MONTOLIT Brooklyn F1-101-115V, Brooklyn F1-131, Brooklyn F1-151-115V, Brooklyn F1-181-115V, Brooklyn F1-181 Instructions For Use Manual

...

ITALIANO

3

ENGLISH

14

2

Art.

Item

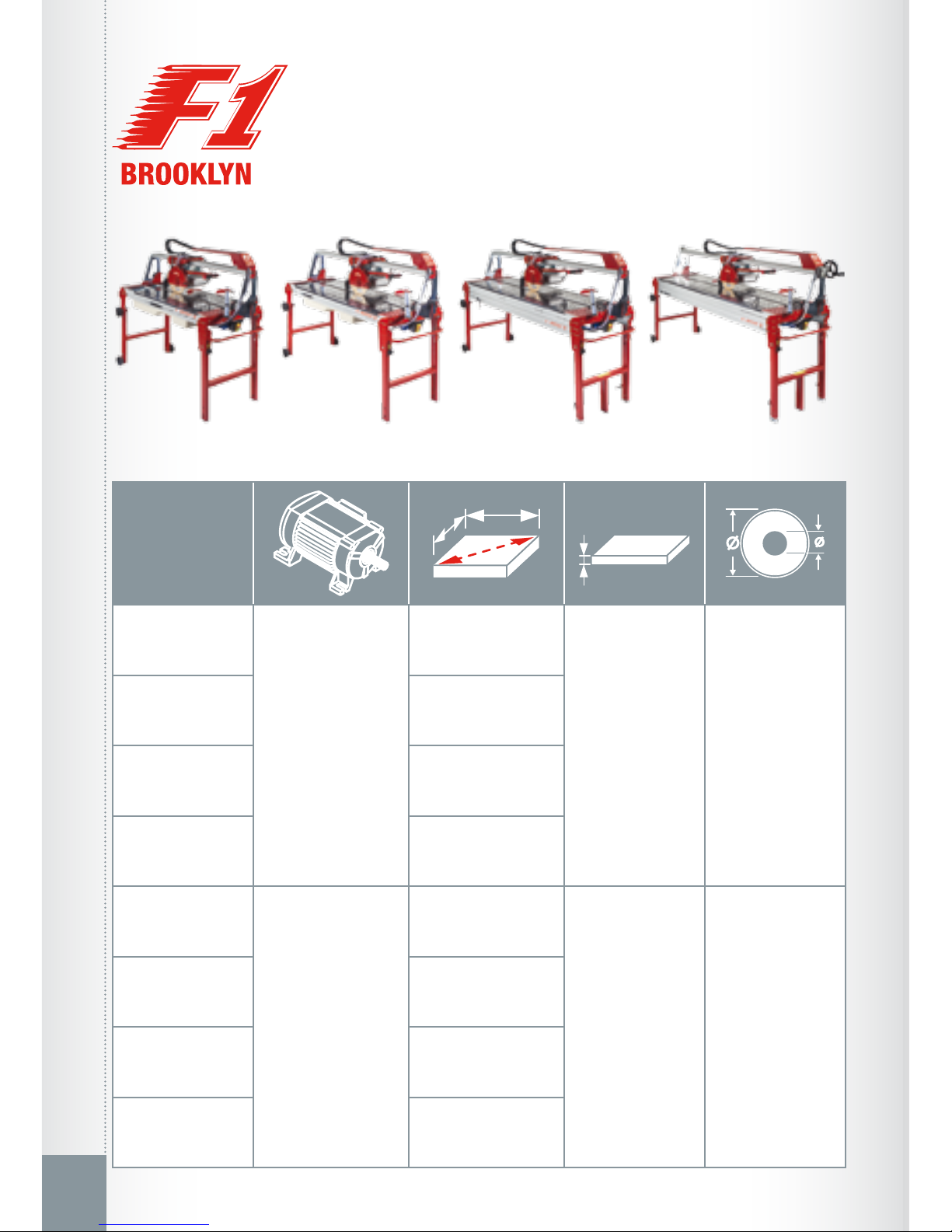

F1-101

230 V~

2,2 kW (3 HP

)

13,5 A

50 Hz

2.800 min

-1

101

(

71x71

)

cm

40 (28x28) inch

0 ÷ 5 cm

0 ÷ 2 inch

250/25,4 mm

10 / 1 inch

F1-131

131

(

92x92

)

cm

51,5

(36x36)

inch

F1-151

151

(

106x106

)

cm

59,5

(41,5x41,5)

inch

F1-181

181

(

128x128

)

cm

71,5

(50x50)

inch

F1-101-115V

115 V~

1,5 kW (2 HP

)

