Montigo H38DF PFC, HP38DF PFC, HL38DF PFC Maintance Manual

High voltage

Toxic

Flammable materials

Corrosive

Fork lift trucks

Danger overhead crane

Explosion risk

Blank

High voltage

Toxic

Flammable materials

Corrosive

Fork lift trucks

Danger overhead crane

Explosion risk

Blank

High voltage

Toxic

Flammable materials

Corrosive

Fork lift trucks

Danger overhead crane

Explosion risk

Blank

High voltage

Toxic

Flammable materials

Corrosive

Fork lift trucks

Danger overhead crane

Explosion risk

Blank

Installation & Maintenance Manual

H38DF PFC

HL38DF PFC

HP38DF PFC

Peninsula

Indoor

DANGER

Read and understand this manual. Improper installation, adjustment, alteration,

service or maintenance can cause serious injury, property damage or even death.

For assistance or additional information consult a qualified installer, service

agency or the gas supplier.

CAUTION

Glass doors on gas fireplaces are extremely hot while the fireplace is on and

remain hot even after the fireplace has been turned off. Safety screens are

available and can reduce the risks of severe burns. Please keep children away

from the fireplace at all times.

Resi

dential Gas

Fireplace

WARNING

Do not store or use gasoline or any other flammable vapors and liquids in the vicinity of

this or any other gas burning appliance. A fire or explosion my occur causing serious

injury, property damage or even death.

NOTICE

Installer: Leave this manual with the appliance. Do not remove.

Consumer: Retain this manual for maintenance and future reference. Do not Discard.

®

C US

XG0816 011012.1

Canadian Heating Products Inc. Langley, BC V4W 4A1 | Montigo Del Ray Corp. Ferndale, WA 98248

DANGER

IF YOU SMELL GAS

Do not try to light any appliance.

Do not touch any electrical switch; do not use any phone in your building.

Immediately call your gas supplier from a neighbor's phone. Follow the gas

supplier's instructions.

If you cannot reach your gas supplier, call the fire department.

H*38DF PFC Peninsula Gas Fireplace

NOTICE

You must read and understand this manual prior to installation, operation or

troubleshooting this appliance. Please retain this owner’s manual for furure reference

and maintenance.

Table of Contents

Safety Alert Key

Introduction

Models .................................................................................3

Installation

Before you Start .................................................................................4

Installation Checklist ...........................................................................4

Section 1: Installation Overview and Product Dimensions .....................5

Section 2: Framing the Fireplace ............................................................6

Clearances .................................................................................6

Installing the Standoffs ...................................................................7

The Nailing Flange Extension ........................................................7

Section 3: The Direct Vent System ..................................................8 - 10

Section 3-1: Converting from T

Section 3-2: Installing a Roof mounted Termination .......................9 - 10

▪ Section 3-2-1: Venting Layout ......................................................9

▪ Roof mounted Terminations

Standard Top V

Top Vent (two elbows one offset) ............................................... 9

Top Vent (multi-elbows and of

Standard Roof Vent (one elbows no offsets) ...........................10

Section 3-3: Installing a Wall mounted

▪ Standard PTO Installation .....................................................11

▪ Pre-installed MSR Frame ......................................................11

▪ Pre-installed BSR Frame ....................................................... 11

▪ Installing MOSR Frame .........................................................11

▪ Installing VSS Termination Shield..........................................11

▪ Installing PTKOG Heat Guard ...............................................11

▪ Section 3-3-1: Venting Layout .............................................12 - 15

▪ Top V

▪ Top Vent, Wall mounted termination (one elbow) ..................12

▪ Top V

▪ Rear Vent, Wall mounted Termination Graph, H*38PF* ........14

▪ Standard Rear Vent, (no elbows or offsets)...........................

▪ Rear Vent, Wall mounted termination (two elbows) ...............15

▪ Section 3-3-2: Venting Components ..............................................16

▪ Section 3-3-3: Heat Shields ...........................................................17

▪ Installing a RHS8 Wall Mounted Heat Shield ........................17

▪ Installing a RHS101 Wall Mounted Heat Shield ....................17

.................................................................................3

.................................................................................4

op Vent to Rear Vent

ent (no elbows or offsets)

fsets)

Termination

ent, Wall mounted Graph, H*38PF*

ent, Wall mounted termination (multi elbow)

.............................8

..................................9

...........................................9

......................... 11

..............................12

................13

15

Section 4: Wiring ...............................................................................18

▪ SIT - IPI gas control and pilot ................................................18

▪ Installing the remote On/Off Wall Switch ..........................18

▪ Honeywell gas control and pilot ...........................................18

Section 5: Installing the Gas Line .........................................................19

Section 5-1: Fuel Conversion ..........................................................19

Section 5-2: Gas Pressure ..............................................................19

Section 5-3: Gas Connection ...........................................................19

Section 6: Finishing ..............................................................................20

▪ Finishing around the replace ...............................................20

▪ Mantels and Surrounds .........................................................20

Section 7: Installing and Removing the Door .......................................21

Section 8: Installing the Accessories .............................................22 - 24

▪ Installing the H38PF* Log set ................................................ 22

▪ Installing the HL38PF* Firestones ......................................... 23

▪ Installing the HP38PF* Log set .............................................24

Section 9: Operation ......................................................................22 - 24

▪ Start-up Sequence for Standing (Continuous) Pilot Ignition .. 25

▪ Start-up Sequence for Honeywell Electronic Ignition ...........26

▪ Start-up Sequence for Proame SIT Electronic Ignition ........ 27

Maintenance

▪ General ...............................................................................28

▪ Cleaning ...............................................................................28

▪ SIT Hi-Lo Burner Adjustment .................................................28

▪ SIT Pilot Burner Adjustment ..................................................28

▪ Troubleshooting .....................................................................29

SIT- Nova 820 Gas Control Valve ........................................29

▪ Replacement Parts ................................................................ 30

Appendix

A. Termination Locations .............................................................. 31

B. Warranty

C. State of Massachusetts. ..........................................................33

........................................................................28 - 30

SIT-Proame Electronic Gas Control Valve ......................... 29

...............................................................................32

Page 2

XG0816 - 011012.1

H*38DF PFC Peninsula Gas Fireplace

High voltage

Toxic

Flammable materials

Corrosive

Fork lift trucks

Danger overhead crane

Explosion risk

Blank

Safety Alert Key

DANGER WARNING

Indicates a hazardous situation which, if not

avoided, WILL result in death or serious

injury or property damage.

