Montgomery Ward ZDW-57061A, ZDW-57062A Owner's Manual

·--

-~-::

' '

.

...

v-·

.-~~

·

""~·-\:"~

~

r\

·.

~~.

*:I

.

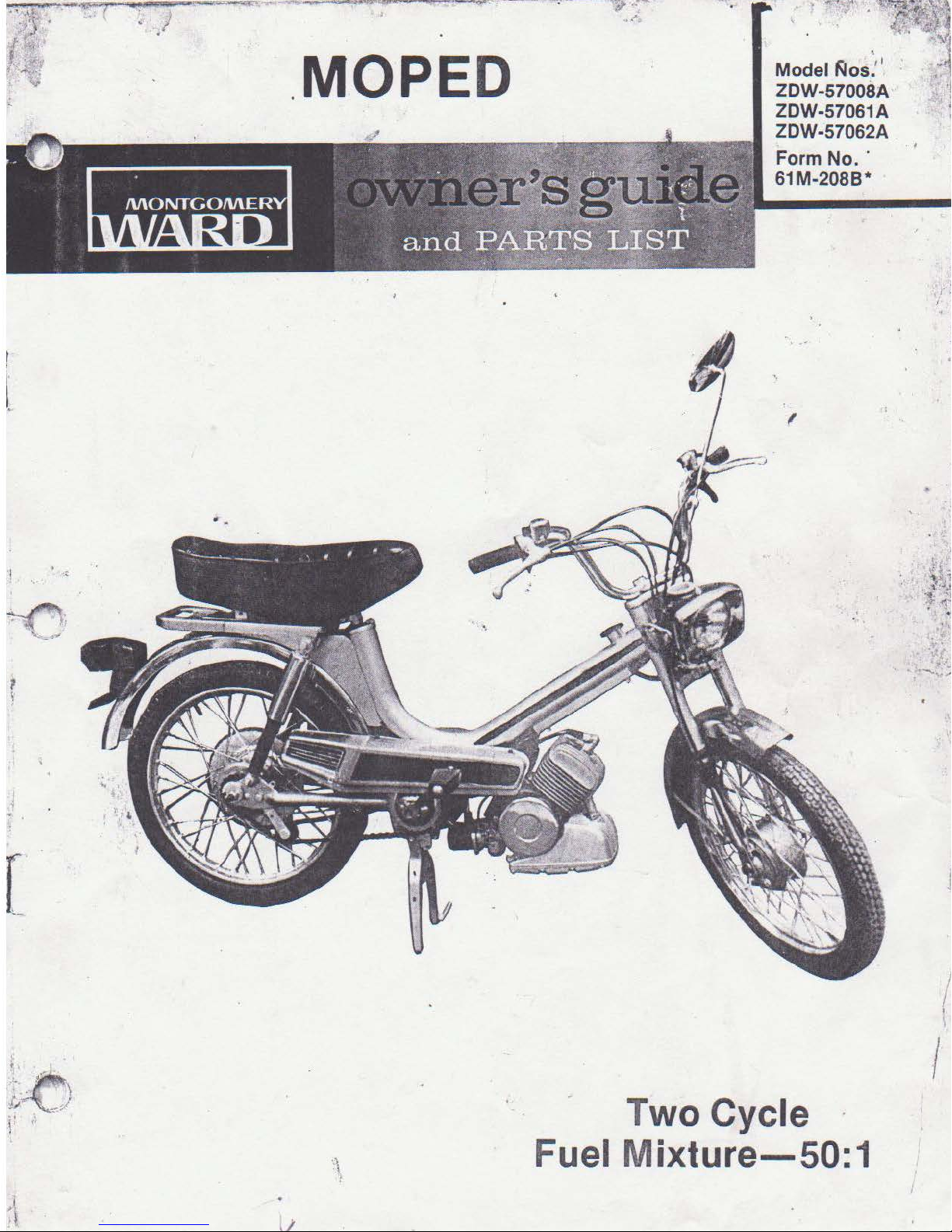

MOPED

Model

ZDW-57008A '!

ZDW-57061A !

ZDW-57062A

Form

61M-208B*

~os

:'

' · .~1

No.·

[

.,

·

...

~(

..

. ,

-..

~·AJ

l

I

(

\

, .

..-.

. . . \

·

·

~

/;

https://manualmachine.com/

Fu

Two Cycle

el

M

ixture-50:1

I

;:::;z

--~---~~~~

e.

--

~-~~~-----~~

I •

•

..

/

Local licensing, age and

TRAINING

1. Read

thor

proper use

2. Never

without

Children should be of

understanding and capacity.

PREPARATION

1.

Check fuel before starting engine. Fuel

mixture

of

Indoors, when engine is running,

engine is

gasoline before starting the engine.

2.

Never start

proper starting position.

the

oughly

allow

proper and close

50:1

regular gasoline). Do

SAFE OPER ATION PRACTICES

traffic

Owner's Manual carefully. Be

familiar

of

the equipment.

children

(2112

still

this

oz.

hot.

MOP

with

the

to

operate a MOPED

adult

sufficient

two

cycle

not ·fill

Wipe

ED

See

off

without

page

IMPORTANT

regulatl.

controls

oil

gasoline tank

ons

may vary

and

sup

ervision.

age,

to 1 gallon

or

while

the

any spilled

being in

9.

MAINTE

1. Keep

2.

from

state

to

state. Check existing local laws.

3.

It

is the absolute understanding that

is

not

a field bike.

comply

requ irements

responsibi

4. The operator should never place

feet

parts.

5. This

ONLY.

6. T

his

manner, such as

hill

7. This

such as pavement.

8. Never operate

surface.

sure the

Never store the unit inside

gasoline in the tank where the fumes may

reach

engine

enclosure.

with

the

lity of. the purchaser.

or

any part

MOPED is designed for ONE AIDER

Carrier

MOPED should not be used in a reckless

climb

MOPED

NANCE AN D STORAGE

all

unit

an

to

is

ing.

is

this

nuts,

is

in

open flame

cool

Any

licensing needed

existing local

In any given area is the sole

of

his body near any moving

not

for

passengers.

jumping

designed

MOPED on wet

bolts

, and screws

a safe operating

or

before

or

obstacles, racing

for

hard surfaces,

of a building

spark.

storing

this

state vehicle

his

hands,

or

slippery t

tight

condition.

