Montigo H34BF, H38BF, H42BF Operation Manual

Installation

®

C US

Operation &

Maintenance

H-Series BF

Gas Fireplace

H34BF

H38BF

H42BF

Warning:

Improper installation, adjustment,

alteration, service or maintenance can

cause injury or property damage. Refer to

this manual. For assistance or additional

information consult a qualied installer,

service agency or the gas supplier.

For Your Safety:

Do not store or use gasoline

or other ammable vapors

and liquids in the vicinity

of this or any other

appliance.

What To Do If You Smell Gas:

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any phone in your building.

• Immediately call your gas supplier from a neighbor's phone. Follow the gas

supplier's instructions.

• If you cannot reach your gas supplier, call the re department.

Safety Notice:

Glass doors on gas replaces are

extremely hot while the replaces is on

and remain hot even after the replace

has been turned off. Safety screens

are available and can reduce the risks

of severe burns. Please keep children

away from the replace at all times.

■ Check local co d e s and

read all instructions prior to

installation.

■ Leave this manual with the

owner.

H-Series BF Gas Fireplace

Table Of Contents Introduction

Introduction .............................................................................. 2

Installation

Installing and Framing the Fireplace .............................. 3

Installing the Gasline ...................................................... 4

The Remote Switch ........................................................

Direct Vent Installation ................................................... 4

General Venting Requirements .........................4

Terminations ......................................................

Converting to Top or Rear Vent model .............. 5

Venting for Top Vent models ..............................

Venting for Rear Vent models ............................ 9

Construction around the replace

Facing .............................................................. 11

Mantels and Surrounds ................................... 11

Wiring ......................................................................... 11

Installing Optional Fans................................................ 11

Removing and Installing the Door ................................ 12

Installing the Logset ..................................................... 13

Installing the Horizontal Trim ........................................ 13

Operation ......................................................................... 14 - 16

Maintenance ....................................................................16 - 17

Warranty ................................................................................. 18

Appendix

A. Termination Locations .............................................. 19

Thank You for choosing a Montigo Gas Fireplace.

About this Fireplace:

The H-Series BF is a replace with a pan-style burner and glowing

embers. This replace is available in two models.

The H34BF is rated for Natural Gas at 18,000 BTU/H (5.28 Kilowatts)

4

5

6

Input or Propane at 18,000 BTU/H (5.28 Kilowatts) Input.

H34BF; Top Vent, Millivolt Pilot.

■

H34BF-I; Top Vent, Intermittent Pilot (HSI).

■

H34BF-A; Top Vent, Electronic Ignition (American Flame).

■

The H38BF is rated for Natural Gas at 26,000 BTU/H (7.62 Kilowatts)

Input or Propane at 26,000 BTU/H (7.62 Kilowatts) Input.

H38BF; Top Vent, Millivolt Pilot.

■

H38BF-I; Top Vent, Intermittent Pilot (HSI).

■

H38BF-A; Top Vent, Electronic Ignition (American Flame).

■

The H42BF is rated for Natural Gas at 34,000 BTU/H (9.97 Kilowatts)

Input or Propane at 28,000 BTU/H (9.97 Kilowatts) Input.

H42BF; Top Vent, Millivolt Pilot.

■

H42BF-I; Top Vent, Intermittent Pilot (HSI).

■

H42BF-A; Top Vent, Electronic Ignition (American Flame).

■

How to use this manual:

This manual covers installation, operation and maintenance. Lighting,

operation and care of this replace can be easily performed by the

homeowner. However, all installation and service work should be

performed by a qualied or licensed installer, plumber, or gastter who

is qualied or licensed by the state, province, region, or governing body

in which the appliance is being installed.

This manual covers all models and unless otherwise specied, the

designation H-Series BF refers to all models. Sections which are

specic to a particular model are marked with a symbol, plus

the appropriate model number.

CAUTIONS

Due to its high operating temperatures, the appliance

should be located out of trafc & away from furniture

and draperies.

Children and adults should be alerted to the hazards

■

of the high surface temperature, which could cause

burns or clothing ignition.

Young children should be carefully supervised when

■

they are in the same room as the appliance.

Clothing or other ammable materials should not

■

be placed on or near the appliance.

