Montesa COTA 4RT 2005 User Manual

Important

This motorcycle is designed and constructed as an operator-only model. The motorcycle load limit and seating configuration do not safety permit the carrying of a

passenger.

Read this manual carefully.

This manual should be considered as a permanent part of the motorcycle and should remain with the motorcycle when resold.

Safety Messages

Your safety and the safety of others is very important. We have provided important

safety messages in this manual and on the COTA 4RT. Please read these messages

carefully.

A safety message alerts you to potential hazards that could hurt you or others.

Each safety message is preceded by a safety alert symbol and one of three

words, DANGER, WARNING, or CAUTION.

These mean:

You WILL be KILLED or SERIOUSLY HURT if you

don’t follow instructions.

You CAN be KILLED or SERIOUSLY HURT if you

don’t follow instructions.

You CAN be HURT if you don’t follow instructions.

Each message tells you what the hazard is, what can happen and what you can do

to avoid or reduce injury.

Damage Prevention Messages

You will also see other important messages that are preceded by the word

NOTICE.

This word means:

Your COTA 4RT or other property can be damaged if you

don’t follow instructions.

The purpose of these messages is to help prevent damage to your COTA 4RT,

other property, or the environment.

NOTICE

!

DANGER

!

WARNING

!

CAUTION

MONTESA COTA 4RT

Owner’s Manual

All information in this publication is based on the latest product information available at the time of approval for printing.

MONTESA HONDA, S.A. reserves the right to make changes at any time without notice and without incurring any obligation.

No part of this publication may be reproduced without written permission.

Contents

1. Operating Instruction

Fuel 1-1

Coolant 1-1

Basic Operation 1-1

Operating Mode 1-2

Controls 1-3

2. Service Data

Specifications 2-1

Service Data 2-2

To rque Values 2-5

Tools 2-7

Lubrication & Seal Points 2-8

Cable & Harness Routing 2-11

3. Service And Maintenance

Maintenance Schedule 3-1

Pre-ride Inspection 3-1

Warming-up Inspection 3-2

Ride Inspection 3-2

After Ride Inspection 3-2

Replacement Parts 3-2

Fuel Line 3-3

Air Cleaner 3-3

Spark Plug 3-4

Valve Clearance 3-4

Engine Oil/Oil Filter 3-6

Engine Idle Speed 3-8

Transmission Oil 3-8

Coolant 3-9

Clutch System 3-10

Exhaust Pipe And Muffler 3-10

Drive Chain 3-11

Drive Chain Slider 3-11

Drive/Driven Sprockets 3-12

Brake Fluid 3-13

Brake Pad Wear 3-14

Brake System 3-14

Handlebar And Steering Head Bearings 3-15

Wheels And Tires 3-15

Front Suspension 3-16

Fork 3-16

Rear Suspension 3-17

Cleaning 3-18

Storage 3-18

4. Engine Servicing

Oil Pressure Relief Valve 4-1

Oil Pump 4-1

Fuel Line Inspection 4-4

Fuel Tank/Fuel Pump 4-6

Injector 4-9

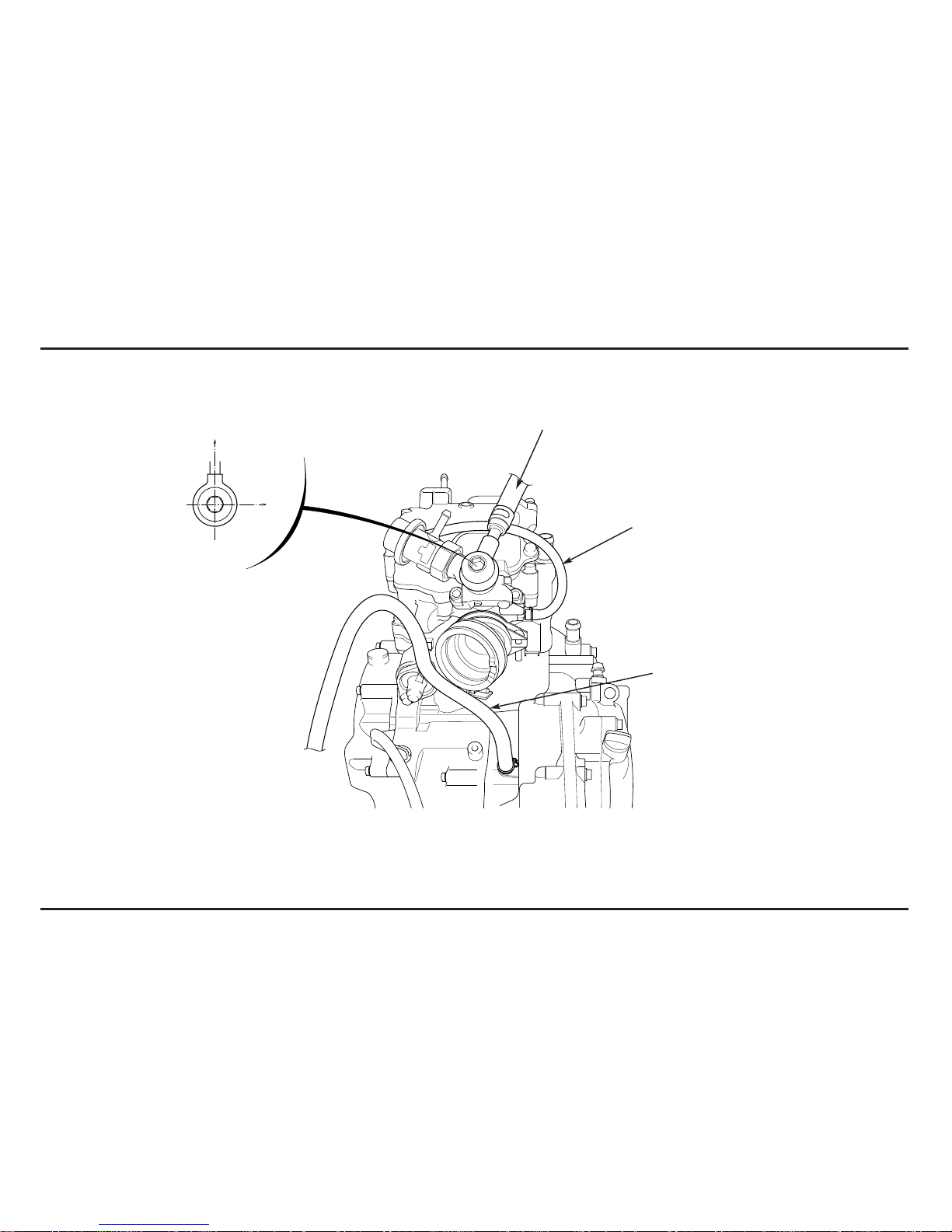

Throttle Body 4-10

Water Seal And Bearing Replacement 4-12

Radiator Removal/Installation 4-14

Engine Removal/Installation 4-15

Cylinder Compression 4-17

Cylinder Head Cover/Camshaft Removal 4-17

Cylinder Head Removal 4-20

Cylinder Head Disassembly 4-22

Cylinder Head Inspection 4-23

Valve Guide Replacement 4-24

Valve Seat Inspection/Refacing 4-25

Cylinder Head Assembly 4-28

Cylinder/Piston 4-29

Cylinder Head Installation 4-34

Camshaft/Cylinder Head Cover Installation 4-35

Right Crankcase Cover 4-37

Clutch Slave Cylinder 4-38

Clutch 4-40

Kickstarter 4-43

Gearshift Linkage 4-44

Left Crankcase Cover 4-46

Flywheel 4-49

Crankcase Separation/Disassembly 4-51

Crankshaft/Transmission Inspection 4-53

Crankcase Bearing Replacement 4-54

Transmission Assembly 4-55

Crankcase Combination 4-56

5. Frame Servicing

Front Wheel 5-1

Fork 5-3

Steering Stem 5-12

Rear Wheel 5-15

Shock Absorber 5-16

Shock Linkage 5-18

Swingarm 5-19

Brake Pad Replacement 5-23

Front Brake Caliper 5-24

Rear Brake Caliper 5-25

Front Master Cylinder 5-26

Rear Master Cylinder 5-27

Brake Pedal 5-27

Clutch Master Cylinder 5-28

6. Electrical Servicing

Charging System Inspection 6-1

Ignition System Inspection 6-3

PGM-FI System Inspection 6-5

PGM-FI 6-6

PGM-FI Self-diagnosis Malfunction Indicator

Lamp (MIL) Failure Codes 6-7

Bank Angle Sensor Inspection 6-8

Engine Stop Switch Inspection 6-9

Cooling Fan System Inspection 6-9

Wiring Diagrams 6-11

To The New Owner

By selecting a MONTESA COTA 4RT as your new

machine, you have placed yourself in a distinguished

family of owners and riders.

The COTA is a high performance trial motorcycle

utilizing the latest trial technology. This motorcycle is

intended for competition use by experienced riders only.

This new trialer was designed to be as competitive as

possible. But motorcycle trial is a physically demanding

sport that requires more than just a fine racing machine.

To do well, you must be in excellent physical condition

and be a skillful rider. For the best possible results, work

diligently on your physical conditioning and practice

frequently.

The purpose of this Manual is to help ensure that you

obtain the greatest possible satisfaction from your new

COTA trialer.

Importance Of Proper Preparation

Proper pre-competition preparation and regular service

is essential to rider safety and the reliability of the

motorcycle. Any error or oversight made by the

technician during preparation or servicing can easily

result in faulty operation, damage to the machine, or

injury to the rider.

Parts Availability

Orders for the parts tend to be concentrated during the

season, so you need to plan your parts orders carefully.

To prevent delays in shipment, place orders on regularly

replaced and fast-wearing parts well ahead of the season

(see page 3-2).

How To Use This Manual

The purpose of this Owner’s Manual is to help ensure

that you obtain the greatest possible satisfaction from

your new COTA trialer; satisfaction with the performance

of the motorcycle, and through success in competition.

If you plan to do any service on your COTA, section 3

describes standard maintenance and sections 4 through

6 contain in information on repair, disassembly,

assembly and special tools.

Follow the Maintenance Schedule recommendation

(page 3-1) to ensure that your COTA is always in peak

operating condition.

Memo

1. Operating Instructions

1-1

(1) BREATHER HOSE (2) FUEL TANK CAP (1) RADIATOR CAP

Fuel

Gasoline: Premium unleaded gasoline (commercially

available unleaded; pump octane number 91

or higher)

Fuel tank capacity: 2.0 liter (0.53 US gal, 0.44 Imp gal)

Disconnect the fuel tank breather hose clamp from the

clutch hose.

Turn the fuel tank cap counterclockwise, then remove the

cap.

Gasoline is highly flammable and is explosive.

You can be burned or seriously injured when

refueling.

• Stop engine and keep heat, sparks, and flame

away.

•Refuel only outdoors.

•Wipe up spills immediately.

Install the fuel tank cap by turning it clockwise.

Install the breather hose clamp onto the clutch hose.

Coolant

The engine of COTA is a water-cooled type. In order to

provide adequate cooling, it is essential that the radiator

be filled with coolant up the proper level (See pag. 3-9).

Coolant: 50/50 Mixture of Coolant and Distilled Water

Removing the radiator cap while the engine is hot

will allow the coolant to spray out, seriously scalding

you.

Always let the engine and radiator cool down before

removing the radiator cap.

When filling the coolant system, be sure to bleed air

completely. If not, the system cannot be sufficiently filled

and will cause overheating.

(1)

Basic Operation

Starting The Engine

Your COTA exhaust contains poisonous carbon

monoxide gas. High levels of carbon monoxide can

collect rapidly in enclosed areas such as a garage. Do not

run the engine with the garage door closed. Even with

the door open, run the engine only long enough to move

your COTA out of the garage.