Allow

in any

to

with

the

unit

to

or

i:

be

OPERATION

;

I

I

1i.:

I

..

~

,

•.

\

,.'!,

\,

\'

1. It

is

recommended

helmet and eye protection.

2.

Manufacturer recommends running

lights

on.

the

operator use a safety

with

3.

Prior

checked and maintained. Front: 25

Rear: 32 P.S.I. Maximum

rear.

4. The tightness

checked after every few hours

See Spoke Adjustment on page 15 .

2

to

each use, the tire pressure should be

P.S.I.,

36

P.S.I.

of

the spokes should

front

of

operation.

and

be

-

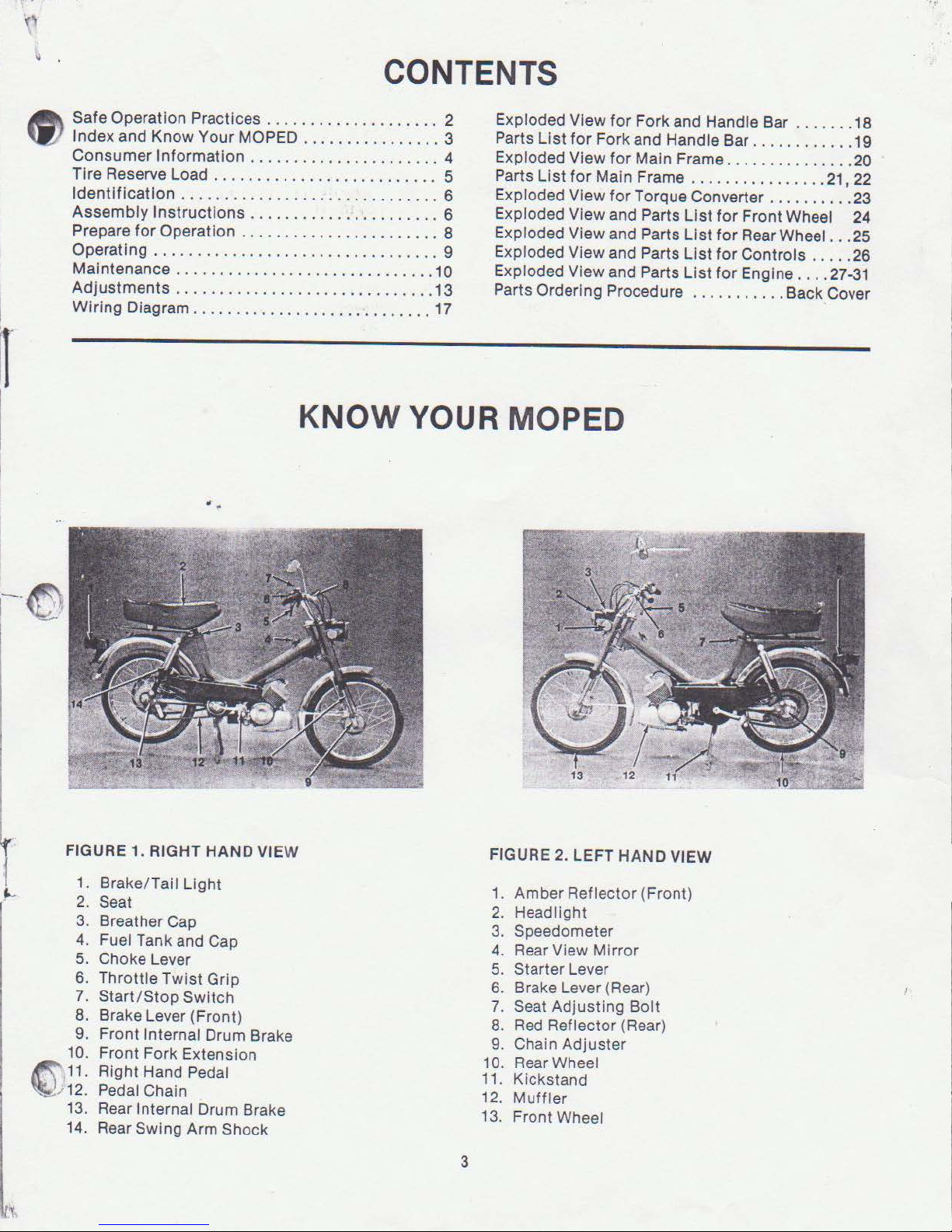

CONTENTS

Safe Operation Practices

Index and Know Your MOPED

Consumer Information

Tire Reserve Load

Identification

Assembly

Prepare

Operating

Maintenance

Adjustments

Wiring Diagram

Instructions

for

Operation

....

............

..............

.........

..........

........................

............

....................

......................

......................

.......................

...

..

.........

.....

..

....

. .

.

.........

.

...............

.................

................

KNOW

.

........

.

..

....

YOUR MOPED

...

...

2

3

4

5

6

6

8

9

10

13

17

Exploded

Parts List

Exploded

Parts

Exploded View for Torque Converter . .

Exploded View and Parts

Exploded View and Parts

Exploded View and Parts

Exploded View and Parts List for Engine

Parts Ordering Procedure

VIew for Fork and Handle Bar

for

Fork and Handle Bar

View

for

Main Frame

List

for

Main Frame

................

List

for Front Wheel

List

for

List

for

...........

............

.......

Rear Wheel

Controls

....

...

18

19

..

......

........

.... 27-

Back Cover

20

21,

22

23

24

...

25

..... 26

31

FIGURE

,._

1 .

2.

3.

4.

5.

6.

7.

8.

9.

10

.

11.

/ 12.

13.

14.

h

1.

RIGHT HAND VIEW

Brake/Tal

Seat

Breather Cap

Fuel Tank and

Choke Lever

Throttle Twist Grip

Start/Stop

Brake Lever (Front)

Front Internal Drum Brake

Front Fork Extension

Right Hand Pedal

Pedal

Rear

Rear Swing Arm Shock

I Light

Cap

Switch

Chain

Internal Drum Brake

FIGURE 2. LEFT HAND VIEW

1.

Amber Reflector (Front)

2. Headlight

Speedometer

3.

4. Rear View Mirror

Starter Lever

5.

6. Brake Lever (Rear)

7. Seat Adjusting

8.

Red

Reflector (Rear)

Bolt

9. Chain Adjuster

10. Rear Wheel

11.

