Montigo MD34-DV-2, Homefire plus MD34-DV-2, Homefire plus MD34DT-2, Homefire plus MD34DR-2, Homefire plus MD34DT-I-2 Operation Manual

...

Installation

Questions? Email us at fireplaces@montigo.com or visit our website at www.montigo.com.

Operation &

Maintenance

MD34-DV-2

Homefire

Warning:

Improper installation, adjustment,

alteration, service or maintenance can cause

injury or property damage. Refer to this

manual. For assistance or additional

information consult a qualified installer,

service agency or the gas supplier.

For Your Safety:

Do not store or use gasoline

or other flammable vapors

and liquids in the vicinity of

this or any other appliance.

What To Do If You Smell Gas:

Do not try to light any appliance.

Do not touch any electrical switch; do not use any phone in your building.

Immediately call your gas supplier from a neighbor's phone. Follow the gas

supplier's instructions.

If you cannot reach your gas supplier, call the fire department.

Modular

Gas Fireplace

n Check local codes and

read all instructions

prior to installation.

n Leave this manual with

the owner.

MD34-DV-2 Homefire

Table Of Contents

Introduction ............................................................................ 2

Installation

Installing the Fireplace Shell ........................................ 3

Installing the Gasline .................................................... 4

The Remote Switch ......................................................4

Direct Vent Installation .................................................. 4

General Requirements ....................................4

Terminations.................................................... 5

Top Vent Through-the-Wall Installations ......... 6

Top Vent Through-the-Roof Installations ........ 8

Rear Vent Through-the-Wall Installations ....... 9

Rear Vent Multi-Elbow Installations ...............10

Construction around the fireplace

Facing ............................................................11

Mantels and Surrounds................................. 11

Wiring ............................................................... 11 - 12

Installing the Logset.................................................... 12

Removing and Installing the Insert ............................13

Removing and Installing the Door .............................13

Operation...................................................................... 14 - 16

Maintenance................................................................. 16 - 17

Warranty................................................................................18

Appendix

A. Termination Locations ...........................................19

CAUTIONS

Due to its high operating temperatures, the appliance

should be located out of traffic & away from furniture and

draperies.

n Children and adults should be alerted to the hazards

of the high surface temperature, which could cause

burns or clothing ignition.

n Young children should be carefully supervised when

they are in the same room as the appliance.

n Clothing or other flammable materials should not be

placed on or near the appliance.

Introduction

About Modular Fireplaces and the Homefire Plus:

The MD34-DV-2 Homefire Plus includes a 25,000 BTU dual burner

and embers. All 34 Series Modular Fireplaces allow quick and

easy upgrades in the future. The MD34-DV-2 can be upgraded to a

Wildfire Burner. Contact your dealer for more information. The

MD34-DV-2 model is available in four versions:

nTop Vent (Product Code MD34DT-2)

nRear Vent (Product Code MD34DR-2)

nElectronic Ignition - Top Vent (Product Code MD34DT-I-2)

nElectronic Ignition - Rear Vent (Product Code MD34DR-I-2)

The MD34-DV-2 is certified as a Vented Gas Fireplace Heater (ANSI

Z21.88-2000 · CSA 2.33-2000) and is rated for:

Natural Gas 24,500 BTU/H (7.2 Kilowatts) Maximum Input

19,500 BTU/H (5.7 Kilowatts) Minimum Input

Propane 23,000 BTU/H (6.7 Kilowatts) Maximum Input

17,700 BTU/H (5.2 Kilowatts) Minimum Input

How to use this manual:

This manual covers all models and unless otherwise specified, the

designation MD34-DV-2 refers to all models. Sections which are specific

to a particular model are marked with a symbol, plus the

appropriate model number.

Warranty and Installation Information:

The Montigo warranty will be voided by, and Montigo disclaims any

responsibility for, the following actions:

n Modification of the fireplace and/or components including Direct-Vent

assembly or glass doors.

n Use of any component part not manufactured or approved by

Montigo in combination with this Montigo fireplace system.

n Installation other than as instructed in this manual.

Consult your local Gas Inspection Branch on installation requirements for factory-built gas fireplaces. Installation & repairs should

be done by a qualified contractor.