CAUTION NOTICE

Indicates a hazardous situation which, if not

avoided, WILL result in minor or moderate

injury.

Introduction

INTRODUCTION

Congratulations on your purchase of a Montigo Fireplace.

With over 30 years of experience, Montigo is committed to providing

you with a gas replace that is not only a beautiful addition to your

space, but that is also designed and manufactured to the highest

safety, reliability and engineering standards.

We strongly encourage you to read and carefully follow the

instructions laid out in this Installation, Operation and Maintenance

Manual and retain it for your future reference. Pay special attention

to all cautions, warnings, and notices throughout this manual

intended to ensure your safety.

This manual covers installation, operation and maintenance.

Lighting, operation and care of this replace can be easily

performed by the homeowner. All installation and service work

should be performed by a qualied or licensed installer, plumber

or gastter as certied by the state, province, region or governing

body where the replace is being installed.

This installation, operation and maintenance manual is applicable

to the models described below. Refer to your rating plate to

verify included options. Throughout this manual instructions are

applicable to all models designated as H*38PF* unless otherwise

noted in the Table.

XG0816 - 011012.1

WARNING

Hot glass will cause

burns. Do not touch

glass until unit is cooled.

Never allow children to

touch glass.

Indicates a hazardous situation which, if not

avoided, COULD result in death or serious

injury or property damage.

Address practices that are important, but

not related to personal injury

MODEL

H38DFPFCN

H38DFPFCN-F

H38DFPFCL

H38DFPFCL-F

HL38DFPFCN

HL38DFPFCN-F

HL38DFPFCL

HL38DFPFCL-F

HP38DFPFCN-F

HP38DFPFCL-F

Warranty Information

Natural Gas

Liquid Propane

Gas Rating

(BTU hr)

Traditional Burner w/

Logset

Premium Burner w/

Logset

Linear Burner w/ Glass

media Accessories

Standing Pilot Ignition

X 34,000 X X

X 34,000 X X

X 32,000 X X

X 32,000 X X

X 34,000 X X

X 34,000 X X

X 32,000 X X

X 32,000 X X

X 34,000 X X

X 32,000 X X

: (See Appendix B)

The Montigo warranty will be VOIDED by, and Montigo disclaims any

responsibility for, the following actions:

► Modication of the replace and/or components including DirectVent assembly or glass doors.

► Use of any component part not manufactured or approved by

Montigo in combination with this Montigo replace system.

► Installation other than as instructed in this manual.

Consult your local Gas Inspection Branch on installation requirements

for factory-built gas replaces. Installation & repairs should be done by

a qualied contractor.

Page 3

Honeywell HSI Ignition

SIT Electronic Ignition

H*38DF PFC Peninsula Gas Fireplace

Installation

IMPORTANT MESSAGE: SAVE THESE INSTRUCTIONS

The H*38PF* Direct Vent replace must be installed in accordance with

these Instructions. Carefully read all the Instructions in this manual

rst. Consult the Local Gas Branch to determine the need for a permit

prior to starting the installation. It is the responsibility of the installer to

ensure this replace is installed in compliance with the manufacturers

instructions and all applicable codes.

BEFORE YOU START:

NOTICE

Installation and repairs should be done by an authorized gas fireplace service technician.

The appliance should be inspected before use and at least annually by a professional. More

frequesnt cleaning may be required due to exessive lint from carpeting, bedding material,

etc. It is imperative that control compartments, burners and circulating air passageways of

the fireplace are kept clean.

CAUTION

Due to high operating temperatures, this appliance should be located out of traffic &

away from furniture and draperies.

Children and adults should be alerted to the hazards of the high surface temperature,

which could cause burns or clothing ignition.

Young children should be carefully supervised when they are in the same room as the

appliance.

Clothing or other flammable materials should not be placed on or near the appliance.

Installation Checklist

Determine the desired install location of your replace.

See Section 1, Dimensions on Page 5, and refer to the Framing

Section 2 for details.

Select the location of your termination and resulting vent run.

Your selected termination location must be the highest point

in the Direct Vent installation.

Should it be impossible to meet the venting requirements laid

out in Section 3: Venting, please contact a local Montigo dealer

regarding the use of a Montigo Power Vent.

Lay out the Vent run; calculating the required elbows and straight

runs of 5"/8" flex or rigid pipe.

Layout Electrical Requirements Refer to Section 4: Wiring for

Details.

Refer to Section 5: Installing the Gas Line for details on the gas

connection and access.

Refer to local codes and guidelines for installation requirements.

Installation and repairs should be done by a qualied

contractor and must conform to:

• Installations in Canada must conform to the local codes or in the

absence of local codes to the current version of Natural Gas and Propane

Installation Code, CSA B149. Electrical Installations must conform to

the local codes or, in the absence of local codes, to the current version

of Canadian Electrical Code, CSA C22.1.1

• Installations in the USA must conform to the local codes or in

the absence of local codes to the current version of National Fuel Gas

Code, ANSI Z223.1/NFPA 54. Electrical Installations must conform to

the local codes or, in the absence of local codes, to the current version

of the National Electrical Code, ANSI/NFPA 70. See Appendix C for

installation within the State of Massachusetts.