Cold Engine Star

ting

1. Shift the transmission into neutral.

2. With the throttle fully closed, operate the kickstarter.

Starting from the top of the kickstarter stroke, kick

through to the bottom with a rapid, continuous

motion.

3. After the engine starts, run it for a few minutes,

“blipping” the throttle, until it warms up enough to

idle.

Do not start the engine with the transmission into gear

while squeezing the clutch lever, so the motorcycle will

move forward.

(1) KICKSTARTER PEDAL

(1)

NOTICE

NOTICE

!

WARNING

!

WARNING

(1)

(2)

Operating Instructions

1-2

(1) ENGINE STOP BUTTON

When you shift the transmission into gear, apply front

brake to prevent the motorcycle move forward.

Stopping The Engine

1. Shift the transmission into neutral.

2. Push the engine stop button until the engine stops

completely.

Break-In Procedure

New Motor

cycle

Following proper break-in procedure helps ensure that

the most important and expensive components on your

new motorcycle will provide maximum performance and

service life. (Also follow proper break-in procedure for a

newly rebuilt engine.)

When riding a new motorcycle, operate the motorcycle

for the first 20 minutes using not more than half throttle

and shifting gears so that the engine does not lug:

Reconditioned Motor

cycle

• After replacing the cylinder and crankshaft, operate

the motorcycle 20 minutes observing the same

cautions as for a new motorcycle.

•When the piston, piston ring, gears, etc. are replaced,

they must be broken in observing the first 30 minutes

using not more than half throttle and shifting gears so

that the engine does not lug:

(1)

(1) UPPER LEVEL LINE (1) ADJUSTER (2) LOCK NUT (1) DUST COVER (2) LOCK NUT (3) ADJUSTER

(A) DECREASE (B) INCREASE

Controls

Clutch

Your COTA has a hydraulically actuated clutch. There are

no adjustments to perform but the clutch system must

be inspected periodically for fluid level and leakage.

If the control lever free play becomes excessive and the

motorcycle creeps or stalls when shifted into gear, or if

the clutch slips, causing acceleration to lag behind

engine speed, there is probably air in the clutch

hydraulic system and it must be bled out.

Clutch Lever

The clutch lever free play can be adjusted by turning the

adjuster.

Free play must be adjusted to provide 0.1 – 1.4 mm

(0.004 – 0.055 in) clearance between the end of the

adjuster and the clutch master cylinder piston.

To increase free play, turn the adjuster clockwise, then

tighten the lock nut securely.

If the clutch lever free play exceeds 30 mm (1.2 in) even

though the end of the adjuster and the clutch master

cylinder piston is adjusted to the minimum of 0.1 mm

(0.004 in), there is probably air in the clutch system and

it must be bled.

Do not adjust the end of the adjuster and the clutch

master cylinder piston below 0.1 mm (0.004 in).

Throttle Grip

Thr

ottle Grip Free Play

Standard throttle grip free play is approximately 3 mm

(0.12 in) of grip rotation.

Adjustment is made with the integral throttle cable

adjuster.

Slide the dust cover off from the integral cable adjuster.

Turning the adjuster in direction “A” will decrease free

play and turning it in direction “B” will increase free

play. Tighten the lock nut after adjustment.

Operate the throttle grip to ensure that it functions

smoothly and returns completely in all steering position.

Operating Instructions

1-3

(1)

(2)

(1)

(1)

(3)

(2)

(A)

(B)

NOTICE

Operating Instructions

1-4

(1) LOCK NUT (2) ADJUSTING BOLT

(A) RAISE THE PEDAL HEIGHT

(B) LOWER THE PEDAL HEIGHT

(1) HANDLEBAR

Brake Pedal Height

The brake pedal height can be adjusted to the rider’s

preference.

To adjust the rear brake pedal height:

1. Loosen the push rod lock nut and brake pedal

adjusting bolt lock nut. Then turn the both adjusting

bolts in direction “A” to raise the pedal, or in direction

“B” to lower it.

2. Tighten the lock nuts at the desired pedal height.

3. After adjustment, check the brake pedal free play at

the top of the pedal.

Make sure that the clearance between the front

adjusting bolt and frame is at least 1 mm (0.04 in).

Handlebar Position, Width And Shape

Position the handlebar so that gripping the bar and

operating the controls is comfortable while both seated

and standing, while riding straight ahead and turning.

Handlebar width can be trimmed with a hacksaw to

better your particular shoulder width and riding

preference. Think this though carefully and cut off just a

small amount at a time from both side equally. It is

obviously much easier to make the handlebar narrower

than it is to add material.

Chamfer the edges to remove burrs and other

irregularities or roughness after shaping.

An alternate handlebar shape. through varying rise or

rearward sweep dimensions, will provide further

adjustment to riding position and may better suit your

particular body size or riding style. Each of the

ergonomic dimensions of the motorcycle were

determined to suit the greatest possible number of riders

based on an average size rider.

(1)

(2)

(B)

(1)

Front Brake Lever

The front brake lever free play can be adjusted by

turning the adjuster.

Free play must be adjusted to provide 0.1 – 1.4 mm

(0.004 – 0.055 in) clearance between the end of the

adjuster and the front brake master cylinder piston.

To increase free play, turn the adjuster clockwise, then

tighten the lock nut securely.

If the brake lever free play exceeds 30 mm (1.2 in) even

though the end of the adjuster and the front brake

master cylinder piston is adjusted to the minimum of 0.1

mm (0.004 in), there is probably air in the brake system

and it must be bled.

Do not adjust the end of the adjuster and the front brake

master cylinder piston below 0.1 mm (0.004 in).

(1) ADJUSTER (2) LOCK NUT

(1)

(2)

(A)

(B)

(A)

(2)

(1)

NOTICE

NOTICE

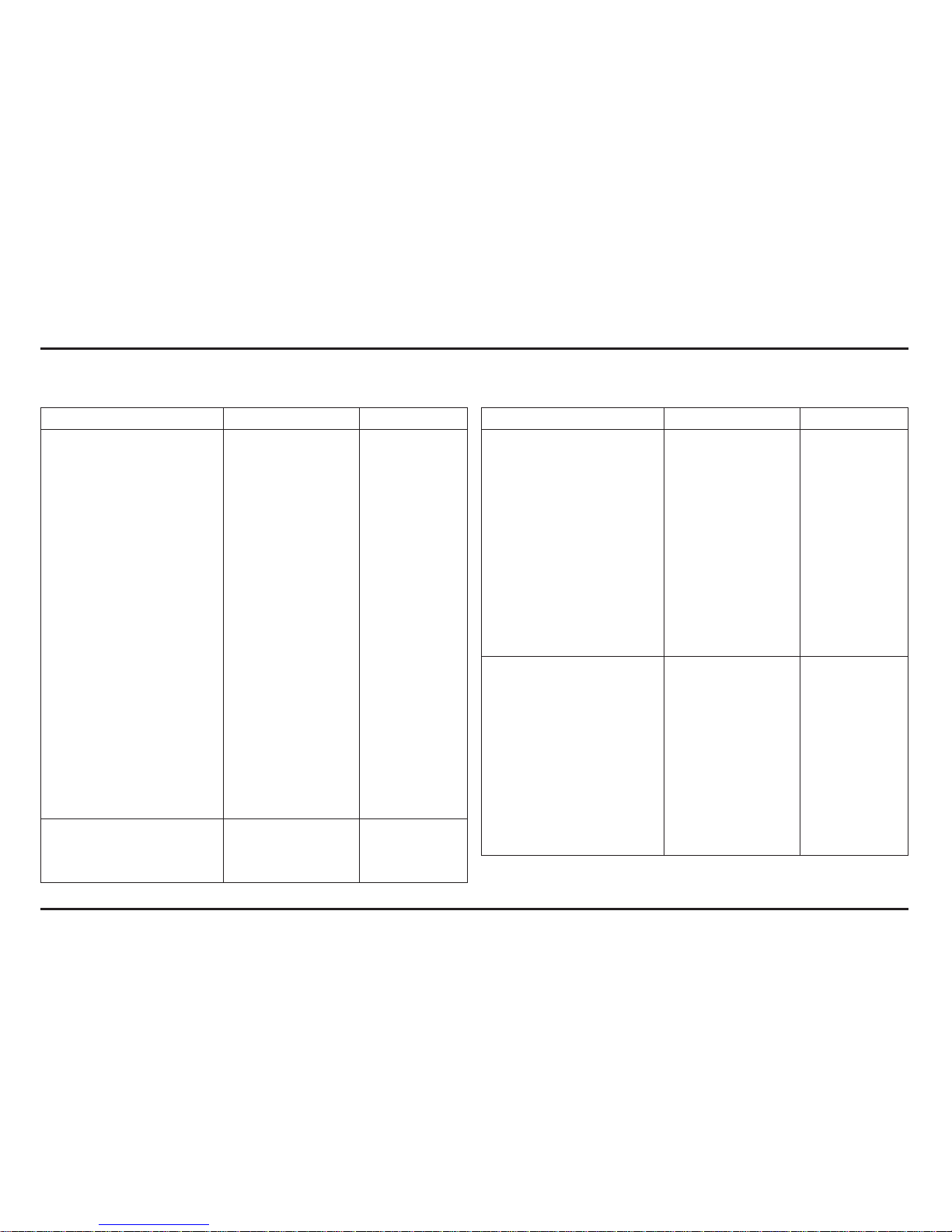

2. Service Data

2-1

Specifications

Item Specification

Dimensions

Overall length 2,016 mm (79.4 in)

Overall width 830 mm (32.7 in)

Overall height 1,130 mm (44.5 in)

Wheelbase 1,321 mm (52.0 in)

Seat height 650 mm (25.6 in)

Ground clearance 335 mm (13.2 in)

Frame

Type Aluminum twin tube

Front suspension Telescopic

Rear suspension Swingarm

Front tire MICHELIN TRIAL 2.75 – 21 TT

Rear tire MICHELIN TRIAL 4.00 R18 TL (tubeless)

Front brake, diameter Single disc, 185 mm

Rear brake, diameter Single disc, 150 mm

Fuel capacity 2.0 liter (0.53 US gal, 0.44 Imp. gal)

Caster angle 23˚ 00’

Trail length 63 mm (2.5 in)

Engine

Type Liquid cooled 4–stroke engine

Cylinder arrangement Single cylinder, 3.5˚ inclined from vertical

Bore and stroke 76.5 x 54.2 mm (3.01 x 2.13 in)

Displacement 249.1 cm

3

(15.2 cu-in)

Compression ratio 10.5 : 1

Valve timing

Intake valve opens 6˚ BTDC (at 1.0 mm lift)

Intake valve closes 27˚ ABDC

Exhaust valve opens 30˚ BBDC

Exhaust valve closes 1˚ ATDC

Lubrication system Forced pressure and wet sump

Starting system Primary kickstarter

Item Specification

Fuel System

Type PGM-FI

Identification number GQP0

Throttle bore 28 mm (1.1 in)

Drive Train

Clutch operating system Hydraulic operated

Clutch type Wet, multi-plate

Transmission 5 speed constant mesh

Primary reduction 3.167 (57/18T)

Gear ratio 1st 2.800 (42/15T)

2nd 2.385 (31/13T)

3rd 2.000 (30/15T)

4th 1.273 (28/22T)

5th 0.815 (22/27T)

Final reduction 4.100 (41/10T)

Gearshift pattern 1 – N – 2 – 3 – 4 – 5

Electrical

Alternator Triple phase output alternator

Ignition system PGM-IGN

Regulator type SCR shorted/triple phase, full wave rectification

Service Data

2-2

Service Data

Item Specification

Lubrication

Specified engine oil Honda Ultra S9 4-stroke motorcycle oil or

Repsol 4T oil

SAE 10W-40

Engine oil capacity

after draining 0.41 liter (0.43 US qt, 0.36 Imp qt)

after oil filter change 0.44 liter (0.46 US qt, 0.39 Imp qt)

after disassembly 0.60 liter (0.63 US qt, 0.53 Imp qt)

Specified transmission oil ELF HTX740

Transmission oil capacity

after draining 0.54 liter (0.57 US qt, 0.48 Imp qt)

after disassembly 0.57 liter (0.60 US qt, 0.50 Imp qt)

Fuel System

Throttle body identification No.

