Page 1

Page 2

Safe Operation Practices

Assembly Instructions. .

Controls. Operation. Adjustments Lubrication. Maintenance Off-Season Storage.

...3 Trouble Shooting Chart. ...4 Electrical System. ...9 Illustrated Parts for Rider. ...

22,24,26,28,3023,25,27,29,31

..11 Parts List for Rider ..12 Illustrated Parts for Transaxles

32,34

..14 Parts List forTransaxles ..14 Parts Information ..18

NOTICE: A data plate with the model number and serial numbers of your unit is located on the frame,

under the seat. Record these numbers in the spaces provided on the back cover of this guide.

33,35

Back Cover

19

21

This

~ WARNING:

unit is equipped with an internal combustion engine and should not be used on or near any unimproved forest-covered, brush-covered or grass-covered land unless the engine's exhaust system is

equipped with a spark arrester meeting applicable local or state laws (if any). If a spark arrester is used, it

should be maintained in effective working order by the operator.

In the State of California the above is required by law (Section 4442 of the California Public Resources

Code). Other states may have similar laws. Federal laws apply on federal lands. A spark arrester muffler is

available at your nearest engine authorized service center.

2

Page 3

(t) :C~~~EI~Ej

To reduce the potential for any injury, comply with the following safety instructions. Failure to comply

with the instructions may result in personal injury.

SAFE OPERATION PRACTICES FOR RIDING VEHICLES

1. Read this owner's manual carefully in its en- 16. Disengage power to attachment(s) and stop

tirety before attempting to assemble or engine before making any repairs or adoperate this unit. Keep this manual in a safe justments. Disconnect the spark plug wire

place for future and regular reference and for and keep the wire away from the plug to preordering replacement parts. vent accidental starting.

2. This unit is a precision piece of power equip- 17. Before attempting to unclog the mower or

ment, not a plaything, Therefore exercise ex- discharge chute, stop the engine. The mower

treme caution at all times. blade(s) may continue to rotate for a few

3. Know the controls and how to stop quickly- seconds after the engine is shut off.

READ THIS OWNER'S MANUAL. Therefore, be sure the blade(s) have stopped

4. Do not allow children to operate vehicle. Do completely. Disconnect the spark plug wire

not allow adults to operate it without proper and keep the wire away from the plug to preinstruction. Only persons well acquainted vent accidental starting.

wit!! these rules of safe operation should be 18. Disengage power to attachment(s) when

allowed to use your mower. transporting or not in use.

5. ~o one sho~ld op.erate th,is u.nit whil~ int'?x- 19. Take all possible precautions when leaving

Icated or while takl~g medication that Impairs vehicle unattended such as disengaging

the senses or reactions. power-take-off, lowering attachments, shift-

6. Wear ~t~rdy, rough-soled work shoe~ and ing into neutral, setting parking brake, stopclose-fitting slacks and shirts to avoid en- ping engine and removing key

tanglement in the moving parts. Never operate .i

a unit in bare feet, sandals, or sneakers. 20. Do ,not stop or, start suddenly when go ng

7. To prevent injury, do not carry passengers or uphill or dow.nhili. Mow up and down face of

give rides. Keep children, pets and by- steep slop~s, ~e~er. across the face. l:'se exstanders out of the area while mowing. Only treme cautlo~ If .It IS necessary to drive th~

the operator should ride on the unit and only trac.tor ~p an Incline or back the tractor dow

r'de in the seat an Incline because the front of the tractor

8. ~heck overhea.d clearance carefully before could lift and raJ;>idly !Iip over backward which

driving under power lines, guy wires, bridges could cause serious Injury.

or low hanging tree branches, before entering 21. Reduce speed on slopes and in sharp turns to

or leaving buildings, or in any other situation prevent tipping or loss of control. Always

where the operator may be struck or pulled keep the tractor in gear when going down

from the unit, which could result in serious in- steep hills to take advantage of engine brak.

jury. ing action.

9. To maintain control of the unit and reduce the 22. Stay alert for holes in terrain and other hidden

possibility of upset or collision, operate the hazards.

tractor .smoothly. Avoid erratic operation and 23. Use care when pulling loads or using heavy

excessive speed.. equipment.

10. Keep the ~rea of operation .clear of all per- A, Use only approved drawbar hitch points.

sons, particularly small children and pets. B Limit loads to those you can safely control,

Stop engine when they are in the vicinity. of C: Do not turn sharply. Use care when back.

your mower. Although the area of oP.eratlon ing.

.should be comple.tely cleared of foreign ob. D. Use counterweight(s) or wheel weights

Jects, a small object ~ay have been over. when suggested in owner's manual.

looked and could be accidently thrown by the ..

mower in any direction and cause injury. 24. Watch out for traffic when crossing or near

11. Clear work area of objects which might be roadways.

picked up and thrown by the mower in any 25. When using any a~tachments, never direct disdirection and cause injury. charge of material t?ward ~y~tanders .nor

12. Stop the blade(s) when crossing gravel drives, allow anyone near vehicle while In operation.

walks or roads. 26. Handle gasoline with care. It is highly flam-

13. Disengage all attachment clutches and shift mable,

into neutral before attempting to start engine. A. Use approved gasoline container.

14. Disengage power to attachment(s) and stop B. Never remove cap or add gasoline to a runengine before leaving operating position. ning or hot engine or fill fuel tank indoors.

15. Do not put hands or feet near or under rotating Wipe up spilled gasoline.

parts. Keep clear of the discharge opening at C. Open doors if engine is run in garage. Ex.

all times as the rotating blade(s) can cause in- haust fumes are dangerous. Do not run

jury. 3 engine indoors.

Page 4

27. Keep the vehicle and attachments in good

operating condition, and keep safety devices

in place. Use guards as instructed in

operator's manual.

28. Keep all nuts, bolts, and screws tight to be

sure the equipment is in safe working condi-

tion.

29. Never store the equipment with gasoline in

the tank inside a building where fumes may

reach an open flame or spark. Allow engine to

cool before storing in any enclosure.

30. To reduce fire hazard, keep engine free of

grass, leaves or excessive grease.

31. The vehicle and attachments should be

stopped and inspected for damage after strik-

ing a foreign object. The damage should be

repaired before restarting and operating the

equipment.

32. Do not change the engine governor settings

or overs peed the engine.33.

When using the vehicle with mower, proceed

as follows:

(1) Mow only in daylight or in good artificial

light.

(2) Never make a cutting height adjustment

while engine is running if operator must

dismount to do so.

(3) Shut the engine off and wait until the

blade comes to a complete stop before

removing the grass catcher.

(4) Check blade mounting bolts for proper

tightness at frequent intervals.

34. Check grass catcher bags frequently for wear

or deterioration. For safety protection, replace

only with new bag meeting original equipment

specifications.35.

Look behind to make sure the area is clear

before placing the transmission in reverse

and continue looking behind while backing

up. Disengage blades before shifting into

reverse and backing up.

36. This unit should not be driven up a ramp onto

a trailer or truck under power, because the

unit could tip over, causing serious personal

injury. The unit must be pushed manually to

load properly.