Kickstand

12.

Muff

ler

13. Front Wheel

3

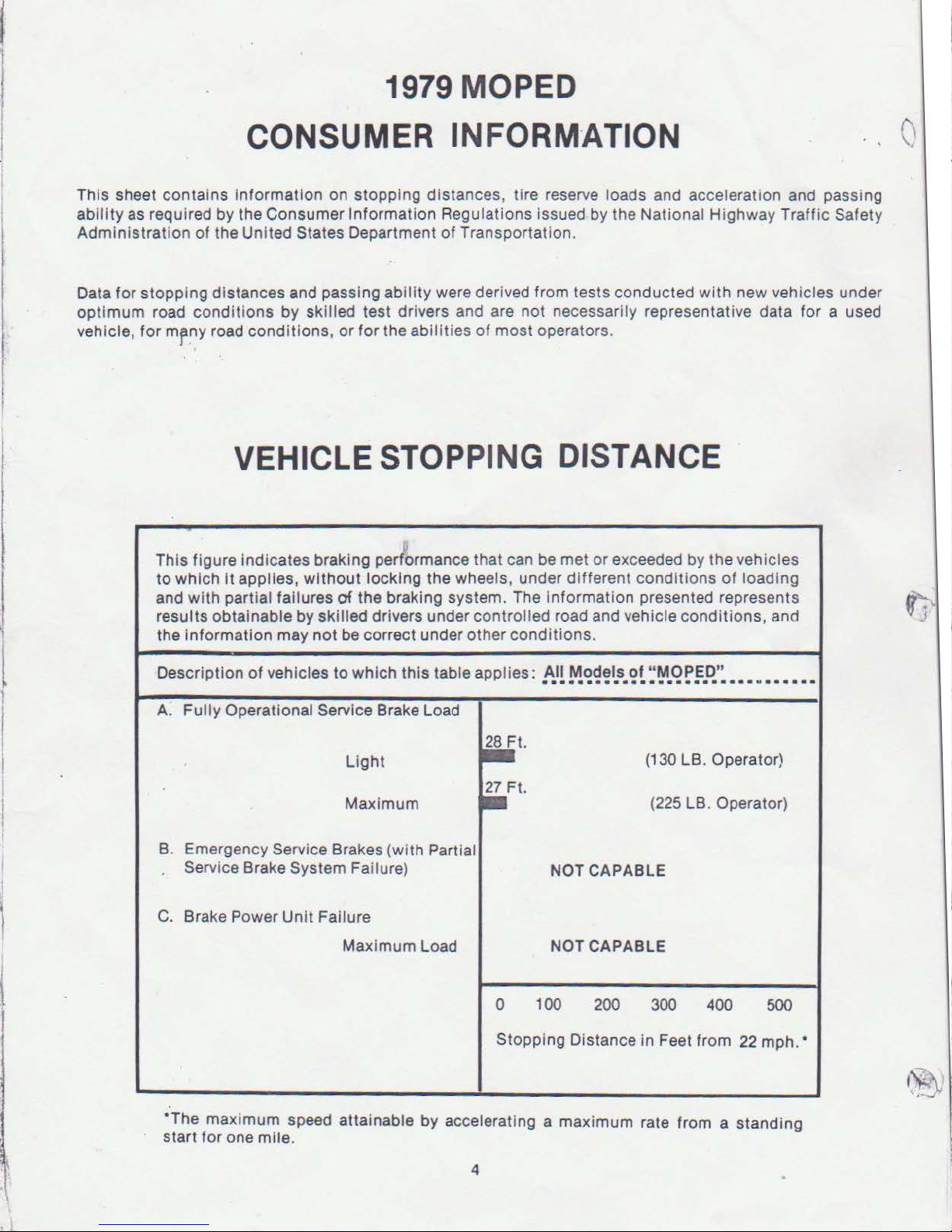

1979 MOPED

CONSUMER

This sheet contains Information on stopping distances, tire reserve loads and acceleration and passing

ability

Administration

as required by the Consumer Information Regulations issued by the National Highway Traffic Safety

of

the United States Department

INFORM

of

Transportation.

·ATION

0

0

•

Data for stopping distances and passing

optimum

vehicle, for

road

mrny

conditions

road conditions,

by skilled test drivers and are not necessarily representative data for a used

or

for the

VEHICLE STOPPING DISTANCE

This figure Indicates braking performance that can be met

to which

and with

resul

the

De

scription

A. F

it

applies, with o

partial failures

ts

obtainable by skilled drivers under controlled road and vehicle conditions, and

Information may n

of

vehicles

ully

Operational Service Brake Load

ut

locking the wheels, under different conditions

of

the braking system. The Information presented represents

ot

be correct under other conditions.

to

which

Light

Maximum

ability

were derived from tests conducted

abilities

thi

s table applies: All Models

of

most operators.

·· ·· ······ ·············· M

28Ft.

,.Ft.

with

new vehicles under

or

exceeded by the vehicles

of

loading

of "MOPED

"

(130 LB. Operator)

(225 LB. Operator)

····

··

B. Emergency

Service Brake System Failure)

C.

Brake Power Unit Failure

*The

maximum speed

for

start

Service Brakes (with Partial

one mile.

NOT CAPABLE

Maximum Load

0 100

Stopping Distance in Feet from 22 mph. •

att

ainable by accelerating a maximum rate from a standing

4

NOT CAPABLE

200

300

400

500

This

table

lists

which

~

percentage

it

applies,

V I each vehicle

TIRE RESERVE LOAD

the tire size designations recommended by the manufacturer for use on the vehicles

with

the recom mended inflation pressure for maximum loading and the tire reserve load

for

each

of

to

which

the tires listed. The tjre reserve load percentage

the table applies.

indic

ated is met

or

exceeded by

to

Descript

ecommended Tire Size Designations

R

ecommended.Cold

R

for Maximum Loaded Vehicle Weight

*The difference, expressed as a percentage

vehicle manufacturer's recommended inflation pressure at the maximum loaded vehicle weight and (b) the .