Page 2

Warranty and Installation Information:

The Montigo warranty will be voided by, and Montigo disclaims any

responsibility for, the following actions:

Modication of the replace and/or components including Direct-Vent

■

assembly or glass doors.

Use of any component part not manufactured or approved by Montigo in

■

combination with this Montigo replace system.

Installation other than as instructed in this manual.

■

Consult your local Gas Inspection Branch on installation requirements

for factory-built gas replaces. Installation & repairs should be done by

a qualied contractor.

Installations in Canada must conform to the current CAN/CGA B-

149.1 and .2 Gas Installation Code and local regulations. If the optional

air-circulating fan kit is installed, it must be electrically grounded in

accordance with CSA C22.1 Canadian Electrical Code Part 1 and/or

Local Codes.

Installations in the USA must conform to local codes, or in the absence

of local codes to the National Fuel Gas Code, ANSI Z223.1-1988. If the

optional air-circulating fan is installed, it must be grounded in accordance

with local codes or, in the absence of local codes, with the National

Electrical Code, ANSI/NFPA 70-1987.

Part No. XG0145

Installation

R

R

N

P

Q

0" clearance

to corners only

M

N

O

N

P

Q

0" clearance

to corners only

R

R

H-Series BF Gas Fireplace

Installing The Fireplace Shell

The replace may be installed in any location that maintains proper clearances to air conditioning ducts, electrical wiring and plumbing. Safety,

as well as efciency of operation, must be considered when selecting

the replace location. Try to select a location that does not interfere

with room trafc, has adequate ventilation, and offers an accessible

pathway for Direct Vent installation. Refer to page 4 - Vent Installation

for more information.

