Page 1

Installation and Operation Instructions

Before attempting to connect or operate this product, please

read these instructions completely.

Igloo Dome

Air-Conditioned Camera Enclosure Solution for Hot, Humid Climates

IGDW75C1N.............. Outdoor air conditioned dome housing with wall and pole mount, clear polycarbonate dome, with 240VAC input, heater / blower,

120 to 24VAC transformer for xed camera

IGDW75T1N............... Tinted version

IGDW7CN-3............... Outdoor IP network ready 7” air conditioned PTZ camera system with 36x zoom day and night camera, MPEG-4 and MJPEG video

compression, full D1. Clear dome, with 24Vac input, heater / blower

IGDW75CS-3............. Outdoor analog version of the IGDW7CN-3

© 2013, Moog Inc. All Rights Reserved

Moog Inc.

Sensor and Surveillance Systems

3650 Woodhead Drive Northbrook, IL. USA 60062

+1.847.498.0700 Fax: +1.847.498.1258 www.moogS3.com

81-IN5434 111213

Page 2

IMPORTANT SAFEGUARDS SAFETY PRECAUTIONS

avvertire l’utente alla presenza delle istruzioni importanti nella

MADEIN

BUY AMERICA COMPLIANT • COUNTRY OF ORIGIN U.S.A.

1 Read these instructions.

2 Keep these instructions.

3 Heed all warnings

4 Follow all instructions.

5 Do not use this apparatus near water.

6 Clean only with damp cloth.

7 Do not block any of the ventilation openings. Install in accordance with the

manufacturers instructions.

8 Cable Runs- All cable runs must be within permissible distance.

9 Mounting - This unit must be properly and securely mounted to a supporting

structure capable of sustaining the weight of the unit.

Accordingly:

a. This installation should be made by a qualied service person and should conform

to all local codes.

b. Care should be exercised to select suitable hardware to install the unit, taking into

account both the composition of the mounting surface and the weight of the unit.

10 Do not install near any heat sources such as radiators, heat registers, stoves, or other

apparatus ( including ampliers) that produce heat.

11 Do not defeat the safety purpose of the polarized or grounding-type plug. A

polarized plug has two blades with one wider than the other. A grounding type

plug has two blades and a third grounding prong. The wide blade or the third

prong are provided for your safety. When the provided plug does not t into your

outlet, consult an electrician for replacement of the obsolete outlet.

12 Protect the power cord from being walked on or pinched particularly at plugs,

convenience receptacles, and the point where they exit from the apparatus.

13 Only use attachment/ accessories specied by the manufacturer.

14 Use only with a cart, stand, tripod, bracket, or table specied by the manufacturer,

or sold with the apparatus. When a cart is used, use caution when moving the cart/

apparatus combination to avoid injury from tip-over.

15 Unplug this apparatus during lighting storms or when unused for long periods of time.

16 Refer all servicing to qualied service personnel. Servicing is required when the

apparatus has been damaged in any way, such as power-supply cord or plug is

damaged, liquid has been spilled of objects have fallen into the apparatus, the

apparatus has been exposed to rain or moisture, does not operate normally, or

has been dropped.

Be sure to periodically examine the unit and the supporting structure to make sure that the integrity

of the installation is intact. Failure to comply with the foregoing could result in the unit separating

from the support structure and falling, with resultant damages or injury to anyone or anything struck

by the falling unit.

CAUTION: TO REDUCE THE RISK OF

ELECTRIC SHOCK, DO NOT REMOVE

COVER ( OR BACK). NO USER- SERVICE-

ABLE PARTS INSIDE. REFER SEVICING

TO QUALIFIED SERVICE PERSONNEL.

The lightning ash with an arrowhead symbol,

within an equilateral triangle, is intended to

alert the user to the presence of non-insulated

“dangerous voltage” within the product’s

enclosure that may be of sufcient magnitude

to constitute a risk to persons.

Este símbolo se piensa para alertar al usuario a la presencia

del “voltaje peligroso no-aisIado” dentro del recinto de los

productos que puede ser un riesgo de choque eléctrico.

Ce symbole est prévu pour alerter I’utilisateur à la presence

“de la tension dangereuse” non-isolée dans la clôture de

produits qui peut être un risque de choc électrique.

Dieses Symbol soll den Benutzer zum Vorhandensein der

nicht-lsolier “Gefährdungsspannung” innerhalb der

Produkteinschließung alarmieren die eine Gefahr des

elektrischen Schlages sein kann.

Este símbolo é pretendido alertar o usuário à presença “di

tensão perigosa non-isolada” dentro do cerco dos produtos

que pode ser um risco de choque elétrico.

Questo simbolo è inteso per avvertire I’utente alla presenza

“di tensione pericolosa” non-isolata all’interno della

recinzione dei prodotti che può essere un rischio di scossa

elettrica

.

The exclamation point within an equilateral

triangle is intended to alert the user to

presence of important operating and

maintenance (servicing) instructions in the

literature accompanying the appliance.

UNPACKING

Unpack carefully. Electronic components can be

damaged if improperly handled or dropped. If an item

appears to have been damaged in shipment, replace

it properly in its carton and notify the shipper.

Be sure to save:

1 The shipping carton and packaging material.

They are the safest material in which to make future

shipments of the equipment.

2 These Installation and Operating Instructions.

Este símbolo del punto del exclamation se piensa para

alertar al usuario a la presencia de instrucciones importantes

en la literatura que acompaña la aplicación.

Ce symbole de point d’exclamation est prévu pour alerter

l’utilisateur à la presence des instructions importantes dans

la littérature accompagnant l’appareil.

Dieses Ausruf Punktsymbol soll den Benutzer zum

Vorhandensein de wichtigen Anweisungen in der Literatur

alarmieren, die das Gerät begleitet.

Este símbolo do ponto do exclamation é pretendido alertar o

usuário à presença de instruções importantes na literatura

que acompanha o dispositivo.

Questo simbolo del punto del exclamaton è inteso per

letteratura che accompagna l'apparecchio.