Installations in Canada must conform to the current CAN/CGA

B-149.1 and .2 Gas Installation Code and local regulations. If the

optional air-circulating fan kit is installed, it must be electrically

grounded in accordance with CSA C22.1 Canadian Electrical Code

Part 1 and/or Local Codes.

Installations in the USA must conform to local codes, or in the

absense of local codes to the National Fuel Gas Code, ANSI

Z223.1-1988. If the optional air-circulating fan is installed, it must

be grounded in accordance with local codes or, in the absence of

local codes, with the National Electrical Code, ANSI/NFPA 70-

1987.

Page 2

Part No. XG0106B

Installation

Installing The Fireplace Shell

The fireplace may be installed in any location that maintains proper

clearances to air conditioning ducts, electrical wiring and plumbing.

Safety, as well as efficiency of operation, must be considered when

selecting the fireplace location. Try to select a location that does not

interfere with room traffic, has adequate ventilation, and offers an

accessible pathway for Direct Vent installation. Refer to page 4 - Vent

Installation for more information.

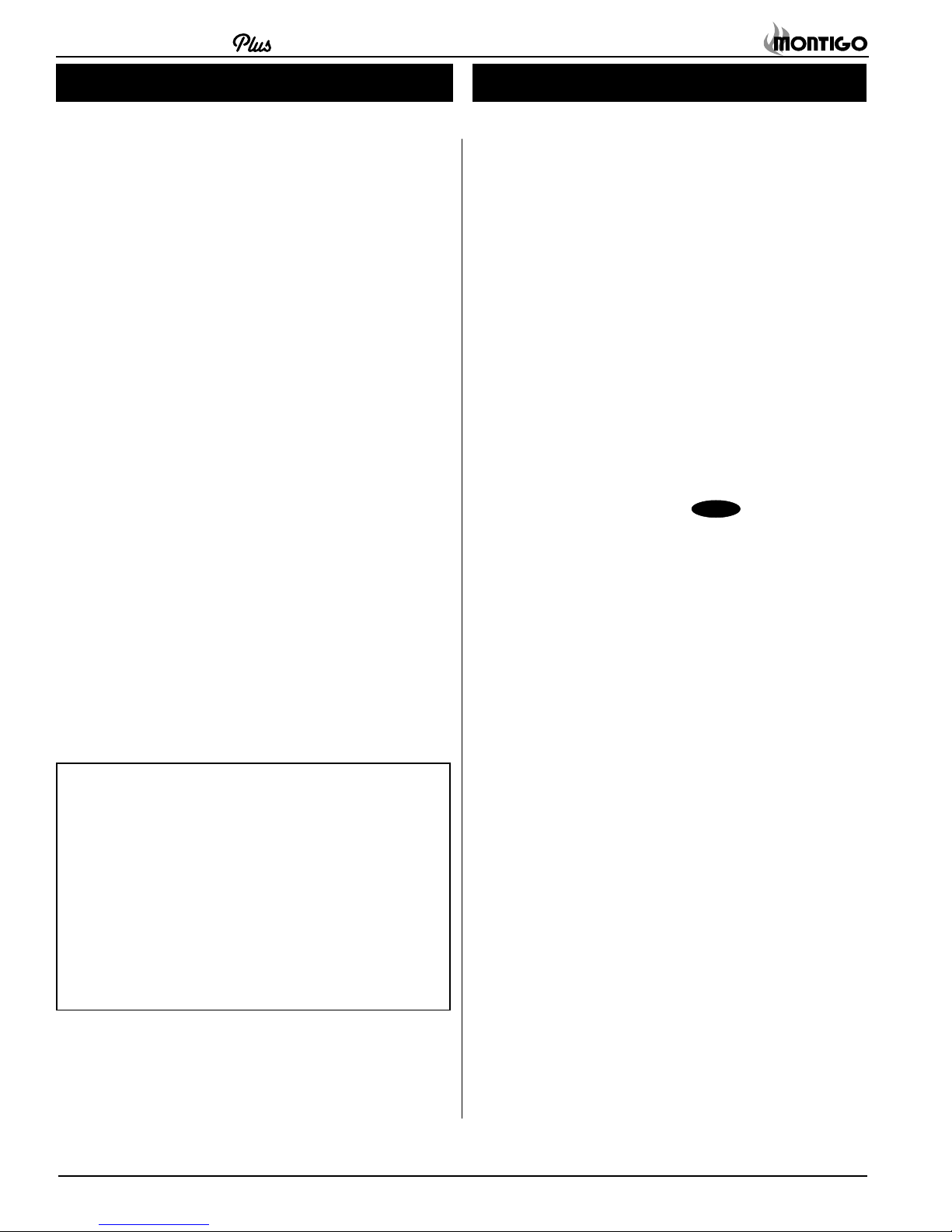

The fireplace dimensions are shown below:

15

8 3/4

31 1/2

Ø7

Top Vent

Ø4

C

34

15

32

Ø7

Ø4

26 1/8

Framing

15 3/4

33

Figure 2. Framing dimensions.

42

22 1/4

MD34-DV-2 Homefire

* When sheetrock is

not used behind the

fireplace, framing

36

59 3/8

33

depth may be

reduced to 15"

Front View

Rear Vent

Figure 1. Fireplace dimensions.

Clearances

The MD34-DV-2 clearances to combustible materials are:

Top - Rear Vent* 7"

Top - Top Vent*** 35"

Back 0"

Side 1"

Floor 0"

Mantle** 10"

* Clearance from the top of the fireplace to a combustible

ceiling within the fireplace enclosure.

** Refer to page 11.

*** If the standard elbow (MEL90) is used with the Low

Clearance Sleeve (CRS30) the Top Clearance is 15".

If the Low Clearance Sleeve (CRS30) is NOT used

over the elbow, the Top Clearance is 35".

Unprotected combustible walls which are perpendicular to the

fireplace opening, must not project beyond the shaded area shown

in Figure 19b.

For protection against freezing temperatures, it is recommended

that outer walls of the chase be insulated with a vapour barrier. This

will reduce the possibility of a cold-air convection current on the

fireplace.

0" clearance

to corners only

Figure 3. Corner framing dimensions.

When installing a shelf over the top of the fireplace, the following

guidelines must be adhered to: For Rear Vent models (MD34DR-2),

the minimum clearance from the top of the fireplace to a shelf is 7". For

Top Vent models (MD34DT-2), the minimum clearance when using the

CRS30 is 15". (Minimum 1" clearance must still be maintained around

the vent pipes.)

Rear Vent

Top Vent

Figure 4. Framing for shelves over the fireplace.

WARNING:

When this appliance is installed directly on carpeting, tile or any

combustible material other than wood flooring, it must be

installed on a metal or wood panel extending the full width and

depth of the appliance.

