MOODY 31, Eclipse 33, Eclipse 38, 336, Eclipse 43 Owner's Manual

...

OWNER'S

MANUAL

© Copyright Marine

Projects

(Plymouth) Limited 1991

All rights

reserved,

including right of reproduction in whole or in

part,

in any form.

Issue 3

Page 1

Introduction

Moody yachts are manufactured by Marine Projects (Plymouth) Limited. High

quality raw materials are used throughout and all major components are

manufactured to strict tolerances to allow for easy replacement and repair during

the yacht's life. Strict quality control exists during the manufacture of all yachts. All

ancillary components such as hatches, winches, pumps, etc. are supplied by

manufacturers with a proven record of quality and reliability.

All specifications given in this handbook are given in good faith. Marine Projects

(Plymouth) Limited implement a policy of continual development and therefore

reserve the right to improve the specification without notice. The specifications

given in this handbook supersede any previously stated specifications.

Marine Projects (Plymouth) Limited, their agents, distributors or publishers cannot

be held responsible for any inaccuracies or

ommissions

in this handbook or for any

injuries to anyone, however caused, engaged in any activity involving a Moody yacht

or its ancillary equipment either on land or in the water.

This manual is intended to give the owner a better understanding of the

construction of a Moody yacht, the layout of its systems and how to service and

maintain it to best effect.

A well maintained yacht is ultimately more reliable and retains a higher resale value.

Safety

It is the duty of the skipper/owner of the yacht to ensure that the vessel and its crew

are fit to go to sea. Information concerning safety at sea can be obtained from the

Royal Yachting Association (RYA),

HM

Coastguards and the International

Maritime Organisation

(IMO),

who provide guidence and booklets on the subject.

