montwill M3-34H, M2-14 User Manual

User manual M3

Alternating voltage / Alternating current signals rms-value (TRMS)

300 VAC, 0-5 AAC

96x24

M3_34HGB.pdf update: 03.11.2015

Technical features:

• red display from -19999…99999 digits (optional green, orange, blue or tricolour display)

• installation depth: 120 mm without plug-in screw terminal

• multi voltage power supply unit 100-240 VAC

• adjustment via factory setting or directly on the sensor signal

• min/max-memory with adjustable permanent display

• 30 additional adjustable support points

• display flashing at threshold value exceedance / undercut

• navigation keys for the triggering of Hold, Tara, display change, setpoint setting, alarm actuation

• flexible alarm system with adjustable delay times

• power measurement and energy measurement at constant voltage

• mathematical functions like reciprocal value, square root, square and rounding

• constant setting / setpoint setting

• sliding averaging

• brightness control via parameter or front keys

• programming interlock via access code

• protection class IP65 at the front

• plug-in screw terminal

• optional: 1 or 2 relay outputs

• optional: 1 independently scalable analog output

• accessories: pc-based configuration-kit PM-TOOL with CD & USB adapter

• on demand: devices for working temperatures of -25°C…60°C

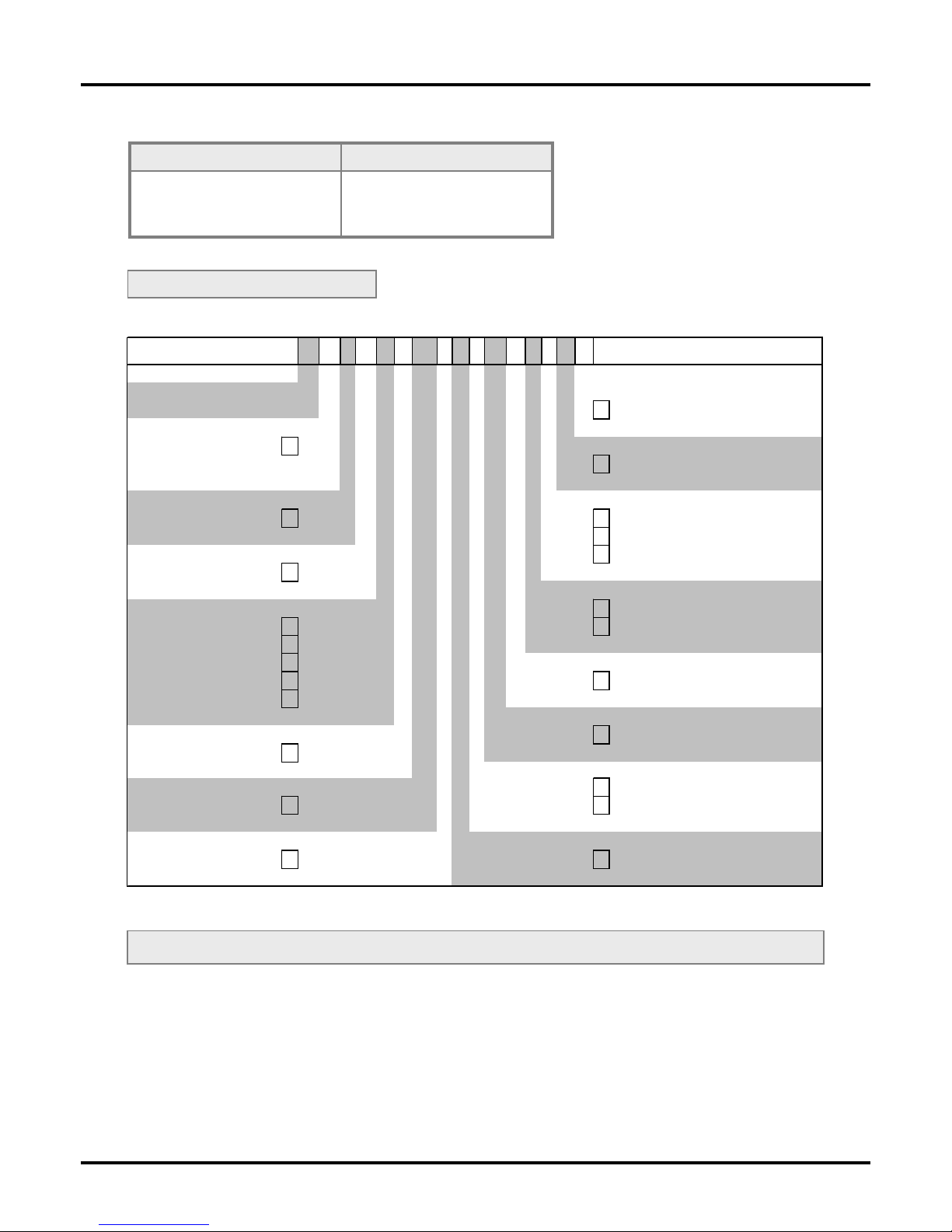

Identification

M3-3VR5B.0H04.S70BD

Alternating current /

Alternating voltage

Housing size: 96x24 mm

ORDER NUMBERSTANDARD TYPES

Please state physical unit by order, e.g. A.