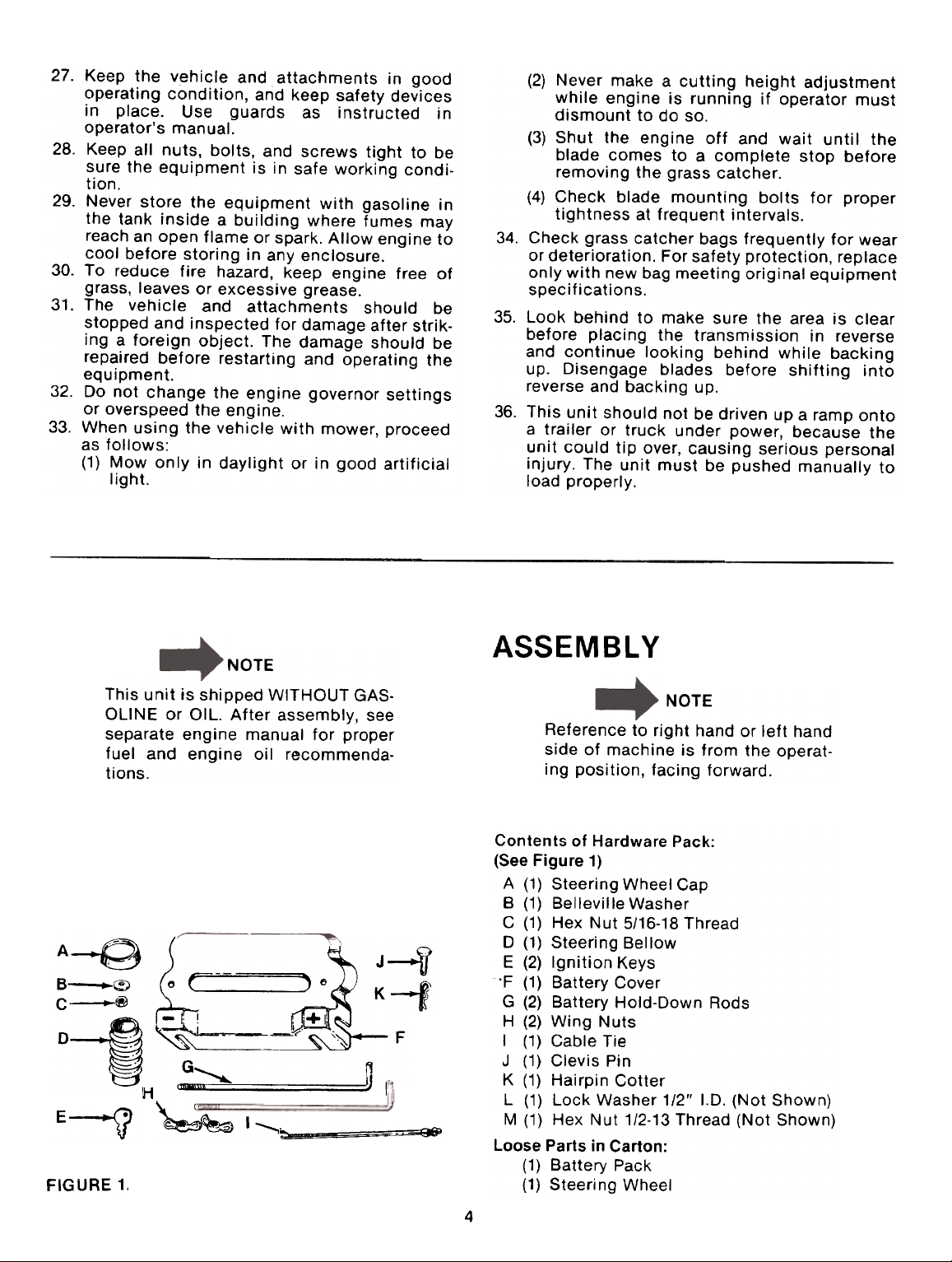

NOTE

This unit is shipped WITHOUT GASOLINE or OIL. After assembly, see

separate engine manual for proper

fuel and engine oil recommendations.

A_' ~ --J -fr

B--I;::;. K ~'

C-@ -f('

D--_~ ~ F

~r -.,~~ ~ r

H

~;:~~ 1

FIGURE 1.

ASSEMBLY

NOTE

Reference to right hand or left hand

side of machine is from the operat-

ing position, facing forward.

Contents of Hardware Pack:

(See Figure 1)

A (1) Steering Wheel Cap

B (1) Belleville Washer

C (1) Hex Nut 5/16-18 Thread

0 (1) Steering Bellow

E (2) Ignition Keys

'F (1) Battery Cover

G (2) Battery Hold-Down Rods

H (2) Wing Nuts

I (1) Cable Tie

J (1) Clevis Pin

K (1) Hairpin Cotter

L (1) Lock Washer 1/2" 1.0. (Not Shown)

~

M (1) Hex Nut 1/2-13 Thread (Not Shown)

Loose Parts in Carton:

(1) Battery Pack

(1) Steeri ng Wheel

E-')J

4

Page 5

BATTERY INFORMATION

~ ~A_R~I_N? -_t

Battery acid must be handled with great care

as contact with it can burn and blister the skin.

It is also advisable to wear protective clothing

(goggles, rubber gloves and apron) when work-

ing with it..

B. Should battery acid accidentally splatter into

the eyes or onto the face, rinse the affected

area immediately with clean cold water. If

there is any further discomfort, seek prompt

medical attention.C.

If acid spills on clothing, first dilute it with

clean water, then neutralize with a solution of

ammonia/water or baking soda/water.

Since battery acid is corrosive, do not pour it

into any sink or drain. Before discarding empty

electrolyte containers, rinse :hem with a

neutralizing solution.E.

NEVER connect or disconnect charger clips to

battery while charger is turned on as it can

cause sparks.

F. Keep all lighted materials (cigarettes, match-

es, lighters) away from the battery as the

hydrogen gas generated during charging can

be combustible.G.

As a further precaution, only charge the battery

in a well-ventilated area.

.Always shield eyes, protect skin and clothing

when working near batteries.

ACTIVATING AND INSTAlliNG THE BATTERY

1. Upon opening the battery pack, you should

receive acid pack, battery, drain tube, filling

adapter and i}9rdware.

WARNING;

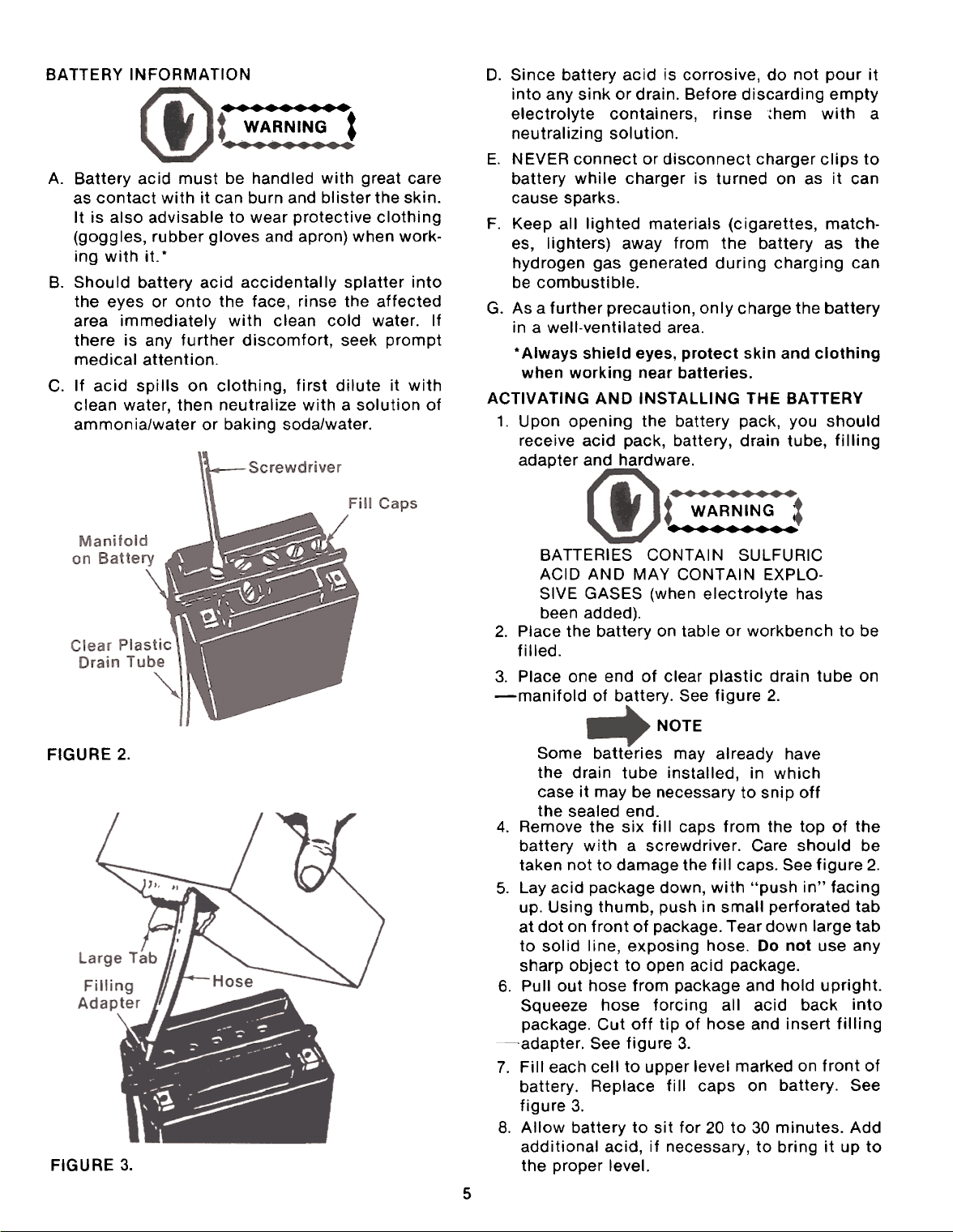

FIGURE 2.

