Montigo PVHFL58-300 User Manual

High voltage

Toxic

Flammable materials

Corrosive

Fork lift trucks

Danger overhead crane

Explosion risk

Blank

High voltage

Toxic

Flammable materials

Corrosive

Fork lift trucks

Danger overhead crane

Explosion risk

Blank

High voltage

Toxic

Flammable materials

Corrosive

Fork lift trucks

Danger overhead crane

Explosion risk

Blank

High voltage

Toxic

Flammable materials

Corrosive

Fork lift trucks

Danger overhead crane

Explosion risk

Blank

Installation & Maintenance Manual

PVHEX58-300 power vent is approved for use with Montigo R320, R320-ST, R420,

R420-ST, and RP620.

NOTICE

PVVEX58-300 power vent is approved for use with Montigo R320, R320-ST, R420,

R420-ST, and RP620.

NOTICE

PVHEX510-300 power vent is approved for use with Montigo R520, R520-ST,

R620-ST, R720, and R820.

NOTICE

PVVEX510-300 power vent is approved for use with Montigo R520, R520-ST,

R620-ST, R720, and R820.

NOTICE

PVHFL58-300 &

PVHFL510-300

5/8 and 5/10

Horizontal Flush

Louvered

Power Vent

WARNING

If the information in these instructions is not followed exactly, a fire or explosion

may result causing property damage, personal injury or death.

DANGER

Do not try to light any appliance.

Do not touch any electrical switch; do not use any phone in your building.

Immediately call your gas supplier from a neighbor's phone. Follow the gas

supplier's instructions.

If you cannot reach your gas supplier, call the fire department.

PVHFL58-300 power vent is approved for use with Montigo R320, R320-ST, R420,

R420-ST, and RP620.

IF YOU SMELL GAS

NOTICE

NOTICE

Installer: Leave this manual with the appliance.

Consumer: Retain this manual for future reference.

NOTICE

This power vent is approved for use with Montigo fireplaces only and is certified to

ANSI Z21.50 / CSA 2.22 vented gas fireplace standard along with the fireplace.

NOTICE

PVHFL510-300 power vent is approved for use with Montigo R520, R520-ST,

R620-ST, R720, and R820.

XG0519 070714

Canadian Heating Products Inc. Langley, BC V4W 4A1 | Montigo Del Ray Corp. Ferndale, WA 98248

PVHFL58-300 & PVHFL510-300 Horizontal Power Vent

Safety Alert Key

Introduction

Specications

Pipe Dimensions PVHFL58-300 ............ 5"/8"

Pipe Dimensions PVHFL510-300 .......... 5"/10"

Maximum Airow: .........................300 CFM

Speed: .......................................... 2700 RPM

Power: ............................................Connect to replace control box

............................................ Refer to replace rating plate

Before Your Begin

General Information

This installation guide covers installation of the External Power Vent

System only. This system is designed to allow installation of gas replaces

that cannot be done with a standard Direct Vent gas replace installa-

tion. Only for use on R-Series, R-Series See-Through and RP-Series.

ONLY USE WITH APPROVED FIREPLACES - see replace

installation manual.

Read through the replace's installation & maintenance manual, as it

must also be adhered to.

Power Cord Harnesses:

EPVH10 - 10 foot power cord and harness

EPVH20 - 20 foot power cord and harness

EPVH30 - 30 foot power cord and harness

EPVH40 - 40 foot power cord and harness

EPVH50 - 50 foot power cord and harness

EPVH60 - 60 foot power cord and harness

EPVH70 - 70 foot power cord and harness

EPVH80 - 80 foot power cord and harness

EPVH90 - 90 foot power cord and harness

EPVH100 -100 foot power cord and harness

For vent congurations and power vent locations,

refer to replace manual.