Issue 3 Page 3

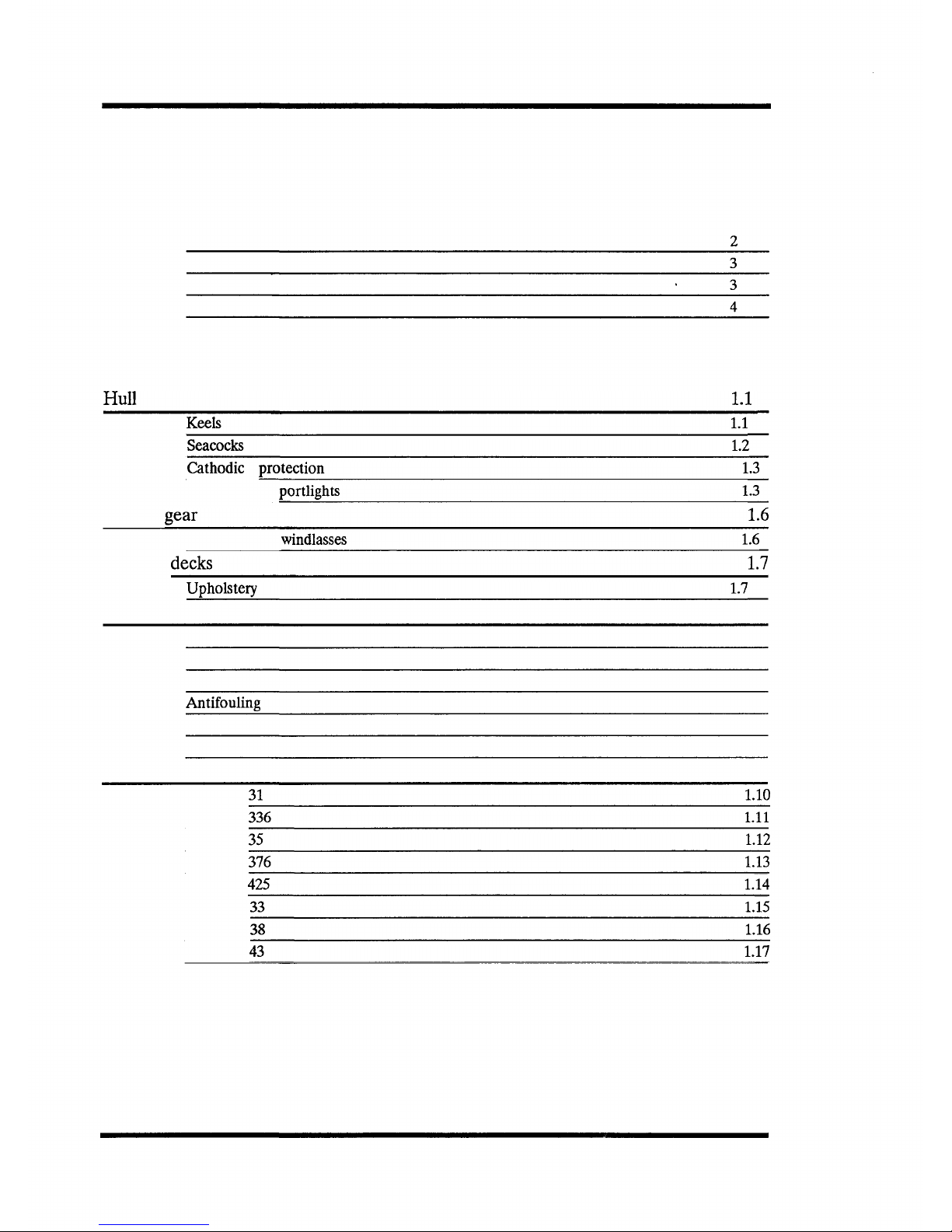

Contents

Details of ownership

Introduction

Safety

Contents

Hull, Deck gear & below decks

Hull___________________________________________Ll_

Keels____________________________________________1.1

Seacocks________________________________________1.2

Cathodic

protection___________________________________1.3

Hatches

and

portlights_________________________________1.3

Deck

gear__________________________________________1.6

Winches

and

windlasses__________________________________1.6

Below

decks_______________________________________1.7

Upholstery_______________________________________1.7

Maintenance 1.8

Hull

Seacocks

Sacrificial anodes

Antifouling

Upholstery

Ventilators

Deck plans

1.8

1.8

1.8

1.9

1.9

1.9

1.10

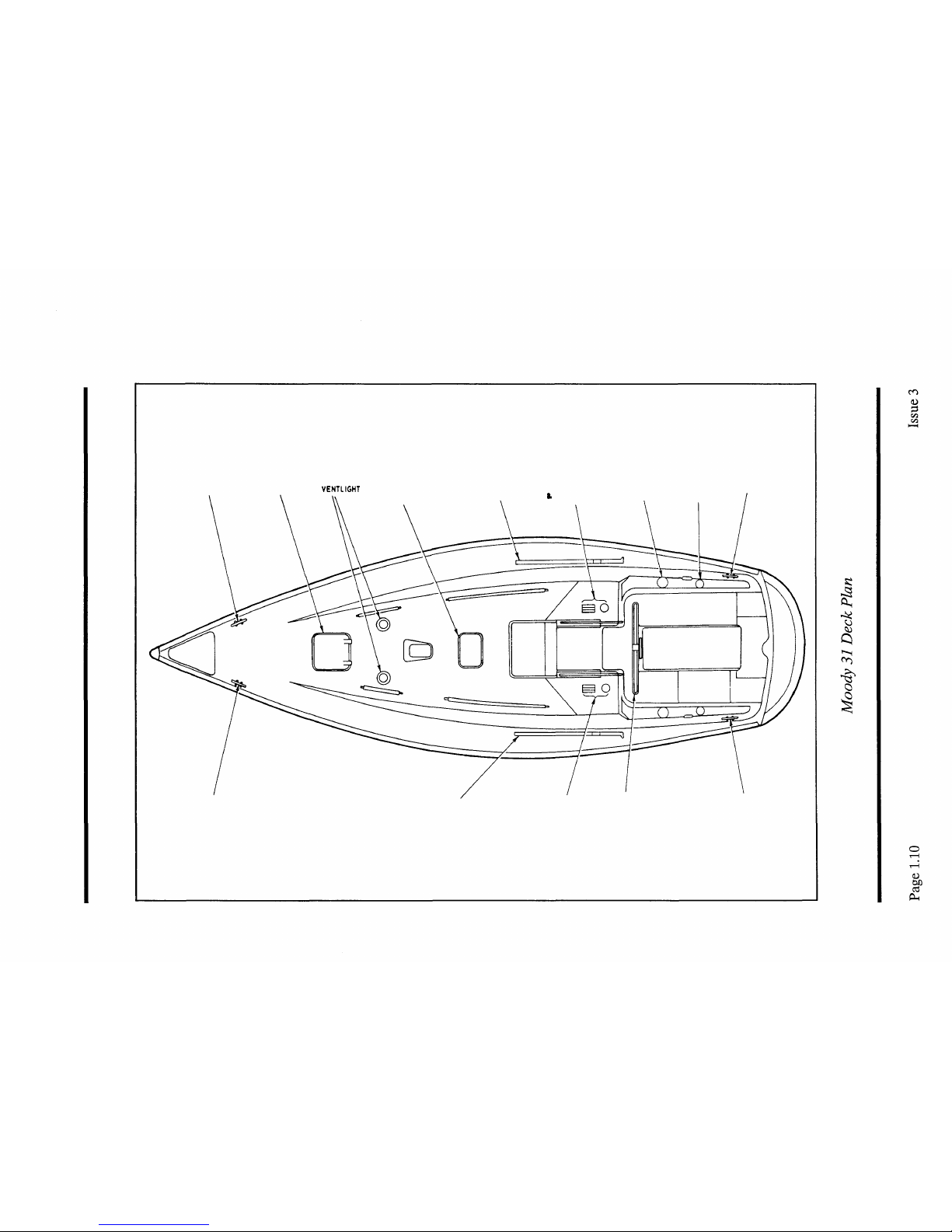

Moody

31____________________________________________1.10

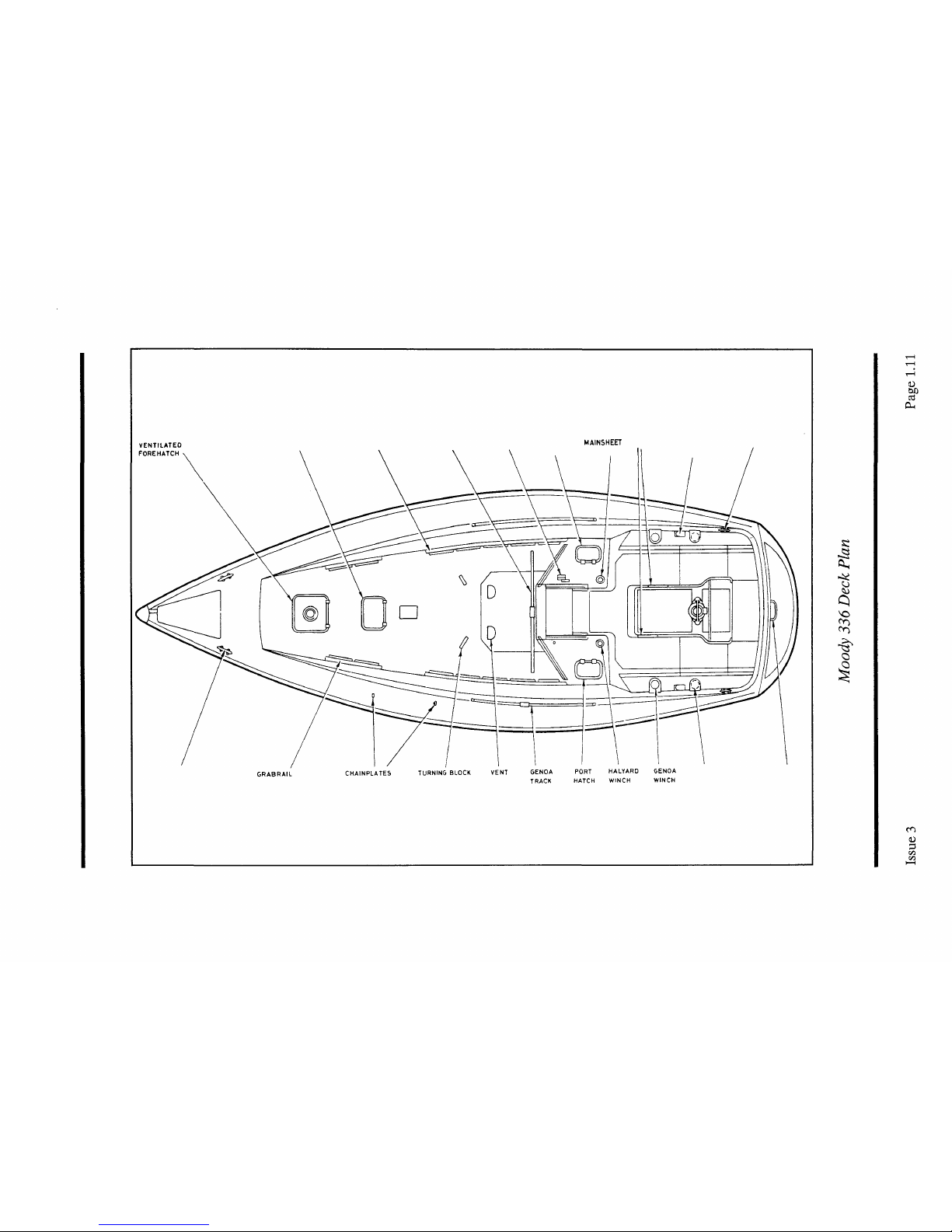

Moody

336___________________________________________1.11

Moody

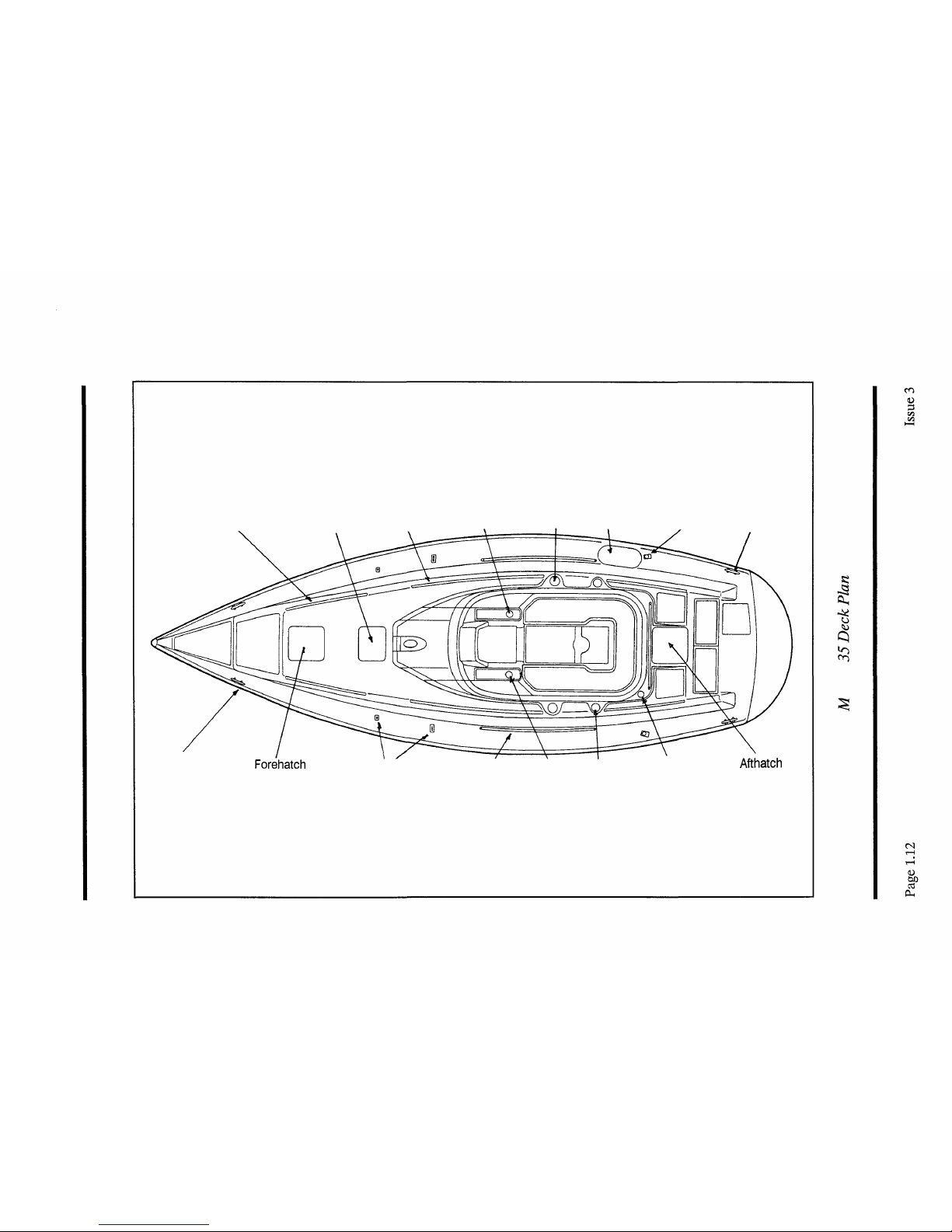

35_________________________________________1.12

Moody

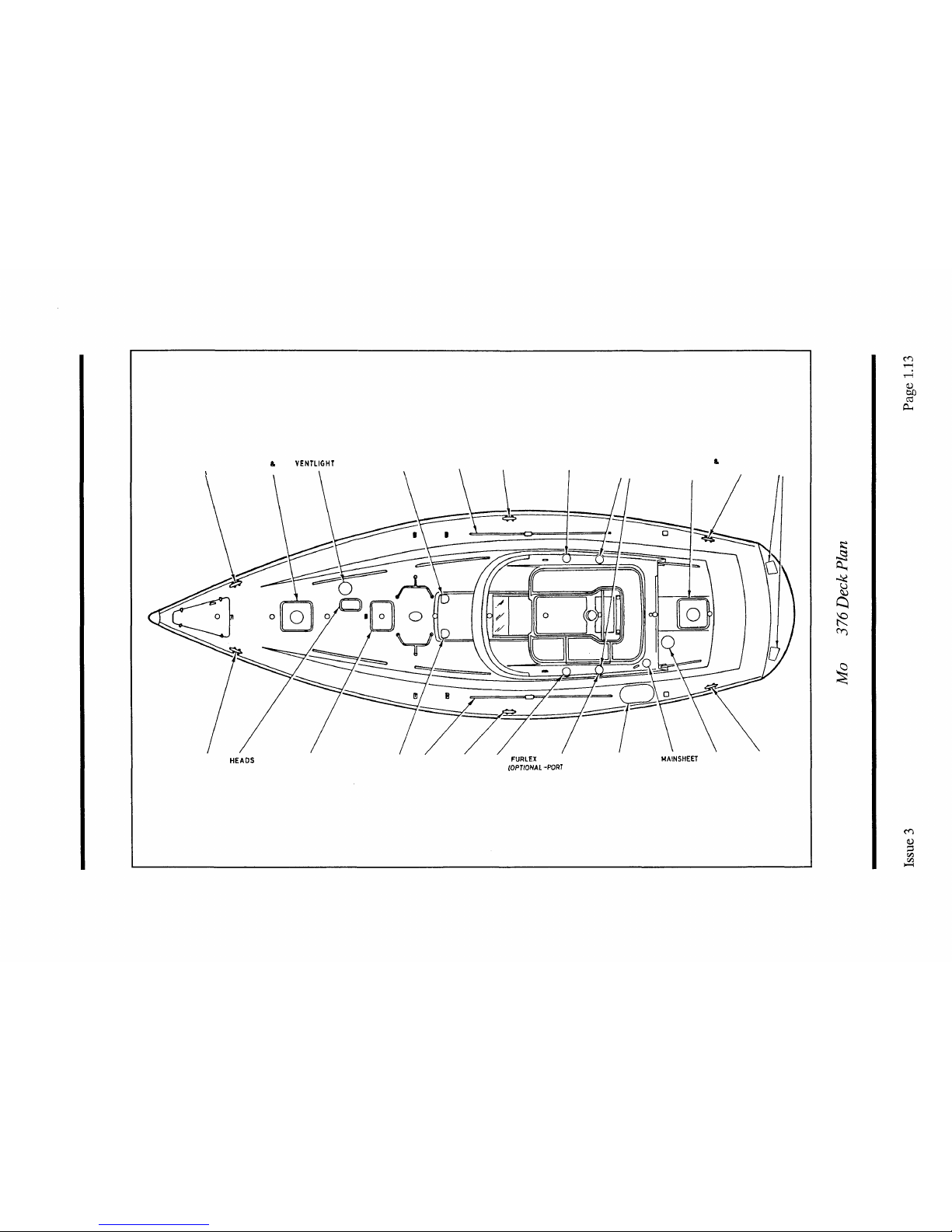

376________________________________________1.13

Moody

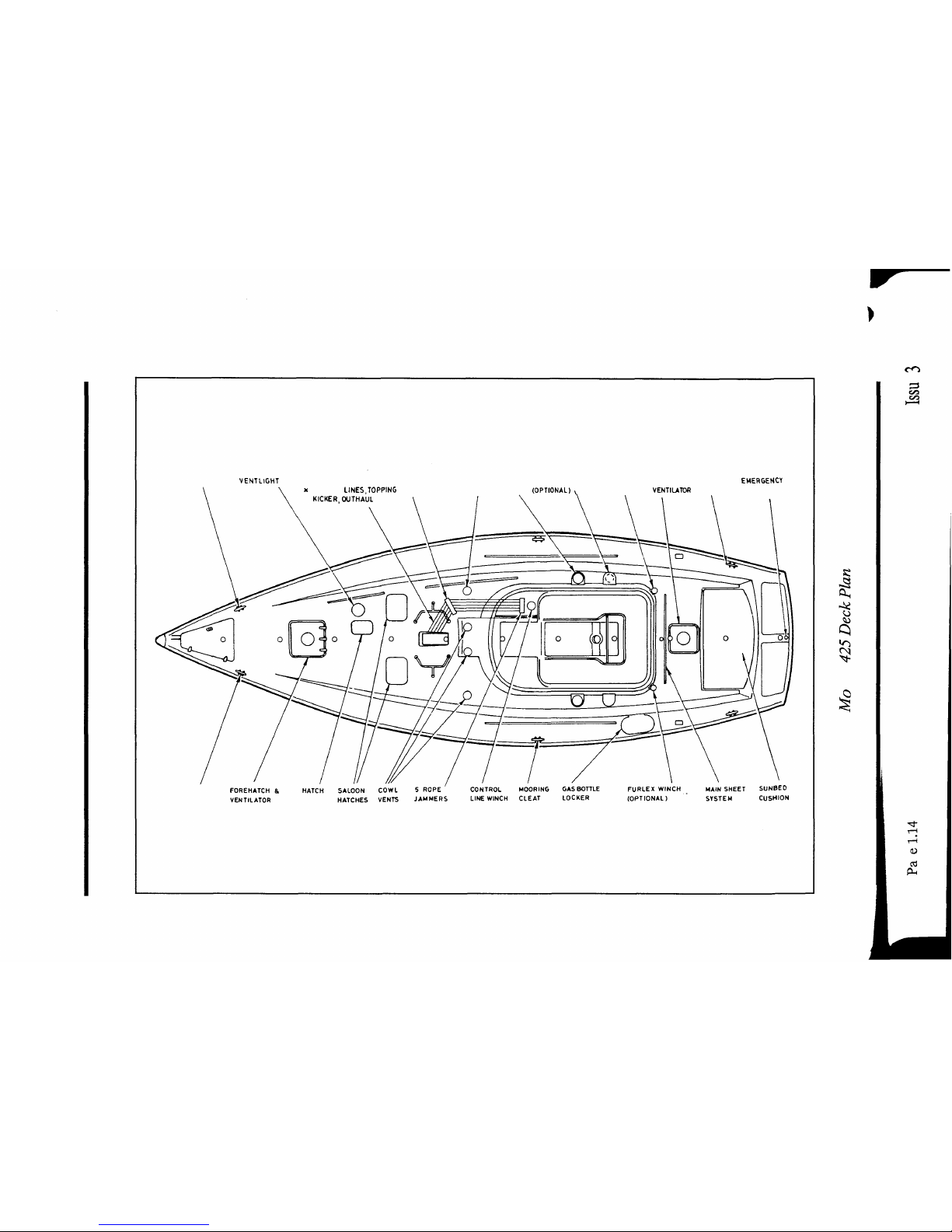

425___________________________________________1.14

Eclipse

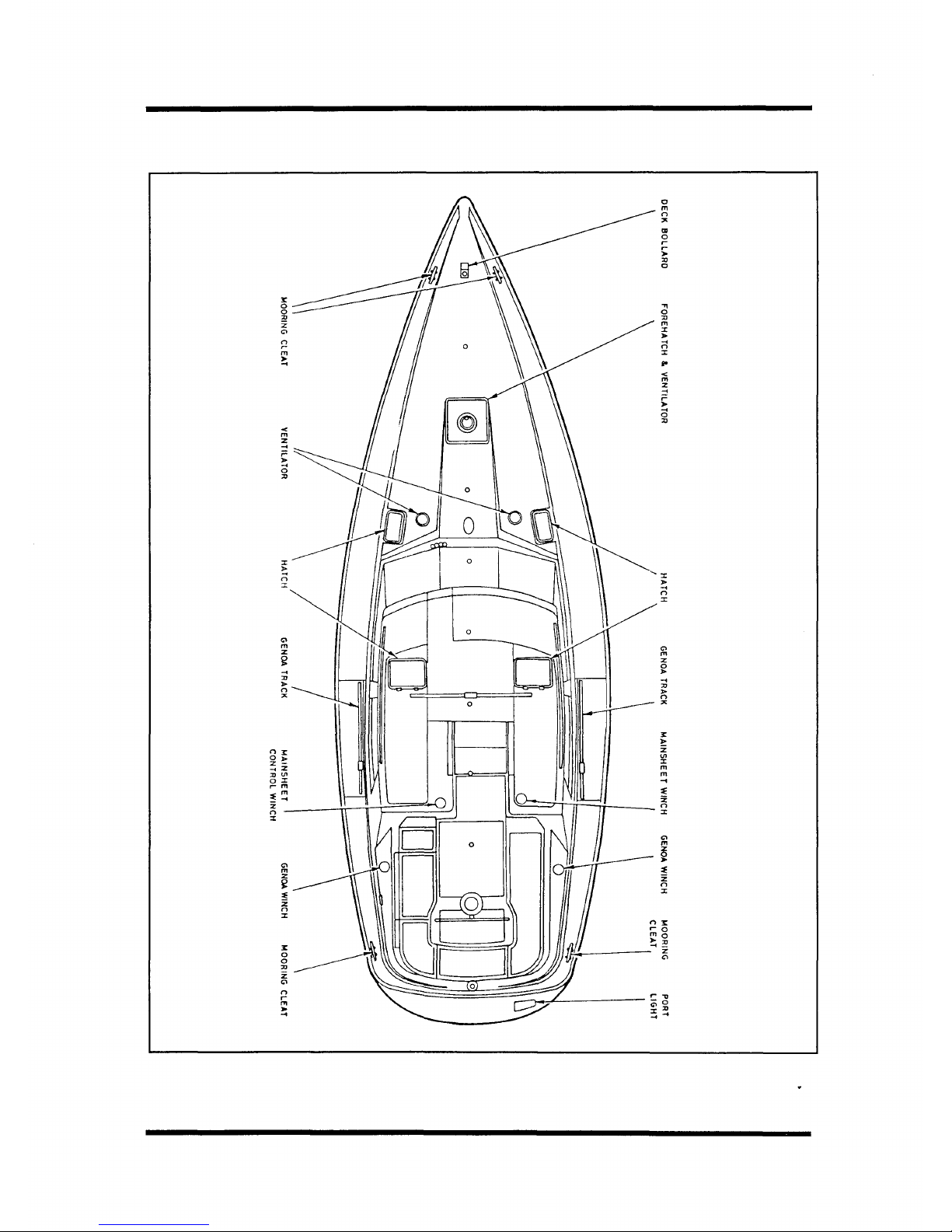

33____________________________________________1.15

Eclipse

38_________________________________________1.16

Eclipse

43_________________________________________1.17

Page 4 Issue 3

Sails,

spars & rigging

Spars

and

rig______________________________________2.1

Rigging_________________________________________2.1

Standing

rigging______________________________________2.1

Running

rigging______________________________________2.6

Sails______________________________________________2.6

Folding

sails________________________________________2.7

Setting

sails___________________________________2.9

Mainsail

reefing____________________________________

2.9

Maintenance________________________________________2.10

Rigging

checks______________________________________2.10

Mast____________________________________2.11

Roller

furling_____________________________________2.11

Sails____________________________________________2.11

Ropes_________________________________________________2.11

Steering systems

Single

station

steering

systems_____________________________________________3.1

Emergency

tiller_____________________________________3.1

Cobra

systems_______________________________________3.1

Constellation

systems___________________________________3.2

Dual

station

steering

systems_______________________________3.2

Inside

steering

station__________________________________3.2

Rudders_________________________________________3.3

Maintenance______________________________________3.4

Rudders__________________________________________3.4

Wheel steering systems__________________

3.4

Steering

system

installation

diagrams_______________________________________3.5

Cobra

5R

delux

steering

system_____________________________3.5

Cobra

5RISS

prestige

steering

system__________________________3.6

Constellation 400 steering system 3.7

Issue 3 Page 5

Engine systems

Engine

options________________________________________4.1

Running-in___________________________________________4.2

Fuel

systems__________________________________________4.3

Fuel

tank_________________________________________4.3

Fuel

stopcock_________________________________________4.3