18 A

60 Hz

3.360 min

-1

101

(

71x71

)

cm

40

(28x28)

inch

0 ÷ 5 cm

0 ÷ 2 inch

250/25,4 mm

10 / 1 inch

F1-131-115V

131

(

92x92

)

cm

51,5

(36x36)

inch

F1-151-115V

151

(

106x106

)

cm

59,5

(41,5x41,5)

inch

F1-181-115V

181

(

128x128

)

cm

71,5 (50x50) inch

mod. 101cm mod. 131cm mod. 151cm mod. 181cm

ENGLISH

14

4

3

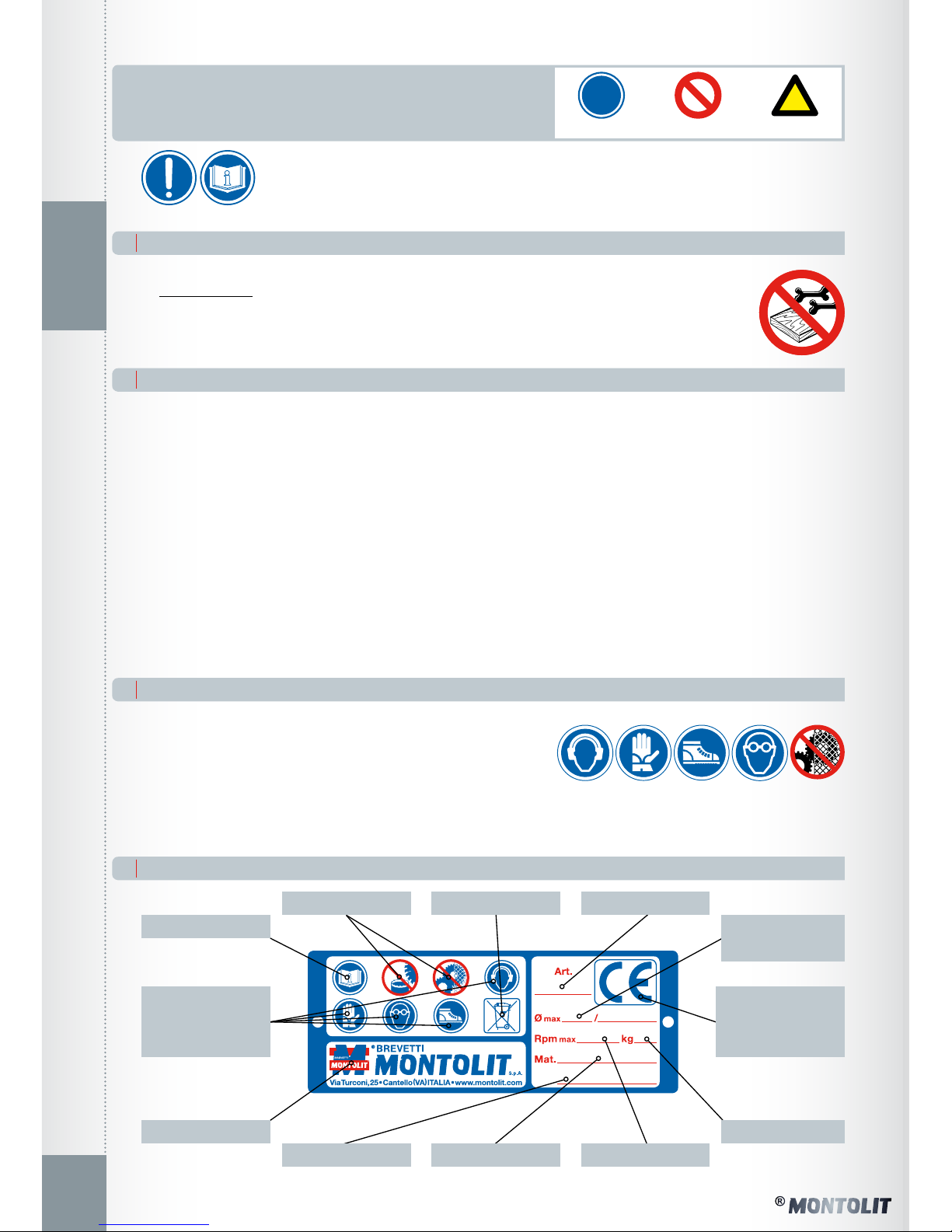

DangerProhibitedNecessity

1

2

European Safety

Certication

Diameter and bore

of diamond disk

Weight

ModelRAEE provisionsProhibitions

Read the instructions

Max RPMRegistration numberYear of production

Personal protective

equipment

Manufacturer name

USAGE INSTRUCTIONS

Carefully read and maintain.

