MOODY 336 MK1 Owner's Manual

Details of ownership

Owners

Address:

Telephone number:

Name of yacht:

Registered number:

Hull number:

Engine number:

Ignition key number:

Cockpit door key number:

Distributor:

name:

-MS-^M^

VHF

call sign and number:

A

B

C

D

E

F

G

H

1

J

K

L

Alpha

Bravo

Charlie

Delta

Echo

Foxtrot

Golf

Hotel

India

Juliet

Kilo

Lima

Phonetic alphabet

Mike

M

N

November

Oscar

O

P

Papa

Quebec

Q

R

Romeo

Sierra

S

T

Tango

U

Uniform

V

Victor

w

Whiskey

X

X-Ray

Y

Z

0

1

2

3

4

5

6

7

8

9

Yankee

Zulo

Zero

Wun

Too

Thuree

Power

Fife

Six

Sev-en

Ate

Nin-er

Page 2 Issue 3

Hull, deck gear & below decks

Hull

Glass Reinforced Plastic (GRP) is used throughout the construction of the hull and

decks. Hull stiffening is achieved using balsa or foam

inside of the hull and by the fitting of bulkheads. Each bulkhead is bonded in

position using GRP and then further secured with bolts through the GRP bonding.

An inner GRP floor also adds to the strength and stability of the hull. Extra

strengthening is also applied to the keel attachment area in order to withstand the

loads imposed on the keel. Deck areas are surfaced with an integrally moulded non

slip finish.

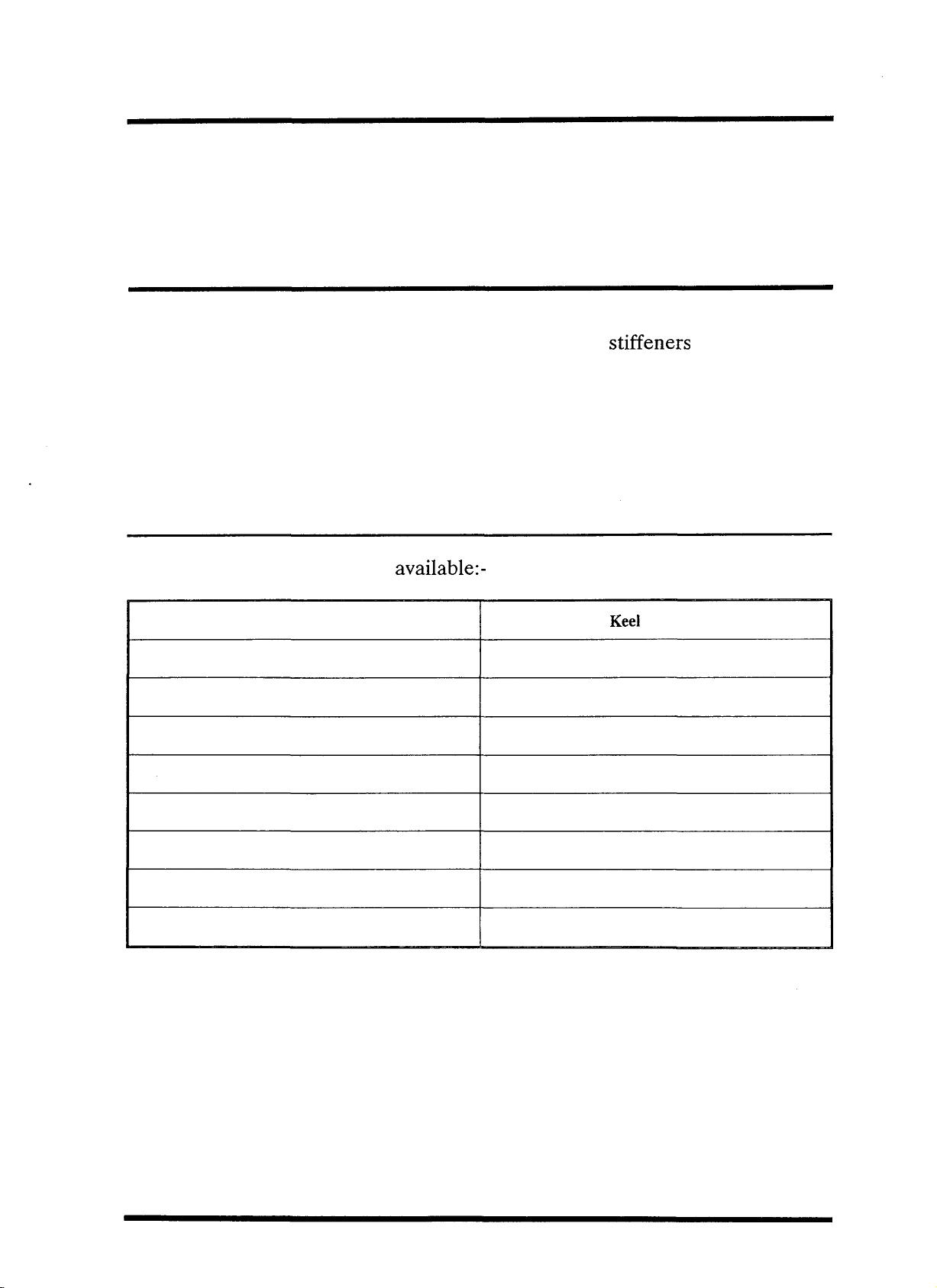

Keels

stiffeners

moulded to the

The following keel options are

Yacht

Moody 31

Moody 336

Moody 35

Moody 376

Moody 425

Eclipse 33

Eclipse 38

Eclipse 43

available:-

Keel

Options

Fin or Bilge

Fin or Bilge

Fin or Bilge

Fin or Scheel

Fin or Scheel

Fin or Bilge

Shoal

Shoal

Issue 3

Page 1.1

Antlfouling

Antifouling

season.

should be checked on a regular basis and replaced at least once a

The

antifouling

used

on

your yacht

is

____________________

Upholstery_______________________________________

Cleaning

Dust and grit should be removed frequently with a soft brush or the upholstery

attachment of a vacuum cleaner.

