montwill PVE 4.001.3422B, PVE 4.001.3522B, PVE 4.001.3722B, PVE 4.001.6422B, PVE 4.001.7782B Operating Instructions Manual

...

status 03/06 - PVE41XGB.doc page 1 of 12

subject to alterations; errors including printer’s errors

Operating instructions for PVE4 units

- panel meter for standard signals

- freely scalable display with set points from –999 up to 9999

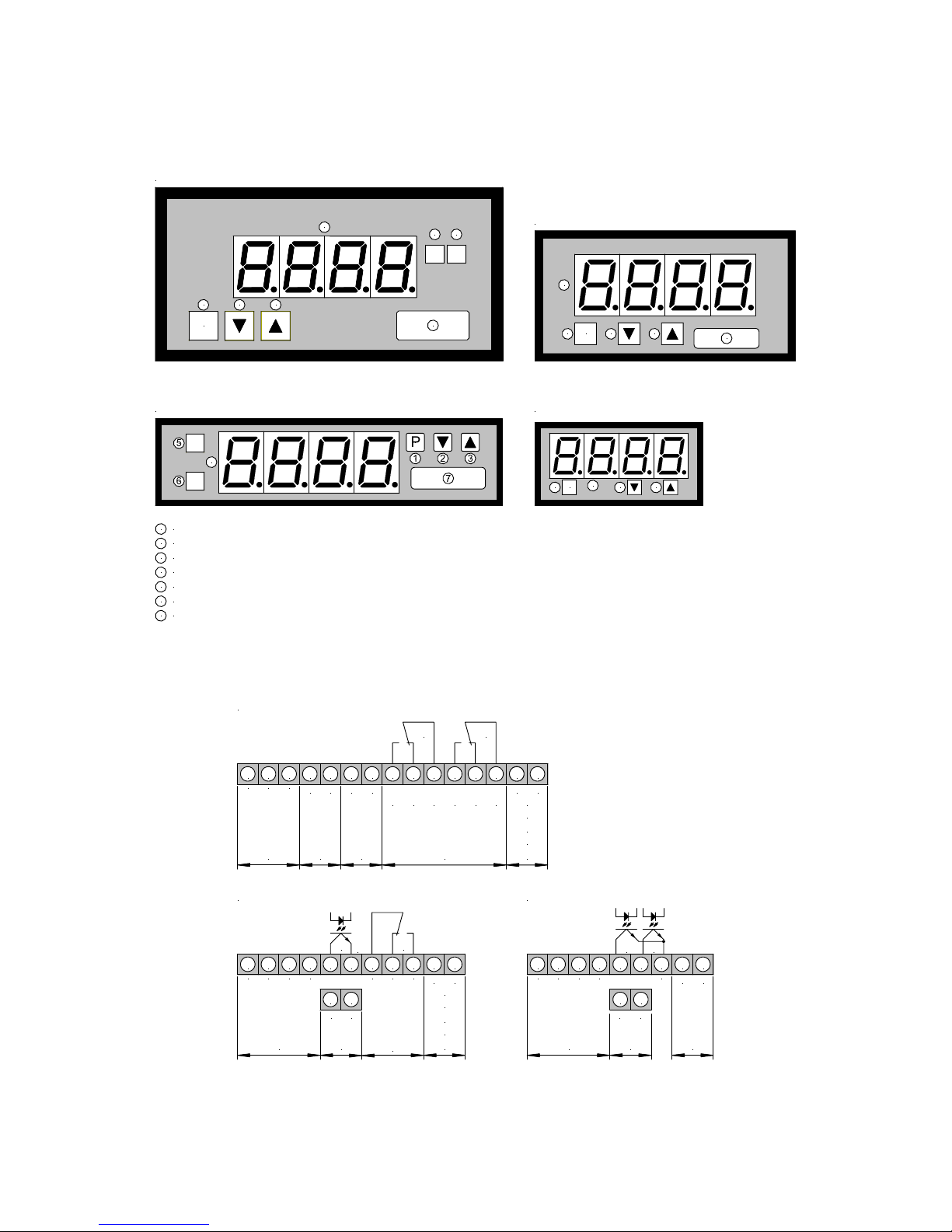

P

1 2 3

6

7

4

Housing size 96x48

5

6

5

7

32

P

1

4

Housing size 96x24

P

4

1 2 3

7

Housing size 72x36

P 2 31

4

Housing size 48x24

1

2

3

4

5

6

7

Program key

Minus key

Plus key

7-segment display

Setpoint indication 1

Setpoint indication 2

Insertable dimensionstrip

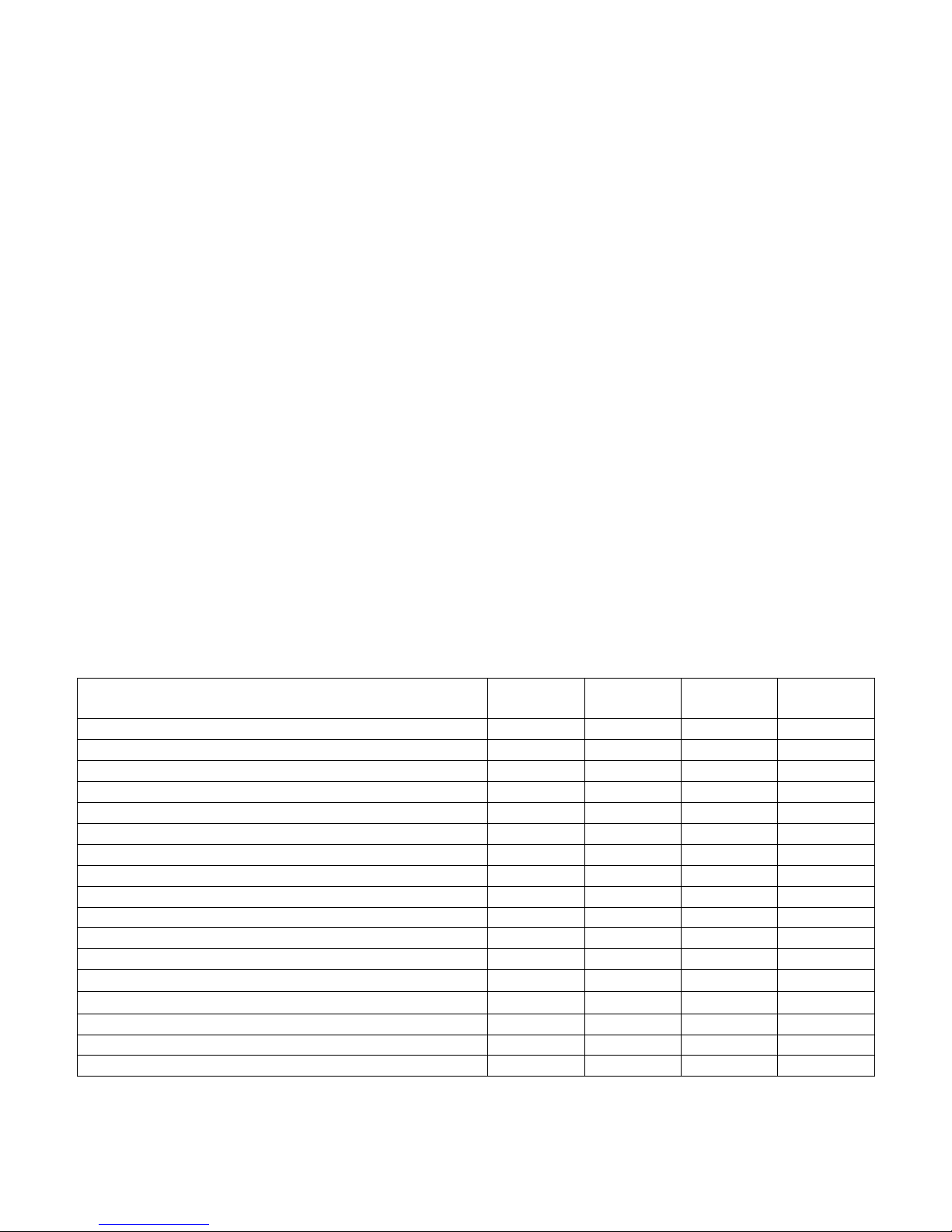

Terminal connection

10V

0/4-20mA

0V

- + + -

sensor

supply

(option)

analog

output

(option)

230V AC

115 V AC

1513121110987654321

- +

24V DC

or

14

or

setpoints

signal

inputs (DC)

S1S2

10V

50V

0/4-20mA

0V

- +

signal input s (DC)

analog-

output

(option)

987

65

4321

- +

24VDC

galv.

insulated

S2

65

COM

S1

10V

50V

0/4-20mA

0V

signal input s (DC)

analog

output

(option)

230V AC

115 V AC

1110987654321

- +

24V DC

or

or

setpoint

- +

65

S2

COM

COM

NC

NO

S1

Housing size 96x48 and 96x24

Housing size 72x36 Housing size 48x24

NONCCOMNONC

COM

status 03/06 - PVE41XGB.doc page 2 of 12

subject to alterations; errors including printer’s errors

Ordering code

TYPE ORDER NUMBER (housing size 96x48)