•

load imposed

WARNING. Failure

recommended when operating at maximum loaded

capacities specified on the tire placard affixed

to

load percentage

capacity may result

ion

of

Vehicles

upon

premature tire failure, unfavorable handling characteristics, and excessive tire wear. The tire reserve

is

ACCELERATION

This figure indicates passing times and distances that can be met

vehicles

The

The high speed pass assumes an initial speed

to

low

speed pass assumes an initial speed

to

Which

Inflation

the tire by the vehicle at that

to

maintain the recommended tire

a measure

In failure of the vehicle components.

the Table Applies :

Pressure

of

tire capacity ,

_A:....:..:..:.

of

tire load rating, between (a) the load rating

condition

to

the vehicle, may result in unsafe operating conditions due

not

of

vehicle capacity. Loading beyond the specified vehicle

AND

which

it

applies

in

the situation diagrammed below.

II_M_o_;d_e_ls_of.:...

Front

Rear

.

inflation

vehicle weight, or loading the vehicle beyond the

'_;'

M~O

.:...

P-=E

2-

1/4-17

25

PSI

32

PSI

pressure

:..::

O

_"

_

__

or

to

increase

_ _

_____

of

a tire at the

tire

pressure as

_

PASSIN G ABILITY

or

of

20 MPH and a

of

50 MPH and a

limiting

limiting

exceeded

speed

speed

of

by the

'

of

35 MPH.

80 MPH.

NOTI

Cl:

The

information

. con trolled road and vehicle

·

;;

under other

Descripllon

LOW SPEED

INITIAL SPEED:

l

of

vehicles

LOWfSPEED PASS

HIGJ-tSPEED PASS

20 MPH

I

·············································-~

1 40 o

55 TRUCK CONSTANT 20 MPH

HIGH SPE

INITIAL SPEED: 50 MPH LIMITING SPEED: 80 MPH

ED

(MOPED NOT CAPABLE)

I

~

l

·····························

~

100

~

c::::J···

55 TRUCK CONSTANT 50 MPH

presented represents results obtainable by skilled drivers under

conditions

conditions.

to

which this table applies:

SUMMARY

1,500

FEE

T

FEET

TOTAL PASSING DISTANCE FEET

TOTAL PASSING TIME SECONDS

•••••••••••• ••••

TOTAL PASSING DISTANCE FEET

TOTAL PASSING TIME SECONDS

····

······

••

·

········

·

····

and the information may not be correct

All Models of "MO

TABLE:

46 SECONDS

SECONDS

PED

"

NOT

CAPABLE

LIMITING SPEED: 35 MPH

I

••••••

•

-·~

·······

··

········-~~~

1+

40+1

· · ·

·············~

100

~

I

5

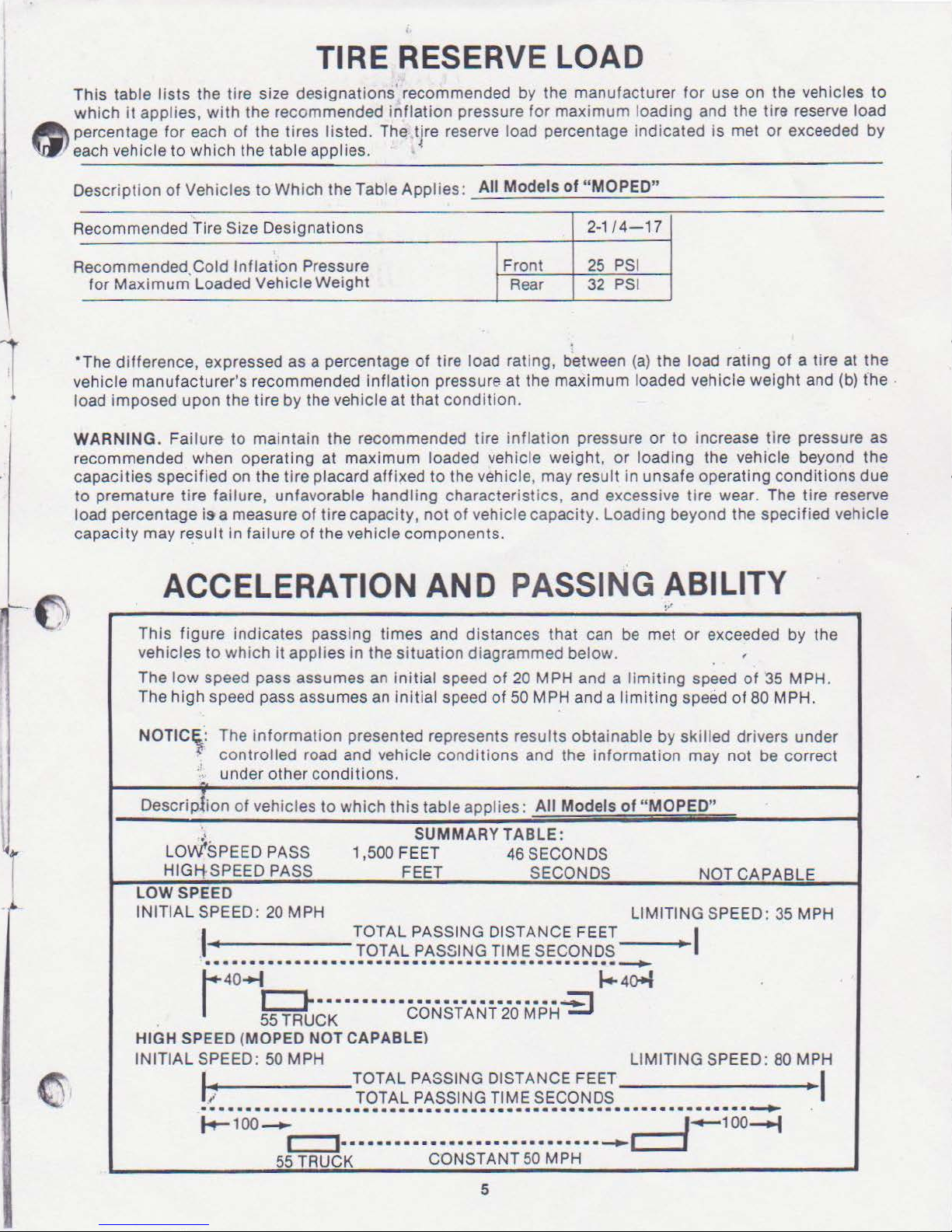

IDENTIFICATION

TOOLS REQUIRED FOR

1. The identification number

cle model number plate

on the main frame under the handle bars. The

identification number

frame on

assembly.

the

left side,

will

be on

(See figure 3.) located

is

also stamped

just

under the rear fork

the

into

vehi-

the

ASSEMBLY

One

7/16"

One

12"

One 6" Adjustable wrench.