FIGURE 3.

BATTERIES CONTAIN SULFURIC

ACID AND MAY CONTAIN EXPLOSIVE GASES (when electrolyte has

been added).

2. Place the battery on table or workbench to be

filled.3.

Place one end of clear plastic drain tube on-manifold

of battery. See figure 2.

NOTE

Some batteries may already have

the drain tube installed, in which

case it may be necessary to snip off

the sealed end.

4. Remove the six fill caps from the top of the

battery with a screwdriver. Care should be

taken not to damage the fill caps. See figure 2.

5. Lay acid package down, with "push in" facing

up. Using thumb, push in small perforated tab

at dot on front of package. Tear down large tab

to solid line, exposing hose. Do not use any

sharp object to open acid package.

6. Pullout hose from package and hold upright.

Squeeze hose forcing all acid back into

package. Cut off tip of hose and insert filling~adapter.

See figure 3.

7. Fill each celt to upper level marked on front of

battery. Replace fill caps on battery. See

figure 3.

8. Allow battery to sit for 20 to 30 minutes. Add

additional acid, if necessary, to bring it up to

the proper level.

D.

A.

5

Page 6

Battery contains sulfuric acid. Refer to warning on

page 5. Antidote: EXTERNAL-Flush with water.

INTERNAL-Drink large quantities of water or

milk. Follow with milk of magnesia, beaten egg or

vegetable oil. Seek prompt medical attention.

EYES: Flush with cool water for at least 15

minutes, then seek immediate medical attention.

Since batteries produce explosive gases, keep all

lighted materials (cigarettes, lighters, matches,

etc.) away. Be sure to charge battery only in wellventilated areas.

KEEP BATTERIES

OUT OF THE REACH OF CHILDREN!

9. The battery can be charged after the 20

minutes sitting period. SLOW CHARGE THE

BATTERY (DO NOT FAST CHARGE) at a maximum bench rate of 1.4 amperes until the

specific gravity reading is 1.260-1.280. Charge

for a minimum of 2 hours and a maximum of 8

hours.

NOTE

Charging rate after battery has been

put into operation: The battery is to

be charged for a period of 14-16

hours. NO LONGER THAN 30

HOURS.

~CAUTION

After battery has been in service,

add only distilled water. DO NOT

ADD ACID.

This engine is equipped with an

alternator. The current for the bat-

tery charger alternator is u nregulated. During normal operation, it is

only necessary to charge the battery:

1. When it is activated for the first

time.

2. Before winter storage.

3. Before using the lawn tractor

after winter storage.

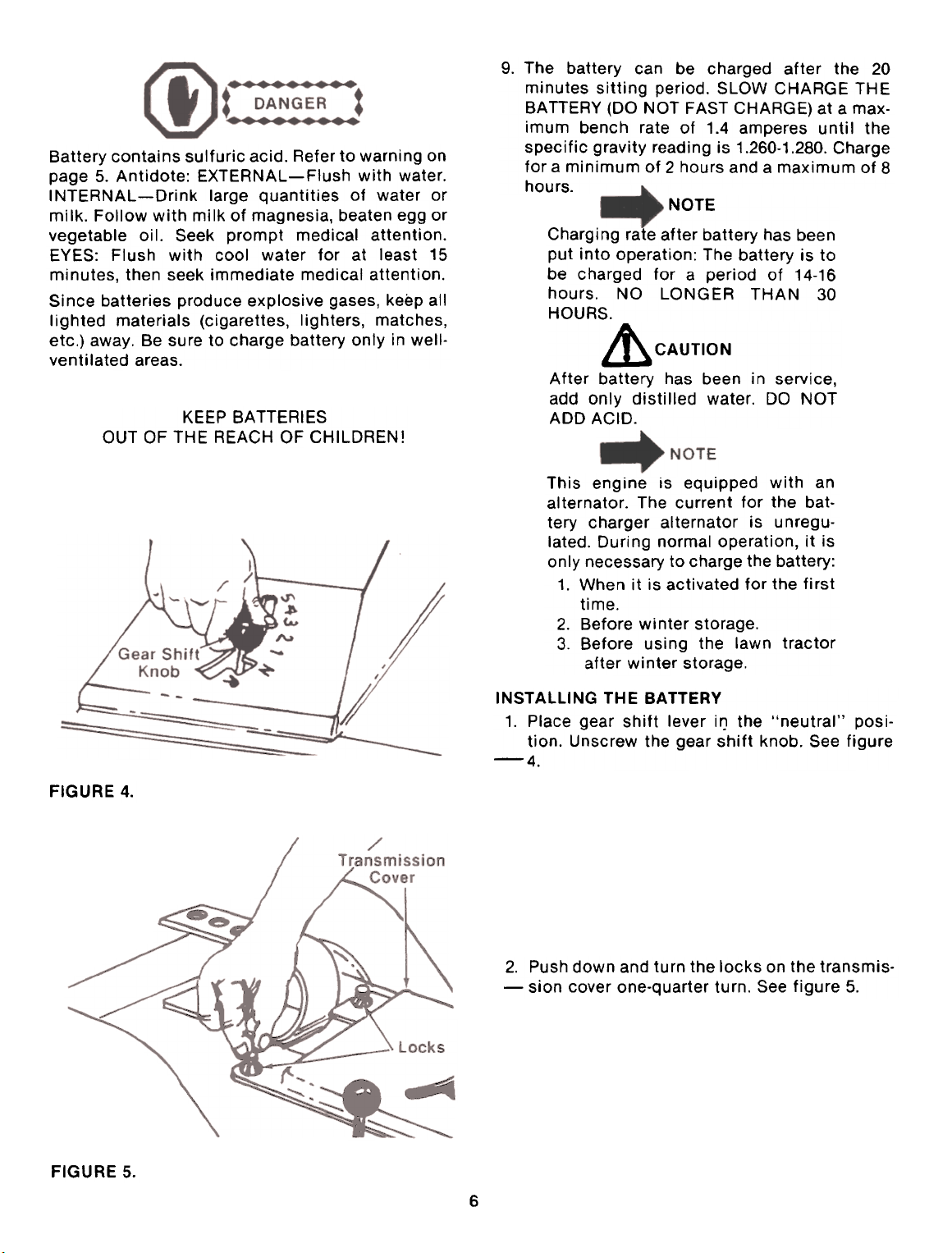

FIGURE 4.

FIGURE 5.

INSTAlliNG THE BATTERY

1. Place gear shift lever it) the "neutral" position. Unscrew the gear shift knob. See figure-4.

2. Push down and turn the locks on the transmis--sian

cover one-quarter turn. See figure 5.