Options – breakdown of order code:

M3-3VR5B.0H04.S72BD

Standard type M-line Dimension

D physical unit

Installation depth mm

144 mm (154 mm ), 3

Version

incl. plug-in terminal B B

Housing size Switching points

B96xH24xD120 mm 3 0 no switc hing point

1 1 relay output

Type of display

2 2 relay output s

V, A V

Protection class

Display colours

1 without keypad, operation via PM-Tool

Blue B 7 IP65 / plug-in terminal

Green G

Red R

Voltage supply

Tricolor (red, green, orange) T S 100-240 VAC

Orange Y

Mea suring input

Numb er of digits

4 AC voltage / AC current, TRMS

5-digit 5

Analog output

Digit height

0 without

14 mm

B

X 0-10 VDC, 0/4-20 mA

Digital input Special measuring input

without 0 H

300 VAC, 5 AA C

Contents

1

1. Brief description 2

2. Safety advices 2

3. Assembly 3

4. Electrical connection 4

5. Description of function and operation 5

5.1. Programming software PM-TOOL 6

6. Setting up the device 7

6.1. Switching on 7

6.2. Standard parameterisation (flat operation level) 7

Value assignment for the triggering of the signal input

6.3. Programming interlock „RUN“ 10

Activation/Deactivation of the programming interlock or change into professional

or flat operation level

6.4. Extended parametersation (professional operation level) 11

6.4.1. Signal input parameters „INP“ 11

Value assignment for the triggering of the signal input incl. linearisation

6.4.2. General device parameters „FCT“14

Superior device functions like Hold, Tara, min/max permanent, setpoint value function /

nominal value function, averaging, brightness control, as well as the control of the

keyboard layout

6.4.3. Safety parameters „COD“ 18

Assignment of user and master code to lock or to receive access to defined parameter such as

analog output and alarms, etc

6.4.4. Analog parameters „Out“ 19

Analog outpur functions

6.4.5. Relay functions „rel“ 21

Parameter for setpoint definition

6.4.6. Alarm parameters „AL1…AL4“ 22

Actuator and dependencies of the alarms

6.4.7. Totaliser (Volume metering) „tot“24

Parameter for calculation of the sum function

7. Reset to factory settings 25

Reset parameters onto the delivery state

8. Alarms / Relays 26

Functional principle of the switching outputs

9. Sensor aligment 27

Diagram of functional sequences for sensors with existing adjustable resistor

10. Technical data 28

11. Error elimination 30

1. Brief description

2

1. Brief description / 2. Safety advices

The panel meter instrument M3-34H is a 5-digit device for AC current / AC voltage signals (TRMS) and a

visual threshold value monitoring via the display. The configuration happens via three keys at the front or by

the optional PC software PM-TOOL. The integrated programming interlock prevents unrequested changes

of parameters and can be unlocked again with an individual code. Optional the following functions are

available: one analog output and interfaces for further evaluating in the unit.

With help of the two galvanic isolated setpoints (optional), free adjustable limit values can be controlled and

reported to a superior master display.

The electrical connection is done via plug-in terminals on the back side.

Selcetable functions like e.g. the recall of the min/max-value, an averaging of the measuring signals, a

nominal presetting or setpoint presetting, a direct threshold value regulation during operation mode and

further measuring setpoints for linearisation, complete the modern device concept.

2. Safety advices

Please read the following safety advice and the assembly chapter 2 before installation and keep it for future

reference.

Proper use

The M3-34H-device is designed for the evaluation and display of sensor signals.

Danger! Careless use or improper operation can result in

personal injury and/or cause damage to the equipment.

Control of the device

The panel meters are checked before dispatch and sent out in perfect condition. Should there be any visible

damage, we recommend close examination of the packaging. Please inform the supplier immediately of any

damage.

Installation

The M3-34H-device must be installed by a suitably qualified specialist (e.g. with a qualification in industrial

electronics).

Notes on installation

• There must be no magnetic or electric fields in the vicinity of the device, e.g. due to transformers, mobile

phones or electrostatic discharge.

• The fuse rating of the supply voltage should not exceed a value of 6A N.B. fuse.

• Do not install inductive consumers (relays, solenoid valves etc.) near the device and suppress any

interference with the aid of RC spark extinguishing combinations or free-wheeling diodes.

• Keep input, output and supply lines separate from one another and do not lay them parallel with each other.

Position “go” and “return lines” next to one another. Where possible use twisted pair. So, you receive best

measuring results.

• Screen off and twist sensor lines. Do not lay current-carrying lines in the vicinity. Connect the screening on

one side on a suitable potential equaliser (normally signal ground).