GQP0A

Throttle grip free play 3 mm (0.1 in)

Engine idle speed 1,800 ± 100 min

-1

(rpm)

Fuel pressure 260 kPa (2.65 kgf/cm

2

, 38 psi) at idle

Fuel pump flow at 12 V 17 cm

3

(0.6 US oz, 0.6 Imp oz) minimum/10 seconds

Injector resistance 11.1 – 12.3 Ω (20˚C/68˚F)

Cooling System

Recommended coolant 50/50 mixture coolant and distilled water

Radiator cap relief pressure 117 kPa (1.2 kgf/cm

2

, 17 psi)

Item Standard Service Limit

Cylinder Head/Valves

Cylinder compression 460 kPa (4.7 kgf/cm

2

, 67 psi) at

–

800 min-1(rpm)

Cylinder head warpage

–

0.05 (0.002)

Valve clearance IN 0.12 ± 0.03 (0.005 ± 0.001)

–

EX 0.30 ± 0.03 (0.012 ± 0.001)

–

Valve stem O.D. IN 4.475 – 4.490 (0.1762 – 0.1768) 4.470 (0.1760)

EX 4.465 – 4.480 (0.1758 – 0.1764) 4.460 (0.1756)

Valve guide I.D. IN/EX 4.500 – 4.512 (0.1772 – 0.1776) 4.552 (0.1792)

Valve stem-to-guide clearance

IN 0.010 – 0.037 (0.0004 – 0.0015)

–

EX 0.020 – 0.047 (0.0008 – 0.0019)

–

Valve guide projection IN 8.0 – 8.3 (0.31 – 0.33)

–

above cylinder head EX 8.2 – 8.5 (0.32 – 0.33)

–

Valve spring free length

Inner 25.41 (1.000) 24.9 (0.98)

Outer 28.32 (1.115) 27.6 (1.09)

Rocker arm I.D. 10.000 – 10.015 (0.3937 – 0.3943) 10.051 (0.3957)

Rocker arm shaft O.D. 9.972 – 9.987 (0.3926 – 0.3932) 9.925 (0.3907)

Rocker arm-to-shaft clearance 0.013 – 0.043 (0.0005 – 0.0017) 0.11 (0.04)

Cam lobe height IN 32.011 – 33.051 (1.2603 – 1.3012) 31.871 (1.2548)

EX 32.855 – 32.935 (1.2935 – 1.2967) 32.748 (1.2893)

Unit: mm (in)

Service Data

2-3

Item Standard Service Limit

Crankshaft/Transmission

Crankshaft runout Right

–

0.03 (0.001)

Left

–

0.05 (0.002)

Connecting rod big end

Side clearance 0.30 – 0.75 (0.012 – 0.030) 0.8 (0.03)

Radial clearance 0.06 – 0.18 (0.002 – 0.007) 0.05 (0.002)

Transmission gear I.D. M4 23.020 – 23.041 (0.9063 – 0.9071) 23.07 (0.908)

M5 23.020 – 23.041 (0.9063 – 0.9071) 23.07 (0.908)

C1 20.020 – 20.041 (0.7882 – 0.7890) 20.06 (0.790)

C2 25.020 – 25.041 (0.9850 – 0.9859) 25.06 (0.987)

C3 25.020 – 25.041 (0.9850 – 0.9859) 25.06 (0.987)

Gear bushing I.D. M5 20.000 – 20.021 (0.7866 – 0.7882) 20.05 (0.789)

C1 17.000 – 17.018 (0.6693 – 0.6700) 17.04 (0.671)

C2 22.000 – 22.021 (0.8661 – 0.8670) 22.04 (0.868)

C3 22.000 – 22.021 (0.8661 – 0.8670) 22.04 (0.868)

O.D. M4 22.979 – 23.000 (0.9047 – 0.9055) 22.96 (0.904)

M5 22.979 – 23.000 (0.9047 – 0.9055) 22.96 (0.904)

C1 19.979 – 20.000 (0.7866 – 0.7874) 19.95 (0.785)

C2 24.979 – 25.000 (0.9834 – 0.9843) 24.95 (0.982)

C3 24.979 – 25.000 (0.9834 – 0.9843) 24.95 (0.982)

Countershaft O.D.

at C1 bushing 16.983 – 16.994 (0.6686 – 0.6691) 16.97 (0.668)

at C2/C3 bushing 21.959 – 21.980 (0.8645 – 0.8654) 21.94 (0.864)

at kickstarter idle gear 16.983 – 16.994 (0.6686 – 0.6691) 16.97 (0.668)

Shift fork I.D. C 11.003 – 11.024 (0.4332 – 0.4330) 11.04 (0.435)

R, L 12.035 – 12.056 (0.4738 – 0.4746) 12.07 (0.475)

Shift fork claw thickness C 4.93 – 5.00 (0.194 – 0.197) 4.8 (0.19)

R, L 4.93 – 5.00 (0.194 – 0.197) 4.8 (0.19)

Shift fork shaft O.D. C 10.983 – 10.994 (0.4324 – 0.4328) 10.97 (0.432)

R, L 11.966 – 11.984 (0.4711 – 0.4718) 11.95 (0.470)

Oil pump

Tip clearance

–

0.20 (0.008)

Body clearance 0.15 – 0.20 (0.006 – 0.008)

–

Side clearance 0.05 – 0.12 (0.002 – 0.004)

–

Unit: mm (in)

Item Standard Service Limit

Cylinder/Piston

Cylinder I.D. 76.500 – 76.515 (3.0118 – 3.0124) 76.54 (3.013)

Taper

–

0.05 (0.002)

Out-of- round

–

0.05 (0.002)

Warpage

–

0.05 (0.002)

Piston O.D. 76.470 – 76.480 (3.0106 – 3.0110) 76.39 (3.007)

Measurement point 5 (0.2) from bottom of skirt

–

Pin bore I.D. 16.002 – 16.008 (0.6300 – 0.6302) 16.03 (0.631)

Piston pin O.D. 15.994 – 16.000 (0.6297 – 0.6299) 15.98 (0.629)

Piston ring

End gap Top 0.20 – 0.30 (0.008 – 0.012) 0.44 (0.017)

Second 0.35 – 0.50 (0.014 – 0.020) 0.64 (0.025)

Oil (side rail) 0.20 – 0.70 (0.008 – 0.028) 0.90 (0.035)

Ring-to-groove clearance

To p 0.065 – 0.100 (0.0026 – 0.0039) 0.115 (0.0045)

Second 0.015 – 0.050 (0.0006 – 0.0020) 0.065 (0.0026)

Cylinder-to-piston clearance 0.020 – 0.045 (0.0008 – 0.0018) 0.18 (0.007)

Piston-to-piston pin clearance 0.002 – 0.014 (0.0001 – 0.0006) 0.04 (0.002)

Connecting rod small end I.D. 16.016 – 16.034 (0.6305 – 0.6313) 16.04 (0.631)

Clutch/Gearshift Linkage

Recommended clutch fluid DOT 4 brake fluid

–

Clutch spring free length 27.6 (1.09) 26.8 (1.06)

Clutch disc thickness 3.22 – 3.38 (0.127 – 0.133) 3.15 (0.124)

Clutch plate warpage

–

0.10 (0.004)

Clutch slave cylinder I.D. 27.000 – 27.021 (1.0630 – 1.0638)

–

Clutch slave piston O.D. 26.940 – 26.960 (1.0606 – 1.0614)

–

Kickstarter Spindle O.D. 16.466 – 16.484 (0.6483 – 0.6490) 16.46 (0.648)

Pinion gear I.D. 16.516 – 16.534 (0.6502 – 0.6509) 16.55 (0.652)

Idle gear I.D. 17.016 – 17.034 (0.6699 – 0.6706) 17.06 (0.672)

Countershaft O.D.

at kickstarter idle gear 16.983 – 16.994 (0.6686 – 0.6691) 16.97 (0.668)

Unit: mm (in)

Service Data

2-4

Item Standard Service Limit

Rear Suspension

Shock absorber spring pre-load

126.5 (4.9)

–

Spring free length 133 (5.2) 130.3 (5.13)

Nitrogen gas pressure 1.27 MPa (13 kgf/cm

2

)

–

Damper rod compressed

force at 10 mm compressed 196 – 232 N (19.9 – 23.6 kgf)

–

Tension adjuster setting 10 clicks from full hard

–

Brakes

Recommended brake fluid DOT 4 brake fluid

–

Front Brake disc thickness 3.5 (0.14) 3.0 (0.12)

Brake disc runout

–

0.15 (0.006)

Rear Brake disc thickness 2.5 (0.10) 2.0 (0.08)

Brake disc runout

–

0.15 (0.006)

Electrical

Spark plug Standard: NGK: CR6EH-9

–

Optional NGK: CR5EH-9

–

Spark plug gap 0.80 – 0.90 (0.031 – 0.035)

–

Ignition coil resistance

Primary 2.6 – 3.2 Ω (20˚C/68˚F)

–

Secondary with plug cap 17.3 – 22.8 kΩ (20˚C/68˚F)

–

Secondary without plug cap

13.5 – 16.5 kΩ (20˚C/68˚F)

–

Ignition pulse generator

Resistance 85 – 115 Ω (20˚C/68˚F)

–

Alternator

Regulated voltage 13.5 – 14.5 V/1,800 min

-1

(rpm)

–

Charging coil resistance 0.7 – 1.0 Ω (20˚C/68˚F)

–

ECT sensor resistance 2.3 – 2.6 kΩ (20˚C/68˚F)

–

Bulbs

Headlight 12V – 35/35 W

–

Position light 12V – 4 W

–

Brake/tail light 12V – 21/5 W

–

Turn signal light 12V – 10 W X 4

–

Unit: mm (in)

Item Standard Service Limit

Wheels/Tires

Axle runout

–

0.20 (0.008)

Tire air pressure Front 39 – 44 kPa (0.40 – 0.45 kgf/cm

2

,

5.6 – 6.5 psi)

–

Rear 29 – 34 kPa (0.30 – 0.35 kgf/cm2,

4.3 – 5.0 psi)

–

Wheel rim runout Radial

–

2.0 (0.08)

Axial

–

2.0 (0.08)

Drive chain slack 25 – 35 (1.0 – 1.4)

–

Drive chain slider thickness

–

2.0 (0.08) from

upper surface

Front Suspension

Left fork spring free length 384.8 (15.14) 377.1 (14.85)

Fork tube runout

–

0.20 (0.008)

Recommended fork fluid Showa SS05

Pre-load adjuster setting 2 turns out from full soft

–

Damping adjuster setting Compression adjuster:

13 clicks from full hard

–

Tension adjuster:

12 clicks from full hard

–

Fork oil level Right 38 (1.5)

–

Left 87 (3.4)

–

Fork oil capacity Right 405 cm3(13.7 US oz, 14.3 Imp oz)

–

Left 410 cm3(13.9 US oz, 14.4 Imp oz)

–

Unit: mm (in)

