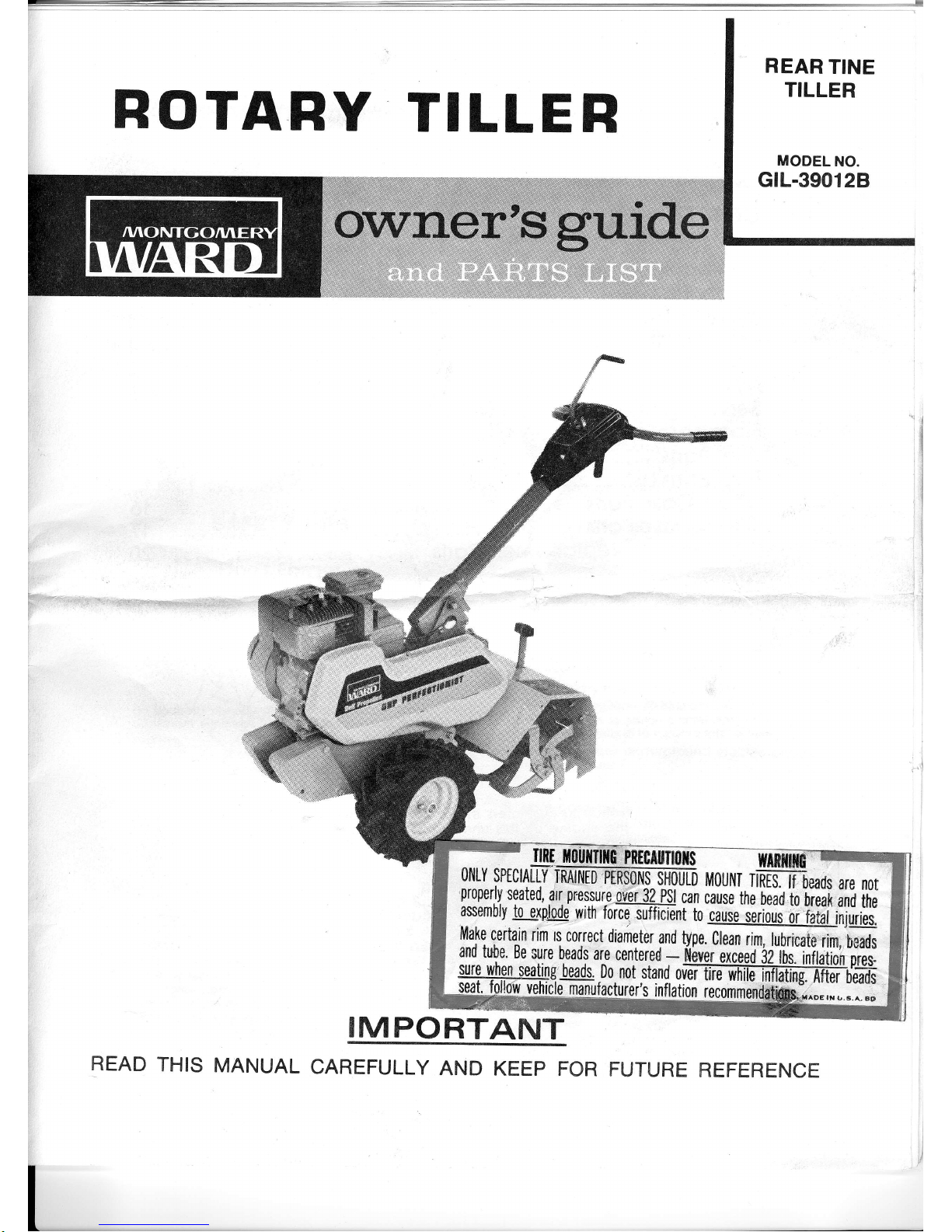

Montgomery Ward GIL-39012B Owner's Manual

REAR

TINE

TILLER

ROTARY

TILLER

-

ilnlu0uulllc,Pnftfl||r|0tw

orlly

sptctRmW

tvt0tltlr

Tifrffibeads

are

nor

pr'perlv

seated,

arr

pnssure

ovbr

34

pgi

can

ciuie

ttre

ilil

hilert

ffi

ih;

assembly

lq_a\pbde

with

forielullicient

to

artae

iiri,iii

ol

Tiiii'i'ijii.iiii.

Make

certain

rim

rs

correct

diarireter

and

type.G.n

rim,

lubricat0,,rim,

,beads

:l9"t9:8"*1,'"ll'^,^{t,ttt'$eno_fl

ilvgiecotaI$iildiil;hp]"ei:

beads.

.Do

not

stand

ovTrffi

tltffi

tatrng-ffiiffi

:

manufacturer's

inflation

recommendetis["-.^:::,

-.

__

IMPORTANT

READ

THIS

MANUAL

CAREFULLY

AND

KEEP

FOR FUTURE

REFERENCE

GONTENTS

Generol

Introduction

Sofety

Tips

3

3

4

4

5

6

I

11

Initiol

Servicing

Controls

ond

Operotion

Storting

Your

Rotory

Tiiler

Adiustments

Seruicing

Storoge

Tiller

Ports

ond

Mointenqnce

Tiller

Ports

List

12

&14

r3&15

Chqin

Cose

Ports

Choin

Cose

Ports

List

16

17

20

How

to

Order

Replocement

ports

WARNING

IMpoRTANT!

