Page 1

moog

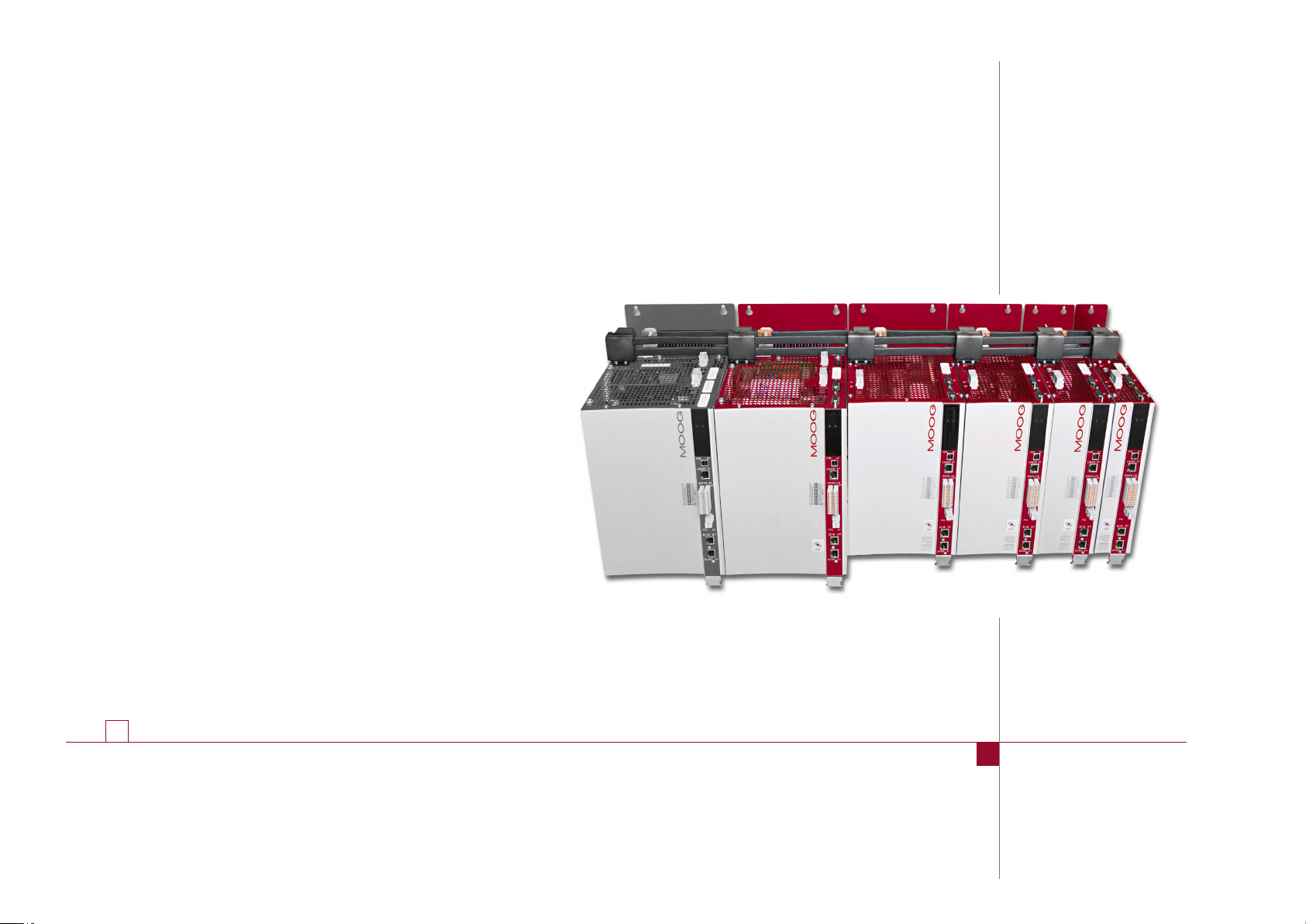

MSD Servo Drive

Operation Manual

DC-AC Servo Drive

Multi-Axis System with sinusiodal regeneration

Page 2

moog

Id. no.: CA97554-001 05/2017

MSD Multi-Axis System Operation Manual DC-AC Servo Drive

MSD Servo drive energy-efficient multi-axis syste

Comprising DC-powered DC-AC Servo Drives and coordinated Power Supply Units

with sinusoidal regenerative power supply, the multi-axis system offers a high degree

of solutions expertise and flexibilit . Reduction of the wiring and shortening of the

installation times are just as easy to achieve as resource-saving, cost-conscious

operation.

2

MSD Servo Drive Operation Manual

Multi-Axis System DC-AC Servo Drive

ID no.: CA97554-001

Date: 06/2017, Rev. 2.1

Applicable as from rmware version: V2.20-01

The German version is the original of this operation manual.

Subject to technical change without notice.

The content of our documentation was complied with the greatest care and attention,

and is based on the latest information available to us.

We should nevertheless point out that this document cannot always be updated

simultaneously with the ongoing technical development of our products.

Information and specifications may be subject to change at any time. Please obtain

information on the latest version at drives-support@moog.com.

Page 3

Table of contents

1 General ..........................................................................................7

1.1 Target group ...............................................................................................................7

1.2 Prerequisites ................................................................................................................7

1.3 Reference documents ..................................................................................................7

1.4 Order code .................................................................................................................. 8

1.5 Data on manufacture ..................................................................................................9

1.6 Scope of supply ...........................................................................................................9

1.7 Pic tog ra ms .................................................................................................................. 9

1.8 Disclaimer ...................................................................................................................9

1.9 Disposal .....................................................................................................................9

1.10 Helpline/Support & Service ........................................................................................10

2 Safety ........................................................................................... 11

2.1 Overview ................................................................................................................... 11

2.2 Measures for your safety ........................................................................................... 11

2.3 General safety instructions and warnings .................................................................. 12

2.4 Intended use ............................................................................................................. 12

2.4.1 Repair ........................................................................................................13

2.5 Misuse ...................................................................................................................... 13

2.6 Responsibility ............................................................................................................ 13

2.7 Relevant laws, standards and directives applied ........................................................ 13

2.8 Declaration of conformity .........................................................................................14

2.8.1

MSD Servo Drive DC-AC Size 1 to 7..........................

..................................14

3 Mechanical installation.................................................................. 15

3.1 Notes for mechanical installation............................................................................... 15

3.2 Switch cabinet layout ................................................................................................ 16

3.2.1 Example: .................................................................................................... 17

3.3 Wall mounting (air cooling).........................................................................................18

3.4 Alignment and arrangement in the group ................................................................. 19

3.4.1 Alignment in the group .............................................................................. 19

3.4.2 Arrangement in the group ......................................................................... 20

3.5 Mounting DC-AC Servo Drive air cooling housing variant .......................................... 21

3.5.1 Dimensions and mounting clearances ........................................................22

3.6 Mounting DC-AC Servo Drive liquid cooling housing variant ..................................... 23

3.6.1 Dimensions and mounting clearances ........................................................23

3.7 Cooling circuit connection.........................................................................................26

4 Electrical installation ..................................................................... 27

4.1 Notes for installation ................................................................................................. 27

4.2 Effective EMC installation..........................................................................................28

4.2.1 Cable type ................................................................................................. 28

4.2.2 Routing of cables .......................................................................................28

4.2.3 Earthing measures ..................................................................................... 28

4.2.4 Shielding measures .................................................................................... 29

4.2.5 External components .................................................................................30

4.3 Overview of the connections .....................................................................................30

4.3.1 Layout, G393-004 (Size 1) to G393-032/G397-035 (Size 4) .......................30

4.3.2 Layout, G393-045/G397-053 (Size 5) to G393-170/G397-210 (Size 6A) .....32

4.3.3 Layout, G397-250 to G397-450 (Size 7) .....................................................34

4.4 Protective earth conductor connection......................................................................36

4.5 Electrical isolation concept ........................................................................................36

moog

Id. no.: CA97554-001 05/2017

Table of contents

MSD Multi-A xis System Operation Manual DC-AC Ser vo Drive

3

Page 4

Table of contents

moog

4.6 Connection of control supply (+24VDC) ..................................................................38

4.6.1 G393-004 (Size 1) to G393-170/G397-210 (Size 6A) ..................................39

4.6.2 G397-250.1 to G397-450 (Size 7) ..............................................................39

4.7 Connection of DC power supply ...............................................................................40

4.8 Control connections ..................................................................................................42

4.8.1 Specification of the control connections ....................................................42

4.8.2 Brake driver ................................................................................................44

4.9 Specification, USB interface ....................................................................................... 45

4.10 Specification, Ethernet interface ................................................................................45

4.11 Option1 ...................................................................................................................45

4.12 Option2 ...................................................................................................................45

4.13 Encoder connection ..................................................................................................46

4.13.1 Encoder connection for synchonous motors ..............................................46

4.13.2 Allocation of motor/encoder cable to the DC-AC Servo Drive .....................46

4.13.3 Ready made encoder cables .......................................................................46

4.13.4 Resolver connection ...................................................................................47

4.13.5 Connection for high-resolution encoders ...................................................48

4.14 Motor connection .....................................................................................................49

4.14.1 Motor connection for synchronous motors ................................................49

4.14.2 Switching in the motor cable .....................................................................52

Id. no.: CA97554-001 05/2017

5 Commissioning ............................................................................. 53

5.1 Notes for commissioning ...........................................................................................53

5.2 Initial commissioning ................................................................................................. 53

5.2.1 Switching on control supply .......................................................................54

5.2.2 Connection between PC and DC-AC Servo Drive ....................................... 54

5.2.3 Configuring parameters .............................................................................54

5.2.4 Controlling drive using Moog Dr iveA Dmini strAtor5 ..................................... 55

5.3 Serial commissioning ................................................................................................. 56

MSD Multi-A xis System Operation Manual DC-AC Ser vo Drive

5.4 Integrated control unit ..............................................................................................57

5.4.1 Function of buttons T1 and T2 ...................................................................58

5.4.2 Display ....................................................................................................... 58

5.4.3 Parameter menu (PA) .................................................................................59

5.4.4 Ethernet IP address menu (IP) ..................................................................... 59

5.4.5 Field bus address menu (Fb) .......................................................................60

4

6 Diagnostics ................................................................................... 63

6.1 Status indication on the device .................................................................................. 63

6.1.1 Device states ..............................................................................................63

6.1.2 Error indication ..........................................................................................63

6.2 Status and error indication in MoogD rive ADmin istr Ator5 ...........................................64

7 Safe Torque Off (STO) ...................................................................67

8 Operation with AC-AC Servo Drive as supply .................................69

8.1 Arrangement of the devices and components ........................................................... 69

8.1.1 Device protection ....................................................................................... 69

8.2 Switch cabinet arrangement with AC-AC Servo Drive as supply .................................74

9 Planning ....................................................................................... 75

9.1 Overview and comparison of the multi-axis systems.................................................. 75

9.2 Application examples ................................................................................................75

9.3 Operation with a Power Supply Unit .........................................................................76

9.4 Operation with AC-AC Servo Drive as supply.............................................................77

9.5 Functional comparison .............................................................................................. 78

9.6 Cost-effectiveness calculation ...................................................................................78

9.7 Dimensioning ............................................................................................................79

9.7.1 Determining the drive power required per axis ..........................................79

9.7.2 Selection of suitable gearboxes and motors ...............................................80

9.7.3 Selection of suitable DC-AC Servo Drives ...................................................80

Page 5

9.7.4 Selection of suitable Power Supply Unit ..................................................... 80

9.7.5 External components .................................................................................82

9.7.6 Selection of a suitable AC-AC Servo Drive as supply ...................................82

9.7.7 External components .................................................................................84

10 Application example .....................................................................85

10.1 Interlocking Power Supply Unit and DC-AC Servo Drives ........................................... 85

A Technical data ...............................................................................87

A.1 Current carrying capacity, MSD Servo Drives DC-AC .................................................87

A.1.1 G393-004 to G393-032 (air cooling, 400VAC) ........................................87

A.1.2 G393-004 to G393-032 (air cooling, 460VAC) ........................................88

A.1.3 G393-004 to G393-032 (air cooling, 480VAC) ........................................89

A.1.4 G393-004 to G393-032 (air cooling, 770VDC) ........................................90

A.1.5 G393-045 to G393-170 (air cooling) .......................................................... 91

A.1.6 G397-016 to G397-032 (liquid cooling, 400VAC) ....................................92

A.1.7 G397-016 to G397-032 (liquid cooling, 460VAC) ....................................93

A.1.8 G397-016 to G397-032 (liquid cooling, 480VAC) ....................................93

A.1.9 G397-016 to G397-032 (liquid cooling, 770VDC) ....................................94

A.1.10 G397-045 to G397-170 (liquid cooling) ......................................................94

A.1.11 G397-250 to G397-450 (liquid cooling) .....................................................95

A.2 Technical data, MSD Servo Drive DC-AC ....................................................................96

A.2.1 G393-004 to G393- 020 / G397-020 to G397-025 .....................................96

A.2.2 G393-024 to G393-072 / G397-026 to G397-084 ..................................... 96

A.2.3 G393-090 to G393-170 / G397-110 to G397-210 .......................................97

A.2.4 G397-250 to G397-450 .............................................................................97

A.3 Power connections ....................................................................................................98

A.4 Current required for the control supply .....................................................................99

A.5 Pre-assembled DC link connections .........................................................................100

A.5.1 DC coupling, Power Supply Unit and DC-AC Servo Drive ......................... 101

A.5.2 DC coupling, DC-AC Servo Drive and DC-AC Servo Drive ......................... 101

A.5.3 DC coupling, AC-AC Servo Drive and DC-AC Servo Drive ......................... 102

A.6 Ambient conditions .................................................................................................104

A.7 Hydrological data for the liquid cooling ................................................................... 105

A.8 Dynamic temperature monitoring ...........................................................................106

A.9 UL certification (Size 1 to Size 7) .............................................................................10 6

Glossary ............................................................................................. 107

moog

Id. no.: CA97554-001 05/2017

Table of contents

MSD Multi-A xis System Operation Manual DC-AC Ser vo Drive

5

Page 6

Table of contents

moog

Id. no.: CA97554-001 05/2017

MSD Multi-A xis System Operation Manual DC-AC Ser vo Drive

6

Page 7

1 General

1.3 Reference documents

The product DVD from Moog contains the complete documentation for the related

product series. The documentation for a product series includes the Operation Manual

(hardware description), Device Help (software description) as well as further

User

Manuals (e.g. field bus description) and Specifications. They are available in the formats

PDF, HTML or chm.

1.1 Target group

Dear user,

the documentation forms part of the device and contains important information on

operation and service. It is aimed at all persons who undertake mounting, installation,

commissioning and servicing work on the product.

1.2 Prerequisites

Prerequisites for the usage of devices from Moog GmbH:

• The documentation on the devices is to be stored so it legible, accessible at all

times and for the entire life of the product.

• Read and ensure you understand the documentation on your device.

•

Qualification: to p event injury or damage, personnel may only work on the

device if they have electrical engineering qualifications

• Knowledge required:

− National health and safety regulations (e.g. VSize 4 in Germany)

− Mounting, installation, commissioning and operation of the device

Work in other areas, for example transport, storage and disposal is only allowed to be

undertaken by trained personnel.

NOTE

This operation manual only applies to the DC-AC Servo Drive for the

MSD Multi-Axis System (referred to in the following as the DC-AC Servo Drive).