Service Data

2-5

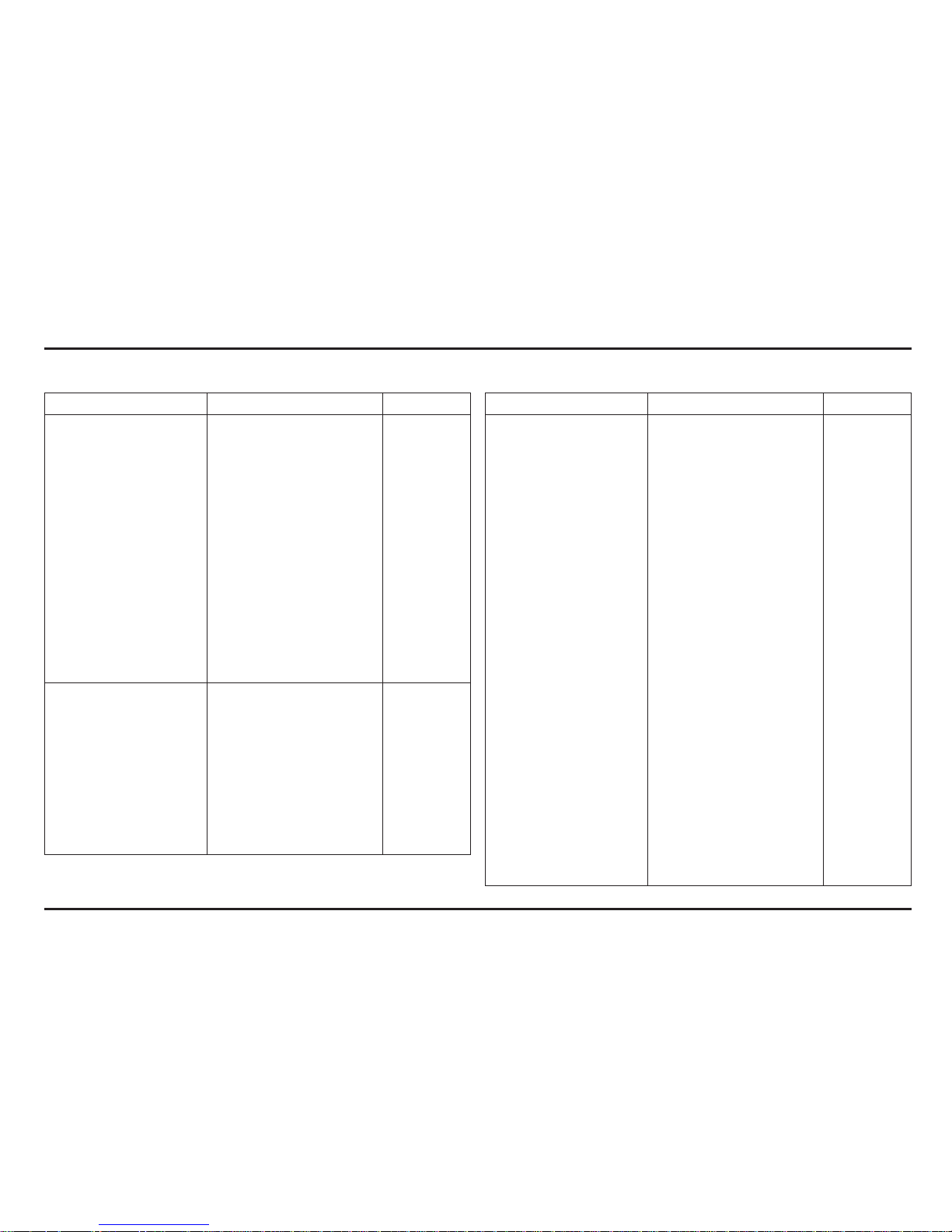

Torque Values

Standard

Tor que

Item

N•m (kgf•m, lbf•ft)

5 mm bolt and nut 5 (0.52, 3.5)

6 mm bolt and nut 10 (1.0, 7)

8 mm bolt and nut 22 (2.2, 16)

10 mm bolt and nut 33 (3.4, 25)

12 mm bolt and nut 53 (5.4, 40)

5 mm screw 4 (0.42, 3)

6 mm screw and flange bolt (SH type) 9 (0.9, 7)

6 mm flange bolt and nut 12 (1.2, 9)

8 mm flange bolt and nut 26 (2.7, 20)

10 mm flange bolt and nut 38 (3.9, 29)

Engine

Threads Torque

Item Q’ty Remarks

Dia. (mm) N•m (kgf•m, lbf•ft)

Transmission oil drain bolt 1 8 22 (2.2, 16) Note 1

Engine oil drain bolt 1 8 22 (2.2, 16) Note 1

Right crankcase cover joint pipe 1 18 18 (1.8, 13) Note 2

Timing hole cap 1 14 7 (0.7, 5.1) Note 3

Bearing set plate socket bolt 4 6 9.8 (1.0, 7) Note 4

Bearing set plate screw 2 6 12 (1.2, 9) Note 4

Bearing set plate flat screw 2 6 9.8 (1.0, 7) Note 4

Cylinder head sealing bolt 1 12 32 (3.3, 24) Note 4

Cylinder head mounting nut 2 9 39 (4.0, 29) Note 1

Cylinder head joint pipe 1 18 18 (1.8, 13) Note 2

Vacuum port joint 1 5 2.5 (0.25, 1.8)

Primary drive gear special bolt 1 12 108 (11.0, 80) Note 1

Flywheel nut 1 18 167 (17.0, 123) Note 1

Cam chain tensioner bolt 1 6 12 (1.2, 9) Note 4

Valve clearance adjusting nut 4 6 14 (1.4, 10) Note 1

Injector holder socket bolt 2 6 9.8 (1.0, 7)

Fuel hose banjo bolt (holder side) 1 18 27 (2.8, 20)

Water pump impeller 1 7 12 (1.2, 9)

Clutch oil bleeder screw 1 8 6 (0.6, 4.3)

Clutch spring bolt 6 6 12 (1.2, 9)

Clutch center lock nut 1 18 69 (7.0, 51) Note 1

Drive sprocket UBS bolt 1 8 31 (3.2, 23)

Shift drum center special bolt 1 8 22 (2.2, 16) Note 4

Shift drum stopper arm bolt 1 6 12 (1.2, 9)

Shift return spring pin 1 8 22 (2.2, 16)

Ignition pulse generator bolt 2 5 5.4 (0.55, 4.0) Note 4

Stator mounting bolt 3 5 5.4 (0.55, 4.0) Note 4

Spark plug 1 10 16 (1.6, 12) Note 2

Notes: 1. Apply clean engine oil to the threads and seating surface.

2. Apply sealant to the threads.

3. Apply grease to the threads.

4. Apply a locking agent to the threads.

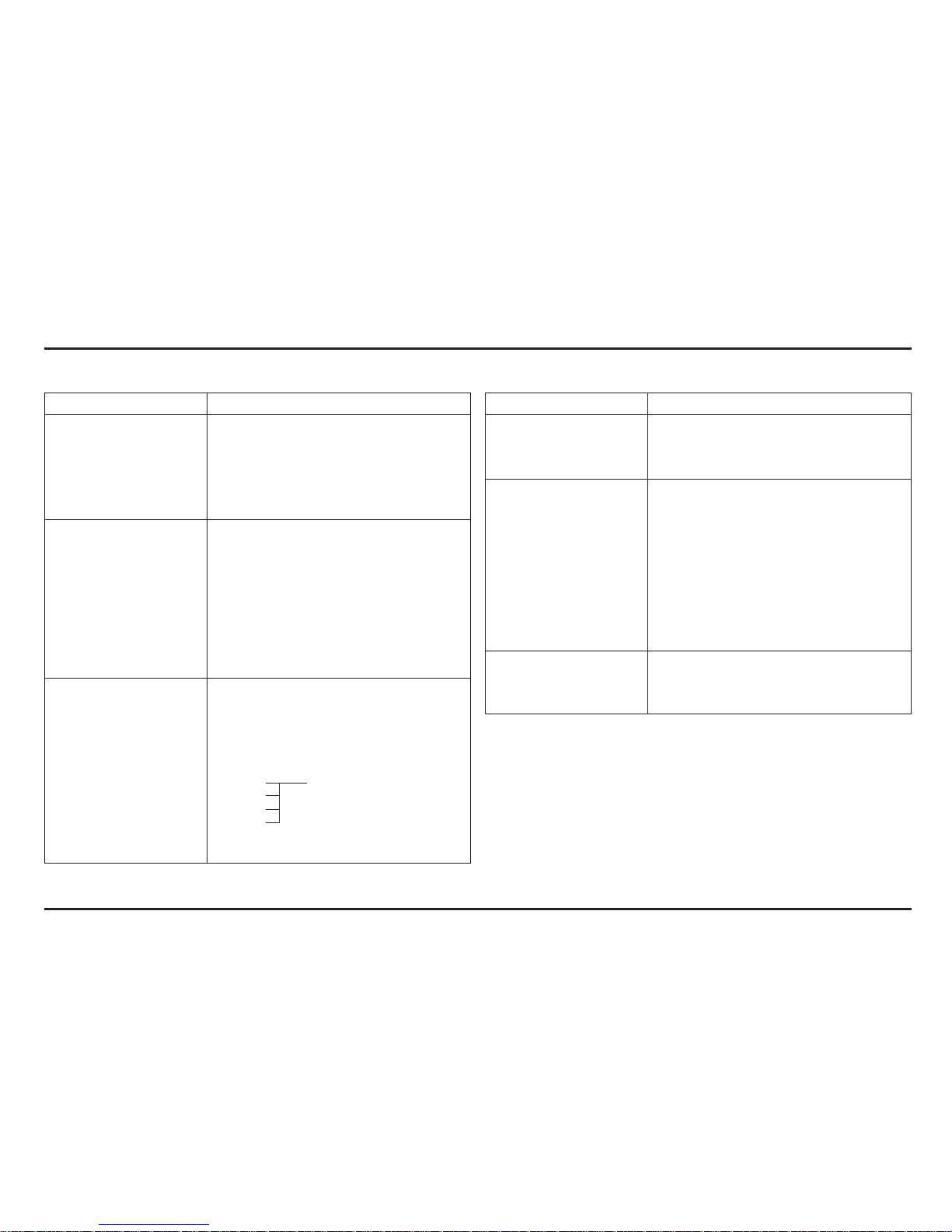

Cylinder stud bolt: Exhaust pipe stud bolt:

101.5 ± 1 mm

17 ± 0.5 mm

Insulator band (cylinder head side): Insulator band (throttle body side):