PVE 4.001.1522B Power supply 230 VAC terminal connection 15=L 14=N

PVE 4.001.1422B Power supply 115 VAC terminal connection 15=L 14=N

PVE 4.001.1722B Power supply 24 VDC terminal connection 15=L+ 14=L–

(galvanic insulated)

TYPE ORDER NUMBER (housing size 96x24)

PVE 4.001.3522B Power supply 230 VAC terminal connection 15=L 14=N

PVE 4.001.3422B Power supply 115 VAC terminal connection 15=L 14=N

PVE 4.001.3722B Power supply 24 VDC terminal connection 15=L+ 14=L–

(galvanic insulated)

TYPE ORDER NUMBER (housing size 72x36)

PVE 4.001.6522B Power supply 230 VAC terminal connection 11=L 10=N

PVE 4.001.6422B Power supply 115 VAC terminal connection 11=L 10=N

PVE 4.001.6722B Power supply 24 VDC terminal connection 11=L+ 10=L–

(galvanic insulated)

TYPE ORDER NUMBER (housing size 48x24)

PVE 4.001.7782B Power supply 24 VDC terminal connection 9=L+ 8=L–

(galvanic insulated)

Options

Housing

96x48

Housing

96x24

Housing

72x36

Housing

48x24

Green LED x x x x

Protection IP54 x x x x

Protection IP65 x x x x

Plug in terminal with protection IP40 x x x

Plug in terminal with protection IP54 x x x

Plug in terminal with protection IP65 x x x

Sensor supply 24 VDC/50 mA x

Sensor supply 24 VDC/50 mA (for UB 24 VDC) x

Sensor supply 24 VDC/20 mA (for UB 230 VAC) x

Sensor supply 24 VDC/20 mA (for UB 115 VAC) x

Sensor supply 10 VDC/20 mA x x

Analogue output 0-10 VDC (12 bit) x x x x

Analogue output 0-20 mA/load 500 Ω

x x x x

Analogue output 4-20 mA/load 500 Ω

x x x x

Setpoints as open emitter x

Dimension strips on request x x x x

Other power supplies on request x x x x

status 03/06 - PVE41XGB.doc page 3 of 12

subject to alterations; errors including printer’s errors

Proper use

The devices of the PVE4 range for standard signals (direct voltage, direct current) are used for the

evaluation of different sensor signals. The electronic circuit alters the sensor signal lying at the input

and displays it in a 7-segment display. The use of the devices regarding to the ambient conditions

must be in accordance to their protection type.

Programming

(see also programming example)

The PVE4 must be installed by a suitably qualified specialist (e.g. with a qualification in

industrial electronics).

1. Assemble the unit in a suitable panel cut-out.

2. Connect device in line with connection diagram. Connect screen of the sensor line with suitable

potential. Switch on supply voltage. This is followed by a segment test with subsequent switching

to operating mode.

3. Press program key [P]. Program number 0 is displayed (lights up).

4. Change program number by simultaneously pressing program key [P] and V key.

5. By pressing the V or W key, the display changes to the value stored under this program number.

6. Change displayed value by pressing the W or V key.

7. With program numbers 1 and 2, the applied voltage (sensor calibration under program number 0

active) can be saved by simultaneously pressing the [P] and W keys. This is confirmed by the

appearance of a horizontal bar in the display. If a different calibration mode (1, 2, 3) is selected, it

is not necessary to apply a voltage to the measuring input. In these modes, all that is needed is to

assign certain display data to the stored restart points (offset and full-scale). The programming is

also carried out under the program numbers 1 and 2 and must be saved with the [P] and W keys.

The appearance of horizontal bars in the display confirms that the save was successful.

8. If no further keys are pressed, the device changes back to operating mode after approx. 7

seconds. This definitively saves all the data, which do not have to be explicitly saved with the P

and W keys.