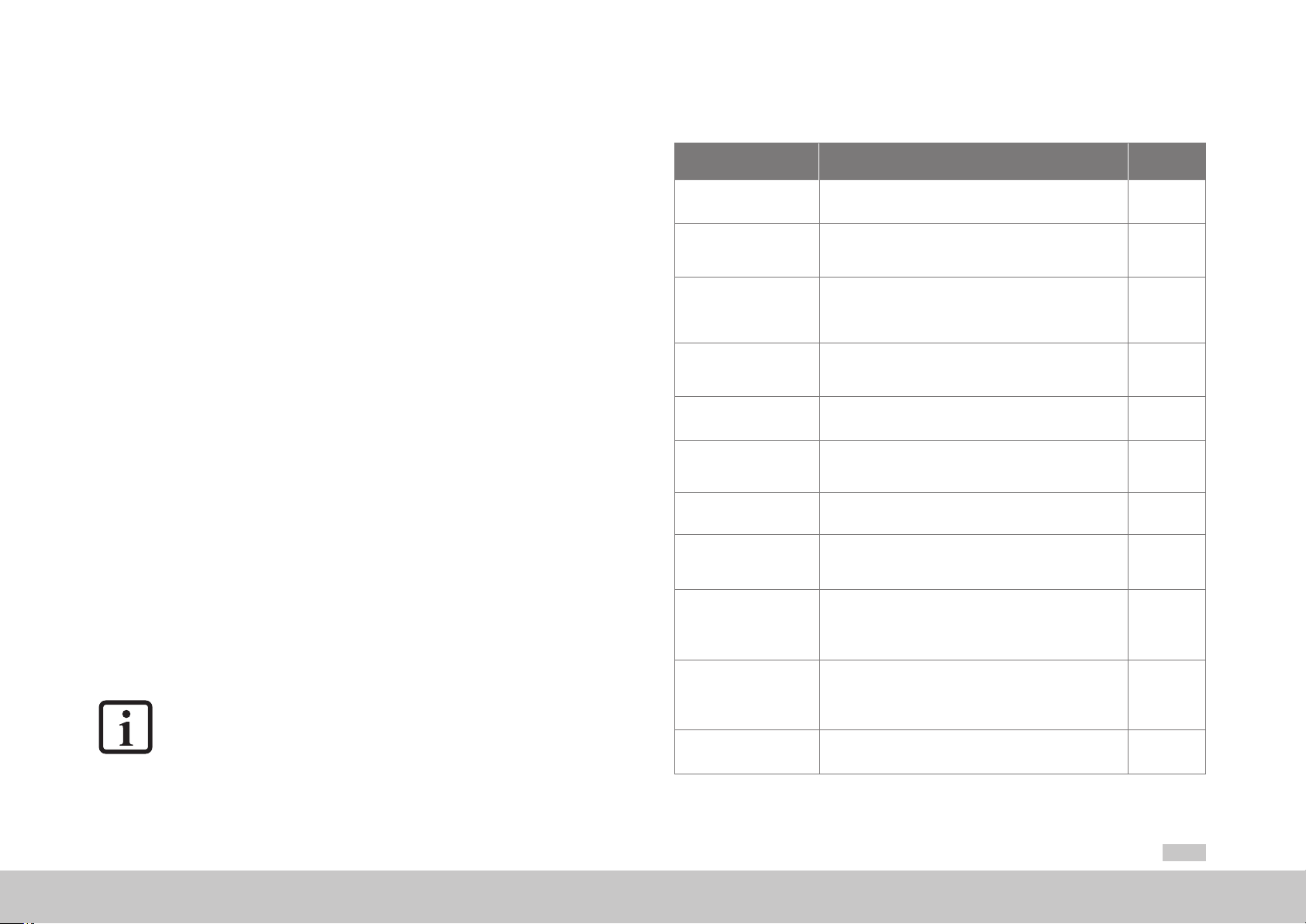

Document Contents

MSD Single-Axis

Servo Drive CompactOperation Manual

MSD Servo Drive

AC-AC Servo Drive

Single-Axis System Operation Manual

MSD Servo Drive

DC-AC Servo Drive

Multi-Axis SystemOperation Manual

MSD Power Supply Unit

Multi-Axis SystemOperation Manual

MSD Servo Drive

Sercos II User Manual

MSD Servo Drive

Sercos III User Manual

MSD Servo Drive Field bus

systems CANopen/EtherCAT User Manual

MSD Servo Drive

Field bus systems

Probus/Pronet

User Manual

Modular Multi-Axis Servo

Drive System - MSD Ordering Catalog

MSD Servo Drive - Device

Help

Program help

DriveADminsitrAtor 5

Moog

PC user software

Safety, mechanical installation, electrical installation,

commissioning, diagnostics, specications, certication and

applicable standards, technical data

Safety, mechanical installation, electrical installation,

commissioning, diagnostics, specications, certication and

applicable standards, technical data

Safety, mechanical installation, electrical installation, commissioning,

diagnostics, STO, operation with AC-AC Servo Drive as supply,

planning, application example, specications, certication and

applicable standards, technical data

Safety, mechanical installation, electrical installation, commissioning,

diagnostics, specication, certication and applicable standards,

technical data

Safety, commissioning, communication phases, parameter interface,

error, warning and status messages, operation modes, weighting,

referencing, touchprobe, parameter lists

Safety, installation and connection, commissioning and conguration,

parameterisation, data transmission, scaling and weighting,

functionality, error message and diagnostics, parameter lists

Safety, commissioning, data transmission, operation modes,

referencing, parameters, technical data

Description and conguration of the parameters for the MSD Servo

Drive on the PROFIBUS/PROFINET eld bus system

Information, notes on ordering, specications and

technical data on:

MSD Single-Axis Servo Drive Compact, MSD Single-Axis System,

MSD Multi-Axis System, safety technology, communication,

technology, function packages, accessories and motors

Description of the software functionality MSD Servo Drive,

rmware versions:

- MSD Single-Axis Servo Drive Compact from V1.30-xx

- MSD Single-Axis System from V3.25-xx

- MSD Multi-Axis System from V3.25-xx

Context-sensitive help for Moog DriveADministrAtor version 5.x

graphic PC user software for initial commissioning and serial

commissioning, operation, diagnostics and project management

ID no.

Format

CA97555-001

PDF

CA65642-001

PDF

CA97554-001

PDF

CA97556-001

PDF

CA65648-001

PDF

CA97557-001

PDF

CA65647-001

CA65645-001

PDF

CDL 29950-en

PDF

CB40859-001

PDF and

HTML

CB19692-001

moog

Id. no.: CA97554-001 05/2017

1 General

MSD Multi-Axis System Operation Manual DC-AC Servo Drive

7

Page 8

1 General

moog

Id. no.: CA97554-001 05/2017

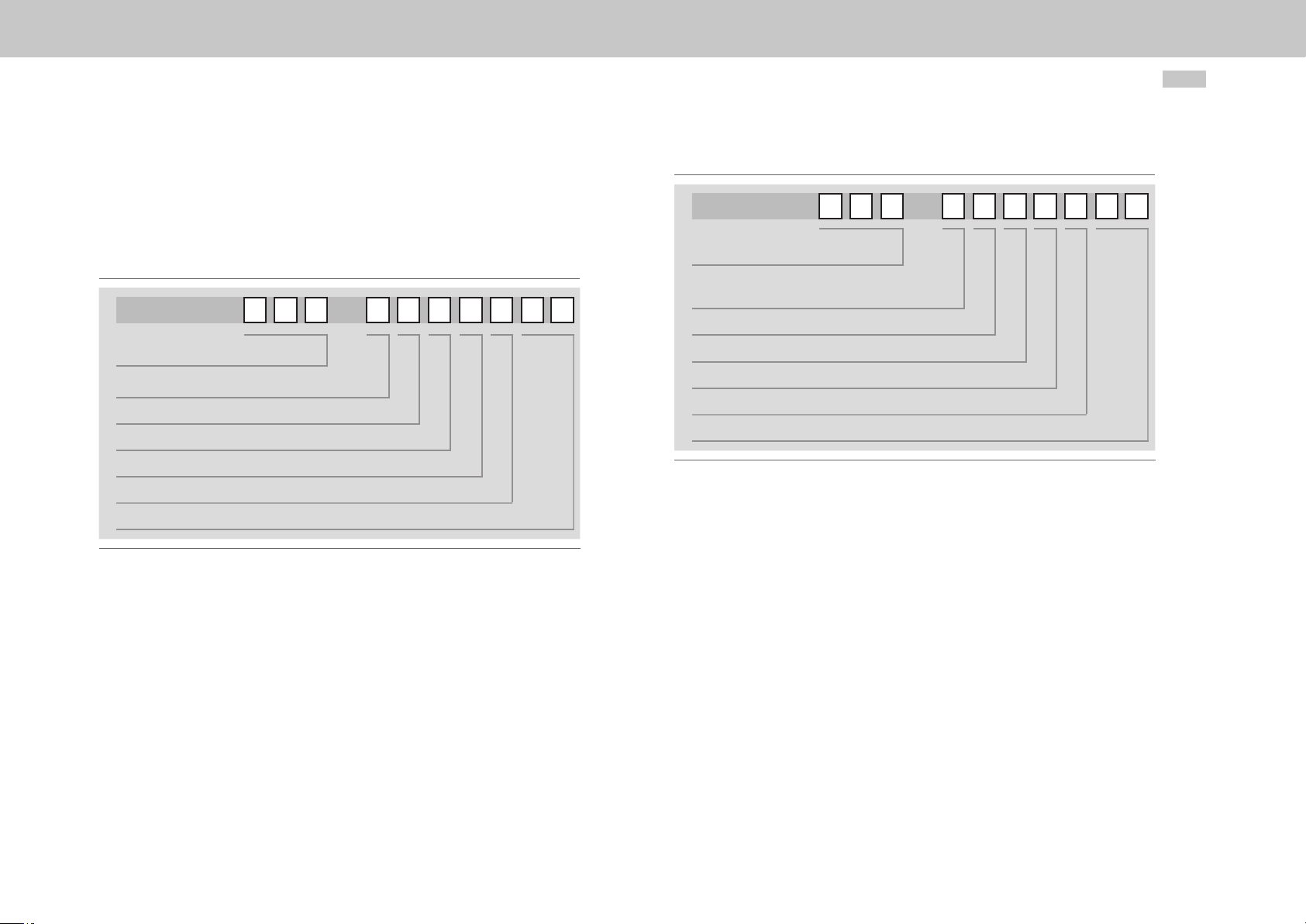

1.4 Order code

The MSDMulti-Axis System has the article designation G393-xxx-xxxxxxx and

G397-xxx-xxxxxxx. This provides information on the related variant of the

MSDServoDrive supplied. The signicance of the individual characters of the article

designation is given in the following order code.

G393 - - -

Rated current

Option 1 (Communication)

Option 2 (Technology)

Option 3 (Safety)

Option 4 (Function package)

Modificatio

Variants

MSD Multi-Axis System Operation Manual DC-AC Servo Drive

G397 - - -

Rated current

Option 1 (Communication)

Option 2 (Technology)

Option 3 (Safety)

Option 4 (Function package)

Modificatio

Variants

Figure 1.2 Order code MSD Servo Drive DC-AC (liquid-cooled)

8

Figure 1.1 Order code MSD Servo Drive DC-AC (air-cooled)

Page 9

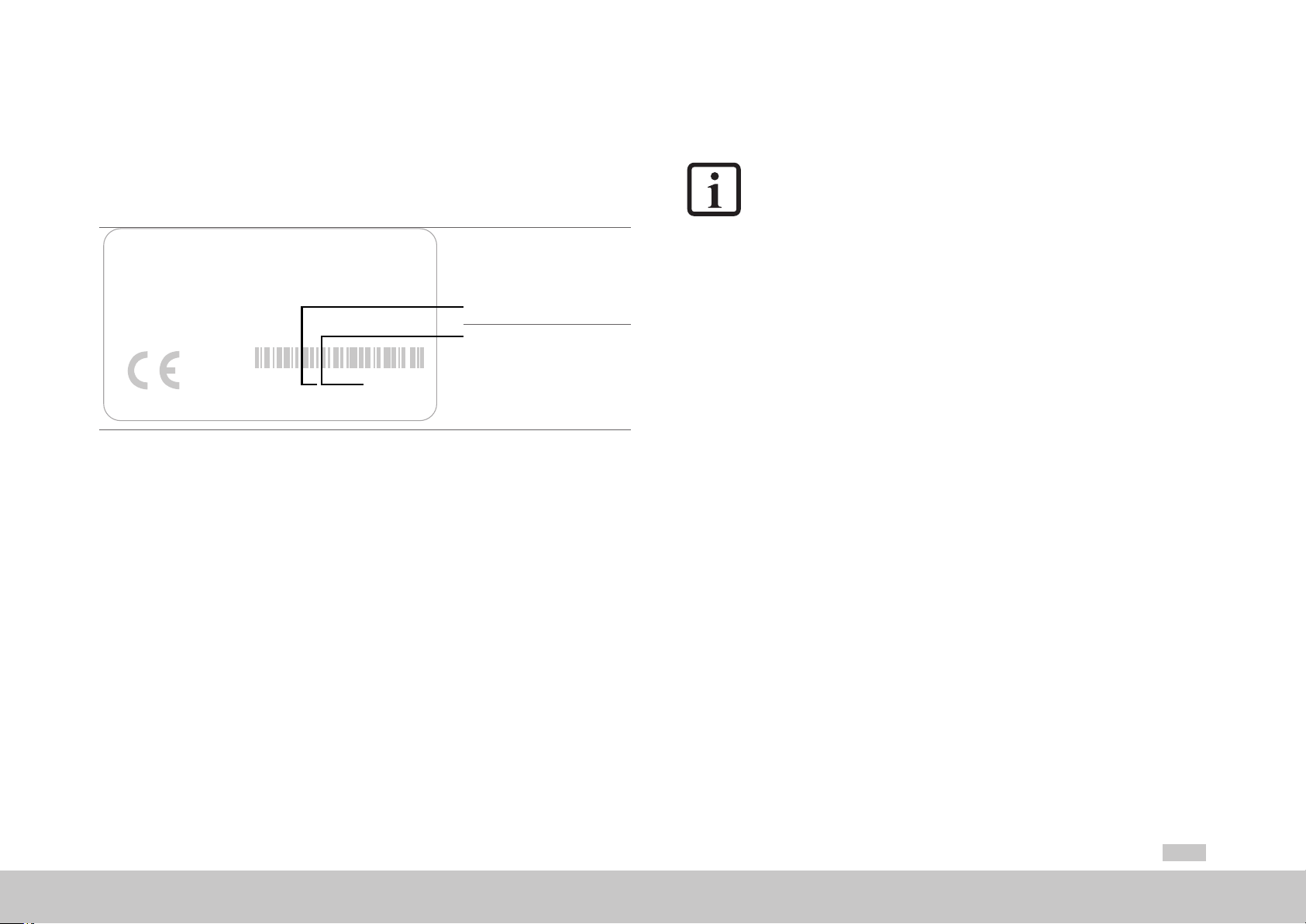

1.5 Data on manufacture

1.7 Pictograms

On rating plates for the servo drives you will find the serial number, from which you can

identify the date of manufacture based on the following key. For the location of the rating

plate on the MSDServoDrive refer to the layouts in chapter4.3, page30

sizes Size 1 to 7.

MOOG

D-71034 Böblingen

www .moog.com/industrial

Made in Germany

Model:: G393-030-000-002

S/N:D116605 Rev. A

In: 230 V AC 3ph, 50/60 Hz

4,0 A

0-230 V AC 3ph, 0-400 Hz

Out:

3,0 A

Year of production

Week of production

for the related

ID : JJWWxxxxx

Figure 1.3 DC-AC Servo Drive hardware rating plate

1.6 Scope of supply

The scope of supply includes:

MSDServoDrive DC-AC

•

Terminal kit for control and power terminals

•

(depending on device power and variant)

•

Set of grommets (on devices with liquid cooling)

• Pre-assembled DC link connections

• Product DVD with booklet

The pictograms used in this operation manual signify the following for the user:

NOTE

Useful information or reference to other documents.

1.