SERVICE

If technical support or service is needed, contact us at

the following number:

CAUTION

RISK OF ELECTRIC SHOCK

DO NOT OPEN

TECHNICAL SUPPORT

AVAILABLE 24 HOURS

1- 800-554 -1124

Page 3

Product Warranty Registration

Register Your Products Online

www.moogS3.com/technical-support/product-registration

Moog values your patronage. We are solely committed to providing you with the highest quality products and

superior customer service. With 3-Year and 5-Year warranties (depending on the product purchased) we stand

behind every product we sell.

See full warranty details at www.moogS3.com/technical-support/warranty-plan/

:

• Simple and Trouble-Free RMA process

• Product / software updates

• Special promotions

• Eliminate the need to archive purchase documents such as receipts, purchase orders, etc.

Page 4

Limited Warranty for Moog Products

MANUFACTURER HEREBY DISCLAIMS ANY REPRESENTATIONS OR WARRANTY THAT THE PRODUCT IS COMPATIBLE WITH ANY COMBINATION OF NON-MANUFACTURER

THE LIABILITY OF Manufacturer, IF ANY, AND PURCHASER’S SOLE AND EXCLUSIVE REMEDY FOR DAMAGES FOR ANY CLAIM OF ANY KIND WHATSOEVER, REGARDLESS

OF THE LEGAL THEORY AND WHETHER ARISING IN TORT OR CONTRACT, SHALL NOT BE GREATER THAN THE ACTUAL PURCHASE PRICE OF THE PRODUCT WITH RESPECT

Moog - Decatur Operations, subsequently referred to as “Manufacturer,” warrants these products to be free from defects in material or workmanship as follows:

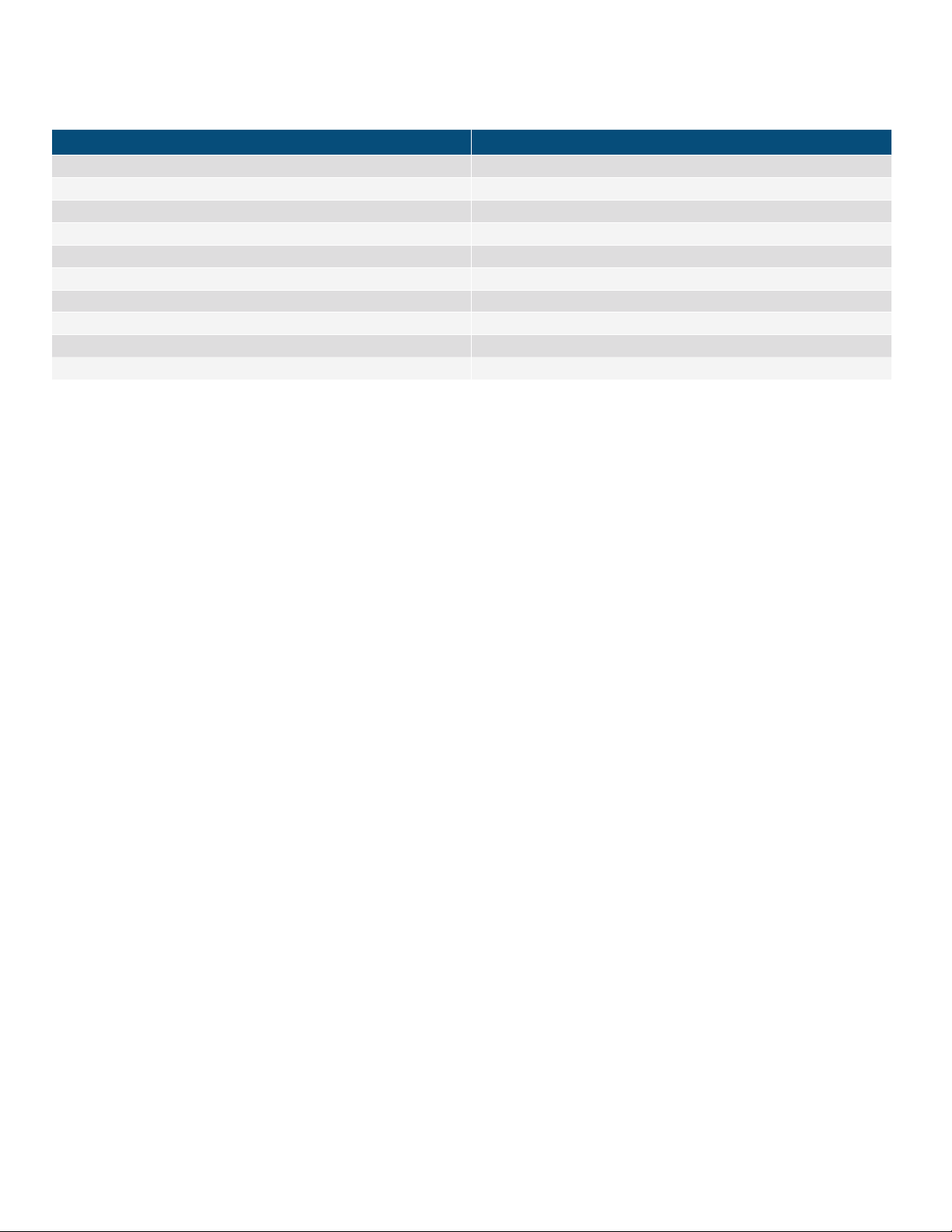

PRODUCT CATEGORY PARTS \ LABOR

All Enclosures and Electronics Five (5) Years

Accessory Brackets Five (5) Years

Controllers Three (3) Years

Power Supplies / IR Illuminators Three (3) Years

™

Poles / PolEvators

Warrior Series

SView Series

DeputyDome

EXO Series

EXO Series

During the labor warranty period, to repair the Product, Purchaser will either return the defective product, freight prepaid, or deliver it to Manufacturer at Moog Decatur

Operations, 2525 Park Central Boulevard, Decatur, Georgia, 30035. The Product to be repaired is to be returned in either its original carton or a similar package affording

an equal degree of protection with a RMA # (Return Materials Authorization number) displayed on the outer box or packing slip. To obtain a RMA# you must contact our

Technical Support Team at 800.554.1124, extension 101. Manufacturer will return the repaired product freight prepaid to Purchaser. Manufacturer is not obligated to

provide Purchaser with a substitute unit during the warranty period or at any time. After the applicable warranty period, Purchaser must pay all labor and/or parts charges.