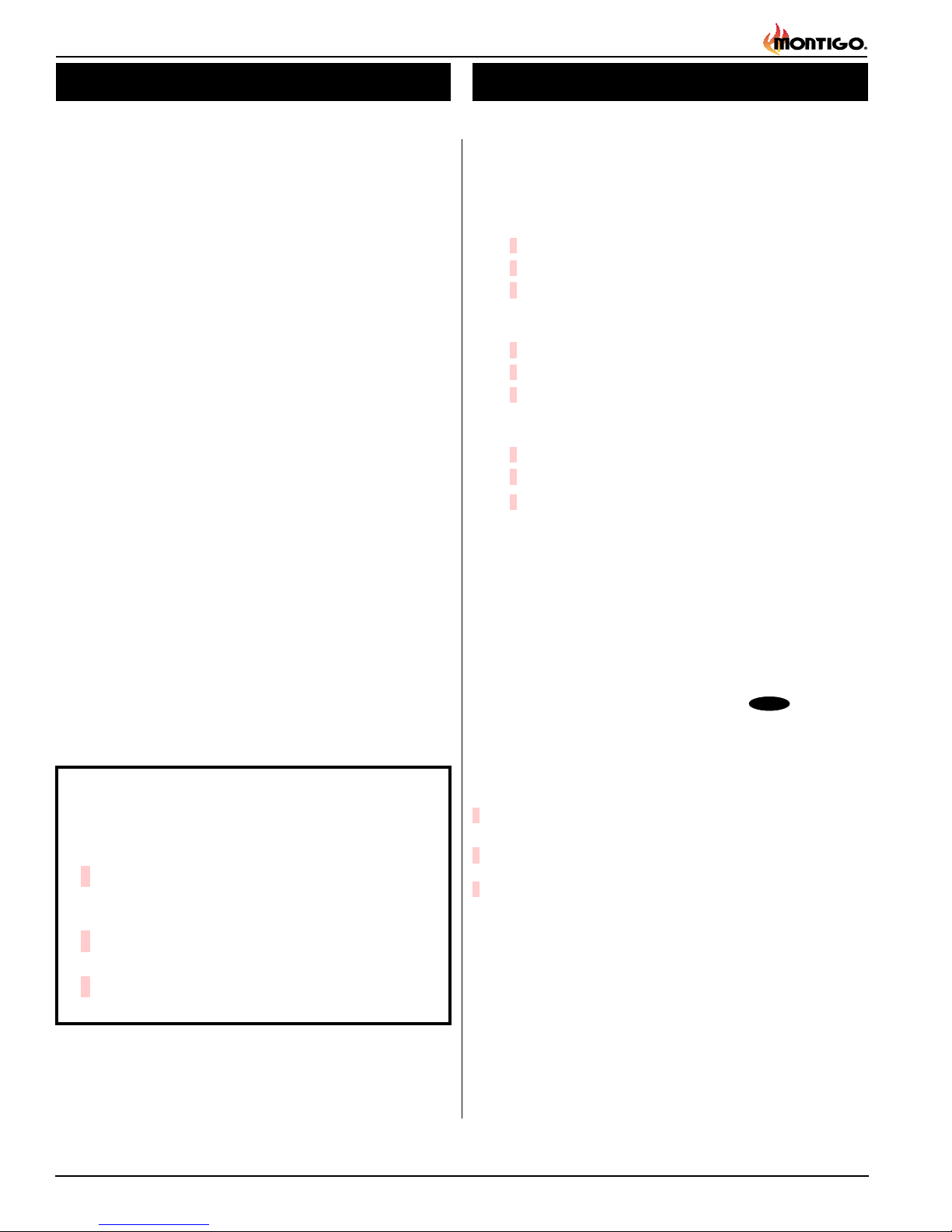

The replace dimensions are shown below:

Top View

Front View

Figure 1. Fireplace dimensions.

A B C D E F G H I J

7

1

1

1

H34BF

H38BF

H42BF

33

/

8 33

3

37

/

4 36

42 40

/

2 31

/

1

3

/

2 34

/

5

/

8 39 1

8 1

4 1

1

/

4 21

/

2 1 17

1

1

/

4 24

/

2 1 18

1

5

/

4 28

/

8 1 20 28 12

Clearances

These clearances apply to all dimensions except the framed opening,

where the clearance to combustibles is 0". The H-Series BF clearances

to combustible materials are:

Side View

3

7

/

8 21

/

8 10 4

1

/

2 25 11

1

/

2 4

1

/

2 4

Framing

* When sheetrock is

not used behind the

fireplace, framing

depth may be reduced

by 5/8"

Figure 2. Framing dimensions.

Figure 3. Minimum Corner framing dimensions.

M N O P Q R

H34BF

H38BF

H42BF

1

39

/

4 33

1

42

/

4 37

3

46

/

8 42 22

3

/

4 20 56

3

/

4 21

1

/

8 62 43

5

/

8 68 48

5

/

8 40 4

7

/

8 4

1

/

8 4

WARNING:

When this appliance is installed directly on carpeting, tile or

any combustible material other than wood ooring, it must be

installed on a metal or wood panel extending the full width and

depth of the appliance.

1

/

4

1

/

4

1

/

4

H34BF H38BF H42BF

Top - Ceiling

Back

Sides

Floor

Mantle**

Flue

* Clearance from the top of the replace to a combustible ceiling within the replace

enclosure.

8 Feet 8 Feet 8 Feet

2" 2" 2"

1" 1" 1"

0" 0" 0"

4" 4" 4"

1" 1" 1"