(digit)

You will find the pictograms used in this operation manual for "safety instructions and

warnings" in chapter 2 Safety.

ACTION TO BE TAKEN

Processing step undertaken by the user or the system.

1.8 Disclaimer

Following the documentation on the devices from Moog is a prerequisite:

•

For safe operation.

•

To achieve stated performance features and product characteristics.

Moog does not accept any liability for injuries, damage or financial losses that esult from

the failure to follow the documentation.

1.9 Disposal

Follow the applicable national regulations! If necessary, dispose of individual parts,

depending on their characteristics and existing national regulations, e.g. as:

• Electrical waste

• Plastic

• Metal

Or engage a certified disposal organisation with scrappin

moog

Id. no.: CA97554-001 05/2017

1 General

MSD Multi-Axis System Operation Manual DC-AC Servo Drive

9

Page 10

1 General

moog

Id. no.: CA97554-001 05/2017

1.10 Helpline/Support & Service

Our Helpline will help you with fast, specific assistance if you have any technical queries

relating to project planning or commissioning your device.

Address: Moog GmbH

Hanns-Klemm Straße 28

D-71034 Böblingen

Phone: +497031622-0

Fax: +497031622-100

E-mail: drives.support@moog.com

If you need service assistance, the Moog specialists will be pleased to be of assistance.

Service - Please contact us:

Phone: +497031622-0

E-mail: info.gemany@moog.com

MSD Multi-Axis System Operation Manual DC-AC Servo Drive

10

Page 11

2 Safety

2.1 Overview

Our devices are state-of-the-art and comply with recognised safety regulations,

nevertheless hazards can arise. In this chapter:

• We provide information on residual risks and hazards that can emanate from

our devices on usage as intended.

• We warn about the foreseeable misuse of our devices.

•

We refer to the necessary care and measures to be taken to prevent risks.

2.2 Measures for your safety

NOTE

Only install and place in operation your device taking into account the

documentation for the related device family!

Our devices are quick and safe to operate. For your own safety and for the safe

functioning of your device, please be sure to observe the following points:

3.

4.

5.

Protection against magnetic and/or electromagnetic fields during

installation and operation.

Persons tted with heart pacemakers, metallic implants and hearing aids etc. must not be allowed

access to the following areas:

• Areas in the immediate vicinity of electrical equipment!

• Areas in which electronics components and servo drives are installed, repaired and operated!

• Areas where motors are installed, repaired and operated!

Motors with permanent magnets pose particular hazards.

During installation observe the following:

• Comply with connection conditions and technical data as per the documentation and the rating

plate!

• Comply with standards and directives on electrical installation, such as cable cross-section,

shielding, etc.!

• Do not touch electronic components and contacts!

Electrostatic discharge can harm people and destroy components!

• Take protection measures and use protective devices as per the applicable regulations

(e.g. IEC/EN60204 or IEC/EN61800-5-1)!

• Take "device earthing" protection measure!

Ambient conditions

•

Follow the instructions on the transport, storage and correct operation of the devices stated in

the Operation Manual in "A Appendix".

1.

2.

moog

Follow safety instructions for the devices:

Follow all safety instructions and warnings in the entire documentation related to the device series.

Electric drives are dangerous:

• Due to electrical voltages up to 480V AC and up to 800V DC

• Even 10min. after switching off the mains supply, dangerously high voltages of ≥50V may

still be present (capacitor charge). So check that electrical power is not present! See also the

warning label on the front panel on the device.

• Rotating parts

• Automatically starting drives.

• Hot components and surfaces

Id. no.: CA97554-001 05/2017

2 Safety

MSD Multi-Axis System Operation Manual DC-AC Servo Drive

11

Page 12

2 Safety

moog

Id. no.: CA97554-001 05/2017

2.3 General safety instructions and warnings

Hazards may emanate from our devices. For this reason it is imperative you follow the

safety instructions and warnings in this document.

DANGER! Risk of injury due to electrical power!

• Carelessness will result in serious injuries or death.

Follow safety instructions and warnings in this document and on the device.

WARNING! Risk of injury due to electrical power!

• Carelessness may result in serious injuries or death.

Follow safety instructions and warnings in this document and on the device.

CAUTION! Risk of injury or damage to the device due to incorrect operation!

• Carelessness may result in minor injuries or

damage.

Follow safety instructions and warnings in this document and on the device.

WARNING! Risk of injury due to hot surfaces and components!

• Carelessness may result in serious burns.

Electronic components may become hot during operation!

Follow safety instructions and warnings in this document and on the device!

MSD Multi-Axis System Operation Manual DC-AC Servo Drive

Pay attention to special safety instructions and warnings that are given here in the document before a

specic action and that warn the user about a specic hazard!

NOTE:

The pictograms may also be used on their own with the signal word, e.g.

in the connection diagrams, however they have the same function as in the

complete warning.

DANGER WARNING CAUTION

12

2.4 Intended use

Our devices are components intended for stationary electrical systems and machines in

the industrial and commercial sector.

The devices in the product range MSD Multi-Axis System conform to the

Machinery Directive 2006/42/EC (Size 1 to Size 6A)

Low Voltage Directive 2014/35/EU (Size 7)

Tested and certied according to applicable standards (see declaration of conformity in

chapter 2.8).

Caution! Damage due to electrostatic discharge!

• Electrostatic discharge can destroy components.

Do not touch electronic components and contacts!

Follow safety instructions and warnings in this document and on the device!

DANGER! Risk of injury due to rotating parts on the motor!

• Carelessness will result in serious injuries or death.

Follow safety instructions and warnings in this document.

When installed in machines it is prohibited to start-up intended operation until it has

been ascertained that the completed machine fully complies with the provisions of the

Machinery Directive (2006/42/EC); compliance with IEC/EN60204 is mandatory.

Starting up intended operation is only permitted on compliance with the EMC Directive

2014/30/EU.

The devices fulfil the demands of the harmonised p oduct standard

You will find information on the installation of your device in chapter “3 Mechanical

installation”.

IEC/EN 61800-5-1.

Page 13

2.4.1 Repair

Only have repairs undertaken by authorised repair shops. Unauthorised opening and

incorrect intervention could lead to death, physical injury or material damage. The

warranty provided by Moog will be rendered void.

2.5 Misuse

Our devices are:

• Not intended for installation in vehicles. Deployment of the device in mobile

equipment is classed as non-standard ambient conditions, and is permissible

only by special agreement.

• Not intended for installation in environments with harmful oils, acids, gases,

vapours, dusts, radiation etc.

Not approved for usage in special applications (e.g. in potentially explosive

•

atmospheres or areas in which there is a risk of fire).

• Not approved for usage outside a switch cabinet

• Not approved for the generation of high-frequency onboard networks for which

the device is not designed

2.6 Responsibility

Pay attention to the topic of “Electrical equipment of machines” in EN60204-1:2006

“Safety of machinery”. The safety requirements on electrical machines defined the e are

intended to protect personnel and machinery or systems.

The emergency stop function (as per IEC/EN60204) shuts down the supply of power to

a machine, which results in the drives coasting down in an uncontrolled manner. To avert

hazards, check whether it is appropriate:

− To keep individual drives in operation

− To initiate specific safety p ocedures

− To incorporate a Safe Torque Off function (Safe Torque Off: movement stop

by "switching off the electrical supply" - STO)

2.7 Relevant laws, standards and directives applied

For information on the laws, standards and directives applied by Moog, refer to the

declaration of conformity.

NOTE:

Depending on the specific application for the devices, other laws, standa ds

and directives with provisions on "Safety" may apply. If necessary, contact the

machine or system manufacturer.

Electronic devices are not fail-safe. The installer and/or operator of a complete machine

or system is responsible for ensuring:

• That the drive is rendered safe if the device fails

• The safety of personnel and machinery

• The complete machine is in correct working order

•

For the risk assessment on the complete machine or system according to

EN ISO 12100 (formerly EN ISO 14121) and EN ISO 13849-1 (formerly

DIN EN 954-1)

moog

Id. no.: CA97554-001 05/2017

2 Safety

MSD Multi-Axis System Operation Manual DC-AC Servo Drive

13

Page 14

2 Safety

moog

Id. no.: CA97554-001 05/2017

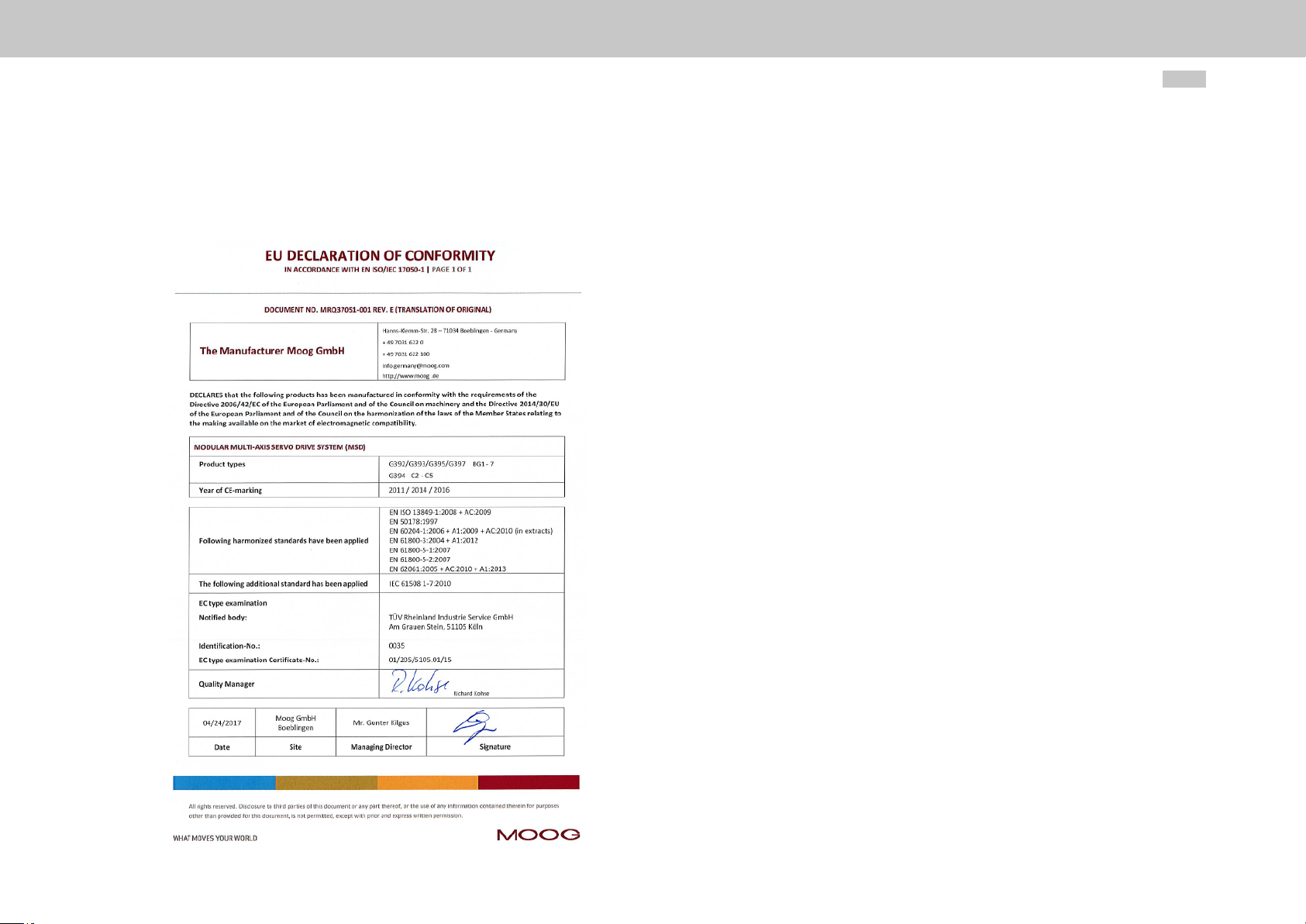

2.8 Declaration of conformity

2.8.1 MSD Servo Drive DC-AC Size 1 to 7

MSD Multi-Axis System Operation Manual DC-AC Servo Drive

14

Page 15

3 Mechanical installation

The device is designed only for installation in a stationary switch cabinet. The switch

cabinet must as a minimum provide IP4x protection. According to ENISO13849-2 the

switch cabinet must have IP54 protection or higher when using the safety function STO

(Safe Torque Off).

3.1 Notes for mechanical installation

WARNING! Risk of injury due to hot surfaces on the device (heat sink)!

• Carelessness may result in serious burns.

The device and especially the heat sink heat up signicantly during operation and can reach

temperatures of up to +100°C (+212°F). Prior to starting work, make sure the device has

cooled down.

On touching there is a risk of burns to the skin. For this reason provide protection against

touching.

During mounting maintain an appropriate distance to neighbouring assemblies.

CAUTION! Damage to the device due to incorrect installation conditions!

The device may suffer irreparable damage.

For this reason

• Moisture must not be allowed to enter the device

• There must not be any aggressive or conductive substances in the ambient air

• Foreign bodies such as drilling chips, screws, washers etc. must not be allowed to fall into

the device

• The ventilation openings must not covered

NOTE:

It is imperative the operation manuals for the DC-AC Servo Drive and the

Power Supply Unit or the supplying AC-AC Servo Drive are followed during

installation of a MSDMulti-Axis System.

The following basic guidelines apply to the arrangement and installation of the Power

Supply Unit or the DC-AC Servo Drive:

• The backing plate must be well grounded.

• To attain the best result for effective EMC installation you should use a

chromated or galvanised backing plate. If backing plates are varnished, remove

the coating from the contact area! The devices Size 1 to Size 4 and Size 7 have

a rear wall made of aluminium. The devices Size 5 and Size 6A have a rear wall

made of aluminised/galvanised sheet steel.

• Maximum degree pollution degree 2 according to IEC/EN 60664-1. You will find

further information on ambient conditions in Table A.29 in the appendix.

• Cooling air must be able to flow th ough the device without restriction.

•

On installation in switch cabinets with convection, i.e. heat loss is dissipated to

the outside via the switch cabinet walls, always fit an inte nal air circulation fan.

If you require further detailed information on installation, please contact the

MoogHelpline (see chapter1.10, page10).

NOTE:

The DC-AC Servo Drives must not be installed in areas where they would be

permanently exposed to vibration.

You will find further information in Table A.27 in the appendix.

moog

Id. no.: CA97554-001 05/2017

3 Mechanical installation

MSD Multi-Axis System Operation Manual DC-AC Servo Drive

15

Page 16

3 Mechanical installation

moog

Id. no.: CA97554-001 05/2017

3.2 Switch cabinet layout

The positioning of the components in the switch cabinet has a significant e fect on the

trouble-free system and machine function. You should take into account the following

points in your planning:

•

Evaluate the assemblies used in relation to EMC.

•

Divide the switch cabinet into zones with different power and interference levels.

•

For devices susceptible to interference, maintain a distance of at least 200mm

(7.87 in) from the following components:

− DC-AC Servo Drive

− Input and output chokes, transformers

− Mains, motor, DC power supply and braking resistor cables (even if shielded)

− Relay and contactors (even if interference-suppressed)

•

For small distances use separators for shielding; fasten the separators directly

and conductively to the backing plate.

•

If a motor contactor or motor choke is used, the component should be directly

positioned directly at the DC-AC Servo Drive.

•

Do not use fluo escent lamps in switch cabinets, as they emit high-frequency

interference.

•

Fit contactors, relays, solenoid valves, switched inductors and capacitors with

suppressors.

•

The mains filter must be mounted on the backing plate as close as possible to

the feed point and with large surface area contact. The backing plate must be

connected to the central earthing point with a low-impedance connection. No

unfilte ed cables are allowed to be laid on the mains input side of the filter so

that no interference can be coupled into the cables.