Page 2

XG0519 - 070714

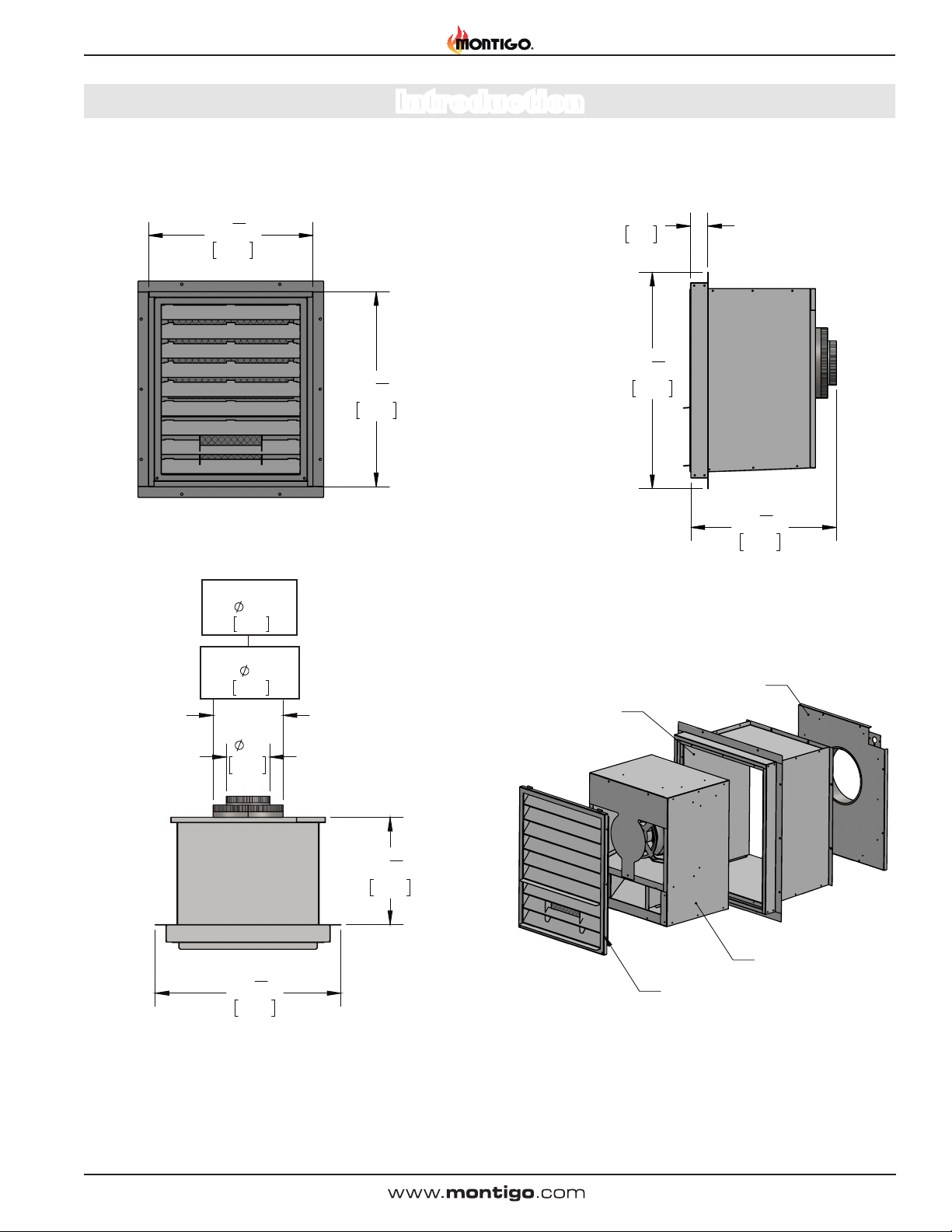

Product Dimensions

3

21

1

8

"

538

12

1

4

"

311

5"

126

8"

203

2"50

24

5

8

"

627

PVHFL58-300 Flush Louvered Power Vent

2"50

Louver Assembly

18

"

4

476

22

565

Introduction

1

"

4

PVHFL58-300 & PVHFL510-300 Horizontal Power Vent

5

24

"

8

627

Front View

PVHEX10-300

10"

254

PVHEX58-300

8"

203

126

21

5"

538

1

"

8

12

311

1

4

Outer Assembly

"

16

421

Side View

Back Cover / Collar

5

"

8

Inner Assembly

XG0519 - 070714

Top View

Figure 1. PVHFL58-300 (Tolerance ± ⅛") [mm]