7 ± 1 mm

7 ± 1 mm

Service Data

2-6

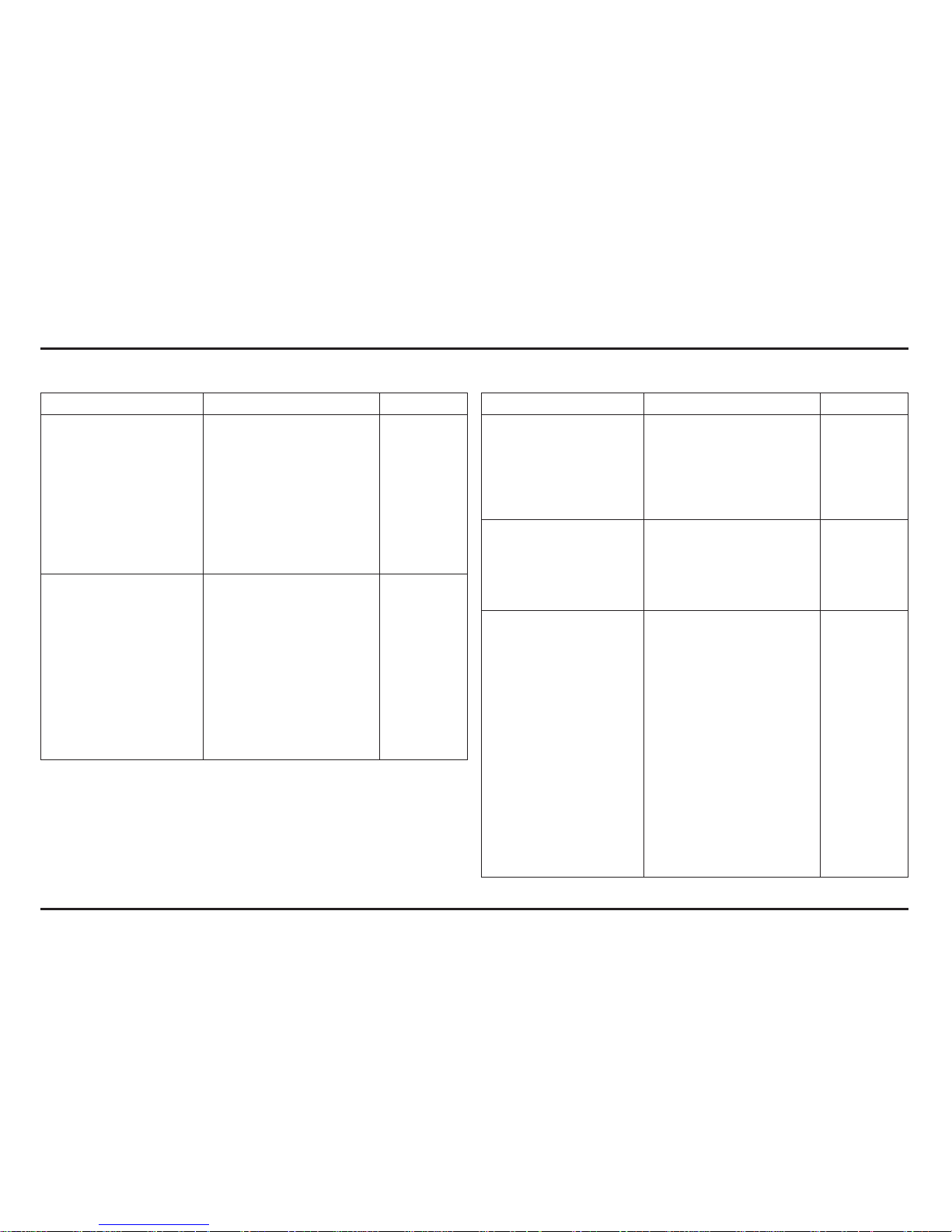

Frame

Threads Torque

Item Q’ty Remarks

Dia. (mm) N•m (kgf•m, lbf•ft)

Handlebar holder bolt 4 8 22 (2.2, 16)

Front axle 1 17 69 (7.0, 51) Note 1

Rear axle 1 17 69 (7.0, 51) Note 1

Final driven sprocket nut 4 8 29 (3.0, 22)

Shock absorber:

Upper mounting bolt/nut 1 10 39 (4.0, 29)

Lower mounting bolt/nut 1 10 39 (4.0, 29)

Fork top pinch bolt 2 8 20 (2.0, 14) Note 1

Fork bottom pinch bolt 4 8 20 (2.0, 14) Note 1

Swingarm pivot nut 1 14 69 (7.0, 51) Note 1

Front brake disc mounting bolt 4 6 18 (1.8, 13) Note 2

Rear brake disc mounting bolt 4 6 17 (1.7, 12) Note 2

Side stand pivot nut 1 10 23 (2.3, 17)

Side stand bracket mounting bolt

28 26 (2.7, 20) Note 2

Exhaust pipe flange bolt 1 6 12 (1.2, 9)

Engine hanger:

Upper hanger bolt/nut 1 8 24 (2.4, 17)

Front hanger bolt 1 10 49 (5.0, 36) Note 1

Down tube mounting bolt 4 8 25 (2.6, 19) Note 1

Front axle holder bolt 2 6 23 (2.3, 17) Note 1

Skid plate:

Front mounting bolt 2 8 26 (2.7, 20)

Throttle housing bolt 2 5 4.2 (0.43, 3.1)

Clutch lever holder bolt 2 5 3.2 (0.33, 2.4)

Front brake master cylinder

holder bolt 2 6 3.2 (0.33, 2.4)

Front brake caliper mounting bolt

28 26 (2,7, 20) Note 2

Brake hose:

Front master cylinder 1 10 27 (2.8, 20)

Front caliper 1 10 27 (2.8, 20)

Rear master cylinder 1 10 27 (2.8, 20)

Rear brake caliper 1 10 27 (2.8, 20)

Brake pedal pivot bolt 1 8 29 (3.0, 22)

Steering head top thread 1 26 5 (0.5, 3.6) Note 1

Threads Torque

Item Q’ty Remarks

Dia. (mm) N•m (kgf•m, lbf•ft)

Steering stem bolt 1 20 88 (9.0, 65) Note 1

Clutch hose (master cylinder) 1 10 20 (2.0, 14)

Rear master cylinder mounting

bolt 2 6 8 (0.8, 5.8)

ECT sensor 1 12 15 (1.5, 11)

Fuel hose banjo bolt

Fuel pump side: 1 12 22 (2.2, 16)

Fuel pump mounting bolt 6 5 7 (0.7, 5.1)

Front spoke nipple 32 BC 3.5 3.2 (0.33, 2.4)

Rear spoke nipple 32 4 2.5 (0.25, 1.8)

Shock absorber spring lock nut 1 50 49 (5.0, 36)

Shock arm bolt/nut 1 10 39 (4.0, 29)

Shock link bolt/nut 2 10 39 (4.0, 29)

Clutch oil bleeder bolt 1 10 23 (2.3, 17)

Rim lock nut 1 8 13 (1.3, 9)

Fork cap 2 36 23 (2.3, 17)

Fork cap bolt-to-adjuster case 1 22 34 (3.5. 25)

Fork adjuster case lock nut 1 10 20 (2.0, 14)

Right fork center bolt 1 14 34 (3.5. 25) Note 2

Left fork center bolt 1 15 34 (3.5. 25) Note 2

Notes: 1. Apply grease to the sliding surface.

2. Apply a locking agent to the threads.

Service Data

2-7

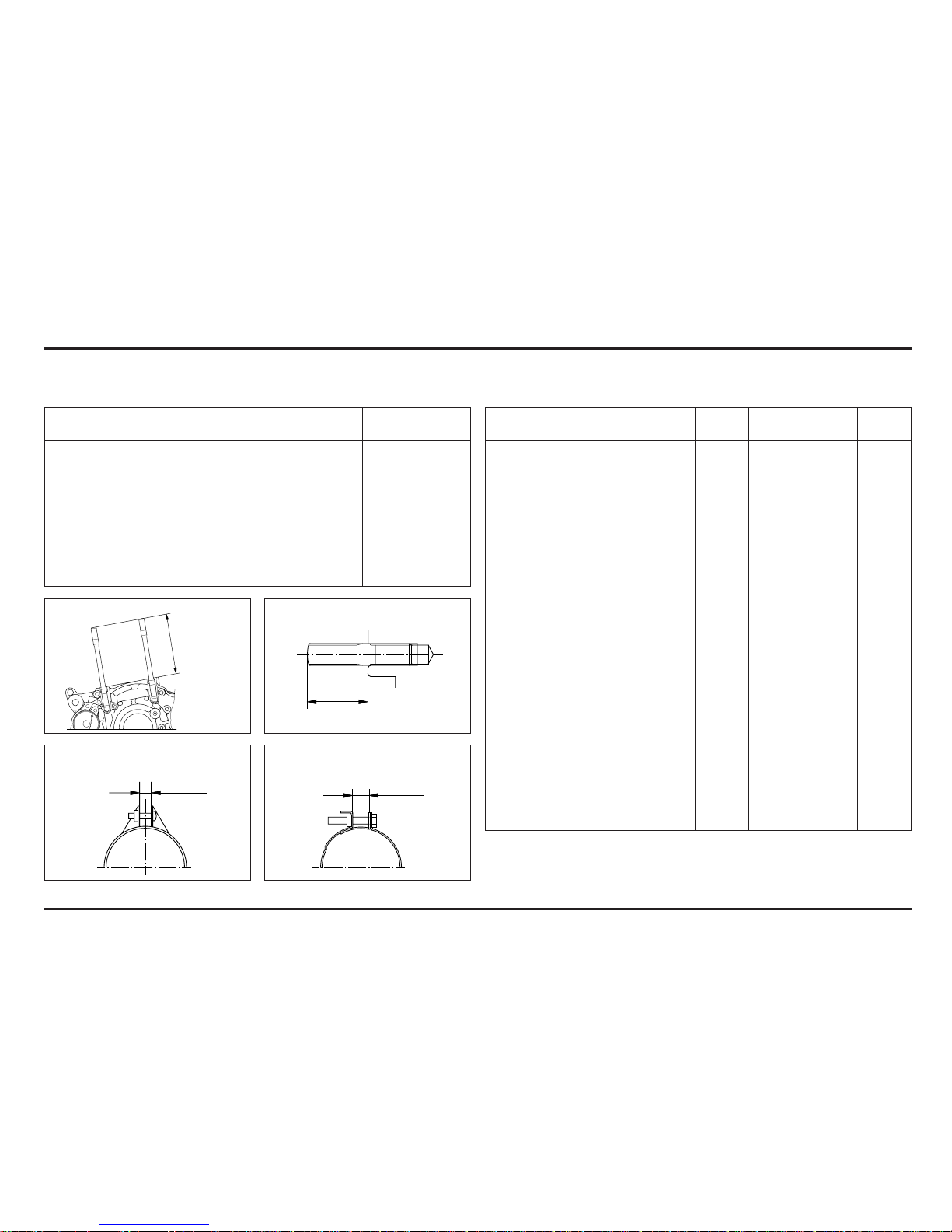

Tools

Special Common

Description Tool number Applicability

Bearing remover, 12 mm 07936–1660101 Water pump bearing

– Remover shaft 07936–1660120

– Remover weight 07741–0010201

Water seal driver 07945–KA30000 Water seal

Attachment, 28 x 30 mm 07946–1870100 Water pump bearing

Clutch center holder 07JMB–MN50301 Clutch center lock nut

Fork seal driver set 07947–4630100 Fork oil seal

Fork damper holder 89515–NN3–821 Right fork socket bolt

Fork damper holder 07930–KA50100 Left fork socket bolt

Ball race remover 07948–4630100 Stem bearing race

Steering stem driver 07946–4300000 Stem lower bearing

Bearing driver 07946–KA50000 Swingarm pivot bearing

Bearing remover 07946–MJ00100 Shock link needle bearing

Swingarm link bearing

Spherical bearing driver 07HMF–KS60100 Shock absorber bearing

Snap ring pliers 07914–3230001 Master cylinder snap ring

* Flywheel holder 89020–NN4–003 Flywheel

* Flywheel puller 89010–NN4–003 Flywheel

Compressor attachment 07959–MB10000 Shock absorber spring

Description Tool number Applicability

Spoke nipple wrench 07701–0020200 Front spoke nipple

Gear holder 07724–0010100 Primary drive gear bolt

Bearing remover head 07746–0050600 Wheel bearing

Bearing remover shaft 07746–0050100 Wheel bearing

Driver 07749–0010000 Bearing removal/installation

Attachment, 24 x 26 mm 07746–0010700 Swingarm pivot bearing

Attachment, 32 x 35 mm 07746–0010100 Right countershaft bearing

Left mainshaft bearing

Attachment, 37 x 40 mm 07746–0010200 Left shift drum bearing

Attachment, 42 x 47 mm 07746–0010300 Right mainshaft bearing

Left countershaft bearing

Right shift drum bearing

Wheel bearing

Ball race

Attachment, 52 x 55 mm 07746–0010400 Crankshaft oil seal

Attachment, 62 x 68 mm 07746–0010500 Left crankshaft bearing

Attachment, 72 x 75 mm 07746–0010600 Right crankshaft bearing

Pilot, 12 mm 07746–0040200 Water pump bearing

Pilot, 17 mm 07746–0040400 Right countershaft bearing

Left mainshaft bearing

Pilot, 20 mm 07746–0040500 Left countershaft bearing

Wheel bearing

Swingarm pivot bearing

Pilot, 22 mm 07746–0041000 Right mainshaft bearing

Pilot, 25 mm 07746–0040600 Right shift drum bearing

Pilot, 30 mm 07746–0040700 Right crankshaft bearing

Pin spanner 07702–0020001 Shock spring adjuster

(2 required)

Shock absorber compressor 07GME–0010000 Shock absorber spring

* Newly designed tool for this model.