MSD Multi-Axis System Operation Manual DC-AC Servo Drive

16

Page 17

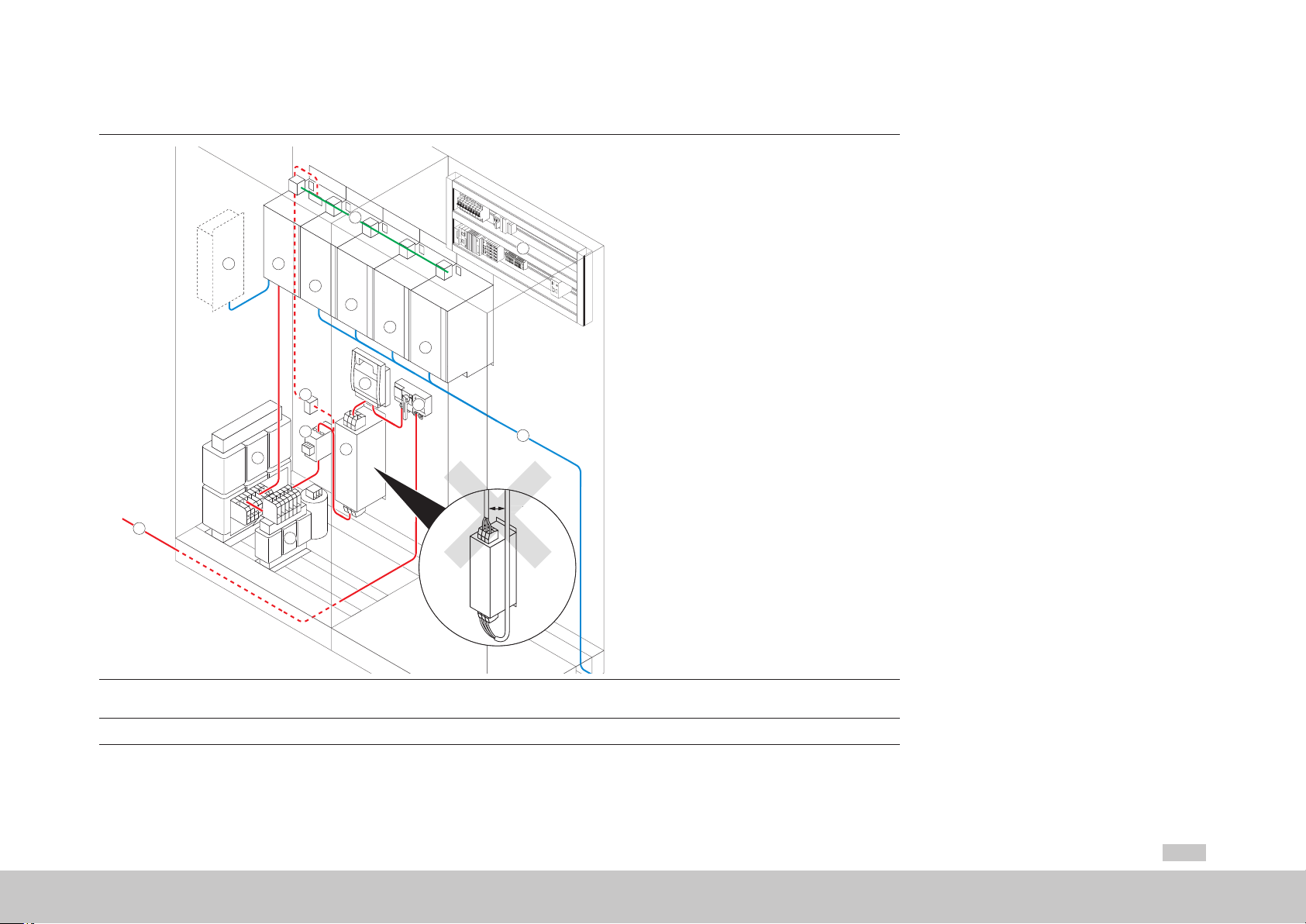

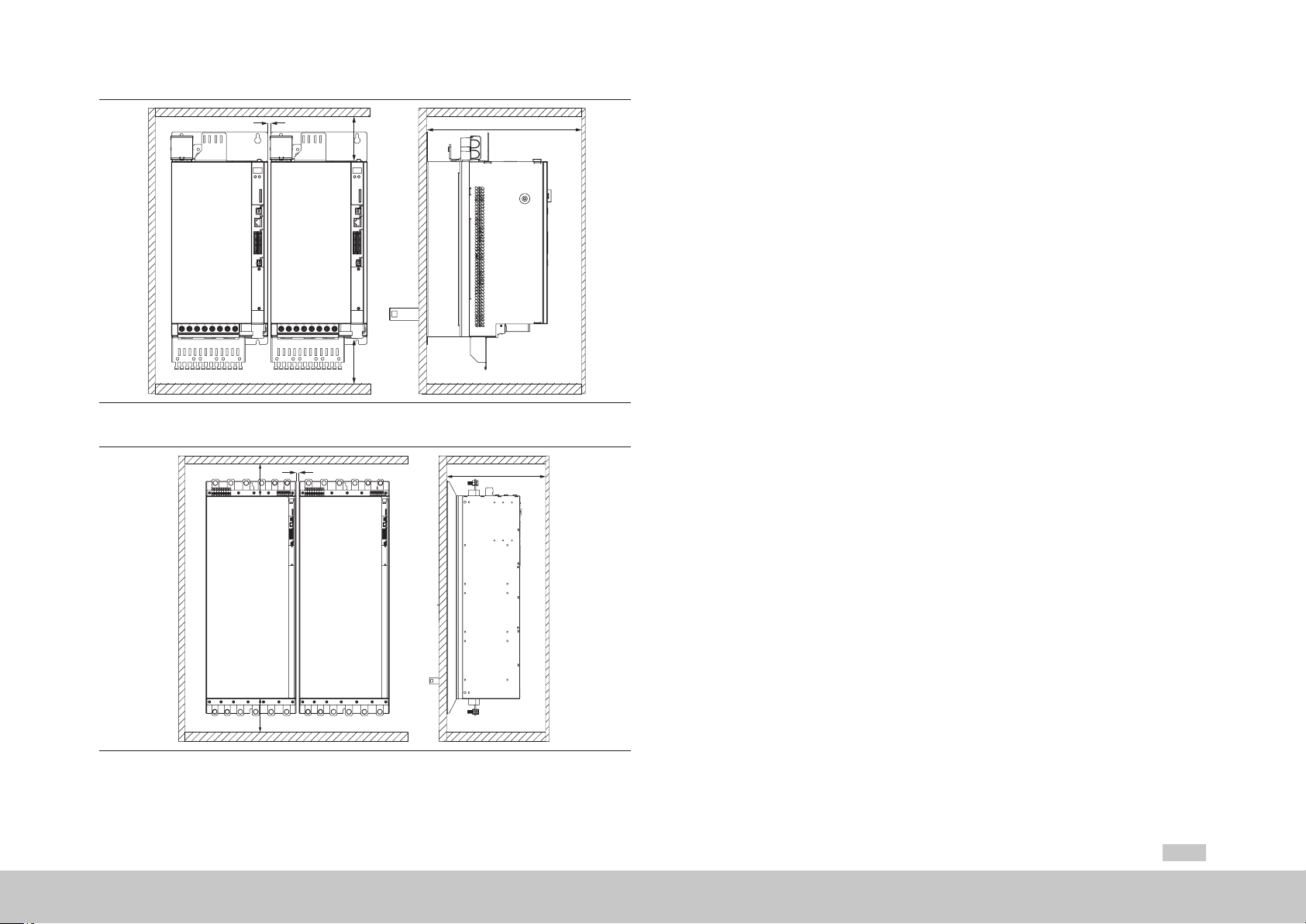

3.2.1 Example:

< 200 mm

< 20

12 9

1) Mains cable

2) Main switch

3) Fuses

4) Mains lter 1)

11

PWR

LOCK

CF

14

5) Circuit breaker

6) Mains contactor

7) Input choke with capacitor connected

8) Step-up choke

Power

COM

Data

Status

10

Reset

RJ-45/Line

RS 232

10

10

10

9) MSD Power Supply Unit

10) MSD Servo Drive DC-AC

11) DC power supply via DC link cable

12) Braking resistor

13) Motor cables

14) Controller 2)

3

0

5

1

OFF

ON

0

2

6

8

1

1) Cables without interference suppression must be laid at a distance of at least 200 mm (7.87 in) from the mains input side of the lter so that no interference can be coupled into the cables.

2) Arrange the controller separated from the power area to prevent EMC coupling mechanisms. Control cables, signal cables and cable shields have been omitted for clarity

7

4

13

Figure 3.1 Example: arrangement in the switch cabinet

moog

Id. no.: CA97554-001 05/2017

MSD Multi-Axis System Operation Manual DC-AC Servo Drive

17

3 Mechanical installation

Page 18

3 Mechanical installation

moog

Id. no.: CA97554-001 05/2017

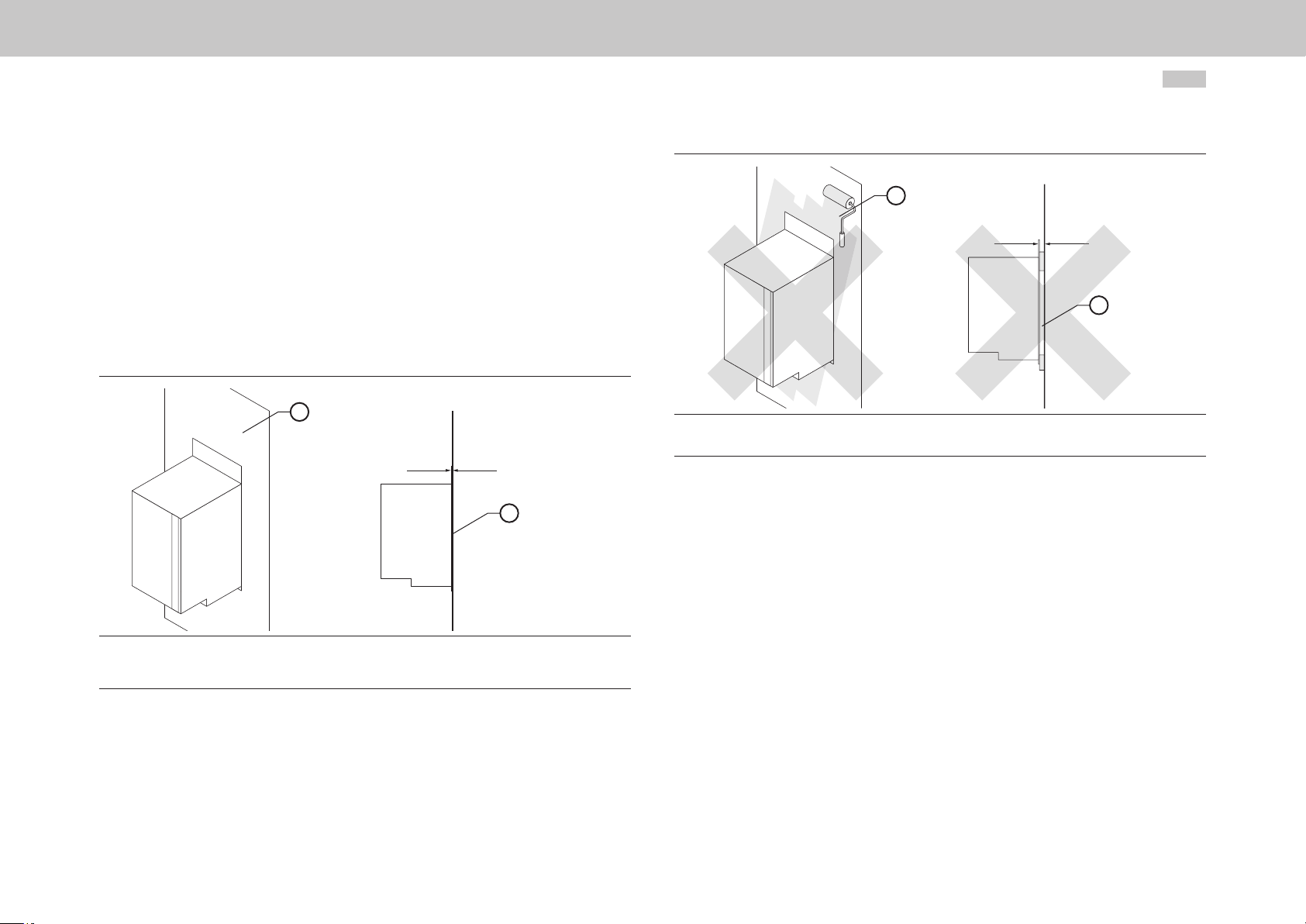

3.3 Wall mounting (air cooling)

•

Use bare metal backing plates.

•

The rear of the DC-AC Servo Drive must have good contact to the switch

cabinet ground. The contact area must be bare metal to establish a good

ground connection to the switch cabinet ground. There must not be an air gap

between the rear wall of the DC-AC Servo Drive and the rear wall of the switch

cabinet.

•

The bases of the chokes must have good contact to the switch cabinet ground.

The contact area must be bare metal to establish a good ground connection to

the switch cabinet ground.

1

= 0 mm

MSD Multi-Axis System Operation Manual DC-AC Servo Drive

1

> 0 mm

2

1) Paint

2) Air gap

Figure 3.3 INCORRECT mounting of DC-AC Servo Drive

2

18

1) Bare metal backing plate

2) Large area contact

Figure 3.2 CORRECT mounting of DC-AC Servo Drive

Page 19

18.5 mm (0.73 in)

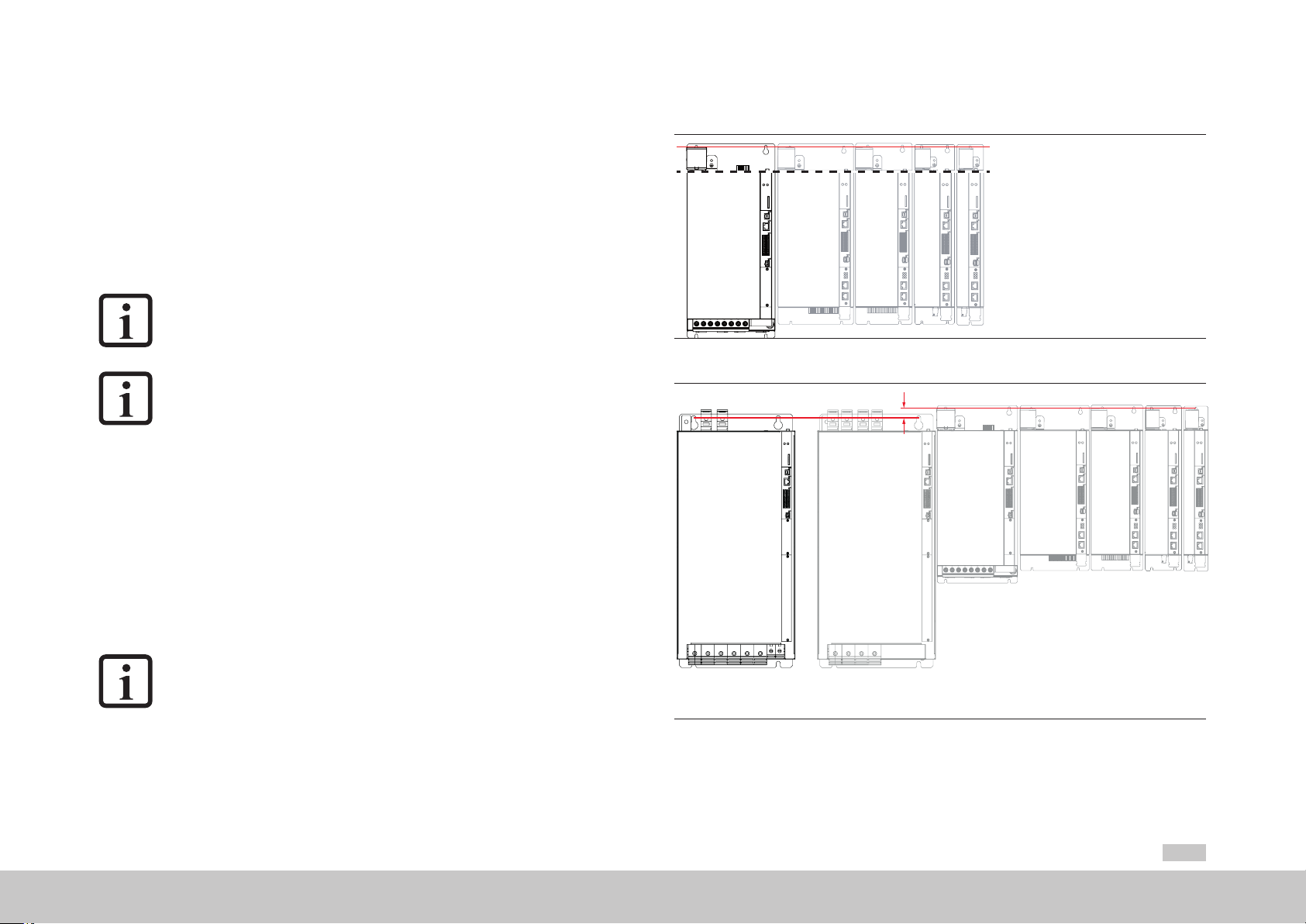

3.4 Alignment and arrangement in the group

•

Devices with different housing variants, such as air cooling and liquid cooling,

can be mounted side-by-side in any combination.