The limited warranty stated in these product instructions is subject to all of the following terms and conditions.

TERMS AND CONDITIONS

1. NOTIFICATION OF CLAIMS: WARRANTY SERVICE: If Purchaser believes that the Product is defective in material or workmanship, then written notice with an explanation

of the claim shall be given promptly by Purchaser to Manufacturer. All claims for warranty service must be made within the warranty period. If after investigation,

Manufacturer determines the reported problem was not covered by the warranty, Purchaser shall pay Manufacturer for the cost of investigating the problem at its then

prevailing per incident billable rate. No repair or replacement of any Product or part thereof shall extend the warranty period of the entire Product. The specic warranty on

the repaired part only shall be in effect for a period of ninety (90) days following the repair or replacement of that part or the remaining period of the Product parts warranty,

whichever is greater.

/ CamEvator Three (3) Years

™

™

™

, NiteTrac™, Igloo Dome, PurgeDome

™

Dome and Fixed Camera Systems* Three (3) Years 6 months if used in auto scan / tour operation

™

GeminEye Visible and Thermal Camera Systems One (1) Year

/ Q-View

™

Three (3) Years

Three (3) Years 6 months if used in auto scan / tour operation

™

Three (3) Years 6 months if used in auto scan / tour operation

2. EXCLUSIVE REMEDY: ACCEPTANCE: Purchaser’s exclusive remedy and Manufacturer’s sole obligation is to supply (or pay for) all labor necessary to repair any Product

found to be defective within the warranty period and to supply, at no extra charge, new or rebuilt replacements for defective parts.

3. EXCEPTIONS TO LIMITED WARRANTY: Manufacturer shall have no liability or obligation to Purchaser with respect to any Product requiring service during the warranty

period which is subjected to any of the following: abuse, improper use, negligence, accident, or acts of God (i.e., hurricanes, earthquakes), modication, failure of the

end-user to follow the directions outlined in the product instructions, failure of the end-user to follow the maintenance procedures recommended by the International Security

Industry Organization, written in product instructions, or recommended in the service manual for the Product. Furthermore, Manufacturer shall have no liability where a

schedule is specied for regular replacement or maintenance or cleaning of certain parts (based on usage) and the end-user has failed to follow such schedule; attempted

repair by non-qualied personnel; operation of the Product outside of the published environmental and electrical parameters, or if such Product’s original identication

(trademark, serial number) markings have been defaced, altered, or removed. Manufacturer excludes from warranty coverage Products sold AS IS and/or WITH ALL FAULTS

and excludes used Products which have not been sold by Manufacturer to the Purchaser. All software and accompanying documentation furnished with, or as part of the

Product is furnished “AS IS” (i.e., without any warranty of any kind), except where expressly provided otherwise in any documentation or license agreement furnished with

the Product. ANY COST ASSOCIATED WITH REMOVAL OF DEFECTIVE PRODUCT AND INSTALLATION OF REPLACEMENT PRODUCT IS NOT INCLUDED IN THIS WARRANTY.

4. PROOF OF PURCHASE: The Purchaser’s dated bill of sale must be retained as evidence of the date of purchase and to establish warranty eligibility.

DISCLAIMER OF WARRANTY

EXCEPT FOR THE FOREGOING WARRANTIES, MANUFACTURER HEREBY DISCLAIMS AND EXCLUDES ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING, BUT

NOT LIMITED TO ANY AND/OR ALL IMPLIED WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE AND/OR ANY WARRANTY WITH REGARD TO ANY

CLAIM OF INFRINGEMENT THAT MAY BE PROVIDED IN SECTION 2-312(3) OF THE UNIFORM COMMERCIAL CODE AND/OR IN ANY OTHER COMPARABLE STATE STATUTE.

PRODUCTS OR NON-MANUFACTURER RECOMMENDED PRODUCTS PURCHASER MAY CHOOSE TO CONNECT TO THE PRODUCT.

LIMITATION OF LIABILITY

TO WHICH SUCH CLAIM IS MADE. IN NO EVENT SHALL MANUFACTURER BE LIABLE TO PURCHASER FOR ANY SPECIAL, INDIRECT, INCIDENTAL, OR CONSEQUENTIAL

DAMAGES OF ANY KIND INCLUDING, BUT NOT LIMITED TO, COMPENSATION, REPLACEMENT LABOR COSTS, REIMBURSEMENT, OR DAMAGES ON ACCOUNT OF THE LOSS

OF PRESENT OR PROSPECTIVE PROFITS OR FOR ANY OTHER REASON WHATSOEVER.