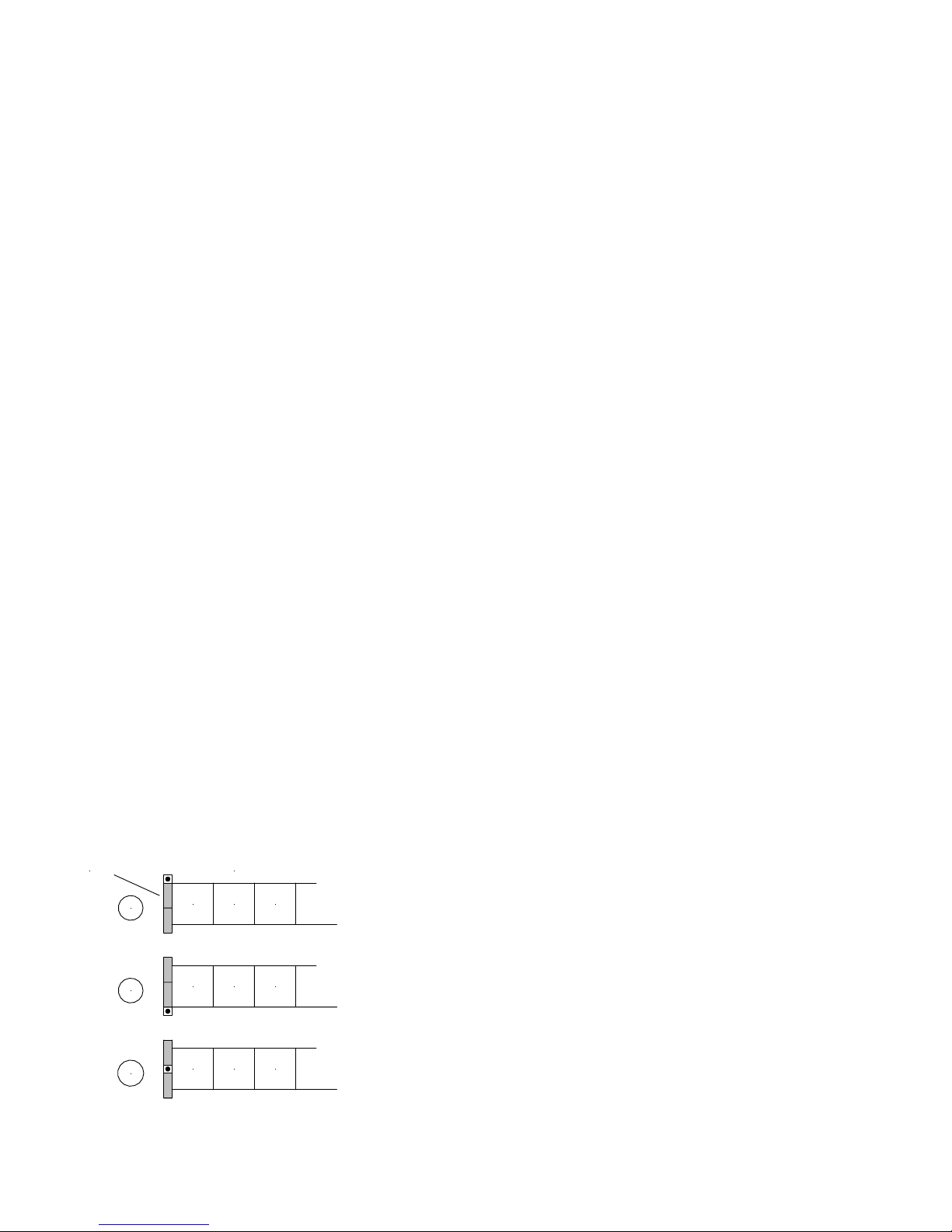

Programming lock

Keyboard lock

Possible jumper settings on the back

Variation 1

Unrestricted programming. The user has access to all program

numbers.

Variation 2

Programming locked, programming is not possible. The

programming mode is blocked.

Variation 3

Restricted programming. The program numbers 1...6 are blocked

for the user. The program number 61...68 (setpoints) can be

freely configured.