Part No. XG0106B

Page 3

MD34-DV-2 Homefire

Installation

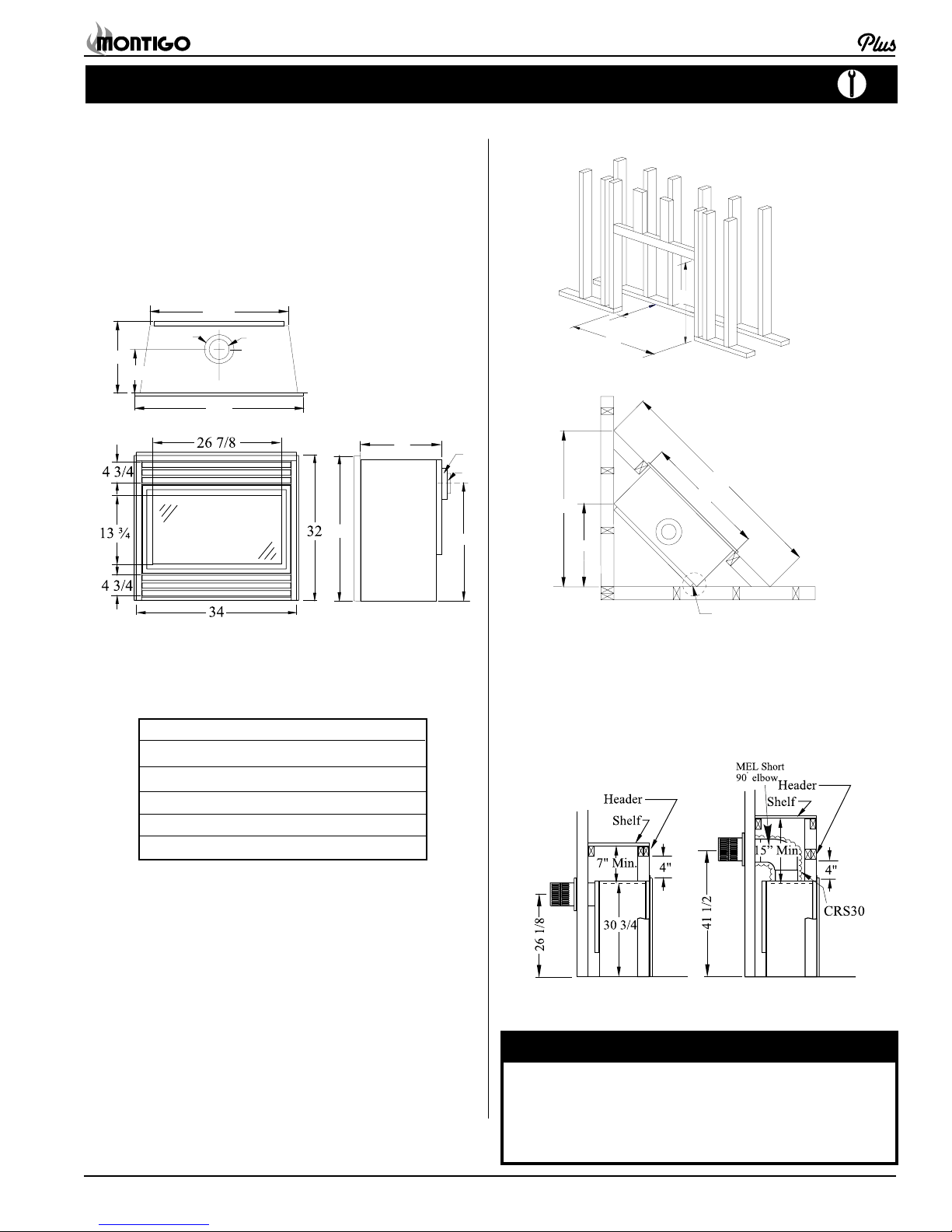

Installing The Gas Line

The gas line must be installed before finishing the MD34-DV-2 Fireplace.

Natural Gas requires a minimum inlet gas supply pressure of 5.5"

W.C. & a manifold pressure of 3.5" W.C. Propane Gas requires a

minimum inlet gas supply pressure of 11" W.C. & a manifold pressure of

10" W.C. Provision must also be made for a 1/8" N.P.T. plugged tapping

and be accessible for test gauge connection immediately upstream of the

gas supply controls to the appliance. The fireplace gas connection and

the main operating gas valve is located behind the removable brass trim

at the bottom of the unit and need only be attached to the gas line with an

approved fitting, as required by the applicable installation codes.

Figure 5. Gas line access.

During any pressure testing of the gas supply piping that excedes 1/ 2

psig (3.5 kPa), the appliance and its individual shutoff valve must be

disconnected from gas supply system.

When pressure testing the gas supply piping system at test pressures of

less than or equal to 1/2 psig (3.5 kPa), the appliance must be isolated

from the gas supply piping system by closing its individual manual shutoff

valve.

Note: After gas line is connected, each appliance connection,

valve and valve train must be checked while under

normal operating pressure with either a liquid solution, or

leak detection device, to locate any source of leak. Tighten

any areas where bubbling appears or leak is detected until

bubbling stops completely or leak is no longer detected.

DO NOT use a flame of any kind to test for leaks.

Vent Installation

This section covers the installation of direct venting and terminations.