** Refer to page 11.

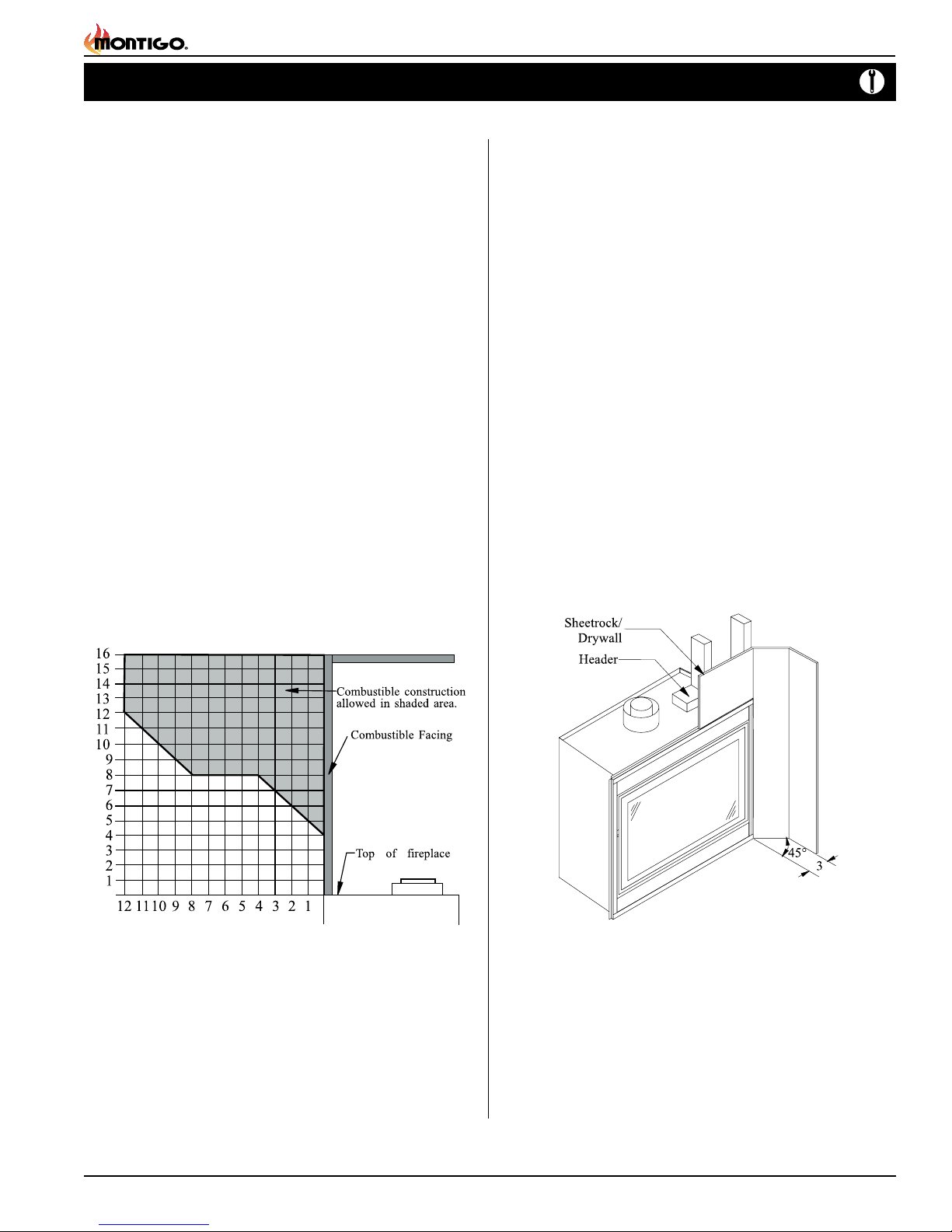

Unprotected combustible walls which are perpendicular to the replace

opening, must not project beyond the shaded area shown in Figure

25.

For protection against freezing temperatures, it is recommended that

outer walls of the chase be insulated with a vapor barrier. This will reduce

the possibility of a cold-air convection current on the replace.