One

Open end

Adjustable wrench.

1f4"

Standard flat screwdriver.

or

box end wrench.

OTHER MATERIALS

REQUIRED

One can

of

two-cycle oil and gasoline.

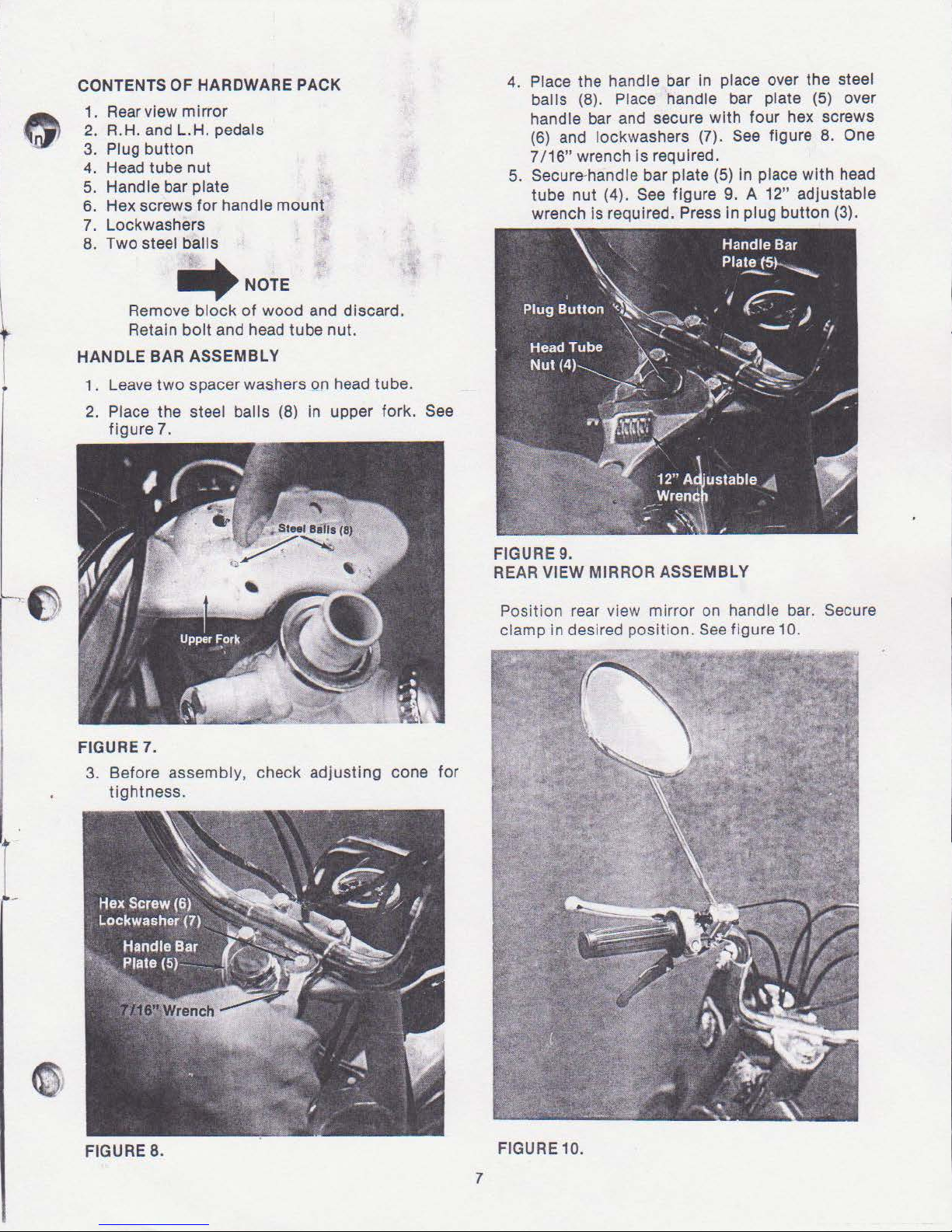

ASSEMBLY

INSTRUCTIONS

The MOPED comes completely assembled wi

the exception

and pedals.

Reference

normal riding position, faci

of

the handle bar, rear view

See figures 5 and 6.

to

right and left hand side are from the

ng

forward.

mirror

th

,

FIGURE 3.