Record

the

unit model

number

ond

its

seriol

number

on the

bock

poge

of this

monuol

for

fulure

reterence

when

ordering

repoir ports

or identificotion

if

unit is

lost

or stolen.

The

monufocturer

reseryes

the

right

lo

mqke

chonges

on

ond

to

odd

improvements

upon

its

products

ol

ony

time

without

notice

or obtigttion.

The

monufqLturer

qiso

resewes

lhe

right

to

discontinue

monufoc-

lure

of ony

product

ot its

discretion

ot ony

iime

Nolice

to

customers

in

lhe

Slofe

of

Colifornio

_

The.engine

on

this

unit

is

trtoT

equipped

with

o

spork

orresting

muffler

USE

OR

OPERATION

OF

THIS

ENGINE

Oil

ANY

lqnEsT

GOVERED,

BBUSH

COVERED

OR

GRASS

COVERED

LAIIID

WITHOUT

A

STATE

APPROVED

SPARK

ABRESTER

IN

EFFECTIVE

WORKIITIG

OR.

DER

COiISTITUTES

A

VIOLATIOil

OF

THE

LAW

OF

THE

STATE

OF

CALIFOBITIIA.

GENERAL

INTRODUCTION

This

Owneis

Guide

hos

been

especiolly

prepored

lo

provide

the

informotion

needed

to

op'eiote

your

tii

ler

with

greoler

sotisfoction.

Reod

this'Owne/i

Guide

ond

the

engine

inslrucfions

corefully.

Be

sure

you

know

whot

the

controls

ore

for

ond

how

they

o[er-

gte:

Ilte

core

your

tiiler

requires

is

smoil,

but'imior_

tont.

Keep

it

cteon

ond

weit

tubricofed.

Witn

prcjber

core

ond

operotion,

os

exploined

in

this

monuof,

you

will

obtoin

long

ond

efficient

service.

This.tiller,

is

.shipped

completely

ossembled.

Afler

reootng

this

monuol

ond

servicing

tiller

the

tiller

is

reody

to

operote.

Informolion

regording

operolion

ond

mointenonce

of

the.engine

is

nol

included

in

this

monuol.

A

sep_

orole

instruction

monuol

is

included

with

your

liller

ond

should

be

consulted

for

oll informoiion

con_

cerning

engine

odjustmenls

ond

operolion.

O Inspect

work

oreo

ond

cleor

ony

objects

thot

ore

not

eorth

or mulch.

o

lmproper

use

of the

rotory

tiller

con resull

in in_

jury.

Give

complete

ond

undivided

ottention

fo

the

work

you

ore

doing.

O

Know

lhe

conlrols

ond

how

they

operote.

o

K.noy

how

to

stop

the

rotory

tiller

ond

engine

in_

stontly.

o

Disengoge

power

ond

stop

engine

before

cleon_

ing,

removing

obstocles,

or

mlking

odjuslment.

a

Keep

children

ond

pets

o

sofe

dislonce

owoy

from

rotory

tiller.

o

Do.

not

ollow

onyone

to

operote

rotory

tiller

with_

out

proper

instruction

ond

supervision.

O

Exercise

coution

to

ovoid

folling.

o

.?on't

sio.rt

the

gngine ond

tines

until

you

ore reocty

lo

slort

tilling.

Stop

the

engine

whenever

you

leov6

the

mochine.

O

Disengoge

clutch

before

slorting

engine.

Keep

honds,

feet

ond

clothing

owoy

from

power_driven

porfs.

Weor

odequoie

footweor

to

prevent

foof

InJury.

O

Keep rotory

tiller

in

good

operoting

condition

ond

keep

sofety

devices

in

ploce.

Do

not

till

neor

underground

electric

cobles

or ir_

rigotion

hoses.

Store

gosoline

in

o

sofe

contoiner.

Store

the

con_

toiner

in

o cool,

dry

ploce.

Not

in

the

house

or

near

heating

appliances.

Open

doors if

engine

is

run

in

goroge.

Exhoust

goses

ore

dongerous.

Fill

gos

tonk

outdoors.

Avoid

spillinq

oosoline.

Don't

fill

lonk

white

engine

is

running

dr inite

you

ore

smoking.

The

replocement

of

ony

porf

on

fhis

product

by

ofher

thon

the

monufocture/s

outhorizdd

reploce_

ment

p.orl

moy

odversely

offect

the

performonce,

durobility

or sofety

of

this

producl.

SAFETY

TIPS

Don't

Forget

thot

SAFETY

storts

with

you!

Yo.ur

rotory

tiller

wos

built

to

the

highest

slondords

in

the

industry.

Howeve_r,

a

rotary

tilleir

is

only

as

safe

as

the

operaror.

