Page 1

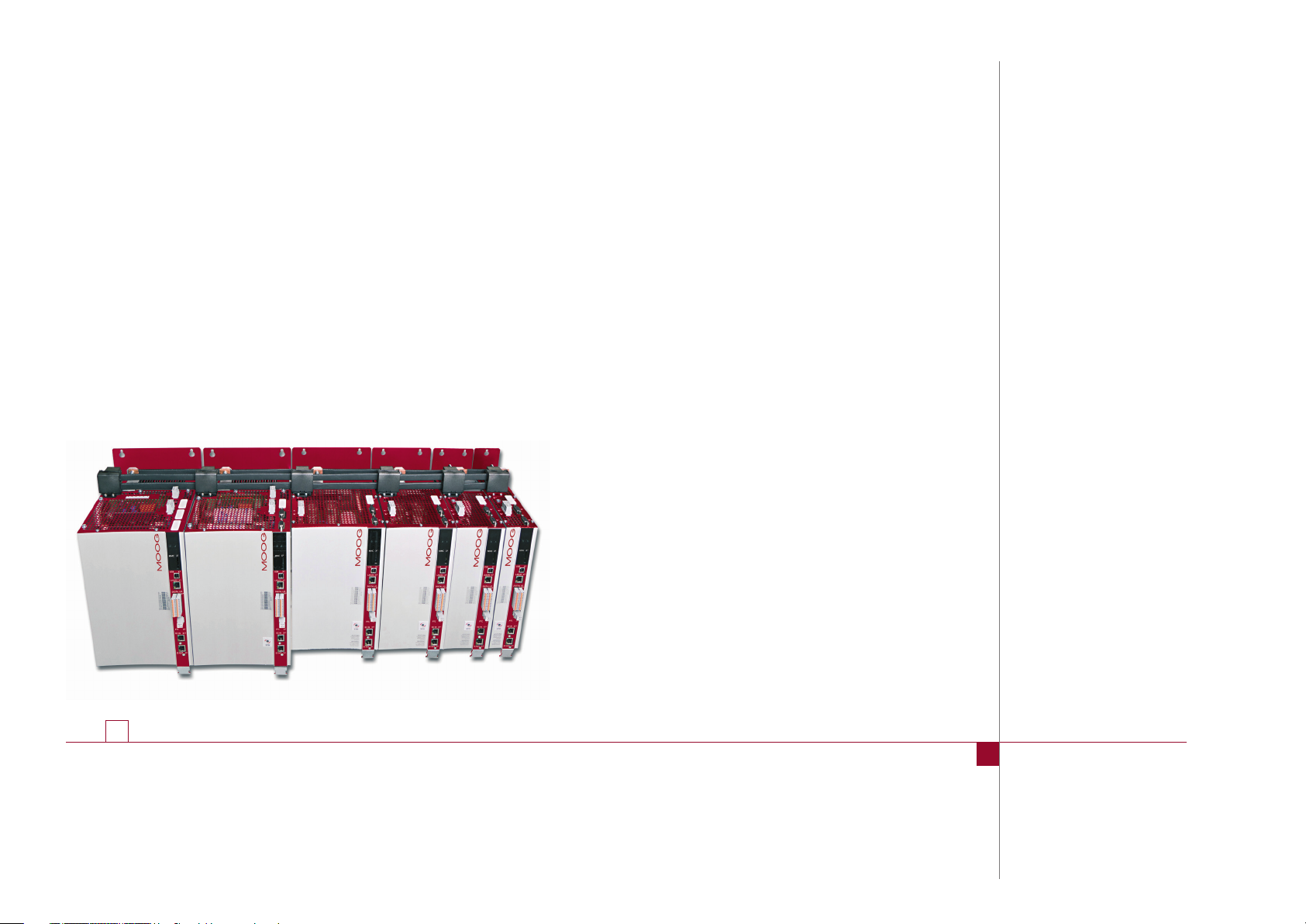

Programmable

Multi-Axis

Servo Drive

Power Supply Unit (PSU)

Sizes 5 and 6A

moog

Operation Manual

Power Supply Unit

with sinusoidal mains feedback

Page 2

moog

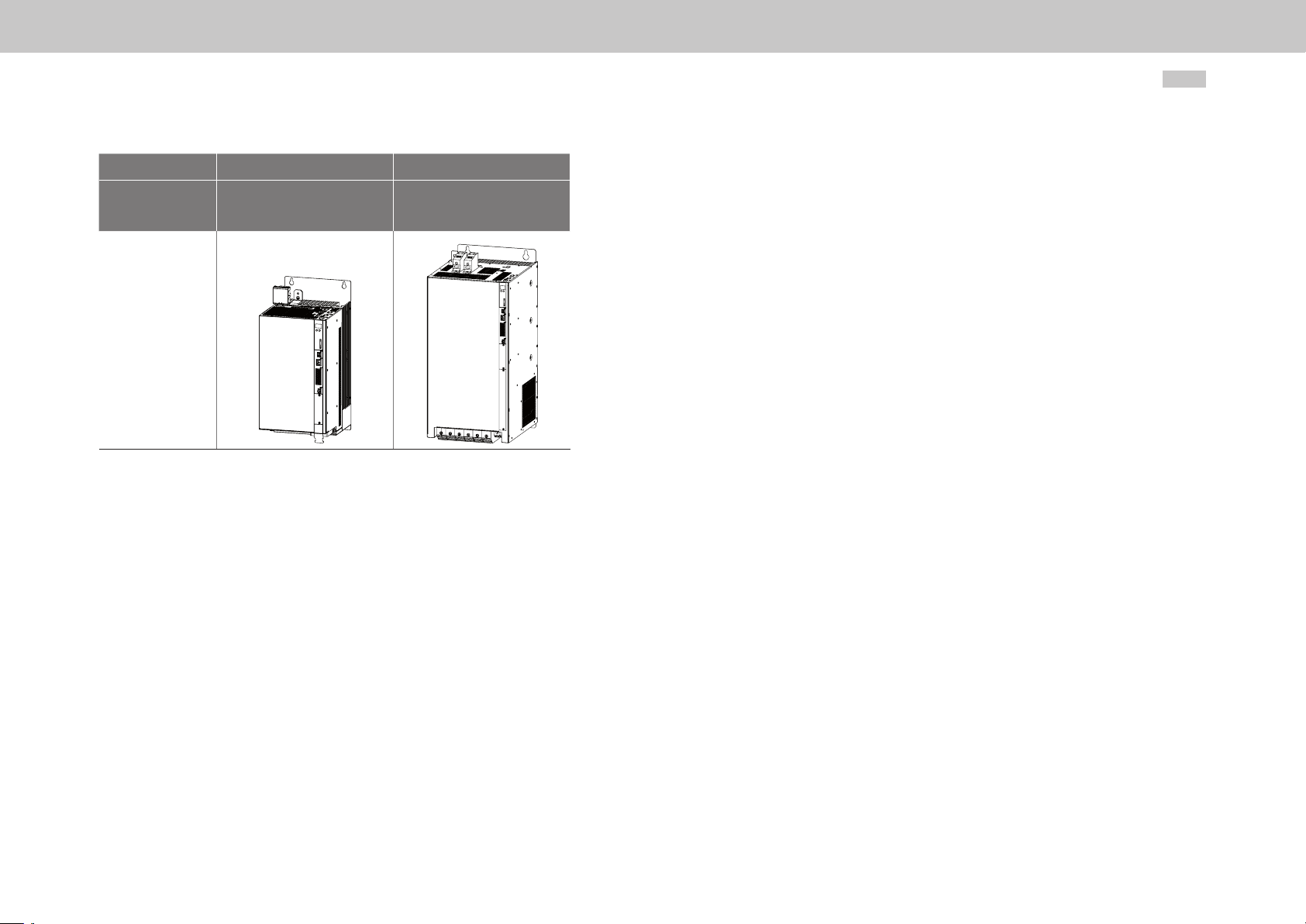

Size Size 5 Size 6A

Device

Picture

ID no.:CA97556-001 Date:03/2015

G396-026

G396-050

G396-075

G396-110

Programmable Multi-Axis Servo Drive Power Supply Unit Operation Manual

2

MSD Servo Drive high-performance drives

The modular design of Multi-Axis Servo Drive ensures optimal integration into the machine process. Whether in high-speed fieldbus communication with the central multi-axis

machine controller or with distributed programmable Motion Control intelligence in the

servo drive, the Multi-Axis Servo Drive is a master of both.

Programmable Multi-Axis

Servo Drive Power Supply Unit (PSU)

Operation Manual

ID no.:CA97556-001, Rev. 2.0

Date: 04/2015

Applicable as from firmware version: V220.13-01

The German version is the original of this Operation Manual.

We reserve the right to make technical changes.

The contents of our documentation have been compiled with greatest care and in

compliance with our present status of information.

Nevertheless we would like to point out that this document cannot always be updated

parallel to the technical further development of our products.

Information and specifications may be changed at any time. For information on the

latest version please refer to drives-support@moog.com.

Page 3

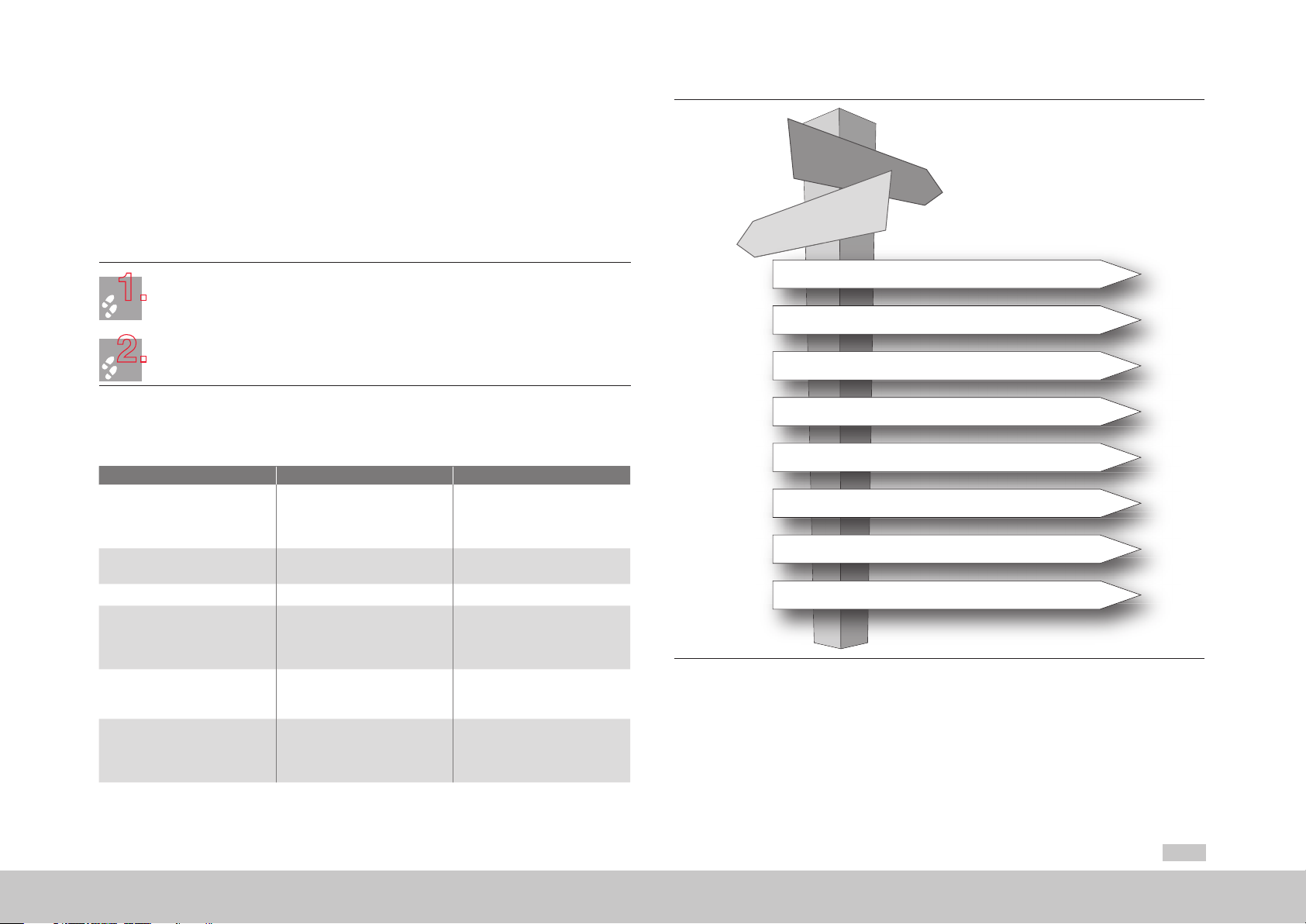

Guide through this document

1.

2.

Dear us er,

We are happy that you have made a decision in favour of a product from Moog. In order

to be able to start using your new device quickly and without problems, we ask you

kindly to read this Operation Manual thoroughly beforehand.

This Operation Manual will enable you to install and commission the Power Supply Unit very

quickly and easily.

Simply follow the step-by-step tables in the various chapters. And away you go!