1 2 3

1 2 3

1 2 3

terminaljumper

1

2

3

status 03/06 - PVE41XGB.doc page 4 of 12

subject to alterations; errors including printer’s errors

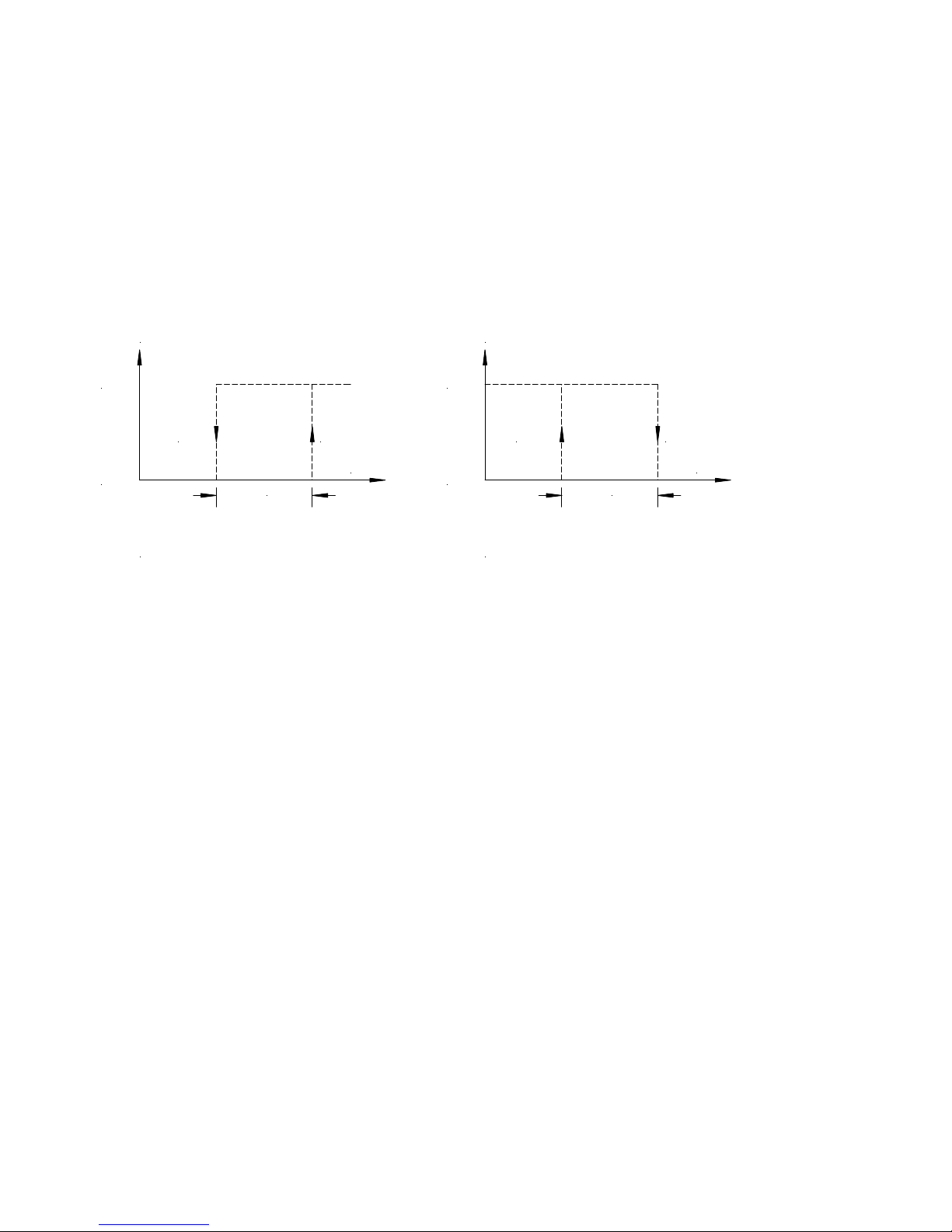

Setpoints

Operating characteristics of the relays

The following diagrams illustrate the behavior of the setpoints (relays). The hysteresis can be programmed freely for each setpoint. In open circuit mode, the respective relay rises on reaching the

threshold, while in closed circuit mode, the respective relay falls when the threshold is reached. By

using the closed circuit mode, for example, a breakdown of the supply voltage can be signaled in the

form of an alarm.

Definition: The hysterisis is the width of the window between the two threshold values of a setpoint!

setpoint

on

off

hysteresis

display

fallen raised

setpoint

on

off

hysteresis

display

raised fallen

Open curcuit mode Closed curcuit mode

MIN/MAX data

Additional functions in normal mode for memory inquiry of the MIN/MAX data.

The MIN/MAX memory is a volatile memory in which, after switching on the device or since the last

erasure, the relevant minimum and/or maximum values are stored.

• By pressing the V key, the MAX memory is displayed.

• By pressing the W key, the MIN memory is displayed.

• Simultaneously pressing the W and V keys erases the memory stored in the display.

Special functions with adjustable fixed zero for the lowest digit of the display

Via program number 9 (PN9 = 1), a permanent zero can be parameterised for the lowest digit. The

lowest (smallest) digit is then – without being rounded up or down – overwritten with a static zero. At

the analogue output and the threshold values for the relays, the lowest digit overwritten with a zero is

nevertheless evaluated. The function is intended to stabilise the display if, due to the sensor value,

permanent drifting or jumping of the displayed measurement occurs at the lowest digit.

status 03/06 - PVE41XGB.doc page 5 of 12

subject to alterations; errors including printer’s errors

Program table

Program

number

Function Remark Display Factory

setting

Measuring input

0 Calibration mode 0 = sensor calibration

1 = 0...10 V

2 = 0...20 mA

3 = 4...20 mA

(Save with P and W)

