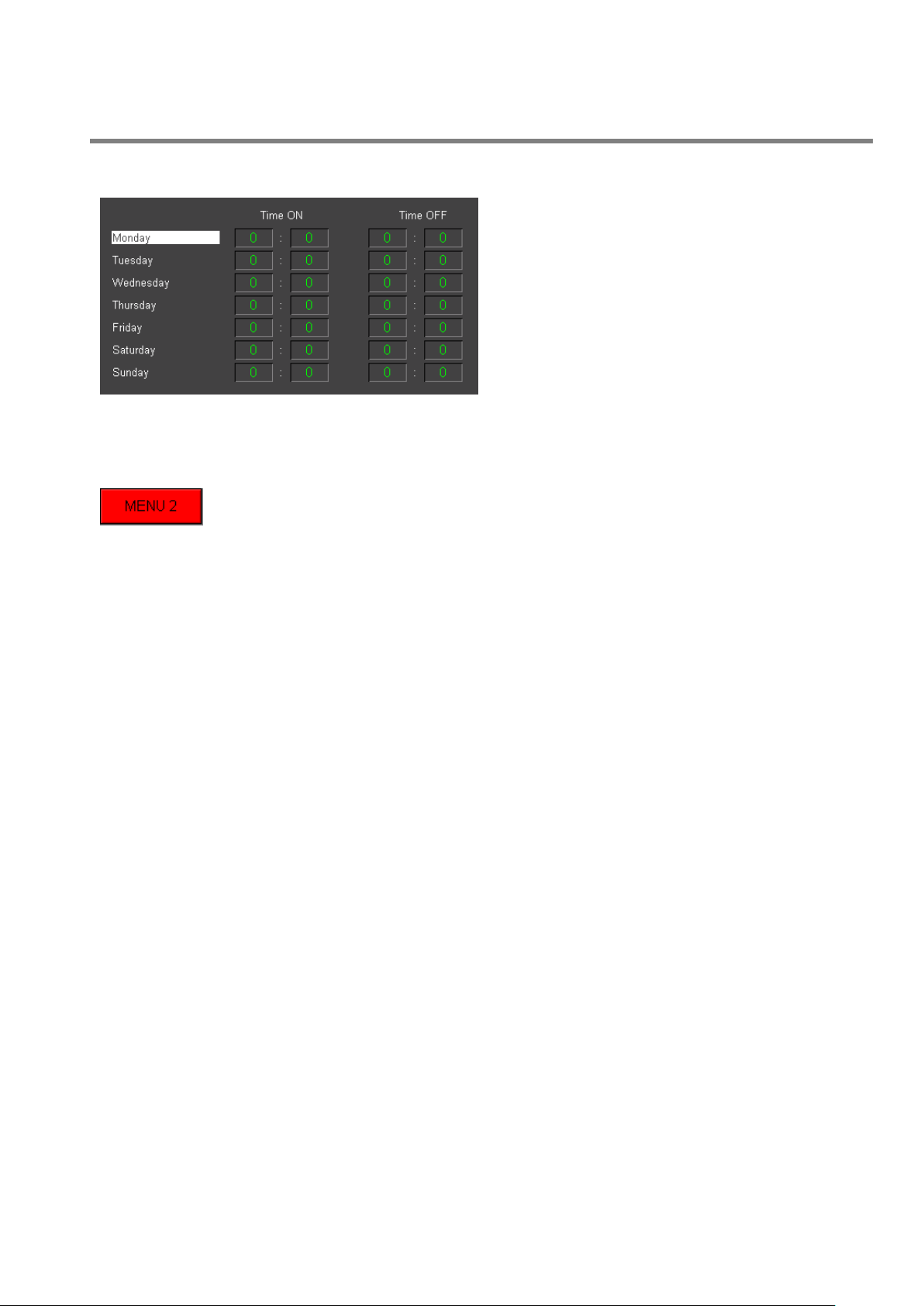

Timer Switch

The Parison Controller can manage a weekly timer switch to activate the machine heating system and it can

manage a production counter.

o You can setup the maximum ON time for digital output depending on a manual command.

18 MAN145-UM-D01A-EN Moog Italiana srl - Bergamo

Page 19

PARISON CONTROLLER

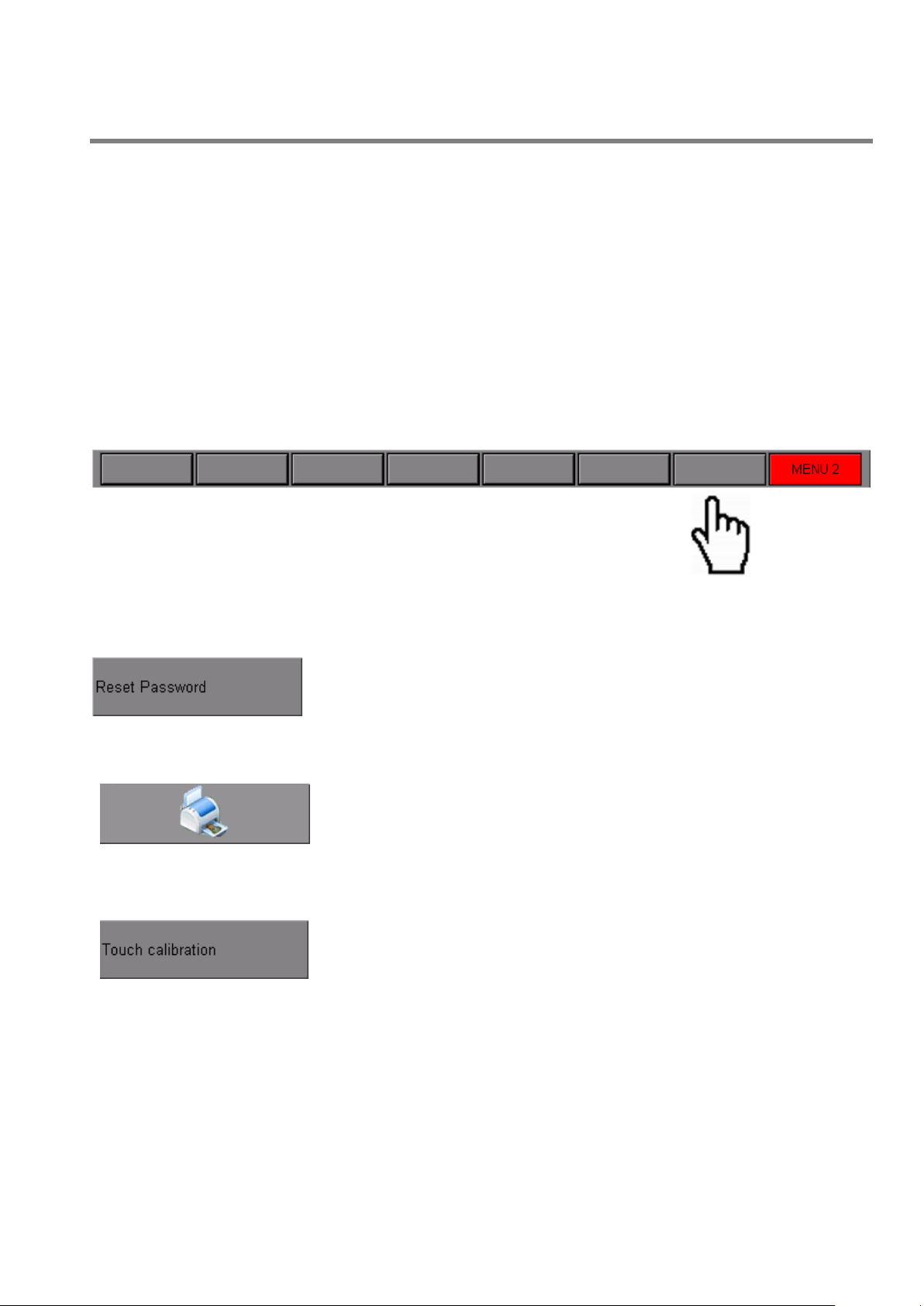

Figure 16

chose the page number and press the softkey

Figure 17

it is also possible to perform the touch calibration keeping pressed the SET

key (entry knob) for 10 seconds

moog

2.5.4 Access.

PARISON CONTROLLER manages 3 access levels to protect data entry:

1. minimum access for machine user. Lock: no password inserted.

2. responsible access for responsible. Acc. Resp. For changing this password enter in Technical Level and

enter in setup machine.

3. service access for installer/serviceman. Acc. Tech. This password is fixed by Moog.

Access to levels 2 and 3 is password-protected. Level 2 persists at power down and power up, while level 3 does

not.

2.5.5 Keyboard test page.

From the input/output page and in manual mode (digital input 13 has to be OFF)

Keeping pressed the button F7 (next to the button MENU 2) for 5 seconds it is possible to access the test page

In this page it is possible to:

Reset the password:

Figure 15

Print the pages:

Perform the touch calibration:

-

Figure 14

Moog Italiana srl - Bergamo MAN145-UM-D01A-EN 19

Page 20

PARISON CONTROLLER

moog

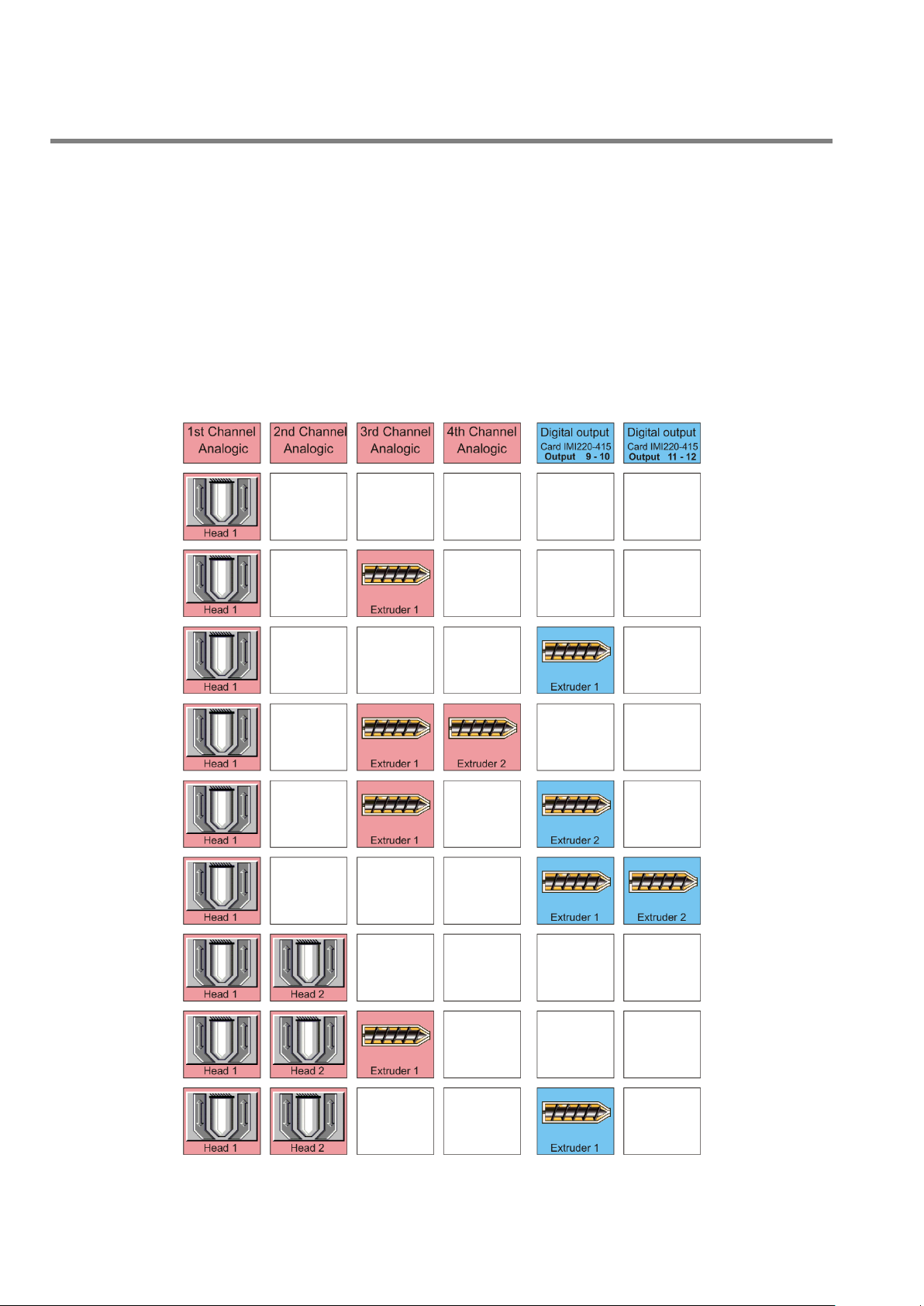

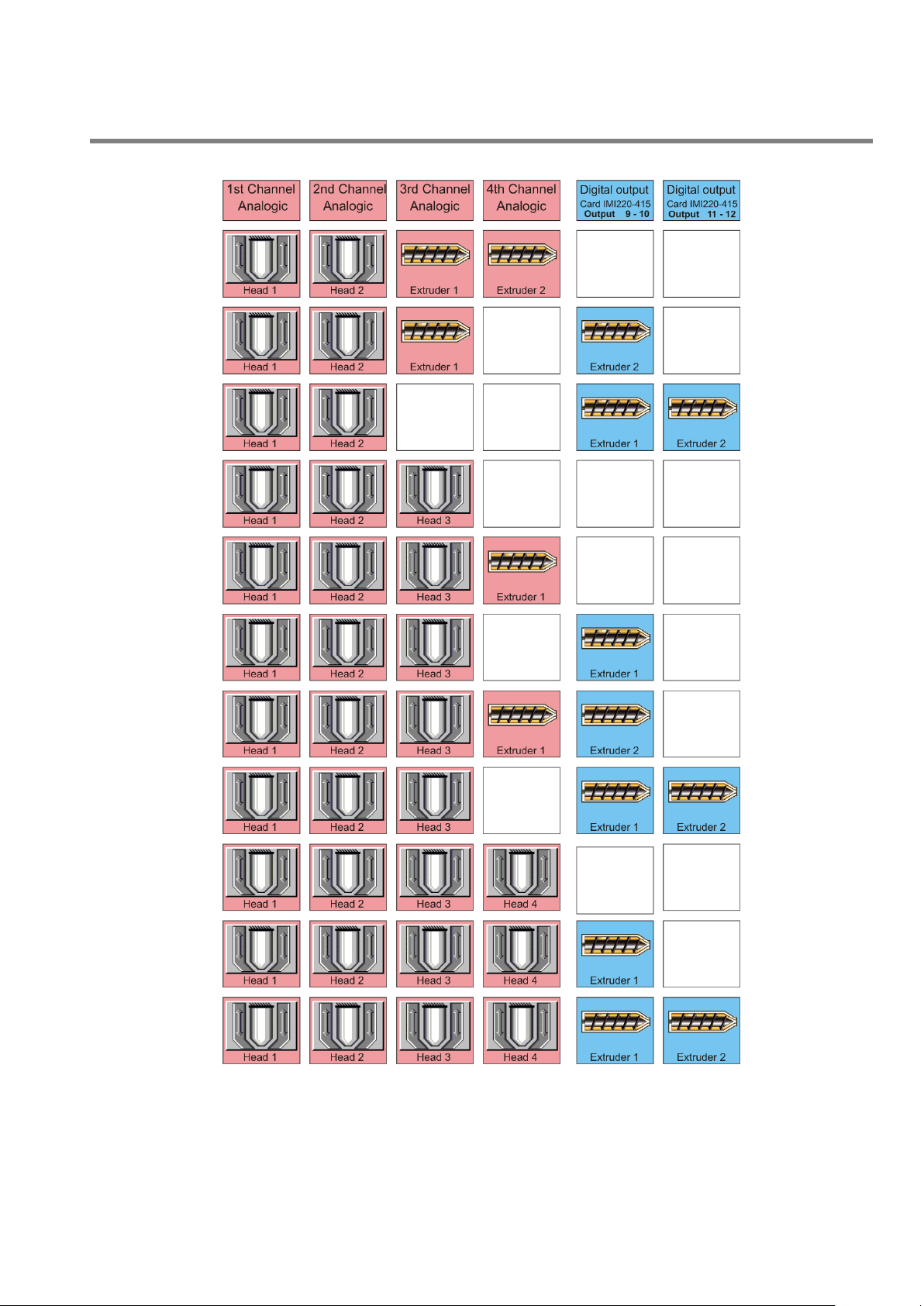

2.5.6 Machine configuration.

Parison Controller can be configured to run in:

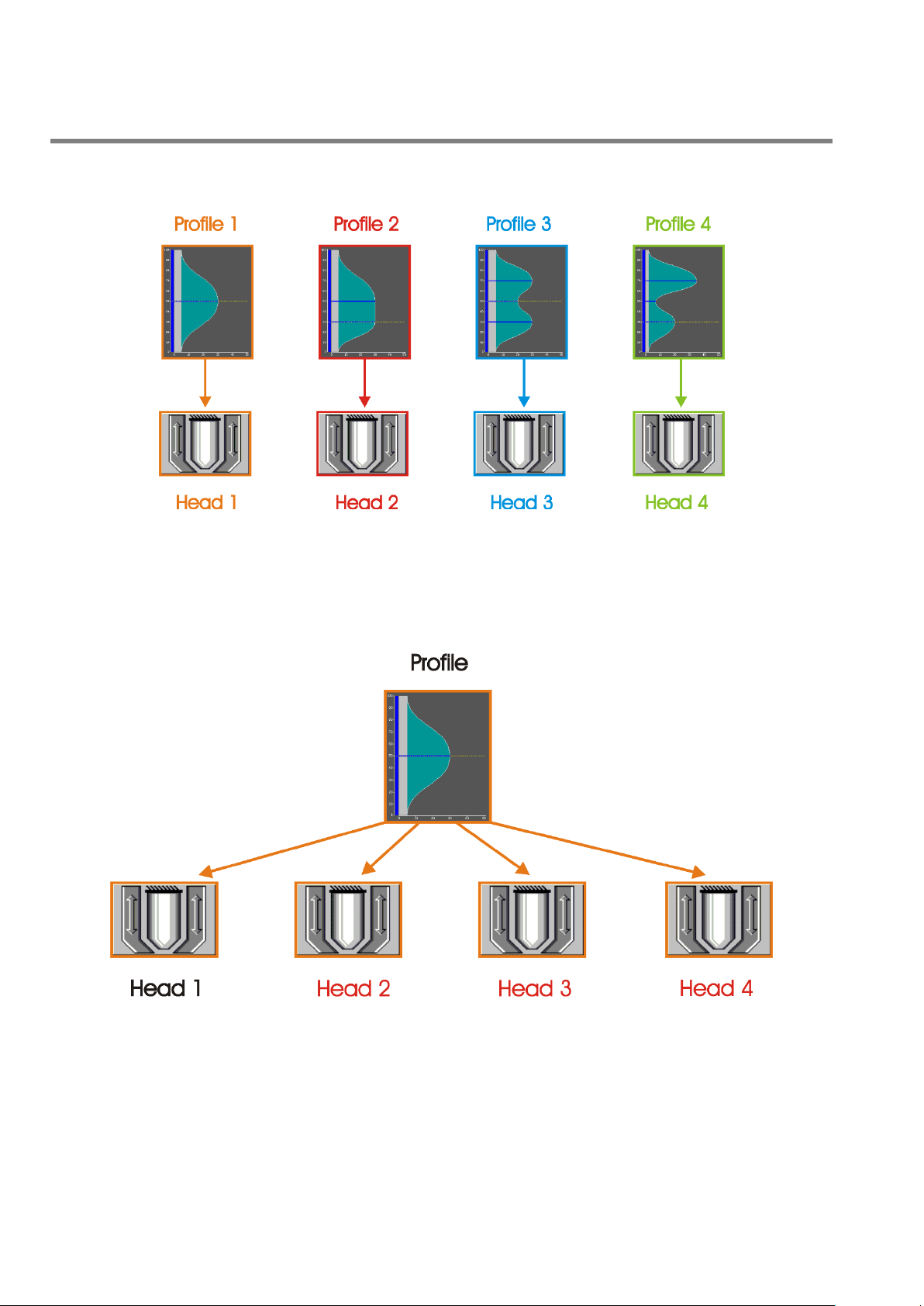

continuous extrusion with independent profiles

in continuous extrusion with unique profile

with accumulator position

time accumulator.

In the following figures it is possible to evaluate all the configurations supported by PARISON CONTROLLER (as

continuous extrusion or position accumulator).

2.5.7 Continuous Extrusion or Time Accumulator.

Figure 18

20 MAN145-UM-D01A-EN Moog Italiana srl - Bergamo

Page 21

PARISON CONTROLLER

moog

Figure 19

In continuous extrusion with independent profiles there are 2 command sets to make regulators 1 and 2

running independently from regulators 3 and 4. In this way it is possible to have a completely synchronized

operation of both parts. Regulators 1 and 2 will run with digital input START1 and regulators 3 and 4 will run with

digital input START2.

Moog Italiana srl - Bergamo MAN145-UM-D01A-EN 21

Page 22

PARISON CONTROLLER

moog

If a new start front is received before the current profile ends, this is interrupted and the next profile immediately

starts. If the new start front is received after the profile ends, the last point value is kept on output.