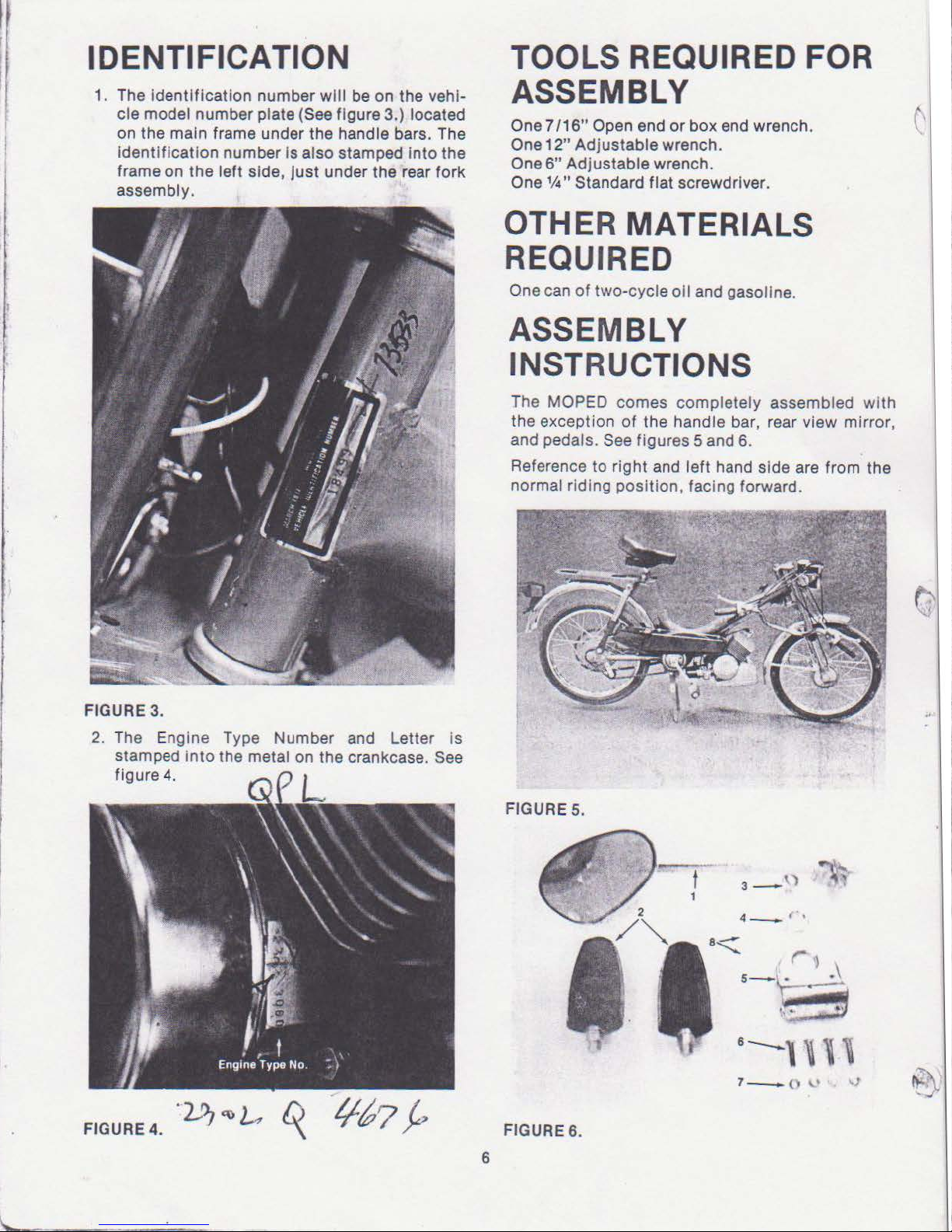

2.

The

stamped

figure

FIGURE

4.

Engine Type Number and Letter is

into

the metal on the crankcase. See

4.

.

'2J1

~

~

~

1167

~

FIGURE 5 .

FIGURES.

6

1

t

4--..-

('

CONTENTSOFHARDWAREPACK

1. Rear view mirror

2. R.H. and L.H. pedals

3. Plug button

4.

Head tube nut

5.

Handle bar plate

6. Hex screws

for

handle mount

7. Lockwashers

8. Two steel

Remove

Retain

HANDLE BAR ASSEMBLY

balls

.NOTE

block

of

wood and discard.

bolt

and head tube nut.

4. Place the handle bar In place over the steel

balls (8). Place handle bar plate (5) over

handle bar and secure with four hex screws

(6)

and lockwashers (7).

7/16"

5.

wrench

is

required.

Secure-handle bar plate

tube nut (4).

See figure 9. A 12" adjustable

wrench is required. Press

See

figure

(5)

in place with head

8.

In plug button (3).

One

1. Leave

2.

two

spacer washers on head tube.

Place the steel balls (8) in upper fork. See

figure 7.

FIGURE 7.

3. Before assembly, check adjusting cone for

tightness.

FIGURE 9.

REAR VIEW MIRROR ASSEMBLY

Posit ion rear view mirror on handle bar. Secure

clamp

in

desired position.

See

figure 10.

FIGURE 8.

FIGURE 10.

7

SEAT ASSEMBLY

1. Place the seat post clamp on seat post.

2.

Line

up

the

two

rear clamps

In rear frame

holes

3.

Tighten

4. Tighten the rear seat clamp

the

pillar

of

MOPED.

clamp nut and

on

bolt

nuts

and screws.

seat with

securely.

I !