6

Page 7

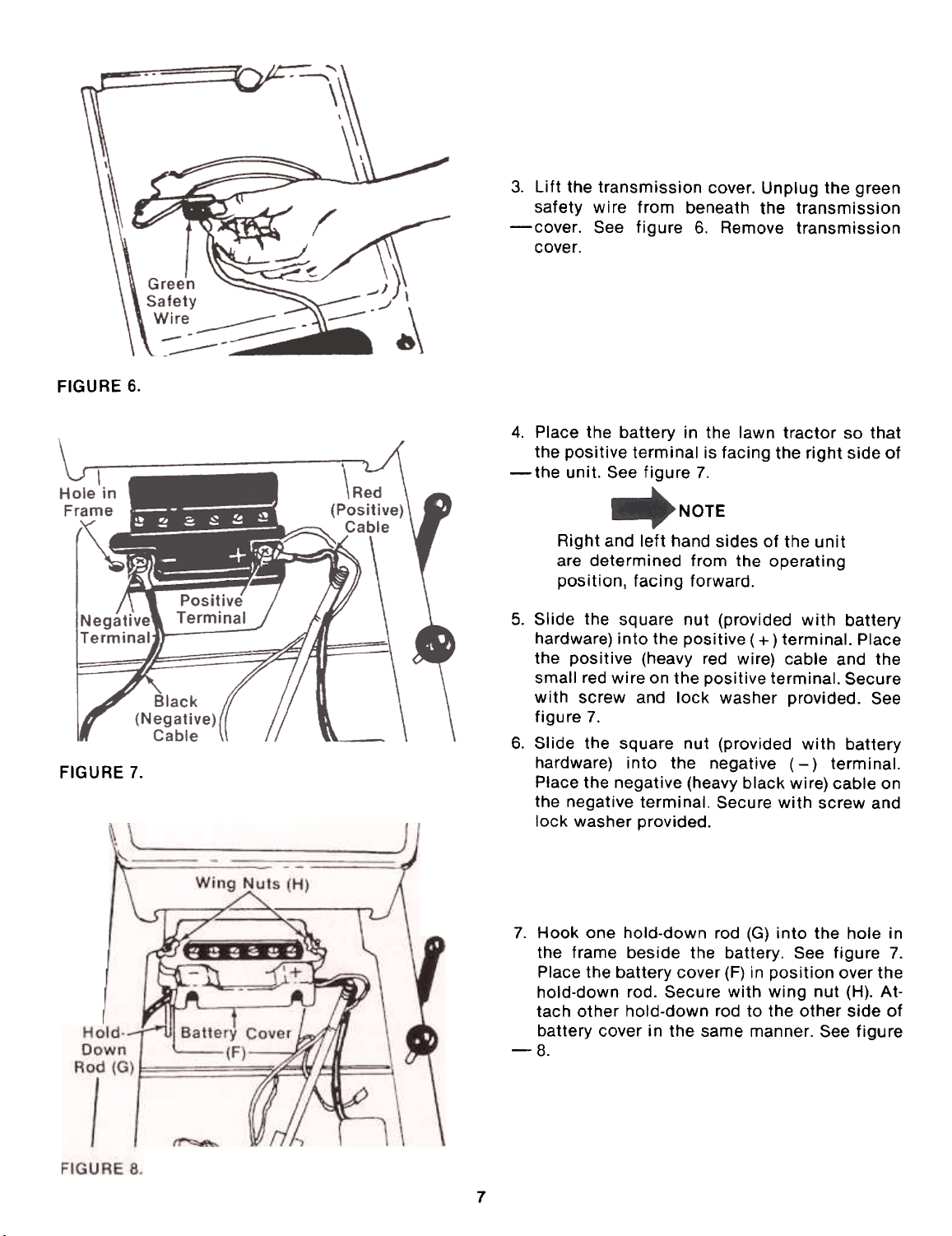

FIGURE 6.

FIGURE 7.

Lift the transmission cover. Unplug the green

safety wire from beneath the transmission-cover.

See figure 6. Remove transmission

cover.

4. Place the battery in the lawn tractor so that

the positive terminal is facing the right side of-the

unit. See figure 7.

NOTE

Right and left hand sides of the unit

are determined from the operating

position, facing forward.

Slide the square nut (provided with battery

hardware) into the positive (+) terminal. Place

the positive (heavy red wire) cable and the

small red wire on the positive terminal. Secure

with screw and lock washer provided. See

figure 7.6.

Slide the square nut (provided with battery

hardware) into the negative (-) terminal.

Place the negative (heavy black wire) cable on

the negative terminal. Secure with screw and

lock washer provided.

3.

5.

7. Hook one hold-down rod (G) into the hole in

the frame beside the battery. See figure 7.

Place the battery cover (F) in position over the

hold-down rod. Secure with wing nut (H). At-

tach other hold-down rod to the other side of

battery cover in the same manner. See figure-8.

7

Page 8

FIGURE 9.

Plastic

Bushing

in Dash

Panel

~! -Hairpin Cotte: (K)

._~

~ :;;;./ Upper Steering Clevis "' \ Shaft Pin (J)

,: I -Lower Steering

, I ;..~~ Shaft

.,..-

lr-::"~

Push the locking end of cable tie (I) through~the

hole in the left frame as shown in figure 9.

Route 1he battery drain tube back to the cable

tie. Place end of cable tie through the slot so a

loop is formed around the drain tube to secure

it. Tighten cable tie and cut off excess end.9.

Plug the green safety wire into the switch

beneath the transmission cover. Refer to

figure 6. Replace the transmission cover and

gear shift knob.

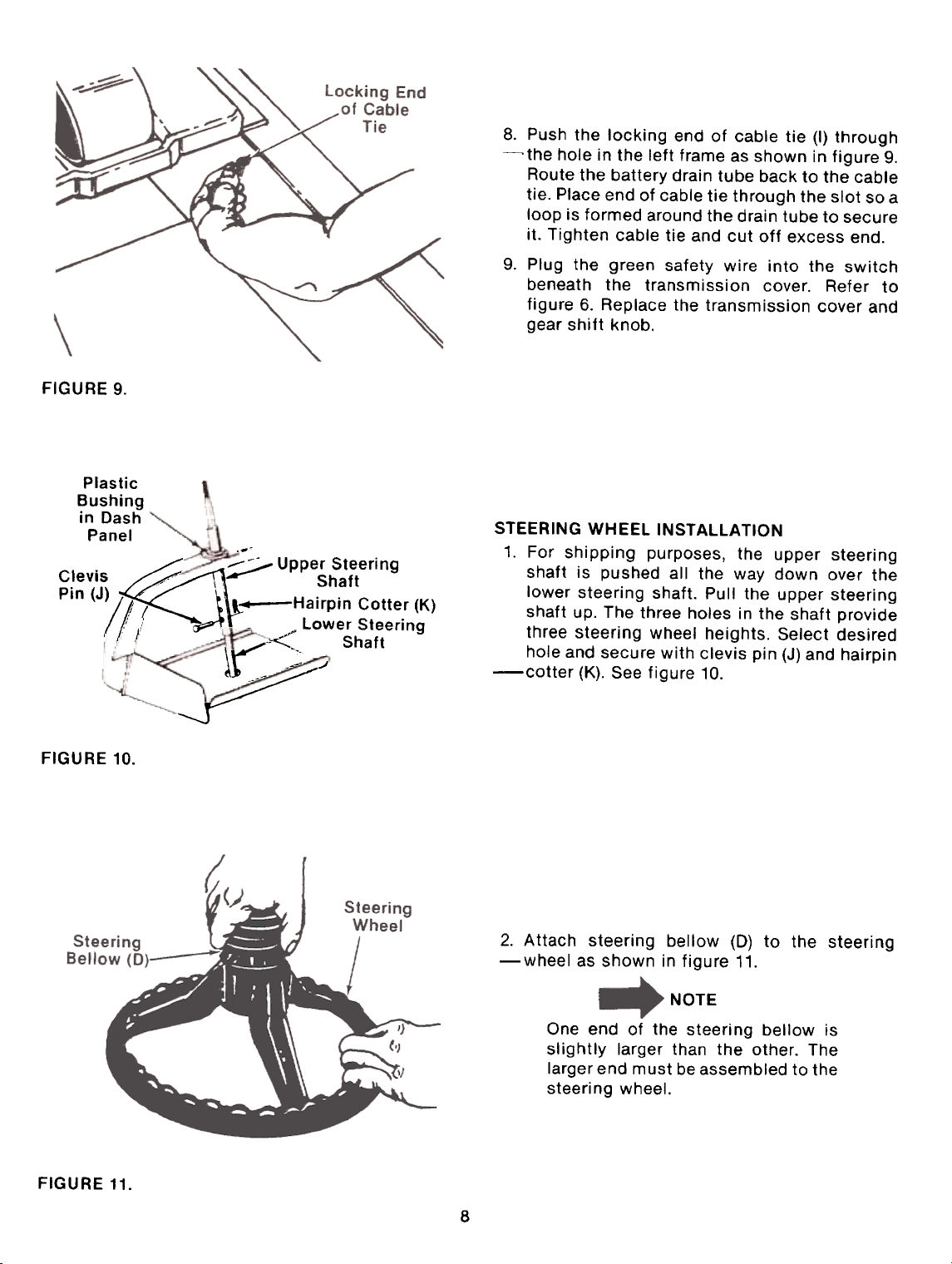

STEERING WHEEL INSTAllATION

1. For shipping purposes, the upper steering

shaft is pushed all the way down over the

lower steering shaft. Pull the upper steering

shaft up. The three holes in the shaft provide

three steering wheel heights. Select desired

hole and secure with clevis pin (J) and hairpin-cotter

(K). See figure 10.