Documentation system for the Programmable Multi-Axis Servo Drive

System (MSD)

Document Contents Description

Programmable Multi-Axis

Servo Drive Power Supply Unit

(PSU)

Operation Manuall

Programmable Multi-Axis

Servo Drive Operation Manual

MSD Servo Drive Device Help Description of base software Software

CANopen/EtherCAT User Manual

SERCOS User Manual

PROFIBUS / PROFINET

User Manual

Mechanical installation, Electrical

installation, Safety, Specification

Mechanical installation, Electrical

installation, Safety, Specification

Description and parameter setting of the MSD Servo Drive on

the CANopen/EtherCAT fieldbus

system

Description and parameter setting of the MSD Servo Drive on

the SERCOS II fieldbus system

Description and parameter

setting of the MSD Servo Drive

on the PROFIBUS / PROFINET

fieldbus system

Hardware and software

Hardware and software

Hardware and software of the

fieldbus option

Hardware and software of the

fieldbus option

Hardware and software of the

fieldbus option

1 Safety

2Overview

3Mechanical installation

4 Electrical installation

5 Commissioning

6 Diagnostics

A Appendix

Index

Figure 0.1 Guide through this document

moog

ID no.:CA97556-001 Date:03/2015

Guide through this document

Programmable Multi-Axis Servo Drive Power Supply Unit Operation Manual

3

Page 4

Guide through this document

moog

ID no.:CA97556-001 Date:03/2015

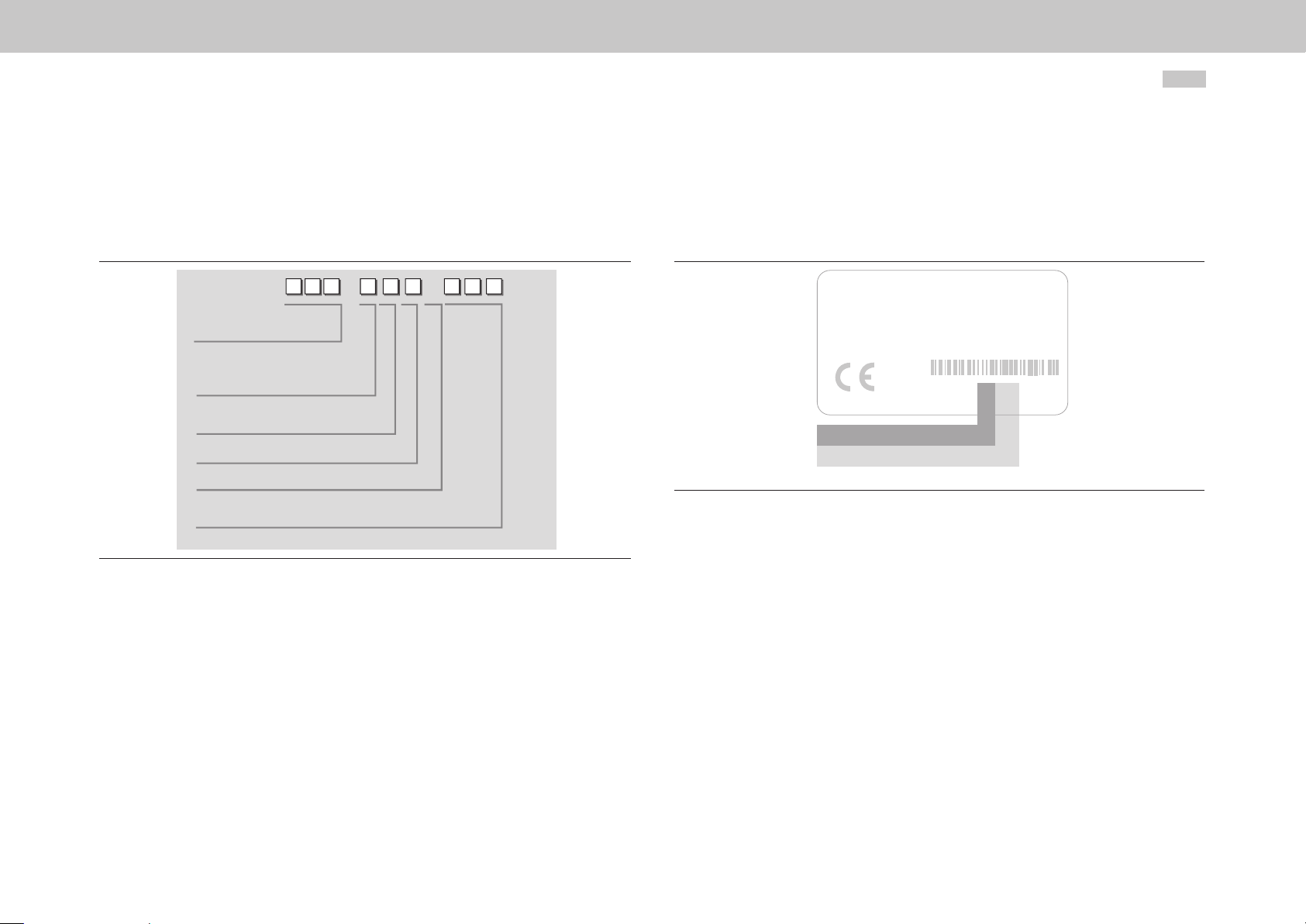

Order code

The order designation indicates the design variant of the Power Supply Unit supplied

to you. For details on the order code refer to the Programmable Multi-Axis Servo Drive

System (MSD) Ordering Catalog.

G396 -

Rated power

Option 1 (Communication)

For future use

Housing/cooling method

Option 4 (Function package)

Variants

- -

Programmable Multi-Axis Servo Drive Power Supply Unit Operation Manual

Production data

On rating plates of the Power Supply Unit you will find the serial number, from which

you can identify the date of manufacture based on the following key. You will find

details of the rating plate’s location on the Power Supply Unit starting on page13.

MOOG

D-71034 Böblingen

www .moog.com/industrial

Made in Germany

Year of production

Week of production

Figure 0.3 Hardware rating plate – Power Supply Unit

Model:: G396-040-000-002

S/N:D116605 Rev. A

In: 230 V AC 3ph, 50/60 Hz

0-230 V AC 3ph, 0-400 Hz

Out:

4,0 A

3,0 A

ID: YYCWxxxxx

4

Figure 0.2 Order code – Power Supply Unit

Supply package

The supply package includes:

y Power Supply Unit (PSU)

y Ready made-up DC link cables for size 5 and size 6A

y Product DVD

Page 5

Required mains connection set

1.

The mains connection set is required to ensure compliance with the intended use of the

Power Supply Unit. The supply package includes:

y Mains filter

y Input choke with membrane capacitor

y Step-up choke

y Shields and clamps

Pictograms

To provide clear guidance, this Operation Manual uses pictograms. Their meanings are

set out in the following table. The pictograms always have the same meanings, even

where they are placed without text, such as next to a connection diagram.

Warning symbols (see also section1.1, p.9)

ATTENTION!

Misoperation may result in damage to the drive or malfunctions.

!

DANGER FROM ELECTRICAL TENSION!

Improper behaviour may endanger human life.

Hints & Tips

NOTE:

Useful information or reference to other documents.

STEP:

Action in a sequence of multiple actions.

moog

ID no.:CA97556-001 Date:03/2015

Guide through this document

Programmable Multi-Axis Servo Drive Power Supply Unit Operation Manual

5

Page 6

Table of contents

moog

ID no.:CA97556-001 Date:03/2015

Table of contents

1 Safety ............................................................................................. 9

1.1 Measures for your safety ............................................................................................. 9

1.1.1 Read the Operation Manual first!.................................................................9

1.1.2 Warning symbols used ............................................................................... 10

1.2 Intended use ............................................................................................................. 10

1.3 Usage contrary to intended use ................................................................................. 10

1.4 Responsibility ............................................................................................................ 11

2 Mechanical installation.................................................................. 13

2.1 Notes for mechanical installation............................................................................... 13

2.2 Effective EMC installation..........................................................................................14

2.2.1 General notes ............................................................................................ 14

2.2.2 Cabinet design ........................................................................................... 14

2.3 Power Supply Unit installation Air-cooled housing ....................................................17

2.3.1 Dimensions, air-cooled housing ................................................................. 18

2.4 Power Supply Unit installation Liquid-cooled housing ............................................... 19

2.4.1 Dimensions, liquid-cooled housing ............................................................20

2.5 Cooling circuit connection.........................................................................................21

2.6 Step-up choke installation ......................................................................................... 22

2.6.1 Dimensions ................................................................................................22

2.7 Installation of input choke with membrane capacitor ................................................ 23

2.7.1 Dimensions ................................................................................................ 23

2.8 Mains filter installation .............................................................................................. 24

2.8.1 Dimensions ................................................................................................24

3 Electrical installation .....................................................................25

3.1 Before you start ........................................................................................................25

Programmable Multi-Axis Servo Drive Power Supply Unit Operation Manual

3.2 Effective EMC installation..........................................................................................25

3.2.1 Cable type .................................................................................................25

3.2.2 Cable laying ............................................................................................... 26

3.2.3 Earthing ..................................................................................................... 26

3.2.4 Shielding .................................................................................................... 27

3.3 Overview of connections ...........................................................................................28

3.3.1 Layout, size 5 (G396 -026 and G396-050) ..................................................28

3.3.2 Layout, size 6A (G396-075 and G396-110) ................................................28

3.3.3 Overview of connections, size 5 and size 6A .............................................. 29

3.3.4 Connection diagram, size 5........................................................................30

3.3.5 Connection diagram, size 6A .....................................................................32

3.4 Connection of PE conductors ....................................................................................33

3.4.1 PE conductor (X11)Power Supply Unit size 5 ..............................................33

3.4.2 PE conductor (X11)Power Supply Unit size 6A ...........................................34

3.4.3 PE conductor components .........................................................................35

3.5 Electrical isolation method ........................................................................................35

3.6 Connection of supply voltages ..................................................................................36

3.6.1 Control supply 24VDC (X9, X10) for size 5 and size 6A ............................36

3.6.2 Precharge and mains synchronisation (X21) for size 5 and size 6A .............37

3.6.3 Mains connection 400/480VAC (X12) for size 5 and Size6A ....................38

3.7 DC power supply connection .................................................................................... 40

3.7.1 DC power supply connection(X11) size 5 ....................................................41

3.7.2 DC power supply connection (X11) size 6A ................................................42

3.8 Control connections (X4)...........................................................................................44

3.8.1 Specification of control connections ..........................................................44

3.8.2 Standard terminal assignment .................................................................... 45

3.9 Functions of the digital inputs ...................................................................................46

3.10 Functions of the digital outputs ................................................................................46

6

Page 7

3.11 Specification of USB port (X2) ................................................................................... 47

3.12 Specification of Ethernet port (X3) ............................................................................ 47

3.13 Option 1 ...................................................................................................................47

3.14 Braking resistor (X12/RB) ........................................................................................... 47

3.14.1 Connection of the external braking resistor ............................................... 47

3.15 Overview of step-up choke connections....................................................................48

3.16 Overview of input choke connections .......................................................................49

3.17 Overview of mains filter connections .........................................................................50

4 Commissioning ............................................................................. 51

4.1 Notes for operation ................................................................................................... 51

4.2 Initial commissioning (actuation via terminals) ...........................................................51

4.2.1 System requirements ................................................................................. 52

4.2.2 Wiring of components ............................................................................... 52

4.2.3 Switching on control voltage (24 VDC) ......................................................53

4.2.4 Communication with the Moog Dr iveA Dmini strAtor 5 ................................. 53

4.2.5 Setting the mains voltage and frequency of the supply system ..................54

4.2.6 Automatic identification of DC link capacity and equivalent time

constant of current control ........................................................................ 55

4.2.7 Setting DC link capacity ............................................................................. 55

4.2.8 Setting DC link voltage .............................................................................. 56

4.2.9 Programming monitoring of the braking resistor ........................................56

4.2.10 Connecting the mains supply voltage ........................................................57

4.2.11 Activating closed-loop control ...................................................................57

4.3 Diagnostics ...............................................................................................................57

4.3.1 Faults and warnings in Moog Dri veAD m inist rAtor 5 .....................................57

4.4 Integrated operator control unit and MMC card .......................................................58

4.4.1 Functions of buttons T1 and T2 ................................................................. 59

4.4.2 Display .......................................................................................................59

4.4.3 Parameters menu (PA) ................................................................................ 60

4.4.4 Ethernet IP address menu (IP) ..................................................................... 61

4.4.5 Fieldbus address menu (Fb) ........................................................................ 62

4.4.6 Firmware update with MMC card .............................................................. 63

5 Diagnostics ...................................................................................64

5.1 Device states .............................................................................................................64

5.1.1 Er r or ..........................................................................................................64

5.2 Error list ....................................................................................................................65

5.3 Helpline/Service ........................................................................................................ 65

A Appendix ......................................................................................66

A.1 Technical data of Power Supply Unit .........................................................................66

A.2 Current consumption of control supply .....................................................................69

A.3 Ready made-up cables ..............................................................................................69

A.4 Hydrological data of liquid cooling ............................................................................70

A.5 Dynamic temperature monitoring .............................................................................70

A.6 Ambient conditions ...................................................................................................70

A.7 Technical data of step-up choke ................................................................................ 72

A.8 Technical data of input choke .................................................................................... 72

A.9 Technical data of mains filter ..................................................................................... 73

A.10 Technical data of mains fuse ..................................................................................... 73

A.11 Technical data of mains contactor ............................................................................. 73

A.12 Technical data of circuit-breaker ................................................................................ 73

A.13 Measures to attain UL approbation (UL508C) size 5 ................................................. 74

A.14 Measures to attain UL approbation (UL508C) size 6A .............................................. 74

B Overview ...................................................................................... 75

moog

ID no.:CA97556-001 Date:03/2015

Table of contents

Index ...................................................................................................78

Programmable Multi-Axis Servo Drive Power Supply Unit Operation Manual

7

Page 8

Table of contents

moog

ID no.:CA97556-001 Date:03/2015

Programmable Multi-Axis Servo Drive Power Supply Unit Operation Manual

8

Page 9

1 Safety

1.

1.1 Measures for your safety

The instructions set out below should be read through prior to initial commissioning

in order to prevent injury and/or damage to property. The safety instructions must be

followed at all times.