Fuel

filter___________________________________________4.3

Water

trap________________________________________4.3

Return

pipes_______________________________________4.3

Fuel

contents_______________________________________4.3

Cooling

systems______________________________________4.4

Raw

water

cooled

engines________________________________4.4

Heat

exchanger

cooled

engines______________________________4.4

Water filter 4.5

Exhaust

systems_______________________________________4.5

Engine

controls________________________________________4.6

Gear

selection_________________________________________4.6

Engine

stop

mechanisms_________________________________4.6

Turbocharged

engines___________________________________4.7

Operating

instructions____________________________________4.7

Stern

gear__________________________________________4.8

Cutlass

bearing______________________________________4.8

Calcium

deposits_____________________________________4.9

Stern

glands________________________________________4.9

Bow thrusters________________________________________4.9

Maintenance________________________________________4.10

Basic

engine

care___________

4.10

Turbochargers______________________________________4.11

Engine

system

installation

diagrams___________________________4.12

Moody

31_________________________________________4.12

Moody

336___________________________________________4.13

Moody

35____________________________________________4.14

Moody

376___________________________________________4.15

Moody

425___________________________________________4.16

Eclipse

33___________________________________________4.17

Eclipse

38___________________________________________4.18

Eclipse 43 ___ 4.19

Page 6 Issue 3

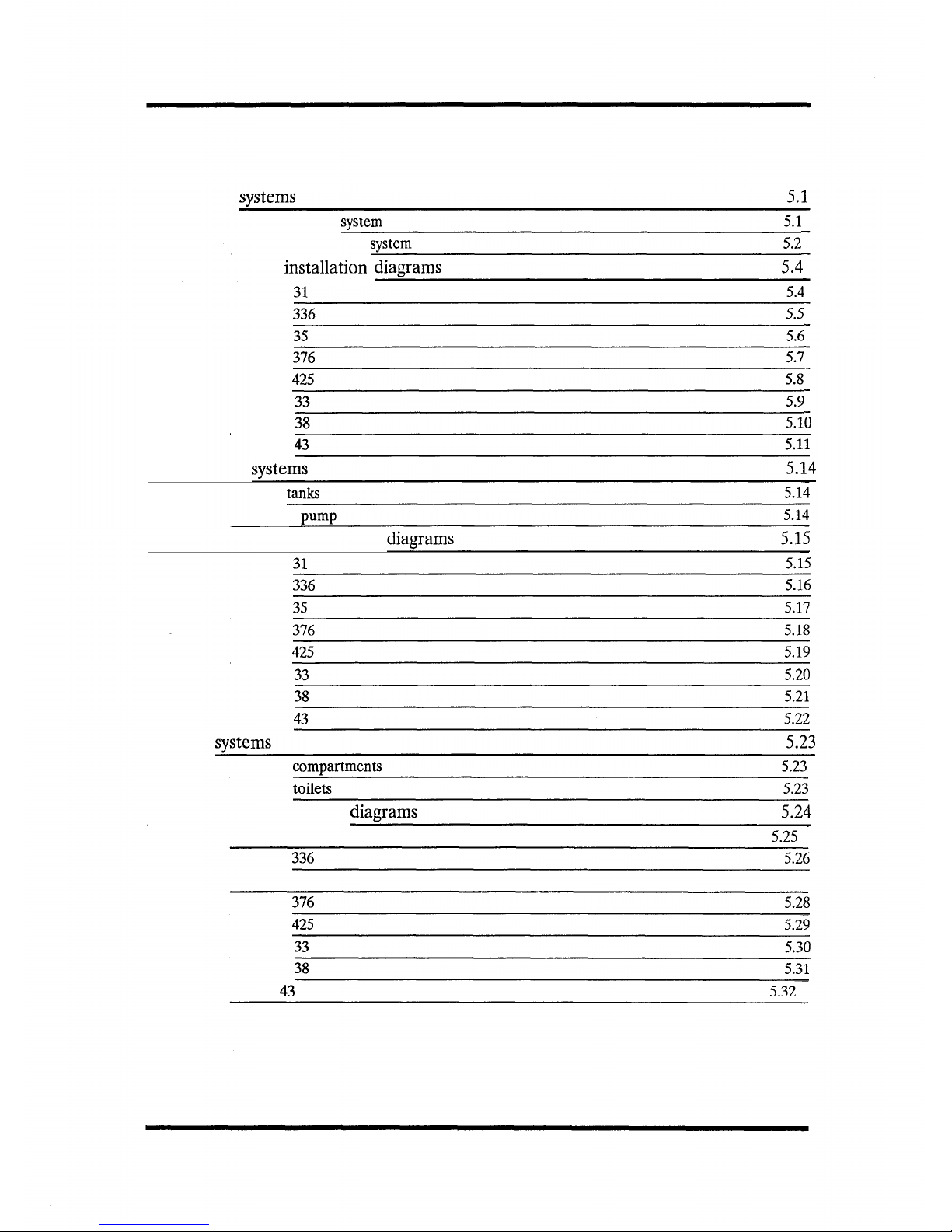

Utilities

Electrical

systems____________________________________5.1

Batteries

- 12V

system__________________________________5.1

Shore

power - 240V

system________________________________5.2

Electrical

system

installation

diagrams__________________________5.4

Moody

31_________________________________________5.4

Moody

336___________________________________________5.5

Moody

35____________________________________________5.6

Moody

376___________________________________________5.7

Moody

425___________________________________________5.8

Eclipse

33___________________________________________5.9

Eclipse

38___________________________________________5.10

Eclipse

43____________________________________________5.11

Freshwater

systems_____________________________________5.14

Water

tanks________________________________________5.14

Pressure

pump_________________________________________5.14

Freshwater system installation

diagrams_________________________5.15

Moody

31____________________________________________5.15

Moody

336___________________________________________5.16

Moody

35____________________________________________5.17

Moody

376___________________________________________5.18

Moody

425___________________________________________5.19

Eclipse

33___________________________________________5.20

Eclipse

38___________________________________________5.21

Eclipse

43___________________________________________5.22

Waste

systems_______________________________________5.23

Shower

compartments__________________________________5.23

Marine

toilets_______________________________________5.23

Waste system installation

diagrams____________________________5.24

Moody 31

5.25

"