Creases

Where creases occur, raise the pile by brushing with a clean, damp cloth. Do not

saturate the fabric as the cotton backing may shrink. When dry, brush in the

direction of the pile with a soft brush.

Stains

Take immediate action, the longer stains are left the more difficult it is to remove

them. Nearly all stains can be removed by sponging lightly with warm water or a dry

foam upholstery shampoo. If this is not

effective,

covers can be removed and dry

cleaned. If heavily stained it is recommended that a reputable upholstery cleaner

is called in.

Ventilators_______________

Ensure that there is no entry of water through the deck seal. Reseal if necessary.

Issue 3 Page 1.9

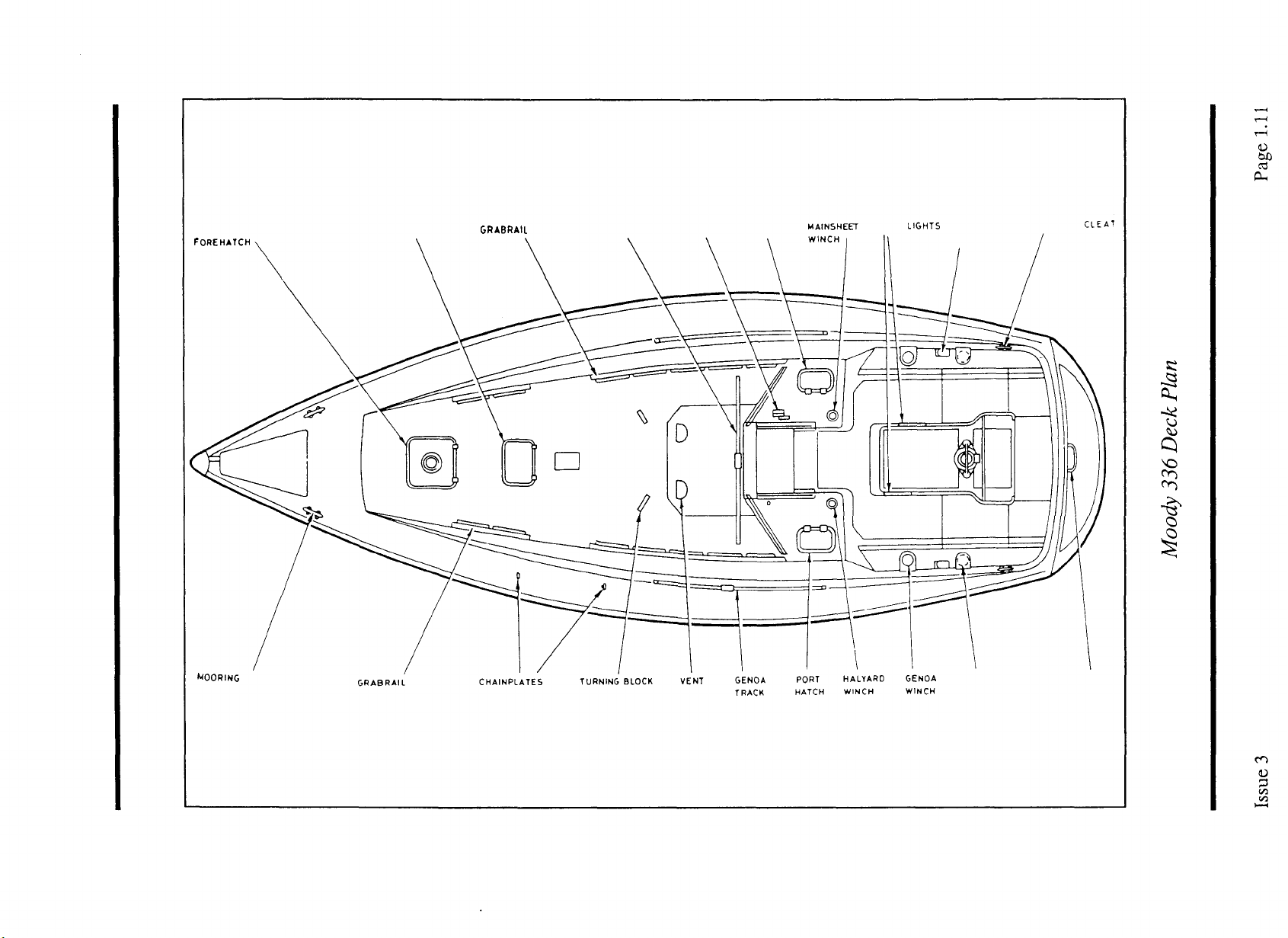

VENTILATED

FOREHATCH

SALOON HATCH

GRABRAIL

MAINSHEET TRACK JAMMER

STARBOARD

HATCH

PORT

LIGHTS

TURNING

BLOCK

MOORING

CLEAT

MOORING

CLEAT

SPINNAKER WINCH

(OPTIONAL)