1.1.1 Read the Operation Manual first!

Read the Operation Manual and the reference documents first!

• Follow the safety instructions!

• Refer to the user information!

Electric drives are dangerous:

• Electrical voltages 230 V AC / 320 V DC to 480 V AC / 770 V DC

Dangerously high voltages ≥ 50 V (capacitor charge) may still be present 10 minutes after

the power is cut to the size 5 and size 6A. The discharge time depends on the number of

drives connected to the multi-axis system. So check that no voltage is connected!

• Rotating parts

• Hot surfaces

Risk of burning by hot components!

• The heat sink of the inverter, the choke, the transformer, the filters and the fuses become

very hot in operation.

− Make sure the components have cooled down to ambient temperature before carrying

out any work. Or wear protective clothing and gloves when working close to hot

components.

Risk of burning by hot coolant!

• The coolant gets hot during operation. Make sure the coolant has cooled down to ambient

temperature before carrying out any work.

Protection against magnetic and/or electromagnetic fields during installation and operation.

• Persons fitted with heart pacemakers, metallic implants and hearing aids etc. must not be

allowed access to the following areas:

− Areas where drive systems are installed, repaired and operated.

− Areas where motors are installed, repaired and operated. Motors with permanent

magnets pose a particular hazard.

NOTE:

If it is necessary to access such areas, suitability to do so must be determined beforehand by a

doctor

Your qualification:

• In order to prevent personal injury and damage to property, only personnel with electrical

engineering qualifications may work on the device.

• The said qualified personnel must be familiar with the contents of the Operation Manual

(see IEC364, DIN VDE0100).

• Knowledge of the national accident prevention regulations (e.g. BGV A3 in Germany)

U

U

V

During installation observe the following instructions:

V

N

N

L+

• Always comply with the connection conditions and technical specifications.

L+

RB

RB

L-

L-

L3

L3

L2

• Comply with the standards for electrical installations, suchas regarding wire cross-section,

L2

L1

L1

PE conductor and earth connections.

• Do not touch electronic components and contacts (electrostatic discharge may destroy

components).

Table 1.1 Safety precautions

moog

Safety

ID no.:CA97556-001 Date:03/2015

Programmable Multi-Axis Servo Drive Power Supply Unit Operation Manual

9

Page 10

Safety

moog

ID no.:CA97556-001 Date:03/2015

1.1.2 Warning symbols used

The safety instructions detail the following hazard classes. The hazard class defines the

risk posed by failing to comply with the safety notice.

Warning symbols General explanation Hazard class to ANSIZ535

ATTENTION!

!

Table 1.2 Explanations of warning symbols

Misoperation may result in damage to

the drive or malfunctions.

DANGER FROM ELECTRICAL

TENSION!

Improper behaviour may endanger

human life.

Serious injury or damage to property may

occur.

Death or serious injury will occur.

1.2 Intended use

The Power Supply Unit is intended for use in a Multi-Axis Servo Drive System. The multiaxis system comprises a Power Supply Unit with the mains connection set and a number

of Multi-Axis Servo Drives connected to it. In motorised mode, the Power Supply Unit

draws power from the supply system and makes it available to the connected Multi-Axis

Servo Drives via the DC link. In regenerative mode the power is stored in the DC link.

Temporarily surplus energy is fed back into the supply network by the Power Supply Unit

in sinusoidal form.

Programmable Multi-Axis Servo Drive Power Supply Unit Operation Manual

Commissioning (i.e. putting the device to its intended use) is only permitted in

compliance with the EMC Directive (2004 /108 /EC).

The Power Supply Unit conforms to the Low Voltage Directive 2006/95/EC.

The Power Supply Unit conforms to the requirements of the harmonised product

standard IEC/EN61800-5-1.

If the Power Supply Unit is used for special applications (e.g.in areas subject to explosion

hazard), the required standards and regulations (e.g. IEC/EN60079-0: "Explosive

atmospheres - Part0: Equipment - General requirements" and IEC/EN60079-1:

"Explosive atmospheres - Part1: Equipment protection by flameproof enclosures‚d’ “)

must always be observed.

Repairs may only be carried out by authorised repair workshops. Unauthorised opening

and incorrect intervention could lead to death, physical injury or material damage. The

warranty provided by Moog would thereby be rendered void.

NOTE:

Deployment of the Power Supply Unit in non-stationary equipment is classed

as non-standard ambient conditions, and is permissible only by special

agreement.

10

1.3 Usage contrary to intended use

The Power Supply Unit additionally performs the function of a reactive power

compensator as required. (For details please consult your project engineer.)

The Power Supply Unit is a component intended for installation in stationary electrical

systems or machines.

When installed in machines the commissioning of the servo drive (i.e. start-up of

intended operation) is prohibited, unless it has been ascertained that the machine fully

complies with the provisions of the Machinery Directive 2006/42/EC; compliance with

IEC/EN60204 is mandatory.

The Power Supply Unit must not be used:

y without the mains connection set (filters, chokes)

y outside a switch cabinet

y in a photovoltaic system

y with a directly connected DC motor

y in island mode

Page 11

1.4 Responsibility

Electronic devices are fundamentally not fail-safe. The company setting up and/or

operating the machine or system is itself responsible for ensuring that the drive is

rendered safe if the device fails.

IEC/EN60204-1: "Safety of machinery - Electrical equipment of machines - Part 1:

General requirements" in the category "Electrical equipment of machines" sets out

safety requirements for electrical controls. They are intended to protect personnel and

machinery, and to maintain the function capability of the machine or system concerned,

and must be observed.

The function of an emergency stop system does not necessarily have to cut the power

supply to the drive. To protect against danger, it may be more beneficial to maintain

individual drives in operation or to initiate specific safety sequences. Execution of

the emergency off measure is assessed by means of a risk analysis of the machine

or plant, including the electrical equipment to ENISO12100: "Safety of machinery General principles for design - Risk assessment and risk reduction", and is determined

with selection of the circuit category in accordance with ENISO13849-1: "Safety of

machinery - Safety-related parts of control systems - Part 1: General principles for

design" (formerly DINEN954-1).

moog

Safety

ID no.:CA97556-001 Date:03/2015

Programmable Multi-Axis Servo Drive Power Supply Unit Operation Manual

11

Page 12

moog

ID no.:CA97556-001 Date:03/2015

Programmable Multi-Axis Servo Drive Power Supply Unit Operation Manual

12

Page 13

2 Mechanical installation

2.1 Notes for mechanical installation

ATTENTION!

During installation, please avoid:

!

y drill chippings, screws or foreign bodies dropping into the device;

y penetration of damp into the device.

ATTENTION!

The device is solely intended for installation in a stationary cabinet. The

!

cabinet must as a minimum provide IP4x protection. The servo drives must not

be installed in areas where they would be permanently exposed to vibrations.

For more information refer to the Table A.13, p.71 appendix.

ATTENTION!

Risk of burning by hot components.

!

The device heats up in operation and at the heat sink may reach temperatures

of up to +100°C (+212 °F). The connected chokes get hot during operation,

possibly reaching temperatures of up to +145°C (+293°F).

Keep a safe distance away from adjacent component assemblies. Make sure

the components have cooled down to ambient temperature before carrying

out any work. Or wear protective clothing and gloves when working close to

hot components.

NOTE:

For installation of the Power Supply Unit within a Multi-Axis Servo Drive

System, be sure also to observe the Operation Manual for the Multi-Axis Servo

Drives.

The layout and installation of the Power Supply Unit and the Multi-Axis Servo Drives is

subject to the following basic rules:

y The backing plate must be well earthed.

y To attain the best result for effective EMC installation use a chromated or

galvanised backing plate. If backing plates are varnished, remove the coating

from the contact area. The size 5 and size 6A models have a rear panel made of

aluminised/galvanised sheet steel.

y Pollution severity 2 to IEC/EN60664-1. For more information on environmental

conditions refer to the Table A.11, p.70 appendix.

y Cooling air must be able to flow through the device without restriction.

y For installation in cabinets with convection (= heat loss is discharged to the

outside via the cabinet walls), always fit an internal air circulation fan.

y Devices with different housing variants (air-cooled and liquid-cooled) can be

installed next to each other in any combination.

y Devices with liquid-cooled housings have a spacer on the rear in place of the

heat sink. Consequently, it is possible to connect to devices with air-cooled

housings using the ready made-up DC link cables without additional measures

to compensate for differing unit depth.

y No minimum clearance between the devices is required. Exceptions to this rule

are the following air-cooled devices:

− Multi-Axis Servo Drive size 6A (Figure 2.5, p.17 and Table 2.1, p.18)

− Power Supply Unit size 6A (Figure 2.9, p.19 and Table 2.2, p.20)

y The maximum distance between the devices is dictated by the supplied ready

made-up cables, and is 2mm (0.08in) (for exceptions see above).

ATTENTION!

Use only the supplied DC link cable for the electrical connections between the

!

devices. If other cables are used, Moog can provide no guarantee of stable

and safe operation.

moog

ID no.:CA97556-001 Date:03/2015

Mechanical installation

Programmable Multi-Axis Servo Drive Power Supply Unit Operation Manual

13

Page 14

Mechanical installation

moog

y Servo Drives may only be installed on one side (to the left or right) of larger

sized devices. On the other side a device of equal or smaller size must be

installed.

y A vertical offset of 18.5mm (0.73in) must be allowed between the top fixing

screws for devices of size 1 to size 5 and devices of size 6A (see Figure 2.5 and

Figure 2.9).

If you need more details on installation please contact the Moog Helpline (see

section5.3, p.65).

ID no.:CA97556-001 Date:03/2015

2.2 Effective EMC installation

2.2.1 General notes

Power Supply Units are components intended for installation in industrial and

commercial plant and machinery. They must only be installed in switch cabinets

providing minimum IP4x protection.

Commissioning (i.e. starting intended operation) is only permitted when strictly

complying with EMC product standard IEC/EN61800-3.

NOTE:

The new EMC product standard for variable-speed electric drives is

IEC/EN 61800-3:2008. The transition period for the old IEC/EN61800-3:1996

ended on October1, 2007.

The installer/operator of a machine and/or item of plant must provide proof of

compliance with the protection targets stipulated in the EMC standard.

The multi-axis system is a special case with regard to EMC installation. The high

DClink voltage (up to 770 V DC) and its routing over long cables between the Power

Supply Unit and Multi-Axis Servo Drives demands great care when implementing EMC

installation.

Programmable Multi-Axis Servo Drive Power Supply Unit Operation Manual

14

2.2.2 Cabinet design

The placement of components in the switch cabinet is a key factor in operating plant

and machinery without disturbance. Your planning should take account of the following

points:

y Assess the assemblies used in terms of their electromagnetic compatibility.

y Split the cabinet into zones of different power and interference levels.

y Keep units susceptible to interference at a minimum clearance of 200mm

(7.87in) from the following components:

− Servo drive

− Input and output chokes, transformers

− Mains, motor, DC power supply and braking resistor cables (even if shielded)

− Relays and contactors (even if interference-suppressed)

y When installing close, use isolating plates mounted directly and conductively on

the backing plate as shielding.

y When using a motor contactor or a reactance coil, the respective component

should be directly mounted to the servo drive.

y Do not use fluorescent lamps in cabinets, as they emit high-frequency

interference.

y Provide contactors, relays, solenoid valves, switched inductors and capacitors

with suppressors.

y The mains filter must be sealed tight as far as possible, and be mounted on

the backing plate across a wide area at the feed-in point. The backing plate

must have a low-resistance connection to the central earthing point. No

unfiltered cables may be routed on the mains input side of the filter, to prevent

interference.

Timely planning and diligent implementation of the EMC installation measures detailed

here will help avoid complex and costly retooling of plant.