As

with

ony

ty-pe

of

powei

equip_

ment,

coretessness

or

error

on

th6

pon

dr the

opeiotbr

con

re.sulf

in injury.

pleose

reoci

ond

follo*

these

Insrructions gn

sofe

operotion

ond

be

cerloin

ony_

one

using

this

rotory

tiller

is

fomilior

with

fhese

sim_

ple

rules:

1.

2.

4.

INITIAL

SERVICING

Before

storling

the

engine,

refer

fo

the

engine

in-

sfructions.

Be

cerloin

lhe

the

engine

cronkcose

is

filled

with

the

proper

type

oil ond thot

oll

en-

gine

service

instructions

hove

been followed

com-

pletely.

Fill

fuel tonk

wilh

o cleon,

fresh,

leod-free

or leod-

ed

"regulor''

grode

of

outomotive

gosoline.

Do

not

mix

oil

with

gosoline.

All nuls

ond bolts

should

be

checked

ond

tight-

ened

during lhe

first

two

(2)

hours

of use.

periodic

checks

should

be mode

thereofler.

The

tires

ore normolly

over-infloted

for

shipping.

The

recommended

lire

pressure

is 20 lbs.

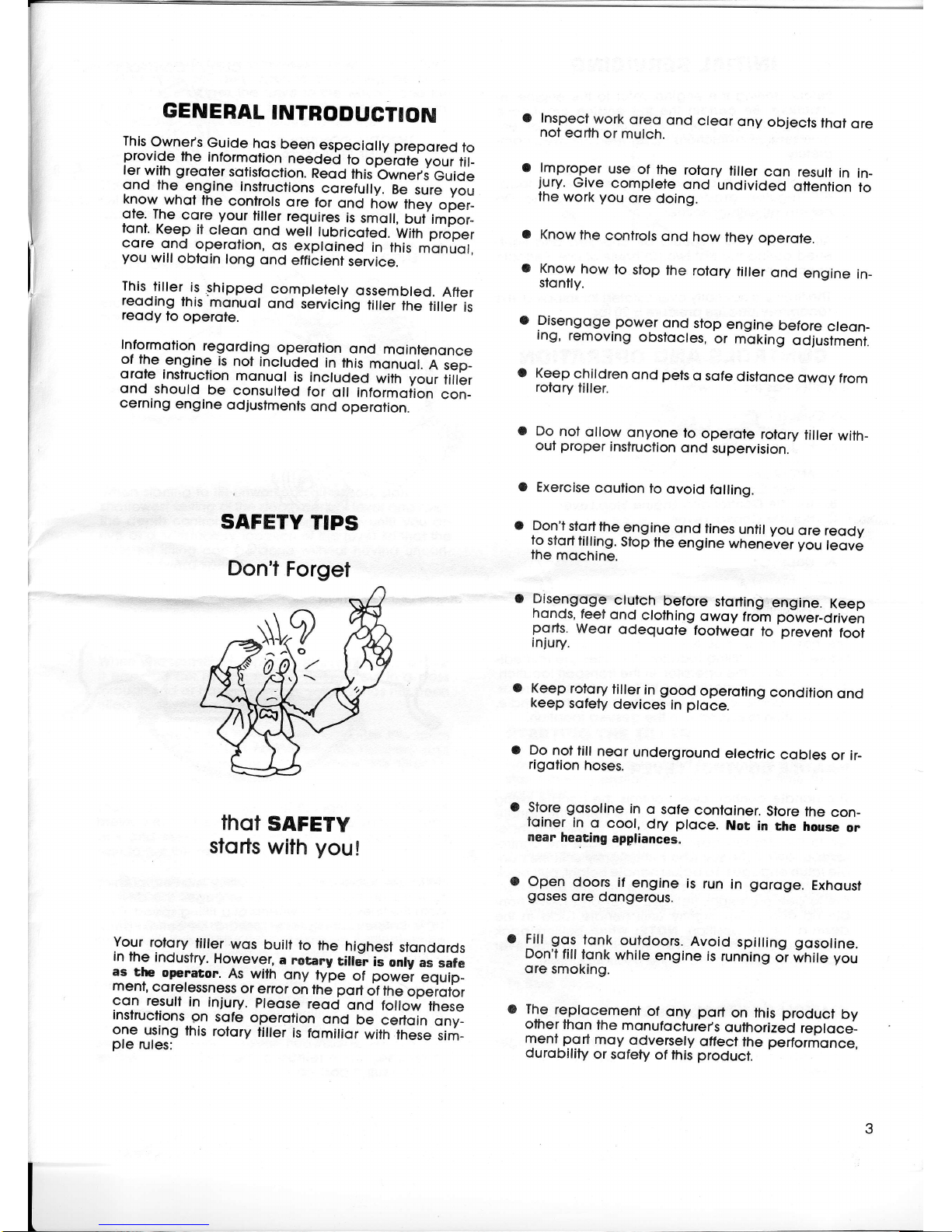

CONTBOLS

AND

OPERATION

This

liller

hos the

following

conlrols:

(Figure

1)

ON

ENGINE

A. Engine

Rewind

Storter

B.