Installation Requirements

n MD34-DV-2 fireplaces are certified for use with Montigo Standard

Series (4" / 7") venting components

n Minimum 1" clearance to combustibles required for vent pipes

n Use only certified Montigo vent components. (Use of other

parts will void the Montigo warranty, and may impede the

operation of the fireplace.)

n All joints must be secured with a minimum of two screws per joint

n Vent terminations must not be recessed in walls or siding

n Horizontal runs must be supported by a minimum of two supports

per horizontal run. A minimusm of one screw on each side of

support is also required

n Flex vent sections may be stretched up to 50% of their total length

(eg. a 24" section may be stretched to 36")

n Maximum horizontal run for a flex section with no vertical rise is 3 feet.

n Flex vent sections over 3 feet must fall within the limits set by the

venting graph and must have a minimum vertical rise of 3 inches

per foot of flex.

n Solid vent sections may be cut less than half way from the tapered end

n Venting components can be used in any combination of solid/rigid

pipe or flex pipe and in any orientation (Male connectors can face

in any direction)

Vent Terminations

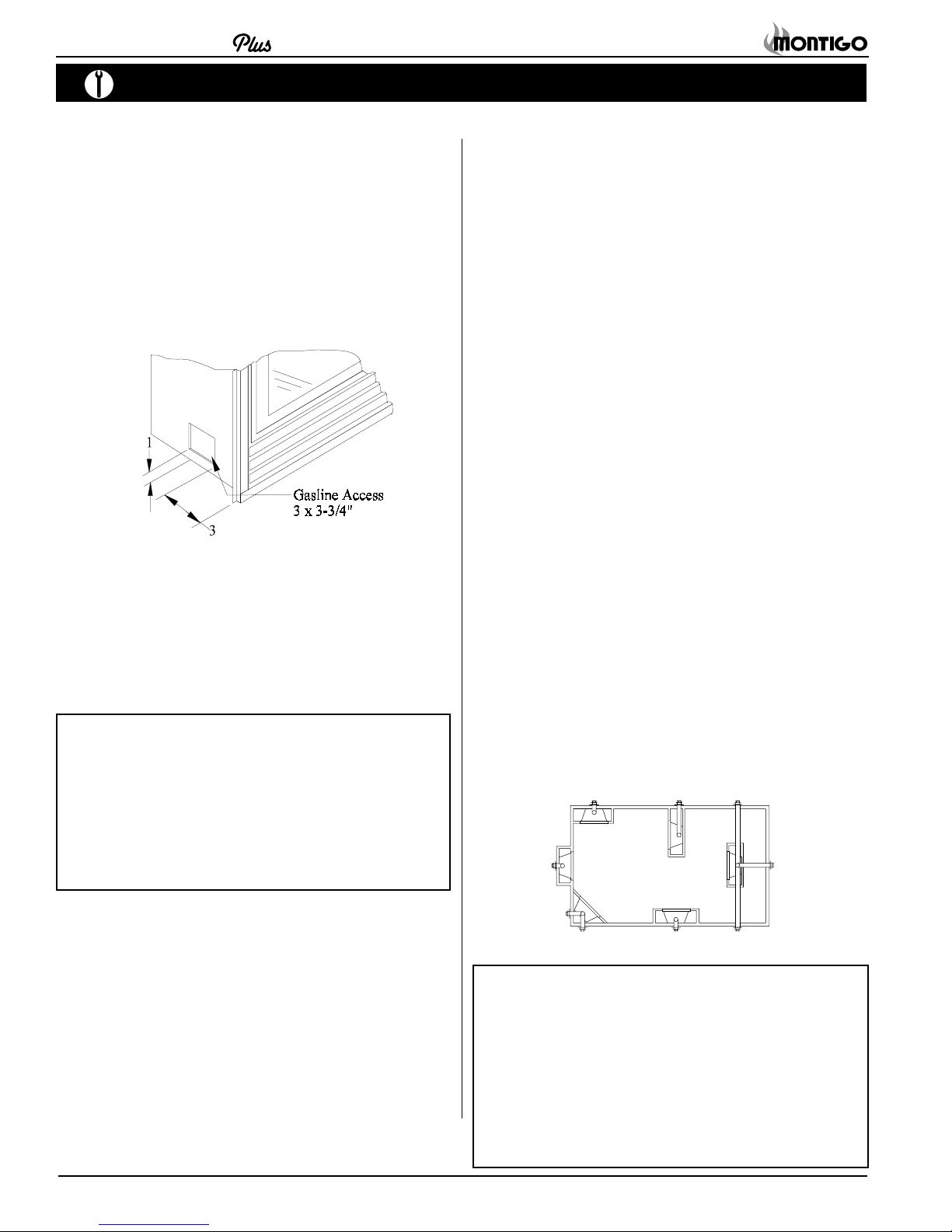

Selecting A Termination Location

Choosing your vent termination location will help to determine whether

you need to use a top vent or rear vent fireplace. Figure 6, below,

shows typical fireplace locations and the venting options they provide.