Page 15

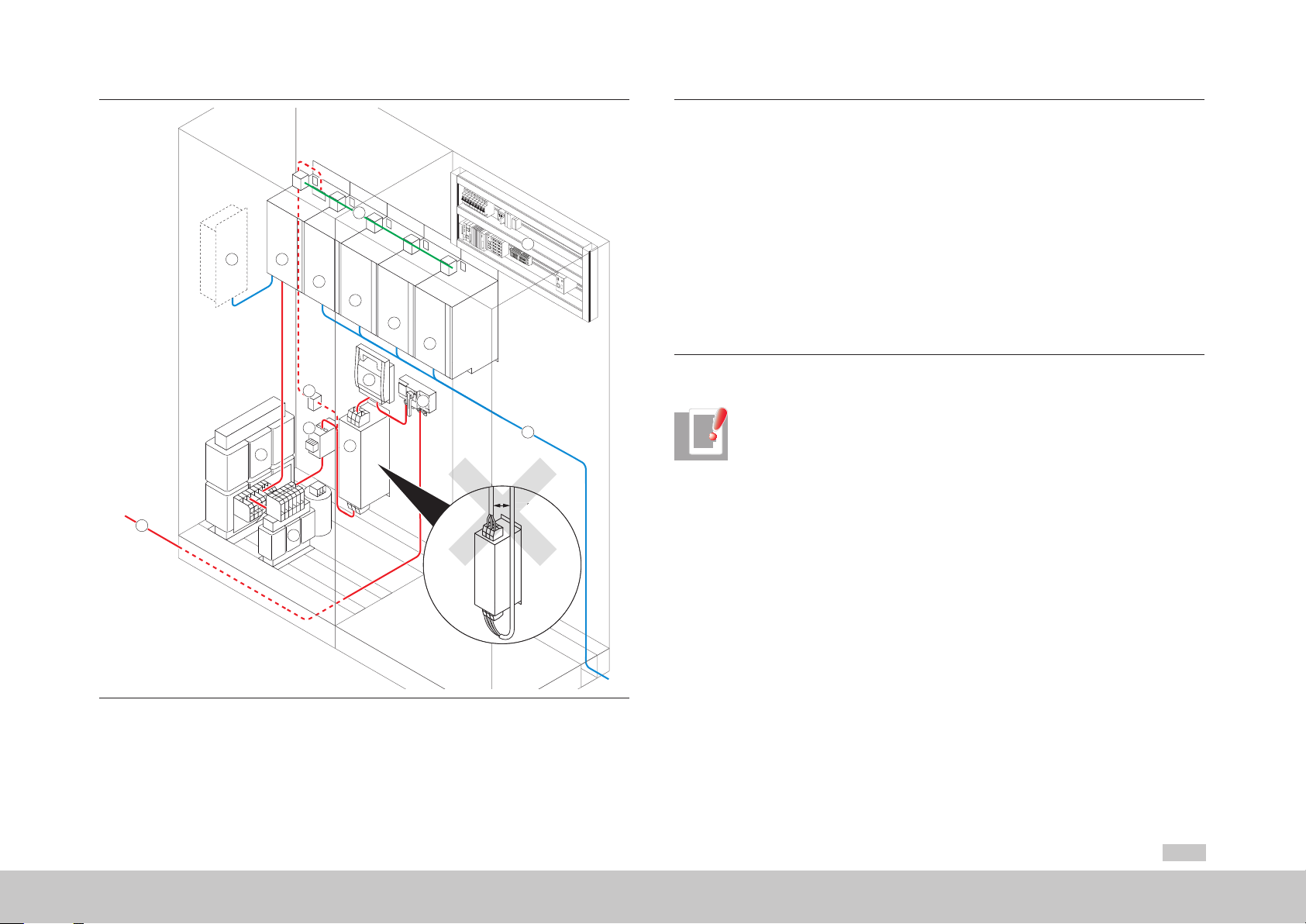

< 200 mm

< 20

12 9

1) Power cable

2) Main s witch

3) Fuses

4) Mains filt er Unfiltered cables must be routed at a distance of least 20 0 mm (7.87in) from the mains input side of the fi lter,

to prevent interfer ence.

5) Circuit-breaker

11

PWR

LOCK

CF

14

6) Mains contactor

7) Input choke with connected capacitor

8) Step-up choke

9) Powe r Supply Unit

Power

COM

Data

Status

10

10

10

10

Reset

RJ-45/Line

RS 232

10) Multi-Axis Servo Drive

11) DC power supply via DC link cable

12) Braking resistor

13) Motor cables

14) Control

3

0

5

1

OFF

ON

0

2

Figure 2.1 Example: Cabinet layout

NOTE:

6

8

4

13

Arrange the control section separately from the power section, so as to avoid

electromagnetic interference mechanisms.

Control and signal cables and shields have been omitted for the sake of clarity.

1

7

y Use metallically bright backing plates.

y The rear panel of the servo drive must have good contact with the switch

cabinet earth. The contact area must be metallically bright, in order to make a

good earth connection to the cabinet earth. There must be no air gap between

the rear panel of the servo drive and the switch cabinet wall.

y The choke bases must have good contact with the cabinet earth. The contact

area must be metallically bright, in order to make a good earth connection to

the cabinet earth.

moog

ID no.:CA97556-001 Date:03/2015

Mechanical installation

Programmable Multi-Axis Servo Drive Power Supply Unit Operation Manual

15

Page 16

Mechanical installation

moog

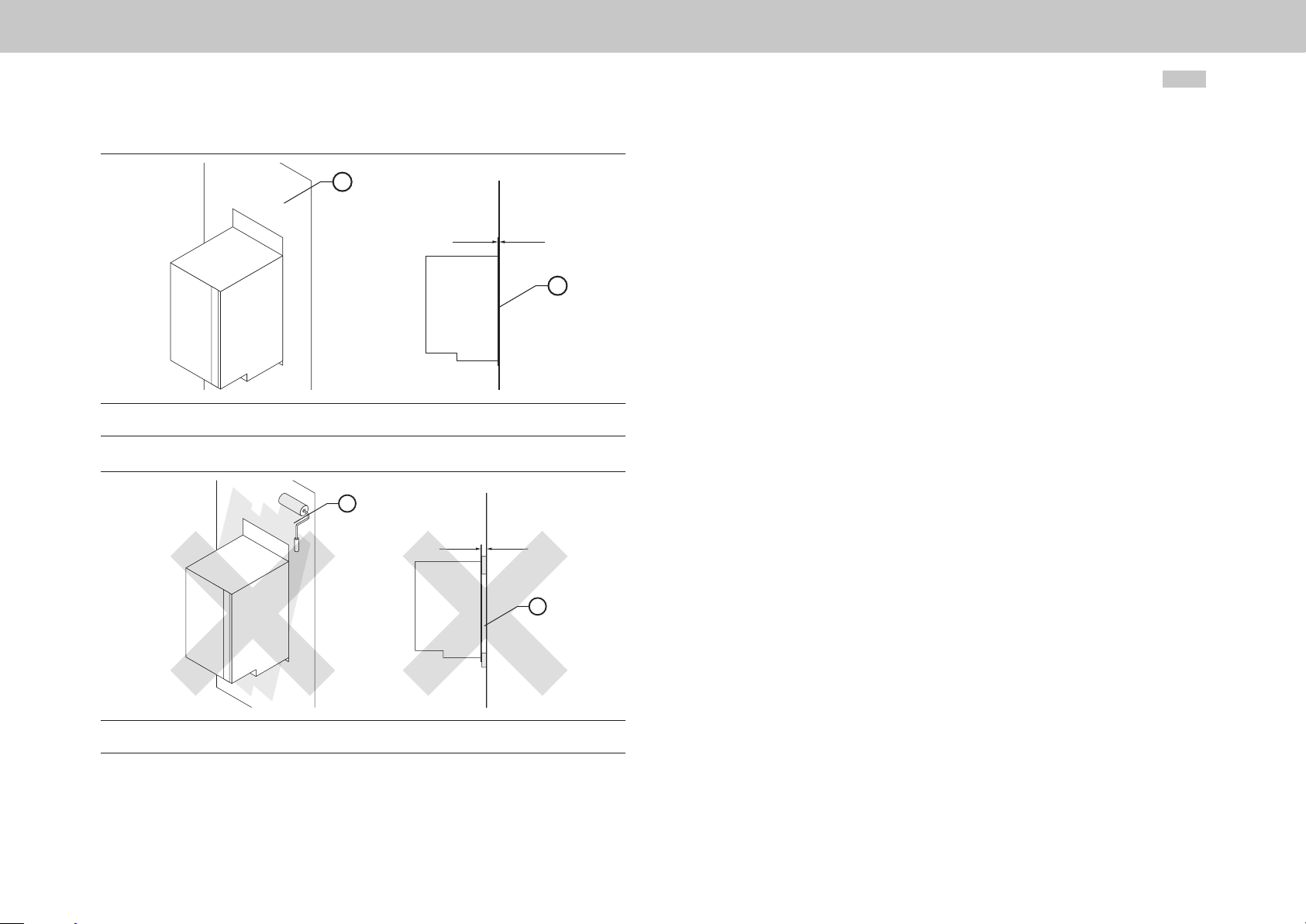

1) Backing plate metallically bright

2) Wide- area contact

Figure 2.2 Servo drive installation CORRECT

ID no.:CA97556-001 Date:03/2015

Programmable Multi-Axis Servo Drive Power Supply Unit Operation Manual

1

= 0 mm

2

1

16

1) Va rnis h

2) Air gap

Figure 2.3 Servo drive installation INCORRECT

> 0 mm

2

Page 17

18.5 mm (0.73 in)

18.5 mm (0.73 in)

Multi-Axis Servo Drive size 1

Multi-Axis Servo Drive size 2

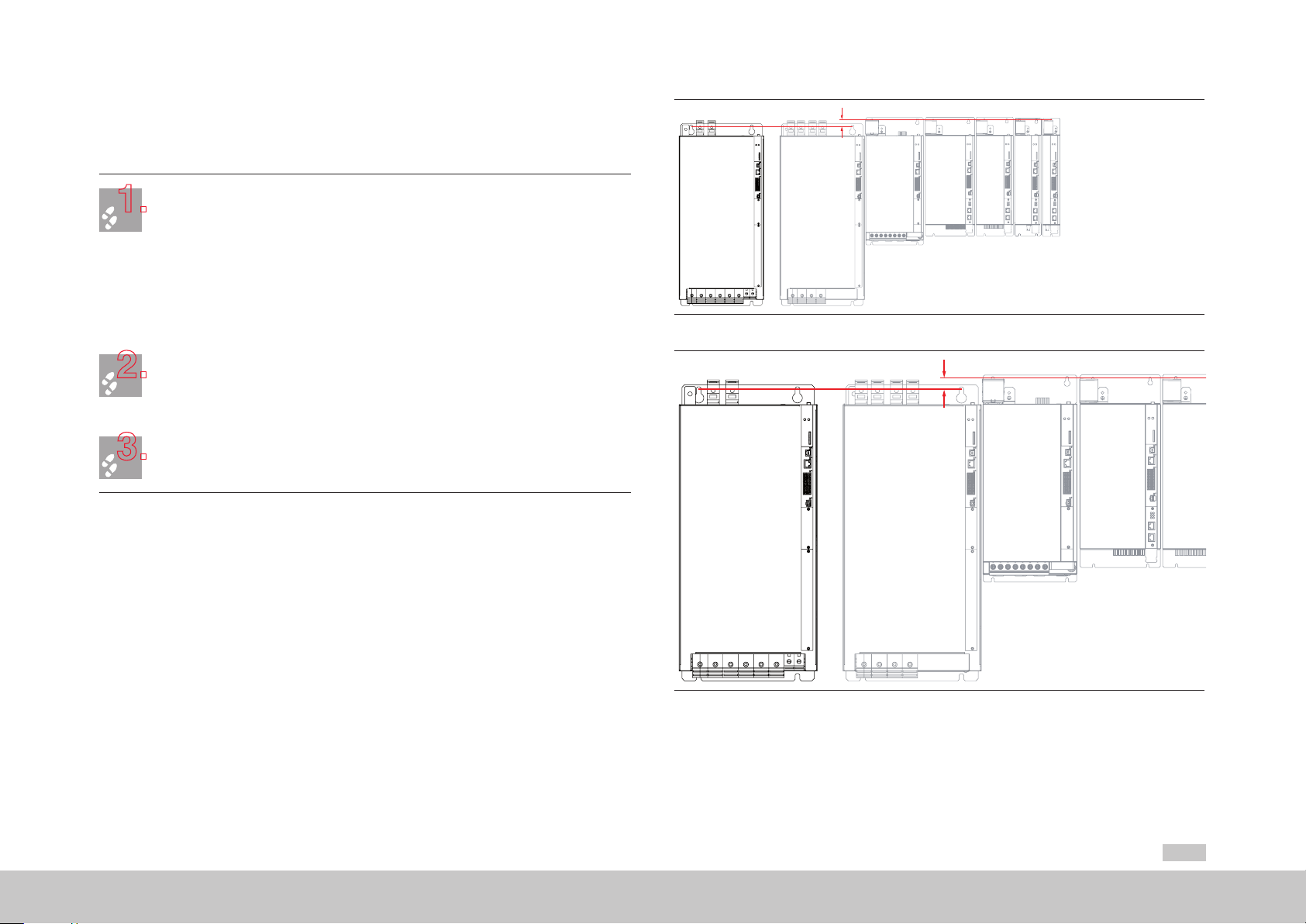

2.3 Power Supply Unit installation

1.

2.

3.

Air-cooled housing

Arrange the devices starting from the Power Supply Unit to the right or left sorted in descending

order of power output, in order to exclude thermal influences. Before installing the devices and

components in the cabinet refer to the instructions relating to EMC installation.

Align Power Supply Unit size 5 and all Multi-Axis Servo Drives in a line along the top edge of

the unit (see dotted line in Figure 2.4). This is necessary in order to execute the DC power supply

using the ready made-up cables.

Align all Multi-Axis Servo Drives in a line along the top edge of the unit. Align Power Supply Unit

size 6A offset 18.5mm (0.73in) down (see Figure 2.5). This is necessary in order to execute

the DC power supply using the ready made-up cables. Be sure to adhere to the mounting

clearances set out in Ta b le 2.1.

Mark out the position of the tapped holes on the backing plate.

Cut a tap for each fixing screw in the backing plate.

Pay attention to the installation clearances. Also take into account the bend radius of the

connecting cables. Dimensional drawings/hole spacing see Figure 2.6 and Tab l e 2.1..

Mount the Power Supply Unit vertically and abutting on the backing plate.

The contact area must be metallically bright. For the DC power supply use the supplied ready

made-up cables. The next stage is installation of the mains connection set.