Page 5

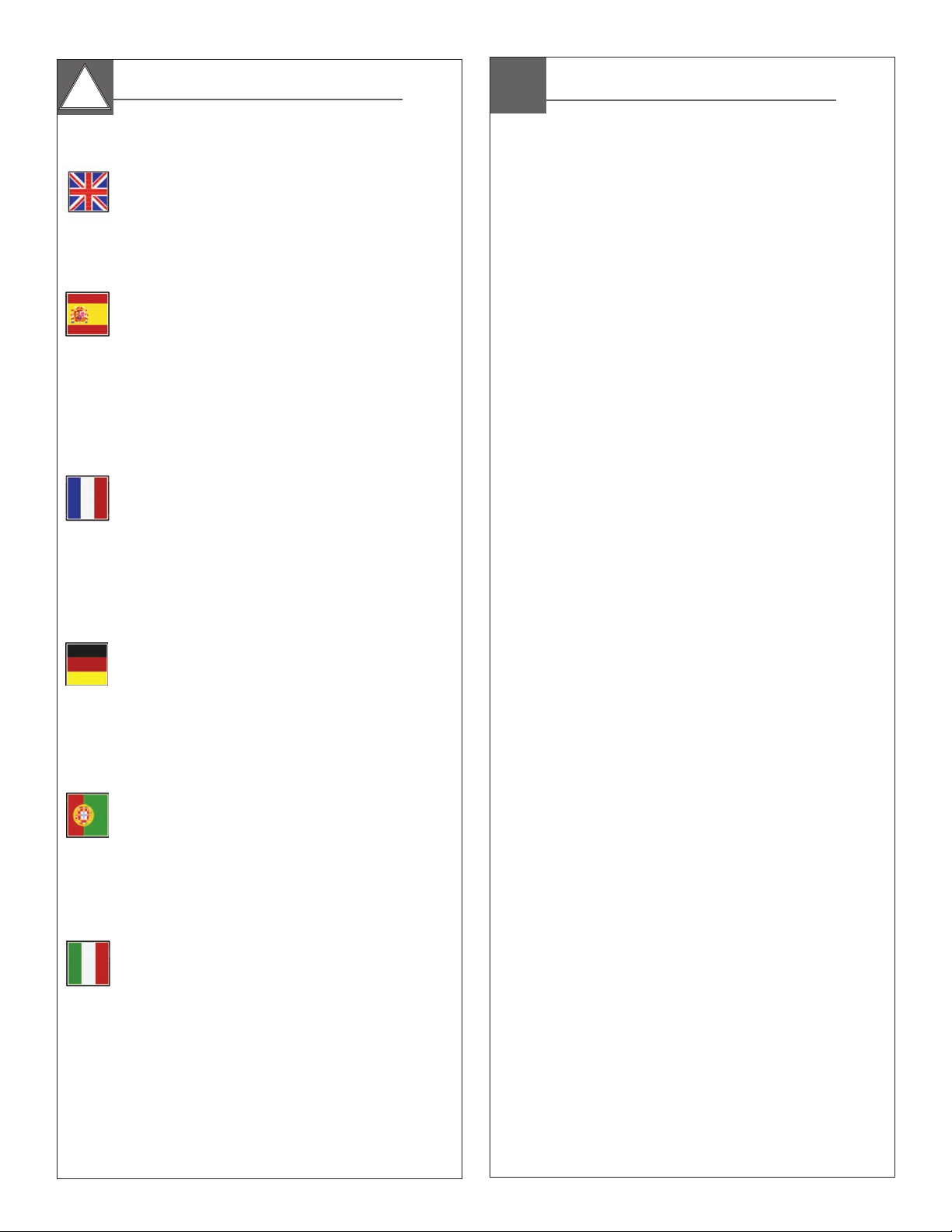

Electrical Specifications

!!

Igloo Dome

Power 120VAC .

50/60 H

2.

300 WATTS.

English

Tools Required: Phillips Head Screwdriver.

Ceiling Support Wires(14 AWG wire min.)

Energía 120VAC.

50/60 H

300 VATIOS.

Español

Las herramientas requirieron: Destornillador principal

Phillips.

Alambres de la ayuda del techo

(14 de alambre del AWG Min.)

Puissance 120VAC.

50/60 H

300 WATTS.

Outils requis : Tournevis phillips.

Français

Fils de soutien de plafond (14 de fil d'A.W.G. mn)

.

2

.

2

Mechanical Options

1. Air ow sensor available to be combined with camera output systems

to monitor the eectiveness of air lter. If improper air ow is detected,

sensor will send alarm. If user by passes air ow sensor, air lter should

be changed approximately every 6 months (depending on monitoring

environment).

2. The Igloo Dome incorporates an automatic cool-down safety

precaution system which deactivates the power of both the camera and

cooling system when internal temperatures exceed 167°F (75°C). Once

safe operating conditions resume, the camera and cooling system will

reactivate.

3. Condensation and water run-o is a by product of the Igloo Dome's

cooling system. To prevent damage to the internal electrical

components, the Igloo Dome consists of a water run-o hose, located

underneath the optical dome. Please use caution that small amounts of

water accumulation will be present directly underneath the Igloo Dome,

resulting in slippery conditions.

* A 50/50 blend of propylene glycol and water has a freezing point of

-26°F. If lower temperature protection is required, it can readily be

attained by increasing the concentration of propylene glycol Antifreeze for example; a 60/40 blend of Antifreeze and water gives antifreeze

protection to -54°F.

Deutsch

Portuguese

Italiano

Energie 120VAC.

50/60 H2.

300 WATT.

Werkzeuge erfordert: Kreuzkopfschraubenzieher.

Decken-Stützdrähte (14 AWG-Lehredraht Min.)

Poder 120VAC.

50/60 de H2.

300 WATTS.

As ferramentas exigiram: Chave de fenda principal de

Phillips.

Fios da sustentação do teto

(14 de fio Calibre de diâmetro de fios Min.)

Potere 120VAC.

50/60 di H2.

300 WATT.

Gli attrezzi hanno richiesto: Cacciavite phillips. Legare

di sostegno del soffitto

(14 del legare dell'AWG min.)

Page 6

1/2" LOWER

MOUNTING BOLTS

STEP 1:

POSITION LOWER MOUNTING BOLTS, WASHERS

AND NUTS AS SHOWN ABOVE., THREAD THE NUTS

UNTIL FLUSH WITH BOLT ENDS

Position lower mounting bolts, washers and nuts as

shown above. Thread the nuts until flush with bolt ends.

• Coloque pernos, arandelas y tuercas más bajos de montaje como se

muestra arriba. Rosque las tuercas hasta rubor con los extremos de

perno.

• Placez les boulons de fixation, les rondelles et les écrous inférieurs

comme montré ci-dessus. Filetez les écrous jusqu'à l'éclat avec des

extrémités de boulon.

• Bringen Sie unterere Befestigungsbolzen, Unterlegscheiben und Nüsse

wie gezeigt oben in Position. Verlegen Sie die Nüsse bis bündiges mit

Schraubbolzenenden.

• Posicione uns mais baixos parafusos, arruelas e porcas de montagem

como mostrado acima. Rosqueie as porcas até o resplendor com

extremidades de parafuso.

• Posizioni i bulloni, le rondelle ed i dadi più bassi di attacco come

indicato sopra. Filetti i dadi fino ad a livello dell'estremità di bullone.

Content of Box

COOLANT

1

2

Thread one retainer extrusion at the end of steel band,

allowing 1” (254mm) of band out. Beveled end of

extrusion to be out.

• Un hilo de retención de extrusión en la final de la banda de acero,

permitiendo 1 "(254 mm), de banda a cabo. Biselados final de

extrusión que se fuera.