• The device is not suitable for installation in areas where there is a risk of explosion.

• Any electrical connection deviating from the connection diagram can endanger human life and/or can destroy

the equipment.

• The terminal area of the devices is part of the service. Here electrostatic discharge needs to be avoided.

Attention! High voltages can cause dangerous body currents.

• Galvanic isolated potentials within one complex need to be placed on a appropriate point (normally earth or

machines ground). So, a lower disturbance sensibility against impacted energy can be reached and

dangerous potentials, that can occur on long lines or due to faulty wiring, can be avoided.

3. Assembly

3

3. Assembly

Please read the Safety advices on page 2 before installation and keep this user manual for future reference.

S

e

a

l

i

n

g

I

n

s

t

a

l

l

a

t

i

o

n

d

e

p

t

h

i

n

c

l

u

d

i

n

g

p

l

u

g

-

i

n

t

e

r

m

i

n

a

l

(

d

e

p

t

h

d

e

p

e

n

d

s

o

n

o

p

t

i

o

n

s

)

1

4

5

,

0

(

1

5

4

,

0

)

9

6

,

0

24,0

Gap for physical uni t

3

,

0

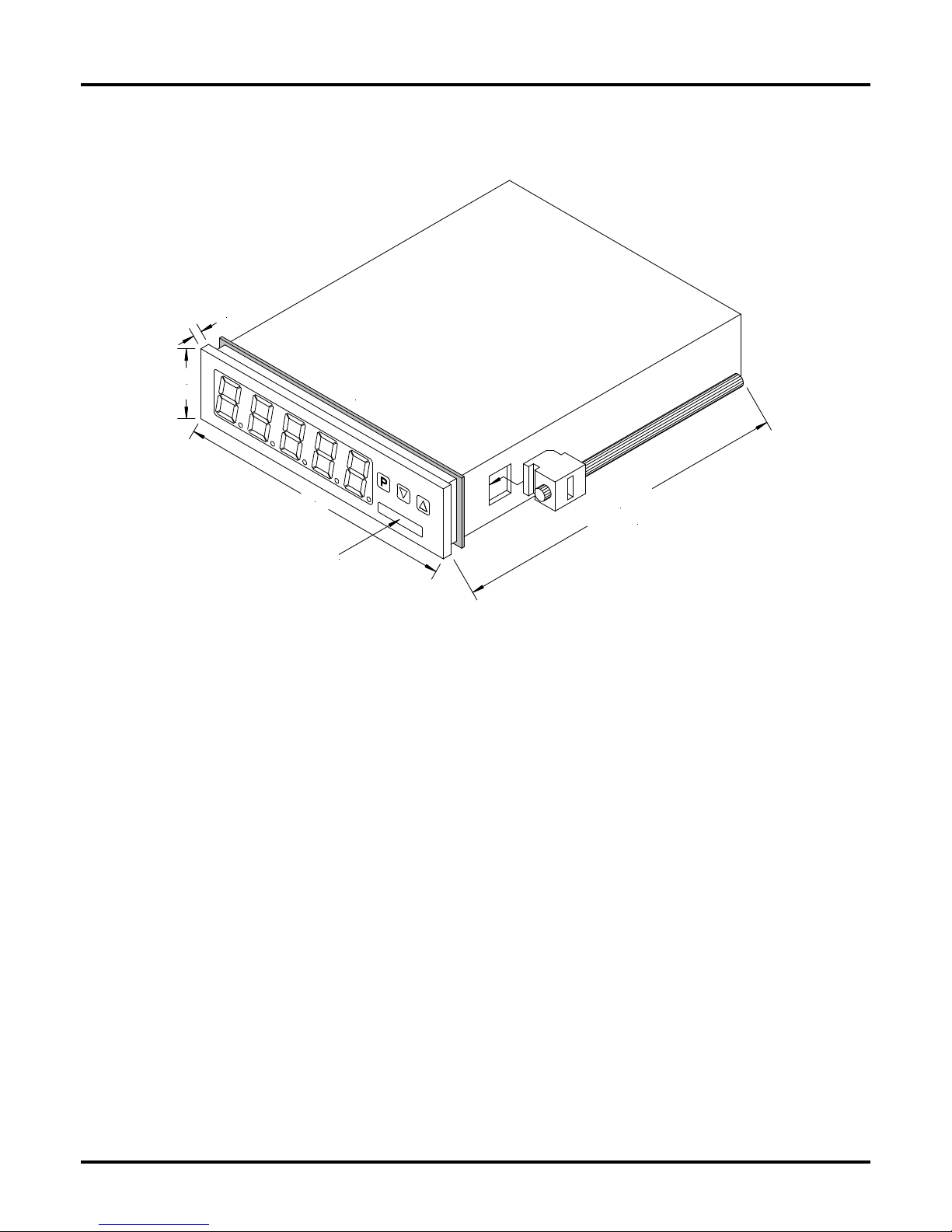

1. After removing the fixing elements, insert the device.

2. Check the seal to make sure it fits securely.

3. Click the fixing elements back into place and tighten the clamping screws by hand. Then use a

screwdriver to tighten them another half a turn.