Engine

Choke

ON HANDLE

BAR

A.

Clutch

Control Lever

B.

Throtlle

Control

ond Engine

Slop Lever

C. Hondle

Control

Lever

ON

TINE

SHIELD

A. Depth

Control Lever

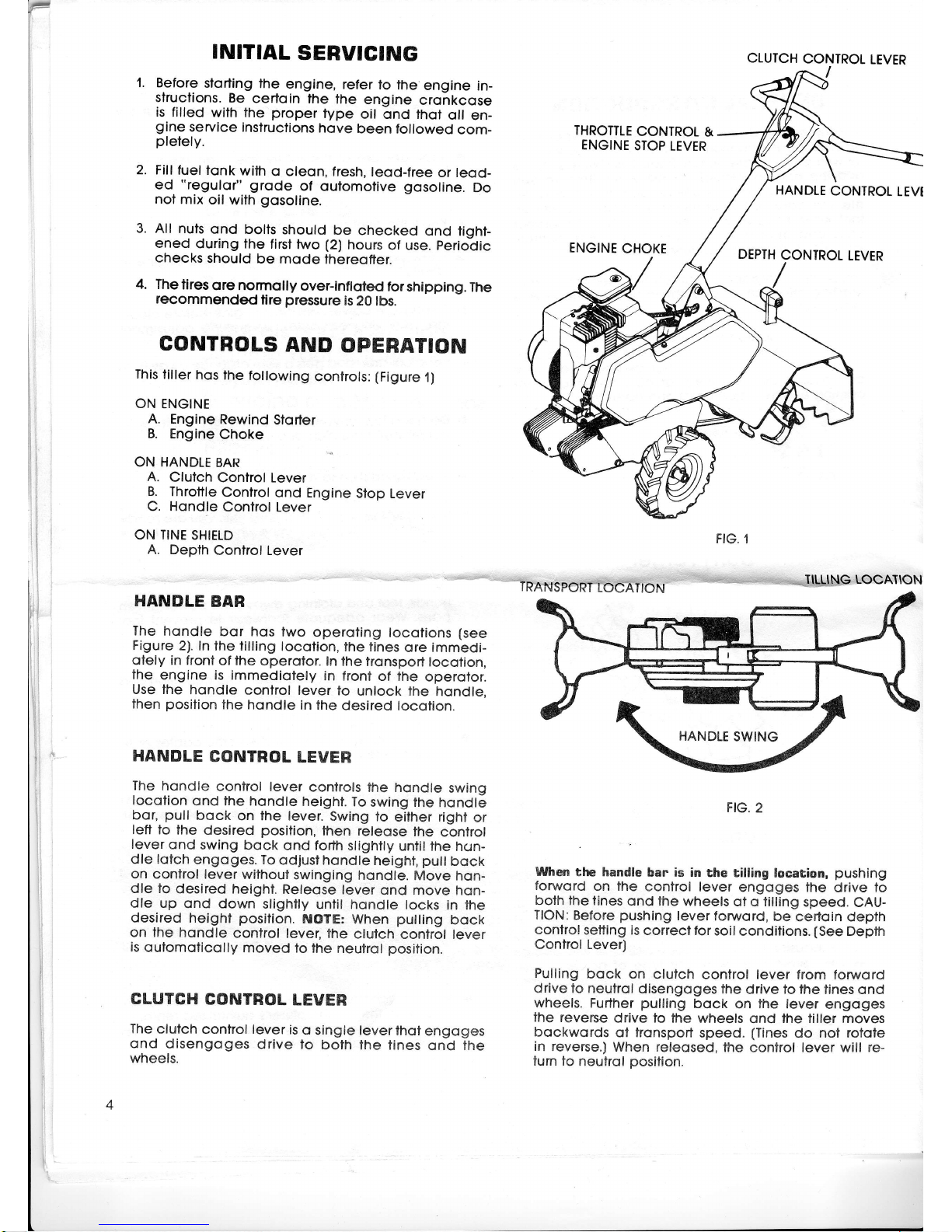

HANDLE

BAR

The

hondle

bor

hqs two

operoting

locotions

(see

Figure

2). In the

filling

locotion,

lhe tines

ore

immedi-

otely in front

of the

operotor.

In

lhe tronsport

locotion,

the

engine is

immediotely

in front

of fhe

operofor.

Use lhe

hondle

control

lever

lo

unlock the

hondle,

then

position

the

hondle

in the

desired

locotion.

HANDLE

CONTROL

LEVER

The hondle

control

lever

conlrols

the hondle

swing

locotion

ond

fhe hondle

height.

To

swing the

hqndle

bor,

pull

bock

on the lever.

Swing

lo

either righl

or

lett to

lhe

desired

posilion,

then releqse

the

conlrol

lever

ond swing

bock

ond forth

slighily

unfil

lhe h<.rn-

dle lofch

engoges.

To

odjusl hondle

heighl,

pull

bock

on control

lever

withoul

swinging

hondle.

Move hon-

dle to

desired

heighl.

Releose

lever

ond move

hon-

dle up

ond

down

slightly

unlil hondle

locks

in lhe

desired

height

position.