Part No. XG0145

Page 3

H-Series BF Gas Fireplace

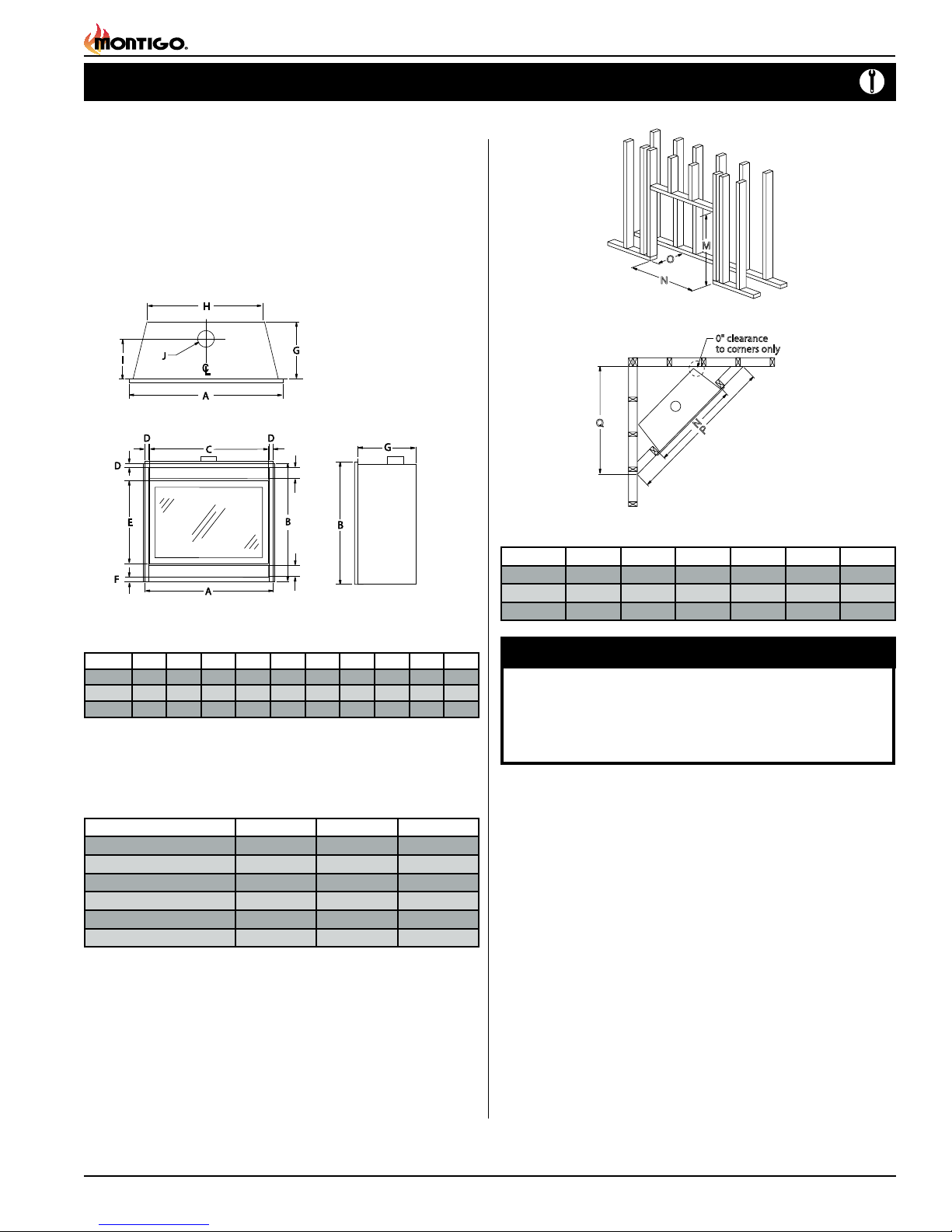

Gasline Access

0.875” dia.

2” height

to center

7”

to center

Burner Tray Gasket

Figure 4b. Gas line access.

Installation

Installing The Gas Line

The gas line must be installed before nishing the H-Series BF Fireplace.

Natural Gas requires a minimum inlet gas supply pressure of 5.5" W.C.

& a manifold pressure of 3.5" W.C. Propane Gas requires a minimum

inlet gas supply pressure of 11" W.C. & a manifold pressure of 10" W.C.

Provision must also be made for a 1/8" N.P.T. plugged tapping and be

accessible for test gauge connection immediately upstream of the gas

supply controls to the appliance. The replace gas connection and

the main operating gas valve is located behind the removable trim at

the bottom of the unit and need only be attached to the gas line with

an approved tting, as required by the applicable installation codes.

To access the replace gas connection the main burner must be

removed as shown below in gure 4b.

• Only use gas shut-off valves approved for use by the state, province,

region, or governing body, in which the appliance is being installed, or

as required by the applicable installation codes.

• Flexible gas connectors must not exceed 3 feet in length, unless it is

allowable within applicable installation codes.

Vent Installation

The H-Series BF is certied for use with standard 4" B-Vent and requires

no B-Vent appliance connector. Simply attach the B-Vent to the replace

ue collar, and secure it using 1/4" sheet metal screws.

Refer to the current CAN/CGA B-149.1 and .2 or ANSI Z223.1-1998

Gas Installation Code for specic vent sizing.

Note: If more than 12 feet of B-Vent is used on the vent

runs, use ceiling supports.

Cautions:

■ Test your B-Vent installation after completion to ensure that

no combustible by products are spilling from the replaces

opening. This draft test should be performed after a three(3)

minute warm up period. The manufacturer will not be

responsible for any installations with inadequate draw.

Note: Due to the top vent clearances to combustible

materials there is no available shelf installation for

the H-Series BF replaces.

Figure 4a. Gas line access.

The appliance and its individual shut-off valve must be disconnected

from the gas supply piping system during any pressure testing of that

system at test pressures in excess of 1/2 psig (3.5 kPa).