FIGURE 10.

FIGURE 11.

~J--~

2. Attach steering bellow (D) to the steering-wheel

as shown in figure 11.

NOTE

One end of the steering bellow is

slightly larger than the other. The

larger end must be assembled to the

steering wheel.

8.

...t~

8

Page 9

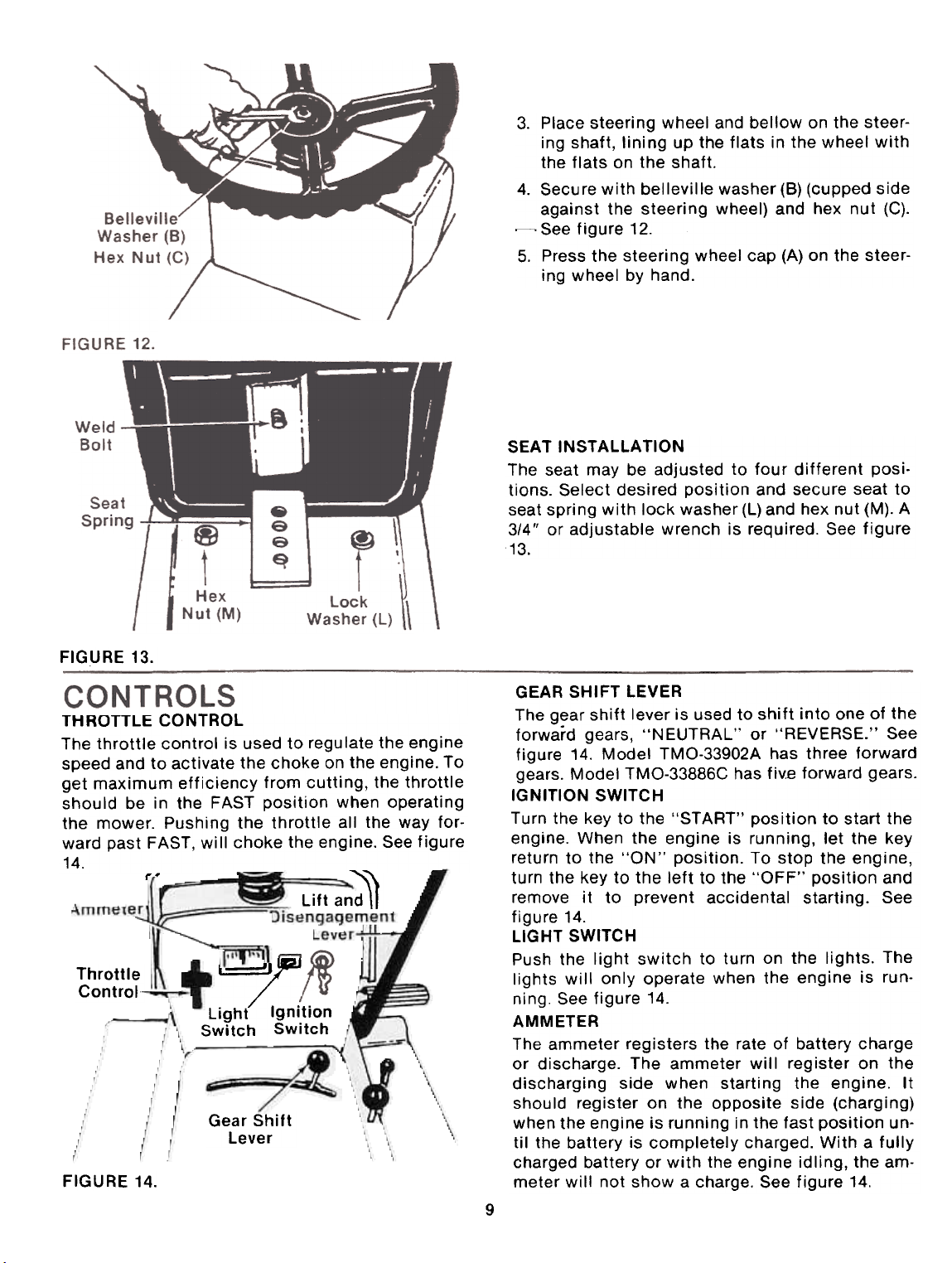

Place steering wheel and bellow on the steering shaft, lining up the flats in the wheel with

the flats on the shaft.4.

Secure with belleville washer (6) (cupped side

against the steering wheel) and hex nut (C).

~ See figure 12.

5. Press the steering wheel cap (A) on the steering wheel by hand.

SEAT INSTAllATION

The seat may be adjusted to four different posi.

tions. Select desired position and secure seat to

seat spring with lock washer (l) and hex nut (M). A

3/4" or adjustable wrench is required. See figure

13.

FIGURE 13.

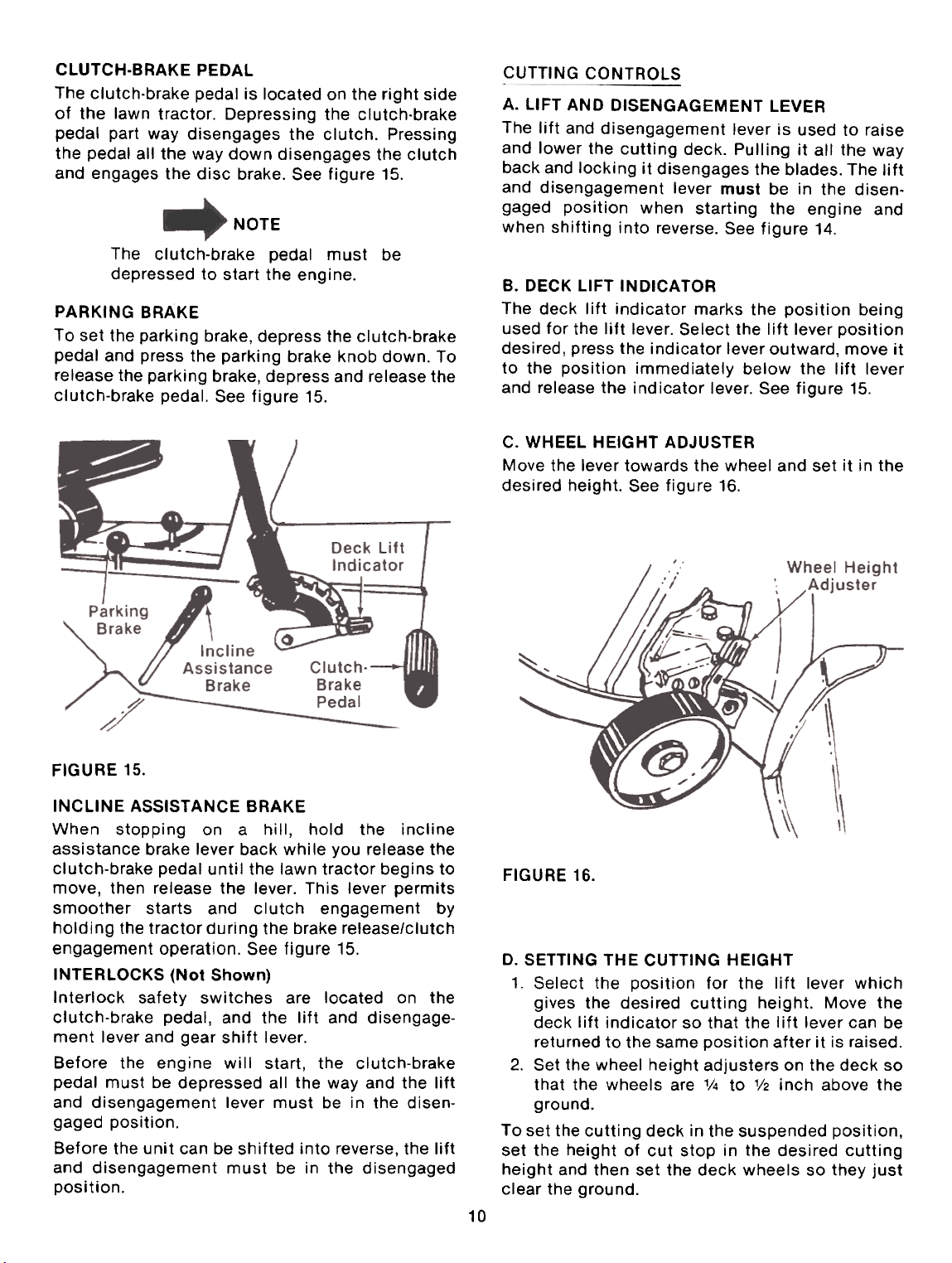

THROTTLE CONTROL

The throttle control is used to regu late the eng ine

speed and to activate the choke on the engine. To

get maximum efficiency from cutting, the throttle

should be in the FAST position when operating

the mower. Pushing the throttle all the way forward past FAST, will choke the engine. See figure