Figure 20

In continuous extrusion with unique profile there are 4 thickness regulators available (ranging from 1 to 4) and

one unique profile drives all of them. The profile issue for all the regulators is with digital input START1.

There is only one work page (Profile) and more setup page of setup for the calibration of the used heads.

In the work page it is possible to change the weight of the profile for every single head. The markers are active only

on head 1.

Figure 21

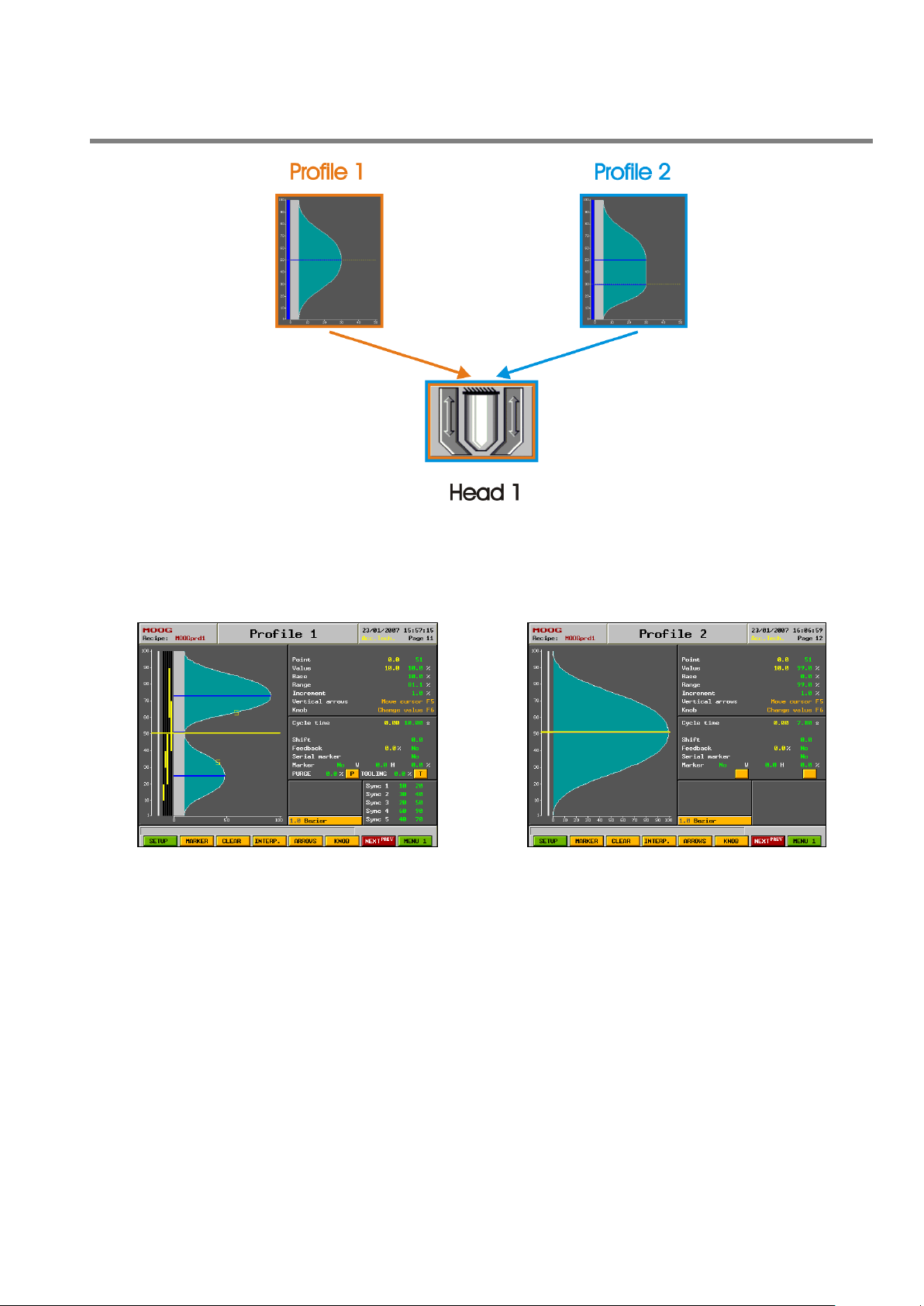

In continuous extrusion with unique profile and with only one head it is possible to enable the alternate

parison function.

Every profile has the start signal (Start 1 => Profile 1, Start 2 => Profile 2), the cycle time and the correction

independent.

22 MAN145-UM-D01A-EN Moog Italiana srl - Bergamo

Page 23

PARISON CONTROLLER

Figure 23

Figure 24

moog

Figure 22

Example alternate profile:

Profile 1 and Profile 2 work with output head 1 in alternate mode. The Profile 1 starts with Start group 1 and the

profile 2 starts with Start group 2.

Moog Italiana srl - Bergamo MAN145-UM-D01A-EN 23

Page 24

PARISON CONTROLLER

2.5.8 Position Accumulator.

moog

Figure 25

24 MAN145-UM-D01A-EN Moog Italiana srl - Bergamo

Page 25

PARISON CONTROLLER

moog

Figure 26

Moog Italiana srl - Bergamo MAN145-UM-D01A-EN 25

Page 26

PARISON CONTROLLER

moog

With accumulator position there are 3 position-dependent thickness regulators available (ranging from 1 to 3).

The thickness regulators follow the accumulator position. Thickness regulators work with independent profiles. The

accumulator extrusion is driven by the digital input START1.

Figure 27

With time accumulator there are 4 thickness regulators available (ranging from 1 to 4). The thickness regulators

are time-base driven by a single start signal (START1). Thickness regulators work with independent profiles.

Cycle time automatic correction not enabled: profile is generated by a fixed setpoint.

Cycle time automatic correction enabled: the time between rising edge of Start1 signal and its falling

edge it is measured; this time becomes the setpoint for the profile generation at next start.

Average correction enabled: carry out the average of 3 latest cycles. The average becomes the setpoint

for profile generation at next start.

If the falling edge of Start1 signal is received before the end of the current profile, the profile is interrupted. If the

falling edge is received after profile end, the setpoint holds the last point value.

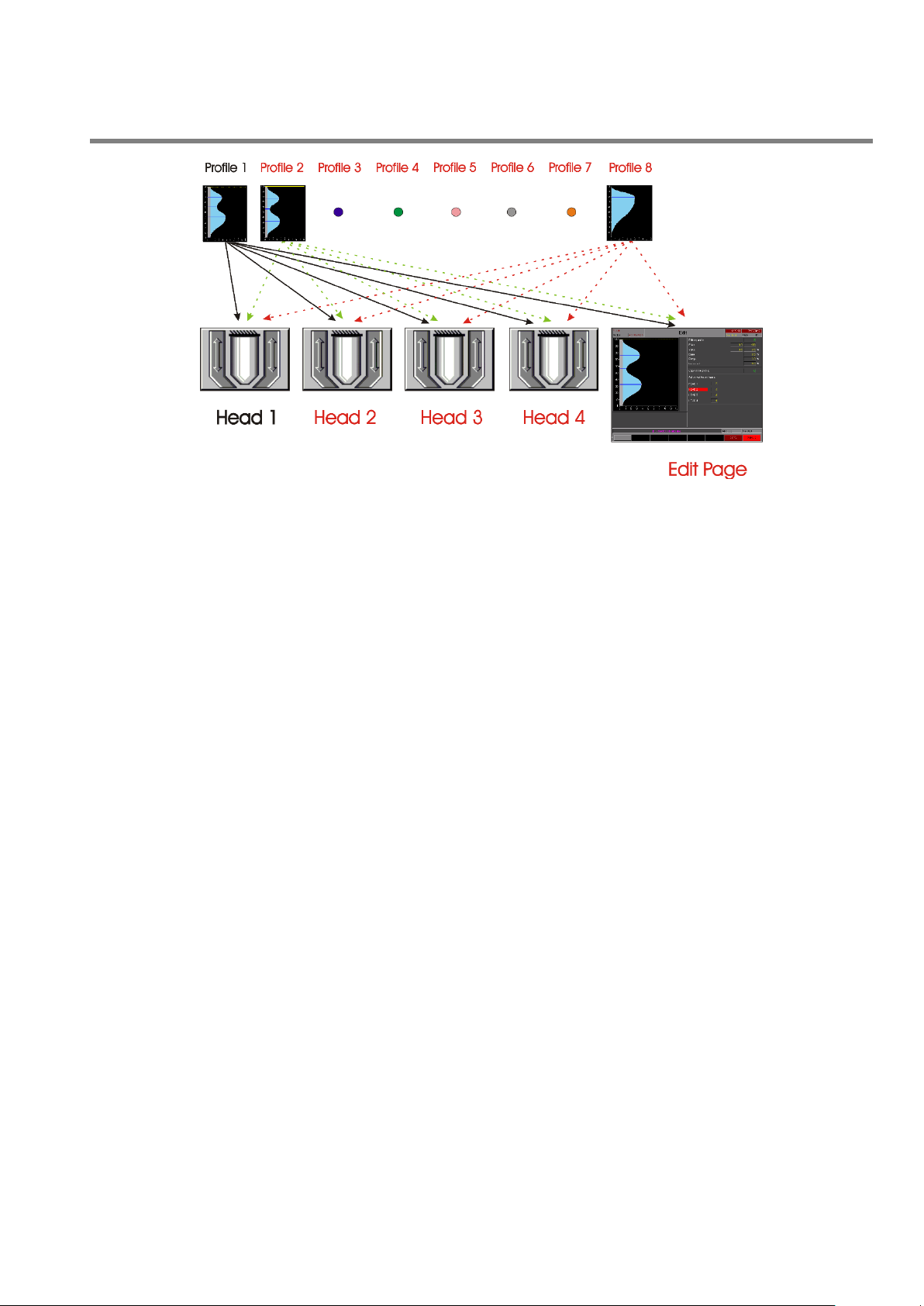

In every machine configuration type (except for alternate parison) it is possible to assign any profile to each head.

If the function Free Profiles Assignment is not enabled (see Setup Machine Page) the assignment of the profiles

is fixed (head 1 = profile 1; head 2 = profile 2, etc.).

26 MAN145-UM-D01A-EN Moog Italiana srl - Bergamo

Page 27

PARISON CONTROLLER

moog

Figure 28

If the function Free Profiles Assignment is enabled (full edit mode; see Setup Machine Page) it is possible to

assign to each head anyone of the 8 profiles available.

The 8 profiles can be displayed, modified and copied (if they are not already assigned to some head) in the Edit

page. In this page it is possible to know which profile each regulator is using.

2.5.9 Control Update Rate.

The close loop sampling time is normally 2 ms.

In continuous extrusion with only one head the control is faster (only 1 ms sampling time).