ELECTRIC WATER CUTTER

• EXCLUSIVELY for the cutting and beveling (Jolly) of porcelain tile, klinker, terracotta, single-red, ceramics, concrete and stone materials.

• For professional use only.

• Before leaving the production workshop, your machine has been subjected to serious testing to ensure its quality, safety and efciency. By carefully following the instructions contained in this manual,

you ensure a long life for your machine under normal usage conditions.

• Before using the machine, carefully read this instruction manual in order to avoid accidents or malfunctions.

• Do not tamper with the protections and guards provided by the manufacturer in any way.

• Do not modify any part of the machine in any way.

• All modications must be made by the manufacturer only.

• Only use original spare parts.

• Brevetti MONTOLIT disclaims any liability in the event of non-compliance.

CAREFULLY FOLLOW THE REGULATIONS IN PLACE REGARDING HEALTH AND SAFETY IN THE WORKPLACE

• The use of individual hearing protectors is mandatory as

per Directive 2003/10/CE.

• The vibrations produced by the machine and evaluated

according to regulation UNI-EN-ISO 5349-1-2004 are

considered to be irrelevant.

IDENTIFICATION PLATE

ENGLISH

15

5

Weight

(kg)

Capacity

(lt)

mod.

101cm

75 25

mod.

131cm

85 25

mod.

151cm

100 25

mod.

181cm

112 25

1

2 3 4 5

6 7

10

•

PATENTED ADJUSTABLE LEGS SYSTEM

•

x mod. 151/181cm

8 9

ASSEMBLY AND PREPARATION

1

2

1

2

ENGLISH

16

6

13 14

15 16

ELECTRIC POWER SUPPLY

WARNING!

• Check the integrity of the cable and breakers.

• Respect the voltage (V) and frequency (Hz) indicated on the machine.

• Carry out the electrical connection with ground (yellow/green) to an IP67

outlet (2P+T) protected by an I∆N 0.01A differential breaker.

• Periodically check the operation of the differential breaker.

• For an extension, use only the IP67 (2P+T) socket and plug and a 3 x

2.5mm2 cable of the H 07 RN-F type (max length 5 m).

• Check the placement of the power cable: it must not obstruct movement,

and should not be subject to shock or damage.

• Remove the electrical connection during each routine or extraordinary

maintenance operation, for the loading of coolant (water), or for the substitution of the diamond disk.

• Models equipped with a thermal protection switch and minimum voltage coil.

• Avoid forcing the motor during processing. The machine has a security system that protects it from

engine overheating; consequently, if the motor is arrested without apparent reason, it is necessary

to wait a few minutes so that the safety circuit is disactivated, as the machine has almost certainly

been subjected to excessive force and the cutting advancement speed must therefore be moderated.

• IP55 single phase engine with electromagnetic emissions below the provided limits.

• In the case of malfunction regarding a breaker, cable, engine, or pump, consult an expert or our

Technical Ofce.

L e ve l H

2

O : 8 c m

L e ve l H

2

O : 8 c m

ENGLISH

17

7

r= 3m

max 5m

1 2 3

CORRECT POSITIONING

• The operator must position himself in a safe and balanced way and must not be distracted during

processing.

• The operator is always responsible for accidents that may occur to other people or their property.

• Do not allow other people to touch the machine or the cable. They must be kept away from the work

space.

• It is advisable to wear rubber gloves and shoes with slip-resistant soles. If you have long hair, it must

be gathered up or a protective cap used. Wear protective goggles.

• Use adequate hearing protection.

• Do not wear large clothing, objects or jewelry that can become stuck in moving parts.

• The work area must be at, dry, free of obstacles, well ventilated and illuminated.

• Do not use the machine near ammable liquids or gas.

• Keep the cable away from high temperatures, oil, and sharp edges.

• Before starting any cutting operation, ensure that the column locking knobs are screwed to the bottom (g. 1), that the legs are locked with the appropriate bolts (g. 2-3), and check the cooling water

level.

Loading...

Loading...