CAUTION! The torque should not exceed 0.1 Nm!

The dimension symbols can be exchanged before installation via a channel on the side!

4. Electrical connection

4

4. Electrical connection

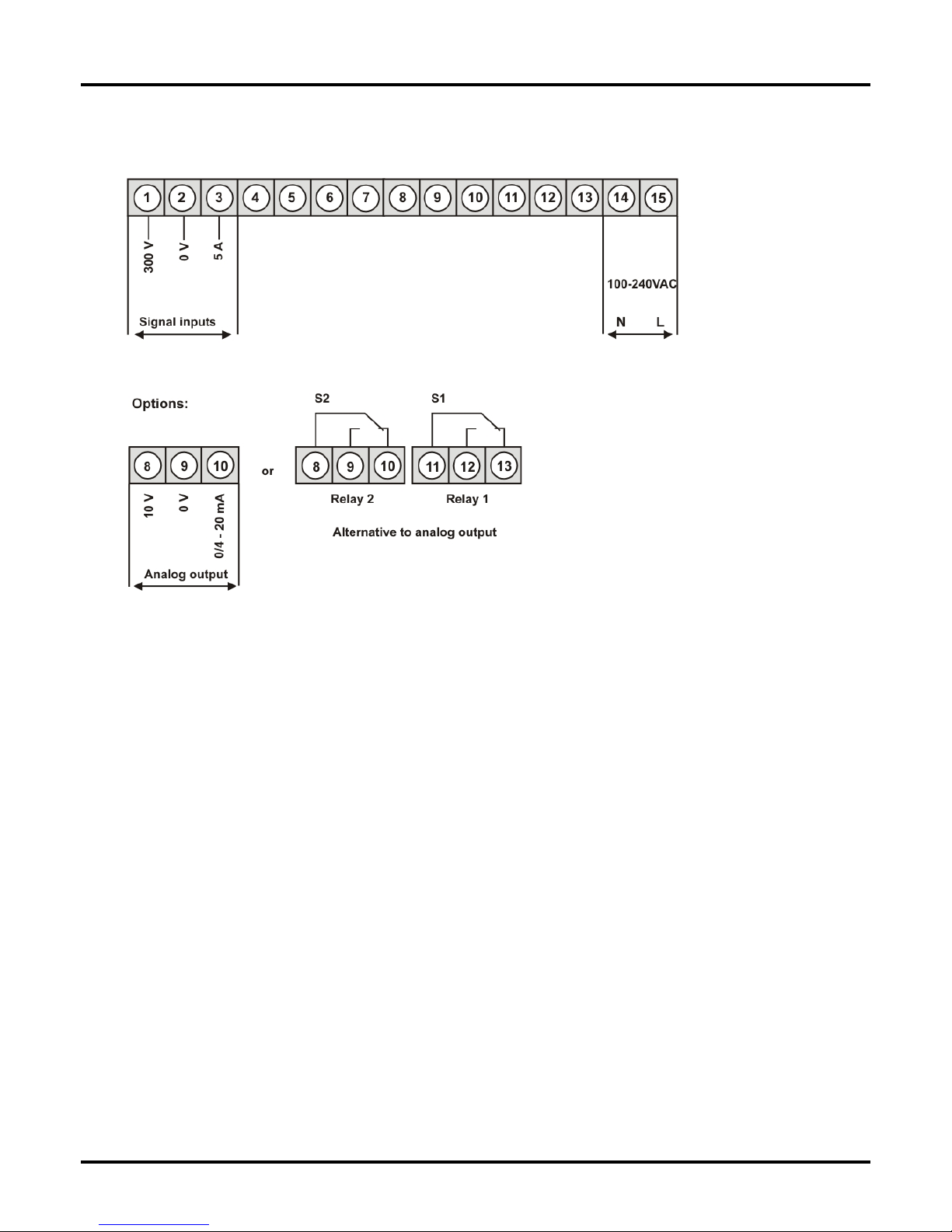

Type M3-3VR5B.0H04.S70BD supply 100-240 VAC 50/60Hz, DC ±10%

5. Description of function and operation

5

5. Description of function and operation

Operation

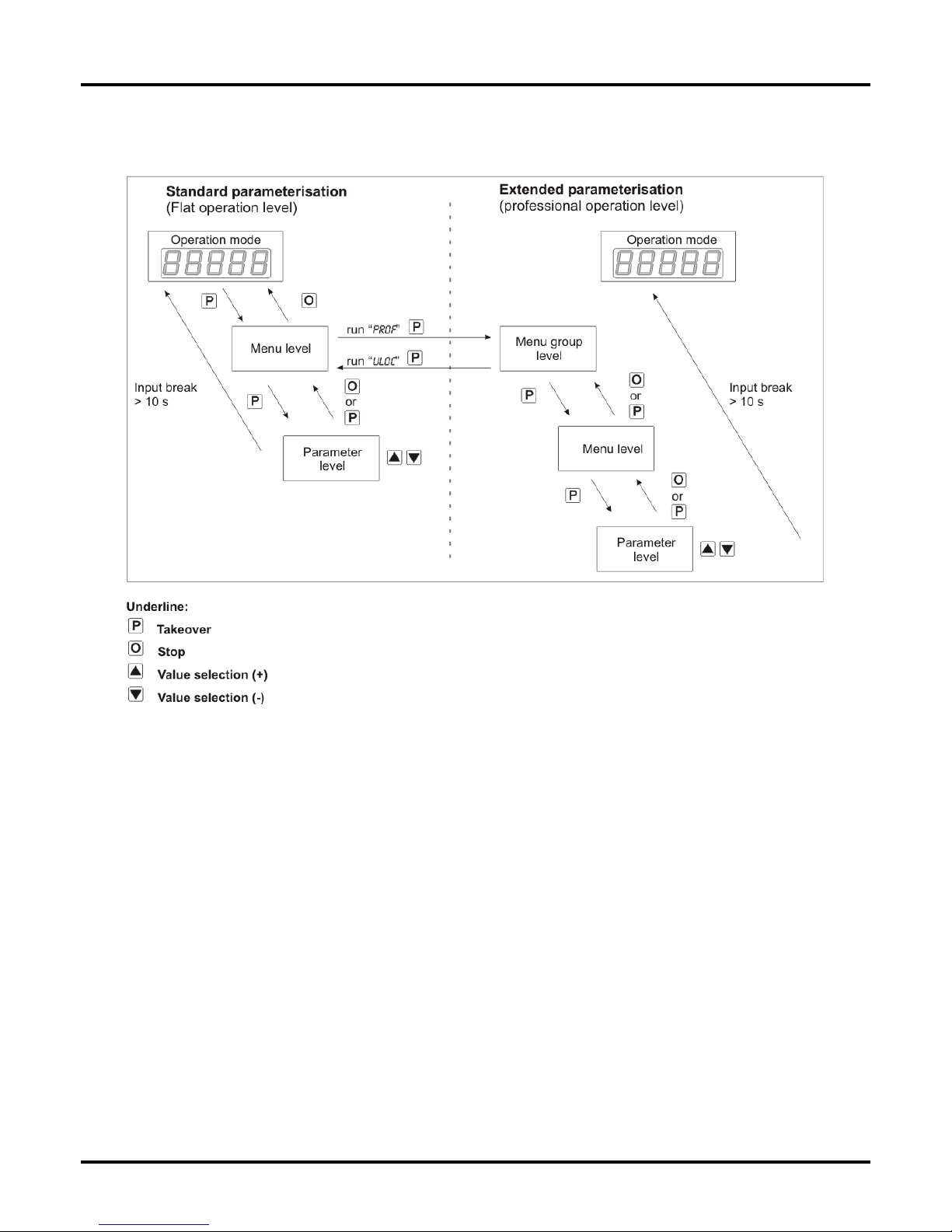

The operation is divided into three different levels.

Menu level (delivery status)

This level was designed for the standard settings of the device. Only menu items which are sufficent to set

the device into operation are displayed. To get into the professional level, run through the menu level and

parameterise prof under menu item RUN.

Menu group level (complete function volume)

Suited for complex applications as e.g. linkage of alarms, setpoint treatment, totaliser function etc. In this

level function groups which allow an extended parameterisation of the standard settings are availabe. To

leave the menu group level, run through this level and parameterise uloc under menu item RUN.

Parameterisation level:

Parameter deposited in the menu item can here be parameterised. Functions, that can be changed or

adjusted, are always signalised by a flashing of the display. Settings that are made in the parameterisation

level are confirmed with [P] and thus safed. Pressing the [O]-key leads to a break-off of the value input

and to a change into the menu level. All adjustments are saved automatically by the device and changes

into operating mode, if no further key operation is done within the next 10 seconds.