•

Devices with the liquid cooling housing variant have a spacer on the rear in

place of the heat sink. As a consequence it is possible to connect devices with

the air cooling housing variant using pre-assembled DC link cables without

additional compensation measures in relation to the device depth.

• The distance between the devices in a row is defined by the pre-assembled

connection cables supplied and is 2mm (0.08in).

NOTE

Devices of Size 6A in the air cooling housing variant are an exception. The

mounting distance between two air-cooled devices of Size 6A is 40mm

(1.57in) (see Figure 3.5).

NOTE

Only use the DC link connections supplied for the electrical coupling of the

devices. If extending the DC link coupling is unavoidable, it is imperative you

pay attention to the requirements in chapterA.5, page103. On the usage of

connection cables that do not meet the requirements, Moog does not provide

any guarantee for stable, safe operation.

•

The DC-AC Servo Drives are allowed to be arranged to the left and/or right

of a Power Supply Unit. On side by side mounting devices with different drive

powers you should arrange the devices in descending order by power rating

(e.g., viewed from the left, Size 4-Size3-Size2-Size1). This arrangement will

minimise the thermal interaction. The Power Supply Unit must always be fitted

beside the DC-AC Servo Drive with the highest power.

On side by side mounting other devices to the multi-axis system, attention is to

be paid to ensuring there is no thermal interaction between the devices.

•

Align the devices along the top edge (dotted line) to ensure trouble-free wiring.

NOTE

Between the upper fastening screws for devices of Size 1 to Size 5 there is a

vertical offset of 18.5mm (0.73in) compared to devices of Size 6A

(see Figure 3.5).

3.4.1 Alignment in the group

MSD

Power Supply Unit

Size 5

MSD Servo Drive DC-AC Size 1

MSD Servo Drive DC-AC Size 4

Figure 3.4 Alignment of DC-AC Servo Drives in relation to Power Supply Unit Size 5 (example)

MSD Power Supply Unit

Size 6A

Wall mounting

Figure 3.5 Alignment of DC-AC Servo Drives in relation to Power Supply Unit Size 6A (example)

MSD Servo Drive DC -AC

MSD Servo Drive DC-AC Size 3

Size 6A

Wall mounting

MSD Servo Drive DC-AC Size 2

MSD Servo Drive DC-AC Size 5

MSD Servo Drive DC-AC Size 4

MSD Servo Drive DC-AC Size 2

MSD Servo Drive DC-AC Size 3

MSD Servo Drive DC-AC Size 1

moog

Id. no.: CA97554-001 05/2017

3 Mechanical installation

MSD Multi-Axis System Operation Manual DC-AC Servo Drive

19

Page 20

MSD Servo Drive DC-AC Size 1

MSD Servo Drive DC-AC Size 2

MSD Servo Drive DC-AC Size 3

MSD Servo Drive DC-AC Size 4

MSD Servo Drive DC-AC Size 5

18.5 mm (0.73 in)

MSD Servo Drive DC -AC

Size 6A

with liquid cooling

MSD Power Supply Unit

Size 6A

with liquid cooling

3 Mechanical installation

moog

Id. no.: CA97554-001 05/2017

Figure 3.6 Alignment of DC-AC Servo Drives in relation to Power Supply Unit Size 7 (example)

MSD Multi-Axis System Operation Manual DC-AC Servo Drive

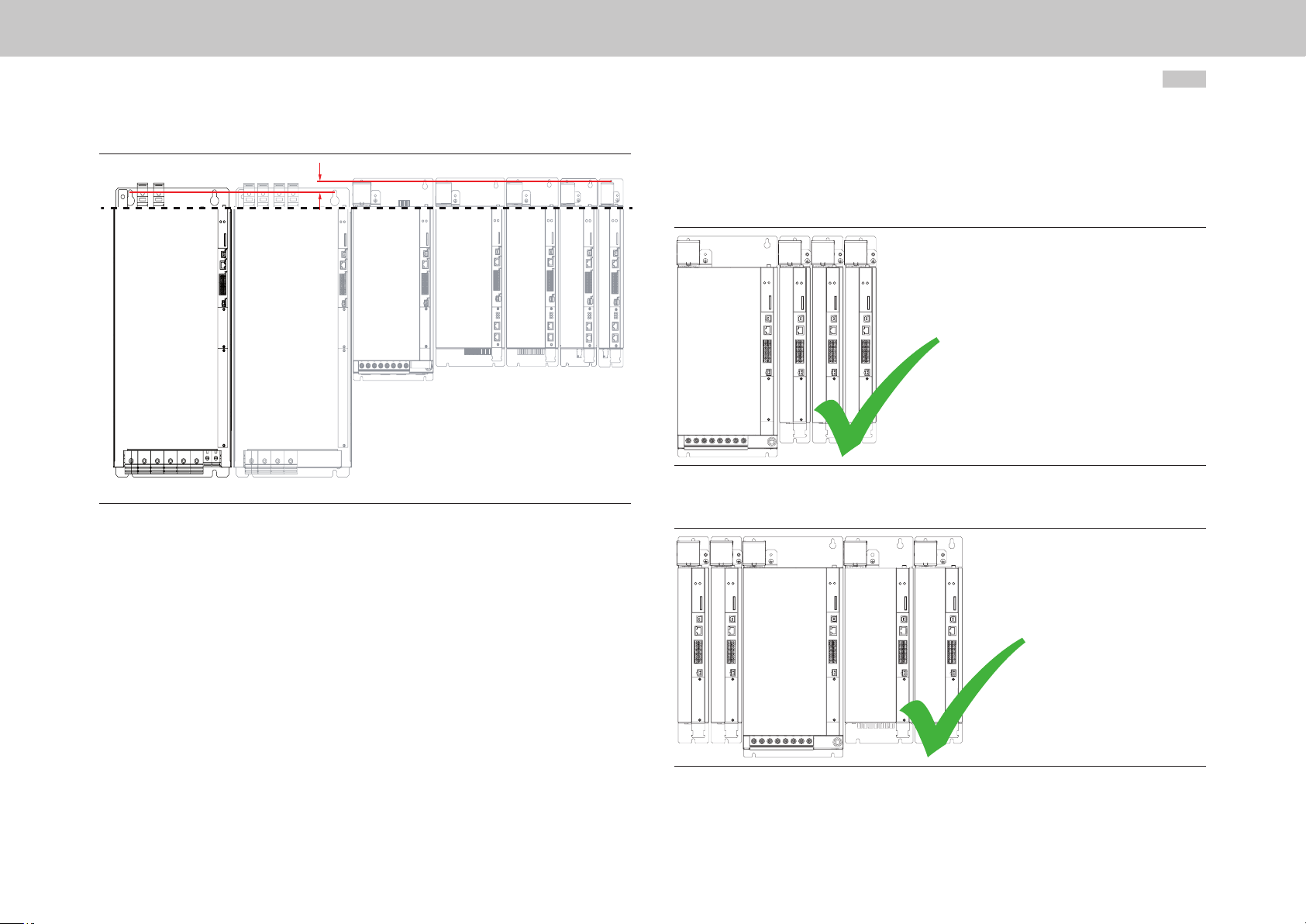

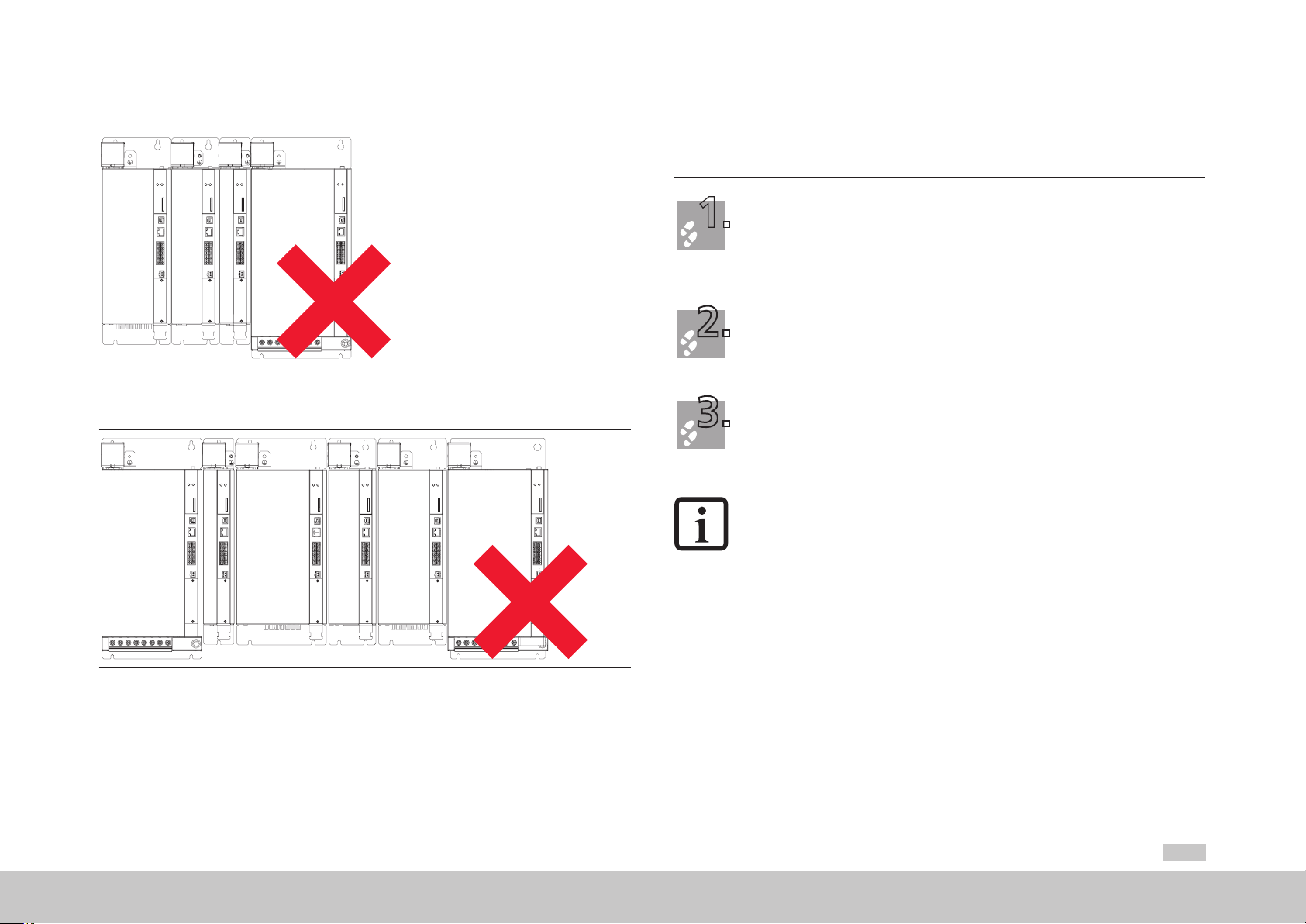

3.4.2 Arrangement in the group

Permissible arrangements

G396

Figure 3.7 Example permissible arrangement: side by side mounting DC-AC Servo Drive

of the same size on one side of the Power Supply Unit

20

G396

Figure 3.8 Example permissible arrangement: side by side mounting DC-AC Servo Drive

of the same size or reducing size on both sides of the Power Supply Unit

Page 21

1.

2.

3.

Impermissible arrangements

G396

3.5 Mounting DC-AC Servo Drive air cooling housing variant

Arrange the devices starting from the Power Supply Unit to the right or/and left sorted in descending

order by power rating to minimise the thermal effects.

Align all devices in a line along the top edge of the devices so that the DC link coupling can be made

using the pre-assembled cables. Between the upper fastening screws for devices of Size 1 to Size 5

there is a vertical offset of 18.5mm (0.73in) compared to devices of Size 6A (see Figure 3.5). For

information on the mounting clearances see Table 3.1.

Mark out the position of the tapped holes on the backing plate.

Drill holes in the backing plate and cut a thread for each xing screw in the backing plate.

Pay attention to the bending radius of the connection cables!

For hole spacing and dimensional drawings see Table 3.1, Figure 3.11 and Figure 3.12.

Figure 3.9 Example of an impermissible arrangement: side by side mounting DC-AC Servo Drive

of increasing size

G396

Figure 3.10 Example of an impermissible arrangement: side by side mounting DC-AC Servo Drive

of increasing and reducing sizes

Mount the DC-AC Servo Drives vertically and side by side mounted in a row on the backing plate.

The contact area must be bare metal. Use the pre-assembled DC link cables supplied for the DC

power supply.

Continue with the electrical installation in chapter4, page27.

NOTE:

The minimum distance specified in the table applies for devices of the same

power. On side by side mounting devices with differ

should arrange the devices in descending order by power rating (e.g., viewed

from the left, Size 4-Size 3-Size 2-Size 1). This arrangement will minimise the

thermal interaction. The Power Supply Unit must always be fitted beside the

DC-ACServo Drive with the highest power.