For a more detailed diagram of allowed termination locations, see

Appendix B.

Installing The Remote Switch

The MD34-DV-2's gas valve, located behind the lower brass trim, may

be connected to a wall switch. The valve generates its own power. This

is a millivolt circuit. Use only low voltage wire, and DO NOT connect any

external power to it.

Refer to Figure 28 for wiring requirements.

Note: The switch location must not exceed 30' from the fireplace.

Page 4

Figure 6. Fireplace locations and vent terminations.

Cautions:Cautions:

Cautions:

Cautions:Cautions:

n Vent terminations can be very hot. If the termination is less

than 7 feet above a public walkway, it should be fitted with a

certified Montigo Heat Guard. (Part no. MTKOG)

n Do not obstruct, or attempt to conceal, the vent termination.

These actions will affect the operation of the fireplace, and

may be hazardous.

n In heavy snow areas, take extra care to prevent snow buildup

from obstructing the vent termination.

Part No. XG0106B

Installation

MD34-DV-2 Homefire

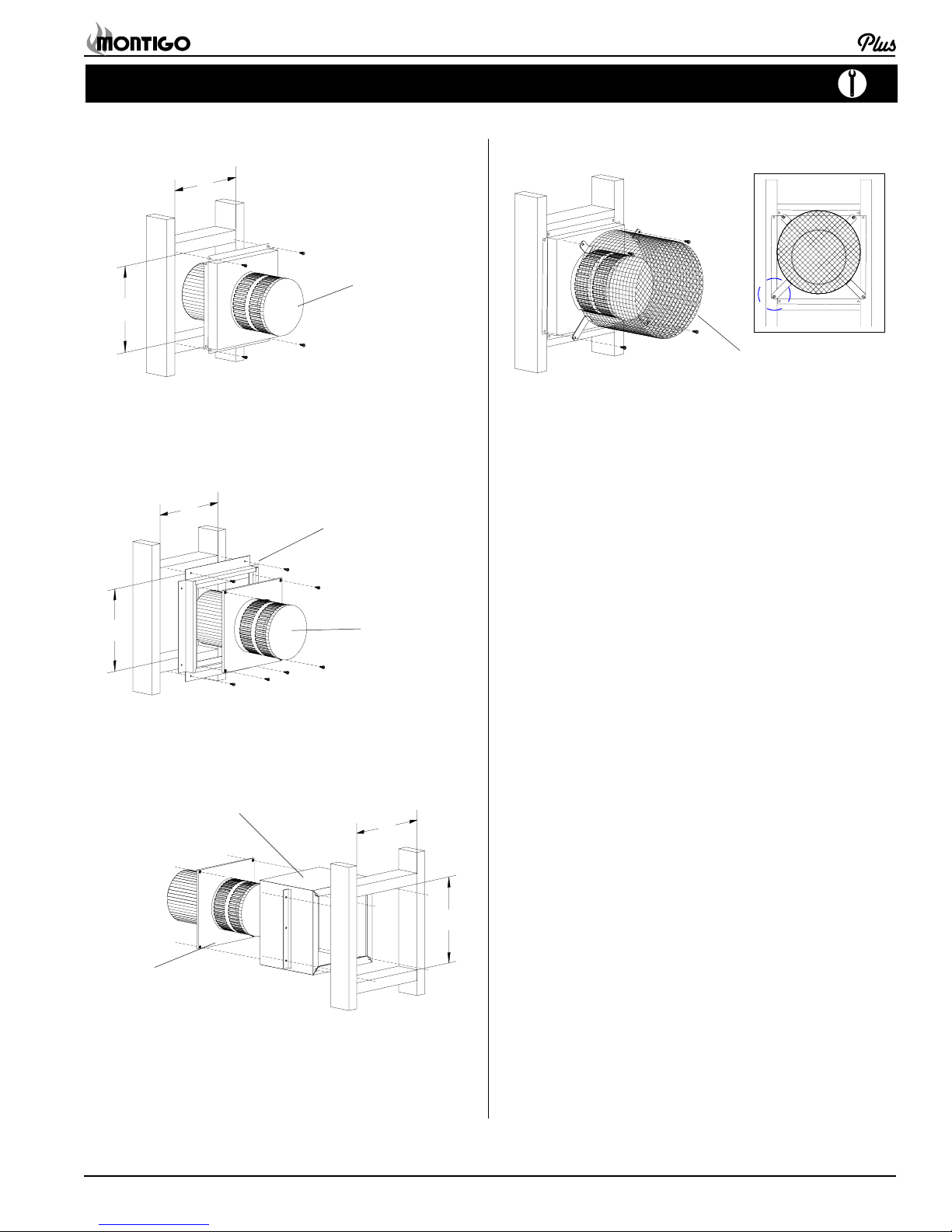

Installing Terminations with Built-In Frames

11

MTO-3F

11

1. Frame the termination opening to 11" x 11".

2. Fasten the termination to the studs using a minimum of 4

screws.

Installing Terminations with MSR Frames

12

MSR

Installing Heat Guards over Terminations

MTKOG

1. Ensure that the two long mounting brackets are facing the

bottom of the termination. (See inset). This will provide more

heat protection at the top of the termination, where temperatures are highest.

2. Attach to the faceplate of the termination using four sheet metal

screws.

12

1. Frame the termination opening to 12" x 12".

2. Fasten the termination to the studs using a minimum of 4

screws.

MTO-3

Installing Terminations with MOSR Frames

MOSR

MTO-3

1. Frame the termination opening to 12" x 12".

2. Fasten the MOSR frame to the interior side of the studs using

a minimum of 4 screws.

3. Insert the termination into the MOSR frame as shown here,

and attach by screwing through the four pilot holes in the

termination.