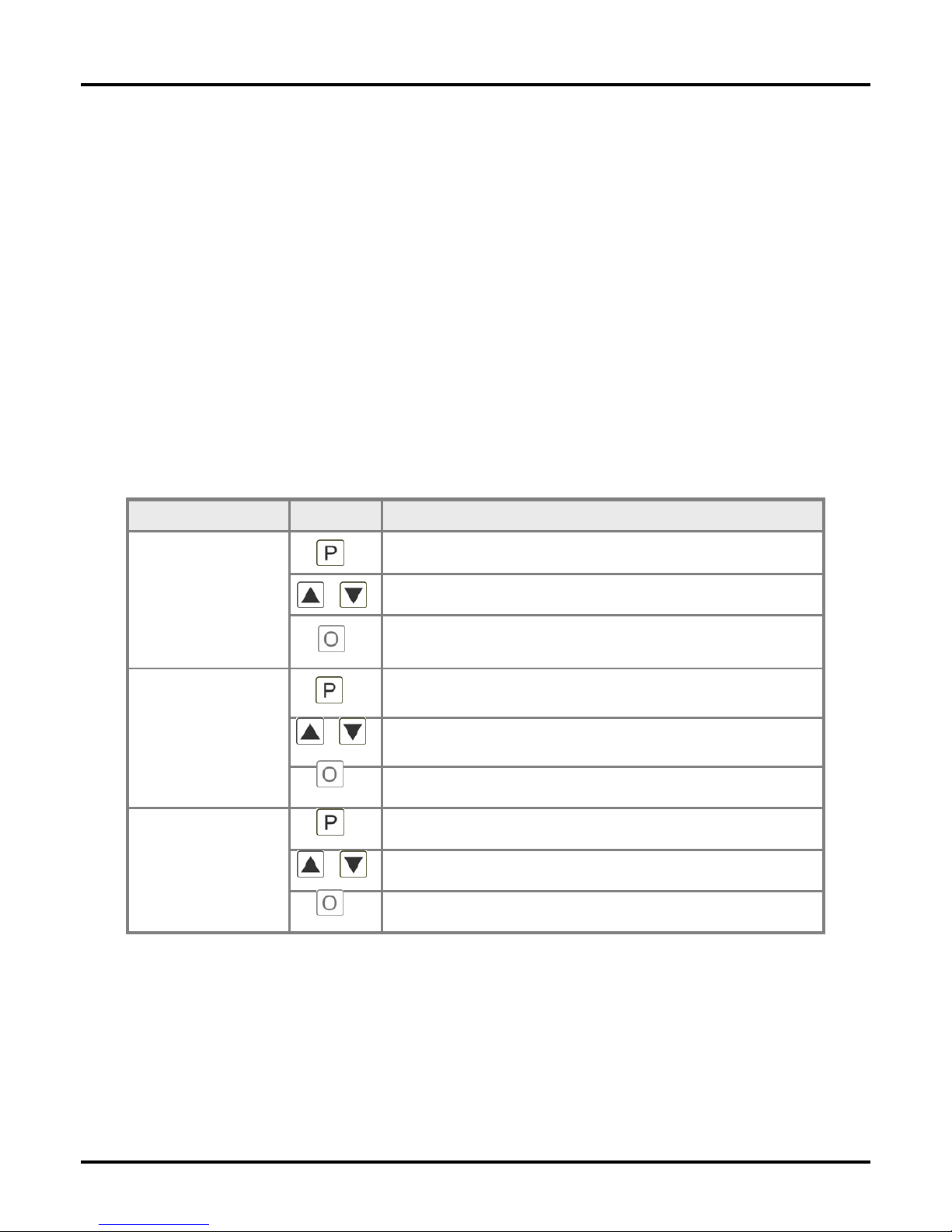

Keys for up and down navigation in the menu group level.

Change to menu level.

Change into menu level or break-off in value input.

Parameterisation-

level

Adjustment of the value / the setting.

Keys for up and down navigation in the menu level.

DescriptionKey

Change into operation mode or back into menu level.

To confirm the changes made at the parameterisation

level.

Change into operation mode.

Change to parameterisation level and deposited values.

Menu-group-level

Menu-level

Level

6

5. Description of function and operation

Function chart:

5.1 Parameterisation software PM-TOOL:

Part of the PM-TOOL are the software on CD and an USB-cable with device adapter. The connection

happens via a 4-pole micromatch-plug on the back side of the device, to the PC-side the connection

happens via an USB plug.

System requirements: PC incl. USB interface

Software: Windows XP, Windows VISTA

With this tool the device configuration can be generated, omitted and saved on the PC. The parameters can

be changed via the easy to handle program surface, whereat the operating mode and the possible selection

options can be preset by the program.

7

6.1. Switching on

Once the installation is complete, start the device by applying the voltage supply. Before, check once again

that all electrical connections are correct.

Starting sequence

For 1 second during the switching-on process, the segment test (8 8 8 8 8) is displayed followed by an

indication of the software type and, after that, also for 1 second the software version. After the starting

sequence, the device switches to operation/display mode.

6.2. Standard parameterisation: (Flat operation level)

To parameterise the display, press the [P]-key in operating mode for 1 second. The display then changes to

the menu level with the first menu item TYPE.