Moog Italiana srl - Bergamo MAN145-UM-D01A-EN 27

Page 28

PARISON CONTROLLER

P/N: Ordering code (Product Code: 145; Release Level: D; hardware

equipment: 001).

Mfg. Date: Release date.

S/N: Serial number.

Reserved: Code reserved to the qualified personnel.

Application Revision

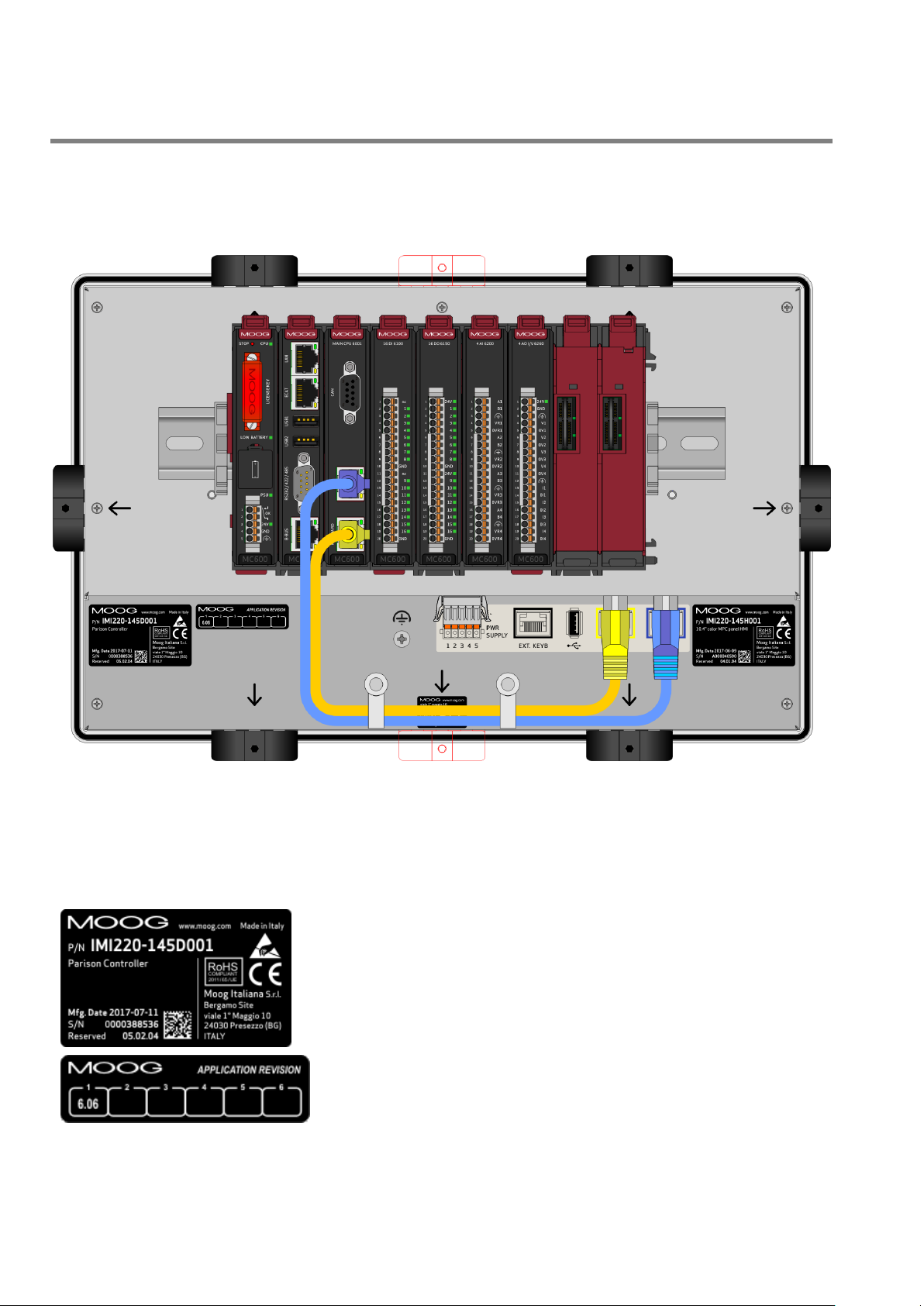

3 Hardware Description.

3.1 Parison Controller Rack based 600 Series (Rear).

moog

Figure 29

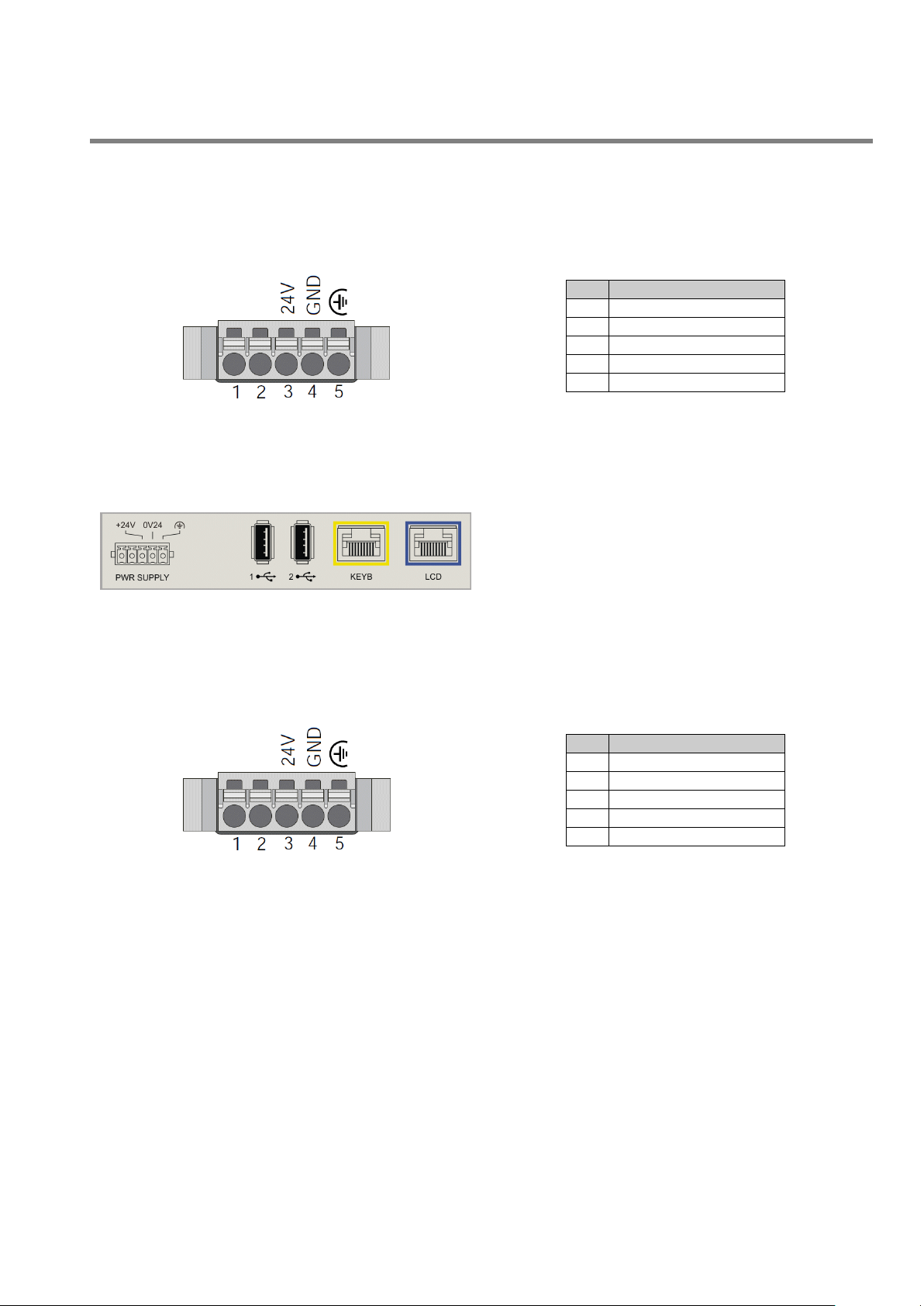

Place 1/2/3 Card IMI220-6001A001 (POWER SUPPLY – MAIN CPU – HMI DRIVER).

Place 4 Card IMI220-6100A001 (16 Digital Input card 24Vdc).

Place 5 Card IMI220-6150A001 (16 Digital Output 24V 0.5A card).

Place 6 Card IMI220-6200A001 (4 Analog Input 16 Bit).

Place 7 Card IMI220-6260A001 (4 Analog Output I/V 16 Bit).

28 MAN145-UM-D01A-EN Moog Italiana srl - Bergamo

Page 29

PARISON CONTROLLER

Figure 30

N°

Signal

1

OK Rely NO contact

2

OK Rely (Common)

3

+ 24V

4

GND

5

Earth

Figure 31

System label: Description of the position of the USB and

video connectors.

PWR SUPPLY: Power Supply of the display.

USB1: front USB device.

USB2: not to use

KEYB: LVDS keyboard connection

LCD: LVDS display connection

Figure 32

N°

Signal

1

Not used

2

Not used

3

+ 24V

4

0V24

5

GROUND

PLC Power Supply:.

moog

Display Power Supply:

Moog Italiana srl - Bergamo MAN145-UM-D01A-EN 29

Page 30

PARISON CONTROLLER

Pin n°

Name

Description

1

nc 2

Start profile group 1

Profile start signal for group 1 regulators

3

Photocell parison group 1

Measure signal of parison length for group 1 regulators

4

Mould ready group 1

Signal for mould ready to collect group 1 parison

5

Purge group 1

External enable for group 1 purge

6

Start profile group 2

Profile start signal for group 2 regulators

7

Photocell parison group 2

Measure signal of parison length for group 2 regulators

8

Mould ready group 2

Signal for mould ready to collect group 2 parison

9

Purge group 2

External enable of group 2 purge

10

GND

11

nc

12

Stand by die gap

Die gap closing signal during accumulation phases

13

Temperature OK

Operation enable of regulators and extruders

14

Emergency

Operation enable

15

Presence alarm in machine

Indication of machine alarm pieces

16

Machine in automatic

Indication of machine in automatic or manual mode

17

Piece discard

Decrease of produced pieces caused by a rejection

18

Not used.

19

Not used.

20

GND

Pin n°

Name

Description

1

+24V

Supply voltage +24V.

2

End filling

Indication of reached accumulator end of filling quota

3

End extrusion

Indication of reached end of extrusion quota

4

Synchronism 1

Sync command n°1 of first thickness regulator

5

Synchronism 2

Sync command n°2 of first thickness regulator

6

Synchronism 3

Sync command n°3 of first thickness regulator

7

Synchronism 4

Sync command n°4 of first thickness regulator

8

Synchronism 5

Sync command n°5 of first thickness regulator

9

Serial marker

Command of serial marker actuator

10

GND

Supply voltage 0V.