• Thread extrusion une retenue à la fin de la bande d'acier, permettant

à 1 "(254mm) de la bande de. Biseauté fin de l'extrusion de ne pas être.

• Rijg een vasthoud-extrusie op het einde van stalen band, waardoor 1

"(254 mm) van de band uit. Schuine einde van de extrusie worden

uitgesloten.

• Passe um retentor extrusão no final da banda de aço, permitindo 1

"(254 milímetros), da banda fora. Biselado final de extrusão de ser fora.

• Iniziatore di estrusione uno fermo alla fine di banda di acciaio,

consentendo 1 "(254 millimetri) di banda fuori. Smussato fine di

estrusione di essere fuori.

Page 7

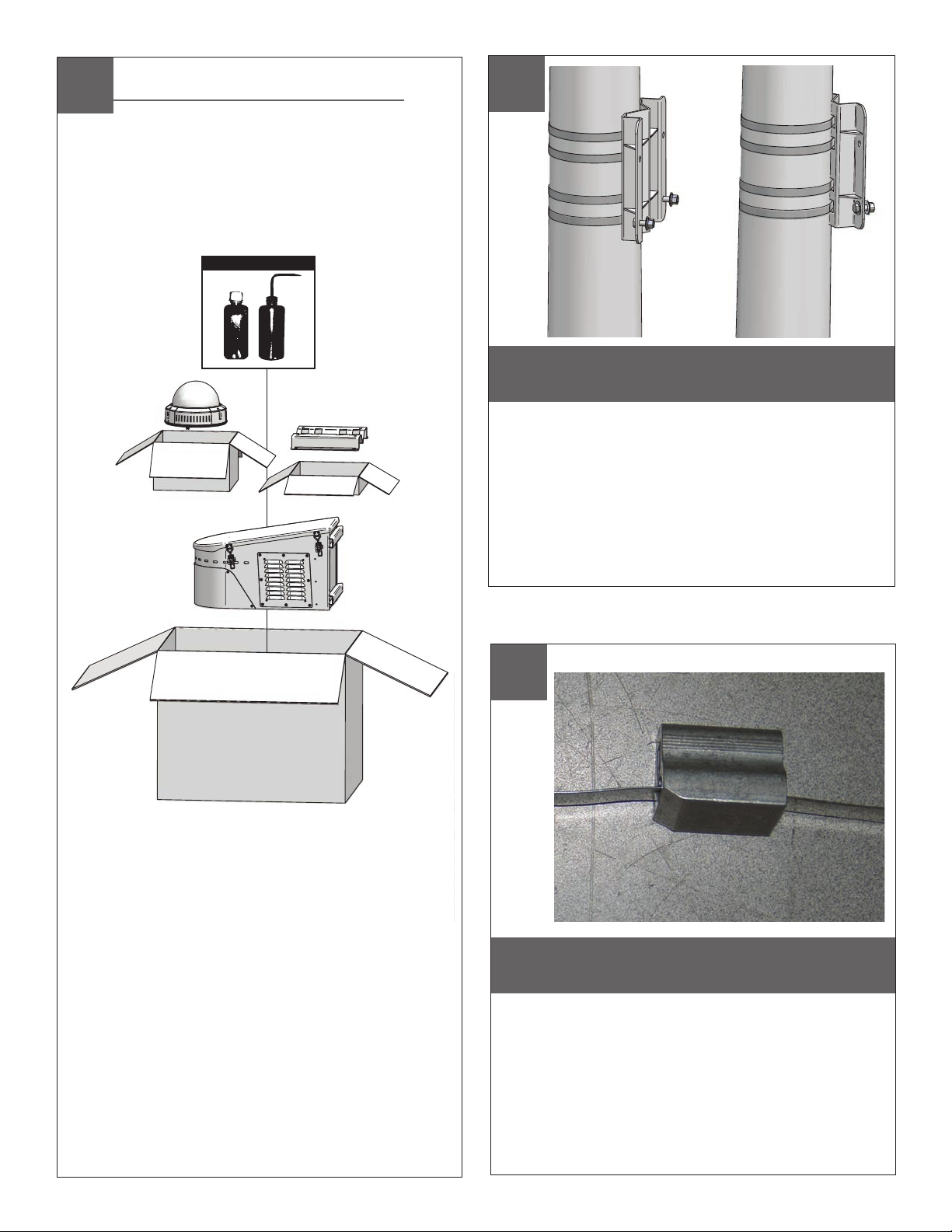

3 4

Carefully bend steel band around beveled end of

extrusion. Hammer bend band to create a sharp

radius.

• Doblar cuidadosamente alrededor de banda de acero biselado final

de la extrusión. Libra doblado la banda para crear un plano de radio.

• Plier soigneusement autour de la bande d'acier biseautée fin de

l'extrusion. Livre bande pliée pour créer un plat de rayon.

• Buig stalen band rond schuine einde van extrusie. Pound gebogen

band voor het maken van een vlakke straal.

• Cuidadosamente dobre aço biselado fim da banda em torno de

extrusão. Libra curvados banda para criar um plano de raio.

• Attentamente piegare acciaio banda intorno smussato fine di

estrusione. Sterlina piegato banda per creare un piatto raggio.

Measure perimeters around pole at desired mounting location.

Measure band from outside edge of threaded retainer extrusion. Allow

for additional 1½” (254 mm) to be placed underneath additional

extrusion. Mark steel band and cut.

•

Medida de distancias en torno a polos de montaje en la ubicación deseada.

Medida de fuera de banda borde de la rosca de retención de extrusión. Dejar

para más 1½ "(254 mm), que se coloca debajo adicionales de extrusión. Marcos

de acero y banda de corte.

• Mesurer les distances autour de pôles de montage à l'emplacement désiré.

Mesure bande de bord extérieur de l'extrusion de retenue fileté. Pour permettre

supplémentaire de 1½ "(254 mm) pour être placées sous d'autres extrusion. Mark

bande d'acier et de coupe.

• Meet afstanden rond de paal te monteren gewenste locatie. Maatregel band van

buiten de rand van het threaded vasthoud-extrusie. Laat voor extra 1½ "(254 mm)

worden geplaatst onder meer extrusie. Mark stalen band en uitgesneden.