14.

t'~

,-- ~

Lift an~

Throttle

Control~

FIGURE 14.

k..==!J/:,

Light Ignition

Switch Switch

Gear Shift

Lever

GEAR SHIFT LEVER

The gear shift lever is used to shift into one of the

forward gears, "NEUTRAL" or "REVERSE." See

figure 14. Model TMO-33902A has three forward

gears. Model TMO-33886C has fivE forward gears.

IGNITION SWITCH

Turn the key to the "START" position to start the

engine. When the engine is running, let the key

return to the "ON" position. To stop the engine,

turn the key to the left to the "OFF" position and

remove it to prevent accidental starting. See

figure 14.

LIGHT SWITCH

Push the light switch to turn on the lights. The

lights will only operate when the engine is run-

ning. See figure 14.

AMMETER

The ammeter registers the rate of battery charge

or discharge. The ammeter will register on the

discharging side when starting the engine. It

should register on the opposite side (charging)

when the engine is running in the fast position un-

til the battery is completely charged. With a fully

charged battery or with the engine idling, the am-

meter will not show a charge. See figure 14.

3.

9

Page 10

CLUTCH.BRAKE PEDALThe

clutch-brake pedal is located on the right side

of the lawn tractor. Depressing the clutch-brake

pedal part way disengages the clutch. Pressing

the pedal all the way down disengages the clutch

and engages the disc brake. See figure 15.

NOTE

The clutch-brake pedal must be

depressed to start the engine.

PARKING BRAKE

To set the parking brake, depress the clutch-brake

pedal and press the parking brake knob down. To

release the parking brake, depress and release the

clutch-brake pedal. See figure 15.

CUTTING CONTROLS

A. LIFT AND DISENGAGEMENT LEVER

The lift and disengagement lever is used to raise

and lower the cutting deck. Pulling it all the way

back and locking it disengages the blades. The lift

and disengagement lever must be in the disengaged position when starting the engine and

when shifting into reverse. See figure 14.

B. DECK LIFT INDICATOR

The deck lift indicator marks the position being

used for the lift lever. Select the lift lever positiondesired,

press the indicator lever outward, move it

to the position immediately below the lift lever

and release the indicator lever. See figure 15.

C. WHEEL HEIGHT ADJUSTER

Move the lever towards the wheel and set it in the

desired height. See figure 16.

FIGURE 15.

INCLINE ASSISTANCE BRAKE

When stopping on a hill, hold the incline

assistance brake lever back while you release the

clutch-brake pedal until the lawn tractor begins to

move, then release the lever. This lever permits

smoother starts and clutch engagement by

holding the tractor during the brake release/clutch

engagement operation. See figure 15.

INTERLOCKS (Not Shown)

Interlock safety switches are located on the

clutch-brake pedal, and the lift and disengagement lever and gear shift lever.

Before the engine will start, the clutch-brake

pedal must be depressed all the way and the lift

and disengagement lever must be in the disen-

gaged position.

Before the unit can be shifted into reverse, the lift

and disengagement must be in the disengaged

position.

FIGURE 16.

D. SETTING THE CUTTING HEIGHT

1. Select the position for the lift lever which

gives the desired cutting height. Move the

deck lift indicator so that the lift lever can be

returned to the same position after it is raised.

2. Set the wheel height adjusters on the deck so

that the wheels are 1/4 to 1/2 inch above the

ground.To

set the cutting deck in the suspended position,

set the height of cut stop in the desired cutting

height and then set the deck wheels so they just

clear the ground.

10

Page 11

OPERA TION

~ ~ CAUTION

~ 1. Keep all shields in place.

". 2. Before leaving operator's position:

~ a. Shift transmission to neutral

". b. Set parking brake

~ c. Disengage attachment clutch

". d. Shut off engine

~ e. Remove ignition key

". 3. Wait for all movement to stop before

~ servicing machine.

'" 4. Keep people and pets a safe distance

~ away from machine.

'" 5. Look to the rear before backing up.

TIRE PRESSURE

For shipping purposes, the tires on your unit may

be over.inflated. Tire pressure should be reduced

before unit is put into operation. Pressure should

be approximately 15 p.s.i. Equal tire pressure

should be maintained on all tires. Maximum tire

pressure is 30 p.s.i.

STARTING THE ENGINE

NOTE

To open the hood, simply lift

up on both sides of the hood.

Do not operate the lawn tractor if

the interlock system is malfunctioning because it is a safety device,

designed for protection.

Set the throttle control in the CHOKE posi-

tion. See figure 14.5.

Turn the ignition key to the "START" position.

When the engine is running, let the key return

to the "ON" position. See figure 14.6.

Move the throttle control to desired engine

speed.

STOPPING THE ENGINE

Turn the ignition key to the left to the "OFF" posi-

tion. Remove the key to prevent accidental start-

ing.

NOTE

A brief break-in period is essential

to ensure maximum engine and

mower life. The break-in consists of

running the engine at half speed for

a period of time required to use one

tank of gasoline. It is also recommended to change crankcase oil

after the first 5 hours of operation.

IMPORTANT

1. Service the engine with oil and gasoline as

described in the engine manual.

2. Depress the clutch-brake pedal and set the

parking brake. See figure 15.3.

Place the lift and disengagement lever in the

DISENGAGED position. See figure 15.

This unit is equipped with a safety

interlock system for your protec-

tion. The purpose of the safety inter-

lock system is to prevent the engine

from cranking or starting unless the

clutch-brake pedal is depressed

and the lift and disengagement

lever is in the disengaged position.

In addition, the lift and disen-

gagement lever must be in the disengaged position when the unit is

put into reverse or the engine will

shut off.

If you strike a foreign object, stop

the engine. Remove wire from sparkplug,

thoroughly inspect the unit

for any damage, and repair the damage before restarting and operating

the mower.

OPERATING THE MOWER

1. Set the desired cutting height.

2. Start the engine as instructed on page 11.

3. Move throttle control to desired engine speed.

4. Depress the clutch-brake pedal and shift into

first gear or reverse.

5. Release clutch-brake pedal slowly to put unit

into motion.

6. Depress the clutch-brake pedal when shifting

gears.

Do not force the gear shift lever!

11

4.

Page 12

The lawn tractor is brought to a stop by

depressing the clutch-brake pedal. The drive

belt will be disengaged and the brake will be

applied.

~ CAUTION

If the unit is not to be used for a

long period, place the gear shift

lever in NEUTRAL, stop the engine,

set the parking break and remove

the key. DO NOT leave the machine

on an incline.

OPERATING THE CUTTING BLADES

The cutting blades may be engaged while the lawn

tractor is moving or standing still. DO NOT engage

the cutting blades abruptly as the sudden belt tension on the pulley may cause the engine to stall.

NOTE

Under normal usage bag material is

subject to wear, and should be

checked periodically. Be sure any

replacement bag complies with the

mower manufacturer's recommen-daitons.

For replacement bags, use only fac-

tory authorized replacement bag

No. 764-0121.

SEAT ADJUSTMENT

The seat may be adjusted to one of four positions.

Remove hex nut and lock washer from under seatspring.After

When the blade drive is engaged,

keep feet and hands away from the

discharge opening, the blades or

any part of the deck.