1212

12

Part No. XG0106B

Page 5

MD34-DV-2 Homefire

Installation

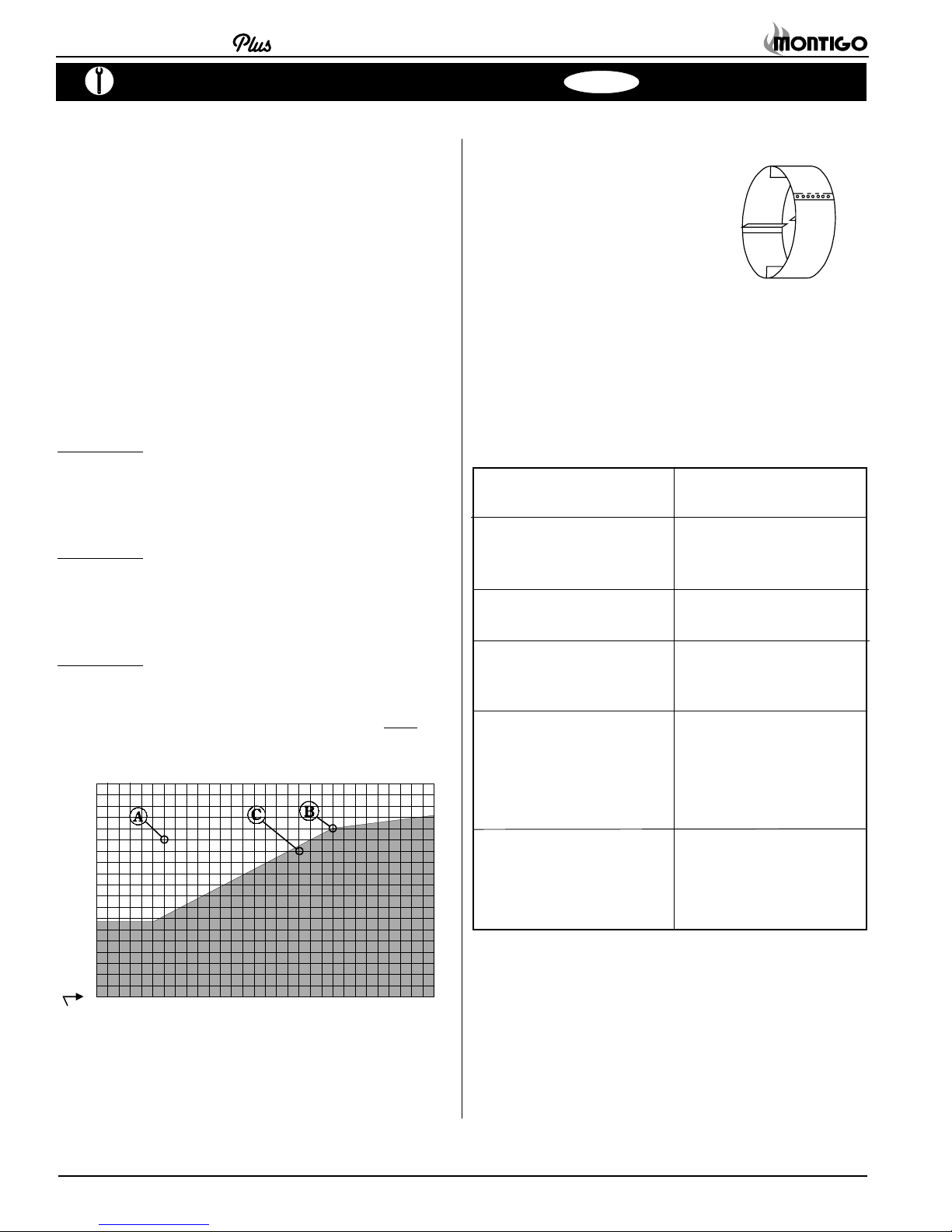

Top Vent Venting Runs

For the MD34-DV-2, there are two types of installations: A) ThroughThe-Wall Installations and B) Vertical (Through-The-Roof) Installations.

A) Through-The-Wall Installations

Before you install any venting, you must determine whether the venting

run will be acceptable. Unacceptable venting can affect the fireplace's

combustion.

The Venting Graph

Measure the vertical height from the fireplace hearth to the centre of the

termination and the horizontal run from the from the fireplace flue collar to

the wall flange of the termination. Plot on the Venting Graph (Fig. 7) with

an 'X'.

If the 'X' falls on or above the top boundary of the shaded area, the

installation is acceptable.

Example A: (Acceptable Installation)

If the vertical dimension from the hearth is 84" and

the horizontal run to the wall flange of the vent

termination is 36", this would be an acceptable

installation.

Example B: (Acceptable Installation)

If the vertical dimension from the hearth is 90" and

the horizontal run to the wall flange of the vent

termination is 126", this would be an acceptable

installation.

Example C: (Unacceptable Installation)

If the vertical dimension from the floor of the fireplace is 78" and the horizontal run to the wall flange

of the vent termination is 108", this would

an acceptable installation.