DANGER

When this appliance is installed directly on any combustible material other than wood

flooring, it must be installed on a metal or wood panel extending the full width and

depth of the appliance or a fire will occur causing serious injury, property damage or

even death.

Page 4

XG0816 - 011012.1

Installation

12 1/2”

8 3/4”

41 1/2”

Ø 5”

Ø 8”

21 5/8”

Glass

4 1/2”

4 1/2”

32 1/8” Glass

6”

4 7/8”

4” Nailing Flange

33”

Rear Vent

25”

35 5/8”

16 3/8”

2

15/16”

2 15/16”

19 1/8”

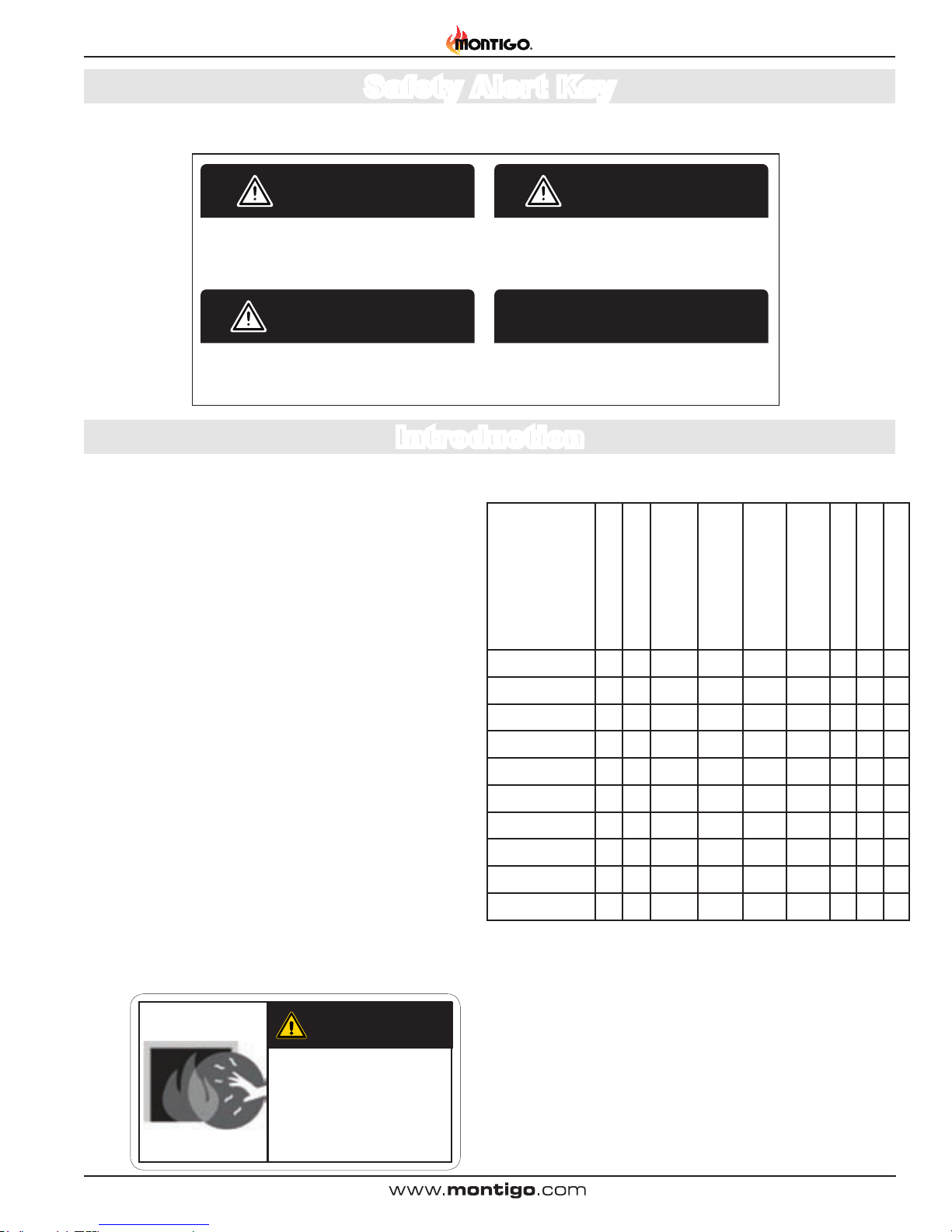

Section 1: Installation Overview and Product Dimensions

H*38DF PFC Peninsula Gas Fireplace

Please review the Installation Checklist on Page 4 for general information

on preparing for a successful installation of your replace.

The H*38PF* replace may be installed in any location that maintains

proper clearances to air conditioning ducts, electrical wiring and plumbing.

The replace dimensions are shown below:

Top View

Safety, as well as efciency of operation, should be considered when

selecting the replace location. Select a location that does not interfere

with room trafc, has adequate ventilation and offers an accessible path

for Direct Vent installation.

C

L

C

L

40”

24 3/4”

Opening

Figure 1. Fireplace dimensions with Nailing Flange Extension shown

Front View

(Tolerance ± ⅛").