Moody

336___________________________________________5.26

Moody 35 5.27

Moody

376________________________________________5.28

Moody

425___________________________________________5.29

Eclipse

33___________________________________________5.30

Eclipse

38___________________________________________5.31

Eclipse

43

5.32

Issue 3 Page 7

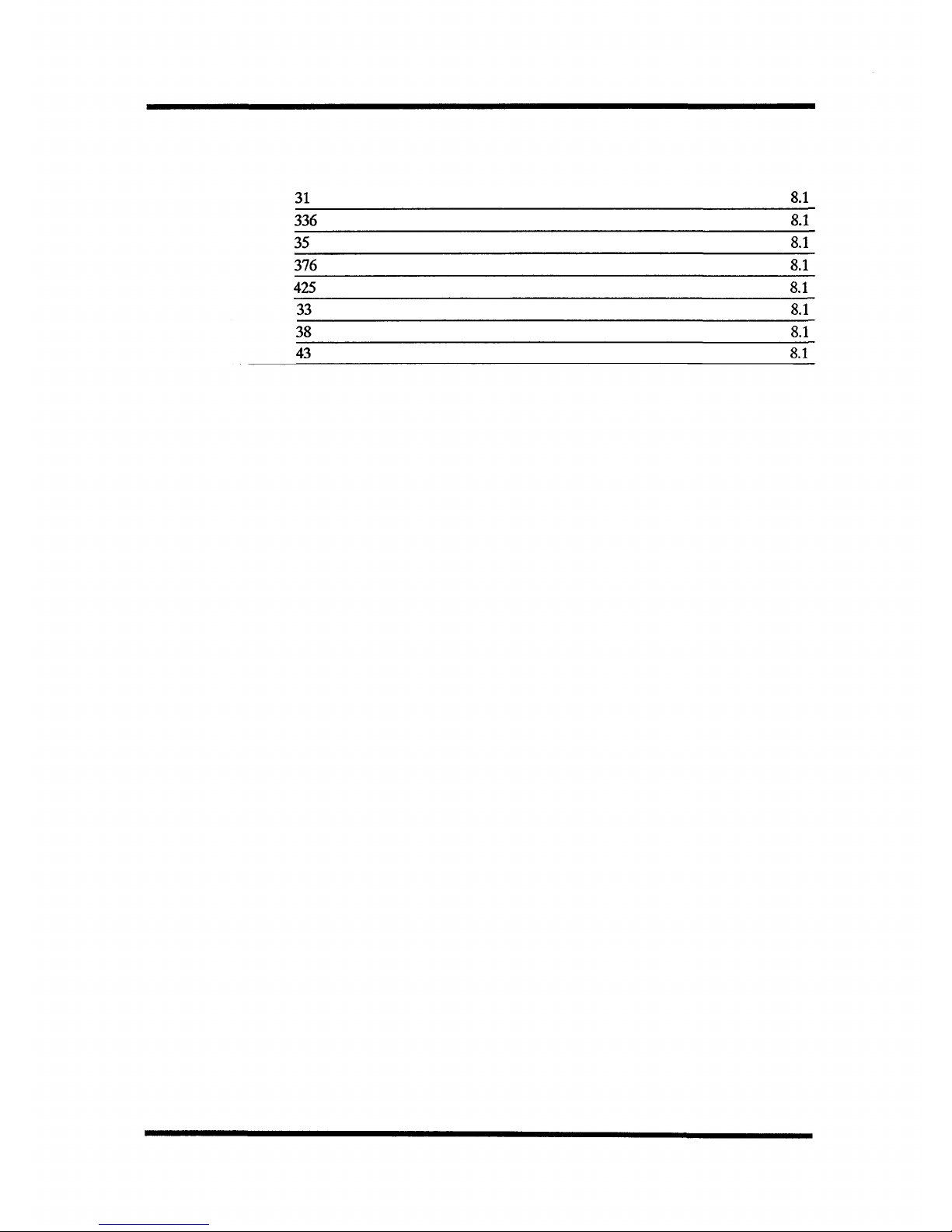

Specifications

Moody

31_________________________________________8.1

Moody

336________________________________________8.1

Moody

35_________________________________________8.1

Moody

376________________________________________8.1

Moody

425___________________________________________8.1

Eclipse

33_________________________________________8.1

Eclipse

38_________________________________________8.1

Eclipse

43_________________________________________8.1

Issue 3 Page 9

Hull,

deck gear & below decks

Hull

Glass Reinforced Plastic (GRP) is used throughout the construction of the hull and

decks. Hull stiffening is achieved using balsa or foam

stiffeners

moulded to the

inside of the hull and by the fitting of bulkheads. Each bulkhead is bonded in

position using

GRP

and then further secured with bolts through the

GRP

bonding.

An inner GRP floor also adds to the strength and stability of the hull. Extra

strengthening is also applied to the keel attachment area in order to withstand the

loads imposed on the keel. Deck areas are surfaced with an integrally moulded non

slip finish.

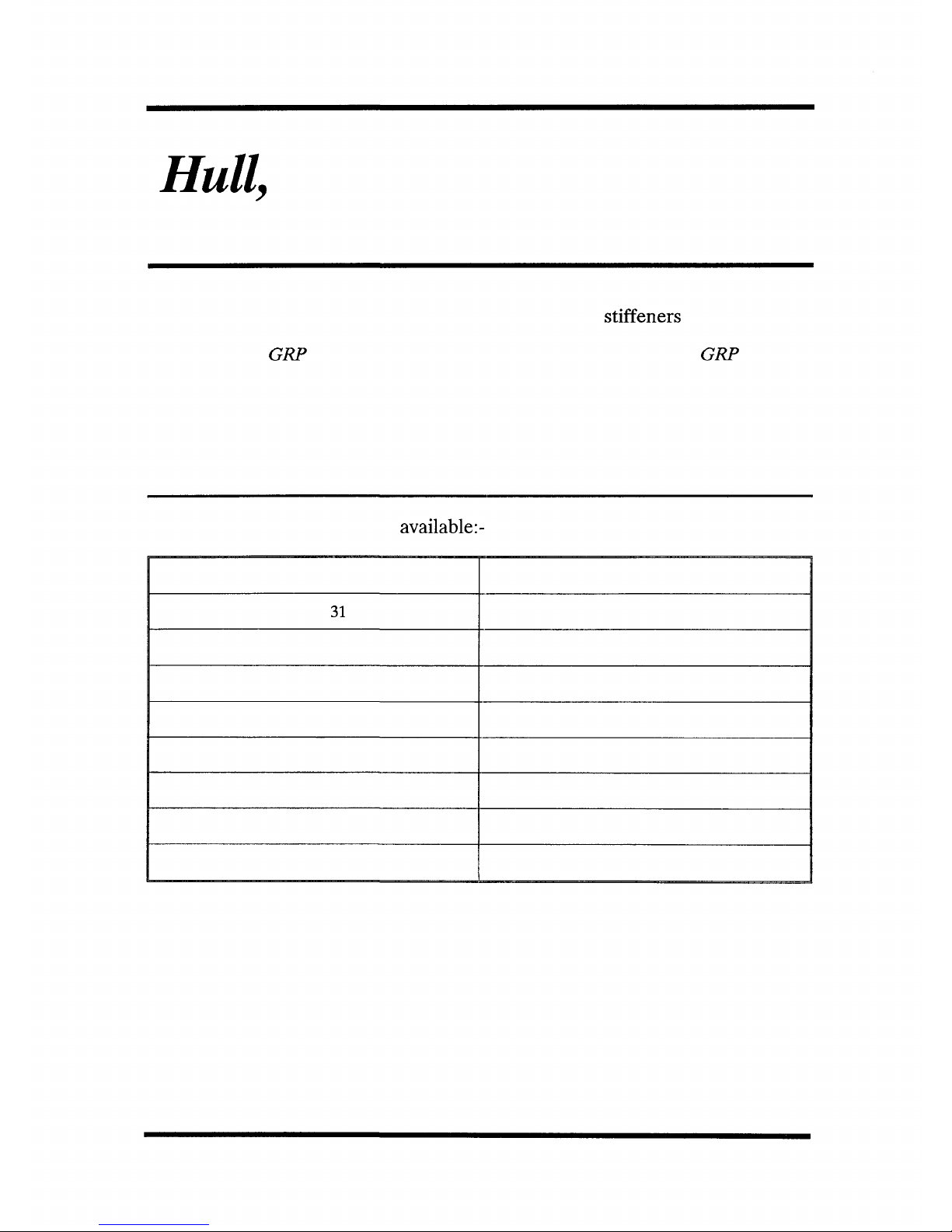

Keels

The following keel options are

available:-

Yacht

Moody

31

Moody 336

Moody 35

Moody 376

Moody 425

Eclipse 33

Eclipse 38

Eclipse 43

Keel Options

Fin or Bilge

Fin or Bilge

Fin or Bilge

Fin or Scheel

Fin or Scheel

Fin or Bilge

Shoal

Shoal

Issue 3

Page 1.1

Seacocks________________________________________

Seacocks are fitted to all inlets and outlets which penetrate the hull below the

waterline. The hull area around the penetration point is reinforced with an internal

plywood backing plate which is resin coated and bedded on compound. With the

exception of the engine cooling system inlet, all current Moody yachts are fitted

with a ball valve combined with a skin fitting.

Water inlet seacock and strainer

This type of seacock is fitted to the engine

cooling system inlet and it is operated as

follows:

1 To open - turn the knob anticlockwise

2 To close - turn the knob clockwise

Skin

fittingi'seacock

This type of seacock is used for sink,

shower and cockpit drains and marine

toilet

inlet and outlets. It is operated as

follows:

1 To open - turn the lever to align with

the inlet/outlet hose.

2 To close - turn the lever until it is at

right angles to the inlet/outlet hose.

INLET HOSE

CONNECTION

SKIN FITTING

LEVER

(SHOWN IN

OPEN POSITION)

Water inlet seacock and strainer

LEVER

(SHOWN

IN OPEN

POSITION)

REINFORCED HOSE

SKIN

FITTING

JUBILEE

CLIP

PLYWOOD

BACKING PLATE

RESIN

COATING

Skin fittingi seacock

Page 1.2

Issue 3

Cathodic protection

All yachts are fitted with hull mounted sacrificial anodes as these give the best

results. These are usually mounted

in

the region of the engine compartment

to

keep

the bonding cable run to a minimum.

Attachment

This is achieved by using studs permanently fixed to the inside of the hull to which

the anode is secured using nuts and locking washers.

Bonding

Bonding cables are internally attached to the mounting studs. The anode is bonded

to the engine, stern tube, rudder stock and

T'

bracket. There is no requirement for

the more remote skin fittings and seacocks or the keel mounting bolts to be

protected.

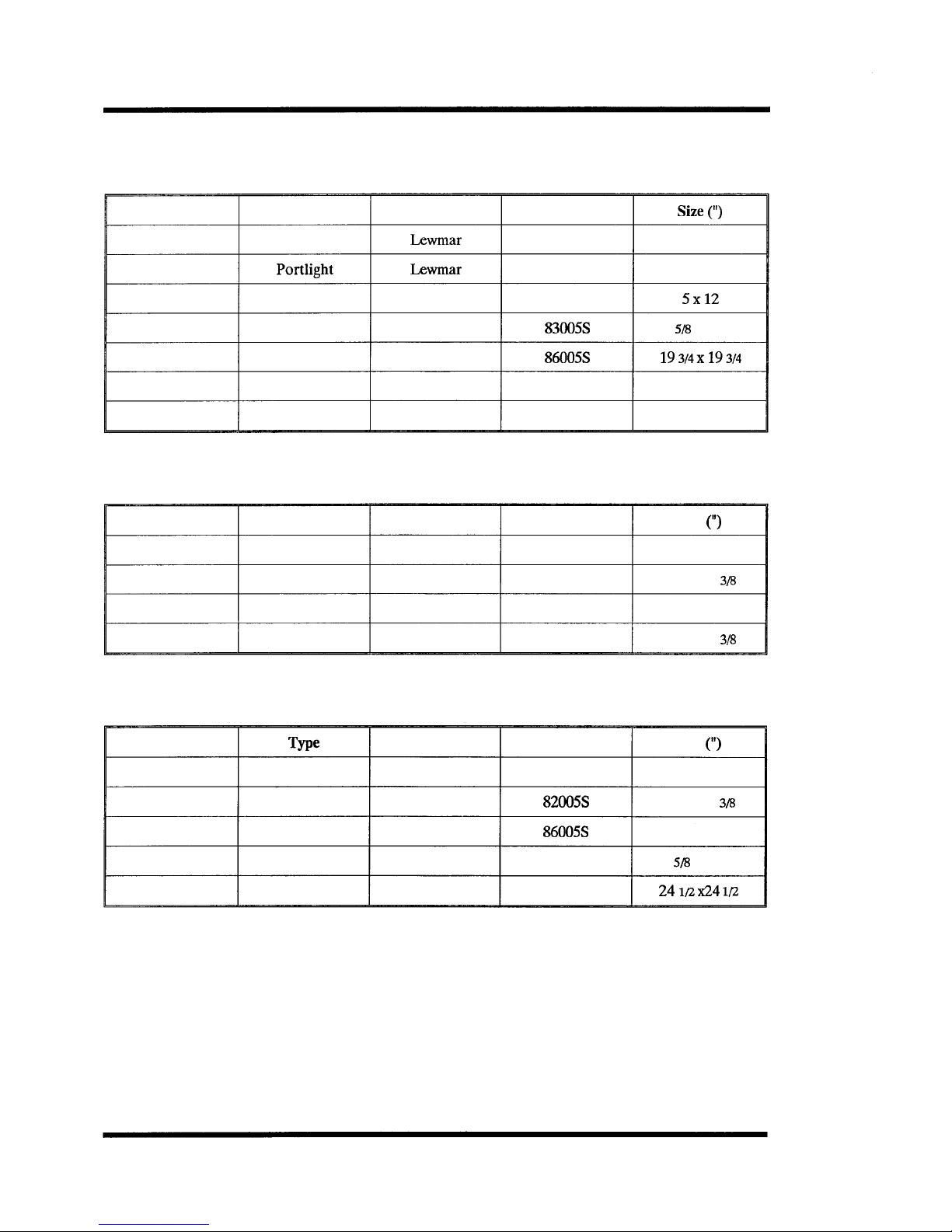

Hatches

and

portlights________________________________

All yachts use the following range of

Lewmar

hatches and portlights;

Moody 31

Quantity

2

1

Type

Portlight

Hatch

Manufacturer

Vetus

Lewmar

Model No.