I

I

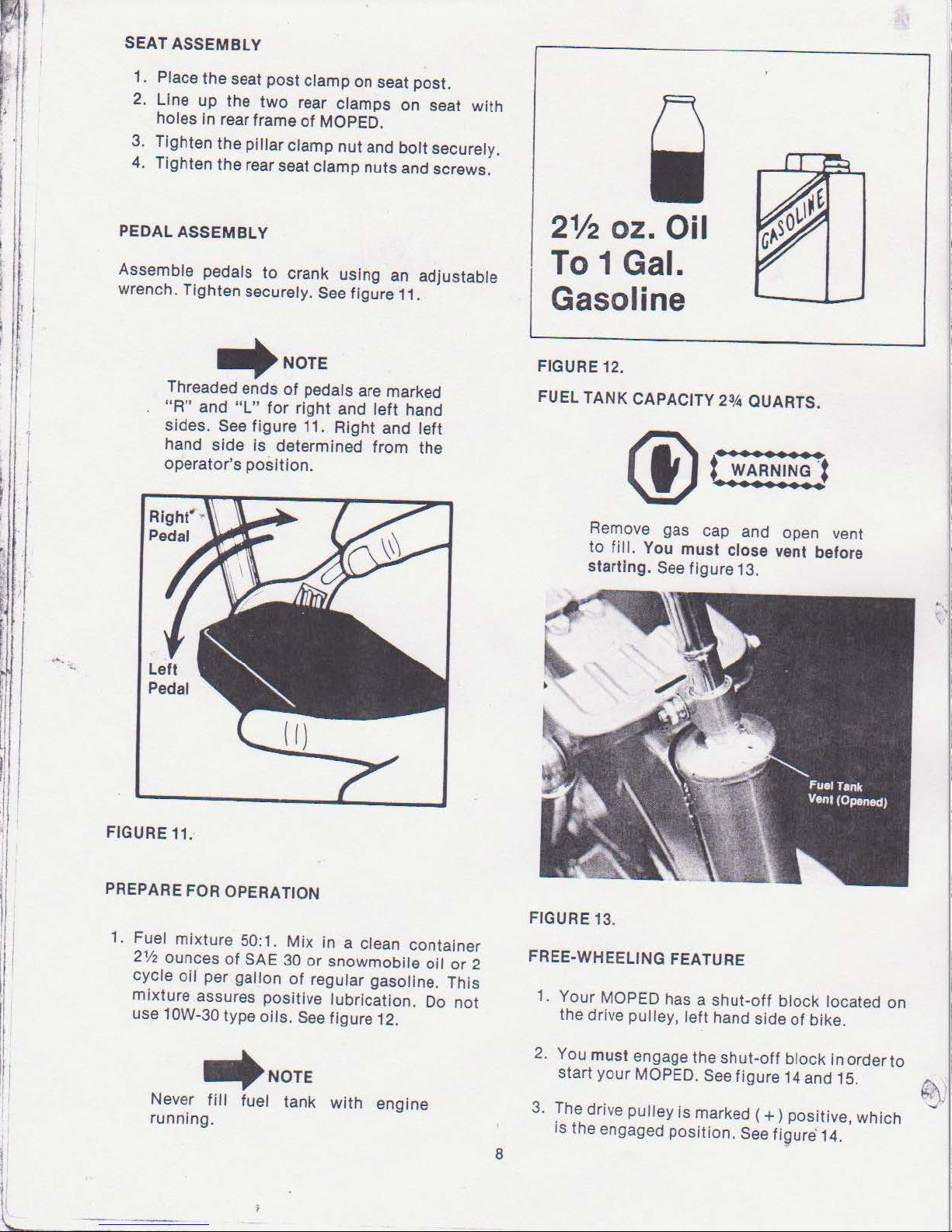

PEDAL

Assemble pedals to crank using an adjustable

wrench. Tighten securely.

ASSEMBLY

See figure 11.

~NOTE

Threaded ends

"R"

and

"L"

sides.

hand

operator's

See figure 11.

side

of

pedals are marked

for

right

and

left

hand

Right

Is determined from the

position.

and

left

2V2

To

oz. Oil

1 Gal.

Gasoline

FIGURE 12.

FUEL

TANK

CAPACITY

Remove gas cap and open vent

fill.

to

starting.

You

must

See

23,4

QUARTS.

close vent before

figure 13.

FIGURE11:

PREPARE FOR OPERATION

1. Fuel mixture 50:1.

2112

ounces

cycle

mixture

use 10W-30 type oils. See figure 12.

of

oil

per gallon

assures positive lubrication. Do

SAE

Mix

30

or

of

regular gasoline. This

~NOTE

Never

running.

fill

fuel tank

in a clean container

snowmobile

with

engine

oil

or

not

2

FIGURE 13.

FREE-WHEELING FEATURE

1. Your MOPED has a shutthe drive pulley, left hand side

2.

You

must

engage the

start

your

MOPED.

3.

The drive pulley

is the engaged position. See

8

See

is

marked

off

block

of

bike.

shut-off

figure 14 and 15.

block in order

(+)positive,

figure

located

which

14.

on

to

~I

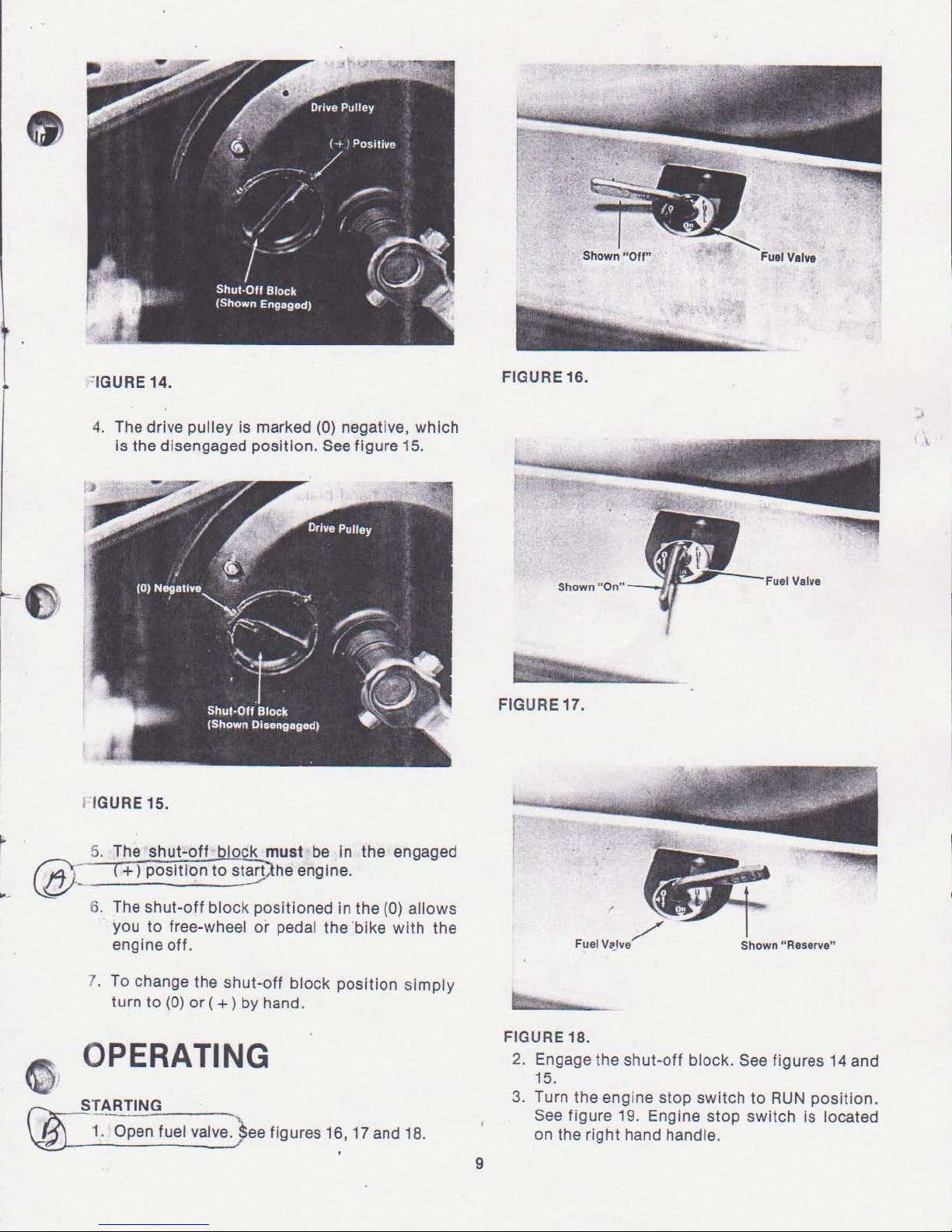

=IGURE 14.

FIGURE 16.

4. The drive pulley

is

the

disengaged

IGURE 15.

is

marked (0) negative, which

position.

See

figure

15.

FIGURE 17.