11

+24V

Supply voltage +24V.

12

Increment extruder 1

Increase command for extruder 1

13

Decrement extruder 1

Decrease command for extruder 1

14

Increment extruder 2

Increase command for extruder 2

15

Decrement extruder 2

Decrease command for extruder 2

16

Enable timer switch

Enable command from timer switch

17

End production

End of product signal

18

Alarm

Alarm signal

19

Head in calibration

Head number 1 in calibration mode

20

GND

Supply voltage 0V.

3.2 Digital Input (Card IMI220-6100A001).

moog

3.3 Digital Output (Card IMI220-6150A001).

30 MAN145-UM-D01A-EN Moog Italiana srl - Bergamo

Page 31

PARISON CONTROLLER

Pin n°

Name

Description

1

A1

Positive analog input 1

2

B1

Negative analog input 1

3

PE

Ground pin for connecting ground and shield

4

VR1

+10V reference voltage for sensors

5

0VR1

0V reference voltage return line

6

A2

Positive analog input 2

7

B2

Negative analog input 2

8

PE

Ground pin for connecting ground and shield

9

VR2

+10V reference voltage for sensors

10

0VR2

0V reference voltage return line

11

A3

Positive analog input 3

12

B3

Negative analog input 3

13

PE

Ground pin for connecting ground and shield

14

VR3

+10V reference voltage for sensors

15

0VR3

0V reference voltage return line

16

A4

Positive analog input 4

17

B4

Negative analog input 4

18

PE

Ground pin for connecting ground and shield

19

VR4

+10V reference voltage for sensors

20

0VR4

0V reference voltage return line

Pin n°

Name

Description

1

24V

Positive analog input 1

2

GND

Negative analog input 1

3

PE

Ground pin for connecting ground and shield

4

V1

Analog output (voltage) 1

5

0V1

Analog output (voltage) return line 1

6

V2

Analog output (voltage) 2

7

0V2

Analog output (voltage) return line 2

8

V3

Analog output (voltage) 3

9

0V3

Analog output (voltage) return line 3

10

V4

Analog output (voltage) 4

11

0V4

Analog output (voltage) return line 4

12

PE

Ground pin for connecting ground and shield

13

I1

Analog output (current) 1

14

0I1

Analog output (current) return line 1

15

I2

Analog output (current) 2

16

0I2

Analog output (current) return line 2

17

I3

Analog output (current) 3

18

0I3

Analog output (current) return line 3

19

I4

Analog output (current) 4

20

0I4

Analog output (current) return line 4

3.4 Analog Input (Card IMI220-6200A001).

moog

3.5 Analog Output (Card IMI220-6260A001).

Moog Italiana srl - Bergamo MAN145-UM-D01A-EN 31

Page 32

PARISON CONTROLLER

Figure 33

Figure 34

Figure 35

moog

3.6 Wiring.

In the following pages some wiring examples with different types of parison controls are presented.

For the actuators which are equipped with a position current feedback signal of 4÷20 mA it has been indicated to

use a buffer to convert the current signal into a voltage signal. This is required because the analog input card 4 AI

6200 accepts only voltage signals.

It is possible to use a 500 Ω resistor to convert the current signal into a voltage signal that can be connected to the

analog input card. The following drawings help to clarify this application; note that one side of the resistor is

connected to input A and to the current signal coming from the actuator; the other side of the resistor is connected

to input B and to the signal zero volt.

For those actuators which have the same wiring arrangement but a voltage feedback instead of a

current feedback, it is possible to directly route the signal to the A pin of the relevant analog input

and connect pin B to the signal common as depicted in the following picture.

32 MAN145-UM-D01A-EN Moog Italiana srl - Bergamo

Page 33

PARISON CONTROLLER

Wiring for Digital Input/Output and Power Supply.

moog

Moog Italiana srl - Bergamo MAN145-UM-D01A-EN 33

Page 34

PARISON CONTROLLER

moog

Wiring for continuous extrusion with Moog servo actuator cable L081-016 (Integrated Electronic Type 15Vdc).

34 MAN145-UM-D01A-EN Moog Italiana srl - Bergamo

Page 35

PARISON CONTROLLER

moog

Wiring for continuous extrusion with Moog servo actuator cable L081-018 (Integrated Electronic Type 15Vdc).

Moog Italiana srl - Bergamo MAN145-UM-D01A-EN 35

Page 36

PARISON CONTROLLER

moog

Wiring for continuous extrusion with Moog servo actuator in current (Integrated Electronic Type 24Vdc).

36 MAN145-UM-D01A-EN Moog Italiana srl - Bergamo

Page 37

PARISON CONTROLLER

moog

Wiring for accumulator head with Moog servo actuator (Integrated Electronic Type 15Vdc).

Moog Italiana srl - Bergamo MAN145-UM-D01A-EN 37

Page 38

PARISON CONTROLLER

moog

Wiring for accumulator head with Moog servo actuator (Integrated Electronic Type 24Vdc).

38 MAN145-UM-D01A-EN Moog Italiana srl - Bergamo

Page 39

PARISON CONTROLLER

Wiring for continuous extrusion with customer actuator.

moog

Moog Italiana srl - Bergamo MAN145-UM-D01A-EN 39

Page 40

PARISON CONTROLLER

Wiring for accumulator head with customer actuator.

moog

40 MAN145-UM-D01A-EN Moog Italiana srl - Bergamo

Page 41

PARISON CONTROLLER

Wiring for continuous extrusion with Moog actuator (With DCDT Type).

moog

Moog Italiana srl - Bergamo MAN145-UM-D01A-EN 41

Page 42

PARISON CONTROLLER

Wiring for accumulator head with Moog actuator (With DCDT Type).

moog

42 MAN145-UM-D01A-EN Moog Italiana srl - Bergamo

Page 43

PARISON CONTROLLER

Wiring for continuous extrusion Moog EMA L875-XXX.

moog

Moog Italiana srl - Bergamo MAN145-UM-D01A-EN 43

Page 44

PARISON CONTROLLER

UNIT: mm

3.7 Terminal measures.

moog

Figure 36

44 MAN145-UM-D01A-EN Moog Italiana srl - Bergamo

Page 45

PARISON CONTROLLER

UNIT: mm

moog

Figure 37

Moog Italiana srl - Bergamo MAN145-UM-D01A-EN 45

Page 46

PARISON CONTROLLER

UNIT: mm

moog

Figure 38

46 MAN145-UM-D01A-EN Moog Italiana srl - Bergamo

Page 47

PARISON CONTROLLER

Figure 40

With Technician or Responsible password, the fields date,

actual time and data format will appear. To change any

value double-click the appropriate field and set the desired

value.

4 Description of the Screen Functions.

4.1 Main Menu.

moog

Main Menu: Main part of the Main Menu.

Access: From all pages with key F8.

Use: Change page to submenus using keys F1 to F8.

4.1.1 Password.

The password is a 4 character string; to insert the value:

double-click on the field and then insert the string with the relative keyboard

press Ent key to confirm the entry

press Esc key to abandon the insertion

4.1.2 Date Change.

For example if you want to set 03/08/2017 (dd/mm/yy), you type 03082017 (as numeric fields) followed by Ent key.

Similarly for the actual time: if you want to set 08:50:00, you type 085000 followed by Ent key.

Is possible to select between European data format (dd/mm/yy) or American data format (mm/dd/yy).

Moog Italiana srl - Bergamo MAN145-UM-D01A-EN 47

Figure 39

Page 48

PARISON CONTROLLER

Work head 1: Setup and display the Parison profiles.

Profile 1: Setup and display the alternate profiles.

Work head 2: Setup and display the Parison profiles.

Profile 2: Setup and display the alternate profiles.

Work head 3: Setup and display the Parison profiles.

Work head 4: Setup and display the Parison profiles.

Accumulator: Setup and display the Accumulator profile.

Work extruder 1: Setup and display the extruder.

Work extruder 2: Setup and display the extruder.

Alarms: Display alarms from PLC and from system.

Main Menu 2: Go to main menu 2.

4.1.3 Function Keys.

moog

48 MAN145-UM-D01A-EN Moog Italiana srl - Bergamo

Page 49

PARISON CONTROLLER

Edit: Editing the Parison profiles. It is possible to access the Edit page only if on

Setup Machine Page the Free Profiles Assignment ON.

Timer Switch: Setup the time of turning on and off the heating. It is possible to

access the Timer Switch page only if on Setup Machine Page you set

Management timer switch ON.

Production: Production data management. It is possible to access the Production

page only if on Setup Machine Page you set Production Control ON.