Page 3

PVHFL58-300 & PVHFL510-300 Horizontal Power Vent

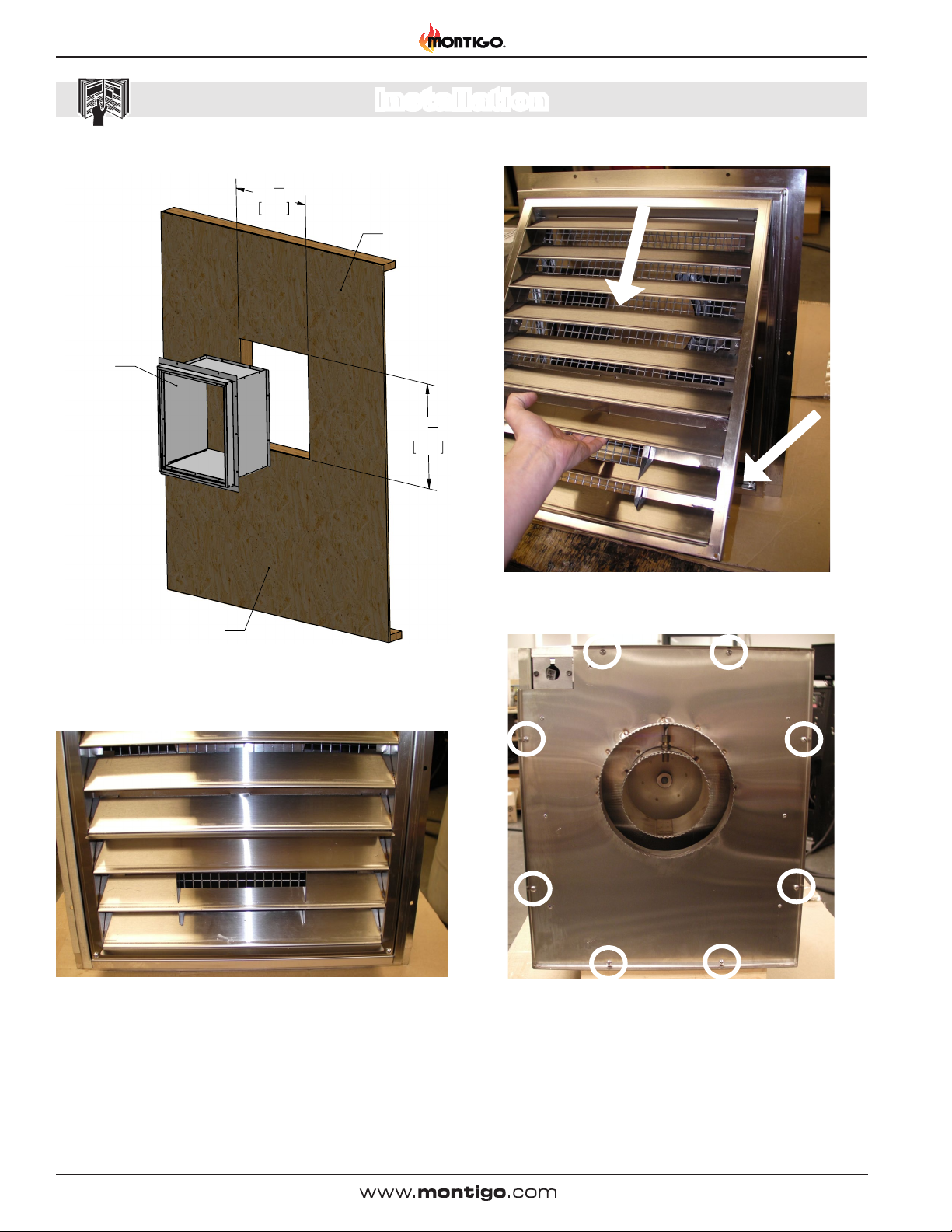

Installation

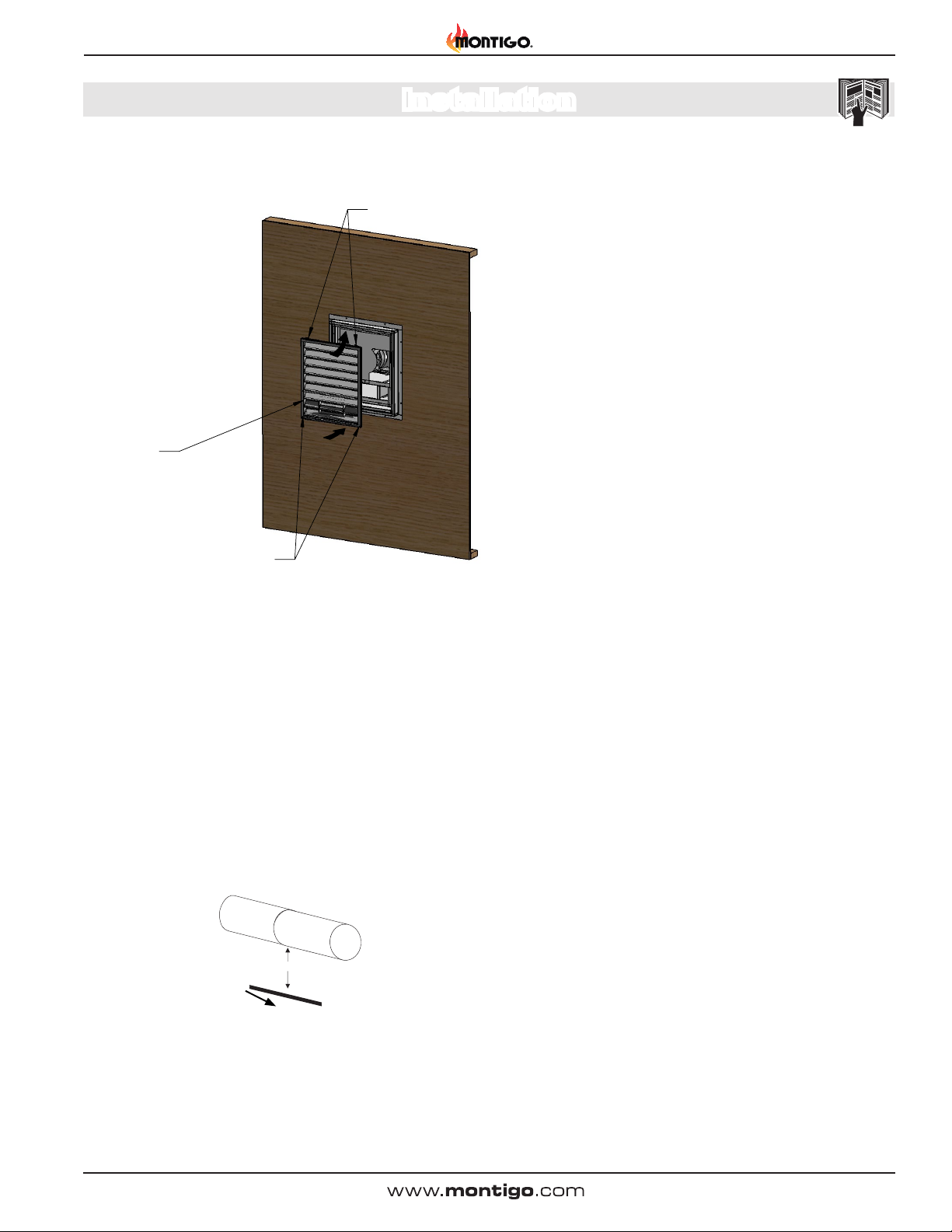

Outer Can

Assembly

Installing the power vent

3

"

18

4

476

Wall Board

Framing

22

565

Step 2: Remove the louver assembly by lifting the bottom end forward and

then dropping the door out of the top latches.

1

"

4

Figure 3a.

Step 3: To remove the inner can from the outer can remove the 8 screws on

the back of the termination.

Figure 2. Framing dimensions

Step 1: Unpack power vent from box. Remove two screws from bottom of the

door. Hold louver assembly securely so it does not fall.

Figure 3.

Figure 3b.