D STEP

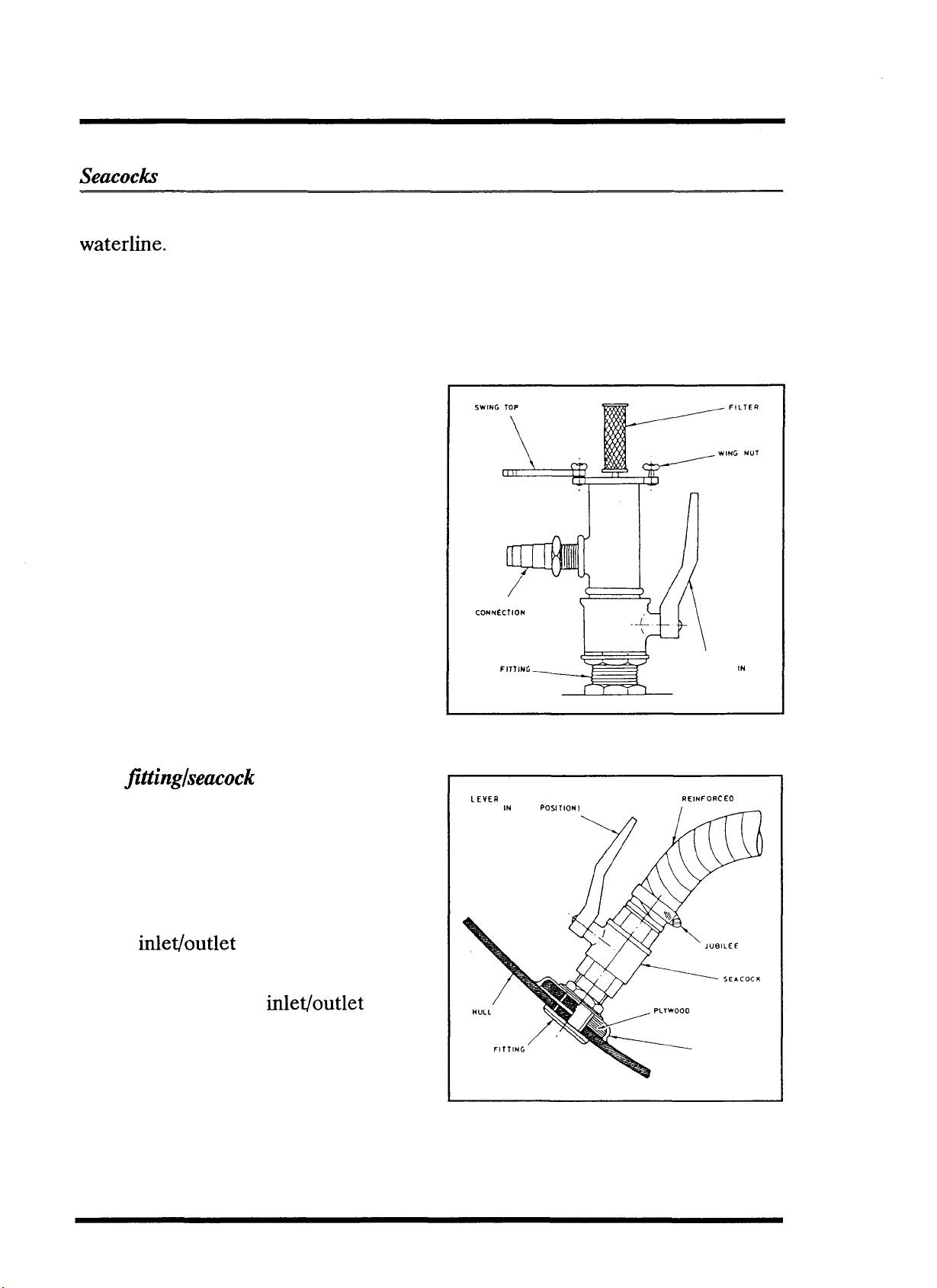

Seacocks________________________________________

Seacocks are fitted to all inlets and outlets which penetrate the hull below the

waterline.

The hull area around the penetration point is reinforced with an internal

plywood backing plate which is resin coated and bedded on compound. With the

exception of the engine cooling system inlet, all current Moody yachts are fitted

with a ball valve combined with a skin fitting.

Water inlet seacock and strainer

This type of seacock is fitted to the engine

cooling system inlet and it is operated as

follows:

1 To open - turn the knob anticlockwise

2 To close - turn the knob clockwise

INLET HOSE

CONNECTION

Skin

fitting/seacock

This type of seacock is used for sink,

shower and cockpit drains and marine

toilet inlet and outlets. It is operated as

follows:

1 To open - turn the lever to align with

the

inlet/outlet

hose.

2 To close - turn the lever until it is at

right angles to the

inlet/outlet

hose.

LEVER

SKIN

FITTING

(SHOWN

OPEN POSITION)

Water inlet seacock and strainer

PLYWOOD

REINFORCED

JUBILEE

BACKING PLATE

RESIN COAT ING

LEVER

(SHOWN

SKIN

IN

OPEN

FITTING

POS(TION)

IN

HOSE

CLIP

Page 1.2

Skin fitting/seacock

Issue 3

Cathodic

protection

All yachts are fitted with hull mounted sacrificial anodes as these give the best

results. These are usually mounted in the region of the engine compartment to keep

the bonding cable run to a

minunum.

Attachment

This is achieved by using studs permanently fixed to the inside of the hull to which

the anode is secured using nuts and locking washers.

Bonding

Bonding cables are internally attached to the mounting studs. The anode is bonded

to the engine, stern tube, rudder stock and

T'

bracket. There is no requirement for

the more remote skin fittings and seacocks or the keel mounting bolts to be

protected.

Hatches

and

portlights________________________________

All yachts use the following range of

Moody 31

Quantity

2

1

Type

Portlight

Hatch

Moody 336

Quantity

1

1

2

Type

Portlight

Portlight

Portlight

Lewmar

Manufacturer

Vetus

Lewmar

Manufacturer

Lewmar

Lewmar

Lewmar

hatches and portlights;

Model No.

PT100

(White)

86005S

Model No.