Top of

Unit

Glass

Side View

39 5/8”

XG0816 - 011012.1

Page 5

H*38DF PFC Peninsula Gas Fireplace

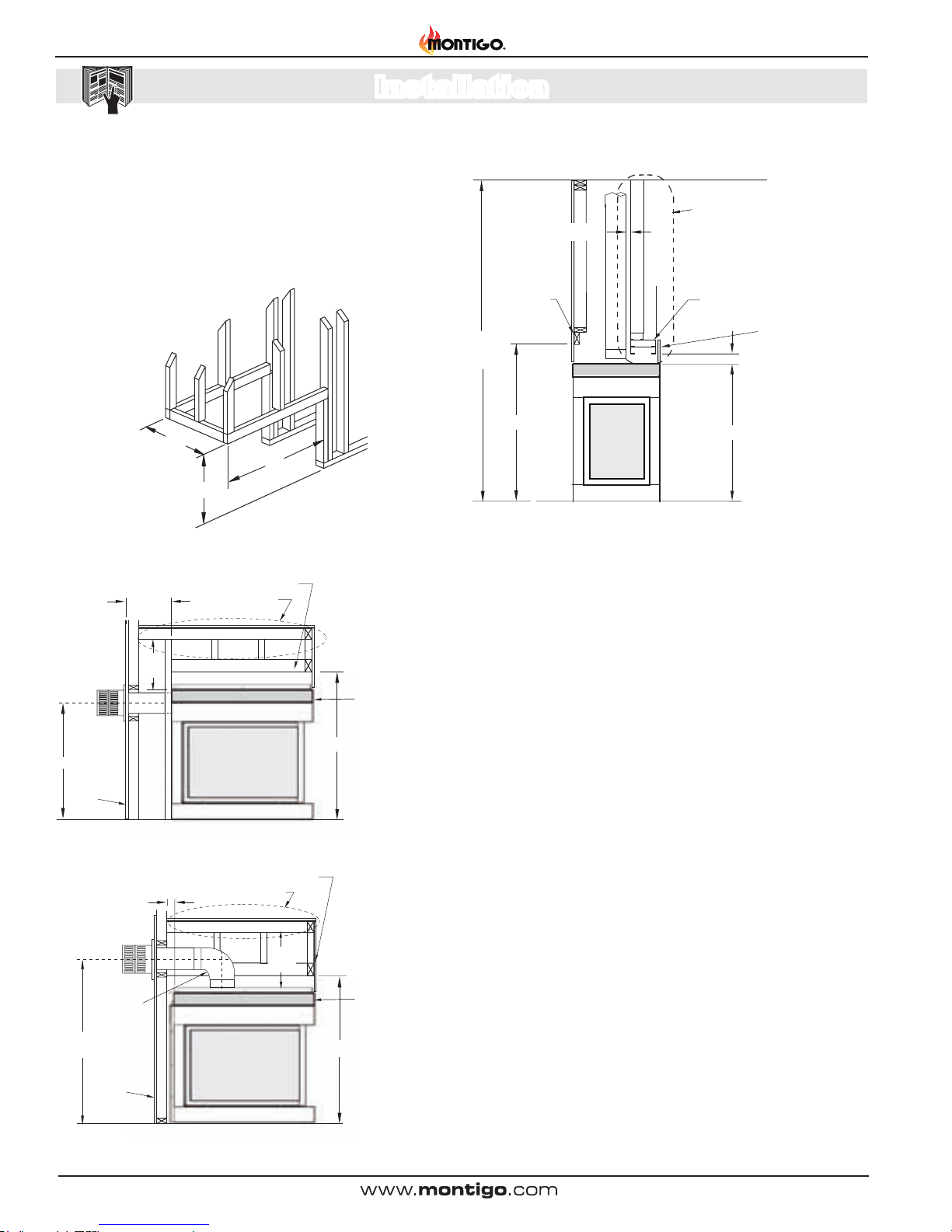

Section 2: Framing

Installation

1). Frame in the enclosure for the unit with framing materials. The

framed opening for the assembled replace is 23 3/4" wide, x 44"

high x 41" deep, see Figure 2

.

NOTE: When constructing the framed opening, please ensure there is

access to install the gas line when the unit is installed. See Figure 21.

23 3/4

41

44

Figure 2. Framing dimensions.

Combustible Header

12” Max.

Combustible Shelf

Top Vent

Ceiling level

Non-Combustible

materials. Alcove

over fireplace.

Non-Combustible

Header

Floor

Non-Combustible

Materials, with Low

profile mantel / Alcove

2”

over fireplace.

39 5/8”

84”

min.

Combustible

Header

44”

Min. 1 ”

Figure 5. Non Combustible Framing with alcove above replace, Top Vent.

11”

Min.

4” Nailing flange

or Non-combustible

material.

44”

33”

Exterior

Wall

Figure 3. Combustible Framing for shelves over the replace, Rear vent.

Combustible Header

Combustible Shelf

17 1/2”

Min.

4” Nailing flange

or Non-combustible

material.

44”

46” Min

58” Min for HP

2” Min.

PEL Short

90 elbow

Exterior

Wall

Figure 4. Combustible Framing for shelves over the replace, Top vent.

Page 6

XG0816 - 011012.1

Installation

H*38DF PFC Peninsula Gas Fireplace

Clearances

When installing a shelf over the top of the replaces, the following

guidelines must be adhered to:

For Rear Vent applications, the minimum clearance is 2" from the rear of

the replace to a wall, or any combustible materials, and 11" clearance

from the top of the replace to the underside of any combustible shelf

materials.

For Top Vent applications, the minimum clearance is 2" from the rear of

the replace to a wall, or any combustible materials, and 17 1/2" to the

underside of any combustible shelf materials.

For Horizontal vent pipes, ensure that 1” clearance is maintained on

sides and bottom of vent runs and 2” above horizontal vent runs to any

combustible material.