Power Supply Unit

size 6A

Figure 2.4 Butt-mounting, axis array, air-cooled, with Power Supply Unit size 5

Power Supply Unit

size 6A

air-cooled

Multi-Axis Servo Drive

size 6A

Multi-Axis Servo Drive size 5

Multi-Axis Servo Drive

size 6A

air-cooled

Multi-Axis Servo Drive size 2

Multi-Axis Servo Drive size 4

Multi-Axis Servo Drive size 3

Multi-Axis Servo Drive size 1

Multi-Axis Servo Drive size 5

Multi-Axis Servo Drive size 4

Multi-Axis Servo Drive size 3

moog

ID no.:CA97556-001 Date:03/2015

Mechanical installation

Figure 2.5 Butt-mounting, axis array, air-cooled, with Power Supply Unit size 6A

Programmable Multi-Axis Servo Drive Power Supply Unit Operation Manual

17

Page 18

Mechanical installation

moog

ID no.:CA97556-001 Date:03/2015

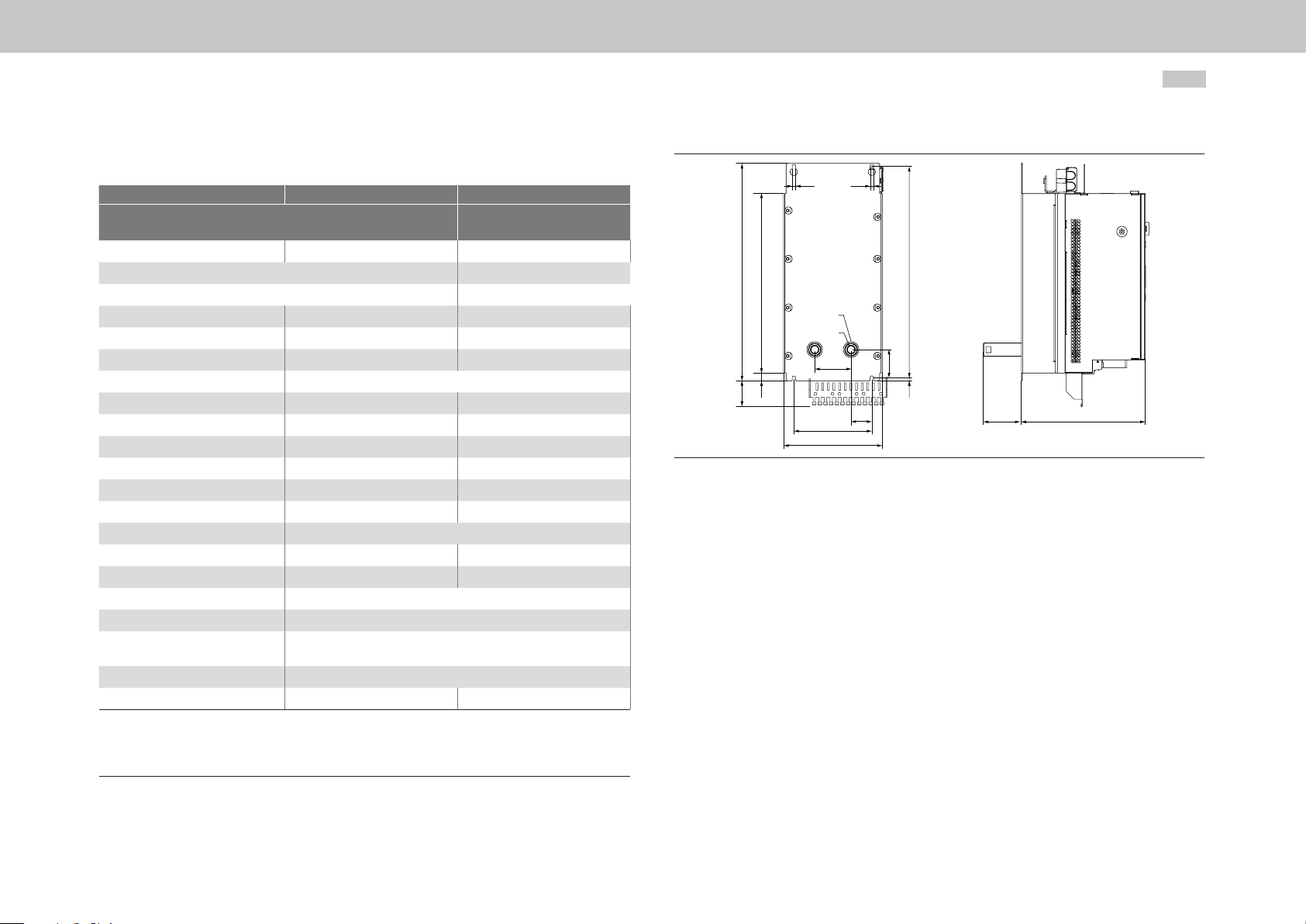

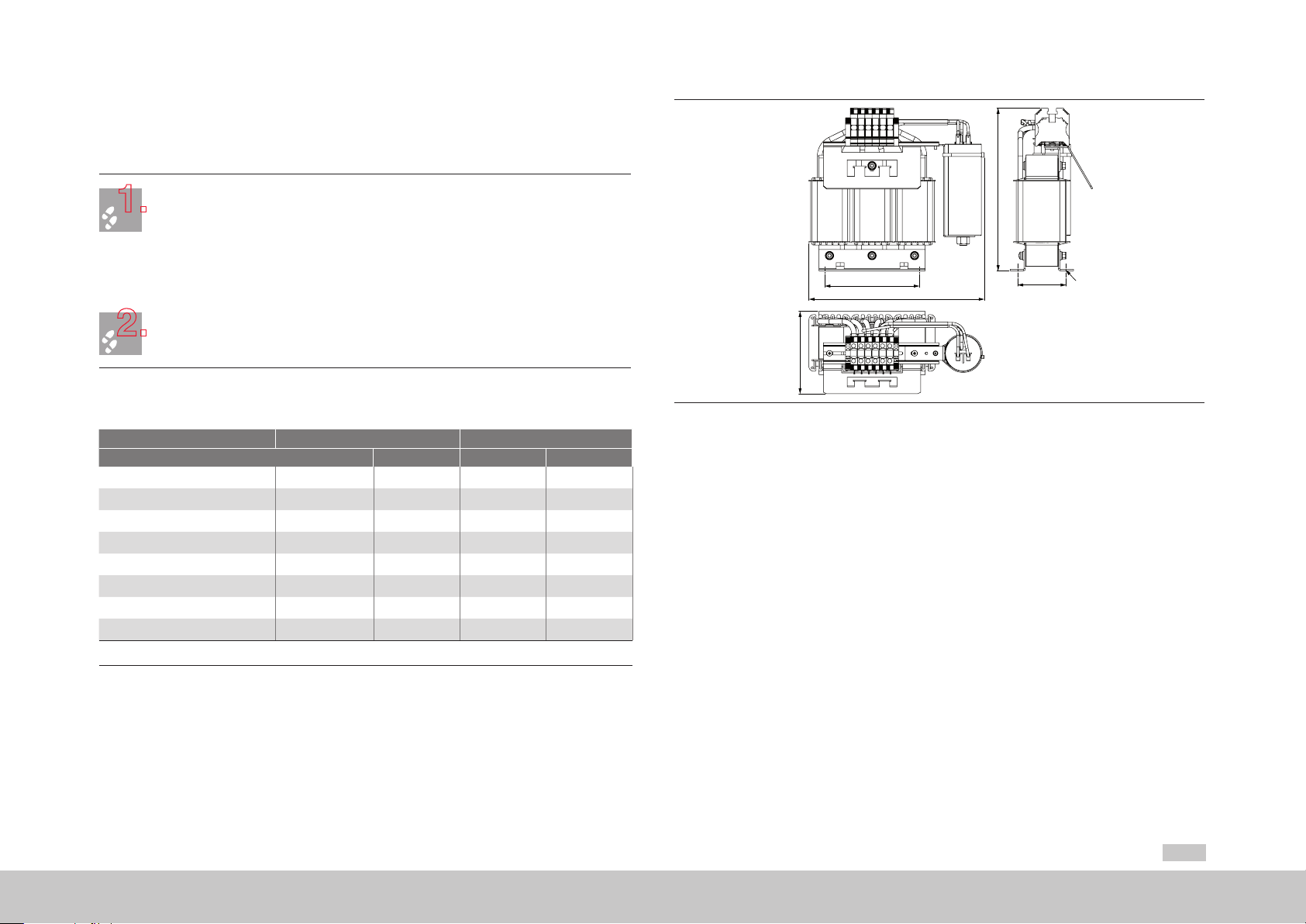

2.3.1 Dimensions, air-cooled housing

Size Size 5 Size 6A

Device

Weight

B (width)

H (height)

T (depth)

A

C

C1

H1

H2

H3

D

Fixing screws

E

F

G

All Dimensions in mm (in),

1) Without terminals, connectors

2) Mounting distance size 6A to other size 6A

3) Also take into account the bend r adius of the connecting cables

Table 2.1 Dimensions, air-cooled housing

1)

1)

3)

3)

G396-026-xxx-xxx

G396-050-xxx-xxx

13 kg (28.7 lb) 32 kg (70.6 lb)

19 0 (7.4 8) 28 0 (11. 02)

345 (13.58) 540 (21.26)

240 (9.45) 322 (12.68)

150 (5.91) 20 0 (7. 87)

407 (16.02) 581 (22.87)

6 (0.24) 10 (0.39)

419 (16 .5 0) 600 (23.62)

15 (0.59) 20 (0.79)

64 (2.52) 166 (6.54)

Ø 6 (0.24) Ø 10 (0.39)

4 x M5 4 x M8

Direct butt-mounted, maximum

2(0.08)

≥30 0 (11. 81) ≥500 (19.69)

≥18 0 (7.0 9)

G396-075-xxx-xxx

G396-110-xxx-xxx

Direct butt-mounted, maximum

2(0.08) / 40

Programmable Multi-Axis Servo Drive Power Supply Unit Operation Manual

D D

H1

H

H2

H3

A

B

Figure 2.6 Dimensional drawing, air-cooled housing, example for size 5

2)

E

C

C1

T

F

G

18

NOTE:

Arrange devices with different drive power in descending order of power

output (e.g. viewed from the left size 4-size 3-size 2-size 1). This minimises the

mutual thermal influence. The Power Supply Unit must always be arranged on

the side of the most powerful servo drive. When butt-mounting other devices

with the multi-axis system, you must make sure that the devices do not affect

one another thermally.

F

Figure 2.7 Mounting distance, air-cooled housing, example for size 5

Page 19

18.5 mm (0.73 in)

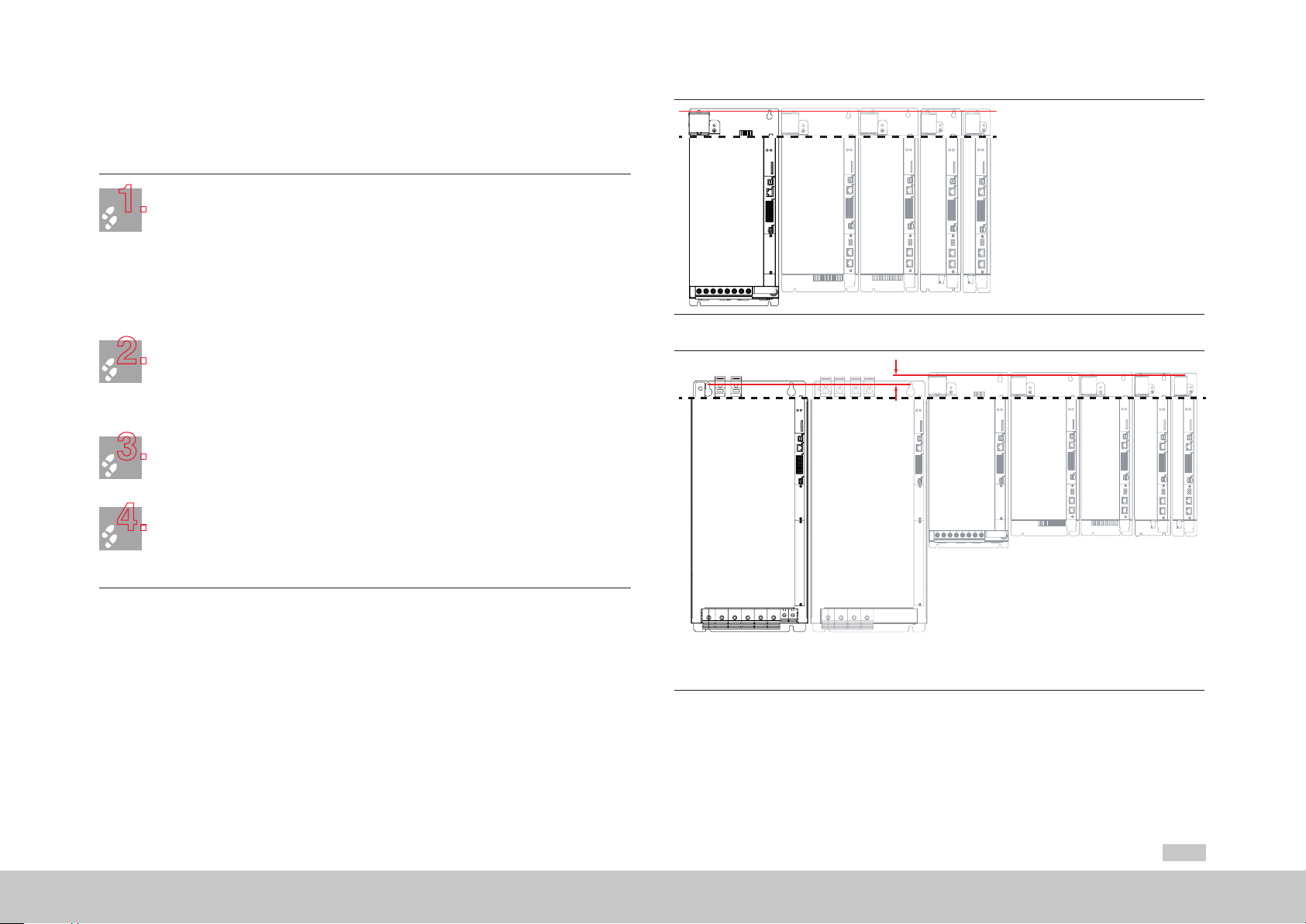

2.4 Power Supply Unit installation

1.

2.

3.

4.

Liquid-cooled housing

Arrange the devices starting from the Power Supply Unit to the right or left sorted in descending

order of power output, in order to exclude thermal influences. Before installing the devices and

components in the cabinet refer to the instructions relating to EMC installation.