Service Data

2-8

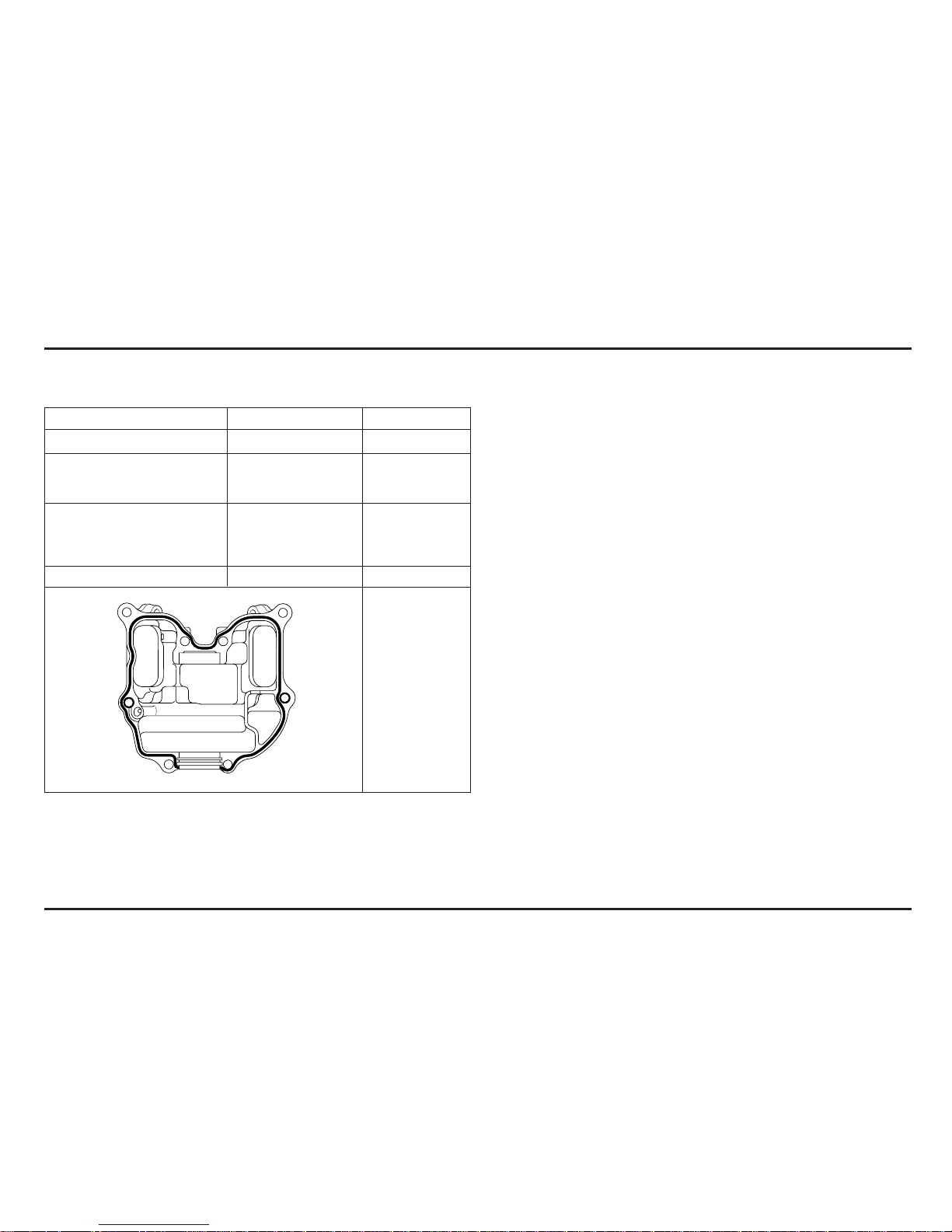

Lubrication & Seal Points

Engine

Item Material Remarks

Crankcase sealing bolt threads and ELF HTX740

seating surface

Cylinder bore inner surface

Cylinder head nut threads and

seating surface

Piston pin bore and outer surface

Piston pin outer surface

Piston ring surface

Crankshaft oil seal lips

Decompressor weight sliding

surface

Valve adjusting nut threads

Oil pump rotor sliding surface

Clutch outer sliding surface

Clutch friction disc surface

Clutch center nut threads and

seating surface

Clutch lifter piece needle bearing

area

Primary drive gear bolt threads and

seating surface

Shift drum grooves

Gearshift spindle serration

Flywheel nut threads and seating

surface

Each bearing

Each O-ring

Crankcase inside (transmission oil) 600 cm

3

Crankcase inside (engine oil) Honda Ultra S9 4-stroke 600 cm

3

engine oil or

Repsol 4T oil

10W-40-MB

Item Material Remarks

Connecting rod small end I.D. Molybdenum oil solution

Connecting rod big end (A 50/50 mixture of

Camshaft outer surface molybdenum disulfide

Rocker arm I.D. grease and engine oil

Valve stem sliding surface

Valve stem end sliding surface

Clutch outer collar sliding surface

Mainshaft spline and gear sliding

surface

Countershaft spline and gear

sliding surface

Shift fork I.D. and gear contact area

Shift fork shaft surface

Kickstarter spindle spline area and

gear sliding surface

Each gear

Right crankshaft bearing set plate Locking agent 6.5 ± 1 mm

bolt threads

Right mainshaft bearing/shift drum

bearing set plate bolt threads

Left coutershaft bearing set plate 3.5 ± 1 mm

bolt threads

Left crankcase sealing bolt threads

Cylinder mounting bolt threads

Cylinder head sealing bolt threads 6.5 ± 1 mm

Cam chain tensioner bolt threads 6.5 ± 1 mm

Shift drum center bolt threads

Ignition pulse generator bolt

threads

Stator mounting bolt threads

Item Material Remarks

Clutch slave cylinder piston/O-ring Silicone grease

Left crankcase cover cap threads Lithium based multiEach oil seal lips purpose grease