PT100

(White)

86005S

Size (")

123/8x51/2

19 3/4 X 19 3/4

Moody 336

Quantity

1

1

2

2

1

1

Type

Portlight

Portlight

Portlight

Hatch

Hatch

Hatch

Manufacturer

Lewmar

Lewmar

Lewmar

Lewmar

Lewmar

Lewmar

Model No.

8906

8912

8932

82005S

86005S

83005S

Size

(")

4x10

5x12

5x15

7 3/4 X 13

3/8

193/4X193/4

15

5/8

X 17 3/4

Issue 3

Page 1.3

Moody 35

Quantity

1

2

1

1

2

2

2

Type

Portlight

Portlight

Portlight

Hatch

Hatch

Hatch Trim Kit

Hatch Trim Kit

Manufacturer

Lewmar

Lewmar

Lewmar

Lewmar

Lewmar

Lewmar

Lewmar

Model No.

8902

8941

8912

83005S

86005S

8776

8775

Size

(")

4x10

5x23

5x12

12

5/8

X 17 3/4

193/4x193/4

n/a

n/a

Moody 376

Quantity

2

1

2

1

Type

Portlight

Hatch

Hatch

Hatchh

Manufacturer

Lewmar

Lewmar

Lewmar

Lewmar

Model No.

8902

82005S

86005S

82005S

Size

(")

4x10

7 3/4 X 13

3/8

19 3/4 X 19 3/4

7 3/4 X 13

3/8

Moody 425

Quantity

4

1

1

2

1

Type

Portlight

Hatch

Hatch

Hatch

Hatch

Manufacturer

Lewmar

Lewmar

Lewmar

Lewmar

Lewmar

Model No.

8941

82005S

86005S

83005S

87005S

Size

(")

5x23

7 3/4 X 13

3/8

19 3/4 X 19 3/4

12

5/8

X 17 3/4

24

1/2x24

1/2

Page 1.4

Issue 3

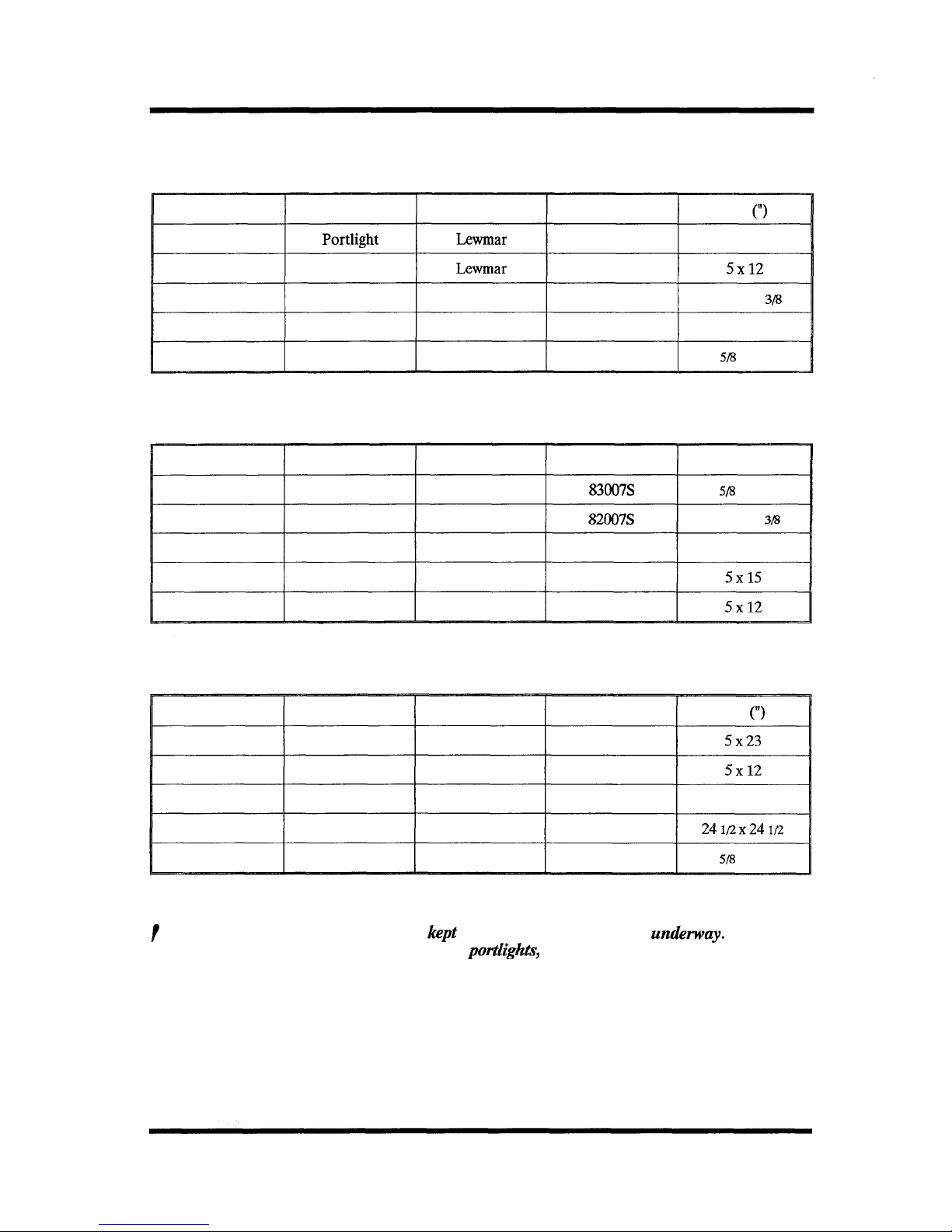

Eclipse 33

Quantity

1

1

2

1

2

Type

Portlight

Portlight

Hatch

Hatch

Hatch

Manufacturer

Lewmar

Lewmar

Lewmar

Lewmar

Lewmar

Model No.

8902

8912

82005S

86005S

83005S

Size

(")

4x10

5x12

7 3/4 X 13

3/8

19 3/4 X 19 3/4

12

5/8

X 17 3/4

Eclipse 38

Quantity

2

3

1

1

1

Type

Hatch

Hatch

Hatch

Portlight

Portlight

Manufacturer

Lewmar

Lewmar

Lewmar

Lewmar

Lewmar

Model No.

83007S

82007S

86007S

8932

8912

Size (")

12

5/8

X 17 3/4

7 3/4 X 13

3/8

19 3/4 X 19 3/4

5x15

5x12

Eclipse 43

Quantity

1

1

4

1

2

Type

Portlight

Portlight

Hatch

Hatch

Hatch

Manufacturer

Lewmar

Lewmar

Lewmar

Lewmar

Lewmar

Model No.

8941

8912

82005S

87005S

85005S

Size

(")

5x23

5x12

7 3/4 X 13 3/8

24i/2x24l/2

14

5/8

x 19 3/4

f

Hull mounted port lights must be

kept

closed and secured when

underway.

Aluminium

* deadlights are supplied for hull mounted

portlights,

a plywood deadlight is supplied for all

transom windows.

Issue 3

Page 1.5

Deck gear

Winches and windlasses

The following

Lewmar

winches are used:

Yacht

Moody 31

Moody 336

Moody 35

Moody 376

Moody 425

Eclipse 33

Eclipse 38

Eclipse 43

Genoa

Sheets

L30c

L40c

L40

L43c

L52st

L40c

L46cst

L52cst

Main

Halyard

L8c

L8c

L8c

L16c

L30c

L7c

L16c

L30c

Genoa

Halyard

'as

main'

'as

main'

'as

main'

L16c

L40c

-

L16c

L40c

Genoa

Furling

Line

-

L8c*

L8c*

L8c

L8c

L6c

L16cst

L16cst

Furling

Mainsail

Controls

-

-

-

L16cst

L16c

L6c

L16cst

L30cst

Mainsheet

-

L8c

-

L8c

L16c

L6c

L16cst

L30cst

Mainsail

Reefing

Lines

L6c

L6c

L6c

-

-

-

L16cst

-

Furling genoa not fitted as standard.

Page 1.6

Issue 3

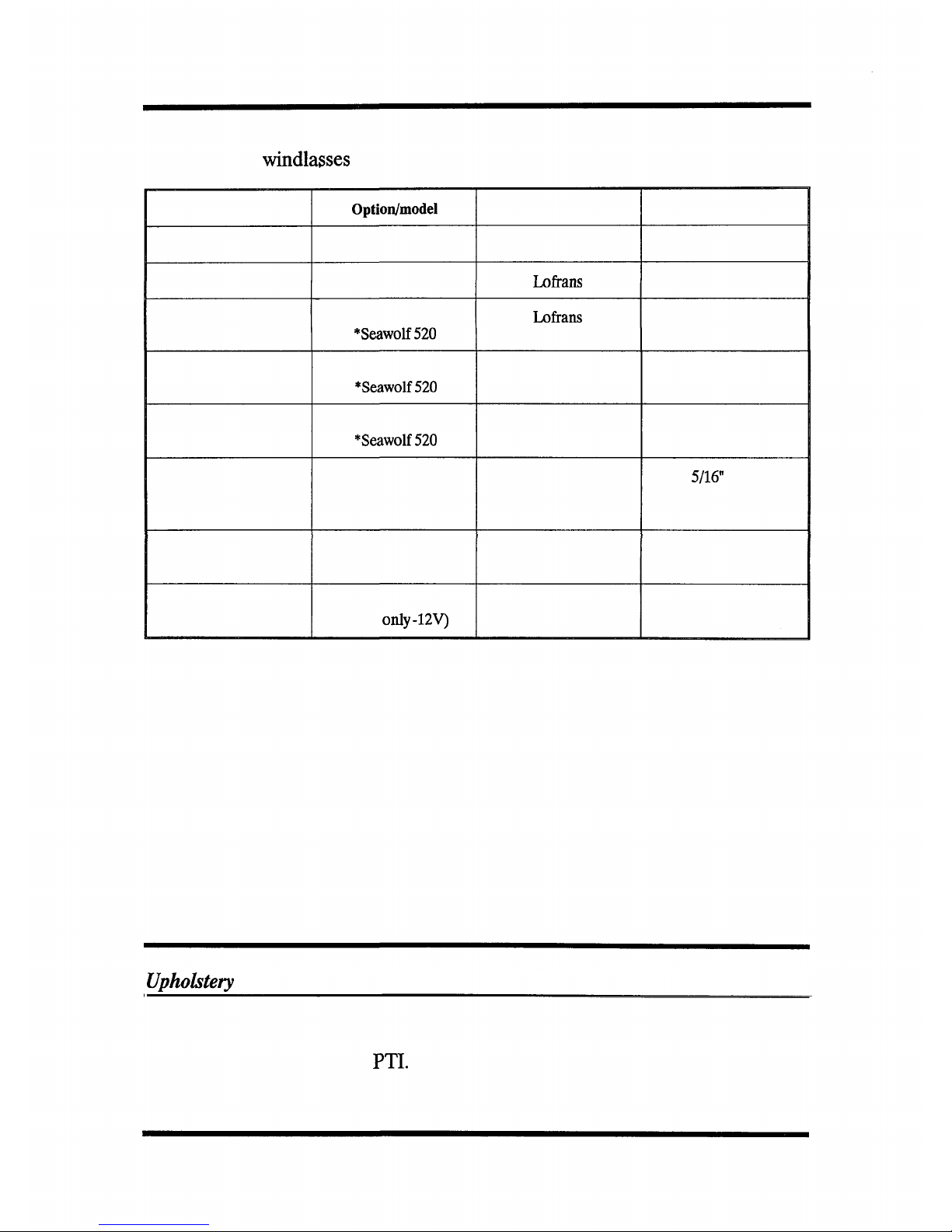

The following

windlasses

are offered as options:

Yacht

Moody 31

Moody 336

Moody 35

Moody 376

Moody 425

Eclipse 33

Eclipse 38

Eclipse 43

Option/model

-

*Royal

*Royal

*Seawolf520

Royal

*Seawolf520

Royal

*Seawolf520

Anchorman (gypsy only)

*Power 700

(gypsy only -12V)

Power 700

(gypsy only -12V)

Power 1000

(gypsy

only

-12V)

Manufacturer

-

Lofrans

Lofrans

Simpson Lawrence

Lofrans

Simpson Lawrence

Lofrans

Simpson Lawrence

Simpson Lawrence

Simpson Lawrence

Simpson Lawrence

Simpson Lawrence

Chain Size

-

8mm

8mm

5/16"

8mm

5/16"

10mm

9.5mm

5/16"

5/16"

9.5mm

9.5mm

* Not fitted as standard - 'Seawolf to be replaced March 1991.