Align Power Supply Unit size 5 and all Multi-Axis Servo Drives in a line along the top edge of

the unit (see dotted line in Figure 2.8). This is necessary in order to execute the DC power supply

using the ready made-up cables.

Align all Multi-Axis Servo Drives in a line along the top edge of the unit. Align Power Supply Unit

size 6A offset 18.5mm (0.73in) down (see Figure 2.9). This is necessary in order to execute

the DC power supply using the ready made-up cables.

Mark out the positions of the tapped holes and the pipe socket on the backing plate.

Drill holes and cut a thread for each fixing screw in the backing plate.

Pay attention to the installation clearances. Also take into account the bend radius of the

connecting cables. Dimensional drawings/hole spacing see Figure 2.8 to Figure 2.10 and

Table 2.2.

Power Supply

Unit size 5

Multi-Axis Servo Drive size 2

Multi-Axis Servo Drive size 4

Figure 2.8 Butt-mounting, axis array, liquid-cooled, Power Supply Unit size 5

Multi-Axis Servo Drive size 3

Multi-Axis Servo Drive size 1

Mount the Power Supply Unit vertically and abutting on the backing plate.

When fitting the hose connections (not supplied) in the pipe sockets, brace with a 22mm

moog

The contact area must be metallically bright. For the DC power supply use the supplied ready

made-up cables.

(0.87in) open-ended wrench in order to prevent damage to the device by torsion.

Ensure a perfect liquid-tight connection (e.g. using a Teflon sealing strip).

For more information on liquid cooling refer to sectionA.4, p.70.

The next stage is installation of the mains connection set.

ID no.:CA97556-001 Date:03/2015

Power Supply Unit

size 6A

liquid-cooled

Figure 2.9 Butt-mounting, axis array, liquid-cooled, Power Supply Unit size 6A

Programmable Multi-Axis Servo Drive Power Supply Unit Operation Manual

Multi-Axis Servo Drive

size 6A

liquid-cooled

Multi-Axis Servo Drive size 5

Multi-Axis Servo Drive size 4

Multi-Axis Servo Drive size 3

Multi-Axis Servo Drive size 1

Multi-Axis Servo Drive size 2

19

Mechanical installation

Page 20

Mechanical installation

moog

ID no.:CA97556-001 Date:03/2015

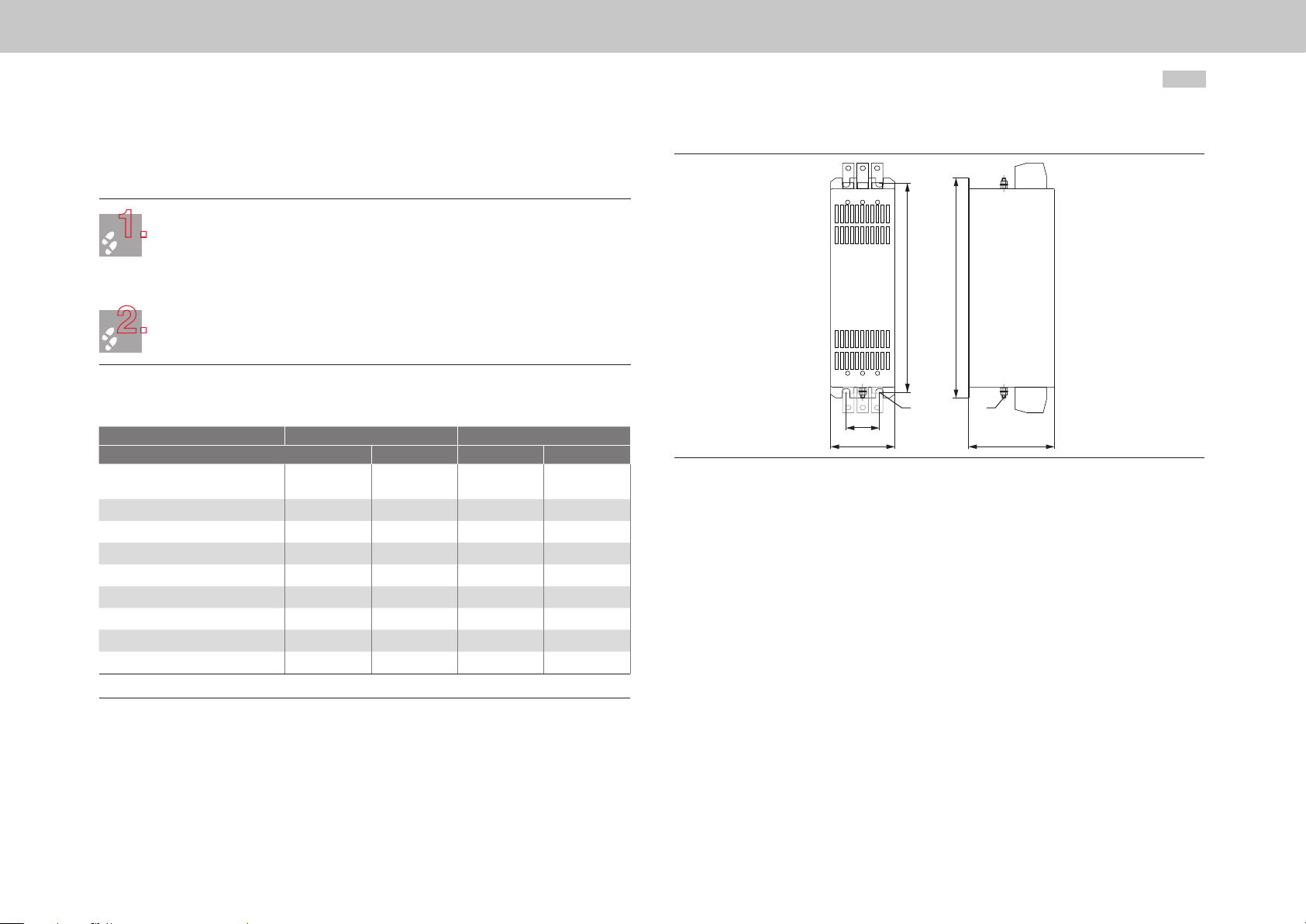

2.4 .1 Dimensions, liquid-cooled housing

Size Size 5 Size 6A

Device

Weight

B (width)

H (height)

T (depth)

A

A1

1)

1)

G396-026-xxx-xxx

G396-050-xxx-xxx

13 kg (28.7 lb) 32 kg (70.6 lb)

19 0 (7.4 8) 280 (11. 02)

345 (13.58) 540 (21.26)

239 (9.41) 28 5 (11.22 )

150 (5.91) 20 0 (7. 87)

40 (1.57) 65 (2.56)

A2

C

407 (16.02) 581 (22.87)

C1

H1

H2

H3

H4

419 (16 .5 0) 600 (23.62)

15 (0.59) 20 (0.79)

54 (2.13) 57 (2.24)

64 (2.52) 166 (6.5 4)

D1

D

Ø 7 (0.28) Ø 10 (0.39)

Fixing screws

S inside thread

D1 Hole for pipe socket

2)

E

2) 3)

F

2) 3)

G

All dimensions in mm (in)

1) Without terminals/connectors

2) See F igu re 2 .11,

3) Also take into account the bend r adius of the connecting cables

≥30 0 (11. 81) ≥ 500 (19.69)

Table 2.2 Dimensions, liquid-cooled housing

70 (2.76)

6 (0.24) 10 (0.39)

74 (2.91)

4 x M6 4 x M8

3/8 inch

Ø 48 (1.89)

Direct butt-mounted, maximum 2 (0.08)

≥18 0 (7.0 9)

G396-075-xxx-xxx

G396-110-xxx-xxx

Programmable Multi-Axis Servo Drive Power Supply Unit Operation Manual

D

H1H4H

D

C

D1

S

A2

H2

A

H3

C1

A1

T1

B

Figure 2.10 Dimensional drawing, liquid-cooled housing, example for size 5

20

T

Page 21

E

F

G

2.5 Cooling circuit connection

NOTE:

Connect the liquid cooling feed to the connection marked. The cooling circuit

must be vented prior to commissioning. For more information on liquid

cooling refer to sectionA.4, p.70.

The device holds approximately 0.5litres of cooling fluid. When the connections have

been cut, there may still be residual fluid in the device which may spill out if it is tipped.

We recommend using a non-drip fluid coupling (not supplied) to prevent leakage of

cooling fluid and enable connecting and disconnecting the device while filled with fluid.

The connection set cooling circuit can be ordered separately.

F

Figure 2.11 Mounting distance, liquid-cooled housing, example for size 5

NOTE:

Arrange devices with different drive power in descending order of power

output (e.g. viewed from the left size 4-size 3-size 2-size 1). This minimises the

mutual thermal influence. The Power Supply Unit must always be arranged on

the side of the most powerful servo drive.

When butt-mounting other devices with the multi-axis system, you must make

sure that the devices do not affect one another thermally.

1

2

1) Liquid connec tion with 3/8inch inside thread

2) 90°angle conne ctor with 3/8inch insid e and outside thread

3) Non-drip fluid coupling

4) Non-drip quick-coupler with hose connection

5) PUR (polyurethane) hose with clamp

Items 2 to 5 are not include d in the supply package.

Figure 2.12 Cooling circuit connection

flow return

2

3

4

5

returnflow

moog

ID no.:CA97556-001 Date:03/2015

Mechanical installation

Programmable Multi-Axis Servo Drive Power Supply Unit Operation Manual

21

Page 22

Mechanical installation

1.

2.

moog

ID no.:CA97556-001 Date:03/2015

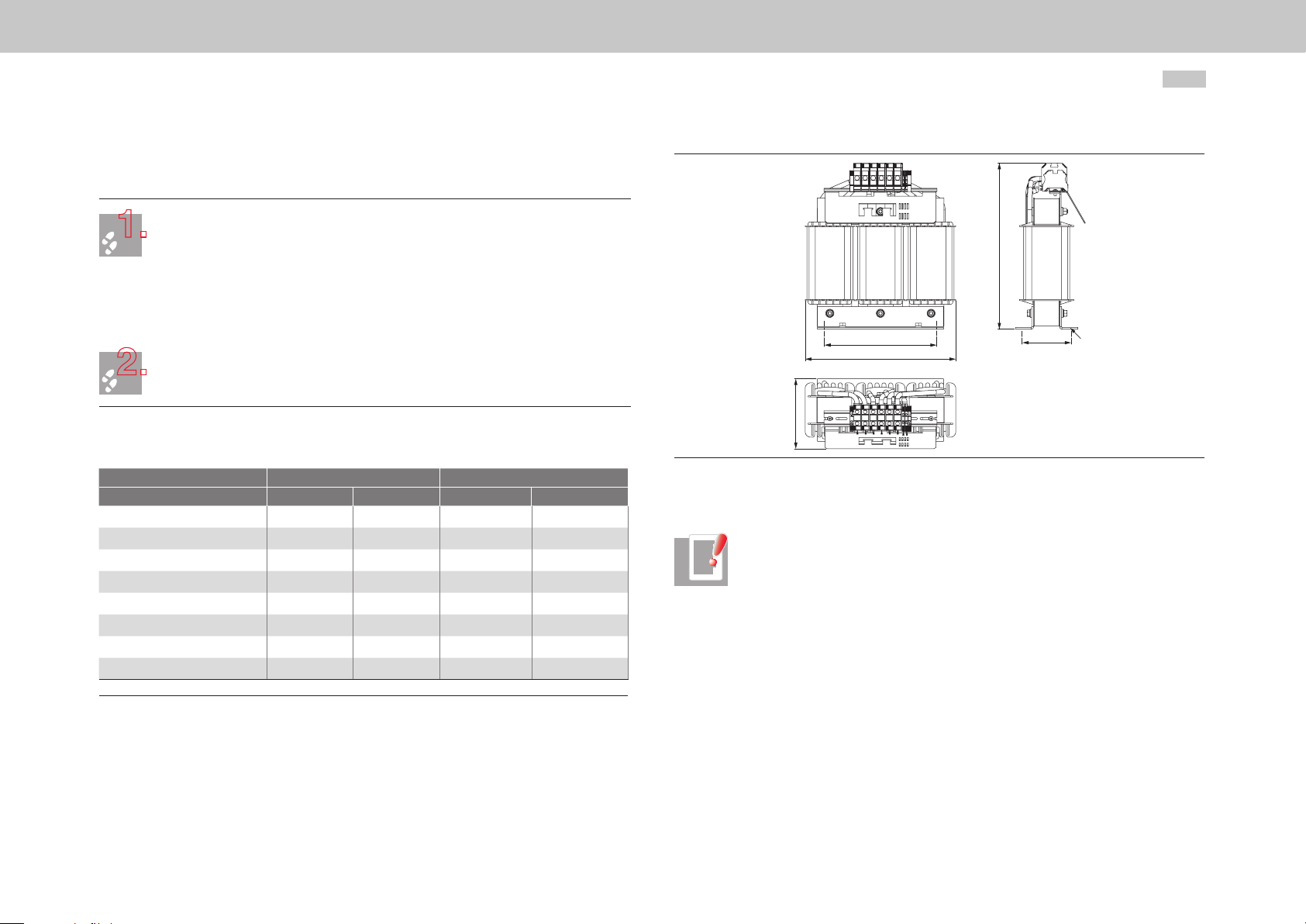

2.6 Step-up choke installation

Arrange the components and cables at a distance of >100 mm (3.94 in) from the step-up choke,

Mount the step-up choke on the mounting rail.