MODEL

H*38PF* 11" 17 1/2" 2" 1" 0" 4"

Top - Rear vent †Top - Top vent †

Rear

Sides

Floor

Mantel

Nailing Flange Extension

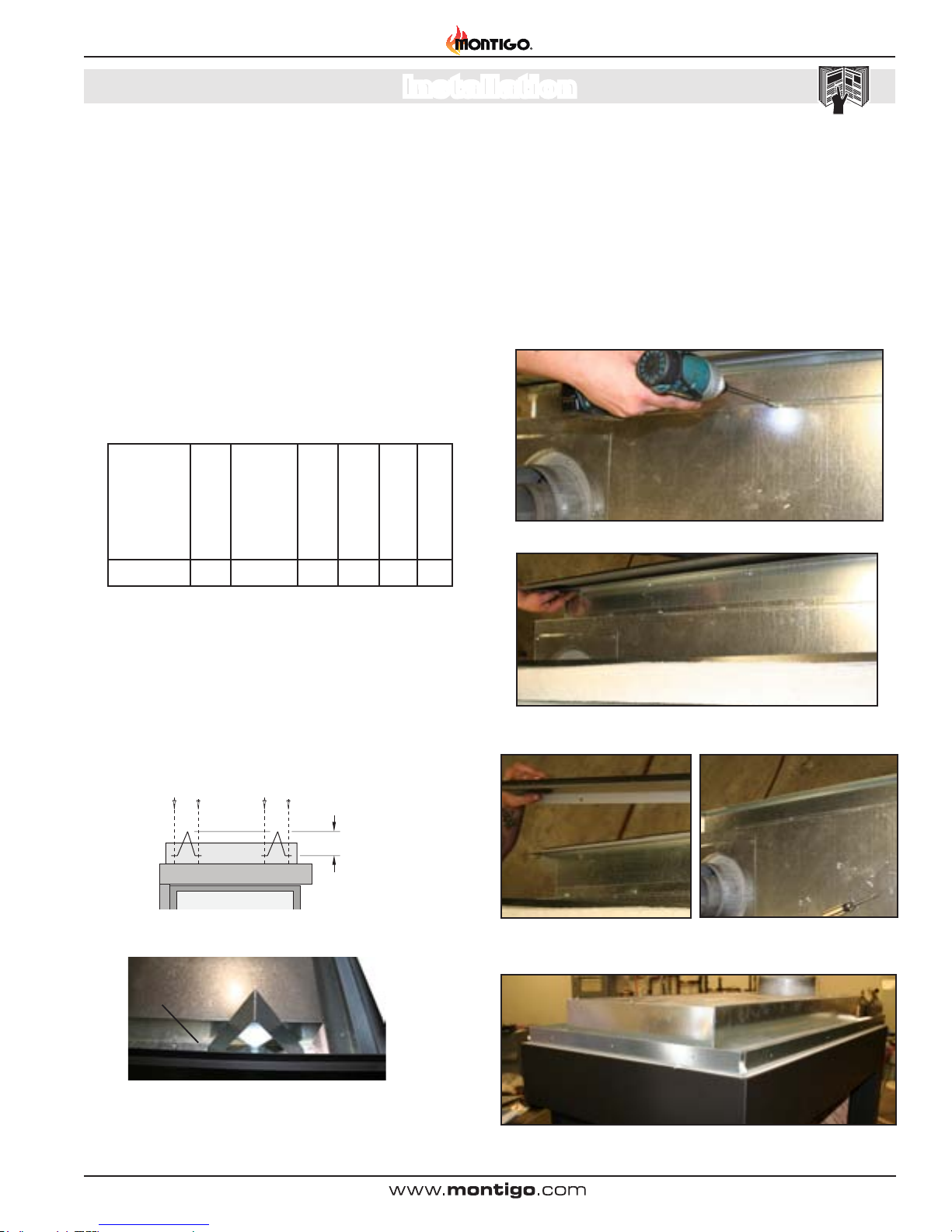

The 4" nailing ange extension is shipped attached to the top edge of

the replace, see Figure 1.

The nailing ange extension may be substituted with a piece of NON-

Combustible material of the same thermal characteristics, ie: cement

board or equivalent to t the opening. This is recommended in applications

where the facing materials will not adhere to the metal nailing ange.

To remove the Nailing Flange Extension follow the directions below:

Figure 7. Remove screws from top of the unit

† Note: Clearance from top of replace to a combustible ceiling within

the replace enclosure.

Installing The Standoffs

To avoid elevated mantel temperatures, all H*38PF*-Series gas

replaces are required to have the supplied standoffs installed.

The replace is supplied with two standoffs. Bend and install these

standoffs on top of the replace ensuring that the height of the standoff

maintains a 8" clearance.

8”

Fasten Standoffs

in gutter

Figure 7a. Remove shell and insulation from the top of unit. Remove screws

from outer edge.

Figure 7b. Remove the nailing ange extension from the unit. Reinstall shell

and insulation. Screw shell in place.

Figure 6. Installing the standoff's.

XG0816 - 011012.1

Figure 7c. Finished removing Nailing Flange extension.

Page 7

H*38DF PFC Peninsula Gas Fireplace

Section 3: Venting

Installation

Montigo supplies a variety of direct venting and termination options.

The direct vent termination location MUST be selected such that

it is the highest point in the venting assembly. It should also be

selected such that it provides the shortest vent run possible. Should

it be impossible to ensure that the termination is the highest point or

should it be impossible to meet the venting guidelines laid out below

please contact your Montigo dealer to discuss power venting options.

NOTES FOR PLANNING VENTING:

Venting can originate from the unit through the top or

through the rear

Venting can terminate through the roof or through an

exterior wall.

Refer to Appendix A - Termination Locations to ensure the

planned termination location is acceptable.

Once the termination location has been established, refer

to the appropriate section below for installation details

All replaces shipped from the factory are Top vent.

See Section 3-1 for converting the unit from top vent to rear vent.

Section 3-1: CONVERTING TO REAR VENT

3. Install the (removed) Rear ue cover and gasket material, to the

Top vent outlet. Fasten the cover with included hardware, as

illustrated Figure 8a.

4. Install the (5" and 8") collars to the rear vent outlet using the

included hardware, as illustrated Figure 8a.

8” Outer Flue

Cover Plate

5” Inner Flue

Cover Plate

8” Outer

Flue Collar

5” Inner

Flue Collar

Figure 8a. Flue cover and collar installation, Rear Vented replace.