On side by side mounting other devices to the multi-axis system, attention is

to be paid to ensuring there is no thermal interaction between the devices.

ent drive powers you

moog

Id. no.: CA97554-001 05/2017

3 Mechanical installation

MSD Multi-Axis System Operation Manual DC-AC Servo Drive

21

Page 22

3 Mechanical installation

moog

Id. no.: CA97554-001 05/2017

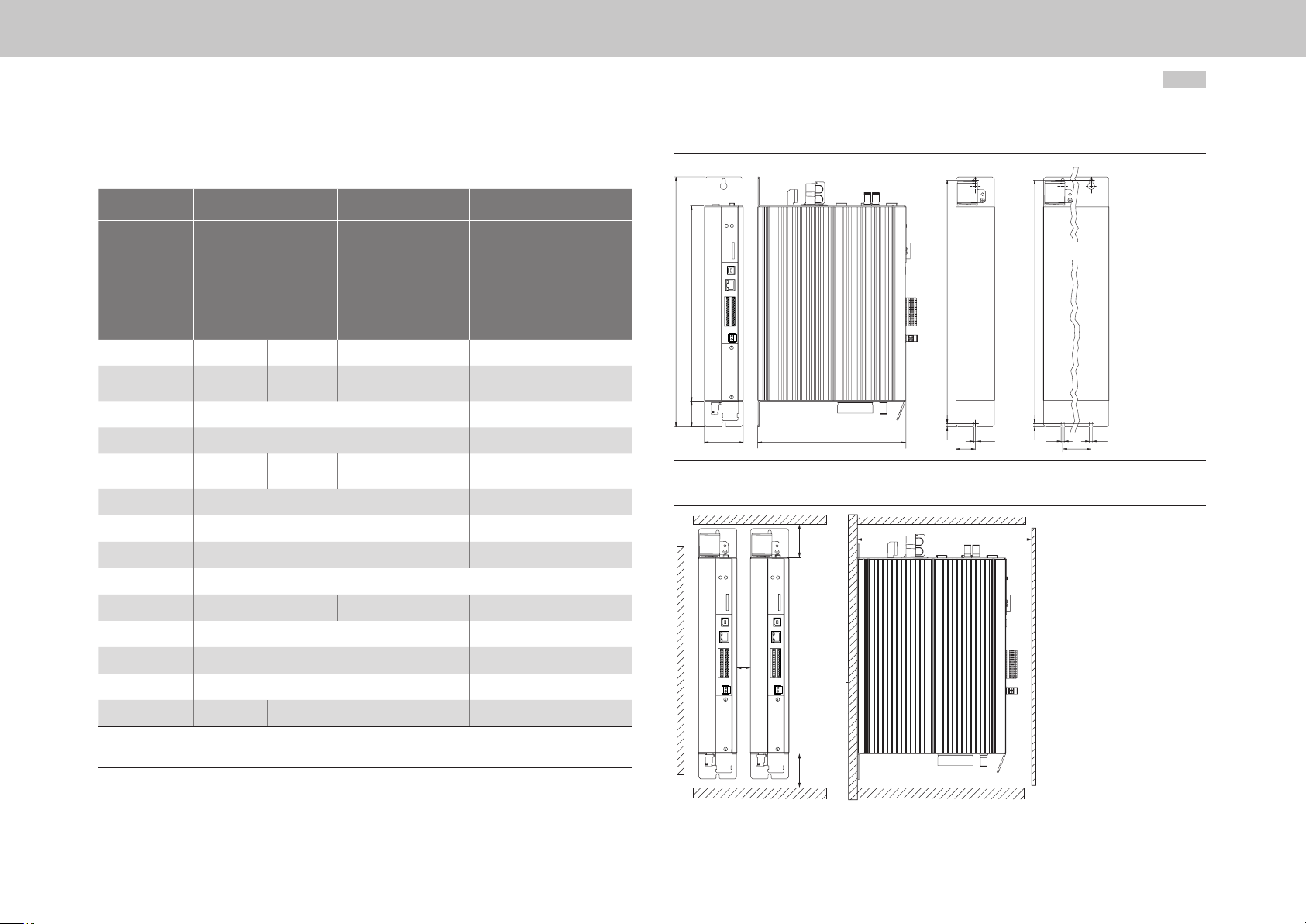

3.5.1 Dimensions and mounting clearances

Size Size 1 Size 2 Size 3 Size 4 Size 5 Size 6A

Device

G393-004

G393-006

Weight kg (lb) 3.4 (7.5) 4.9 (10.8) 6.5 (14.3) 7.5 (16.5) 13 (28.7) 32 (70.6)

B (width) 58.5 (2.30) 90 (3.54) 130 (5.12)

1)

H (height)

1)

D (depth)

A 29.25 (1.15) 50 (1.97) 80 (3.15)

C 382 (15.04) 406.5 (16) 581 (22.87)

C1 5 (0.2) 6 (0.24) 10 (0.39)

D (Ø) 4.8 (0.19) 5.6 (0.22) 9.5 (0.37)

E Direct side by side mounting, maximum 2 (0.08) 40 (1.57)

3)

F

3)

G

≥100 (3.94) ≥150 (5.91) ≥180 (7.09)

G393-008

G393-012

G393-016

G393-020

G393-024

171

(6.73)

G393-032

G393-045

G393-060

G393-072

190 (7.48) 280 (11.02)

G393-090

295 (11.61) 345 (13.58) 540 (21.26)

224 (8.82) 240 (9.45) 322 (12.68)

120

(4.72)

150 (5.91) 200 (7.87)

≥270 (10.63) ≥300 (11.81) ≥500 (19.69)

G393-110

G393-143

G393-170

2)

MSD Multi-Axis System Operation Manual DC-AC Servo Drive

Size 1

H2

TB D

C1 C1

Figure 3.11 Dimensional drawing, air cooling housing variant

F

G

Size 2 ... Size 6

CCH1 H

DD

22

AA

H1 392 (15.43) 418.5 (16.48) 600 (23.62)

H2 38.5 (1.52) 15 (0.59) 20 (0.79)

Screws 2 x M4 4 x M4 4 x M5 4 x M8

1) Without terminals/connectors 3) The bend radius of the connection cables must be taken into account

2) Mounting distance Size 6A to other Size 6A All dimensions in mm (in)

Table 3.1 Dimensions and mounting clearances, air cooling housing variant

E

F

Figure 3.12 Mounting distances, air cooling housing variant

Page 23

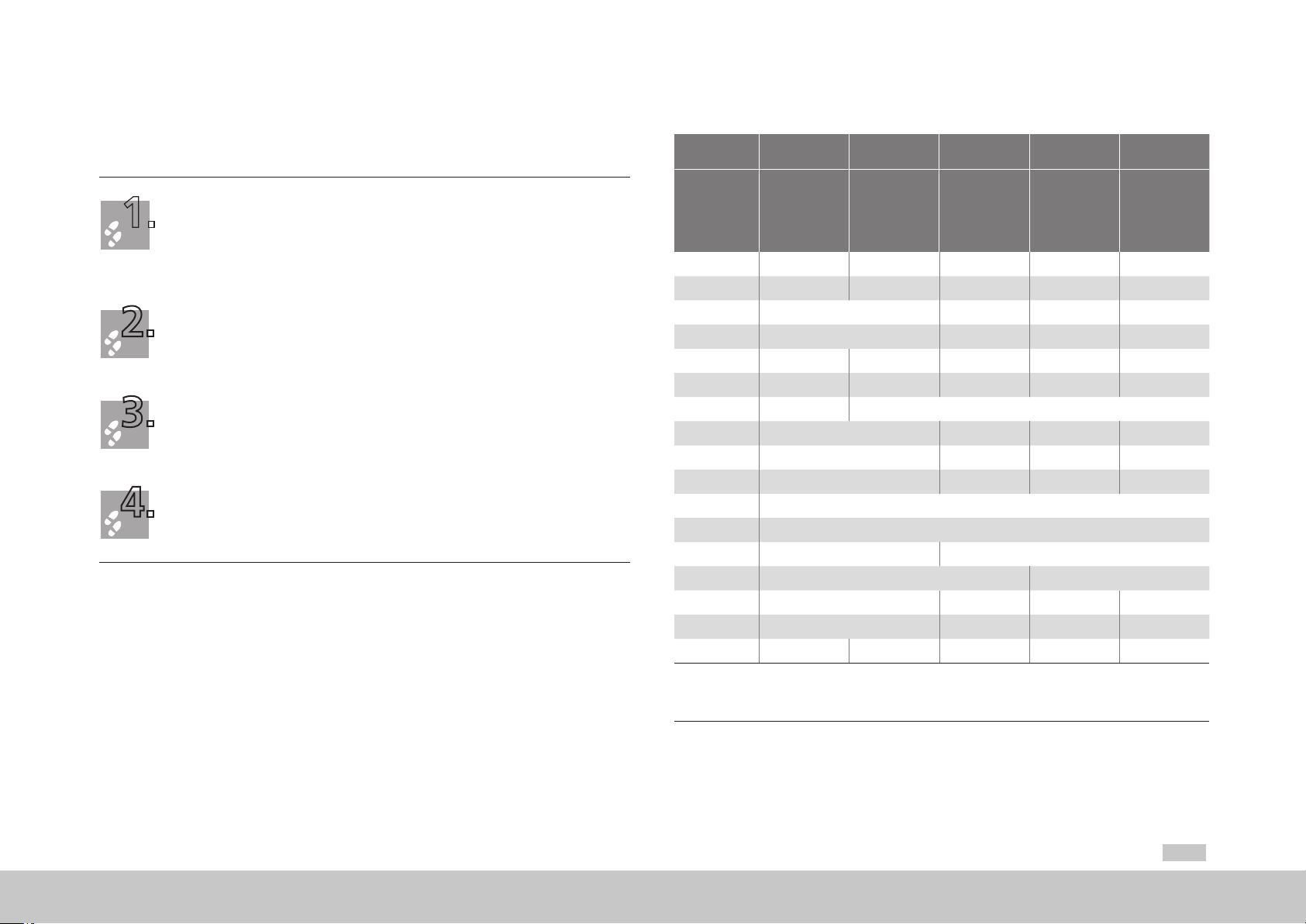

3.6 Mounting DC-AC Servo Drive

1.

2.

3.

4.

3.6.1 Dimensions and mounting clearances

liquid cooling housing variant

Arrange the devices starting from the Power Supply Unit to the right and/or left sorted in descending

order by power rating to minimise the thermal effects.

Align all devices in a line along the top edge of the devices so that the DC link coupling can be made

using the pre-assembled cables. Between the upper fastening screws for devices of Size 1 to Size 5

there is a vertical offset of 18.5mm (0.73in) compared to devices of size Size 6A (see Figure 3.5).

For information on the mounting clearances see Table 3.2.

Mark out the position of the tapped holes and the pipe ttings on the backing plate.

Drill holes and cut a thread for each xing screw in the backing plate.

Pay attention to the bending radius of the connection cables!

For hole spacing and dimensional drawings see Table 3.2, Figure 3.13 and Figure 3.14.

Mount the DC-AC Servo Drives vertically and side by side mounted in a row on the backing plate.

The contact area must be bare metal. Use the pre-assembled DC link cables supplied for the

DC power supply.

On screwing the hose connections (not included in the scope of supply) into the pipe ttings, lock the

pipe ttings using a 22mm (0.87in)open-ended wrench to prevent damage due to the application

of torque to the device.

Pay attention to a perfectly sealed connection without leaks (e.g. using Teon sealing tape).

Continue with the electrical installation in chapter4, page27.

Size Size 3 Size 4 Size 5 Size 6A Size 7

Device

G397-020

G397-025

Weight kg (lb) 6.5 (14.3) 7.5 (16.5) 13 (28.7) 32 (70.6) 100 (220.5)

B (width) 130 (5.12) 171 (6.73) 190 (7.48) 280 (11.02) 380 (14.96)

1)

H (height)

1)

D (depth)

A 80 (3.15) 120 (4.72) 150 (5.91) 200 (7.87) 150 (5.91)

A1 10 (0.39) 25 (0.98) 40 (1.57) 65 (2.56) 29 (1.14)

A2 60 (2.36) 70 (2.76)

C 382 (15.04) 406.5 (16) 581 (22.87) 952 (37.48)

C1 5 (0.2) 6 (0.24) 10 (0.39) 12 (0.47)

D (Ø) 4.8 (0.19) 6.5 (0.26) 9.5 (0.37) 12 (0.47)

D1 48 (1.89) (Ø hole for pipe socket)

E Direct side by side mounting, maximum 2 (0.08)

2)

F

2)

G

H1 392 (15.43) 418.5 (16.48) 600 (23.62) 971 (38.23)

H2 38.5 (1.52) 15 (0.59) 20 (0.79) 60 (2.36)

H3 70 (2.76) 70 (2.76) 54 (2.13) 56.5 (2.22) 124 (4.88)

All dimensions in mm (in)

1) Without terminals/connections

2) Also pay attention to the bending radius of the connection cables

295 (11.61) 346.5 (13.64) 540 (21.26) 952 (37.48)

224 (8.82) 238.5 (9.39) 285 (11.22) 286.5 (11.28)

≥150 (5.91) ≥180 (7.09)

G397-026

G397-035

≥300 (11.81) ≥500 (19.69)

G397-053

G397-070

G397-084

G397-110

G397-130

G397-170

G397-210

G397-250

G397-325

G397-450

moog

Id. no.: CA97554-001 05/2017

3 Mechanical installation

Table 3.2 Dimensions and mounting clearances, liquid cooling housing variant

MSD Multi-Axis System Operation Manual DC-AC Servo Drive

23

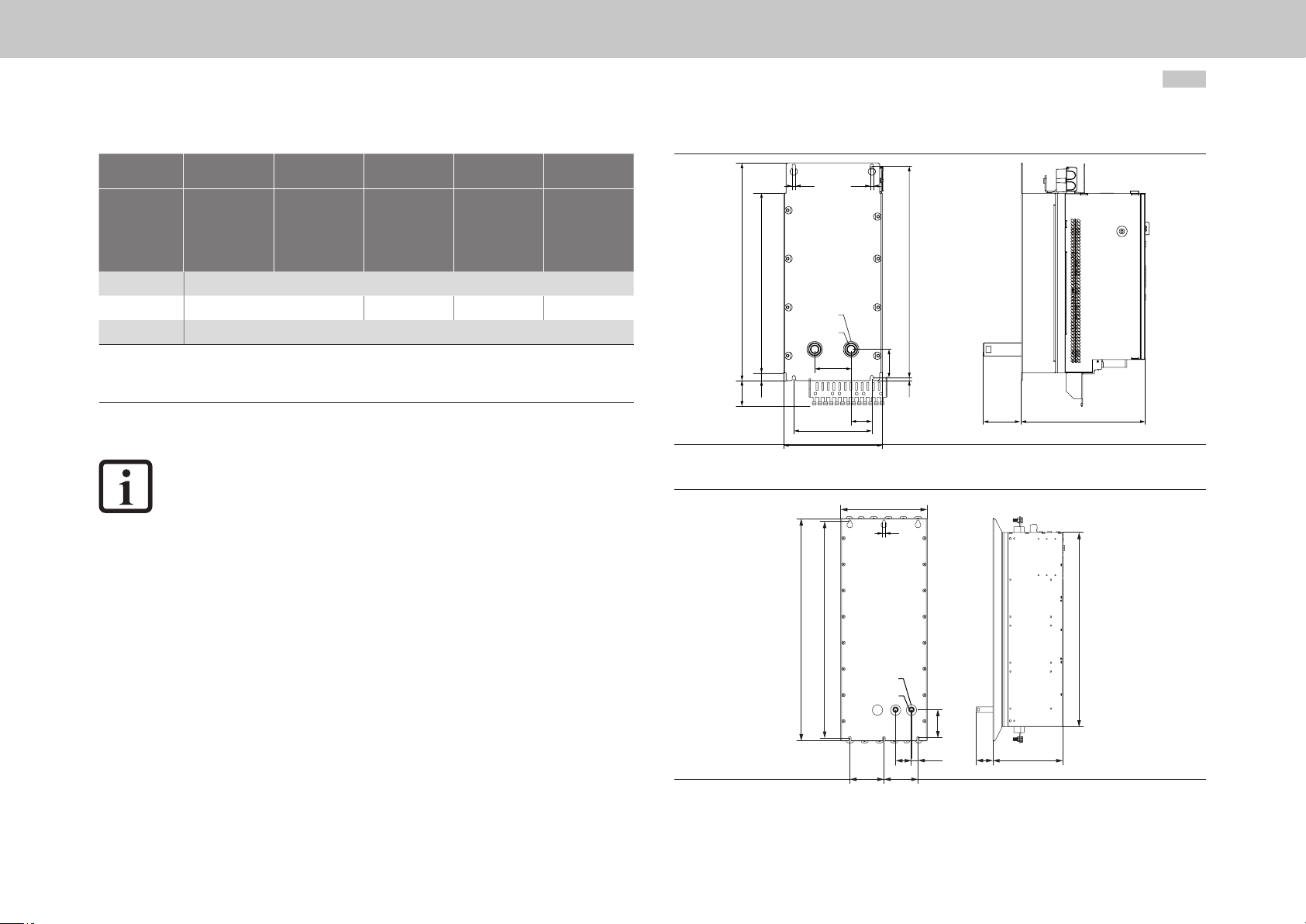

Page 24

B

3 Mechanical installation

moog

Id. no.: CA97554-001 05/2017

Size Size 3 Size 4 Size 5 Size 6A Size 7

Device

G397-020

G397-025

S [inch] 3/8 (female thread)

Screws 4 x M4 4 x M6 4 x M8 6 x M10

T1 73.5 (2.89)

All dimensions in mm (in)

1) Without terminals/connections

2) Also pay attention to the bending radius of the connection cables

Table 3.2 Dimensions and mounting clearances, liquid cooling housing variant

G397-026

G397-035

G397-053

G397-070

G397-084

G397-110

G397-130

G397-170

G397-210

NOTE:

The minimum distance specified in the table applies for devices of the same

power. On side by side mounting devices with different drive powers you

should arrange the devices in descending order by power rating (e.g., viewed

from the left, Size 4-Size 3-Size 2-Size 1). This arrangement will minimise the

thermal interaction. The Power Supply Unit must always be fitted beside the

DC-AC Servo Drive with the highest power.