2.6.1 Dimensions

For size Size 5 Size 6A

For model G396-026 G396-050 G396-075 G396-110

B (width)

H (height)

T (depth)

A

A1

D1

Fixing screws

Weight

All dimensions in mm (in) and excluding terminals/connectors

Table 2.3 Step-up choke dimensions

so as to minimise influencing of the adjacent components by magnetic leakage flux and ensure

adequate air circulation for cooling. Position the step-up choke as close as possible to the Power

Supply Unit.

Mark out the position of the tapped holes on the mounting rail.

Cut a tap for each fixing screw in the backing plate.

Take into account the bend radius of the connecting cables.

Dimensional drawings/hole spacing see Figure 2.13 and Tabl e 2.3.

The tapping area will provide you with good, full-area contact. The contact area must be

metallically bright, in order to make a good earth connection to the cabinet earth.

239 (9.41) 29 9 (11.77) 335 (13.19) 380 (14.96)

273 (10.79) 30 0 (11.81) 34 4 (13.54) 3 99 (15.71)

124 (4. 88) 135 (5. 31) 158 (6.22) 200 ( 7. 87)

185 (7.28) 210 (8.27) 248 (9.76) 280 (11. 02)

75 (2.95) 95 (3.74) 122 (4.80) 127 ( 5.0)

10 x Ø 18 (0.71) 12 x Ø 20 (0.79) 12 x Ø 20 (0.79) 12 x Ø 20 (0.79)

4 x M8 4xM10 4xM10 4xM10

16 kg (35.27 lb) 27 kg (59.52 lb) 37.5 kg (82.67 lb) 56 kg (123.46 lb)

Programmable Multi-Axis Servo Drive Power Supply Unit Operation Manual

H

D1

A

B

T

Figure 2.13 Dimensional drawing, step-up choke, example for size 5 and size 6A

NOTE:

The step-up choke is a primary heat source, and should be treated as a

hotspot component. This component is cooled by natural air convection

(gravity circulation). In order to make effective use of this physical effect, this

component should be installed in the lower plinth area of the switch cabinet

on stable mounting rails (permitting unhindered air flow from below). When

selecting the position, air inlet at the filter mat or – better still – at the input

fan zone is advisable.

A1

22

Page 23

2.7 Installation of input choke with membrane

1.

2.

capacitor

Arrange the components so as to ensure sufficient air circulation for cooling. As the membrane

Mount the input choke on the mounting rail.

capacitor has a viscose filling, the input choke must be installed upright with the membrane

capacitor.

Mark out the position of the tapped holes on the mounting rail.

Cut a tap for each fixing screw in the backing plate.

Take into account the bend radius of the connecting cables.

Dimensional drawings/hole spacing see Figure 2.14 and Tabl e 2 .4 .

The tapping area will provide you with good, full-area contact. The contact area must be

metallically bright, in order to make a good earth connection to the cabinet earth.

2.7.1 Dimensions

For size Size 5 Size 6A

For model G396-026 G396-050 G396-075 G39 6 -110

B (width)

H (height)

T (depth)

A

A1

D1

Fixing screws

Weight

All dimensions in mm (in) and excluding terminals/connectors

28 9 (11. 3 8) 289 (11.38) 342 (13.47 ) 348 (13.70)

252 (9.92) 268 (10.55) 292 (11.50) 321 (12.6 4)

119 (4 . 8 6 ) 136 (5.35) 175 (6.89 ) 175 (6. 89)

156 ( 6.14) 156 (6.14) 176 (6.93) 176 (6.93)

63 (2.48) 80 (3 .15) 95 (3.74) 95 (3.74)

7 x Ø 13 (0.51) 7 x Ø 13 (0.51) 9 x Ø 13 (0.51) 9 x Ø 13 (0.51)

4 x M6 4 x M6 4 x M8 4 x M8

10.5 kg (23.15 lb) 14 kg (30.86 lb) 20 kg (44.09 lb) 22 kg (48.50 lb)

H

A

B

T

Figure 2.14 Dimensional drawing, input choke, example for size 5

A1

D1

Table 2.4 Input choke dimensions

moog

ID no.:CA97556-001 Date:03/2015

Mechanical installation

Programmable Multi-Axis Servo Drive Power Supply Unit Operation Manual

23

Page 24

Mechanical installation

1.

2.

moog

ID no.:CA97556-001 Date:03/2015

2.8 Mains filter installation

Arrange the components so as to ensure sufficient air circulation and cooling.

Mount the mains filter on the backing plate.

2.8 .1 Dimensions

For size Size 5 Size 6A

For model G396-026 G396-050 G396-075 G 396-110

Type

B (width)

H (height)

T (depth)

A

C

G Ø

Mounting screws

Weight

All dimensions in mm (in) and excluding terminals/connectors

Mark out the position of the tapped holes on the backing plate.

Cut a tap for each fixing screw in the backing plate.

Take into account the bend radius of the connecting cables.

Dimensional drawings/hole spacing see Figure 2.15 and Table 2.5.

The tapping area will provide you with good, full-area contact. The contact area must be

metallically bright.

FFU 3 x 56 K FFU 3 x 80 K FFU 3 x 130 K FFU 3 x 180 K

85 (3.35) 8 0 (3.15) 90 (3.54) 130 (5.12)

250 (9.84) 270 (10.63) 270 (10.63) 380 (14.96)

90 (3.54) 135 (5.31) 150 (5.91) 180 (7. 0 9)

60 (2.36) 60 (2.36) 65 (2.56) 102 (4.02)

235 (9.25) 225 (8.86) 255 (10.04) 365 (14.37)

5.4 (0.21) 6.5 (0.26) 6.5 (0.26) 6.5 (0.26)

M5 M6 M6 M6

1.9 kg (4.19 lb) 2.6 kg (5.73 lb) 4.2 kg (9.26 lb) 6.0 kg (13.23 lb)

Programmable Multi-Axis Servo Drive Power Supply Unit Operation Manual

H

C

A

B

Figure 2.15 Dimensional drawing, mains filter, example for size 5 and size 6A

Ø G PE

T

24

Table 2.5 Mains filter dimensions

Page 25

3 Electrical installation

3.1 Before you start

Please be sure to observe the following notices and warnings before and during

electrical installation.

DANGER FROM ELECTRICAL TENSION!

Danger to life! Never wire or disconnect electrical connections while they are

!

live. Always disconnect the power before working on the device. Dangerously

high voltages ≥50V (capacitor charge) may still be present 10minutes after

the power is cut to the size 5 and size 6A. The discharge time depends on

the number of drives connected to the multi-axis system. So check that the

power has been cut! Hazardous voltage may be applied to the device, even if

the device does not show any visual signs or emit any audible signals. On the

size 5 and size 6A for example: with mains voltage applied to terminal X12 or

X21 and missing control voltage +24V on X9, X10. So check that no voltage is

connected!

ATTENTION!

Installation must only be carried out by qualified electricians who have

!

undergone instruction in the necessary accident prevention measures.

ATTENTION!

The device heats up in operation and at the heat sink may reach temperatures

!

of up to +100°C (+212°F). The connected chokes heat up in operation and

may reach temperatures of up to +145°C (+293°F). Keep a safe distance from

adjacent assemblies.

ATTENTION!

During installation, please avoid:

!

y screws or cable residues dropping into the device;

y penetration of damp into the device.

NOTE:

For installation of the Power Supply Unit within a Multi-Axis Servo Drive

System, be sure also to observe the Operation Manual for the Multi-Axis Servo

Drives.

3.2 Effective EMC installation

3.2.1 Cable type

y Use shielded mains power, motor and signal cables as set out in Figure 3.7,

p.30. Use a cable type with double copper braiding, with 60 - 70%

coverage, for all shielded connections.

y If very large cable cross-sections have to be installed, shielded single wires may

also be used instead of shielded cables.

ATTENTION!

Use only the supplied DC link cable for the electrical connections between the

!

devices. If other cables are used, Moog can provide no guarantee of stable

and safe operation.

moog

ID no.:CA97556-001 Date:03/2015

Electrical installation

Programmable Multi-Axis Servo Drive Power Supply Unit Operation Manual

25

Page 26

Electrical installation

moog

ID no.:CA97556-001 Date:03/2015

3.2.2 Cable laying

Pay attention to the following points when laying cables:

y Lay mains, motor and signal cables isolated from each other. Observe a

minimum clearance of 200mm (7.87in).

y When installing close, use isolating plates mounted directly and conductively on

the backing plate as shielding.

y Lay the conductors tight to the earth potential. When using plastic cable ducts,

they must be mounted directly on the backing plates or the frame. Cables must

not be spanned over free space, otherwise they might act as antennas.

y Avoid unnecessary cable lengths and “spare loops”.

y Lay long cables at locations not susceptible to interference. Otherwise

additional coupling points may be created.

y Lay motor cables without interruptions (e.g. not via terminals) and by the

shortest route out of the cabinet.

y Twist cables of the same circuit.

y Ideally, lay the signal cables isolated from the encoder cables.

y All signal cables should be grouped together and routed away upwards.

y Avoid extending cables by way of terminals.

y Earth residual wires on at least one side, so as to prevent static.

Programmable Multi-Axis Servo Drive Power Supply Unit Operation Manual

26

3.2.3 Earthing

All earthed points and components must, as far as possible, be routed by low-resistance,

highly conductive means directly to the central earthing point (e.g. PE rail, main earth).

This creates an earthing system which connects all connection locations in a star

configuration to the earthing point. This central earthing point must be unambiguously

defined. This earthing point can be expanded across the entire backing plate with an

EMC connection.

Pay attention to the following points in relation to earthing:

y Earthed surfaces act as shields and reduced electromagnetic fields in the

surrounding area. Consequently, metallic surfaces should be connected to earth

via low-resistance HF connections. In EMC terms, it is not the cross-section of

the cable which is decisive, but the surface on which high-frequency currents

(caused by the skin effect) can discharge.

y Connect the PE conductors of the components in a star configuration inside the

cabinet.

y Avoid plug-in connections.

y Also connect the walls and doors of the cabinet to earth.

y Large openings in the cabinet (windows, fans, display) will impede the shielding

effect of the cabinet and must be protected by additional shielding for the HF

area.

y Earth residual wires on at least one side, so as to prevent static.

y Remove paint and corrosion from contact points and connect them across a

wide area.

y Tin-plated, galvanised, aluminised or cadmium-plated elements should be

preferred to painted components. This will also avoid having to scratch off

varnish layers. Avoid plug-in connections, or use multiple contacts for the shield

connection in the connector. The Power Supply Units have a rear panel made of

aluminised and galvanised sheet steel.

y For more information on the PE conductor cross-section see Table 3.2, p.33.

Page 27

3.2.4 Shielding

Shielding should take account of the following points:

y Use shielded mains power, motor and signal cables as set out in Figure 3.7,

p.30. Use a cable type with double copper braiding, with 60 - 70%

coverage, for all shielded connections.

y Apply the shield on both sides, across a wide area. Extending the shield to the

earthing point by a wire (pigtail) will reduce the shielding effect by as much as

90%.

Figure 3.1 Shield connection CORRECT

Figure 3.2 Shield connection INCORRECT - do not use an extension wire to the earthing point

(pigtail)

Figure 3.3 Power Supply Unit shield connection

y Do not strip the shield too early.

y Shields must not be used for current carrying, such as replacing the N or PE

conductor.

y The shielding effect can be improved by laying in metal ducts/pipes.

y If very large cable cross-sections have to be installed, shielded single wires may

also be laid instead of shielded cables.

y Shields must be applied on at least one side. Multi-layer application is

recommended, otherwise equipotential bonding currents may flow through

widespread systems. If long earth connections are subject to interference, they

can be made by way of coupling capacitors. This enables a high-frequency

connection to discharge interference, without transmitting the 50Hz

component.

y The choke bases must have good contact with the cabinet earth. The contact

area must be metallically bright, in order to make a good earth connection to

the cabinet earth.

moog

ID no.:CA97556-001 Date:03/2015

Electrical installation

Programmable Multi-Axis Servo Drive Power Supply Unit Operation Manual

27

Page 28

Electrical installation

X12

moog

ID no.:CA97556-001 Date:03/2015

3.3 Overview of connections

The following shows the layout with the corresponding positions of connectors and

terminals. To aid orientation, the connectors and terminals are labelled by abbreviations.