Page 4

XG0519 - 070714

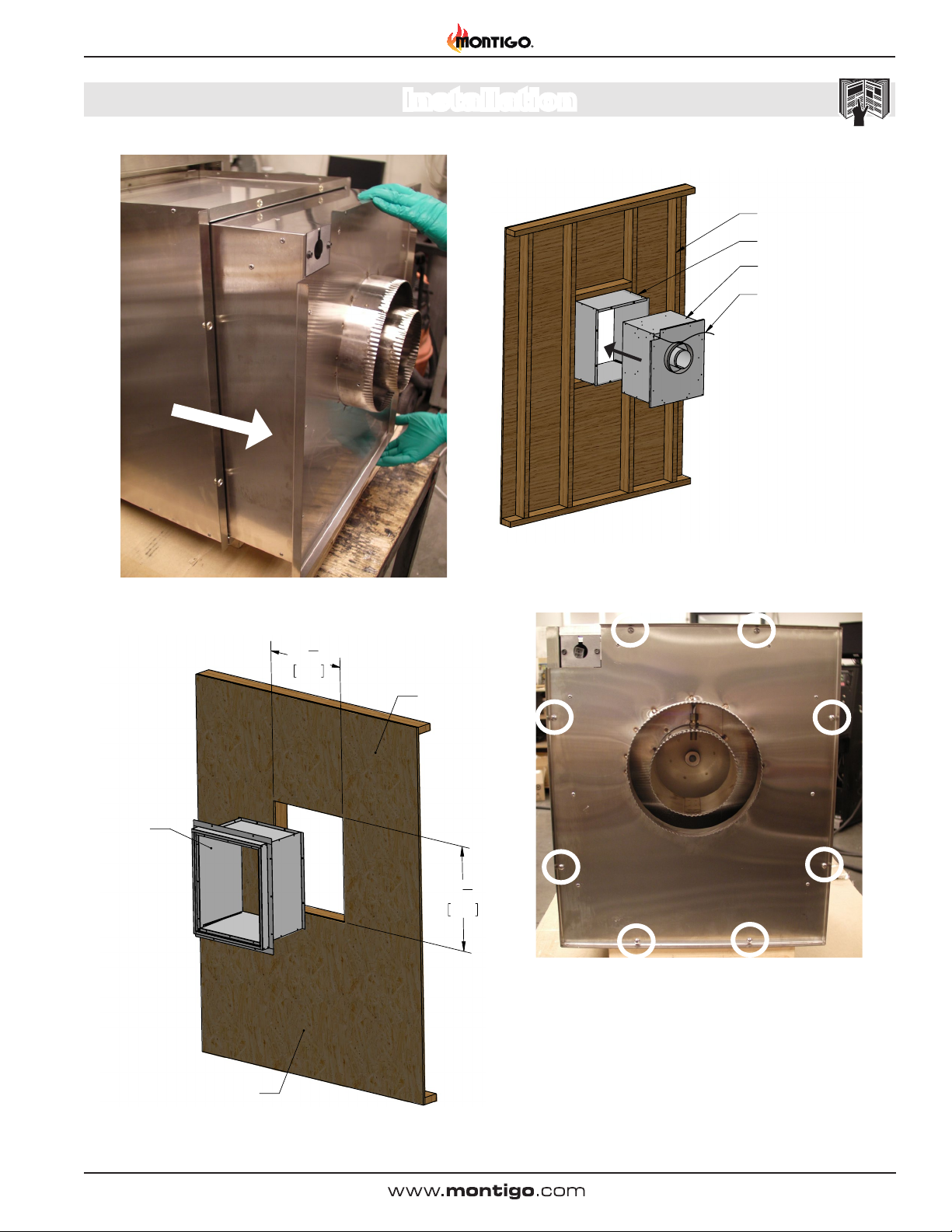

Installation

PVHFL58-300 & PVHFL510-300 Horizontal Power Vent

Step 4: Slide the inner can out by pulling

Figure 3c.

Step 6: Slide the inner can assembly into the outer can assembly from the

inside of the house.

Structure

Outer Can Assembly

Inner Can Assembly

Power Cord from Power Vent

All framing shown is combustible

Figure 3e.

Step 7: Screw inner can back to outer can using 8 screws.

Step 5: Screw outer can assembly into the wall

3

18

4

476

Outer Can

Assembly

All framing shown

is combustible

"

Framing

1

22

"

4

565

Figure 3f.

Figure 3d.

XG0519 - 070714

Wall Board

Page 5

PVHFL58-300 & PVHFL510-300 Horizontal Power Vent

Installation

Step 8: Remove two screws securing electrical plate.

Figure 3g.

Step 9: Remove the power vent power cable from inside the electrical

channel.

Step 11: Attach the power cable from the power vent to the control cable.

Figure 3j.

Step 12: Push all the excess cable back into the electrical channel of the

power vent. Screw the electrical plate back on the power vent.

Figure 3h.

Step 10:Take the electrical harness [EPVH-10-100] that will communicate

with the power vent and attach the strain relief for it to the electrical plate.

Tighten the nut on the strain relief.

Figure 3i.

Page 6

Figure 3j.

Figure 3k.

XG0519 - 070714

Step 13: Reinstall the door.

Louver

Assembly

PVHFL58-300 & PVHFL510-300 Horizontal Power Vent

Installation

Tabs

Screw

Locations

Figure 3l.

Step 14: Connect vent pipe to power vent collar as required.

Note: If you are intending to service power vent from inside the house, use a

4-foot ex pipe to allow for easy removal of pipe from power vent.

Wiring Installation

Conduit & Wiring clearances

Connect the power vent harness as outlined. Connect the wiring to

the replace as outlined in the schematic shown in gure 4a. Ensure

that the proper clearances are maintained for the wiring and conduit.

When installing the wiring it must never run above the vent run and it

must be at least 1" clear of all venting.

Wire

1” Clearance

Figure 4. Conduit and Wiring

XG0519 - 070714

Page 7

Loading...

Loading...