NOTE:

When

pulling

bock

on the

hondle

conlrol lever,

the

clutch

conirol lever

is

outomoticolly

moved

to

the neutrol

position.

CLUTCH

GONTROL

LEVER

The

clutch

control lever

is

o

single lever

thot

engoges

ond

disengoges

drive to

both

the tines

ond lhe

wheels.

FIG,2

When

the handle

bar is in

the tilling

location,

pushing

forwsrd

on

lhe

control lever

engoges the

drive fo

bolh

the fines

ond the

wheels

ot o tilling

speed.

CAU-

TION:

Before

pushing

lever

forword,

be

cerloin depih

control

setting is

correcf for

soil

conditions.

(See

Depih

Confrol Lever)

Pulling

bock

on clulch

control lever

from forword

drive lo

neutrol

disengoges

the drive to

the tines ond

wheels.

Further

pulling

bock

on lhe lever

engoges

lhe reverse

drive to the

wheels

qnd

the tiller moves

bockwords

ot fronsport

speed.

(Tines

do not

rotote

in reverse.)

When releosed,

the

confrol lever will

re-

lurn to

neutrol

position.

tl

j

i

I

CLUTCH

CONTROL

LEVER

THROTTLE

CONTROL

&

ENGINE

STOP

LEVER

HANDLE

CONTROL

LEVI

ENGINE

CHOKE

DEPTH

CONTROL

LEVER

When

the handle

bar is in

tnansport

location,

fhe

clufch

control

lever

will

only

operofe

by

pulling

the

lever

bock.

This

engoges

the

drive to

the

wheels

ond the

tiller moves

forword

of tronsporl

speed.

When

re-

leosed,

fhe

control lever

refurns

to

neulrol.

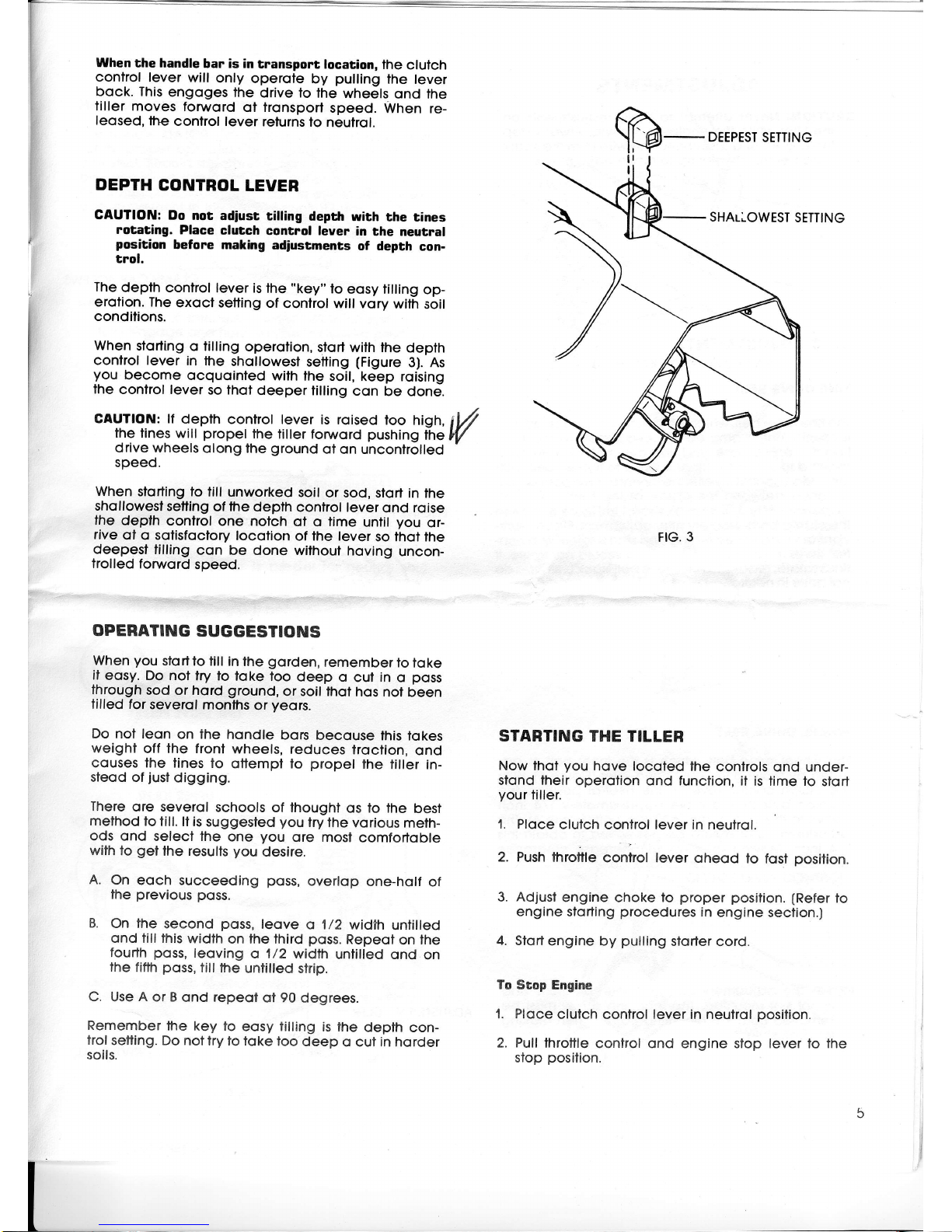

DEPTH

CONTROL

LEVER

GAUTION:

Do nor

adiust

rilling

depth

wfth

rhe tines

rotatang.