Use the following instructions to convert a H*38PF* for Rear Vent use:

1. Remove the Rear ue cover and gasket (5" and 8") on the ue

outlet, as shown in Figure 8.

2. Next, Remove the Top ue collar's (5" and 8") on the ue outlet,

as shown in Figure 8.

Flue Collar

8” Outer

Flue Collar

5” Inner Flue

Cover Plate

Outer

Flue

Outer Plate

Figure 8. Flue cover and collar removal, Top Vented replace.

Page 8

XG0816 - 011012.1

Installation

H*38DF PFC Peninsula Gas Fireplace

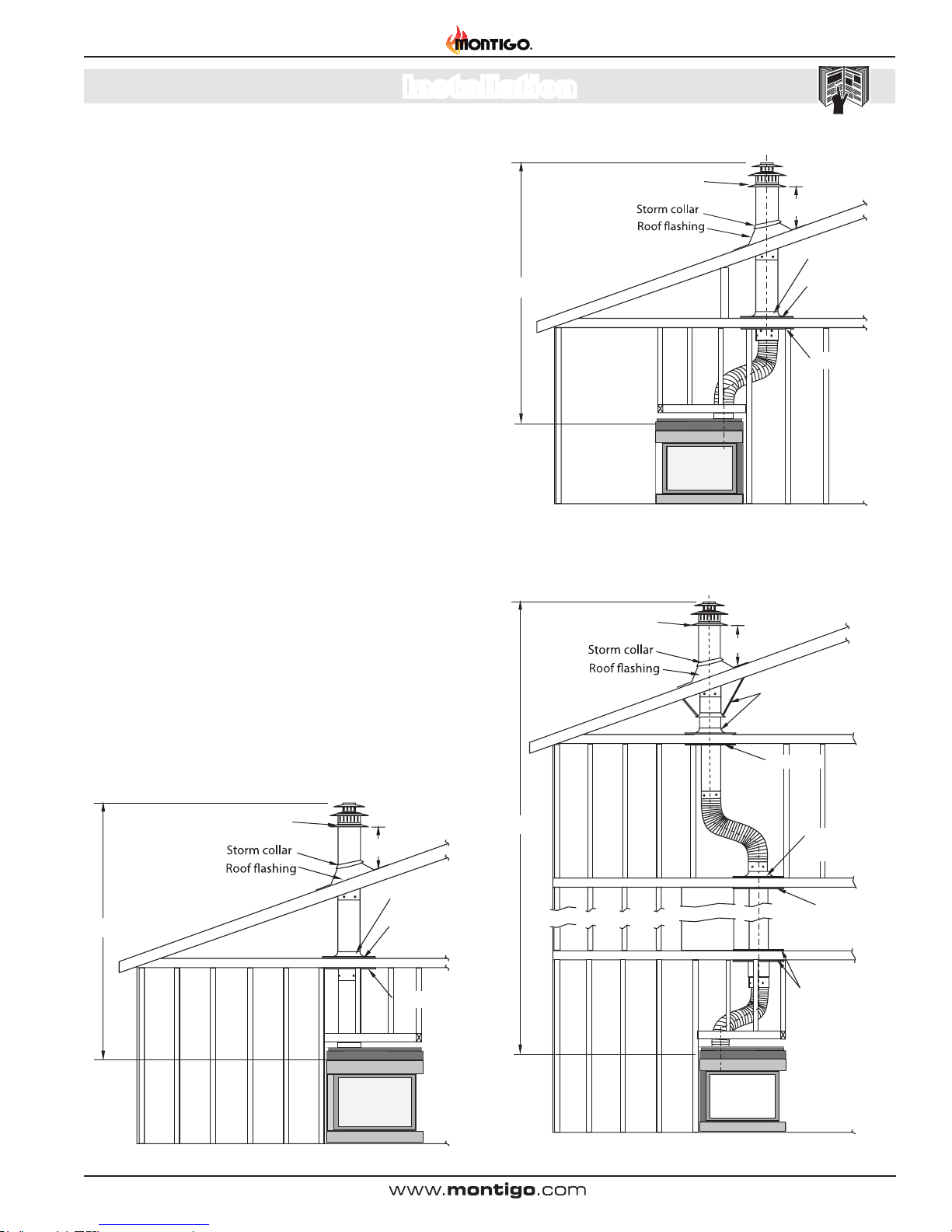

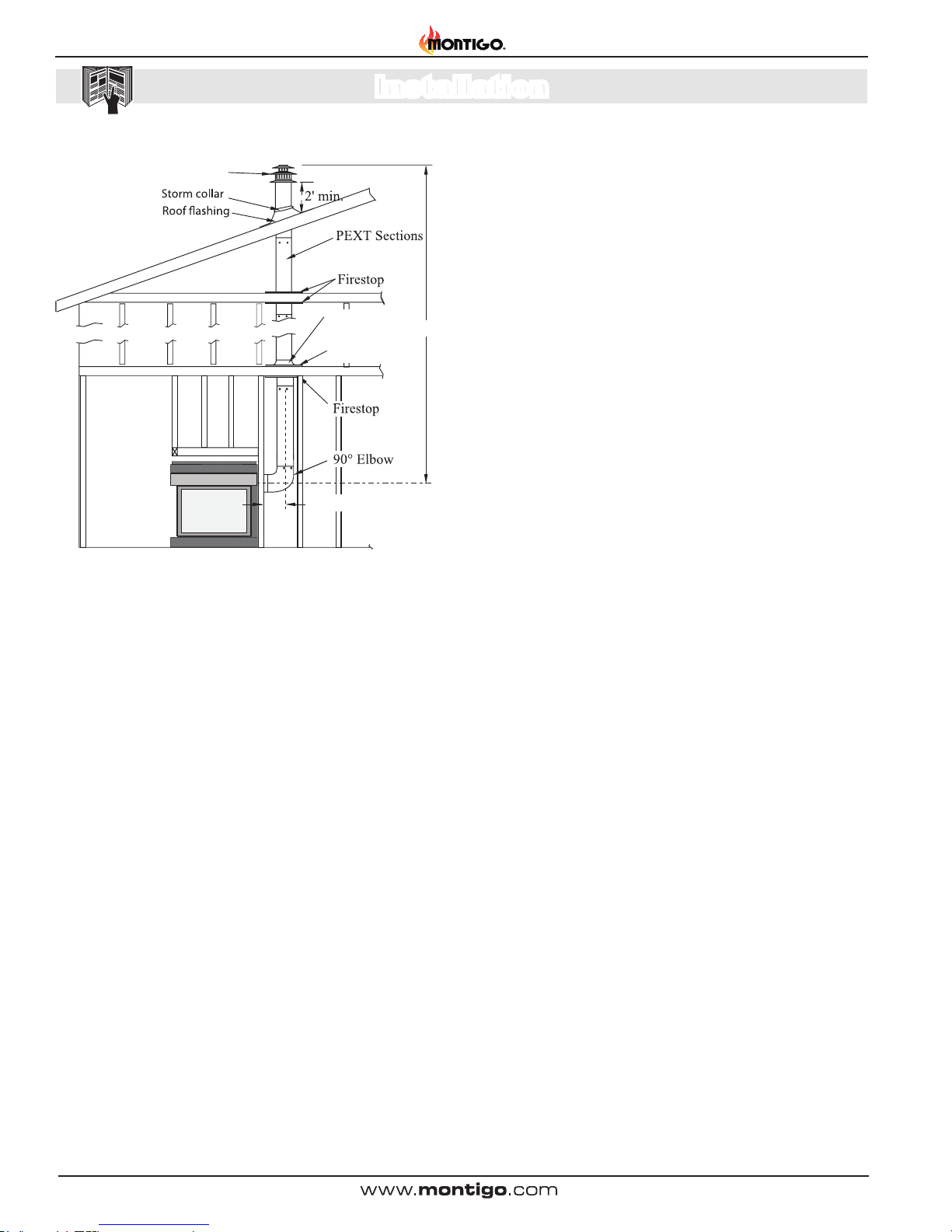

Section 3-2: INSTALLING A ROOF MOUNTED DIRECT VENT

TERMINATION (PVTK-1)

This section applies to installations where the direct vent termination will be roof mounted.

Section 3-2-1: VENTING LAYOUT

Selection of components and details of venting lay out should

adhere to the following guidelines:

The maximum termination point is 32’ above the replace (NOTE:

if the maximum termination height is used, the ame pattern

may be affected).

The Vertical termination must be a minimum 2’ higher than

where the termination exits the roong materials, (asphalt

shingles, cedar shakes, etc). This distance should be measured

from the high side of the roof slope where the ue ashing

intersects the roong materials. (see Figures 9 - 9c).

For a detailed diagram of allowed termination locations, see

Appendix A.

Termination location must be a minimum 6’ from a mechanical