6. Setting up the device

6. Setting up the device

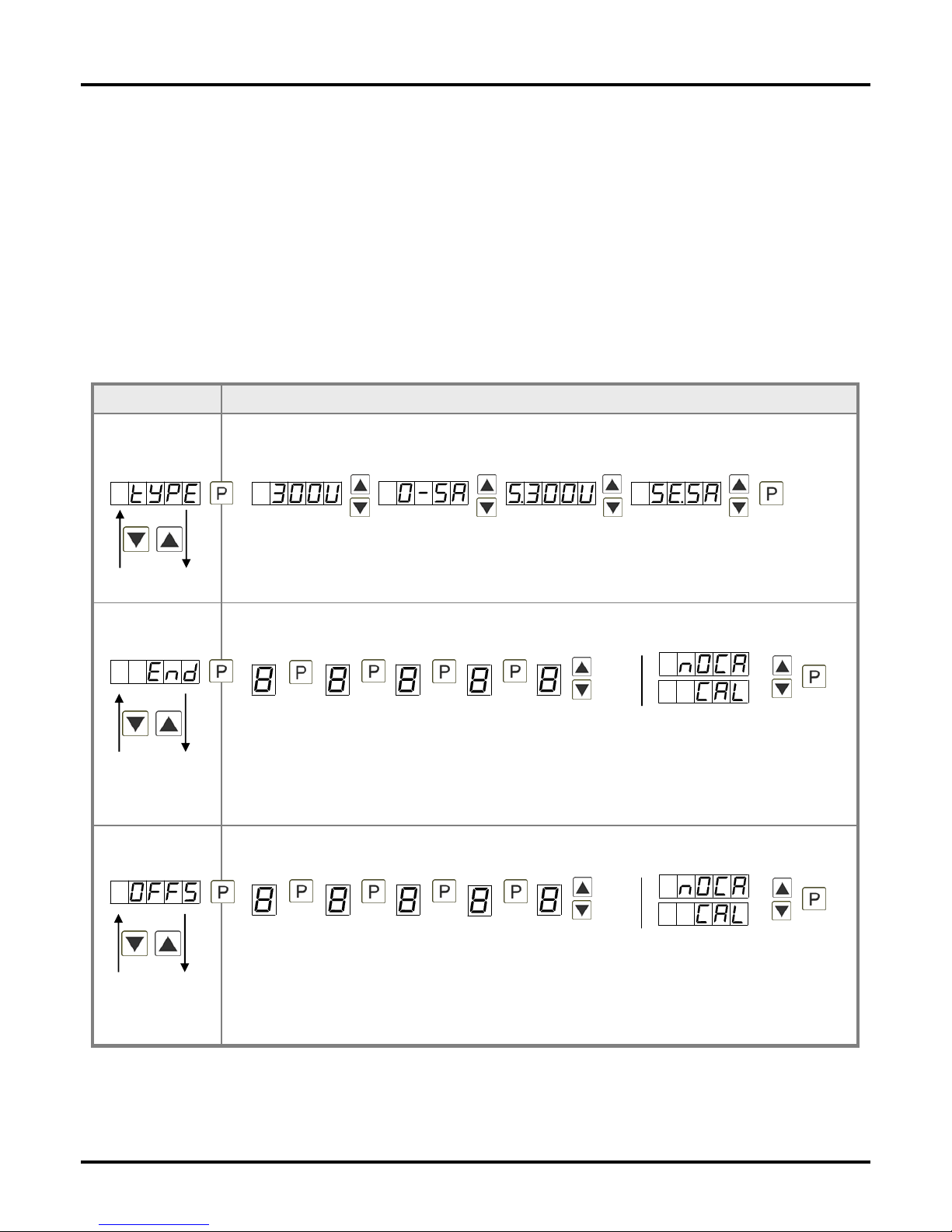

Setting the end value of the measuring range, END:

Default: 10000

Set the end value from the smallest to the highest digit with [▲] [▼] and confirm each digit with

[P]. A minus sign can only be parameterized on the highest value digit. After the last digit, the

display switches back to the menu level. If Sens was selected as input option, you can only

select between noca and cal. With noca, only the previously set display value is taken over, and

with cal, the device takes over both the display value and the analogue input value.

Setting the start/offset value of the measuring range, offs:

Default: 0

Enter the start/offset value from the smallest to the highest digit with [▲] [▼] and confirm each

digit with [P]. After the last digit the display switches back to the menu level. If Sens was

selected as input option, you can only select between noca and cal. With noca, only the

previously set display value is taken over, and with cal, the device takes over both the display

value and the analogue input value.

Selection of the input signal, tYPE:

Default: s.30ou

Available as measuring input options are 0-300 VAC or 0-5 AAC signals as works calibration

(without application of the sensor signal) and S.300v and se.5a as sensor calibration (with the

sensor applied). Select with [▲] [▼] and confirm the selection with [P].