8906

8912

8932

Size

(")

12

3/8

X 5

1/2

19 3/4 X 19 3/4

Size

(")

4x10

5x12

5x15

Issue 3

2

1

1

Hatch

Hatch

Hatch

Lewmar

Lewmar

Lewmar

82005S

86005S

83005S

7 3/4 X 13

19 3/4 X 19 3/4

15

5/8

3/8

X 17 3/4

Page 1.3

Deck gear

Winches and windlasses

The following Lewmar winches are used:

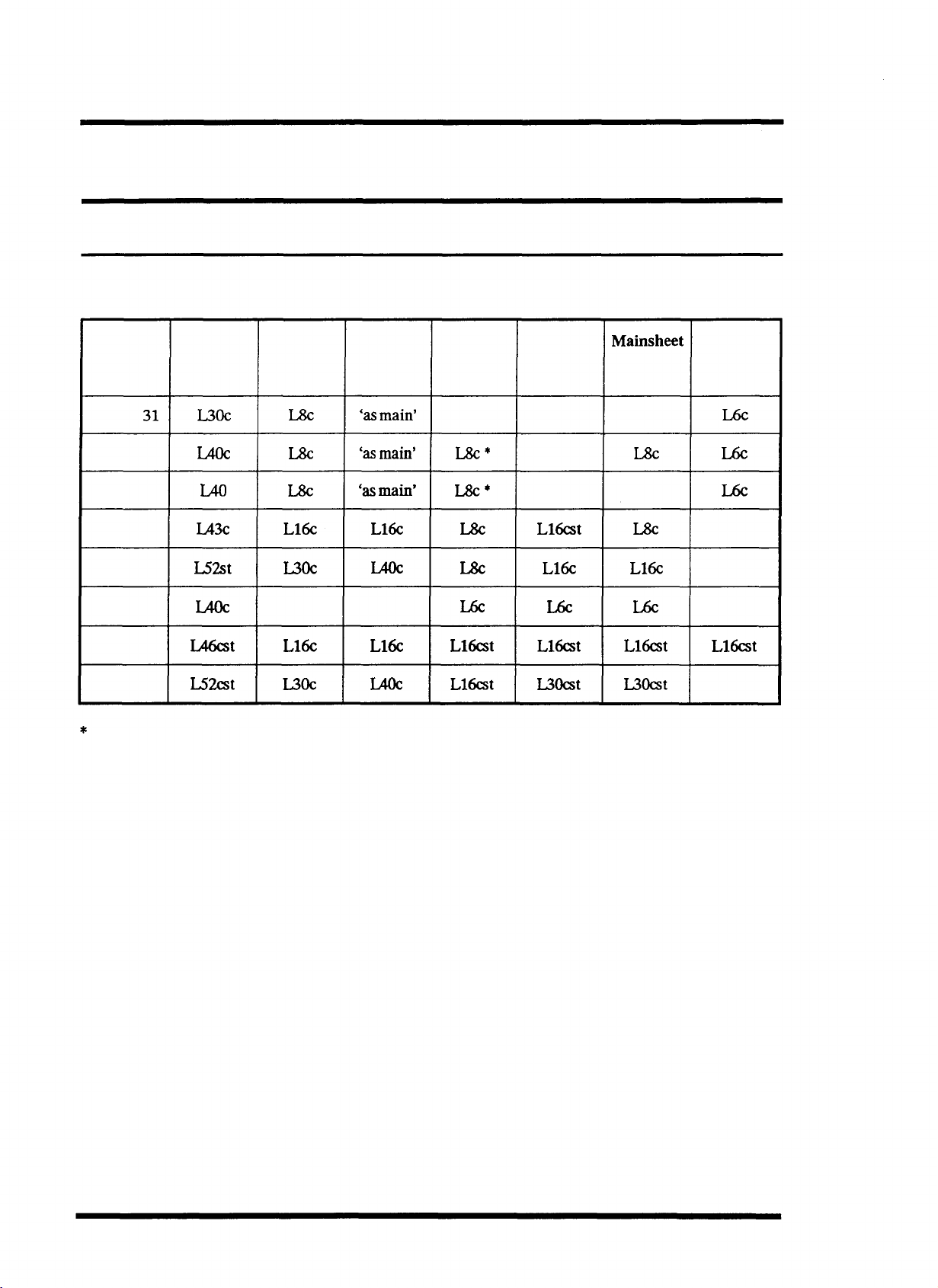

Yacht

Moody

Moody 336

Moody 35

Moody 376

Moody 425

Eclipse 33

Eclipse 38

Eclipse 43

31

Genoa

Sheets

L30c

L40c

L40

L43c

L52st

L40c

L46cst

L52cst

Main

Halyard

L8c

L8c

L8c

L16c

L30c

L7c

L16c

L30c

Genoa

Halyard

'as

main'

'as

main'

'as

main'

L16c

L40c

-

L16c

L40c

Furling genoa not fitted as standard.

Genoa

Furling

Line

-

L8c*

L8c*

L8c

L8c

L6c

L16cst

L16cst

Furling

Mainsail

Controls

-

-

-

L16cst

L16c

L6c

L16cst

LSOcst

Mainsheet

-

L8c

-

L8c

L16c

L6c

L16cst

L30cst

Mainsail

Reefing

Lines

L6c

L6c

L6c

-

-

-

L16cst

-

Page 1.6

Issue 3

The following windlasses are offered as options:

Yacht

Moody 31

Moody 336

Moody 35

Moody 376

Moody 425

Eclipse 33

Eclipse 38

Eclipse 43

Option/model

-

*Royal

*Royal

*Seawolf520

Royal

*Seawolf520

Royal

*Seawolf520

Anchorman (gypsy only)

*Power 700

(gypsy only -12V)

Power 700

(gypsy

only

-12V)

Power 1000

(gypsy only -12V)

Manufacturer

-

Lofirans

Lofrans

Simpson

Simpson Lawrence

Simpson Lawrence

Simpson Lawrence

Simpson Lawrence

Simpson Lawrence

Simpson Lawrence

Lawrence

Lofrans

Lofrans

Chain Size

-

8mm

8mm

5/16"

8mm

5/16"

10mm

9.5mm

5/16"

5/16"

9.5mm

9.5mm

* Not fitted as standard -

'Seawolf

to be replaced March 1991.