On side by side mounting other devices to the multi-axis system, attention is

to be paid to ensuring there is no thermal interaction between the devices.

G397-250

G397-325

G397-450

MSD Multi-Axis System Operation Manual DC-AC Servo Drive

D

H1H4H

H2

Figure 3.13 Dimensional drawing, liquid cooling housing variant, based on Size 5 as an example

H1 C

D

C

D1

S

A2

A

B

H3

C1

A1

D

T1

T

H

24

D1

S

H3

T

A1A2

AA

Figure 3.14 Dimensional drawing, liquid cooling housing variant, based on Size 7 as an example

T1

Page 25

E

Figure 3.15 Mounting distance, liquid cooling housing variant, based on Size 5 as an example

F

F

G

F

F

Figure 3.16 Mounting distance, liquid cooling housing variant, based on Size 7 as an example

moog

Id. no.: CA97554-001 05/2017

E

G

3 Mechanical installation

MSD Multi-Axis System Operation Manual DC-AC Servo Drive

25

Page 26

3 Mechanical installation

moog

Id. no.: CA97554-001 05/2017

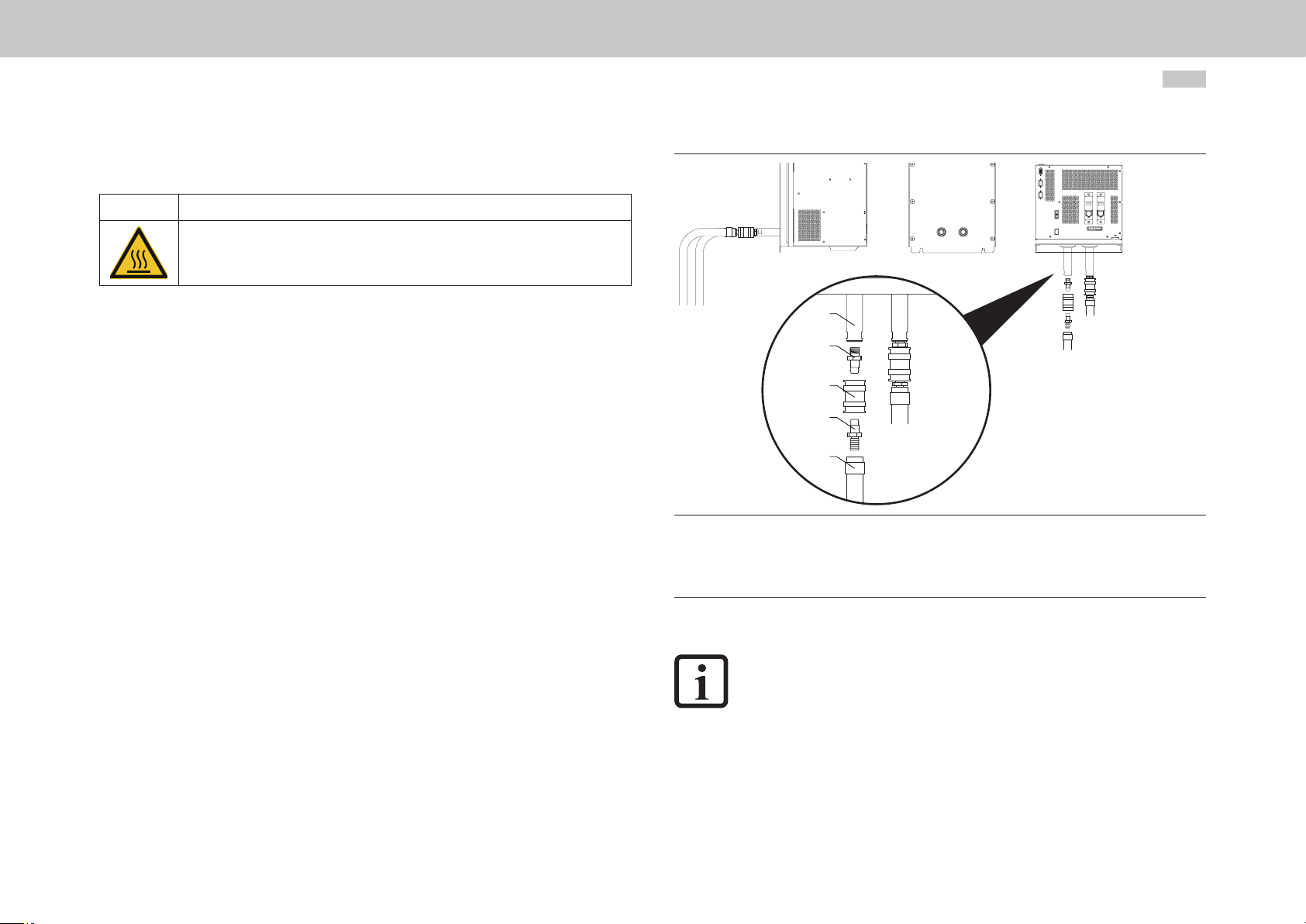

3.7 Cooling circuit connection

WARNING! Risk of injury due to hot coolant!

• Carelessness may result in serious burns.

In operation the coolant reaches high temperatures. Prior to starting work, make sure the coolant

has cooled down.

The devices with liquid cooling have a capacity of up to 0.5l of coolant depending on

the size. After the disconnection of the connections, liquid may be left in the device and

escape if the device is tipped. We recommend the usage of a self-sealing liquid coupling

(not included in the scope of supply) to prevent the coolant escaping and to make it

possible to disconnect and connect in the filled state

MSD Multi-Axis System Operation Manual DC-AC Servo Drive

1

2

3

4

5

1) Liquid connection with 3/8inch female thread

2) Self-sealing quick-release connection with 3/8inch male thread

3) Self-sealing liquid coupling

4) Adapter for hose connection

5) PUR (polyurethane) hose with clip

26

Figure 3.17 Cooling circuit connection, based on Size 6A as an example

NOTE:

Items2 to 5 are not included in the scope of supply and are to be ordered

separately.

Page 27

4 Electrical installation

4.1 Notes for installation

It is imperative you pay attention to the following warnings and safety instructions prior to

and during installation.

DANGER! Risk of injury due to electrical power!

• Carelessness will result in serious injuries or death.

Never wire or disconnect electrical connections while they are live! Before making any change

the device is to be disconnected from the mains. Even 10min. (Size 1 to 4) / 30min. (Size 5 to 7)

after mains off,

dangerously high voltages of ≥50V may still be present (capacitor charge). So

check that electrical power is not present!

Work on the device must only be carried out after the DC link voltage has dropped below a

residual voltage of 50V

(on Size 1 to 6A to be measured on the terminals X11/L+ and L-, on Size 7 on the terminals X11/

ZK- and X11/ZK+).

Dangerous voltage may be present at the device, even if the device is not emitting

any visual or audible signals/indications (e.g. with mains voltage applied to terminal X11 and

missing control supply +24V DC on X9/X10 or X44)!

WARNING! Risk of injury due to hot surfaces on the device (heat sink)!

• Carelessness may result in serious burns.

The device and especially the heat sink heat up signicantly during operation and can reach

temperatures of up to +100 °C (+212 °F). Prior to starting work, make sure the device has

cooled down.

On touching there is a risk of burns to the skin. For this reason provide protection against

touching.

During mounting maintain an appropriate distance to neighbouring assemblies.

NOTE:

Along with this operation manual, it is imperative the manuals for the Power

Supply Unit or the supplying AC-AC Servo Drive are read on installing the

complete MSD Multi-Axis System.

WARNING! Risk of injury due to hot coolant!

• Carelessness may result in serious burns.

In operation the coolant reaches high temperatures. Prior to starting work, make sure the coolant

has cooled down.

moog

Id. no.: CA97554-001 05/2017

4 Electrical installation

MSD Multi-Axis System Operation Manual DC-AC Servo Drive

27

Page 28

4 Electrical installation

moog

Id. no.: CA97554-001 05/2017

4.2 Effective EMC installation

4.2.1 Cable type

•

Use only shielded mains, motor and signal cables as shown in Figure 4.1. For all

shielded connections use cables with double copper braiding with 60 to 70%

coverage.

•

If it is necessary to lay very large cable cross-sections, instead of shielded

cables it is also possible to use separate individually shielded wires.

NOTE

Only use the DC link connections supplied for the electrical coupling of the

devices. If extending the DC link coupling is unavoidable, it is imperative you

pay attention to the requirements in chapterA.5, page103. On the usage of

connection cables that do not meet the requirements, Moog does not provide

any guarantee for stable, safe operation.

4.2.2 Routing of cables

You should take into account the following points on laying the cables:

•

Route mains, motor and signal cables separated from one another. Maintain a

distance of at least 200mm (7.87in).

•

For smaller distances use separators for shielding; fasten the separators directly

and conductively to the backing plate.

•

Route the cables close to ground potential. On the usage of cable ducts made

of plastic, the cable ducts must be fastened directly to the backing plates or the

frame. Open space must not be spanned, as otherwise the cables could act

like antennae.

•

Route motor cables without interruptions (e.g. not via terminals) and lay them by

the shortest route out of the switch cabinet.

•

If a motor contactor or a motor choke is used, the component should be

positioned directly at the DC-AC Servo Drive and the shielding on the motor

cable should not be stripped back too far.

•

Avoid unnecessary cable lengths and "loops of spare cable".

MSD Multi-Axis System Operation Manual DC-AC Servo Drive

•

Route long cables in places not be susceptible to interference. Otherwise

coupling points may be created.

•

Twist wires for the same electrical circuit.

•

Ideally, route the signal cables separated from encoder cables.

•

All signal cables should be combined and routed away upward.

•

Avoid extending cables via terminals.

28

4.2.3 Earthing measures

All earthed points and components must be routed directly to the central earthing

point (e.g. PE rail, main earth) with as low an impedance as possible and with good

conductivity. In this way an earthing system is produced that connects all connections to

the earthing point in a star topology. This central earthing point is to be clearly defined.

This earthing point can be extended to the entire backing plate with an effective EMC

connection.

You should take into account the following points for the earthing:

•

Earthed surfaces act as shielding measures and reduce electromagnetic fields

in the surrounding area. For this reason metal surfaces should be connected

to ground with low-impedance HF connections. In terms of EMC it is not the

cross-section of the cable that is definitive, but the surface over which high

frequency currents caused by the skin effect can flow awa .

•

Connect the protective earth conductors for the components in the switch

cabinet using a star topology.

•

Avoid the use of connectors.

•

Also connect the walls and doors of the switch cabinet to ground.

•

Larger openings in the switch cabinet (window, fan, display) degrade the

shielding effect of the cabinet and must be protected with additional shielding

measures for the HF range.

•

Earth unused cores at one end as a minimum so that there is no electrostatic

charging.

•

Free contact areas of paint and corrosion and make large area connections.

Page 29

•

The usage of tinned, galvanised, aluminised or cadmium-plated elements is to

be preferred over painted components; it will then not be necessary to remove

the paint. Connectors are to be avoided, or several contacts are to be used for

the shield connection in the connector.

For further information on the cross-section of the protective earth conductor see

chapter4.4, page36.

4.2.4 Shielding measures

You should take into account the following points for the shielding measures:

•

Use only shielded mains, motor and signal cables as shown in Figure 4.1,

page29. For all shielded connections use cables with double copper

braiding with 60 to 70% coverage.

•

Connect the shield at both ends using a large area connection. Extending the

shield to the earthing point using a wire (pigtail) reduces the shielding effect by

up to 90%.

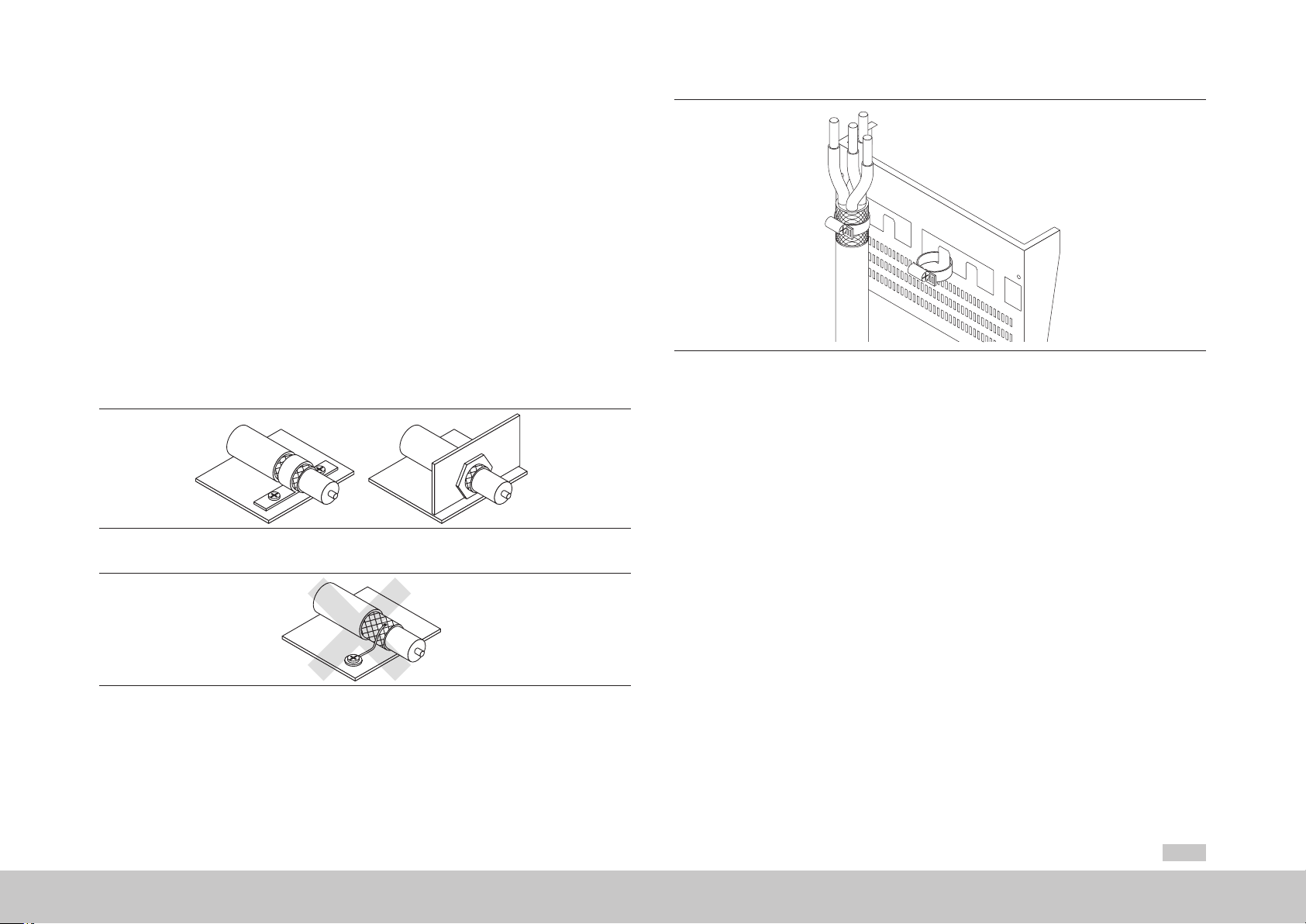

Figure 4.1 CORRECT shield connection

Figure 4.3 Shield connection

•

Do not strip back too far the shield.