Move the lift and disengagement lever into the

DISENGAGED position to raise the deck and

disengage the blades.

When the machine is used for other

than mowing operations, the blade

drive should be disengaged.

GRASS CATCHER Part No. 194-015-088 is

available as optional equipment for the lawn trac-

tor shown in this manual.

The mower should not be operated

without the entire grass catcher or

chute deflector in place.

desired seat location is selected, secure

seat to seat spring with lock washer and hex nut.

A 3/4" or adjustable wrench is required. See figure

17.

FIGURE 17.

STEERING WHEEL ADJUSTMENTThere

are three height positions for the steeringwheel.

To adjust the height of the steering wheel,

remove the hairpin cotter and clevis pin shown in

figure 18. Place the steering wheel in the positiondesired

and secure with hairpin cotter and clevispin.

7.

12

Page 13

r---~

J\

FIGURE 18.

WHEEL ADJUSTMENTThe

caster (forward slant of the king pin) and the

camber (tilt of the wheels out at the top) require no

adjustment. Automotive steering principles have

been used to determine the caster and camber on

the tractor. The front wheels should toe.in 1/8

inch.To

adjust the toe-in, follow these steps.

1. Remove the hex nut and lock washer, and

drop the tie rod end from the wheel bracket.

See figure 19.

2. Loosen the hex jam nut on tie rod.

3. Adjust the tie rod assembly for correct toe-in.

J

FIGURE 20. TOE-IN DIAGRAM

CARBURETOR ADJUSTMENT

Front of Tractor

-----

R

',

~ WARNING t

'

If any adjustments are made to the

engine while the engine is running(e.g.

carburetor), disengage allclutches,

and blades. Keep clear of

all moving parts. Be careful of

heated surfaces and muffler.

Minor carburetor adjustment may be required to

compensate for differences in fuel, temperature,

altitude and load. To adjust the carburetor, refer to

the separate engine manual packed with your unit.

BRAKE ADJUSTMENT

During normal operation of this machine, the

brake is subject to wear and will require periodic

examination and adjustment.

& CAUTION

Do not have the engine running

FIGURE 19.

Dimension "B" should be approximately 1/8" less

than Dimension "A." See figure 20.

A.) To increase Dimension "B," screw tie rod into

tie rod end.

B.) To decrease Dimension "B." unscrew tie rod

from tie rod end.

C.) Reassemble tie rod. Check dimensions. Read-

just if necessary.

L

To adjust the brake, proceed as follows.

13

when you adjust the brake.

1. Tighten the inside nut until the cam lever can

not be moved by hand.

2. Loosen the inside nut until the cam lever can

be pushed forward so that there is a 1/8" to

3/16" space between the cam lever and stop

bolt. See figure 21.

Page 14

FIGURE 21.

FIGURE 23.

Tighten the outside nut against the inside nut,

using two 1/2 II wrenches. See figure 22.

NOTE

Friction pads must be replaced when

the inside of cam lever touches the

housing.

FIGURE 22.

STEERING SHAFT

Lubricate steering shaft at least once a season

with light oil.

TRANSAXLE

The transaxle is lubricated and sealed at the factory and does not require checking. If disassembled for any reason, lubricate with 24 oz. of E.P.

Lithium grease.

FRONT WHEELS

The front wheels are provided with grease fittings.

Lubricate at least once a season with automotive

multi-purpose grease.

PIVOT POINTS

Lubricate all pivot points with light oil at least

once a season.

..:;;.

~WARN~N_G- .

Disconnect the spark plug wire

and ground against the engine before performing any repairs or main-

tenance.

STEERING GEARS

Lubricate teeth of steering gears with automotive

multi-purpose grease after every 25 hours of

operation or once a season. See figure 23.

3.

,'

CRANKCASE OIL

Check the oil level in the crankcase before each

use of the machine and after every five hours ofoperation.

Oil level should be maintained as in-

structed in the separate engine manual.

After the first five hours of operating a newengine,

drain the oil from the crankcase while

engine is still hot and refill crankcase with new

oil; thereafter change the oil every 25 hours ofoperation.

Refer to the engine manual.

14

Page 15

AIR CLEAN ER

Under normal operating conditions, the air

cleaner, located on top of the carburetor, must be

serviced after every ten hours of use. Under ex-

tremely dusty operating conditions, the air

cleaner must be serviced after every hour of

operation. To service the air cleaner, refer to the

separate engine manual packed with your unit.

CLEANING ENGINE AND BLADE HOUSING

Any fuel or oil spilled on the machine should be

wiped off promptly. Grass, leaves, and other dirt

must not be left to accumulate around the cooling

fins of the engine or on any part of the machine.

Clean the underside of the blade housing after

each mowing.

SPARK PLUG

The spark plug should be cleaned and the gap

reset once a season. Spark plug replacement is

recommended at the start of each mowing

season; check engine manual for correct plug

type and gap specification.

CUTTING BLADE

A. Removal for Sharpening or Replacement

t WARNING:

.~ Be sure to disconnect and ground

the spark plug wire and remove

ignition key before working on the

cutting blade to prevent accidentalengine

starting.

1. Remove the large bolt and lock washer which

holds the blade and adapter to the blade spin-

dle.2.

Remove the blade and adapter from the spin-

dle. Be careful not to lose the key on the spin-

dle.3.

If the blade or blade adapter needs replacing,

remove the two small bolts, lock washers and

nuts which hold the blade to the adapter.

B. Sharpening

Remove the cutting blade by following the direc-

tions of the preceding section.

When sharpening the blade, follow the original

angle of grind as a guide. It is extremely important

that each cutting edge receives an equal amount

of grinding to prevent an unbalanced blade. An unbalanced blade will cause excessive vibration

when rotating at high speeds, may cause damage

to the mower and could break, causing personal

injury.

blade can be tested for balance by balancing

it on a round shaft screwdriver. Remove metal

from the heavy side until it balances evenly.

NOTE

It is recommended that the blade

always be removed from the adapter

for the best test of balance.

Reassembly

Before reassembling the blade and the blade

adapter to the unit, lubricate the spindle and the

inner surface of the blade adapter with light oil.

Lubricating the bolt holes, bolts and inner surface

of the nuts with light oil is also recommended, A 4

oz. plastic bottle of light oil lubricant is available.

Order part number 737-0170. Engine oil may also

be used.

When replacing the blade, be sure to install the

blade with the side of the blade marked "Bottom"

(or with part number) facing the ground when the

mower is in the operating position. Make certain

key is in place on the crankshaft.

Blade Mounting Torque

3/8" Dia, Bolt 375 in. lb. min., 450 in, lb. max,

5/16" Dia. Bolt 150 in. lb. min., 250 in. lb. max.

To insure safe operation of your unit, ALL nuts

and bolts must be checked periodically for correct

tightness.

FUEL FILTER

Your unit is equipped with a replaceable in-line

fuel filter. Replace filter whenever contamination

or discoloration is noticed. Order replacement

filter through your engine authorized service

dealer,

BELT REMOVAL AN D REPLACEM ENT

Disconnect the spark plug wire and

ground it against the engine.

Figures 24 throlAgh 28 are shown

with the unit tipped up for clarity.

It is not necessary to tip the unit

to remove the belts.

Removing the Deck Belt

1. Place the lift lever in the disengaged position.

2. Remove the two hex bolts (belt keepers) from

the engine pulley belt guard. See figure 24.

The

C.

15

Page 16

FIGURE 24.

3. Unhook the deck belt from the engine. pulley.

4. Place the lift lever in the engaged (all the way

forward) position.

5. Disconnect the six deck links by removing the

hairpin cotters and flat washers.

6. Slide the deck from beneath the lawn tractor.

7. Remove the belt guards at each deck pulley by

removing the hex bolts, lock washers and hex

nuts. See figure 25.

8. Remove and replace the belt, following the in-

structions in reverse order.

u

..."

Pulleys ,.f

,f"

~ .

~ .

Bolts

Lock Washers

Hex Nuts,

~

;)7

FIGURE 25.

Removing the Drive Belt

1. Follow steps 1 through 3 on removing the

deck belt.

2. Remove the two bolts, lock washers and nuts

on each side of the frame which hold the

engine pulley belt guard to the frame. See

figure 26.

,;/

f.

FIGURE 26.