Using the windlass

It is recommended that your anchor chain is suitably marked to indicate the

amount of chain you have out while at anchor.

When lying at anchor in a heavy swell the chain will snatch either causing chain slip

or excessive loads to be applied to the windlass. For safety it is recommended that

a rope bridle be applied to transfer the load to a cleat.

Below decks

Upholstery_______________________________________

Your yacht has been upholstered with either the Christiana, Ravenna, Dash or

Onyx range of materials. They all meet the Fire and Safety Regulation Act and

have been tested to BS5852

to the maintenance section.

PTI.

For information on care of your upholstery refer

Issue 3

Page 1.7

Maintenance

Hull

Minor scratches and abrasions should be attended to in their early stages, initially

by using a medium grade rubbing compound. If this is ineffective, rub the area

lightly with 400 grade wet and dry paper (used with water) until the mark

disappears. Smooth the area with 800 grade followed by 1200 grade (both wet) and

then apply a silicone free wax polish.

Stress cracks should be looked at by an expert and some remedial action taken.

f Rubbing with abrasive compounds and materials removes the

* layer, great care should be taken.

gelcoat.

As this is only a thin

Annual cleaning

Wash the hull annually with warm water containing a little detergent. Stubborn

stains and polish should be removed with a recommended release agent or oil

removing fluid. Polish the hull with a silicone free wax polish.

Seacocks_______________________________________

Check regularly:

1 Security of attachment

2 Security and condition of hose and hose clips

3 Free operation of the valve

Sacrificial anodes _ __

The anode should be replaced when it is approximately two thirds eroded. If any

doubt exists as to whether the anode will survive the season - change it! The core

of the anode is a galvanised steel strip which provides the attachment lugs for the

anode. The anode is removed by undoing the two securing nuts and washers. It is

recommended that when replacing the anode, the nuts, washers and backing sheet

are also replaced.

Page 1.8 Issue 3

Sails, spars & rigging

Spars and rig

Your yacht is fitted with a

support, proper handling and caring routine

durable. Information on stepping the mast can be gained from the Kemp handbook

supplied with the yacht.

Kemp

aluminium mast and boom which, given good

mainenance,

should be remarkably

Rigging___________________

Standing

The standing rigging is the only support provided for the mast and it is vital that it

is adjusted and maintained correctly. In a seaway, if the rig is too slack, the mast

head or spreader area can build up movement thereby increasing the shock loading

on the stays. On the other hand, overtensioned rigging puts a higher total load on

the stays and can be just as damaging. The entire standing rigging is stainless steel

including all terminals, toggles, bottle screws and wire ropes. Some yachts are fitted

with a furling headsail system and an

information refer to

supplied with the yacht.

rigging____________________________________

'Hints

in-mast

and advice on rigging and tuning your Kemp

furling mainsail system. For further

Mast',

Rigging

Stainless steel rigging stretches and should therefore be regularly checked and

adjusted, particularly during the first season. It is recommended that reference be

made to the instructions given in

Mast'

adjustment

supplied with the yacht.

'Hints

and advice on rigging and tuning your Kemp

IssueS

Page

2.1

Maintenance

Rigging checks

During the sailing season when your yacht is in commission, regular maintenance

checks should be carried out and particularly before a long voyage.

1 Examine all

steel/wire

ropes for corrosion, wear and damage.

2 Examine all terminations for signs of wear, cracks or damage. Pay particular

attention to all split pins, they should be the largest size possible to pass through

the cotter pinhole with at least 3/4" protruding through the hole.

3 Examine all bottle screws for signs of wear or damage and ensure they are

safety',

i.e. the inner threads are visible through both safety holes. Where bottle

'in

screws are covered with tape or plastic tubing, remove to enable examination.

4 Ensure the ends of the spreader bar are protected to prevent sail

chafing.Ensure

the rig is correctly adjusted.

5 Remove halyards from the mast leaving messenger lines for

rereefmg.

6 Check all running rigging for signs of wear, paying particular attention to all eye

splices and end terminations. On the wire/rope halyards check the wire rope

splice. If the rope side of the splice is starting to swell then the wire has started

to rust and the halyard should be replaced. Wash halyards which are not being

replaced and soak rope joins in linseed oil (also soak joins on new halyards).

7 Check over the standing rigging paying particular attention to the wire where it

enters the swage fittings. Should there be any sign at all of cracking in any one

of the wire strands then replace the shroud concerned.

8 Look for signs of wear of ridging on clevis pins where they may rock or work in

chain plates or shroud tangs, also look for corresponding wear on mating fittings.

9 Where shrouds locate into mast by means of a shroud terminal in a slot, ensure

that there is no undue wear.

10

Renew all split pins for recommissioning.

Pane

2.10

IssueS

Mast________________________________^^^^^^^^^^_^^

See autumn overhaul in Kemps

mast'

Roller

booklet.

furling_____________________________________

'Hints

and advice on rigging and tuning your Kemp

Roller furling gear must be lubricated and cleaned regularly in accordance with the

manufacturers

recommendations..

Sails___________________________________________

Sails should be checked regularly and repairs effected for the following:

1 Chaffing occurring mainly at spreaders and on foot of large sails.

2 Tears at batten pockets and at all attachment points, tack, clew, head, sail and

reefing cringles.

3 Any other damage.

4 When a sail is lowered it should be bagged and stowed below as soon as possible.

5 On return to harbour, release the tension on the clew outhaul of the main,

remove batterns, flake the sail over the boom, secure with ties and put on sail

cover.

6 Furling headsails and mainsails should be checked carefully

for

any signs of wear

on the stitched seams.

Ropes____________________________________________

All ropes should be checked regularly during the season for the following:

1 Signs of wear or damage where constantly cleated, clamped or passed round

sheave blocks or through fairleads.