The appliance must be isolated from the gas supply piping system by

closing its individual manual shut-off valve during any pressure testing

of the gas supply piping system at test pressures equal to or less than

1/2 psig (3.5 kPa).

Note: After gas line is connected, each appliance connection,

valve and valve train must be checked while under normal

operating pressure with either a liquid solution, or leak

detection device, to locate any source of leak. Tighten any

areas where bubbling appears or leak is detected until

Page 4

bubbling stops completely or leak is no longer detected.

DO NOT use a flame of any kind to test for leaks.

Installing The Standoffs

To avoid elevated mantel temperatures, all H-Series BF gas

replaces are required to have the supplied standoffs installed.

The replace is supplied with two standoffs. Bend and install these

standoffs on top of the replace ensuring that the height of the standoff

maintains a 6" clearance.

Figure 5. Installing the standoff's.

Installing the Nailing Flange

Extension

Once the replace is placed into the framed opening, the supplied

nailing extension must be placed along the top edge of the replace,

and nailed in place to the framing, as illustrated below.

Figure 6. Installing the Nailing Flange Extension.

H38BF

H42BF

Part No. XG0145

Installation

H-Series BF Gas Fireplace

Installing The Remote Switch

The H-Series BF's gas valve, located behind the lower trim, may be

connected to a wall switch. The valve generates its own power on a

millivolt circuit. Use only low voltage wire, and DO NOT connect

any external power to it.

Refer to Figure 30 for wiring requirements.

Note: The switch location must not exceed 30' from the replace.