Using the windlass

It is recommended that your anchor chain is suitably marked to indicate the

amount of chain you have out while at anchor.

When lying at anchor in a heavy swell the chain will snatch either causing chain slip

or excessive loads to be applied to the windlass. For safety it is recommended that

a rope bridle be applied to transfer the load to a cleat.

Below decks

Upholstery_______________________________________

Your yacht has been upholstered with either the Christiana, Ravenna, Dash or

Onyx range of materials. They all meet the Fire and Safety Regulation Act and

have been tested to BS5852

PTL

For information on care of your upholstery refer

to the maintenance section.

Issue 3

Page 1.7

Maintenance

Hull

Minor scratches and abrasions should be attended to in their early stages, initially

by using a medium grade rubbing compound. If this is ineffective, rub the area

lightly with 400 grade wet and dry paper (used with water) until the mark

disappears. Smooth the area with 800 grade followed by 1200 grade (both wet) and

then apply a silicone free wax polish.

Stress cracks should be looked at by an expert and some remedial action taken.

f Rubbing with abrasive compounds and materials removes the

gelcoat.

As this is only a thin

* layer, great care should be taken.

Annual cleaning

Wash the hull annually with warm water containing a little detergent. Stubborn

stains and polish should be removed with a recommended release agent or oil

removing fluid. Polish the hull with a silicone free wax polish.

Seacocks________________________________________

Check regularly:

1 Security of attachment

2 Security and condition of hose and hose clips

3 Free operation of the valve

Sacrificial

anodes____________________________________

The anode should be replaced when it is approximately two thirds eroded. If any

doubt exists as to whether the anode will survive the season - change it! The core

of the anode is a galvanised steel strip which provides the attachment lugs for the

anode. The anode is removed by undoing the two securing nuts and washers. It is

recommended that when replacing the anode, the nuts, washers and backing sheet

are also replaced.

Page 1.8 Issue 3

Antifouling______________________________________

Antifouling

should be checked on a regular basis and replaced at least once a

season.

The

antifouling

used

on

your

yacht

is

_____________________

Upholstery_________________________________________

Cleaning

Dust and grit should be removed frequently with a soft brush or the upholstery

attachment of a vacuum cleaner.

Creases

Where creases occur, raise the pile by brushing with a clean, damp cloth. Do not

saturate the fabric as the cotton backing may shrink. When dry, brush in the

direction of the pile with a soft brush.

Stains

Take immediate action, the longer stains are left the more difficult it is to remove

them. Nearly all stains can be removed by sponging lightly with warm water or a dry

foam upholstery shampoo. If this is not effective, covers can be removed and dry

cleaned. If heavily stained it is recommended that a reputable upholstery cleaner

is called in.

Ventilators______________________________________

Ensure that there is no entry of water through the deck seal. Reseal if necessary.

Issue 3 Page 1.9

MOORING CLEAT FOREHATCH

VENTLIGHT

MOORING CLEAT

HATCH GENOA TRACK WINCH & CLUTCHES GENOA WINCH SPINNAKER WINCH MOORING CLEAT

(OPTIONAL) \ FOR MAIN I GENOA \ (OPTIONAL)

GENOA TRACK

SPINNAKER WINCH &

CLUTCHES (OPTIONAL)

MAIN SHEET TRACK

MOORING CLEAT

SALOON HATCH GRABRAIL

MAINSHEET TRACK JAMMER STARBOARD

MAINSHEET

PORT LIGHTS TURNING

HATCH \ WINCH |

||

BLOCK

MOORING CLEAT

MOORING CLEAT

SPINNAKER WINCH

(OPTIONAL)

D STEP

Grabrail

Saloon hatch Grabrail

Genoa Gas bottle Turning

winch locker block Mooring cleat

Mooring cleat

Forehatch

chain plates Genoa track Halyard Spinnaker Roller furling

winch winch winch

Afthatch

!

MOORING CLEAT FOREHATCH & VENTLIGHT

i

VENTILATOR

COWL VENT GENOA TRACK MOORING CLEAT GENOA WINCH SPINNAKER AFT HATCH

8.

MOORING PORT

WINCH VENTILATOR CLEAT LIGHTS

MOORING CLEAT

HEADS

HATCH SALOON HATCH COWL VENT GENOA MOORING GENOA

FURLEX

WINCH GAS BOTTLE

MAINSHEET

VENTLIGHT MOORING

TRACK CLEAT WINCH

(OPTIONAL-PORT

SIDE ONLY) LOCKER WINCH CLEAT

NOTE:

EMERGENCY TILLER ACCESS UNDER BUNK IN AFT CABIN

<S

t

co

CD

MOORING CLEAT

VENTLIGHT

5 LINES LEADING AFT 5 SHEAVE COWL GENOA SPINNAKER WINCH MAIN SHEET HATCH & MOORING

EMERGENCY

(2 i FURLING

LINES,TOPPING

DECK ORGANISER VENT WINCH

(OPTIONAL) v WINCH

VENTILATOR

CLEAT TILLER ACCESS

LIFT,

KICKER,

OUTHAUL

)

t

,O

MOORING CLEAT

DO

«J

PH

Eclipse 33 Deck Plan

Issue 3

Page 1.15

Hatch

Hatch Mainsheet track

Mainsheet

winch

Forehatch

Genoa

track Halyard winch Genoa Roller furling Turning

winch winch block

I

•fj*

Sails, spars & rigging

Spars

and

rig___________________________

Your yacht is fitted with a Kemp aluminium mast and boom which, given good

support, proper handling and caring routine mainenance, should be remarkably

durable. Information on stepping the mast

can

be gained from the Kemp handbook

supplied with the yacht.

Rigging______________________________

Standing

rigging_____________________________________

The standing rigging is the only support provided for the mast and it is vital that it

is adjusted and maintained correctly. In a seaway, if the rig is too slack, the mast

head or spreader area can build up movement thereby increasing the shock loading

on the stays. On the other hand, overtensioned rigging puts a higher total load on

the stays and can be just as damaging. The entire standing rigging is stainless steel

including all terminals, toggles, bottle screws and wire ropes. Some yachts are fitted

with a furling

headsail

system and an

in-mast

furling mainsail system. For further

information refer to

'Hints

and advice on rigging and tuning your Kemp

Mast',

supplied with the yacht.

Rigging adjustment

Stainless steel rigging stretches and should therefore be regularly checked and

adjusted, particularly during the first season. It is recommended that reference be

made to the instructions given in

'Hints

and advice on rigging and tuning your Kemp

Mast'

supplied with the yacht.