6. The

7. To change the

shut-off

you

to

engine

turn

to

block

free-wheel

off.

shut-off

(0)

or

( + ) by hand.

positioned

or

pedal the 'bike

block

OPERATING

STARTING

oc;-·

Open fuel

valve.)ee

figures 16,

in

the (0) allows

with

position

17

simply

and 18.

the

FIGURE 18.

2.

3.

9

Shown "Reserve"

Engage the

15.

Turn the engine stop switch to

See

figure 19. Engine stop switch

on the

shut-off

right

hand handle.

block. See figures 14 and

RUN

position.

is

located

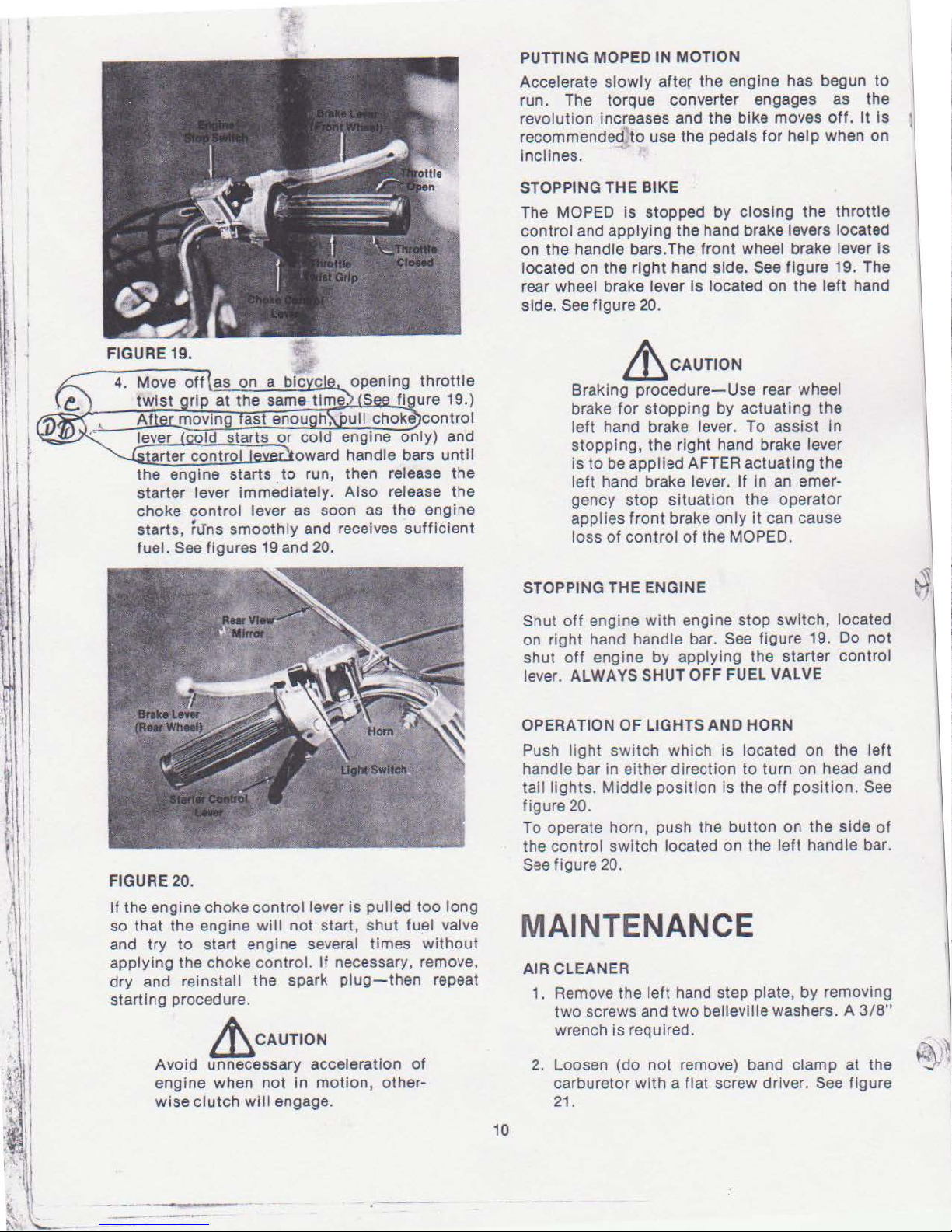

PUTTING

Accelerate

run. The torque converter engages as the

revolution increases and the bike moves

recommended

inclines.

STOPPING THE BIKE

The MOPED

control and applying the hand brake levers located

on the handle bars. The

located on the right hand side.

rear wheel brake lever

side.

MOPED IN MOTION

slowly

See figure 20.

after

to

use the pedals for help when on

is

stopped

the

engine has begun

by

closing the

front

wheel brake lever Is

See

figure 19. The

Is located on the

off.

throttle

left

hand

It

to

Is

~CAUTION

Braking

brake

left

stopping, the right hand brake lever

is

to

left

gency

applies

loss

procedure-Use

for

stopping

hand brake lever. To

be applied AFTER actuating

hand brake lever.

stop

situation

front

brake

only

of

control

of

the MOPED.

rear wheel

by

actuating the

assist

If

In

an

the operator

it

can cause

In

the

emer-

FIGURE 20.

If

the engine choke control lever

so that the engine

and try

applying the choke

dry and reinstall the spark plug- then repeat

starting procedure .

to

start engine several times

will

contr

not

ol.

is

pulled

start , shut fuel valve

If

necessary, remove,

too

long

without

~CAUTION

Avoid unnecessary acceleration

engine when

wise

clutch

not

will

in motion, other-

engage.

of

STOPPING THE ENGINE

Shut

off

engine

on right hand handle bar.

shut

off

engine by applying the starter control

lever.

ALWAYS SHUT OFF FUEL VALVE

OPERATION OF LIGHTS AND HORN

Push

li

ght

handle bar in either direction to turn on head and

taillights.

figure 20.

To operate horn, push the button on the side

the control sw itch located on the

See figure 20.

with

engine stop switch, located

See figure 19. Do

switch

Middle position is the

which

is

located on the

off

position.

left

not

left

See

of

handle bar .

MAINTENANCE

AIR CLEANER

1. Remove the

two

screws and

wrench

2.

Loosen (do not remove) band clamp at the

carburetor with a

21.

left hand step plate,

two

belleville washers. A 3/ 8"

is

required.

flat screw driver. See figure

by

removing

10

Loading...

Loading...