air inlet.

Termination location must be a minimum 18” from a parapet wall.

A maximum of two offsets (each offset is made up of 2-90°

bends) may be made.

Firestops must be installed as required by National & local codes.

Ensure all runs are supported with a minimum of 3 supports

per 10’ of venting.

Install all roof ashing and storm collars as shown.

PVTK1

Termination

2’ min.

Support ring

32’ max.

Figure 9a. Top vent, Roof mounted with 1 offset (1 offset= two 90° bends).

PVTK1

Termination

Obstacle

2’ min.

Support plate

Firestop

Support straps or

support plate & ring

Roof mounted Terminations

The following details are some possible congurations for Roof

mounted terminations.

PVTK1

Termination

2’ min.

Support ring

32’ max.

Figure 9. Top vent, Roof mounted termination with no offset in vent run.

Support plate

Firestop

XG0816 - 011012.1

Firestop

32’ max

Obstacle

Figure 9b. Top vent, Roof mounted with 2 offsets (1 offset= two 90° bends).

Support plate

& ring

Firestop

Firestop

Page 9

H*38DF PFC Peninsula Gas Fireplace

P

VTK1

Termination

Installation

Support plate

Support ring

12” Max.

Figure 9c. Rear vent, Roof mounted venting (1 = 90° bend).

32’ Ma.x

Page 10

XG0816 - 011012.1

Installation

H*38DF PFC Peninsula Gas Fireplace

Section 3-3: INSTALLING A WALL MOUNTED DIRECT VENT

TERMINATION

This section applies to installations where the direct vent termination will be wall mounted.