3.3.1 Layout, size 5 (G396-026 and G396-050)

X11

PE

X21

X9/X10

D1/D2

T1/T2

X1

X2

X3

X4

SW

HW

X5

Option 1

Programmable Multi-Axis Servo Drive Power Supply Unit Operation Manual

3.3.2 Layout, size 6A (G396-075 and G396-110)

SW

HW

PE

X21

X11

X9/X10

D1/D2

T1/T2

X1

X2

X3

X4

X5

Option 1

28

Figure 3.4 Layout, size 5

X12

Figure 3.5 Layout, size 6A

Page 29

USB 1. 1

MMC-Slo t

ISD00

ISD01

ISD02

OSD02

Relai s

ENPOENPO

Control

Ser vice

interface

Ser vice

interface

ISDSH

ISA00+

ISA00ISA01+

ISA01-

+24V( U

H

)

3

4

5

6

10

15

16

17

9

23

24

22

RSH

12

11

1

2

14

13

ZK

�

ZK+

L3

L2

L1

ISD03

ISD04

ISD05

18

19

20

ISD0621

OSD01

8

OSD00

7

OSD04

DGND

DGND

X

12

X

4

X

10

X

9

X

2

D

1

,

D

2

T

1

,

T

2

X

1

Ether net

X

3

+

�

X

21

L2

L3

N

L1

HREL

MMC

MultiMediaCar d

INSER T

–

+

–

+

1

2

1

2

Mains contactor

X

11

DC link cables

(Size 6A protected)

24 V DC supply for

control electronics (U

V

)

DC link

Top

Bottom

Front

Option 1

Communication

fieldbuses

KTY temp. sensor

of step-up choke

X

5

RB

�

RB+

Braking resistor

Power connection

Mains synchronisation

and precharge

3.3.3 Overview of connections, size 5 and size 6A

Figure 3.6 Overview of connections, size 5 and size 6A

moog

Electrical installation

ID no.:CA97556-001 Date:03/2015

No. Designation Function Page

D1, D2

T1, T2

Option 1

X10, X 9

7-segment display Device status display p.64

Pushbuttons Service functions p.59

Communications

Slot for MMC removable

X1

storage device

USB 1.1 port Service interface, Plug & Play connection to PC p.47

X2

Ethernet port Service interface, fast TCP/IP port (RJ45) p.47

X3

Control connections

X4

Temperature monitor

X5

connection

Optional module for fieldbusses, e.g. SERCOS,

PROFIBUS-DP, EtherCAT or CANopen

Enables firmware download without PC for example p.63

8 digital inputs, 3 digital outputs, 1 additional relay

output

KTY temperature sensor of step-up choke p.48

Connection of control supply UVSupply voltage for control electronics of servo drive,

24 V DC

X11

DC power supply

Connection of DC power supply (size 6A protected),

PE connection

AC power connection (supply and mains feedback),

X12

Power connection

PE connection with shield, braking resistor,

(DC power supply connection, Power Supply Unit

size 6A to Multi-Axis Servo Drive size 6A)

X21

SW, HW

Connection of mains

synchronisation/DC link

precharge; auxiliary relay

Rating plates Software and Hardware rating plates p.4

Mains synchronisation, DC link precharge, mains

connection after precharge

Shield connection to earth Possible via shield (optional) -

Table 3.1 Key to overview of connections, size 5 and size 6A

Programmable Multi-Axis Servo Drive Power Supply Unit Operation Manual

p.47

p.44

p.36

p.40

p.41

p.38

p.38

p.47

p.43

p.37

29

Page 30

Electrical installation

moog

ID no.:CA97556-001 Date:03/2015

3.3.4 Connection diagram, size 5

8 9 10

L1

L1.1

L2

L2.1

L3

L3.1

L2

L1

6

L2.1

L1.1

5

L2

L1

4

L2.1

L1.1

3

2

1

L3

L3.1

L3

L3.1

Programmable Multi-Axis Servo Drive Power Supply Unit Operation Manual

30

Key

L1.1

L1

L2.1

L2

L3.1

L3

7

11

24 V DC

PE

12

13

maximum 8 A

14

nc

EtherCAT

+ �

X11X11

Multi-Axis

Servo Drive

X9/10X9/10

X12X12

UVW

HREL

15

X5

L1 L2

L3 N

X21

Power Supply Unit

16 19 19

X12

L1 L2

+ �

X11

L3

�+ �+

X9/10

ZK RB

+ �� +

+ � �+ �+�+ �+

Multi-Axis

Servo Drive

EtherCAT

UVW

17

1) Mains f uses

2) Mains supply/eme rgenc y stop

3) Shiel d plates (grey)

4) Step-up choke with KTY temperature sensor

5) Above a ca ble length of >500 mm (19.69 in)

shielded cables should be used

6) Input choke with membrane cap acitor

7) Mains contactor (af ter precharge by HR EL)

8) Mains fi lter

9) Short-circuit-proof cables

10) Circuit-breaker

11) Multi-axis sy stem On/Off

12) External 24 V DC control supply

13) Auxiliary contactor (precharge/synchronisation)

14) Connection of DC link pr echarge and mains

synchronisation

15) Floating contact:250 V AC/5 A or 30 V DC/6 A

(active wh en precharge complete)

16) Power Supply Unit size 5

17) AC power co nnecti on

18) Brakin g resistor w ith tempe rature sens or

19) Multi-Axis Servo Drive

20) Cabinet

21) Field

L1 L2 L3 PE

Figure 3.7 Power Supply Unit connection diagram (schematic view)

20

�

18

Motor

3~

Motor

3~

Page 31

NOTE:

Risk of Power Supply Unit destruction by incorrect wiring. Figure 3.7 shows

!

only a schematic view of the connection layout. The positions of the terminals

may vary according to device.

NOTE:

You will find a selection of potential mains contactors, circuit-breakers and

fuses in sectionA, p.66.

moog

ID no.:CA97556-001 Date:03/2015

Electrical installation

Programmable Multi-Axis Servo Drive Power Supply Unit Operation Manual

31

Page 32

Electrical installation

moog

ID no.:CA97556-001 Date:03/2015

3.3.5 Connection diagram, size 6A

8 9 10

L1

L1.1

L2

L2.1

L3

L3.1

L3

L2

L1

6

L3.1

L2.1

L1.1

5

L3

L2

L1

4

L3.1

L2.1

L1.1

3

2

1

Programmable Multi-Axis Servo Drive Power Supply Unit Operation Manual

32

Key

L1.1

L1

L2.1

L2

L3.1

L3

7

11

24 V DC

12

13

maximum 8 A

14

nc

HREL

15

X5

L1 L2

L3 N

X21

Power Supply Unit

16 19 19

X12

L1 L2

+ �

X11

L3

�+ �+

X9/10

ZK RB

+ �� +

+ �

X11

Multi-Axis

Servo Drive

EtherCAT

UVW

EtherCAT

+ �

X11

Multi-Axis

Servo Drive

�+ �+�+ �+

X9/10X9/10

X12X12

UVW

17

1) Mains f uses

2) Mains supply/eme rgenc y stop

3) Shiel d plates (grey)

4) Step-up choke with KTY temperature sensor

5) Above a ca ble length of >500 mm (19.69 in)

PE

shielded cables should be used

6) Input choke with membrane cap acitor

7) Mains contactor (af ter precharge by HR EL)

8) Mains fi lter

9) Short-circuit-proof cables

10) Circuit-breaker

11) Multi-axis sy stem On/Off

12) External 24 V DC control supply

13) Auxiliary contactor (precharge/synchronisation)

14) Connection of DC link pr echarge and mains

synchronisation

15) Floating contact:250 V AC/5 A or 30 V DC/6 A

(active wh en precharge complete)

16) Power Supply Unit size 6A

17) AC power co nnecti on

18) Brakin g resistor w ith tempe rature sens or

19) Multi-Axis Servo Drive

20) Cabinet

21) Field

L1 L2 L3 PE

Figure 3.8 Power Supply Unit connection diagram (schematic view)

20

21

�

18

Motor

3~

Motor

3~

Page 33

NOTE:

1.

2.

Risk of Power Supply Unit destruction by incorrect wiring. Figure 3.8 shows

!

only a schematic view of the connection layout. The positions of the terminals

may vary according to device.

NOTE:

You will find a selection of potential mains contactors, circuit-breakers and

fuses in sectionA, p.66.

3.4 Connection of PE conductors

The PE conductor cross-section depends on the cross-section of the outer conductor,

and is defined as follows in IEC/EN61800-5-1. The leakage current is > 3.5 mA. Use PE

conductors with a cross-sectional area of ≥10mm2 (0.02in2) (Cu).

Cross-sectional area of outer conductors

[mm2 (in2)]

Q ≤ 16 (0.03) Q

16 (0.03) < Q ≤ 35 (0.05) 16 (0.03)

35 (0.05) < Q Q/2

Table 3.2 PE conductor cross-section

3.4 .1 PE conductor (X11)Power Supply Unit size 5

Minimum cross-sectional area

of corresponding PE conductor [mm2 (in2)]

moog

ID no.:CA97556-001 Date:03/2015

Earth each Power Supply Unit and Multi-Axis Servo Drive!

Connect the PE terminal X11/PE of the Power Supply Unit to the PE terminals X11/PE of the butt-

Connect the PE terminal X11/PE of the Power Supply Unit directly to the PE rail (main earth) in

the cabinet.

Select the PE conductor cross-section as per Table 3.2.

Use a suitable PE conductor for the purpose (screw M5). Also comply with local and national

regulations and conditions.

mounted Multi-Axis Servo Drives in series.

Use the ready made-up PE conductors.

Programmable Multi-Axis Servo Drive Power Supply Unit Operation Manual

33

Electrical installation

Page 34

Electrical installation

1.

2.

X12

PE

PE

X11

PE

X11

PE

X11

PE

X11

PE

X11

Multi-Axis Servo Drive size 4

Multi-Axis Servo Drive size 3

Multi-Axis Servo Drive size 2

Multi-Axis Servo Drive size 1

Power Supply Unit

size 5

moog

Figure 3.9 Schematic: Connection of the PE conductor

ID no.:CA97556-001 Date:03/2015

Programmable Multi-Axis Servo Drive Power Supply Unit Operation Manual

3.4.2 PE conductor (X11)Power Supply Unit size 6A

Earth each size 6A supply unit and each size 6A Multi-Axis Servo Drive separately.

Connect the PE terminal X11/PE of the Power Supply Unit directly to the PE rail (main earth) in

the cabinet.

Use a suitable PE conductor for the purpose (screw M8). Also comply with local and national

regulations and conditions.

Select the PE conductor cross-section as per Table 3.2, p.33.

Earth all other Multi-Axis Servo Drives size 5 to size 1 via a common PE conductor! Connect all

other PE terminals X11/PE of the butt-mounted Multi-Axis Servo Drives in series.

Connect the PE terminal X11/PE of the first butt-mounted Multi-Axis Servo Drive to the PE rail

(main earth) in the cabinet.

Use a suitable PE conductor for the purpose. Also comply with local and national regulations and

conditions.

Use the ready made-up PE conductors.

34

Figure 3.10 Detail: Connection of the PE conductor

Page 35

3.4.3 PE conductor components

1.

X12

PE

PE

X11

PE

X11

PE

X11

PE

X11

PE

X11

PE

X11

Multi-Axis Servo Drive size 5

Multi-Axis Servo Drive size 4

Multi-Axis Servo Drive size 3

Multi-Axis Servo Drive size 2

Multi-Axis Servo Drive size 1

Power Supply Unit

size 6A

Figure 3.11 Schematic: Connection of the PE conductor

Connect the PE terminals of all other components, such as mains filters etc., in star configu-

ration to the PE rail (main earth) in the cabinet. See Figure 3.7, p.30.

Also comply with local and national regulations and conditions.

WARNING!

The chokes have no PE connection. They are intended solely for installation in

a cabinet, as with IP00 protection they offer no protection against direct or

indirect touch contact.

3.5 Electrical isolation method

The control electronics, with its logic (µP), the inputs and outputs, are electrically

isolated from the power section (mains supply/DC link). All control terminals are

designed as safety extra-low voltage/protective extra-low voltage (SELV/PELV) circuits

and must only be operated with voltages from 5 V to 50 V, as per the relevant

specification. This provides reliable protection against electric shock on the control side.

The control electronics therefore need a separate control supply, compliant with the

requirements of a SELV/PELV.

The opposite overview shows the potential supplies for the individual terminals in detail.

This concept also delivers higher operational safety and reliability of the Power Supply

Unit.

SELV = Safety Extra Low Voltage

Figure 3.12 Detail: Connection of the PE conductor

moog

ID no.:CA97556-001 Date:03/2015

Electrical installation

PELV = Protective Extra Low Voltage

Programmable Multi-Axis Servo Drive Power Supply Unit Operation Manual

35

Page 36

Electrical installation

V

moog

USB1.1

X2

X4/15

ISD00

ISD01

ISD02

ISD03

ISD04

ISD05

X4/21

ISD06

X4/10

ENPO

X4/22

ISDSH

X4/14

F1

X4/7

ϑ

F2

ϑ

F3

ϑ

F4

ϑ

DGND

DGND

OSD00

U

X4/2

H

X4/13

X4/1

ID no.:CA97556-001 Date:03/2015

µP

GNDµP

I

LIM

DGND

I

LIM

DGND

I

LIM

DGND

I

LIM

DGND

µP

PE

V

µP

GNDµP

GNDµP

36

Ethernet

X3

Programmable Multi-Axis Servo Drive Power Supply Unit Operation Manual

3.6 Connection of supply voltages

The power supply for the Power Supply Unit is separated into the supplies for

control and power sections. The control supply must always be connected first, so

Mains synchronisation

X21

that activation of the Power Supply Unit can first be checked and the device can be

parameterised for the planned application.

3.6 .1 Control supply 24VDC (X9, X10) for size 5 and size 6A

X5/ϑ +

KTY temp. sensor

of step-up choke

X5/ϑ −

X4/3

X4/4

X4/5

X4/6

ISA00+

ISA00-

ISA01+

ISA01-

X9/+

X9/-

X10/+

X10/-

U

U

V

Supply for

control electronics

24 V DC

V

maxiumum 10 A

L1 L2

HREL

L3 N − +− +

X21X9/10

Figure 3.14 Connection of control supply

WARNING!

Hazardous voltage may be applied to the device, even if the device does not

A/D

GNDµP

A/D

GNDµP

V

µP

show any visual signs or emit any audible signals (e.g. with mains voltage

applied to terminal X12) and missing control voltage (+24V on X9, X10)!

+ −

X11

24 V DC

+ −+ − − +− +− +− +

X11X11

X9/10X9/10

DGND

DGND

DGND

PE GNDµP

Complex, in

DGND RC element Polyswitch

part nonlinear,

impedance

OSD01

OSD02

X4/8

X4/9

Figure 3.13 Electrical isolation method, size 5 and size 6A

ATTENTION!

Take suitable measures to provide adequate cable protection (e.g. fusing

!

X4/12

RSH

X4/11

GNDµP

F3

GNDµP

ϑ

X4/23

X4/24

OSD04

10AgG). If the permissible current capacity is exceeded, an additional

separate control supply must be connected.

NOTE:

The external control supply also supplies the digital inputs and outputs as well

as the control section (I

CONTROLSECTION

+ I