Issue 3 Page 2.1

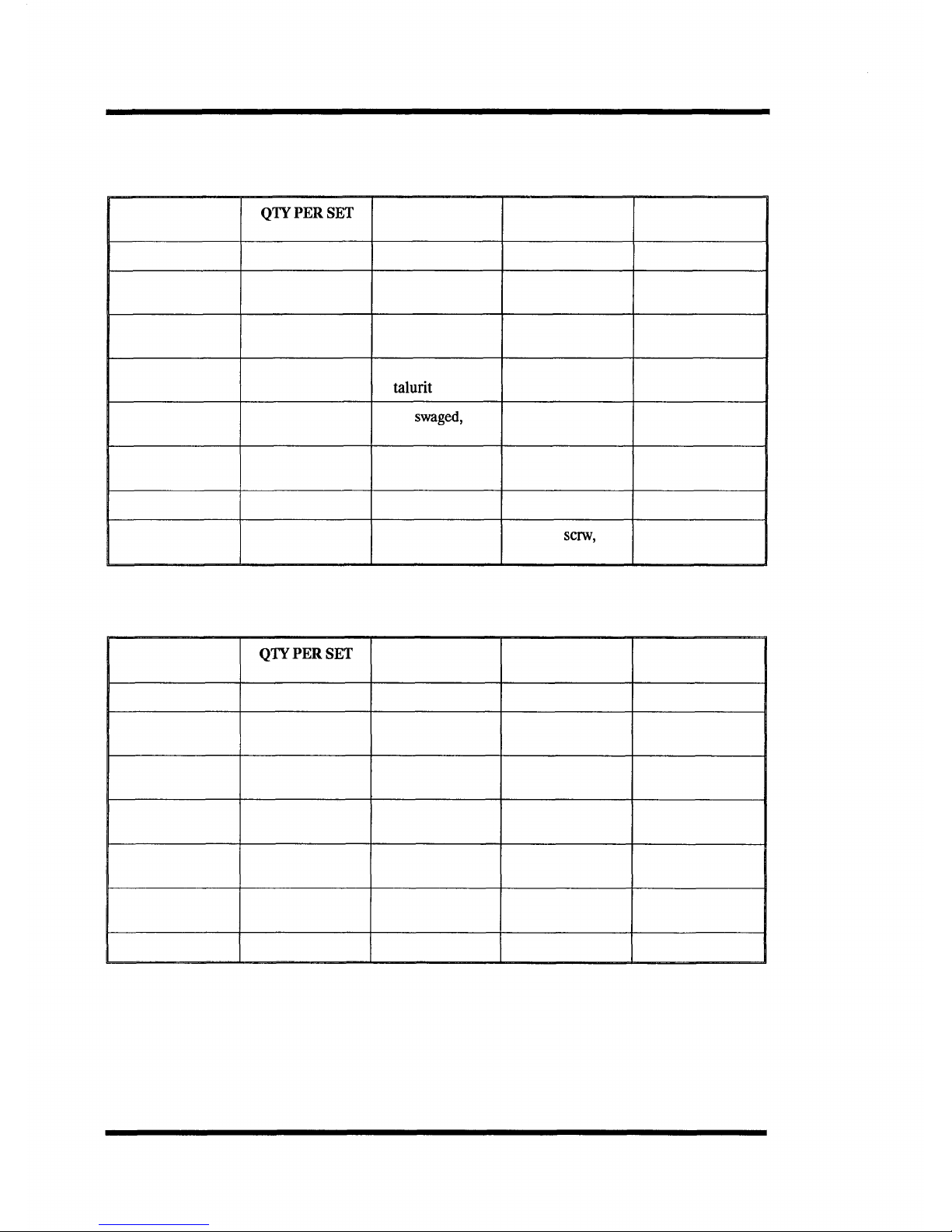

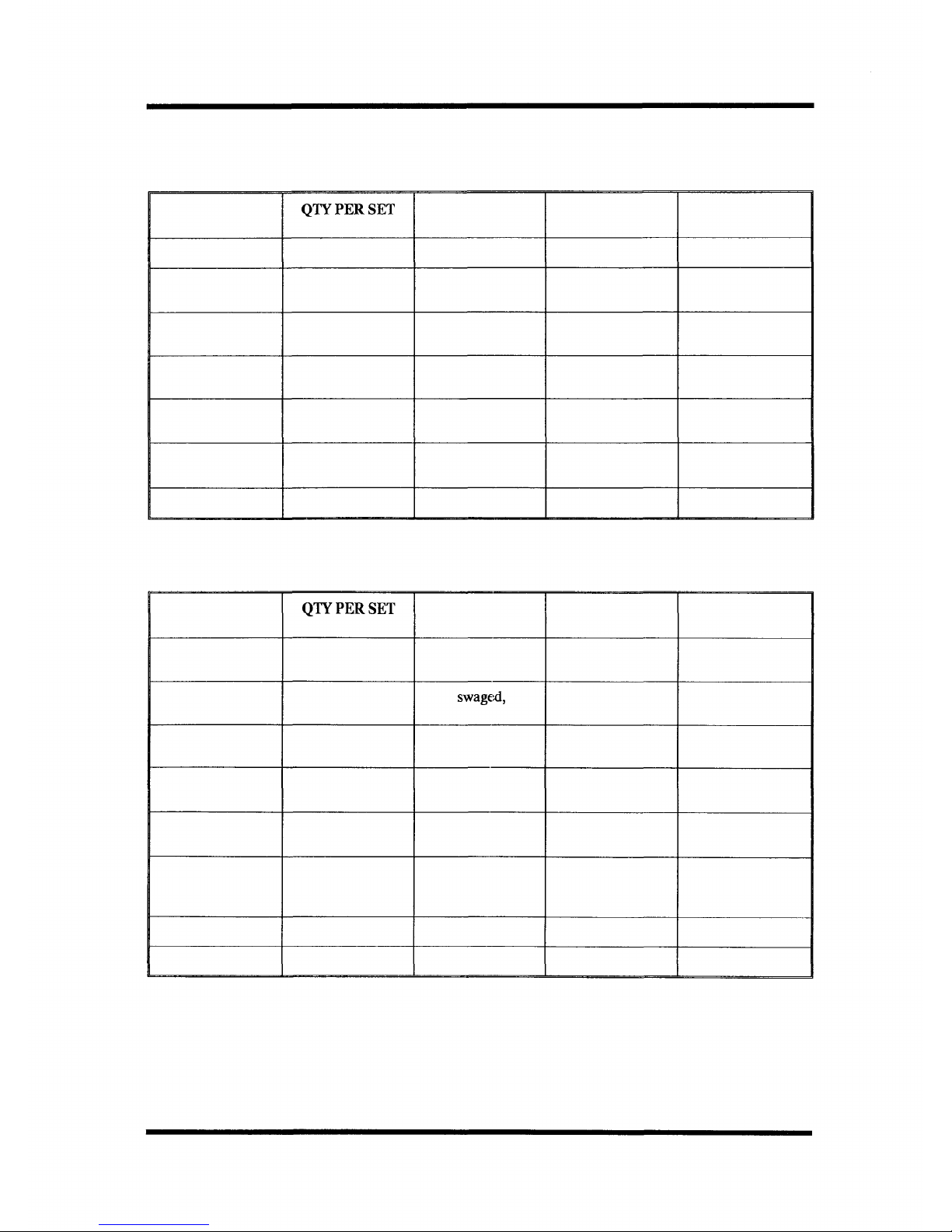

Moody 31

STAY

FORESTAY

INNER

FORESTAY

CAP SHROUD

INTERMEDIATE

FORWARD

LOWER

AFT LOWER

BACKSTAY

BACKSTAY

SPAN

QTYPERSET

1

1

2

0

0

2

1

0

TOP END

FITTING

Eye swaged

Tee

Tee

Eye swaged, eye

talurit and tee

Eye swaged, eye

talurit and tee

Tee

Eye swaged

Eye swaged, eye

talurit and tee

BOTTOM END

FITTING

Fork

Rigging screw and

roller

Rigging screw and

roller

Rigging screw,

swageless and roller

Rigging screw,

swageless and roller

Rigging screw and

roller

Rigging screw

Rigging

scrw,

eye,

fork and swageless

OVERALL

LENGTH (M)

12.23

5.875

11.51

0

0

6.115

12.64

0

Moody 336

STAY

FORESTAY

INNER

FORESTAY

CAP SHROUD

INTERMEDIATE

FORWARD

LOWER

AFT LOWER

BACKSTAY

QTYPERSET

1

0

2

2

2

2

1

TOP END

FITTING

Eye swaged

-

Shroud

Shroud

Shroud

Shroud

Eye terminal

BOTTOM END

FITTING

Rigging screw

-

Rigging screw and

roller

Rigging screw and

roller

Rigging screw and

roller

Rigging screw and

roller

Rigging screw

OVERALL

LENGTH (M)

14.00

0

12.62

9.025

5.00

5.00

14.50

Page 2.2

Issue 3

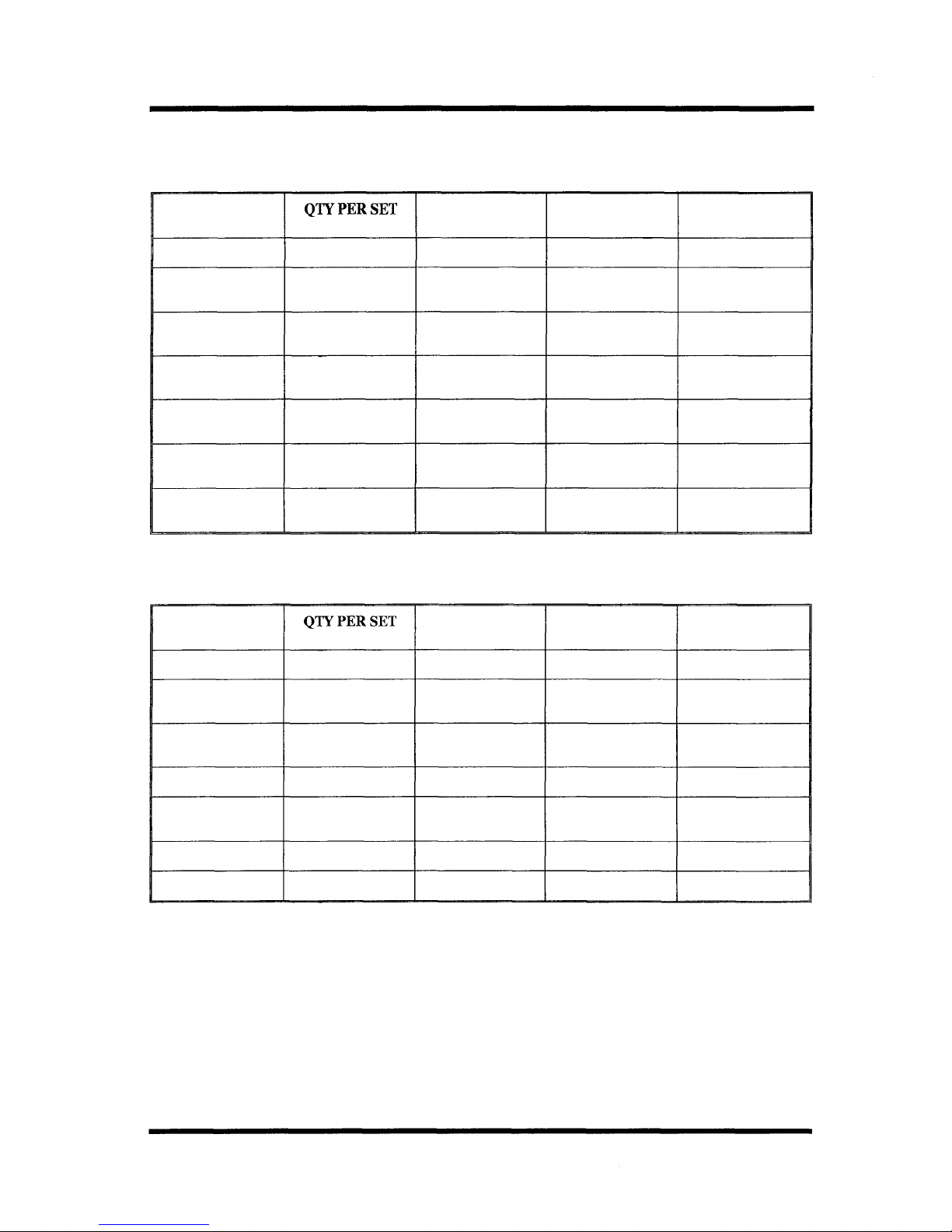

Moody 35

STAY

FORESTAY

INNER

FORESTAY

CAP SHROUD

INTERMEDIATE

FORWARD

LOWER

AFT LOWER

BACKSTAY

QTYPERSET

1

0

2

2

2

2

1

TOP END

FITTING

Eye swaged

-

Shroud

Shroud

Shroud

Shroud

Eye swaged

BOTTOM END

FITTING

Rigging screw

-

Rigging screw and

roller

Rigging screw and

roller

Rigging screw and

roller

Rigging screw and

roller

Rigging screw and

roller

OVERALL

LENGTH (M)

13.275

0

12.6

9.01

5.095

5.0

14.105

Moody 376

STAY

FORESTAY

INNER

FORESTAY

CAP SHROUD

INTERMEDIATE

FORWARD

LOWER

AFT LOWER

BACKSTAY

QTYPERSET

0

1

2

2

0

2

1

TOP END

FITTING

-

Shroud

Shroud

Shroud

-

Shroud

Eye swaged

BOTTOM END

FITTING

-

Rigging screw and

roller

Rigging screw and

roller

Rigging screw

-

Rigging screw

Rigging screw

OVERALL

LENGTH (M)

0

4.58

14.07

9.52

0

4.9

15.445

Issue 3

Page 2.3

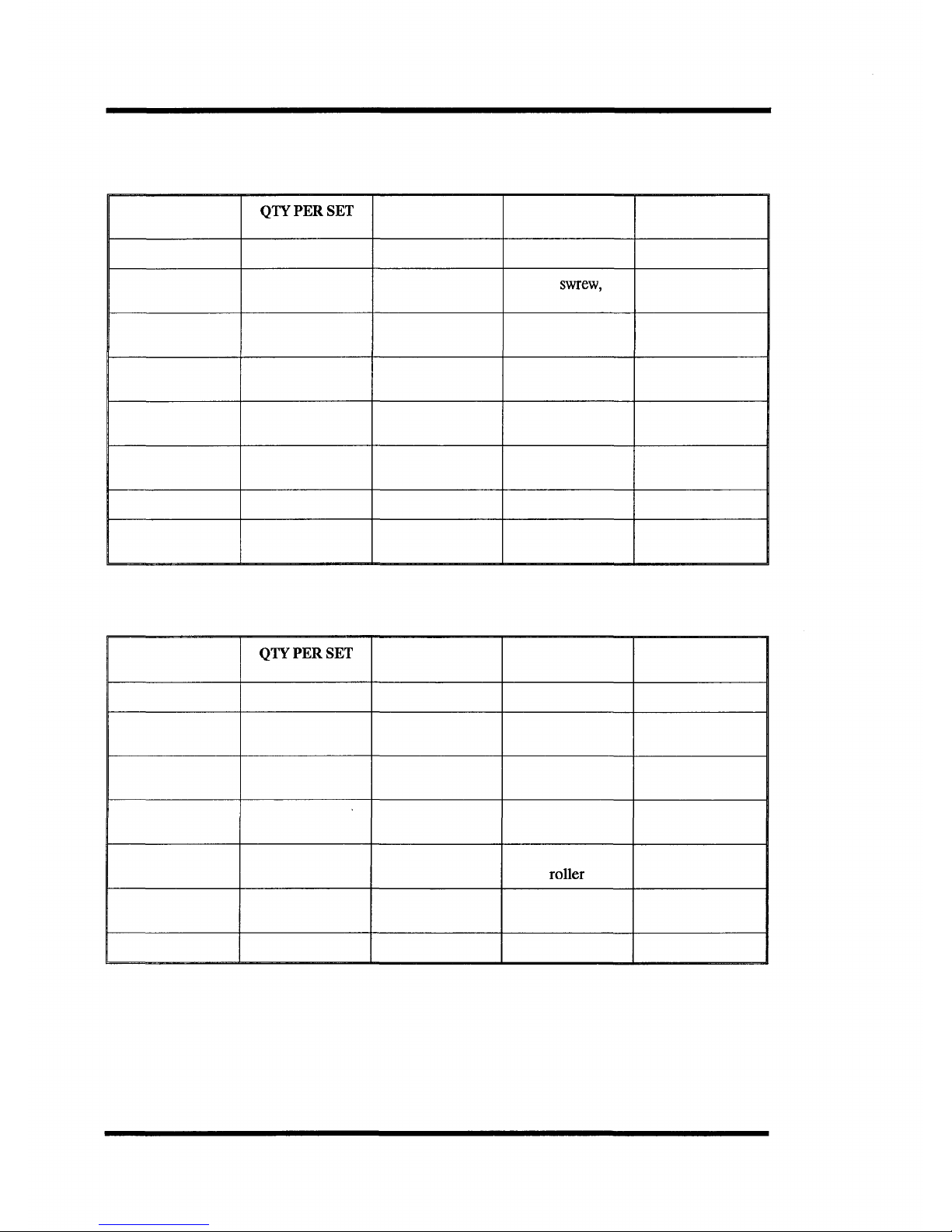

Moody 425

STAY

FORESTAY

INNER

FORESTAY

CAP SHROUD

INTERMEDIATE

FORWARD

LOWER

AFT LOWER

BACKSTAY

BACKSTAY SPAN

QTYPERSET

1

0

2

2

2

2

1

0

TOP END

FITTING

Eye swaged

Eye swaged, eye

talurit and tee

Tee

Tee

Eye swaged, eye

talurit and tee

Eye swaged, eye

talurit and tee

Eye swaged

Eye swaged, eye

talurit and tee

BOTTOM END

FITTING

Fork

Rigging

swrew,

eye,

swageless and roller

Rigging screw and

roller

Rigging screw and

roller

Rigging screw,

swageless and roller

Rigging screw,

swageless and roller

Rigging screw

Rigging screw, eye,

fork and swageless

OVERALL

LENGTH (M)