• Medida de distâncias de cerca de pólo na montagem local desejado. Medida

banda de fora de borda enfiada retentor extrusão. Permitir adicionais para 1½

"(254 mm) devem ser colocados debaixo adicionais extrusão. Mark banda de aço

e de corte.

• Misura le distanze intorno al polo di montaggio posizione desiderata. Misura banda

al di fuori del bordo del fermo filettati estrusione. Consenti per ulteriori 1½ "(254 mm)

ad essere messi sotto supplementari estrusione. Mark acciaio banda e taglio.

5

Thread mounting hardware and additional retainer extrusion

at opposite end of steel band. Refer to Block 1 and 2 for

instructions.

• Rosca de montaje de hardware adicional y anticipo de extrusión en el

extremo opuesto de la banda de acero. Consulte a Bloque 1 y 2 para

obtener instrucciones.

• Thread matériel de montage et de retenue supplémentaire d'extrusion

à face en acier fin de bande. Reportez-vous à bloc 1 et 2 pour les

instructions.

• Rijg de montage van extra hardware en vasthoud-extrusie op het

andere uiteinde van stalen band. Raadpleeg Blok 1 en 2 voor

instructies.

• Rosca de montagem e hardware adicional retentor extrusão na

extremidade oposta da banda de aço. Referem-se Bloco 1 e 2 para

obter instruções.

• Iniziatore di montaggio e supplementari fermo estrusione a fine opposta

fascia di acciaio. Fare riferimento al blocco 1 e 2 per le istruzioni.

6

Place assembly around pole at desired mounting location.

Insert bolt through retainer extrusions. Head of bolt needs to

lock into end of retainer.

• Lugar de reunión en torno a polos de montaje en la ubicación deseada.

Inserte el perno de retención a través de extrusiones. Jefe de la saeta a las

necesidades de bloqueo en la final del retenedor.

• Lieu de rassemblement autour de pôles de montage à l'emplacement désiré.

Insérer boulon de retenue extrusions. Chef de boulon doit en fin de verrouillage de la bague de retenue.

• Plaats vergadering rond de paal te monteren gewenste locatie. Plaats bout

door vasthoud extrusies. Hoofd van de bout moet vastklikken einde van

vasthoud.

• Colocar cerca de montagem em poste montagem local desejado. Inserir

ferrolho através retentor extrusões. Chefe do ferrolho precisa ser encaixado na

extremidade do dispositivo de retenção.

• Luogo di montaggio intorno al polo di montaggio posizione desiderata.

Inserire il bullone attraverso fermo estrusioni. Capo del bullone deve bloccare

in fine di fermo.

Page 8

7

Thread nut to end of bolt and tighten with wrench.

• Hilo para poner fin a la tuerca de tornillo y apretar con llave.

• Thread noix à la fin de boulon et serrez avec clé.

• Thread moer tot het einde van de bout en draai met de moersleutel.

• Thread porca para o fim do ferrolho e aperte com a chave inglesa.

• Iniziatore dado alla fine del bullone e serrare con la chiave inglese.

8

Installation is complete when nut is tight / secure and all slack has been removed from steel band.

• La instalación es completa cuando es apretado la tuerca / garantizar la seguridad de todos y la atonía se ha eliminado de la banda

de acero.

• L'installation est terminée lorsque l'écrou est serré, sécurité et tous les mou a été retiré de la bande d'acier.

• De installatie is volledig wanneer moer is strak / beveiligde en alle speling verwijderd is van staal-band.

• A instalação está completa quando porca é apertado / seguro e todos folga foi removido da banda de aço.

• L'installazione è completa quando il dado è stretto / e tutte le sicuro slack è stata rimossa dalla banda di acciaio.

Page 9

9

10

From

(4) holes

A-Z

Repeat for multiple band applications.

• Repetición para los usos de venda múltiples.

• Répétition pour des applications de bande multiples.

• Wiederholung für mehrfache Bandanwendungen.

• Repetição para aplicações de faixa múltiplas.

• Ripetizione per le applicazioni di fascia multiple.

11

Locate and drill (4) holes 2” deep

• Localice y perfore (4) los agujeros 2” profundamente

• Trouvez et forez (4) les trous 2 » profondément

• Lokalisieren Sie und bohren Sie (4) Löcher 2“ tief

• Encontre e perfure (4) furos 2” profundamente

• Individui e perfori (4) fora 2„ in profondità

12

Place the mounting plate against the wall

• Coloque la pletina contra la pared

• Placez le plat de support contre le mur

• Setzen Sie die Montageplatte gegen die Wand

• Coloc a placa de montagem de encontro à parede

• Disponga il giunto di supporto contro la parete

Attach with (4) anchor bolts, (4) lock washers, and (4)

flat washers

• Fijación con (4) los pernos de ancla, (4) arandelas de cerradura, y (4) arandelas

planas

• Attache avec (4) des boulons d'anchrage, (4) rondelles de freinage, et (4) rondelles

plates

• Befestigung mit (4) Ankerbolzen, (4) Federringe und (4) flache Unterlegscheiben

• Anexo com (4) parafusos de escora, (4) arruelas de fechamento, e (4) arruelas lisas

• Attaccatura con (4) bulloni d'ancoraggio, (4) ranelle di bloccaggio e (4) rondelle

piane

Page 10

STEP 1:

MOUNT ADAPTER PLATE TO POLE BY STEEL STRAPS

Mount adapter plate to pole by steel straps

• Coloque pernos, arandelas y tuercas más bajos de montaje como se

muestra arriba. Rosque las tuercas hasta rubor con los extremos de

perno.

• Placez les boulons de fixation, les rondelles et les écrous inférieurs

comme montré ci-dessus. Filetez les écrous jusqu'à l'éclat avec des

extrémités de boulon.

• Bringen Sie unterere Befestigungsbolzen, Unterlegscheiben und Nüsse

wie gezeigt oben in Position. Verlegen Sie die Nüsse bis bündiges mit

Schraubbolzenenden.

• Posicione uns mais baixos parafusos, arruelas e porcas de montagem

como mostrado acima. Rosqueie as porcas até o resplendor com

extremidades de parafuso.

• Posizioni i bulloni, le rondelle ed i dadi più bassi di attacco come

indicato sopra. Filetti i dadi fino ad a livello dell'estremità di bullone.