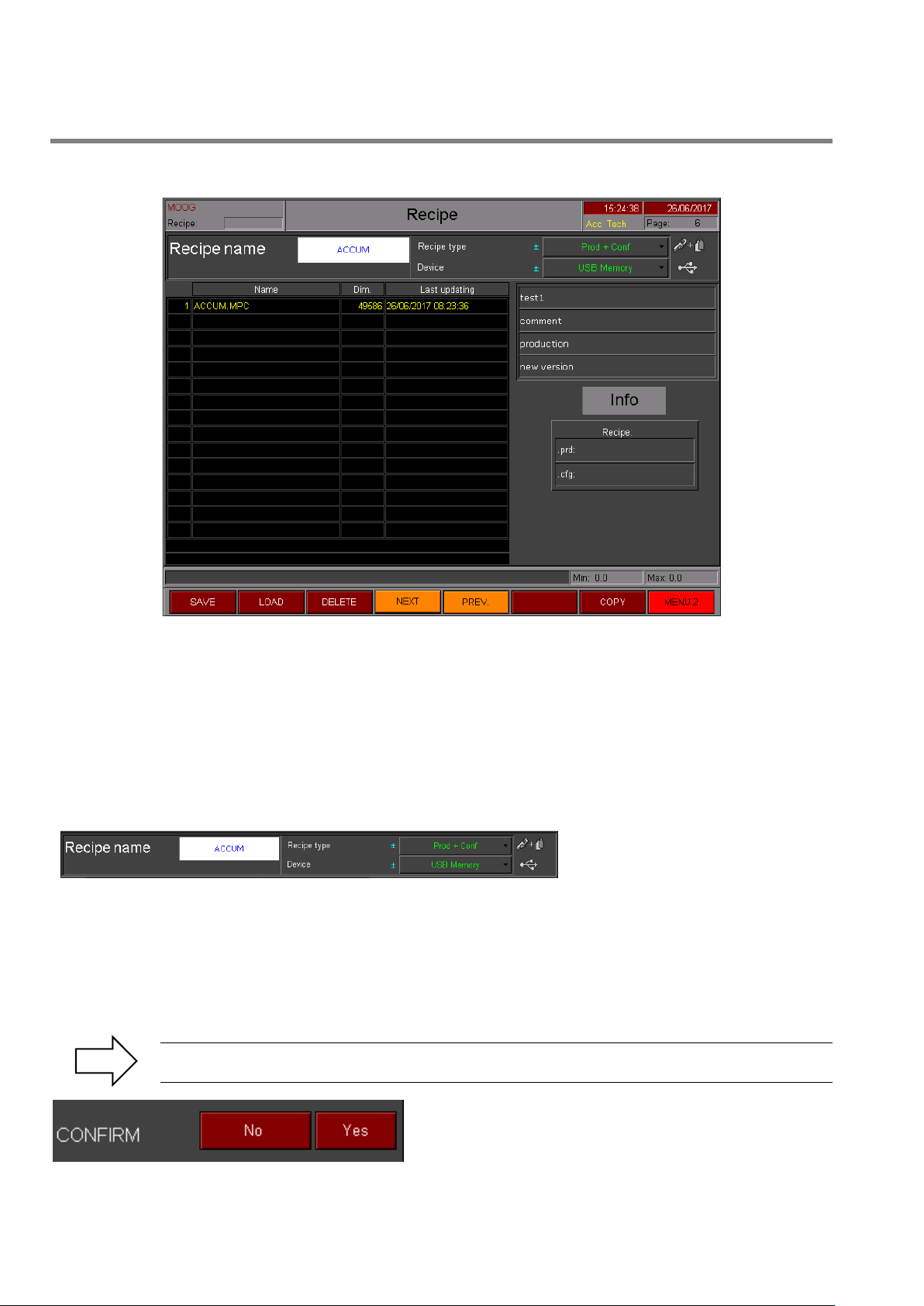

Recipe: Recipe management. It is possible to access the recipe page only if you

insert a Technician or Responsible password.

All Profiles: open the all profiles page where it is possible to view all active

profiles at a glance.

Input / Output: Monitor status input/output digital/analogical data.

4.2 Main Menu 2.

moog

Main Menu 2: Second part of the Main Menu.

Access: From Main Menu with key F8.

Use: Enter submenus.

4.2.1 Function Keys.

Figure 41

Moog Italiana srl - Bergamo MAN145-UM-D01A-EN 49

Page 50

PARISON CONTROLLER

Setup Machine: Setup the machine configuration. It is possible to access the

machine setup page only if you insert a password of Technician level.

Main Menu: Go to main menu 1.

moog

50 MAN145-UM-D01A-EN Moog Italiana srl - Bergamo

Page 51

PARISON CONTROLLER

It is possible to select one of the following

types of machine (in manual mode):

Continuous extrusion to independent

profile.

Continuous extrusion to unique profile.

With accumulator position.

With time accumulator.

4.3 Machine Setup.

moog

Figure 42

Machine Setup: Configure the machine.

Access: From Main Menu 2 with key F7.

Use: Configure the PARISON CONTROLLER according to the typology of the machine that will be

connected.

ATTENTION: to modify some parameters the digital input number 13 (machine in

automatic mode) has to be OFF. This operation is permitted only if the machine is in

manual mode.

4.3.1 Function of the machine.

Moog Italiana srl - Bergamo MAN145-UM-D01A-EN 51

Page 52

PARISON CONTROLLER

Figure 43

Number of heads: Select(in manual mode) how many heads are

connected (range 1 ÷ 4).

Number of extruders: Select (in manual mode) how many extruders

have to be managed by the controller. (0 to 2).

Number points profile: Select (in manual mode) how many points

the Parison profile wants (range 10 - 400 points). The change of the

points number of the profile could show some anomalies in the

visualization of the profile shape. It is necessary to reset the old

profiles and draw the new one (see the reference table).

Task Time 1 ms

Cycle time

> 0.4 sec

0.3 0.4 sec

0.2 0.3 sec

0.1 0.2 sec

Suggested points

400

300

200

100

Task Time 2 ms

Cycle time

> 0.8 sec

0.6 0.8 sec

0.4 0.6 sec

0.2 0.4 sec

Suggested points

400

300

200

100

moog

4.3.2 General setup of the machine.

Technician password: Write the password for Technician level. This Password is permanently saved. With this

level password is possible to modify every field.

Responsible password: Write the password for Responsible level. This Password is permanently saved. With

this level password is possible to modify every field but all the setup pages are disabled.

Current language: Select the visualization language. The following languages are available:

English, Italian, German, French, Spanish, Portuguese, Danish, Russian, Turkish, Greek, Chinese, Japanese.

Number synchronisms: Number of synchronisms. The controller can manage up to 5 sync points driving a specific

output. With the Continuous extrusion mode the syncs are edited in the Work Head page where Profile 1 is active.

With Accumulator position mode they are edited in the Accumulator page.

Mode sync 1 (or 2/3/4/5): (visible in Accumulator position mode) Select synchronism mode: Filling, Extrusion or

both. This parameter sets the accumulator movement in which the sync is active.

Default interpolation: Select default interpolation used when you insert a new master in the profile.

4.3.3 How to chose the correct points number:

Task Time is 1 ms if 1 head is active in continuous extrusion mode. Task Time is 2 ms in all other cases.

Reference table:

Points = Cycle time (s) / Task time (s)

52 MAN145-UM-D01A-EN Moog Italiana srl - Bergamo

Page 53

PARISON CONTROLLER

Figure 44

Alternate parison: (visible in Continuous extrusion to unique

profile mode and with only one head) Decides if the head has to

work with one or two alternated profiles.

Production Control: Enable or disable the visualization of the

Production page.

Visualize serial marker: Enable or disable the visualization of

the serial marker in head 1 work page.

Visualize marker: Enable or disable the visualization of the

markers in all heads pages.

Vis. horizontal ruler: Enable the visualization of the horizontal

ruler in the profile pages.

Vis. vertical ruler: Enable the visualization of the vertical ruler

in the profile pages.

Figure 45

Output N°x type: is possible to select (in

manual mode) the command output type,

Voltage or Current, for each channel. The

yellow labels on the right show what

actuator is connected to each channel.

moog

4.3.4 Machine Settings.

Vis. Feedback as a line: Enable the feedback visualization as a line in the profile pages. It is recommended with

cycles times shorter than 5 seconds.

Autorange profile: Enable auto-range profile to resize the horizontal rulers. (Range 0 - 25, 0 - 50, 0 - 100).

Free profiles assignment: (not visible when Alternate parison is enabled) Enable the visualization of the Edit

Profile page and the possibility to assign different profiles to each head (from 1 to 8).

Management timer switch: Enable or disable the visualization of the Timer page.

Visualize shift: To enable the function in case of use of the shift on the profile. It allows a better interpolation

between the first and the last point of the profile.

Brightness: Manage the TFT Brightness (seven levels:

Time functioning: Counter indicating how long the Parison Controller has been ON.

4.3.5 Output selection.

to increase, - to decrease).

+

With current command is possible to select the current range:

- Current Command +/- 7.5 mA.

- Current Command +/- 15 mA.

- Current Command +/- 30 mA.

- Current Command +/- 50 mA.

- Current Command +/- 75 mA.

- Current Command +/- 100 mA.

4.3.6 Languages.

It is possible to select one of the following languages:

English, Italian, German, French, Spanish, Portuguese, Danish, Russian, Turkish, Greek, Chinese, Japanese.

Moog Italiana srl - Bergamo MAN145-UM-D01A-EN 53

Page 54

PARISON CONTROLLER

moog

54 MAN145-UM-D01A-EN Moog Italiana srl - Bergamo

Page 55

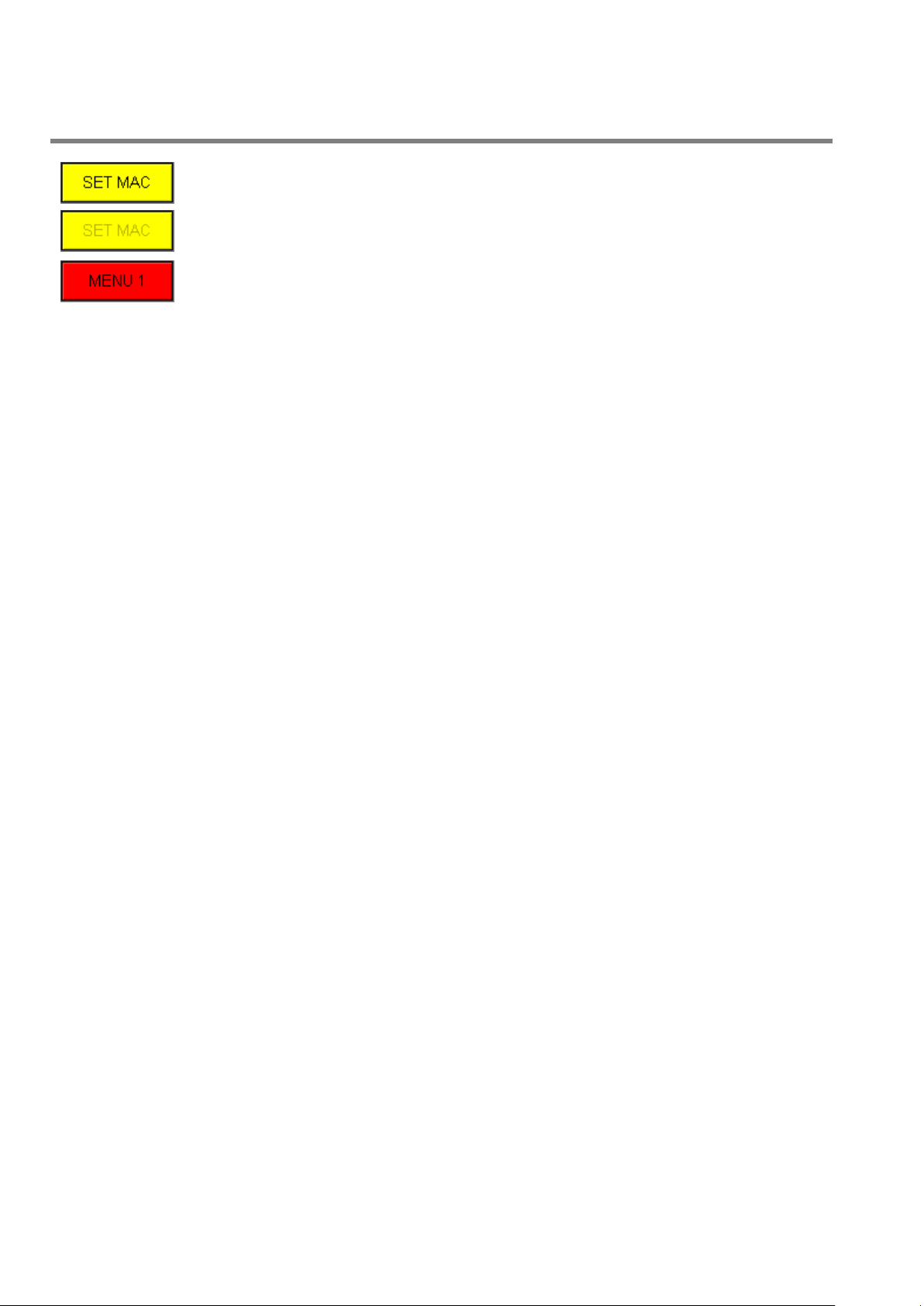

PARISON CONTROLLER

SET MAC2: Select Setup page 2.