0 / 1 / 2 / 3 0

1 Input of desired indication

value for full scale

Dependent on selected

calibration mode

e.g. 10 V measuring input =

end value 300.0

(Save with P and W)

-999...9999 2000

2 Input of offset for indication

value

Dependent on selected

calibration mode

e.g. 4 mA measuring input =

initial value 0.0

(Save with P and W)

-999...9999 0

3 Setting of decimal point With V to the desired decimal

point

no decimal

point

4 Input of display time Display time = measuring time

Integrated measuring process

0.1...10.0

seconds

1,0

Analogue output optional

5 Input of final value for

analogue output

e.g. 300.0 as in programming

example

-999...9999 2000

6 Input of offset for analogue

output

e.g. 0.0 as in programming

example

-999...9999 0

Set lowest digit in the display to a permanent zero

9 Zeroise lowest digits in the

display

0 = no permanent zero

1 = permanent zero on lowest

digit

0 / 1 0

Setpoint S1

61 Threshold Threshold -999...9999 500

62 Hysteresis Width of window between the

two threshold values of a

setpoint

0...9999 1

63 Closed circuit / open circuit Working principle 0 / 1 1

Setpoint S2

66 Threshold Threshold -999...9999 1500

67 Hysteresis Width of window between the

two threshold values of a

setpoint

0...9999 1

68 Closed circuit / open circuit Working principle 0 / 1 1

status 03/06 - PVE41XGB.doc page 6 of 12

subject to alterations; errors including printer’s errors

Notes on programming

The following programming examples describe the two different tuning methods for setting the

device. A brief explanation will first be given on documenting the display procedure after pressing the

[P] key.

If the keyboard lock is not set (see programming lock), pressing the [P] key will always switch to

programming mode with the program number 0. For approx. 3 seconds, a 0 will appear in the display,

preceded by a P – see programming examples. After 3 seconds, the calibration mode 0 will flash

alternately with the program number 0 for a further 4 seconds. By pressing the W or V keys, the

value stored for the calibration mode is displayed for approx. 3 seconds, during which it can be

changed with the W or V keys. After the 3 seconds have elapsed, the program number 0 flashes

alternately with the currently set calibration mode for further 4 seconds. The changed value can be

saved by simultaneously pressing the [P] and W keys simultaneously. The device acknowledges this

by displaying 4 horizontal bars. Changing to program number 1 is done by pressing the [P] and V

keys.

All further settings can be made by following the above procedure. If you are in programming mode

and do not press any key within 7 seconds, the device automatically reverts from the programming

mode to the operating mode. You can change back again to programming mode at any time by

pressing the [P] key.

Programming example

1. Sensor calibration / Tuning the measuring section to a real measuring value

When using the sensor calibration, a voltage or current signal must be applied to the display unit for

the scaling. Furthermore, it must be ensured that the device is supplied with the correct auxiliary

voltage. During sensor calibration, the device is tuned to a real measuring value.

The base for this programming example is the basic value after resetting to the factory settings.

For the sensor calibration, a zero must always be stored under program number 0!

Measuring input: 0/4...20 mA

Measuring signal: 4...20 mA

Display: 4 mA = 0.0

20 mA = 300.0

Display time: 2.0 seconds

Set point S1: 60.0 and closed circuit

falling at 60.0 and rising at 58.0

(corresponding hysteresis = 2.0)

Set point S2: 150.0 and open circuit

Rising at 150.0 and falling at 80.0

(corresponding hysteresis = 70.0)

Analogue output: Measuring signal 4 mA corresponds to a display of 0.0 and 0 V at the analogue

output.

Measuring signal 20 mA corresponds to a display of 300.0 and

10 V at the analog output.

status 03/06 - PVE41XGB.doc page 7 of 12

subject to alterations; errors including printer’s errors

Programming example

Start of programming

Switch on supply voltage!

Segment test

Operating mode

Calibration mode

Enter program mode

To memorized value with W.

Full scale

Connect 20mA to the measuring

input. To program number 1 with P

and V.

To memorized value with W or V.

Set free scalable value.

Memorize value with P and W.

Take over by display of transversal

bars.

Offset

To program number 2 with P and

V.

Connect measuring value 4mA. To

memorized value with W or V.

Memorize value with P and W.

Take over by display of transversal

bars.

Decimal point

To program number 3 with P and

V.

To memorized value with W or V.

Set decimal point.

Display time

To program number 4 with P and

V.

To memorized value with W or V.

Set display time

Analogue output

(optionally)

Final value

To program number 5 with P and

V.

To memorized value with W or V.

Set free scalable final indication

value for analogue output.

Offset

To program number 3 with P and

V.

To memorized value with W or V.