Parameterisation levelMenu level

8

6. Setting up the device

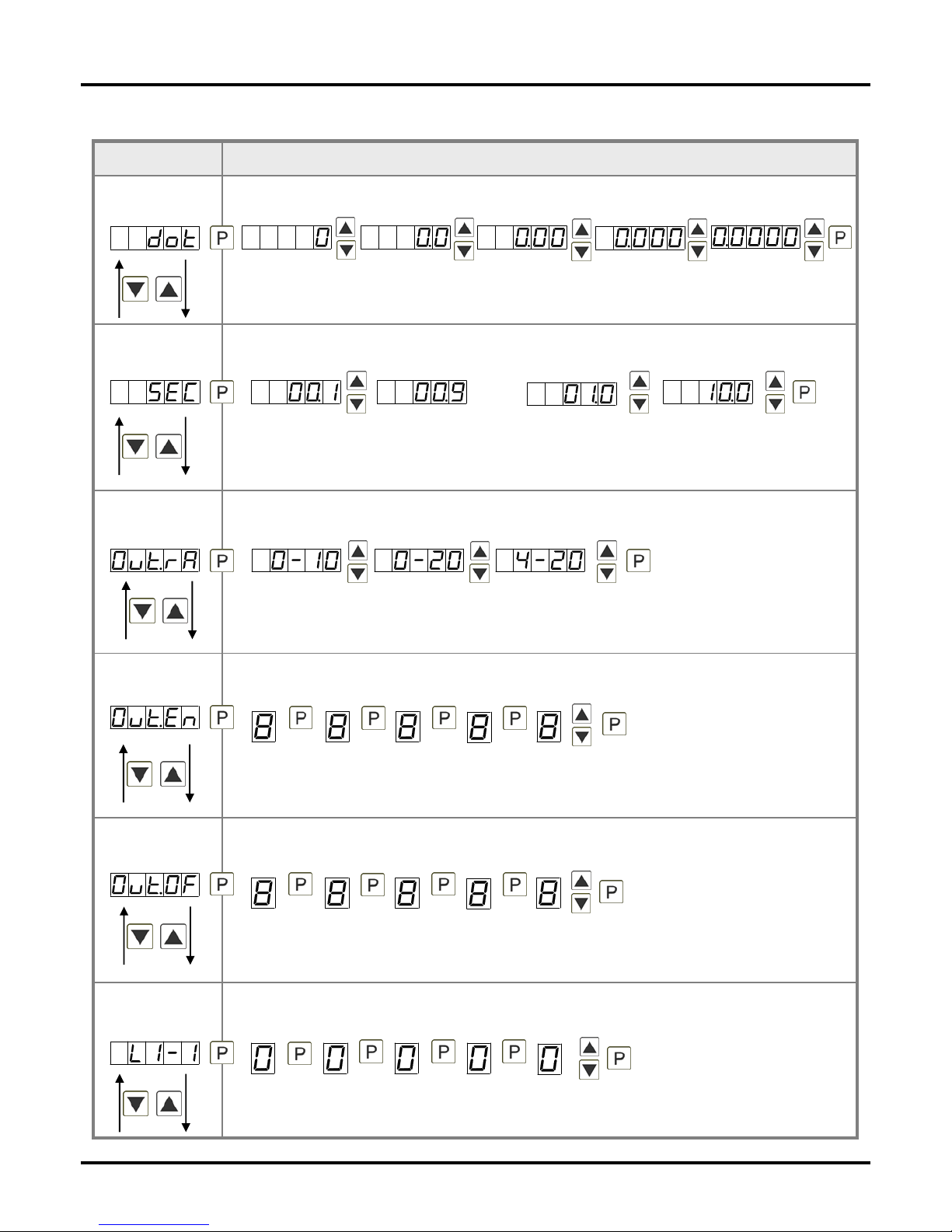

Setting up the initial value of the analog output, Out.OF:

Default: 00000

The final value is adjusted from the smallest digit to the highest digit with [▲] [▼] and digit by

digit confirmed with [P]. A minus sign can only be parameterised on the highest digit. After the

last digit, the device changes back into menu level.

Setting up the final value of the analog output, Out.En:

Default: 10000

The final value is adjusted from the smallest digit to the highest digit with [▲] [▼] and digit by

digit confirmed with [P]. A minus sign can only be parameterised on the highest digit. After the

last digit, the device changes back into menu level.

Threshold values / limits, LI-1:

Default: 2000

This value defines the threshold, that activates/deactivates an alarm.

Selection of analog output, Out.rA:

Default: 4-20

Three output signals are available: 0-10 VDC, 0-20 mA and 4-20 mA, with this function, the

demanded signal is selected.

Setting up the display time, SEC:

Default: 1.0

The display time is set with [▲] [▼]. The display moves up in increments of 0.1 up to 1 second

and in increments of 1.0 up to 10.0 seconds. Confirm the selection by pressing the [P] button.

The display then switches back to the menu level again.

Setting the decimal point, dot:

Default: 0

The decimal point on the display can be moved with [▲] [▼] and confirmed with [P]. The

display then switches back to the menu level again.

Parameterisation levelMenu level

then

Loading...

Loading...