Water seal lips

Right crankcase cover water hose Sealant

joint threads

Cylinder head water hose joint

threads

Cylinder head cover mating surface Three Bond 1215B

Service Data

2-9

Service Data

2-10

Frame

Item Material Remarks

Steering head bearing race and Multi-purpose grease

bearings

Steering head dust seal lips

Swingarm pivot needle bearing

Swingarm pivot dust seal lips

Shock link/shock arm needle

bearings

Shock link/shock arm dust seal lips

Kickstarter arm joint sliding

Brake lever pivot sliding surface

Side stand pivot sliding surface

Brake pedal pivot sliding surface

Chain tensioner roller bearings

Clutch lever pivot sliding surface

Wheel bearing spinning area

Wheel axle threads

Step joint pin surface

Throttle pipe sliding surface and 4-stroke engine oil

throttle wire drum

Throttle housing screw threads Molybdenum disulfide

grease

Brake hydraulic system inside DOT 4 brake fluid

Clutch hydraulic system inside

Air cleaner element Engine oil

Throttle cable sliding surface Cable lubricant

Handlebar grip Honda bond A or

equivalent

Item Material Remarks

Drive chain adjuster stopper screw Locking agent

threads

Side stand bracket bolt threads

Steering stopper bolt threads

Drive chain slider mounting screw

threads

Rear brake hose clamp screw

threads

Cooling fan nut threads

Service Data

2-11

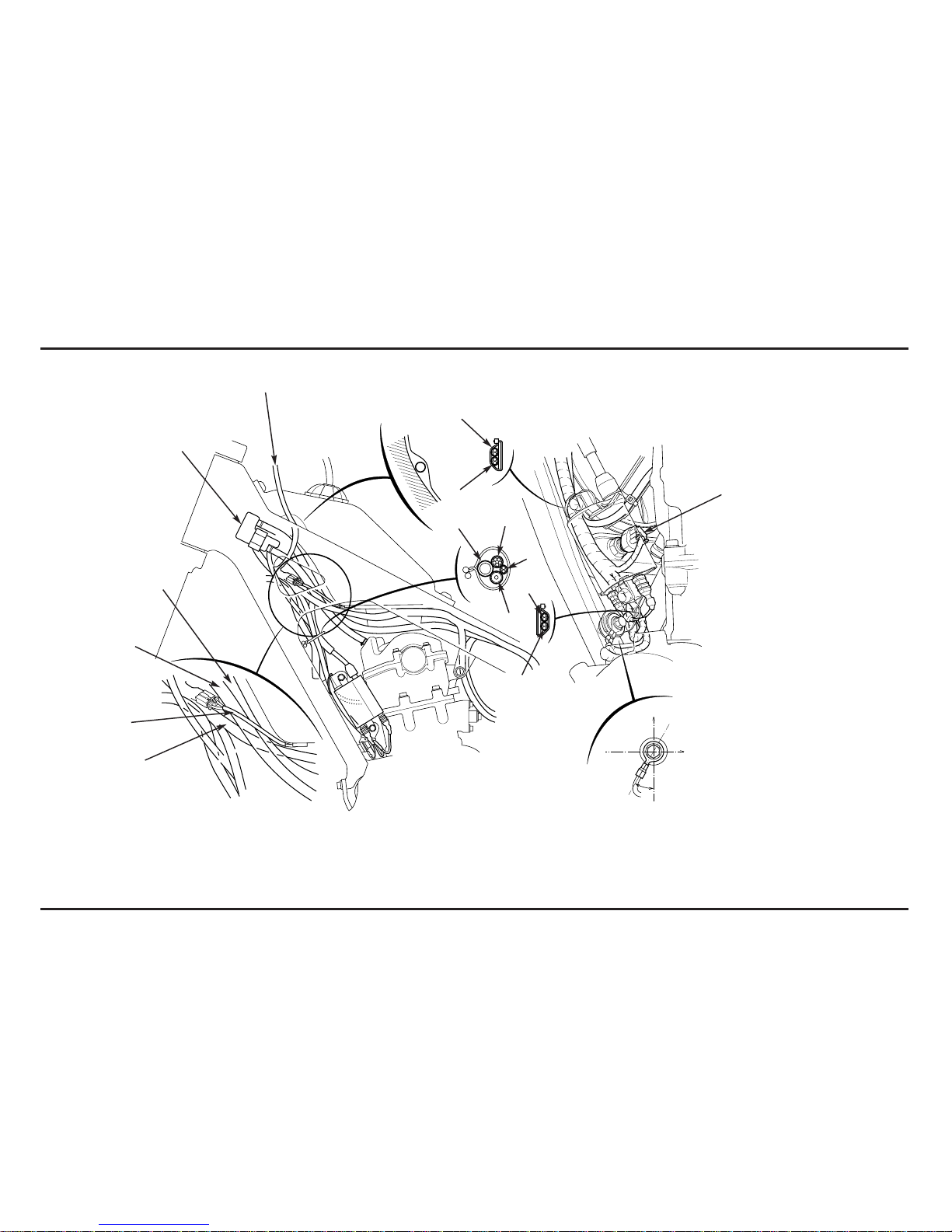

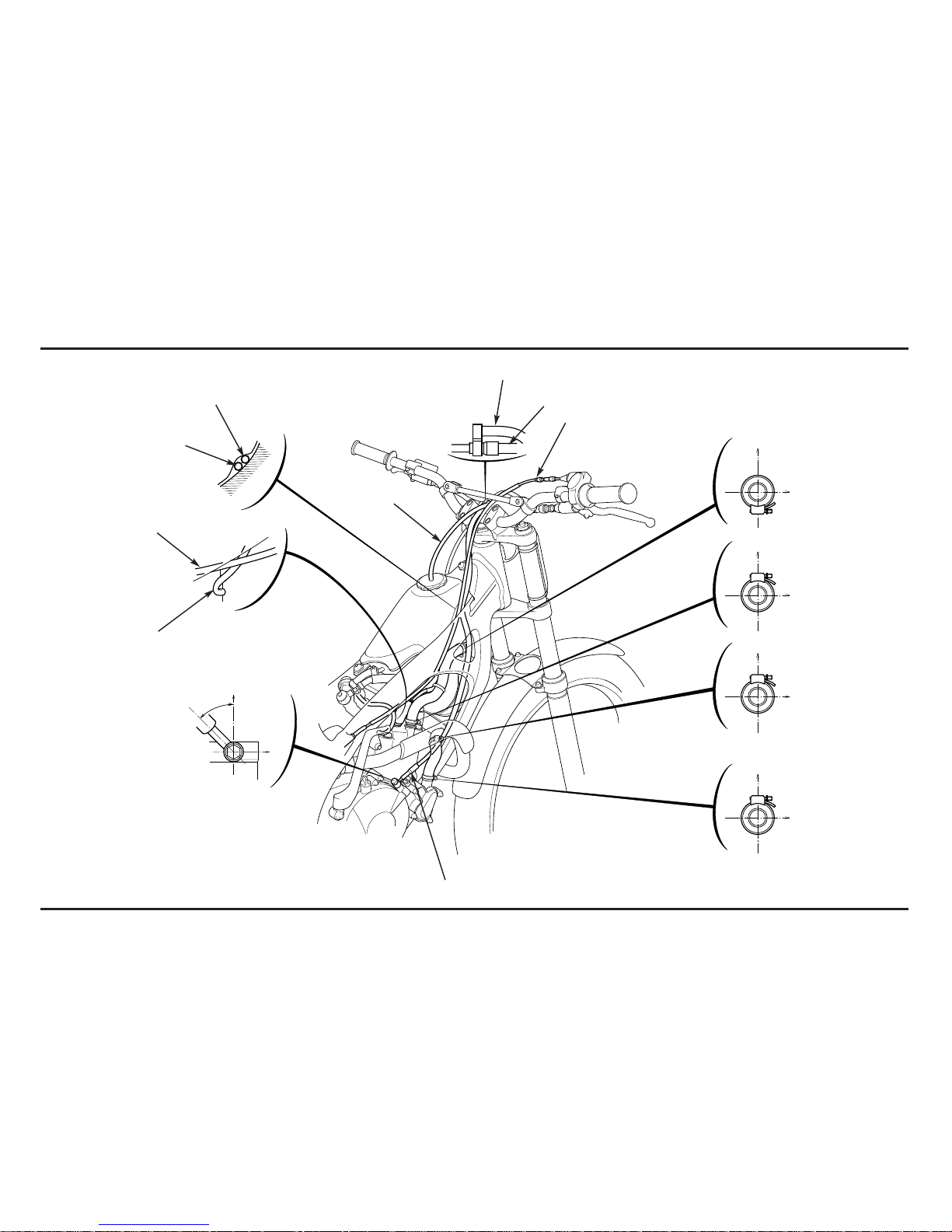

Cable & Harness Routing

(1) FRONT BRAKE HOSE

(2) THROTTLE CABLE

(3) CLUTCH HOSE

(4) ENGINE STOP SWITCH CONNECTOR

(2)

(1)

(3)

(4)

20 – 30˚

Front

Front

Front

Service Data

2-12

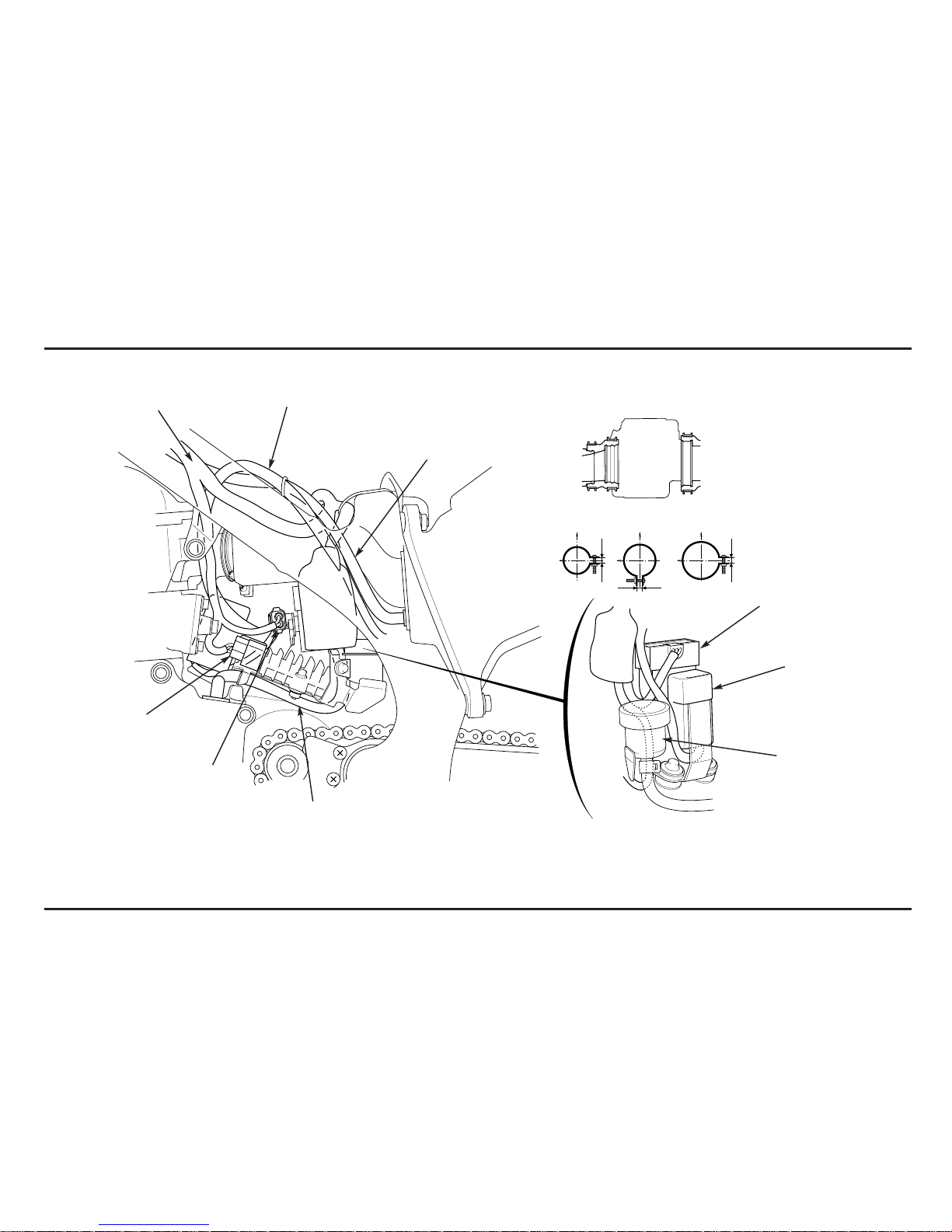

(1) MAIN WIRE HARNESS

(2) FUEL PUMP WIRE

(3) CRANKCASE BREATHER HOSE

(4) CRANKCASE BREATHER JOINT HOSE

(5) STRAGE TANK

(6) ENGINE STOP SWITCH WIRE

(7) FAN MOTOR WIRE

(8) RADIATOR OVERFLOW HOSE

(9) SPARK PLUG WIRE

(5)

(8)

(7)

(12)

(10)

(2)

(1)

(3)

(4)

Upper

Right

20 – 30˚

(6)

(7)

(9)

(1)

(10)

(10) WIRE HARNESS (TO IGNITION COIL)

(11) WIRE HARNESS (TO GROUND)

(12) ECT SENSOR

(11)

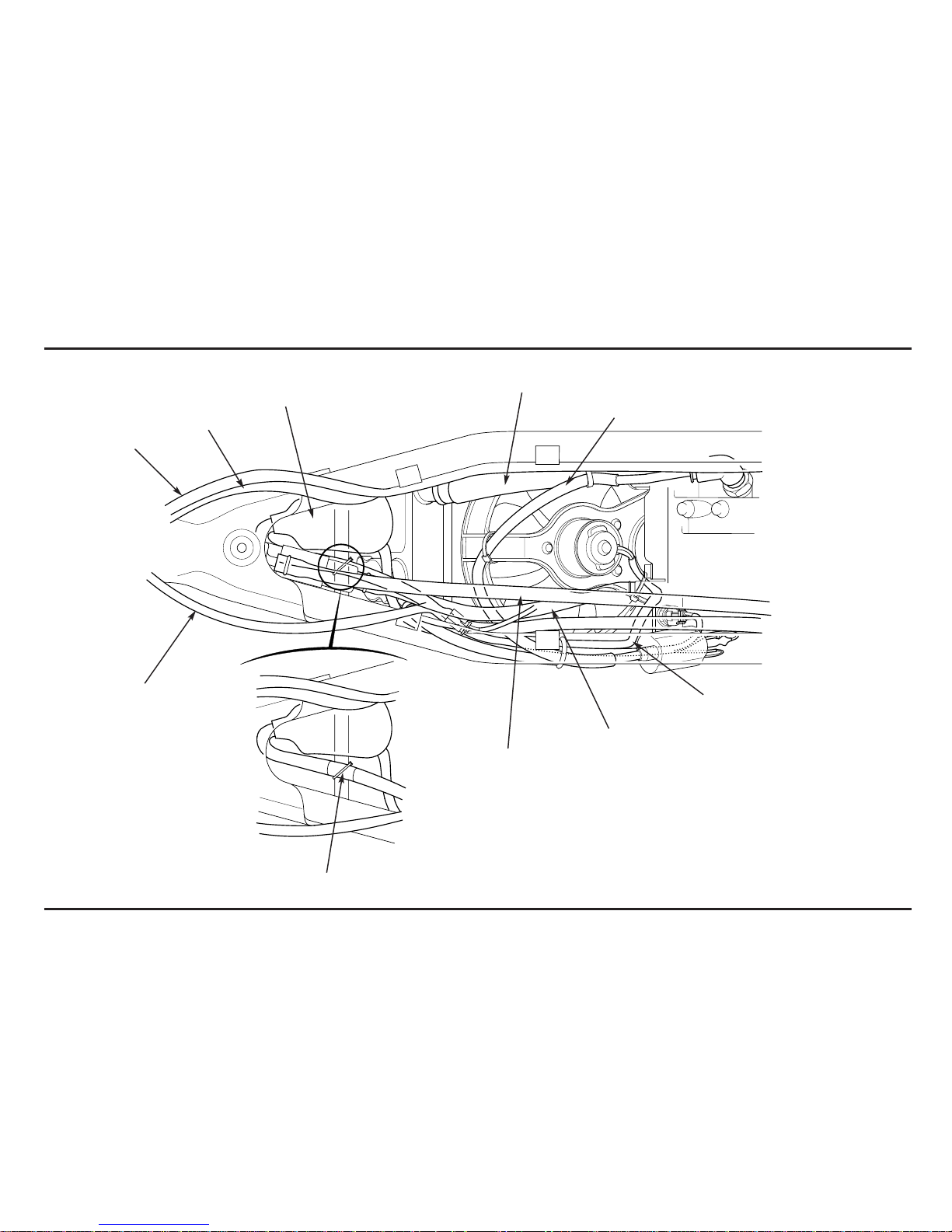

Service Data

2-13

(2)