2 Damage to whipping or heat shrink sleeves.

3 All splices are serviceable. It is important where polyester ropes are spliced to

steel wire ropes, such as halyards.

IssueS

Page

2.11

Running rigging

The running rigging comprises all the lines and relative mechanics used to hoist and

control the sails, this includes halyards, sheets, guys, lifts, downhauls and outhauls

together with their various shackles, blocks, cleats and winches. It is essential that

they are inspected regularly for any signs of wear or stress. Information on types of

cordage, wire ropes and fittings can be gained from a good chandler.

Sails

All yachts are supplied with Lucas sails which are manufactured from woven

dacron. This material has good tensile strength, resists abrasion and is not unduly

affected by moisture, however, it can be damaged by ultra-violet light and should

not therefore be exposed unnecessarily to sunlight. If treated with care and

maintained correctly these sails should give many seasons good service.

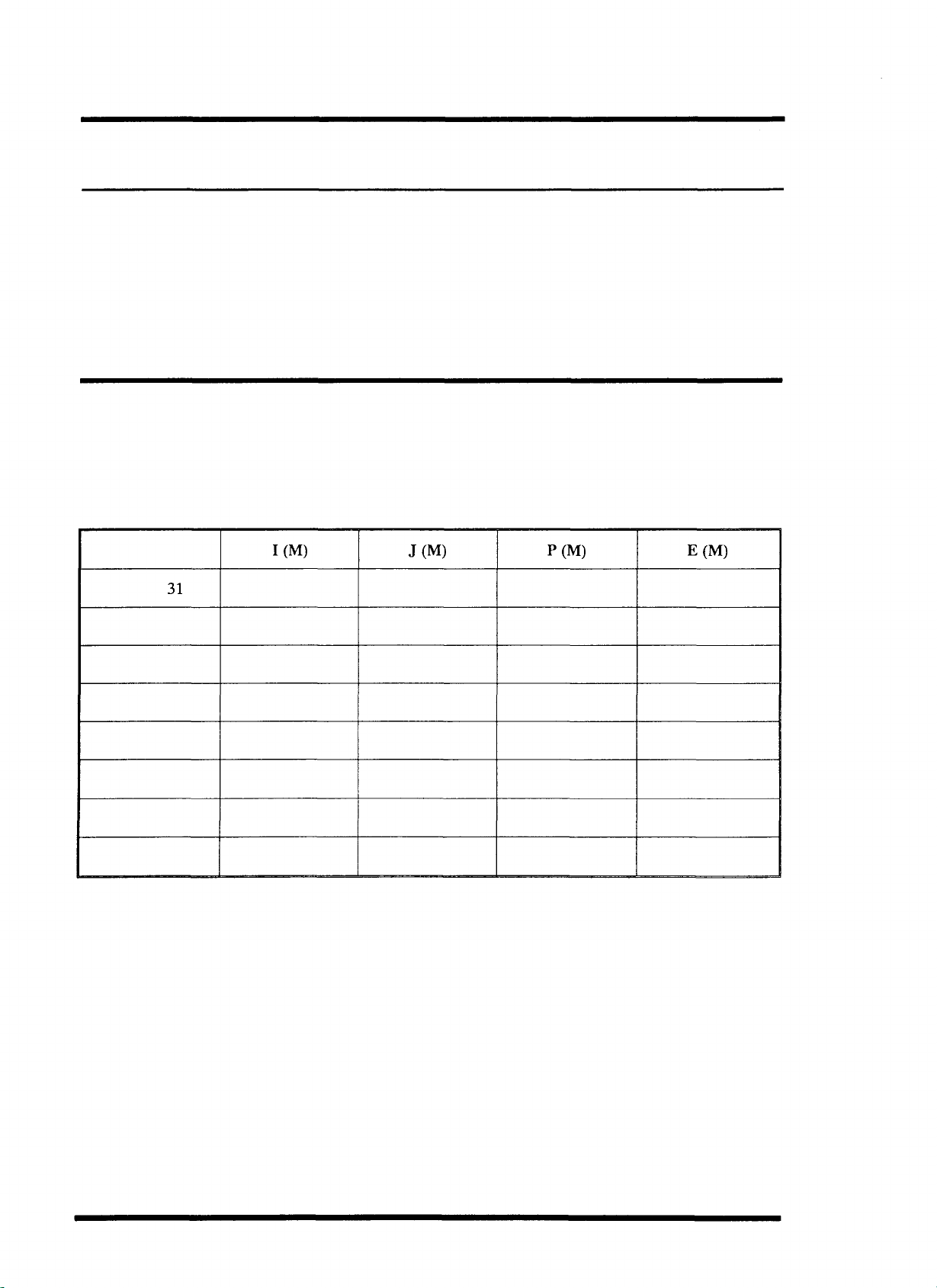

Yacht

Moody

Moody 336

Moody 35

Moody 376

Moody 425

Eclipse 33

Eclipse 38

Eclipse 43

31

I(M)

11.73

12.88

12.88

14.33

15.77

12.19

14.33

16.00

J(M)

3.81

4.11

4.09

4.57

5.03

3.10

4.57

5.03

P(M)

10.21

10.97

10.90

12.60

13.95

10.51

12.50

14.02

E(M)

3.51

3.73

3.78

4.34

4.72

3.50

4.34

4.72

Page 2.6 Issue 3

Folding Sails

Mainsail

If your yacht does not have a

of folding is with the sail still on the boom:

1 Tighten topping lift to support boom.

2 Lower the sail fully.

3 Ensure the coachroof hatches are closed.

4 Ease the tension in the foot of the sail by releasing the clew

5 Remove the battens to minimise stretch and chafing in the batten pockets.

6 Stand close to the mast on the opposite side of the pile of mainsail.

7 With an assistant at the leech, take hold of the sail about eighteen inches from

the boom , pull up together and lay the sail halfway over the boom. The bottom

of the hanging fold should be just below the bottom of the boom.