Setpoint S1

To program number 61 with P and

V.

status 03/06 - PVE41XGB.doc page 8 of 12

subject to alterations; errors including printer’s errors

To memorized value with W or V.

Set free scalable value for setpoint

S1.

Hysteresis S1

To program number 62 with P and

V.

To memorized value with W or V.

Set hysteresis for S1.

Working principle S1

To program number 63 with P and

V.

To memorized value with W or V.

Set open circuit.

Setpoint S2

To program number 66 with P and

V.

To memorized value with W or V.

Hysterese S2

To program number 67 with P and

V.

To memorized value with W or V.

Set hysteresis for S2.

Working principle S2

To program number 68 with P and

V.

To memorized value with W or V.

Programming terminated.

2. Factory calibration (standard signals)

When using the factory calibration, there is no need to apply a measuring voltage to the display unit

for scaling. It must be ensured that the device is supplied with the correct auxiliary voltage and that

the correct measuring input is selected. The settings refer to calibration values preset in the factory.

These calibration values are an integral part of the device programming and cannot be erased by

resetting to the factory settings.

The starting basis for this programming example are the basic values following a reset to the factory

settings.

With the factory calibration, a 1, 2 or 3 must be stored under program no. 0.

status 03/06 - PVE41XGB.doc page 9 of 12

subject to alterations; errors including printer’s errors

Programming example

Measuring input: 0/4...20 mA

Measuring signal: 4...20 mA

Display: 4 mA = 0.0

20 mA = 300.0

Display time: 2.0 seconds

Setpoint S1: 60.0 and closed circuit

falling at 60.0 and rising at 58.0

(corresponding hysteresis = 2.0)

Setpoint S2: 150.0 and open circuit

rising at 150.0 and falling at 80.0

(corresponding hysteresis = 70.0)

Analogue output: Measuring signal 0 V corresponds to a display of 0.0 and

0 V at the analogue output.

Measuring signal 10 V corresponds to a display of 300.0 and

10 V at the analogue output.

Start of programming

Switch on supply voltage

Segment test

Operating mode

Calibration mode

Enter program mode

To memorized value with W or V.

Select parameter 1 for input 0...10 V.

Memorize value with P and W. Take

over by display of transversal bars.

Full scale

Select program number 1: Full scale

To memorized value with W or V.

Set free scalable value.

Memorize value with P and W. Take

over by display of transversal bars.

Offset

Select program number 2: Offset

To memorized value with W or V.

Memorize value with P and W. Take

over by display of transversal bars.

Decimal point

Select program number 3:

Decimal point.

To memorized value withW or V.

Set decimal point.

The further settings are the same as

in programming example 1.

Proceed to the section on display

time.

status 03/06 - PVE41XGB.doc page 10 of 12

subject to alterations; errors including printer’s errors

Configuration for transmitter connections

Input 0/4...20mA

Com 0V

Supply voltage

230VAC

115VA C

Transmi tter

LN

+-

L-

L+

Input 0/4...20mA

Com 0V

Supply voltage

230VAC

115 VAC

Transmitter

LN

+

+

-

Input 0...10V

L+

L-

Sensor supply

Sensor supply

Input 0/4...20mA

Com 0V

Supply voltage

24VDC

Transmi tter

L+L-

+-

Input 0/4...20mA

Com 0V

Supply voltage

24VDC

Transmitter

L+L-

+

+

-

Input 0...10V

Input 0/4...20mA

Com 0V

Supply vopltage

230VAC

115VAC

24VDC

Transmitter

+-

Sensor supply minus

Sensor supply plus

Input 0/4...20mA

Com 0V

Supply voltage

230VAC

115VAC

24VDC

Transmitter

+

+

-

Input 0...10V

Sensor supply minus

Sensor supply plus

Notes, factory settings and error elimination

After the supply voltage is switched on, the device performs a reset including a segment test (all the

LED light up). It then carries out a self-test. Should any fault occur during this procedure, the word

HELP appears in the display. This also applies to normal operation. This function serves to protect

the surrounding components and units. If the word HELP appears in the display, a reset must be

made to the factory settings. A reset is performed by switching on the supply voltage with the P key

pressed. The display remains until the P key is released in the segment test, after which the default

data are stored. The unit must now be reprogrammed to the user-specific data.

status 03/06 - PVE41XGB.doc page 11 of 12

subject to alterations; errors including printer’s errors

Technical data

Dimensions Housing 96 x 48 x 134 mm, including screw terminal

Assembly cut out 92.0

+0.8

x 45.0

+0.6

mm

Housing 96 x 24 x 134 mm, including screw terminal

Assembly cut out 92.0

+0.8

x 22.0

+0.6

mm

Housing 72 x 36 x 97 mm, including screw terminal

Assembly cut out 68.0

+0.7

x 33.0

+0.6

mm

Housing 48 x 24 x 91 (T=101 including plug in terminal)