Place

clutch

control leyer

in

the neutral

position

before

makhrg

adiustments

of depth

con-

trol.

The

depth

conirol lever

is the

"key"

to

eosy tilling

op-

erotion. The

exoct setting

of

control will

vory

wilh

soil

condilions.

When

storling

o tilling

operotion,

stort with the

depth

confrol lever

in

lhe

shollowesf

setting

(Figure

3).

As

you

become

ocquointed

with

the soil,

keep roising

the

control lever

so thof deeper

tilling

con be done.

CAUTfON: ff

depth

control lever

is roised

loo

high,

iV

the

lines will

propel

the

tiller fonruord

pushing

the

lV

drive wheels

olong

the

ground

of on uncontrolled

speed.

When

sforting to till

unworked

soil

or sod,

sfort in the

shqllowest

setting

of fhe

depth

confrol lever

ond

roise

lhe

depth

control

one notch

ol o time

unlil

you

or-

rive

ol o

sofistocfory

locolion

of

the

lever

so thot the

deepest

tilling

con

be done

without hoving

uncon-

frolled

fonvord

speed.

OPEBATING

SUGGESTIONS

When

you

slortfo till

in the

gorden,

remember

to

toke

it

eosy.

Do

nol lry to

loke too

deep o

cul

in

o

poss

through

sod

or hord

ground,

or soil thot

hos

nol been

tilled for

severol

monfhs

or

yeors.

Do nol leon

on the hondle

bors

becouse

fhis tokes

weight

off the front

wheels, reduces

troction,

ond

couses the tines

to

ottempl

to

propel

the

filler in-

steod of

just

digging.

There

ore severol

schools of thought

os to the

best

method

to

till. lt is

suggested

you

lry

the vorious

meth-

ods ond

select the

one

you

ore

most

comfortoble

with lo

get

lhe resulfs

you

desire.

A.

On eoch succeeding

poss,

overlop

one-holf

of

the

previous

poss.

B.

On the

second

poss,

leove

o 1/2

width

untilled

ond till lhis

width

on lhe third

poss.

Repeot

on ihe

fourth

poss,

leoving

o 1/2 width

untilled ond

on

the

fiflh

poss,

tillthe

untilled

strip.

C. Use A or B

ond repeoi

ot 90

degrees.

Remember

the

key

to eosy tilling

is the

depth

con-

trol

setting. Do

nottry lo toke

loo

deep

o cut in horder

soils.

FIG.

3

STARTING THE

TILLER

Now thot

you

hove locoted

the

controls ond

under-

sfond lheir operotion

ond function, il is

time to

stort

your

tiller.

1. Ploce

clutch

confrol lever in neulrol.

2. Push

throttle

control lever

oheod

to

fosl

position.

3. Adjust

engine

choke

lo

proper posilion.

(Refer

to

engine slorting

procedures

in

engine seclion.)

4.

Slort

engine by

pulling

slorler

cord.

To Stop

Engine

1. Ploce

clutch

control

lever

in neutrol

position.

2. Pull

fhrottle

control ond engine

slop

lever

to the

stop

posilion.

SHAULOWEST

SETTING

ADJUSTMENTS

CAUTION:

Never

ofiempt

to

moke-odjustments

on

fhe

liller

while

the

engine

is

running.

Alwoys

stop

lhe

engine

ond

disconnecl

the

wirelrom

tn6

spoit

plug

before

ottempling

to

moke

odjustments.