8 Take a further foot of sail and fold back over the boom in the opposite direction.

9 Continue this layering action until the entire sail is laid over the boom.

self-furling

mainsail system, one of the easiest methods

outhaul.

10

Secure the sail to the boom using sail ties.

11

The halyard can either be removed and stowed or left attached to the head of

the sail. If left on the sail, secure to the boom by passing a sail tie through the

head of the sail and then tension the halyard.

12

If the sail is to remain folded for more than a few hours, put the sail cover on to

prevent damage.

Issue 3 Page 2.7

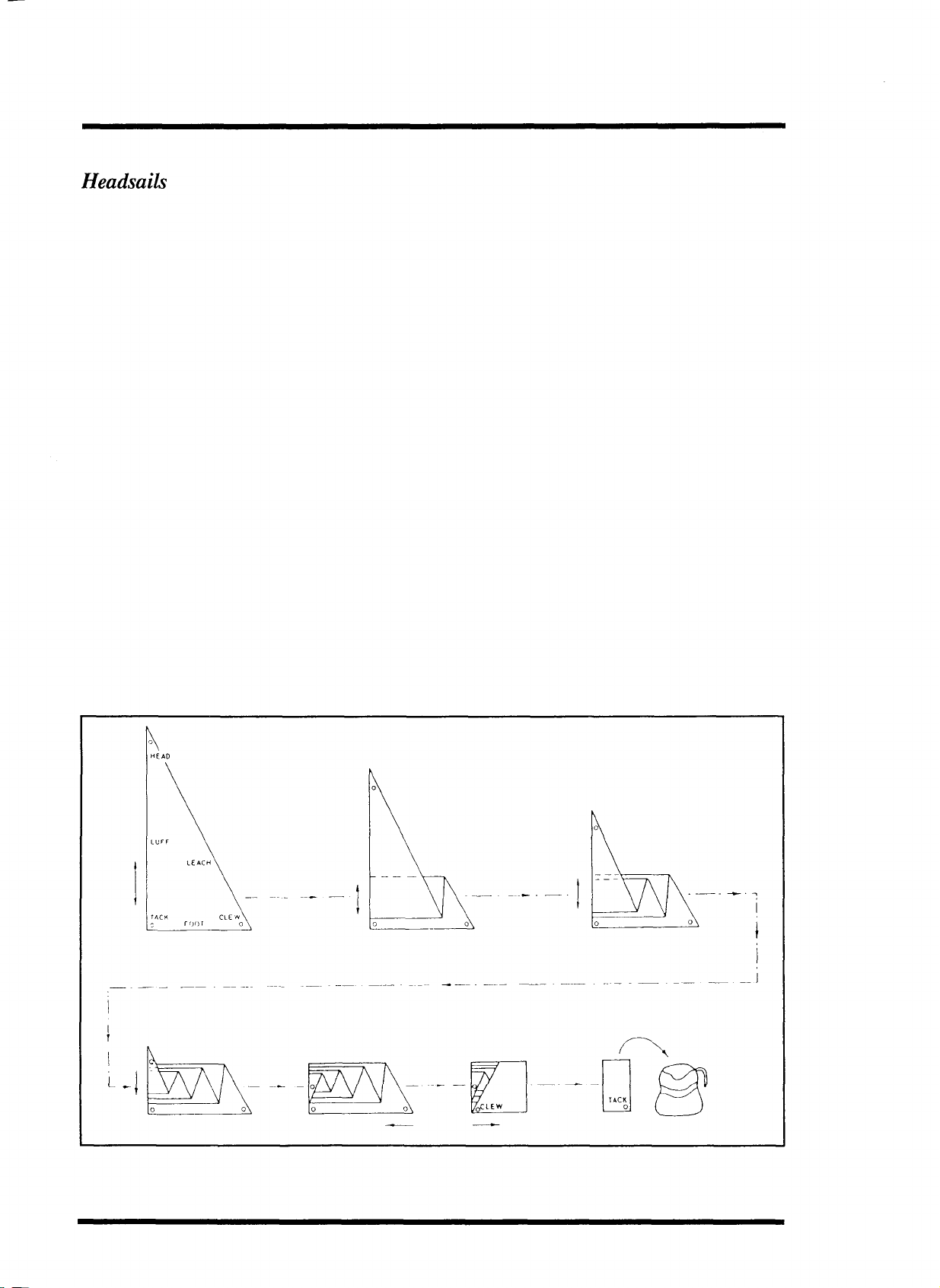

Headsails

Some yachts are fitted with furling headsails but if not, the headsail must be

removed and bagged when not in use.

Bagging

1 Put the head of the sail into the sailbag.

2 Work the luff, leech and body of the sail in together.

3 Leave the tack and clew until last and pass the sailbag neck cord through both

tack and clew before drawing tight. This enables the tack to be connected to the

stemhead and the sheets to be fitted to the clew before the sail is released from

the sailbag. The sheets can then be run back and secured without being snatched

by the sail. The sail can also be hanked to the forestay, one hank at a time, until

only the head is left to be attached to the halyard. In adverse conditions sails

bagged in this way can save a great deal of time on the foredeck.

Folding

1 Lay the headsail out flat in a convenient position, a pontoon or jetty is ideal.

2 The sail should then be folded following the steps illustrated.

L

_

Folding a headsail

Page 2.8 Issue 3

Setting sails

No yacht

included to assist in setting sails correctly.

Hoisting

Whilst this is a very straight forward procedure in itself, the amount of tension in

the halyard depends on wind conditions. All modern sails respond well to differing

tensions. Hoist the sail fully ensuring that on a mainsail there are no wrinkles in the

luff and also that on a

between the hanks. Creases in a sail are the first sign of incorrect tension and

depending on their position on the sail, indicate whether there is too much or too

little tension in the halyard.