PREV | NEXT: Fast selection of the next or previous Setup page. The next and

previous Setup Page depends on the current machine configuration.

MENU 2: Select Main menu, page 2.

4.3.7 Function Keys.

moog

Moog Italiana srl - Bergamo MAN145-UM-D01A-EN 55

Page 56

PARISON CONTROLLER

Enable digital output during

calibration

Enable digital output number 16 (output is ON when head 1 is in calibration

mode)

Die gap management with

continuous extrusion

Enable the die gap function also in continuous extrusion. To reach the die gap

position is necessary to use digital input number 9: Stand by die gap (connect

digital output 2 and digital input 9 to reach the die gap position at the end of

extrusion)

Auto change page with

alternate parison

Enable the automatic selection of profile 1 and profile 2 pages. With Start 1

signal, profile 1 page is selected; with Start 2 signal, profile 2 page is selected

Touch sound

Enable the beep at every keypress on the display

Base/Range/Purge level

access

Set the password level required to activate the purge function

Enable PWDS

Configure the selected control channel as a Partial Wall Thickness Distribution

System (PWDS); the relevant axis is used to control a deformable die used to

obtain more material on certain portions of the extruded material and less on

the others

PWDS in mm

The deformation of the die will be expressed in mm rather than in percentage

Calibration

When the deformation is expressed in mm these fields are used to set the

admissible range that will be available in the work page

moog

4.4 Machine Setup 2.

Machine setup: Configure the machine.

Access: From Setup Machine with key F2.

Use: Configure the PARISON CONTROLLER according to the typology of the machine that will be

connected.

4.4.1 Machine settings - page 2.

Figure 46

56 MAN145-UM-D01A-EN Moog Italiana srl - Bergamo

Page 57

PARISON CONTROLLER

SET MAC: Select Setup page 1

PREV | NEXT: Fast selection of the next or previous Setup page. The next

and previous Setup pages depend on the current machine configuration

MENU 2: Select Main menu, page 2.

4.4.2 Function Keys.

moog

Moog Italiana srl - Bergamo MAN145-UM-D01A-EN 57

Page 58

PARISON CONTROLLER

Figure 48

From left to right:

Vertical ruler: (white) If enabled in Setup Machine Page (Vis. vertical ruler).

From 1 to max 400 points to navigate.

Horizontal ruler: (white) If enabled in Setup Machine Page (Vis. horizontal

ruler). Percentage scale from 1 to 100 % max. Default number is 100, but if

Autorange profile in Setup Machine Page is enabled, the horizontal ruler is

resized.

Serial Marker: Vertical logical state diagram showing the serial marker

activation along the profile.

Synchronisms: (only if enabled): 5 vertical lines that display 5 synchronisms

signals defined by a couple of start and stop points.

Bargraph: Shows the working point of selected head as feedback. In case of

extrusion (or time based mode) the bargraph will be red and start at point 1. In

case of Filling the bargraph will be blue and start at max point.

4.5 Work Head n / Profile n.

moog

Figure 47

Work Head n: Parison page n° (n° = 1 to 4).

Access: From Main Menu with key F1...F4.

Use: Edit parison profile and parameters for the die opening. Each regulator uses an analog input to

read the mandrel actual position and an analog output to drive the mandrel positioning actuator.

4.5.1 Profile Editor.

The line is yellow, if working during Extrusion, green if working during Filling and red if working both in Extrusion

and Filling. Synchronisms are visible only on profile 1.

4.5.2 Profile parameters.

58 MAN145-UM-D01A-EN Moog Italiana srl - Bergamo

Page 59

PARISON CONTROLLER

Figure 49

Profile associate: (Only if Free profiles assignment is

enabled) Profile number associated to the head.

Point: Shows in yellow the actual point during the movement

in accordance with the red bar graph on the right side of the

screen. In green the position of the cursor in the Parison field.

Value can be changed from 1 to 400 to set the cursor position.

Figure 50

Cycle time: Displays in yellow the Parison

cycle time during the movement and in green

the Parison cycle time in seconds.

Weight: Change the weight of the profile.

Shift: It is possible to indicate by how many

points (N) to shift the profile. Once the last

point of the profile is reached, the setpoint

continues from point 1 until point N-1.

moog

Value: Shows in yellow the desired percentage setting and in green the value of the point where the cursor is in

the Parison field. By changing this value (0 to 100% max) it is possible to add a new setpoint or modify the existing

one at the cursor position.

Base: Displays the minimum profile value. By changing the base it is possible to shift the whole profile. Range: 0%

to Max limit (Profile). The max limit added to the range must be less or equal to 100% (base + range <= 100).

Range: Displays the profile range as difference between maximum and minimum value. By changing the range it

is possible to resize the entire profile. Range: 1% to Max limit ( Weight). The max limit added to the base must be

inferior or equal to 100% (base + range <= 100).

Increment: This is the amount by which the setpoint value is incremented or decremented when editing the profile

at the cursor position.

Vertical arrows: Shows the vertical arrows active function (chapter 2.5.4).

Knob: Shows the entry knob active function (chapter 2.5.4).

4.5.3 Cycle parameters.

Feedback: If activated, it allows to see the actual value of the profile measured by the transducer (in red) beside

the theoretical one. Head: Allows to choose the feedback of the desired head in case of unique profile. The yellow

field shows the actual value in percentage.

Serial marker: Enable (YES) or disable (NO) the serial marker in the profile. Enable the digital output command

of serial marker actuator on card IMI220-415A001 to identify the points of the profile on the final product.

Marker: Enable (YES) or disable (NO) all markers in the profile. It is possible to setup the markers on each profile.

For each profile you can setup different values of marker length in points and width in percentage.

W: Marker Width (in points). Value corresponding to the working gap with the preceding and following points related

to the position where the Marker has been set.

H: Marker Height (in percentage). Value corresponding to the working gap with the opening and closing points

related to the position where at the Marker has been set.

Moog Italiana srl - Bergamo MAN145-UM-D01A-EN 59

Page 60

PARISON CONTROLLER

Figure 51

In the example two markers are placed at points 30 and 70. The red line shows

the feedback.

With W (Width) = 5 points and H (Height) = 3%, the value will be increased up

to 3% from point 25 (30 - 5), reset to the programmed value at point 30 and

decreased by 3% until point 35 (30 + 5).

PURGE: Purge referred to this head. It is possible to indicate a setpoint,

expressed in %, for the head opening. Purge is driven by a special function key

or digital input. Purge through digital input is possible only if the function is

configured and the machine is in manual mode. This command activated during

the issuing of a profile becomes active only at the end of the same profile. The

buttons that control this function are toggle type.

TOOLING: Tooling referred to this Head. It is possible to indicate a setpoint,

expressed in %, for the tooling function. Tooling is driven through a special

function key. This command activated during the issuing of a profile becomes

active only at the end of the same profile. The buttons that control this function

are toggle type.

Die gap position: Available with accumulator or continuous

extrusion. If enabled it sets the die gap position of the head.

Figure 52

Weight: With unique profile it allows to add an additional

weight on every single head. (not visible in profile).

moog

4.5.4 Die gap

4.5.5 Weight

60 MAN145-UM-D01A-EN Moog Italiana srl - Bergamo

Page 61

PARISON CONTROLLER

Figure 53

Bezier: Interpolation between two masters: the

interpolation type visualized corresponds to the area

where the cursor is placed. The smooth parameter is

included between 0.5 and 2.0 with step 0.1.

Figure 54

Linear: Interpolation between two masters: the

interpolation type visualized corresponds to the area

where the cursor is placed.

4.5.6 Interpolation.

moog

Moog Italiana srl - Bergamo MAN145-UM-D01A-EN 61

Page 62

PARISON CONTROLLER

Figure 55

Flat: Interpolation between two masters: the

interpolation type visualized corresponds to the area

where the cursor is placed.

Figure 56

Parabolic 1: (parabola with tangent 0 on start point)

Interpolation between two masters: the interpolation

type visualized corresponds to the area where the

cursor is placed.

Figure 57

Parabolic 2: (parabola with tangent 0 on end point)

Interpolation between two masters: the interpolation

type visualized corresponds to the area where the

cursor is placed.

moog

62 MAN145-UM-D01A-EN Moog Italiana srl - Bergamo

Page 63

PARISON CONTROLLER

Figure 58

Synchronisms: Only if enabled in Machine setup page. Each synchronism is

defined by a pair of start and stop points along the profile (1…400 max). They are

represented also by vertical lines on the left of the profile-edit-field.

Figure 59

Figure 60

The Profile editor is similar

to the normal head’s one

except that the zero point

of the horizontal axis is not

always on the left side but

depends on the calibration

settings

In Figure 59 the PWDS is

setup in % and the zero

point is in the middle

In Figure 60 the PWDS is

setup in mm and is

calibrated from -8 to +2

mm.

moog

4.5.7 Synchronisms.

4.5.8 Work Head n for PWDS Control

Any channel can be dedicated to control a Partial Wall Thickness System (PWDS). When a control channel is

configured for this function, some of the parameters available for a normal parison head are meaningless and

therefore are not visible both in the setup and working pages.