Remove the engine pulley belt guard by slip.

ping it back and to the right. See figure 27.

FIGURE 27.

Remove the bolt, lock washer and nut which

hold the idler pulley to the idler bracket. See

figure 28.

NOTE

Upon reassembly, the hub side of

the idler pulley must be assembled

against the idler bracket.

3.

11M""",,

4.

16

Page 17

G.ound 10 F,.m.

1

I

~

,j II Vr

~

16 ,

\

/

_3

6,

---4

"I -' T~~ I I f

~

;. 0'

j ,Ic

r~1

~uu..d

I

14 I (

PARTS LIST FOR ELECTRICAL SYSTEM MODEL TMO.33902A

REF. PART DESCRIPTION REF. PART DESCRIP

1 725.0459 Circuit Breaker 9 725-0916 Ground Wire

2 725-0759 Spring Switch (Reverse 10 725-0222 Head Light

Safety) 11 725.0976 Ground Wire 7.25" Lg.

3 725-0975 Ground Wire 9.0" Lg. (Black (Black)

Neg.) 12 725-1042 Wire Harness

4 725-0514 12 Volt Battery 13 725-0925 Ammeter

5 725-0577 Safety Switch (Clutch) 14 725-0803 Safety Switch (P.T.a.)

6 725-0201 Ignition Key 15 725-0771 Solenoid

7 725-0267 Ignition Switch 16 725-0150 Electric Wire (Red Pas.)

8 725-0634 Light Switch

~-\ -:--~~

8

~~ 81ue

7 81ac

~ "."'4

~_.

I r

!;Ic'\,2;,,-:C,," ,..

12 I

Tecum.e" Eng;ne~'-:--"'",,[==J

===::~~-~ "'O". _

&\

SI.'le, 11 /1

Yellow (JI G,o"nO

Black /

B'ue

F,.me

10,

I.

10

TIONNO. NO. NO. NO.

G'~un.

r-E

I/~

9

2 GrounC 10

/ (0)

,~

£ 15

Rd ~

~ ~

~ .

n~l: ~r~

.Bloc.

~-G L ~ed ---

-~ ,

16 --ROd---:-? ~

0.

a;

""0

~~-~-'-'"~--~ I~ .

~?~~

9

!~ ;,,0".. -..,

10

"c 1

~~: ~ All

j&S Eng,ne

/ ~~; ~;l

,~=::~ ~

/ G..un~

11 to

St.,t.,

'W1 ~~2

G'oun.~

~,

/~

F..me

2

~,.a--<5

~13

~

~I~~

~

~~~~

~~~~

-~".

.

---

Page 18

Page 19

TM Q.33902A

T M Q.33886C 10 H.P. 38// LAWN TRACTORS

PARTS LIST FOR MODELS TMO.33902A AND TMO-33886C

\NO.

732-0414

14665 -615

3 '

712-0272

4

736-0463

5

723-0302

6

710-0473

7

723-0155

751-0172

8

9

726-0153

751-0173

726-0207

09960

712-0287

736-0329

725-0222

710-0118

723-0360

14781 -615

712-0113

14606

13863

14619

13862

710-0726

710-0524

PART

NO.

REF,

T!

10

11

12

13

14

15

16

17

18

19

22

23

24

25

26

27

28 710-0134

DESCRIPTION

Hood Spri ng

Hood

Hex Sems Nut #10-24 Thd.*

FI-Wash. .281" 1.0. x .62"

0.0. x .051

Hood Stop 7" Lg.

Truss Hd. Scr. #10-24 x 112"

Lg.*

Fuel Cap Gauge

Fuel Tank

Tie Strap

Fuel Line

Hose Clamp

Headlight Retainer

Hex Nut '/4-20 Thd.*

L-Wash. '/4" 1.0.*

Headlight

Hex Bolt 5/16-18 x .75" Lg.*

Foot Pad

Grille Ass'y.

Wing Nut '/4-20 Plastic

Lower Frame

Grille Mount Brkt.-L.H.

Front Pivot Brkt.

Grille Mount Brkt.-R.H.

Hex Wash. Hd. AB- Tap Scr.

5/16 x .75" Lg.

Truss Hd. Scr. '/4-20 x 1.75"

Lg.*

Carriage Bolt '/4 -20 x .62"

REF.I

~I

48

50

51

52

54

57

59

61

63

64 710-0258

67

69

70

71

72

73

75

79

80

81

82

PART

NO.

726-0222

14607

712-0267

736-0119

757-0264

710-0726

731-0561

726-0151

710-0227

749-0517

710-0255

14748

14749

15933

831-0692

746-0500

746-0504

725-0267

725-0201

712-0206

736-0921

710-0376

Lg.*

29

30

33

36

37

38

39

42

43

44

45

46

47

14604 -615

761-0169

710-0323

14671

14655

710-0118

14602

731-0708

711-0222

725-0514

14603

15823

725-0759

Running Board (R.H. & L.H.:

Blade Brake Ass'y.

Truss Mach. Scr. 5/16-18 x

.75" Lg.*

Fender Clamp

Fender (R.H. & L.H.)

Hex Bolt 5/16-18 x .75" Lg.*

R.H. Side Frame

Battery Cover

Battery Hold Down Rod

12-Y Battery

L.H. Side Frame

Transmission Panel

Reverse Safety Switch

732-0354

83

725-0634

84

725-0925

86

731-0511

88

738-0526

89

712-0287

90

91

710-0621

93

735-0144

712-032494

9596757-0272

736-0463

DESCRIPTION

Insulator Nut Plate

Hitch Plate

Hex Nut 5/16-18 Thd.*

L-Wash. 5/16" 1.0.*

Seat Ass'y.

Hex Wash. Hd. AB- Tap Scr.

5/16 x .62" Lg.

Tool Tray

Fastener

Truss Hd. Scr. #8 x .50"

Lg.

Hex Bolt 1/4-20 x .62"

Lg.*

Grille Support Rod (R.H. &

L.H.)

Truss Hd. Scr. 1/4-20 x .75"

Lg.*

R.H.-Grille Side Panel

L.H.-Grille Side Panel

Dash Panel Ass'y.

Throttle Control Box Ass'y.

Throttle Control Wire

(TMO-33902A)

Throttle Control Wire

(TM 0-33886C)

Ignition Switch

~gnition Key

Hex Nut V2-13 Thd.*

L-Wash. V2" 1.0.*

Hex Bolt 5/16-18 x 1.00"

Lg.*

Seat Spring

Light Switch

Ammeter

Molding Strip 27" Lg.

Running Board Rod

Hex Nut 1/4-20 Thd.*

Hex Bolt 5/16-18 x .75" Lg.*

Rubber Wash. V2" 1.0. x

1.0" 0.0.

Hex Sems Ins. L-Nut 1/4-20

Thd.

Trim Strip

FI-Wash. .296 1.0. x .62" 0.0.

*Common Hardware-May be purchased locally.

Important: Do not order by reference number

(Ref. No.).

NOTE: Specifications subject to change without

notice or obligation.

23

Page 20

Page 21

Page 22

Page 23

Page 24

Page 25

Page 26

Page 27

Page 28

Page 29

Page 30

Page 31

Page 32

HOW TO 08T AIN

REPLACEMENT PARTS AND SERVICE

The merchandise you have purchased from us has been

carefully engineered and manufactured under Wards rigid

quality standards and should give you satisfactory and

dependable operation. However, like all mechanical merchan-

dise, it may occasionally require adjustment, replacement

parts or maintenance. Should you ever need technical

assistance or parts, please contact or write your nearest Wards

Retail Store, Central Service Center, Catalog Store or Catalog

House.

Provide the following:

1. Model, serial number and all of the other data shown on the

model plate

2. The date and the Wards branch from which you purchased

your merchandise.

3. State briefly the trouble you are having.

4. Also give the part number or numbers as shown in the parts

list that came with the product.

Replacement Parts will be made available at current prices. If

requested, prices will be quoted in advance when not listed.

If you order parts by mail, you will pay the transportation

charges from the shipping point.

PART NO. 770-3439

UNIT MODEL NO.

UNIT SERIAL NO.

ENGINE MODEL NO.

TYPE NO.

CODE NO.

PRINTED IN U.S.A.

134-696-088

134-697-088

Loading...

Loading...