Sheeting and trimming

The basic rule of sail sheeting is "let it out till it flaps,

Trimming and sheeting are best explained in books specifically written for the

purpose. It is recommended that every yacht's library has one.

wil

sail well if the sails are badly set. The points which

headsail

the luff does not curve away from the forestay

pul

follow

it in till it stops."

are

therefore

Kicker

This controls the amount of twist in the mainsail and also ensures that the boom

does not

strap, the only exception being when the mainsail is sheeted in hard. The easiest

way to tension the lacking strap to the optimum position is by using the top batten

as a guide. This should be parallel to the boom. If it lies to leeward, tighten the

kicking strap and if it lies to windward loosen it.

Mainsail

All current production yachts are fitted with either slab reefing or in-mast furling

systems.

'kick

reefing______________________________________

up'.

Therefore, there must always be some tension in the kicking

Issue 3 Page 2.9

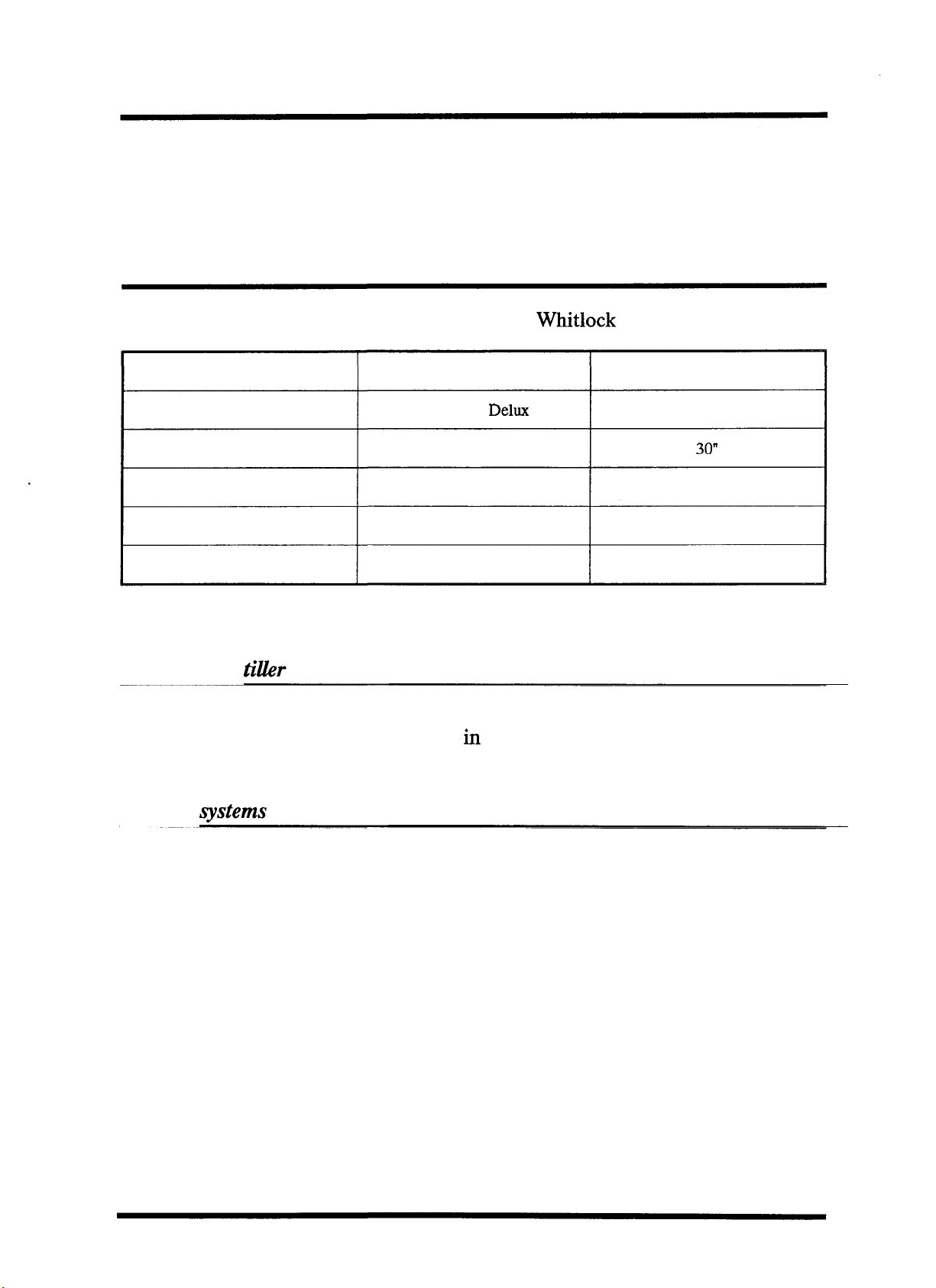

Steering systems

Single station steering systems

All steering systems fitted are manufactured by

Yacht

* Moody 31

Moody 336

Moody 35

Moody 376

Moody 425

Model

Cobra 5R

Cobra 5R Delux

Constellation 400

Constellation 400

Constellation 400

Delux

Whitlock

Marine

Wheel Size

26"

30"

36"

36"

36"

* Tiller steering is standard on Moody 31, wheel steering fitted only as an option.

Emergency

tiller___________________________________

All yachts, less those fitted with two steering positions as standard, are supplied

with an emergency tiller. This is fitted

hi

a tiller socket located either within the

yacht or externally under a blanking cover.

Cobra

systems____________________________________

The system is complete with friction brake and integral stainless steel output lever.

The system consists of:

Universal tiller lever, bored and keyed to suit the rudder stock.

Stainless steel draglink complete with rose joints and rudder stop ring, fitted

beneath the pedestal.

Either Retrofit guard rail or a single lever engine control and guard rail (see

illustrations on pages 3.5 and 3.6.

Issue 3

Page 3.1

Loading...

Loading...