TIGHTEN ALL FOUR BOLTS

13

14

Tighten all bolts securely

• Apriete todos los pernos con seguridad

• Serrez tous les boulons solidement

• Ziehen Sie alle Schraubbolzen sicher fest

• Aperte todos os parafusos firmemente

• Stringa saldamente tutti i bulloni

15

Hang the Igloo Dome unit onto the wall mount

• Cuelgue la unidad Deputy2 sobre el montaje de la pared

• Accrochez l'unité Igloo Dome sur le bâti de mur

• Hängen Sie die Iglu-Haubemaßeinheit auf die Wandeinfassung

• Pendure a unidade da abóbada do Igloo na montagem da parede

• Appenda l'unità Igloo Dome sul supporto della parete

3/8" UPPER

16

MOUNTING BOLTS

SLOTS ON

MOUNTING PLATE

STEP 2:

REST THE IGLOODOME UPPER MOUNTING BOLTS

ON THE SLOTS OF THE ADAPTER PLATE.

INSERT LOWER BOLTS, WASHERS AND NUTS AND

Rest the IglooDome upper mounting bolts on the slots of

the adapter plate. Insert lower bolts, washers and nuts

and tighten all (4) bolts

• Coloque pernos, arandelas y tuercas más bajos de montaje como se

muestra arriba. Rosque las tuercas hasta rubor con los extremos de

perno.

• Placez les boulons de fixation, les rondelles et les écrous inférieurs

comme montré ci-dessus. Filetez les écrous jusqu'à l'éclat avec des

extrémités de boulon.

• Bringen Sie unterere Befestigungsbolzen, Unterlegscheiben und Nüsse

wie gezeigt oben in Position. Verlegen Sie die Nüsse bis bündiges mit

Schraubbolzenenden.

• Posicione uns mais baixos parafusos, arruelas e porcas de montagem

como mostrado acima. Rosqueie as porcas até o resplendor com

extremidades de parafuso.

• Posizioni i bulloni, le rondelle ed i dadi più bassi di attacco come

indicato sopra. Filetti i dadi fino ad a livello dell'estremità di bullone.

Page 11

17 18

Release latches (2) to open the cover

• Cierres de lanzamiento (2) para abrir la cubierta

• Verrous de dégagement (2) pour ouvrir la couverture

• Entriegelungshebel (2), zum der Abdeckung zu öffnen

• Travas de liberação (2) para abrir a tampa

• Fermi di rilascio (2) aprire la copertura

19

Support cover in open position using the brace

• Apoye la cubierta en la posición abierta usando el apoyo

• Soutenez la couverture en position d'ouverture utilisant le croisillon

• Stützen Sie Abdeckung in der geöffneten Position unter Verwendung

der Klammer

• Suporte a tampa na posição aberta usando a cinta

• Sostenga la copertura nella posizione aperta usando il gancio

STEP 3:

COMPLETE ELECTRICAL CONNECTIONS

Route power and video cables through the water tight

feed (at the base of the unit)

• Encamine los cables de la energía y del vídeo a través de la

alimentación apretada del agua (en la base de la unidad)

• Conduisez les câbles de puissance et de vidéo par l'alimentation serrée

de l'eau (à la base de l'unité)

• Verlegen Sie Energien- und Videokabel durch die feste Zufuhr des

Wassers (an der Unterseite der Maßeinheit)

• Distribua cabos do poder e do vídeo através da alimentação

apertada da água (na base da unidade)

• Diriga i cavi del video e di potere attraverso l'alimentazione stretta

dell'acqua (alla base dell'unità)

Page 12

20

INPUT

GND

N

L

OUTPUT

GND

N

L

Connect wires as shown, use minimum of 14 AWG

• Conecte los alambres como se muestra, utilice el mínimo de AWG 14

• Reliez les fils comme montré, employez le minimum d'A.W.G. 14

• Schließen Sie Drähte wie gezeigt an, verwenden Sie Minimum von

AWG-Lehre 14

• Conecte fios como mostrado, use um mínimo de Calibre de diâmetro de

fios 14

• Colleghi i legare come indicato, usi un minimo dell'AWG 14

Route cables and connect as shown

• Encamine los cables y conecte como se muestra

• Conduisez les câbles et reliez comme montré

• Verlegen Sie Kabel und schließen Sie wie gezeigt an

• Distribua cabos e conecte-os como mostrado

• Diriga i cavi e colleghi come indicato

21

Remove right side louver panel

• Quite el panel de la lumbrera del derecho

• Enlevez le panneau d'auvent de côté droit

• Entfernen Sie Luftschlitzverkleidung der rechten Seite

• Remova o painel da grelha do lado direito

• Rimuova il pannello della feritoia della parte di destra

22

Set louver aside

• Fije la lumbrera a un lado

• Placez l'auvent de côté

• Stellen Sie Luftschlitz beiseite ein

• Ajuste a grelha de lado

• Regoli la feritoia da parte

Page 13

23

Remove cap and still reservoir with Propylene Glycol/

water mix. Use mix ratio specified or container (*)

• Quite el casquillo y aún el depósito con la mezcla del glicol/del agua

de propileno. Utilice el cociente de la mezcla especificado o el

envase

• Enlevez le chapeau et toujours le réservoir avec le mélange de

propylèneglycol/eau. Utilisez le rapport de mélange spécifique ou le

récipient

• Entfernen Sie Kappe und noch Vorratsbehälter mit Propylenglykol-/wassermischung. Benutzen Sie das spezifizierte Mischungsverhältnis

oder Behälter

• Remova o tampão e ainda o reservatório com a mistura do

glicol/água de Propylene. Use a relação da mistura especific ou o

recipiente

• Rimuova la protezione ed ancora il bacino idrico con la miscela del

glicol/acqua di propilene. Utilizzi il rapporto della miscela specificato o

il contenitore

* Refer to the Mechanical Operations section of the instructions for

proper mixture proportions

24

Initial liquid level should be between “High” and “Low”

markers

• El nivel líquido inicial debe estar entre “los marcadores altos” y “bajos”

• Le niveau liquide initial devrait être entre les « hauts » et « bas »

marqueurs

• Flüssiges zuerstniveau sollte zwischen „den hohen“ und „niedrigen“

Markierungen sein

• O nível líquido inicial deve estar entre “marcadores elevados” e

“baixos”

• Il livello liquido iniziale dovrebbe essere fra “gli alti„ ed indicatori “bassi„

Page 14

25

Power up the unit by activating the “Primer” button as

shown to circulate coolant through system. Add

coolant after system stabilizes-if required (should be

between the “High” and “Low” marker.