Assembly cut out 45.0

+0.6

x 22.2

+0.3

mm

Fixing snap-in, quick-fix system with plastic clips for wall

thicknesses up to 50 mm

Housing material PC/ABS blend, color black, UL94V-0

Protective system front IP40, connection IP00

Weight (96x48) approx. 450 g

Weight (96x24) approx. 290 g

Weight (72x36) approx. 200 g

Weight (48x24) approx. 75 g

Connection on the back with terminals up to 2.5 mm

2

Connection (48x24) on the back with terminals up to 1.5 mm

2

Input Range (96x48) 0-10 V, 0-20 mA, 4-20 mA

Range (96x24) 0-10 V, 0-20 mA, 4-20 mA

Range (72x36) 0-10 V, 0-50 V, 0-20 mA, 4-20 mA

Range (48x24) 0-10 V, 0-50 V, 0-20 mA, 4-20 mA

The maximum permitted value on the input clips is

is 120% of the nominal value.

All ranges can be selected via connecting clip.

Input resistance

96x48 Ri with 10 V= ~100 kΩ, 20 mA=~100 Ω

96x24 Ri with 10 V= ~100 kΩ, 20 mA=~100 Ω

72x36 Ri with 10 V= ~100 kΩ, 50 V= ~500 kΩ, 20 mA=~100 Ω

48x24 Ri with 10 V= ~100 kΩ, 50 V= ~500 kΩ, 20 mA=~100 Ω

Output Sensor supply Sensor supplies are galvanic insulated!

96x48 24 VDC/50 mA – 10 VDC/20 mA

96x24 24 VDC/20 mA for power supply 230/115 VAC

24 VDC/50 mA for power supply 24 VDC/DC

(other voltage supplies on request)

Relay output

96x48 charge 230 VAC/5 A – 30 VDC/2 A,

with ohm resistive burden

Switching cycles 0.5 * 10

5

at max. contact rating

5 * 10

6

mechanically

All other sizes charge 240 VAC/0.25 A – 24 VDC/1 A,

with ohm resistive burden

Switching cycles 2 * 105 at max. contact rating

10 * 106 mechanically

Analogue output 0-10 VDC (12 bit) galvanic insulated!

0-20 mA (12 bit) - load 500 Ohm galvanic insulated!

4-20 mA (12 bit) - load 500 Ohm galvanic insulated!

Open collector switching voltage 5-40 VDC; I

max.

=100 mA

Accuracy Resolution -999 up to 9999

status 03/06 - PVE41XGB.doc page 12 of 12

subject to alterations; errors including printer’s errors

Measuring fault +/-0.2% of measuring range, +/- 1 digit

Temp. coeff. 100 ppm/K

Measuring principle voltage/frequency converter

Mains unit Supply voltage 230/115 VAC +/- 10% (50-60 Hz)

24 VDC +/-10% galvanic insulated

Mains unit Power consumption

96x48 approx. 5 VA

96x24 approx. 5 VA

72x36 approx. 3 VA

48x24 approx. 2 VA

Indication Display 7-segment-LED, 14 mm or 10 mm high, red

(with option RG red/green, only for 96x48)

4-digit = indication 9999 digit

Overflow indication of 4 transversal bars

Display time adjustable from 0.1 ... 10.0 seconds

Ambient Working temperature 0... + 60

{

C

conditions Storing temperature -20... + 80 {C

CE symbol

For unrestricted use of the device in accordance with the guideline on electromagnetic

compatibility 89/336/EWG, analogue input lines must be screened off. The screen must be

places on one side as close to the device as possible.

Housing:

96x48 72x36

96x24 48x24

9

6

48

9

0

1

1

1

43

5

1

3

1

(

w

i

t

h

p

l

u

g

i

n

t

e

r

m

i

n

a

l

1

4

8

)

9

6

24

8

9

5

1

3

1

21

1

1

1

(

w

i

t

h

p

l

u

g

i

n

t

e

r

m

i

n

a

l

1

4

8

)

7

2

36

6

5

5

9

7

32

w

i

t

h

p

l

u

g

i

n

t

e

r

m

i

n

a

l

1

1

5

m

m

7

7

4

8

24

4

2

5

9

1

21

7

7

w

i

t

h

p

l

u

g

i

n

te

r

m

i

n

a

l

1

0

0

m

m

Loading...

Loading...