•

Shields are not allowed to be used to carry power, e.g. as a substitute for the N

or PE conductor.

•

The shielding effect can be improved by laying in metal ducts/tubes.

•

If it is necessary to lay very large cable cross-sections, instead of shielded

cables it is also possible to lay separate individually shielded wires.

•

Shields must be connected at one end as a minimum. Connection at

multiple points is recommended, otherwise potential equalisation currents

may flow in physically extensive installations. If the e is interference with long

ground connections, these can be connected using coupling capacitors.

These capacitors will provides a high-frequency connection for suppressing

interference without transmitting the 50-Hz components.

Figure 4.2 INCORRECT shield connection - do not extend to the earthing point (pigtail)

moog

Id. no.: CA97554-001 05/2017

4 Electrical installation

MSD Multi-Axis System Operation Manual DC-AC Servo Drive

29

Page 30

(Size 3 + 4)

(Size 1+2) SW

1.

2.

3.

4.

5.

4 Electrical installation

moog

Id. no.: CA97554-001 05/2017

4.2.5 External components

•

Place larger loads near the supply.

•

Contactors, relays, solenoid valves (switched inductances) must be wired with

suppressors. The wiring must be directly connected to the respective coil.

•

Any switched inductance should be at least 200mm (7.87in) away from the

process controlled assemblies.

If you require further detailed information on installation, please contact the Moog

Helpline.

4.3 Overview of the connections

Determine the terminal assignment that applies to your device.

For G393-004 (Size 1) to G393-032/G397-035 (Size 4) in chapter4.3.1, page30

For G393-045/G397-053 (Size 5) to G393-170/G397-210 (Size 6A) in chapter4.3.2, page32

For G397-250 to G397-450 (Size 7) in chapter4.3.3, page34

Connect all necessary input and output units to the control connections (chapter4.6, page38),

the optional interfaces (chapter4.11, page45) and/or (chapter4.12, page45) and the DC link

if necessary.

Connect encoder (chapter4.13, page46) and motor (chapter4.14, page49).

MSD Multi-Axis System Operation Manual DC-AC Servo Drive

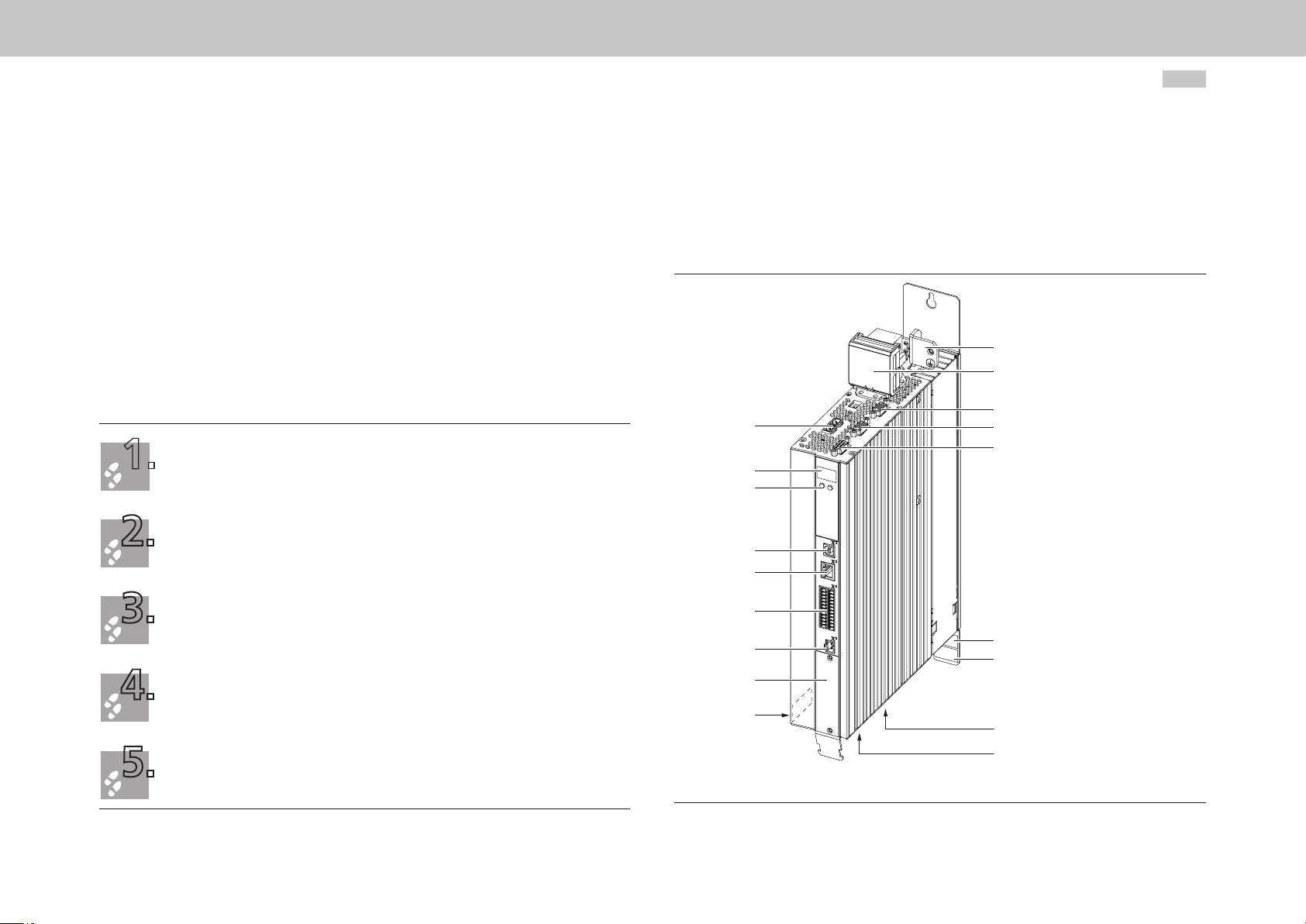

4.3.1 Layout, G393-004 (Size 1) to G393-032/G397-035 (Size 4)

In the following you will find the layout with the corresponding positions of the

connectors and terminals. For improved clarity we have added an abbreviation to the

designation for the connectors and terminals.

PE

X11

X8

X9, X10

D1, D2

T1, T2

X2

X3

X4

X7

X6

30

With the aid of the pre-assembled connection cables (DC-L), connect the protective earth conductor

(chapter4.4, page36) and the supply voltages (chapter4.7, page40).

Continue with commissioning in chapter5, page53.

X5

Option 1

HW: Hardware rating plate

SW: Software rating plate

Figure 4.4 Layout, G393-004 (Size 1) to G393-032/G397-035 (Size 4)

(based on G393-004 Size 1 as an example)

SW

HW

X12

X13

Page 31

Service

Top side

interface

Service

interface

Control

Analog setpoint 1

Analog setpoint 2

+24 V DC against

E/A-GND

Diagnosis

STO

Relay

Digital0

Digital1

Digital2

E/A-GND

Communication

Field buses

D1, D2

T1, T2

3

ISA00+

4

ISA00-

5

ISA01+

6

ISA01-

15

16

17

ISD03

18

ISD04

19

ISD05

20

ISD0621

10

22

12

11

23

24

7

OSD00

8

OSD01

9

1

DGND

2,14

13

DGND

USB 1.1

Ethernet

ISD00

ISD01

ISD02

ENPO (STO)

ISDSH (STO)

RSH

Relay

OSD04

OSD02

+24 V (U

H

Option 1

Abbreviation Designation Details

Encoder

Resolver

DC-L

PE

DC +

DC -

D1, D2 7-segment display chapter 5.4.2

T1, T2 Button chapter 5.4.1

X2 USB 1.1 interface chapter 4.9

)

V

X3 Ethernet interface chapter 4.10

X4 Control connections chapter 4.8

Option1 Communication chapter 4.11

X11 Connection for DC supply chapter 4.7

DC-L DC link cables chapter A.5

X2

X3

X4

X11

Danger!

X10

X9

X8

X7

X6

DC +

DC -

Option 2

54321

15 14 13 12 11

10 9876

4321

9876

DC-link

+

1

-

2

+

1

-

2

24 V DC Power supply

for control electronic (U

Technology

8

6

PE Connection for PE conductor chapter 4.4

Front

X5

+

-

X9, X10 Connection for control supply chapter 4.6

X8 (Option2) Technology chapter 4.12

Triggering of motorbrake

1

X13/1 do not connect!

GND

U

V

W

L-

L+

2

3

4

X13/4 do not connect!

DC-link

(Connect nothing!)

Motor

3

~

X13

X12

)

Danger!

X7 Connection for high-resolution encoder chapter 4.13

X6 Connection for resolver chapter 4.13.4

X5 Connection for motor temperature sensor chapter 4.14

X13 Connection for motor brake chapter 4.8.2

X12 Connection for motor chapter 4.14

Table 4.1 Key to layout and connection diagram, G393-004 (Size 1) to G393-032/G397-035

(Size 4)

Bottom side

Figure 4.5 Connection diagram, G393-004 (Size 1) to G393-032/G397-035 (Size 4)

moog

Id. no.: CA97554-001 05/2017

4 Electrical installation

MSD Multi-Axis System Operation Manual DC-AC Servo Drive

31

Page 32

4 Electrical installation

moog

Id. no.: CA97554-001 05/2017

4.3.2 Layout, G393-045/G397-053 (Size 5) to G393-170/ G397-210 (Size 6A)

In the following you will find the layout with the corresponding positions of the

connectors and terminals. For improved clarity we have added an abbreviation to the

designation for the connectors and terminals.

PE

X11

X20

X9, X10

X8

X7

X6

D1, D2

T1, T2

PE

X11

MSD Multi-Axis System Operation Manual DC-AC Servo Drive

X20

X9, X10

X8

X7

X6

D1, D2

T1, T2

X2

X3

X4

X5

32

X2

X3

X4

X5

SW

HW

Figure 4.6 Layout, G393-045/G397-053 to G393-072/G397-084 (Size 5, without shield plates)

Option 1

Option 1

SW

HW

X12

Figure 4.7 Layout, G393-090/G397-110 to G393-170/G397-210 (Size 6A, without shield plates)

Page 33

Top side

DC-L

Front

X11

only

BG 6a

X10

X9

X20

X8

X7

X6

X5

X12

Danger!

DC +

DC -

DC +

DC -

+24 V

OSD03

Option 2

54321

15 14 13 12 11

10 9876

4321

9876

GND

ZK+

ZK-

1

2

1

2

+

-

U

V

W

DC-link

+

-

+

-

1

2

3

only BG5:

DC link

(Connect nothing!)

24 V DC Power supply for

control electronic (U

24 V DC Power supply

for brake (I

= 2.0 A)

IN

Triggering for

motor brake

Technology

8

Encoder

6

Resolver

Motor

3

~

PE

DC +

DC -

DC +

DC -

)

V

Service

interface

Service

interface

Control

Analog setpoint 1

Analog setpoint 2

+24 V DC against

DGND

Diagnosis

Digital0

Digital1

Digital2

E/A-GND

Communication

Field buses

Relay

STO

D1, D2

T1, T2

USB 1.1

Ethernet

3

ISA00+

4

ISA00-

5

ISA01+

6

ISA01-

15

ISD00

16

ISD01

17

ISD02

18

ISD03

19

ISD04

20

ISD05

ISD0621

10

ENPO(STO)

22

ISDSH(STO)

12

RSH

11

23

Relay

24

OSD04

7

OSD00

8

OSD01

9

OSD02

1

DGND

2

+24 V (U

14

13

DGND

Option 1

)

H

Danger!

X2

X3

X4

Bottom side

Figure 4.8 Connection diagram, G393-045/G397-053 (Size 5) to G393-170/G397-210 (Size 6A)

Abbreviation Designation Details

D1, D2 7-segment display chapter 5.4.2

T1, T2 Button chapter 5.4.1

X2 USB 1.1 interface chapter 4.9

X3 Ethernet interface chapter 4.10

X4 Control connections chapter 4.8

Option1 Communication chapter 4.11

X11 Connection for DC supply chapter 4.7

DC-L DC link cables chapter A.5

PE Connection for PE conductor chapter 4.4

X9, X10 Connection for control supply chapter 4.6

X8 (Option2) Technology chapter 4.12

X7 Connection for high-resolution encoder chapter 4.13

X6 Connection for resolver chapter 4.13.4

X5 Connection for motor temperature sensor chapter 4.14

X20 Connection for motor brake chapter 4.8.2

X12 Connection for motor chapter 4.14

HW Hardware rating plate Figure 4.6

SW Software rating plate Figure 4.7

Table 4.2 Key to connection diagram, G393-045/G397-053 (Size 5) to G393-170/G397-210

(Size 6A)

moog

Id. no.: CA97554-001 05/2017

4 Electrical installation

MSD Multi-Axis System Operation Manual DC-AC Servo Drive

33

Page 34

Brake (+)

Top side

T

ZK−

W

4 Electrical installation

moog

Id. no.: CA97554-001 05/2017

MSD Multi-Axis System Operation Manual DC-AC Servo Drive

34

4.3.3 Layout, G397-250 to G397-450 (Size 7)

In the following you will find the layout with the corresponding positions of the

1

connectors and terminals. For improved clarity we have added an abbreviation to the

designation for the connectors and terminals.

ZK−

ZK+

ZK+

PE

PE

X11

X45

X44

X8

D1, D2

X7

X6

1, T2

X2

X3

X4

X5

Option 1

SW

HW

RB−

RB+

PE

X12

U

V

Service

interface

Service

interface

Control

ENPO

Communication

Field buses

2

,

D

D

1

2

,

T

T

USB 1.1

X2

Ether net

X3

X4

3

ISA00+

4

ISA00-

5

ISA01+

6

ISA01-

15

ISD00

16

ISD01

17

ISD02

18

ISD03

ISD04

19

ISD05

20

ISD0621

10

ENPO

22

ISDSH

12

RSH

11

23

Relay

24

OSD04

7

OSD00

8

OSD01

9

OSD02

1

DGND

2

+24V(U

)

14

13

H

DGND

Option 1

X11

Danger!

X45

Danger!

X44

X8

X7

X6

X5

Front

X12

Danger!

Bottom side

Option 2

5 4321

15 14 13 12 11

10 9876

4321

9876

ZK−

ZK−

ZK+

ZK+

PE

PE

1

2

3

4

5

6

7

+

-

+

-

W

V

U

Dc link

via DC-Link cables

Reserved

+

–

Reserved

+24 V

OSD03

GND

5

9

Reserved

24 V Power supply for

control electronic (UV)

24 V DC Power supply

for brake (IIN = 2.0 A)

Triggering for

mitir brake

e. g. add. encoder

8

Encoder

6

Resolver

Motor

3~

(+)

Brake (-)

Figure 4.9 Layout, G397-250 to G397-450 (Size 7, without shield plates)

Figure 4.10 Connection diagram, G397-250 to G397-450 (Size 7)

Page 35

Abbreviation Designation Details

D1, D2 7-segment display chapter 5.4.2