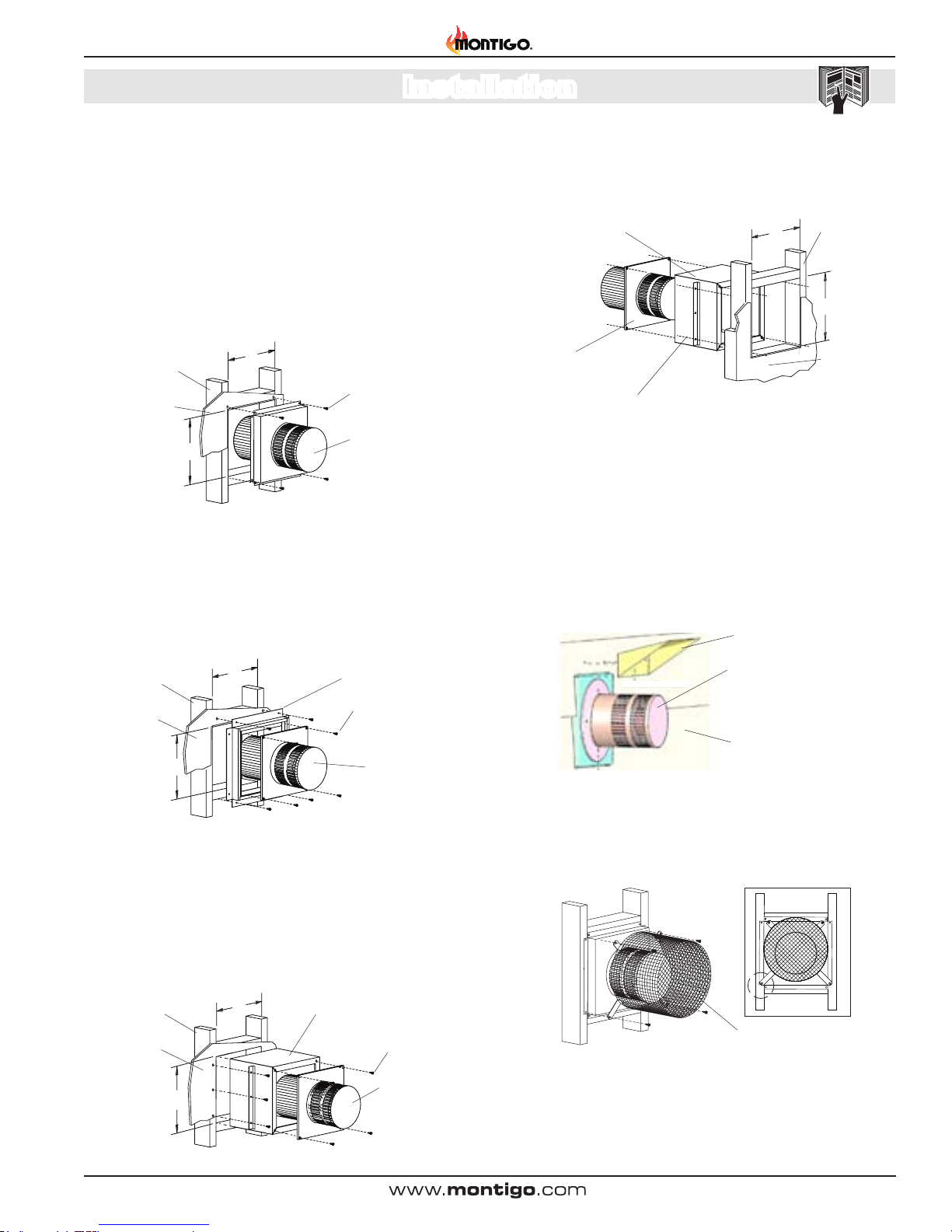

1). Installation of Termination with built in frame

A Termination with a Built-In Frame is installed during framing of a structure.

1. Frame the termination opening to 11" x 11".

2. Install exterior sheathing to the structure framing.

3. Fasten the termination to the sheathing using a minimum of 4 screws.

11”

Framing

Exterior

Sheathing

1”

Figure 10. Installing a PTO-F termination.

Fastening Hardware,

minimum 4-screws

PTO-4F (5"/8")

Termination

2). Installation of termination frame at time of framing

Terminations with a MSR frame allow the installation of the frame prior

to installation of the termination.

1. Frame the termination opening to 12" x 12".

2. Secure the MSR Frame to the exterior sheathing of the structure.

3. Fasten the termination to the MSR Frame using a minimum of 4 screws.

2”

Framing

1

MSR Frame

4). Installation of termination from inside structure

A Termination with a MOSR Frame is installed from the inside of the

structure. These are commonly used in high-rise construction.

MOSR Frame

PTO-4 (5"/8")

Termination

Fastening Hardware,

minimum 4-screws

Figure 10c. Installing a PTO termination with the MOSR frame.

12”

Framing, concrete or other

materials

12”

Exterior Sheathing, concrete or

other materials

1. Frame the MOSR opening to 12" x 12".

2. Fasten the MOSR frame to the interior side of the studs, concrete,

or nished wall construction using a minimum of 4 screws.

3. Insert the termination into the MOSR frame as shown here, (from

the inside) and attach to the MOSR by installing a min. quantity of

4 bolts into the threaded nuts on the MOSR Frame.

5). Installation of a termination shield for Vinyl Siding

The VSS Termination shield is installed when the exterior of a structure

is clad with Vinyl siding. It is placed directly above, and on-center with

the termination.

VSS Vinyl shield

PTO-4 (5"/8")

Termination

Exterior

Sheathing

12”

Figure 10a. Installing a PTO termination with the MSR frame.

Fastening Hardware,

minimum 4-screws

PTO-4 (5"/8")

Termination

3). Installation of termination frame at time of framing in

Masonry

Terminations with a BSR frame allow the installation of the frame in

masonry prior to the installation of the termination

1. Frame the BSR opening to 12" x 12".

2. Secure the BSR Frame to the exterior sheathing of the structure.

3. Fasten the termination to the BSR Frame using a minimum of 4 screws.

2”

Framing

Exterior

Sheathing

12”

Figure 10b. Installing a PTO termination with the BSR frame.

1

XG0816 - 011012.1

BSR Frame

Fastening Hardware,

minimum 4-screws

PTO-4 (5"/8")

Termination

Exterior Vinyl

siding

Figure 10d. Installing the VSS Vinyl Shield.

Installing Heat Guards over Terminations is recommended

in installations where the termination is located within 7' feet above

grade, or above a pedestrian walkway, and may be Required by code

in Public areas.

PTKOG (5"/8")

Figure 11. Installing a PTO termination heat guard.

1. Ensure that the two long mounting brackets are facing the bottom of

the termination. (See inset). This will provide more heat protection

at the top of the termination, where temperatures are highest.

2. Attach to the faceplate of the termination using four sheet metal

screws.

Page 11

Loading...

Loading...