108

96

84

72

60

48

36

24

12

0

12 24 36 48 60 72 84 96 108 132120 144 156 168 180

0

Hearth

Horizontal Run (in.)

Figure 7. MD34-DV-2 Top Vent Venting Graph

NOT be

Top Vent

Heat Shields

Due to high flue temperatures, heat shields

are required on all 34 Series Modular

Direct Vent installations (except those with

vertical terminations) at the point where the

venting connects to the termination. With

the heat shield, vent clearances can be

maintained at 1".

Figure 8. Heat Shield. Install by sliding over the vent pipe where it

passes through combustible construction.

Available Top Vent Components

The following venting components are available for the MD34-DV-2

Top Vent:

A - Termination MTO-3 (3" length)

MTO-3F (3" length)

B - Stucco Kits MSR (stucco frame)

MOSR (stucco can)

BSR (brick can)

D - Flex sections MFL-1 (12" section)

MFL-18 (18" section)

MFL-2 (24" section)

MFL-3 (36" section)

MFL-4 (48" section)

E - Solid sections EXT-18 (18" f/f section)

MEXT-1 (12" m/f section)

MEXT-2 (24" m/f section)

MEXT-3 (36" m/f section)

MEXT-4 (48" m/f section)

F - Elbows

NOTES: All dimension lengths for vertical or horizontal runs

are measured from center of the vent pipe.

Venting runs must fall within the limits set by the

venting graph (see Figure 7).

MEL-90M (m/m 90° elbow)

MEL-90F (f/f 90° elbow)

MEL-90FM (f/m 90° elbow)

EEL-45 (f/m 45° elbow)

Page 6

Part No. XG0106B

Loading...

Loading...