In the working page the following parameters are not present:

Base

Weight

Head

Tooling

Die gap position

Moog Italiana srl - Bergamo MAN145-UM-D01A-EN 63

Page 64

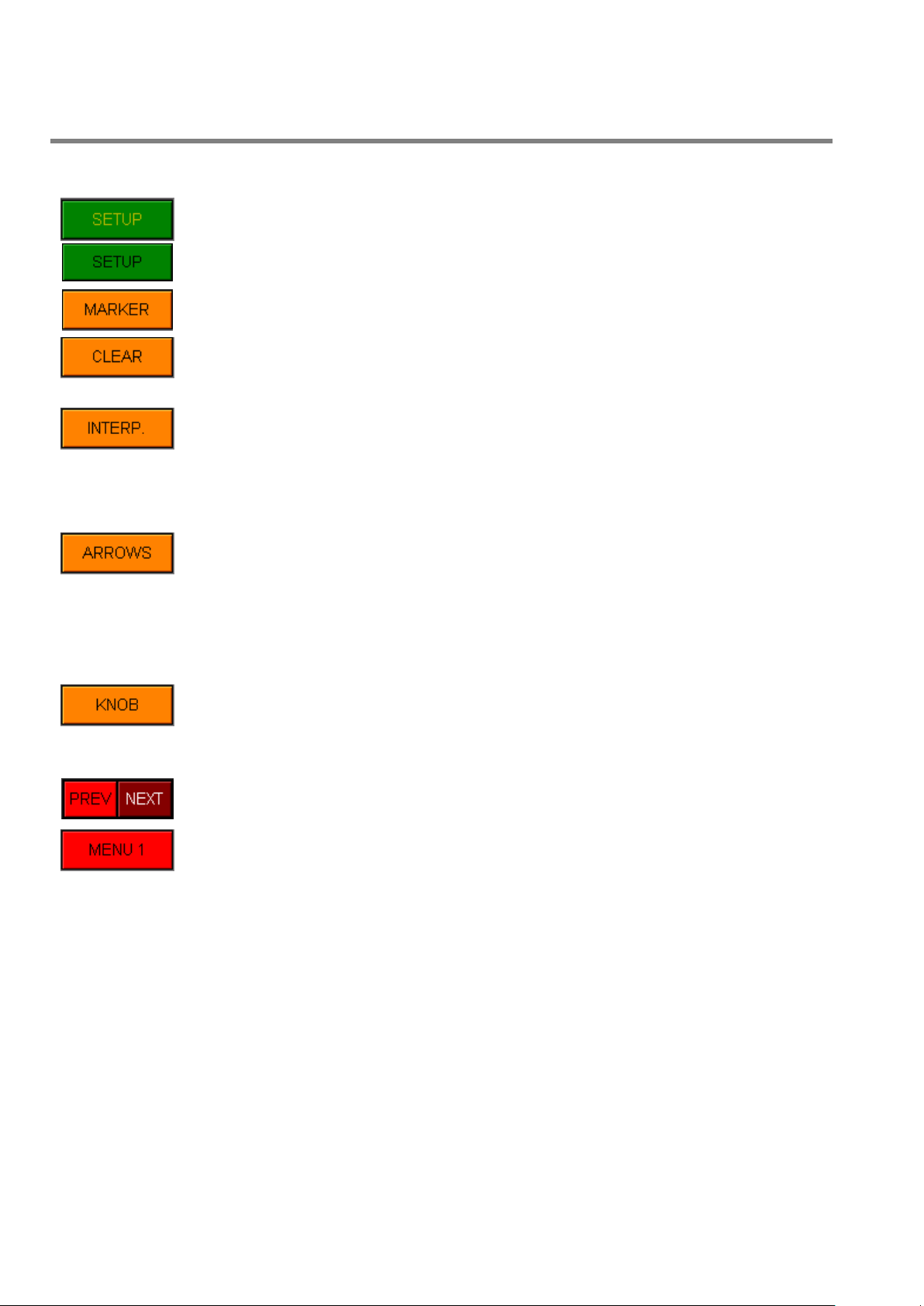

PARISON CONTROLLER

SETUP: (yellow) Disable. (black) Enter in the setup page.

MARKER: Add or remove a marker on the profile.

CLEAR + SHIFT: Clear all the profile points. Before creating a new profile (only in this

case) it's necessary to use this function to ensure a correct initialization of the new

profile.

INTERPOLATION: Change the interpolation. Changes the interpolation type between

the two masters where the cursor is placed. There are 5 possibilities: Bezier, Linear,

Flat, Parabolic 1, Parabolic 2. The default interpolation is the one that has been set in

the Machine setup page.

ARROWS: Selects how the Vertical Arrows have to work:

- Move cursor: move the cursor up and down.

- Next master: move the cursor on the master.

- Drag master: drag the master up and down.

- Next marker: move the cursor on the marker.

- Drag marker: drag the marker up and down.

- Drag SM: drag the Serial Marker up and down.

- Selects profile: select a part of the profile.

- Drag selection: drag the selection up and down.

KNOB: Selects how the Knob has to work:

- Change value: rotate the knob to change the value.

- Change base: rotate the knob to change the base.

- Change range: rotate the knob to change the range.

- Change interp: rotate the knob to change the interpolation.

- Change smooth: rotate the knob to change the Bezier smoothness value.

- Setup SM: rotate the knob to setup the Serial Marker.

NEXT: Fast selection of the next or previous work head page.

MENU 1: Go to main menu 1 page.

4.5.9 Function Keys.

moog

64 MAN145-UM-D01A-EN Moog Italiana srl - Bergamo

Page 65

PARISON CONTROLLER

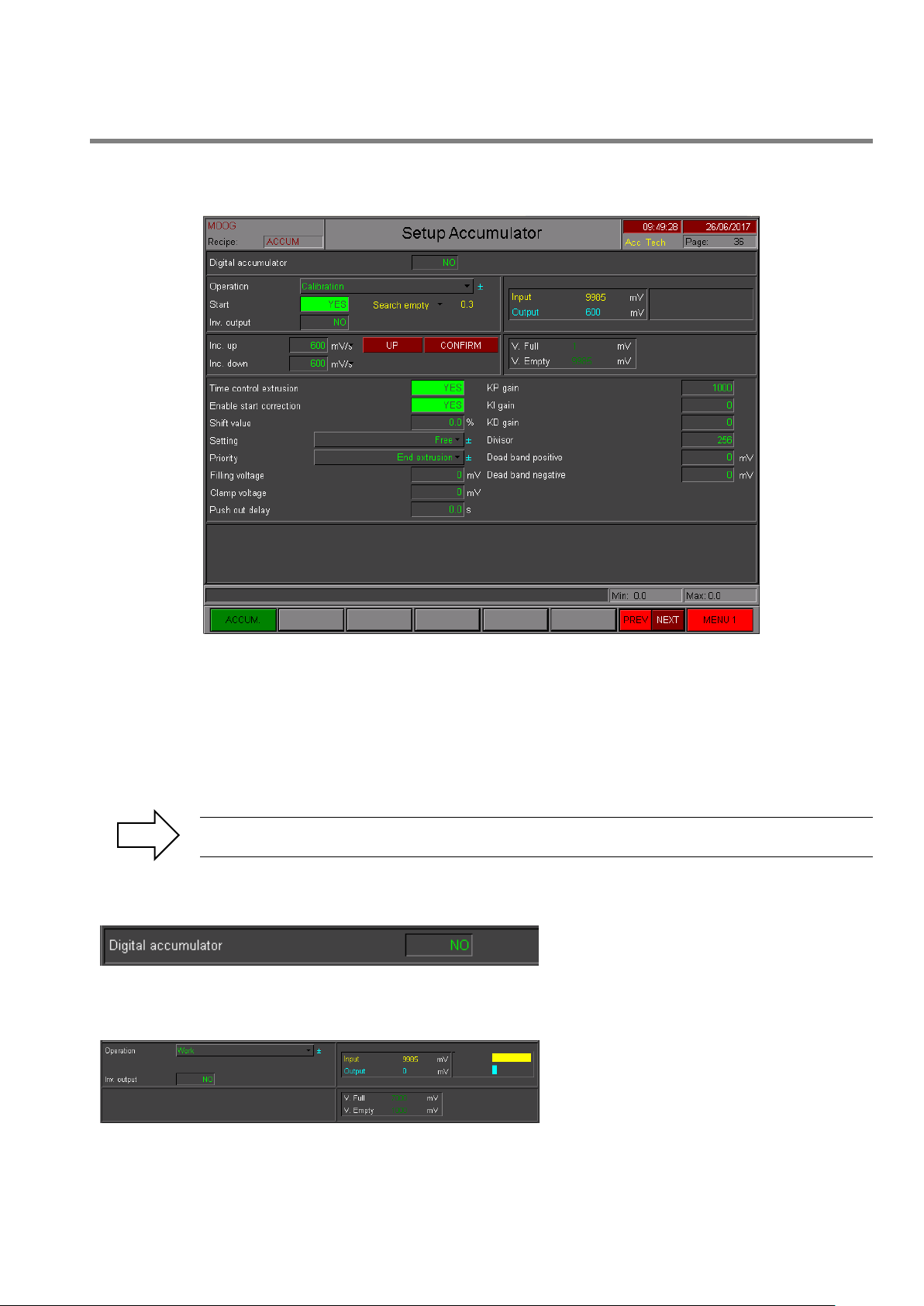

4.6 Head Setup.

moog

Figure 61

Setup 1| Head n: Setup 1 | Head n. page (n. = 1 to 4).

Access: From Work Page n. with key F1.

Use: For the calibration and the setup of the head parameters.

The regulator can operate in closed loop (with no-intelligent actuators) or in open loop (with intelligent actuators

that operate with an on-board closed loop). The input value is calibrated in range 0% - 100.00% through the

definition of upper stroke voltage and lower stroke voltage. In case of intelligent actuators the calibration points are

set to 0 mV and 10000 mV which are the correct values if no calibration is required.

In the normal polarity an increasing output command moves the actuator downwards (rod extracts)

and the feedback input value increases too.

It is possible to correct the polarity of both the command and feedback with specific settings in the setup page.

The procedure to check the wirings is described in the next chapter: “Check wirings”.

Moog Italiana srl - Bergamo MAN145-UM-D01A-EN 65

Page 66

PARISON CONTROLLER

moog

4.6.1 Check wirings.

To check the correct wiring:

Choose open loop calibration.

With the UP/DOWN keys verify the correct movement: if the UP key is pressed, the moving part has to

move up, if the DOWN key is pressed the moving part has to move down.

o If the movement is OK :

Check the bar graphs movement (yellow and blue). If bar graphs are moving in the same

direction, also the input is OK and it is possible to perform the calibration in close loop.

If the bar graphs are moving in opposite directions, reverse the input polarity by inverting

the parameter Inv. input in the head setup page

o If the movement is not OK :

Reverse the input polarity by inverting the parameter Inv. output in the head setup page

After this, the movement should be correct. If bar graphs are moving in the same

direction, also the input is OK and it is possible to perform the calibration in close loop.

If the bar graphs are moving in opposite directions, reverse the input polarity by inverting

the parameter Inv. input in the head setup page

66 MAN145-UM-D01A-EN Moog Italiana srl - Bergamo

Page 67

PARISON CONTROLLER

Select open loop

calibration

Verify UP/DOWN

movement

Moveme

Verify bar graphs

Same

direction

It is possible

Change the input

variable

Change the

Put YES the

variable

Verify bar graphs

movement

Same

direction

Yes

No

No

Yes

Yes

No

moog

To better understand how to perform a correct calibration see the following flow chart.

output inversion

output wiring

movement

wiring or put YES

the input inversion

the calibration

in close loop

Moog Italiana srl - Bergamo MAN145-UM-D01A-EN 67

The parameter used to reverse the input polarity is only used during the close loop calibration. In

work mode the polarity is derived by the values of "Vup" and "Vdown" and the polarity reversal