16.38

0

15.55

10.76

6.04

5.96

17.05

0

Eclipse 33

STAY

FORESTAY

INNER

FORESTAY

CAP SHROUD

INTERMEDIATE

FORWARD

LOWER

AFT LOWER

BACKSTAY

QTYPERSET

0

0

2

2

2

2

1

TOP END

FITTING

-

-

Shroud

Shroud

Shroud

Shroud

Eye swaged

BOTTOM END

FITTING

-

-

Rigging screw and

roller

Rigging screw and

roller

Rigging screw and

roller

Rigging screw and

roller

Rigging screw

OVERALL

LENGTH

0

0

11.913

8.304

4.418

4.241

13.375

Page 2.4

Issue 3

Eclipse 38

STAY

FORESTAY

INNER

FORESTAY

CAP SHROUD

INTERMEDIATE

FORWARD

LOWER

AFT LOWER

BACKSTAY

QTYPERSET

0

0

2

2

2

2

1

TOP END

FITTING

-

-

Shroud

Shroud

Shroud

Shroud

Eye swaged

BOTTOM END

FITTING

-

-

Rigging screw and

roller

Rigging screw and

roller

Rigging screw and

roller

Rigging screw and

roller

Rigging screw

OVERALL

LENGTH (M)

0

0

13.97

9.665

5.37

5.24

12.0

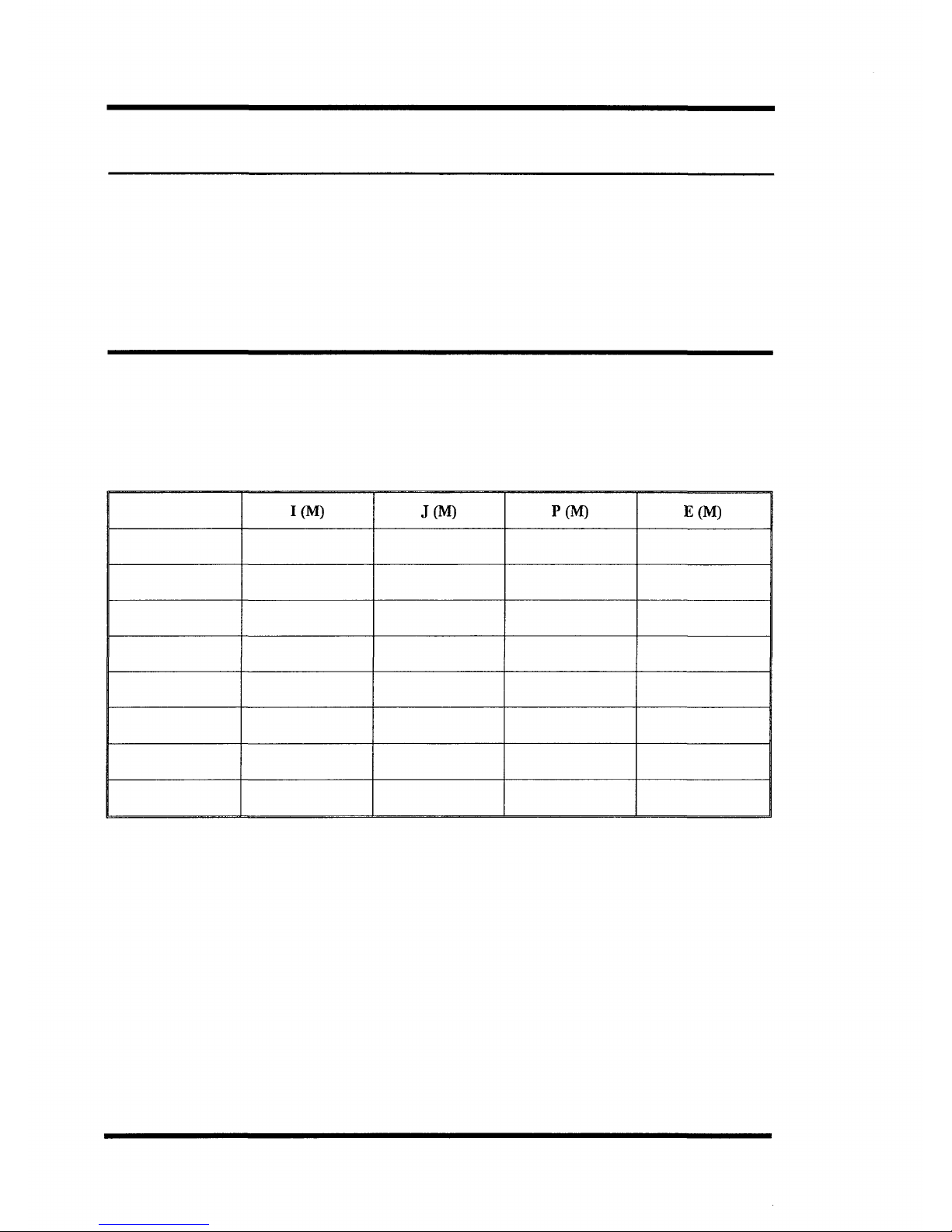

Eclipse 43

STAY

FORESTAY

INNER

FORESTAY

CAP SHROUD

INTERMEDIATE

FORWARD

LOWER

AFT LOWER

BACKSTAY

BACKSTAY SPAN

QTYPERSET

0

0

2

2

2

2

1

2

TOP END

FITTING

Eye swaged, eye

talurit and tee

Eye swaged, eye

talurit and tee

shroud terminal

Shroud terminal

Shroud terminal

Eye swaged, eye

talurit and shroud

terminal

Eye swaged

Eye swaged

BOTTOM END

FITTING

Rigging screw, eye

and swageless

Rigging screw, eye,

swageless and roller

Rigging screw and

roller

Rigging screw and

roller

Rigging screw and

roller

Rigging screw and

roller

Fork

Rigging screw

OVERALL

LENGTH

16.63

0

15.53

10.93

6.24

6.07

13.60

4.22

Issue 3

Page 2.5

Running rigging

The running rigging comprises all the lines and relative mechanics used to hoist and

control the sails, this includes halyards, sheets, guys, lifts, downhauls and outhauls

together with their various shackles, blocks, cleats and winches. It is essential that

they are inspected regularly for any signs of wear or stress. Information on types of

cordage, wire ropes and fittings can be gained from a good chandler.

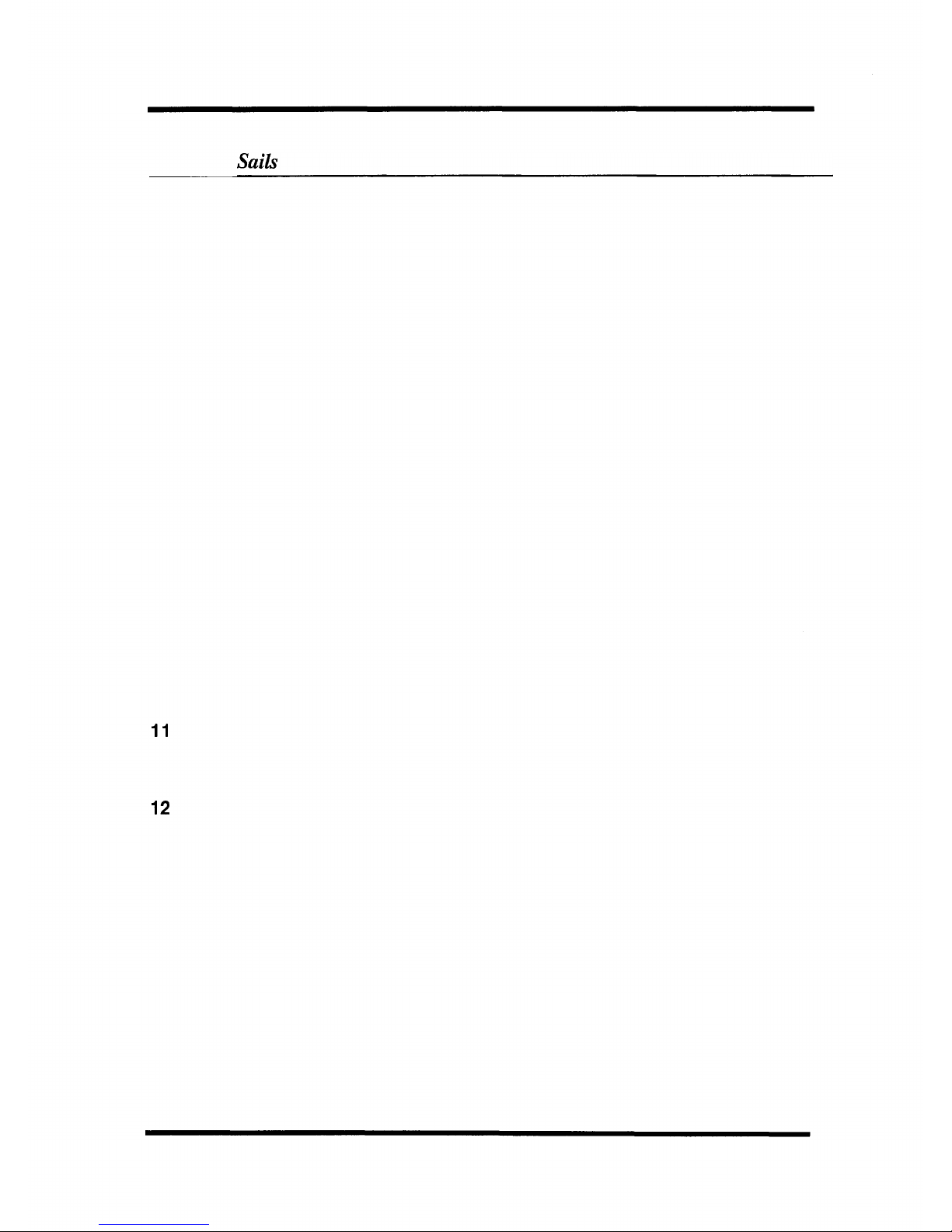

Sails

All yachts are supplied with Lucas sails which are manufactured from woven

dacron. This material has good tensile strength, resists abrasion and is not unduly

affected by moisture, however, it can be damaged by ultra-violet light and should

not therefore be exposed unnecessarily to sunlight. If treated with care and

maintained correctly these sails should give many seasons good service.

Yacht

Moody 31

Moody 336

Moody 35

Moody 376

Moody 425

Eclipse 33

Eclipse 38

Eclipse 43

I(M)

11.73

12.88

12.88

14.33

15.77

12.19

14.33

16.00

J(M)

3.81

4.11

4.09

4.57

5.03

3.10

4.57

5.03

P(M)

10.21

10.97

10.90

12.60

13.95

10.51

12.50

14.02

E(M)

3.51

3.73

3.78

4.34

4.72

3.50

4.34

4.72

Page 2.6

Issue 3

Folding

Sails_____________________________________

Mainsail

If your yacht does not have a self-furling mainsail system, one of the easiest methods

of folding is with the sail still on the boom:

1 Tighten topping lift to support boom.

2 Lower the sail fully.

3 Ensure the coachroof hatches are closed.

4 Ease the tension in the foot of the sail by releasing the clew outhaul.

5 Remove the battens to minimise stretch and chafing in the batten pockets.

6 Stand close to the mast on the opposite side of the pile of mainsail.

7 With an assistant at the leech, take hold of the sail about eighteen inches from

the boom , pull up together and lay the sail halfway over the boom. The bottom

of the hanging fold should be just below the bottom of the boom.

8 Take a further foot of sail and fold back over the boom in the opposite direction.

9 Continue this layering action until the entire sail is laid over the boom.

1 o Secure the sail to the boom using sail ties.

11

The halyard can either be removed and stowed or left attached to the head of

the sail. If left on the sail, secure to the boom by passing a sail tie through the

head of the sail and then tension the halyard.

12

If the sail is to remain folded for more than a few hours, put the sail cover on to

prevent damage.

Issue 3 Page 2.7

Loading...

Loading...