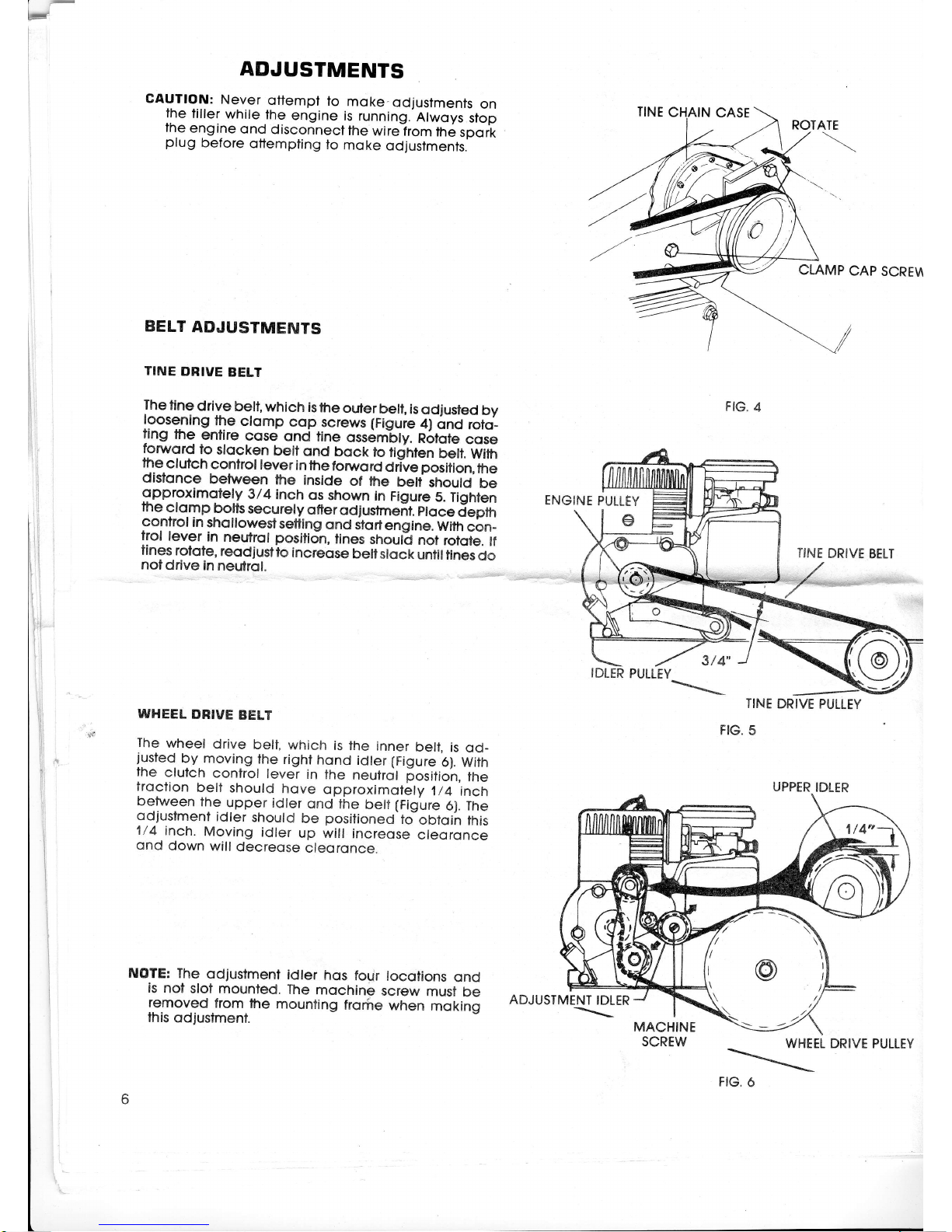

BELT

ADJUSTMENTS

TINE

DBIVE

BELT

The

tine

drive

belt,

which

is

the

outer

be[,

is

odjusted

by

l9_9s9ning

the

ctomp

cop

screws (Figuie

4)

onct

roto_

ang

me

enflre

cose

qnd

tine

ossembly.

R6lote

cose

fonrord

to

stocken

belt

ond

bock

to

fidnten

belt,

With

the

clutch

control

lever

in

the

forword

drlve

position,

the

disfonce

between

the

inside

of fhe

betf

shoutd

be

$Pproximotely

3/4

inch

os

shown

in

Figure

5.

Tighten

the

clo.m

p

bolts

secu

rety

ofter

od

j

ustmeit.

eto

ce

jepm

control

in

shollowestsetting

ond

itortensine.

With

cbn_

trol

lever

in

neutrol

position,

tines

shoult

not

rofote.

lf

flnes

rotote,

reodjustto

increqse

bellslock

untiltines

do

notdrive

in

neutrol.

WHEEL

DRIVE

BELT

The

wheel

drive

belt,

which

is the

inner

beli,

is

od_

justed

by. moving

the

right

hond

idter

(Figure

6).

With

the

clutch

confrol

lever

in

the

neutrcjl

[ositioh,

tfre

troclion

belt

should

hove

opproximoiely

1/4

inch

between

the

upper

idler

ond

the

belf

(Figure

6). The

qdiustment

idler

should

be

positioneO-to

oOtqih

this

1/4

inch.

Moving

idler

up will

increose

cteoronce

ond

down

will

decreose

cleoronce.

ENGINE

PULLEY

c

ADJUSTMENT

IDLER

\

TINE

DRIVE

PULLEY

FIG.

5

CLAMP

CAP

SCRE\A

TINE

DRIVE

BELT

FIG.

4

3t4

NOTE:

The

odjustment

idler

hos

four

locotions

ond

is

nol

sloi

mounted.

The

mochine

screw

must

be

removed

from

the

mounting

frorire

when

moking

this

odjustmenl.

MACHINE

SCREW

WHEEL

\

FIG.