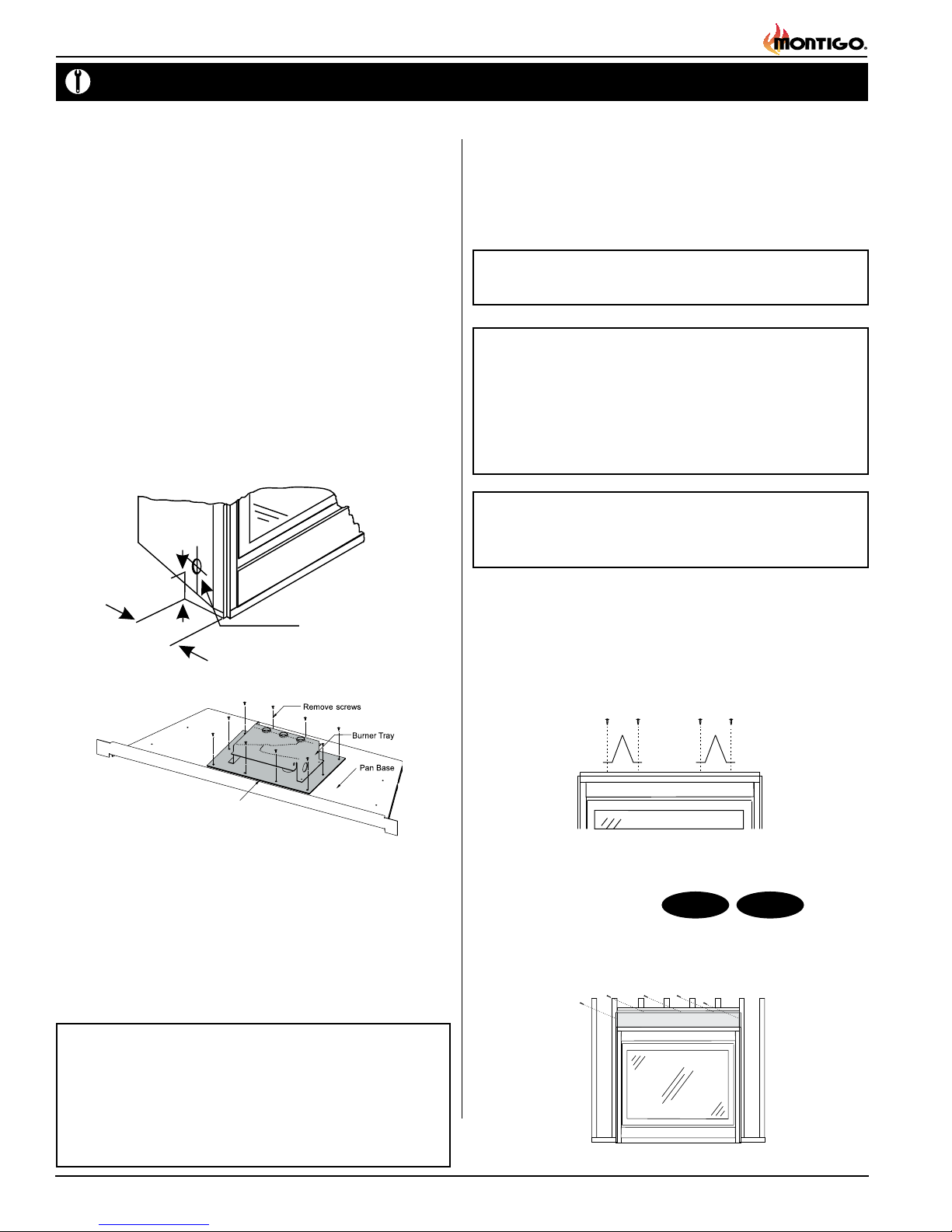

Finishing Around the Fireplace

Combustible mantels and mouldings may be safely installed over the

top and on the front of the replace provided that they do not project

beyond shaded area shown in Figure 7. Side wall clearances are 3".

Combustible surrounds may be installed with 3" clearance to the side

of the replace as shown in Figure 8.

Fireplace Facing

When selecting the nish material for your replace, it is important to

remember the following: THE PERFORATED VALVE COVER MUST

NOT BE OBSTRUCTED IN ANY WAY - to do so restricts the air

supply for the control compartments and heat exchanger it also

prevents access for servicing controls.

The face of the replace may be painted to match the room decor,

provided you use a heat-resistant paint. Decorative facing must not

extend past the replace opening at all, because it will interfere with

the access to retainers for removal of glass door.

Mantels & Surrounds

NOTE: National Canadian Gas Association mantel test requirements

are for re hazard prevention to combustible materials.

New technology, to meet consumer and government demands for the

wise use of energy, has prompted us to manufacture many models of

replaces which are hot, fuel and energy efcient.

Please be aware; temperatures over the mantel will rise above normal

room temperature and walls above replace may be hot to touch.

Warning:

When covering the upper metal portion of the replace with a noncombustible material Please Note: The decorative facing materials

may be subject to temperatures in excess of 250° F. This should be

considered when selecting facing materials.

We recommend careful consideration be given to the effects of elevated

mantel temperatures which may be in excess of product design, for

example: candles, plastic or pictures. This can cause melting, deformation,

discoloration or premature failure of T.V. and radio components.

Painting:

Special care is recommended by the Master Painters and Decorators

Association, when painting the replace surrounds, to select and apply

a quality Alkyd sealer prior to the applying of latex paints. This is to

prevent leaching of water from evaporation and causing a brownish

staining effect to paint over coats.

Figure 7. Combustible mantles and facings.

Part No. XG0145

Figure 8. Combustible surrounds.

Page 5

H-Series BF Gas Fireplace

Honeywell (Q3450)

Pilot Assembly

Pilot Electrical

Harness Connector

Honeywell Gas

Control (SV9501M)

Gas Control

Connector

Fuse

Limit

Switch

Wall

Switch

Fan Plug

Receptacle

Junction Box

Junction Box Cover

White

Black

Green

40 VA

Transformer

115VAC

24VAC

Grnd Screw

ADJ.

AUX Learn

Remote/Off

Continuous

Pilot

Off/On

S I

IPIPOWER

6VAC 200mA

AC ADAPTOR

Wall Switch (SWI)

Brown

Brown

Black

White

Green

White

Orange

Pilot

Main

Manual

Hi/Lo

Main Gas InputMain Gas Output

White (Sensor)

Orange (Igniter)

Control

Module

Emergency

Battery

Power

(4 x AA)

Pilot Assembly

Red

Black

Red

Black

O

p

tio

n

a

l

Wiring

Installation

Gas Control and Pilot Wiring

H-Series BF-I

Figure 9. Wiring for the H-Series BF-I with Honeywell gas control and pilot.

H-Series BF-A

Spill Switch

Gas Control and Pilot Wiring

Figure 10. Wiring for the H-Series BF-A with American Flame gas control

and pilot.

Page 6

Part No. XG0145

Loading...

Loading...