• Accione para arriba la unidad activando el botón de la “cartilla”

como se muestra para circular el líquido refrigerador a través de

sistema. Agregue el líquido refrigerador después de sistema estabilizarsi está requerido (debe estar entre “el marcador alto” y “bajo”.

• Mettez l'unité en actionnant le bouton de « amorce » comme montré

pour circuler le liquide réfrigérant par le système. Ajoutez le liquide

réfrigérant après système stabiliser-si requis (devrait être entre le « haut

» et « bas » marqueur.

• Treiben Sie oben die Maßeinheit an, indem Sie wie gezeigt den

„Zündkapsel“ Knopf aktivieren, um Kühlmittel durch System zu verteilen.

Fügen Sie Kühlmittel nach System hinzu, stabilisieren-wenn erfordert

(sollte zwischen der „hohen“ und „niedrigen“ Markierung sein.

• Pnha acima a unidade ativando a tecla da “primeira demão” como

mostrado para circular o líquido refrigerante através do sistema.

Adicione o líquido refrigerante após o sistema estabilizar-se exigido

(deve estar entre “o marcador elevado” e “baixo”.

• Alimenti in su l'unità attivando il tasto “dell'iniettore„ come indicato per

fare circolare il liquido refrigerante attraverso il sistema. Aggiunga il

liquido refrigerante dopo il sistema stabilizzare-se richiesto (dovrebbe

essere fra “l'alto„ ed indicatore “basso„.

26

The air intake filters should be periodically checked.

They should be cleaned or replaced. To replace,

unfasten the nuts holding the filter frame. Replace and

remount using nuts as shown.

• Los filtros de la toma de aire deben ser comprobados periódicamente.

Deben ser limpiados o ser substituidos. Para substituir, desate la

tenencia nuts el marco del filtro. Substituya y remonte con tuercas

como se muestra.

• Les filtres d'entrée d'air devraient être périodiquement vérifiés. Ils

devraient être nettoyés ou remplacés. Pour remplacer, desserrez

l'exploitation nuts l'armature de filtre. Remplacez et remount à l'aide

des écrous comme montrés.

• Die Lufteintritfilter sollten regelmäßig überprüft werden. Sie sollten

gesäubert werden oder ersetzt werden. Um zu ersetzen, lösen Sie die

nuts Holding der Filterrahmen. Ersetzen Sie und remount mit Nüssen wie

gezeigt.

• Os filtros da entrada de ar devem periòdicamente ser verific. Devem

ser limpados ou substituído. Para substituir, desate a terra arrendada

nuts o frame do filtro. Substitua e remount usando porcas como

mostradas.

• I filtri dalla presa di aria dovrebbero essere controllati periodicamente.

Dovrebbero essere puliti o sostituiti. Per sostituire, sciolga la tenuta nuts

la struttura del filtro. Sostituisca e remount per mezzo dei dadi come

indicati.

Page 15

27

Mount louver panel(s)

• Los paneles de la lumbrera del montaje

• Panneaux d'auvent de bâti

• Einfassungsluftschlitzverkleidungen

• Painéis da grelha da montagem

• Pannelli della feritoia del supporto

Page 16

Replacement Parts List

1 RPFD7501 TRIM RING FD75

4 RPFD703 DOME CLAMPING BRACKET

10 RPFSSR06 STRAIN RELIEF CONNECTOR

11 RPFSRT20 NPT-3/8" NYLON LOCK NUT

12 RPVL3411 HEAT PUMP

13 RPVL3295 SUN SHIELD

14 RPVL3203 SIDE DOOR

15 RPVL3202 FILTER

16 RPGK3560 SIDE DOOR GASKET LEFT

17 RPVL3200 FILTER FLANGE

18 RPFSRT22 STRAIN RELIEF CONNECTOR

19 RPFSSR12 NYLON LOCK NUT

20 RP76VL2001 FLOW SENSOR

21 RPVL3566 RESERVOIR&PUMP ASSEMBLY

22 RPVL3552 FILTER FLANGE

23 RPGK3198 SIDE DOOR GASKET RIGHT

24 RPVL3180 SIDE DOOR RIGHT

25 RPVL3562 FLOW SENSOR SHIELD

26 RPCONN12 12 POS CONNECTOR

27 RPCONN15 15 POS CONNECTOR

28 RPGK3561 COVER GASKET

29 RPVL2003 CONNECTOR BOARD

30 RP70TRANS12 REPLACEMENT TRANSFORMER 96 VA

Igloo Dome

26

27

15

14

16

17

13

11

10

9

28

29

30

25

20

21

18

19

12

8

15

23

24

22

2

RPGK3524

FD7T

3

FD7C

5

RPVL3414

6

RPGK3521

7

RPVL2593

8

RPVL3164

9

RPGK3209

rebmuNtraP

TRIM RING INSULATION

TINTED REPLACEMENT CAPSULE

CLEAR REPLACEMENT CAPSULE

CAMERA BRACKET

HOUSING INSULATION

HOUSING

BOARD SHELF

TOP INSULATION

noitpircseD

7

6

5

4

3

2

1

Page 17

Replacement Parts List

31 RPVIMU3ES POWER SUPPLY

32 RPBLEH12 BLOWER 60 X 60 X 25

33 RPPLTCONT PELTIER DEVICE CONTROL BOARD

34 RPVL2004 CONTROL BOARD

39

RPVL3210

POLE MOUNT BRACKET

Igloo Dome

32

31

33

34

35

36

37

38

39

35

RPZPSA6012

36

RPVLBL08

37

RPGK3415

38

RPIGRDTR

rebmuNtraP

POWER SUPPLY

120X38mm FAN

RADIATOR SEALING

RADIATOR

37

noitpircseD

Loading...

Loading...