6

ROTATE

UPPER

IDLER

DRIVE

PULLEY

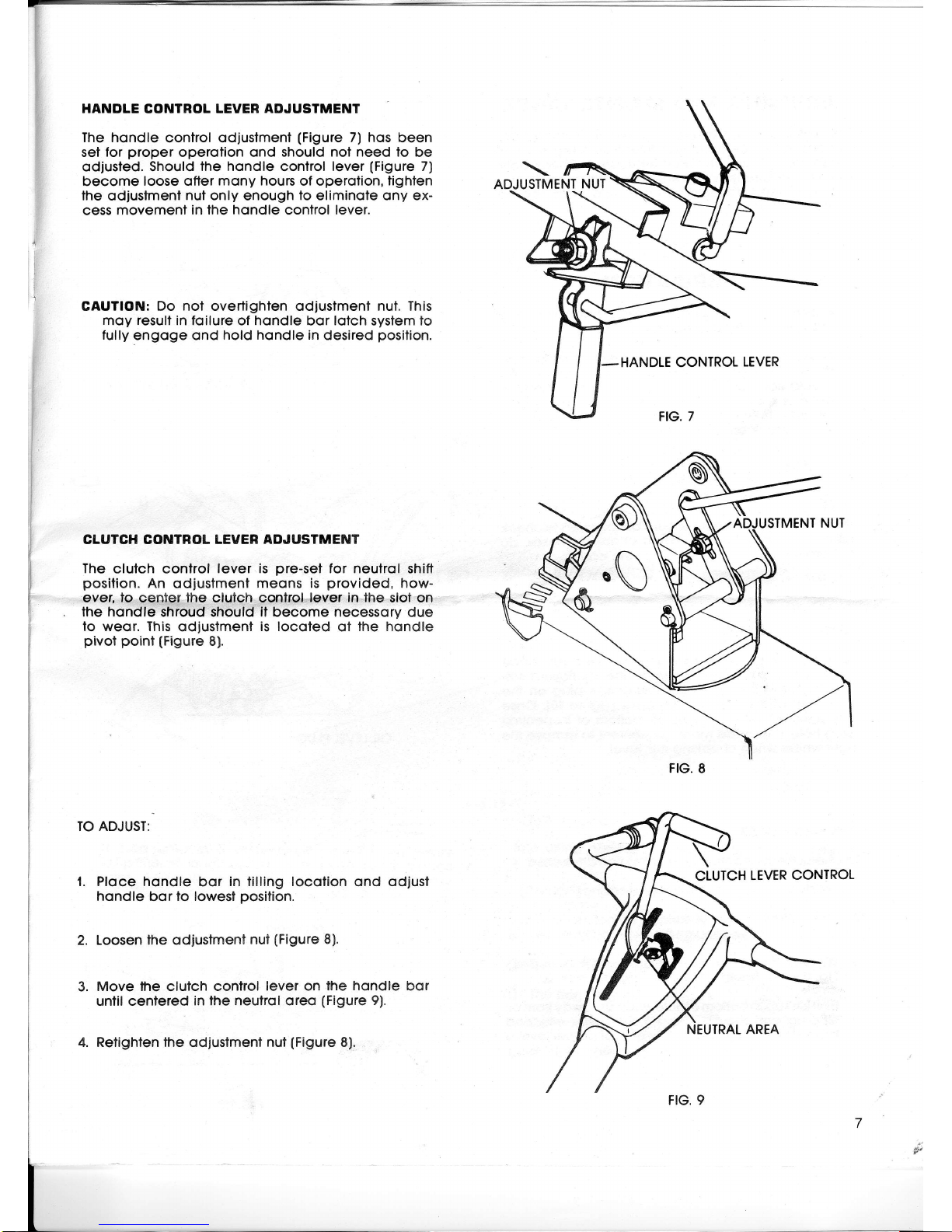

HANDLE CONTROL LEVER

ADJUSTMENT

The hondle

control odjustmenl

(Figure

7) hos been

set

for

proper

operotion ond

should not need to

be

odiusfed.

Should the hondle control lever

(Figure

7)

become

loose ofter

mony hours

of operolion,

tighlen

the

odjustmenl

nul only

enough

lo eliminote ony ex-

cess movement

in the hondle confrol lever.

CAUTION: Do nol overtighlen odjuslmenf nut. This

moy

result

in foilure of hondle bor lotch system lo

fully

engoge ond

hold hondle in

desired

position.

CLUTCH CONTROL LEVER

ADJUSTMENT

The

clutch control

lever is

pre-set

for neutrol

shitt

position.

An odjustmenf

meons is

provided,

how-

ever, lo center the clulch control

lever in

lhe slot on

the hondle shroud should it become necessory

due

to weor. This

odiustmenl

is locoted

ot

fhe hondle

pivol point

(Figure

8)

TO ADJUST:

1. Ploce hondle

bor

in litling locotion ond odjusl

hondle bor to lowesf

posifion.

2. Loosen

the odiustment

nut

(Figure

8).

3.

Move lhe

clutch

control

lever on

the hondle

bor

unfil cenfered

in lhe neutrol oreo

(Figure

9).

4. Retighten fhe odjustmenl nut

(Figure

8).

ADJUSTMENT

NUT

CLUTCH

LEVER CONTROL

NEUTRAL AREA

Loading...

Loading...