(1) WIRE HARNESS

(2) THROTTLE CABLE

(3) CLUTCH HOSE

(4) CONNECTOR BOOT

– FAN MOTOR 2P (BLACK) CONNECTOR

– POWER CONNECTOR

(4)

(5)

(7)

(8)

(9)

(1)

Clamp at white tape

(5) UPPER RADIATOR HOSE

(6) SPARK PLUG WIRE

(7) FAN MOTOR WIRE

(8) CRANKCASE BREATHER HOSE

(9) CRANKCASE BREATHER JOINT HOSE

(3)

(6)

Service Data

2-14

(1)

(1) INTAKE VACUUM HOSE

(2) THROTTLE CABLE

(3) CLUTCH HOSE

(4) FUEL TANK BREATHER HOSE

(2)

(2)

(3)

(4)

(4)

(3)

(2)

(3)

40 – 50˚

Service Data

2-15

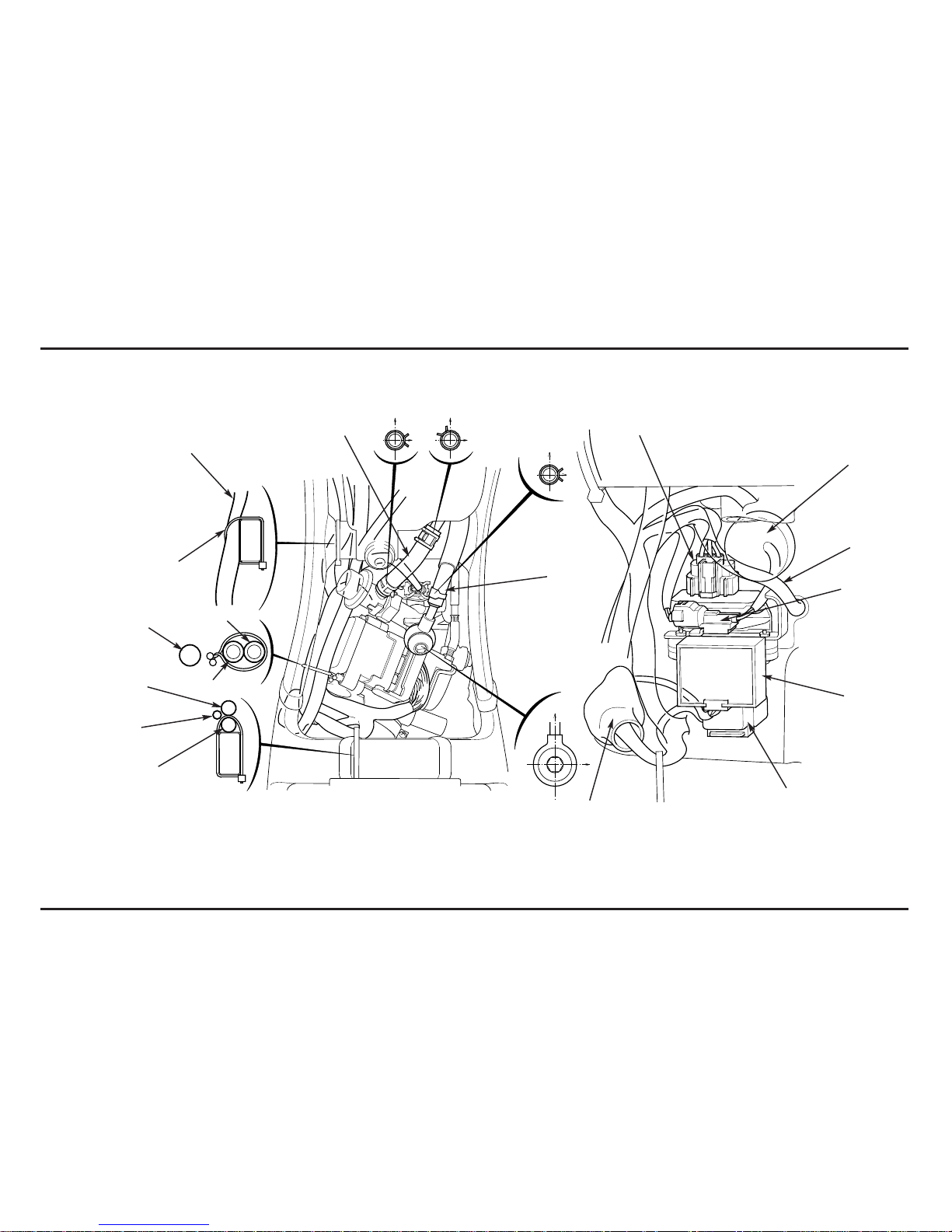

(1) MAIN WIRE HARNESS

(2) TRANSMISSION BREATHER HOSE

(3) CRANKCASE BREATHER JOINT HOSE

(4) ALTERNATOR WIRE

(5) CONDENSER 2P (BLACK) CONNECTOR

(6) REGULATOR/RECTIFIER 5P (BLACK) CONNECTOR

(1)

(2)

(3)

(6)

(5)

(4)

(7)

(8)

(9)

(7) ENGINE STOP RELAY

(8) FAN MOTOR RELAY

(9) REAR BRAKE RESERVOIR TANK

Service Data

2-16

(1)

(2)

(3)

(4)

(6)

(5)

(6)

(9)

(10)

(5)

(11)

(12)

(13)

(1) MAIN WIRE HARNESS (TO CONNECTOR COVER)

(2) MAIN WIRE HARNESS (TO RELAY)

(3) MAIN WIRE HARNESS (TO ECU)

(4) CRANKCASE BREATHER JOINT HOSE

(5) TRANSMISSION BREAHTER HOSE

(6) WIRE HARNESS

(7) FUEL RETURN HOSE

(8) FUEL FEED HOSE

(9) REGULATOR/RECTIFIER 5P (BLACK) CONNECTOR

(10) CONDENSOR

(11) CONDENSOR 2P (BLACK) CONNECTOR

(12) BANK ANGLE SENSOR

(13) FAN MOTOR RELAY

(14) CONNECTOR COVER

Clamp at white tape

(7)

(8)

(14)

Service Data

2-17

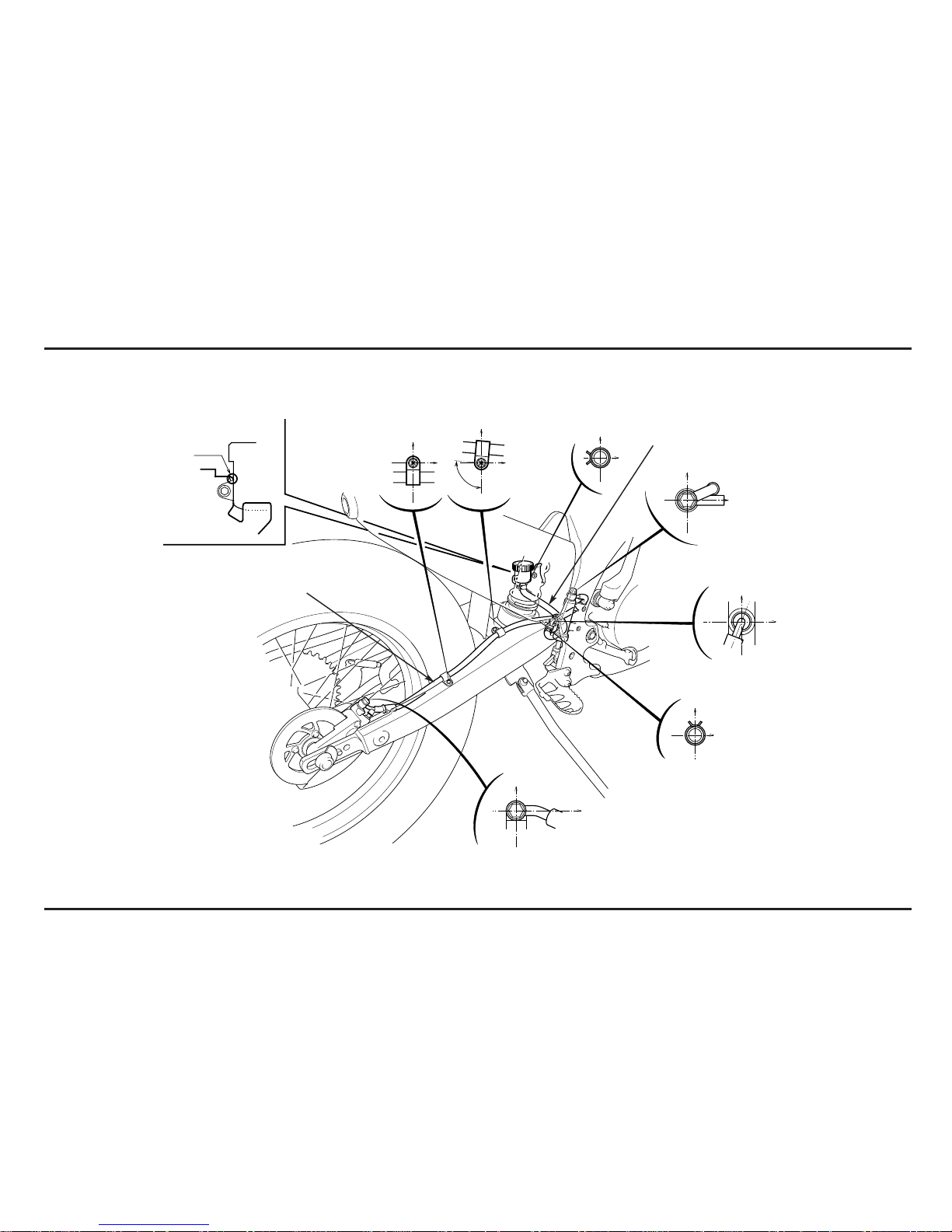

(1) REAR BRAKE HOSE

(2) REAR BRAKE RESERVOIR HOSE

(1)

(2)

90 – 95˚

Service Data

2-18

(1) FUEL FEED HOSE

(2) INTAKE VACUUM HOSE

(3) TRANSMISSION BREATHER HOSE

(1)

(2)

(3)

3. Service And Maintenance

3-1

Pre-ride Inspection

For your safety, it is very important to take a few moments

before each ride to walk around your COTA 4RT and

check its condition.

Improperly maintaining this COTA 4RT or failing to

correct a problem before riding can cause a crash in

which you can be seriously hurt or killed.

Always perform a Pre-ride and Pre-race inspection

before every ride and correct any problems.

Check the following items before you get on the COTA 4RT:

• Fuel, oil and water leaks

• Coolant for proper level

• Spark plug for proper heat range, carbon fouling and

spark plug cap terminals for looseness

•Clutch operation

• Steering head bearings and related parts for condition

• Damaged or distorted frame

• Throttle grip and throttle valve operation

•Tires for damaged or improper inflation pressure

•Front and rear suspension for proper operation

•Front and rear brakes, for proper operation

• Drive chain for correct slack and adequate lubrication

• Drive chain slider and roller for damage or wear

• Loose bolts, screws and other fasteners

Maintenance Schedule

Perform pre-ride Inspection at each scheduled maintenance period.

I: Inspect and clean, Adjust, Lubricate or Replacement if necessary. C: Clean, R: Replace, L: Lubricate.

Frequency

Each race Every 6

or about races or Every half

Every

Remarks

2,5 h. about 15 h. a year

year

Item

Fuel Line I

Throttle Operation I

Air Cleaner C

Check the air cleaner after riding in dusty area

Spark Plug I R

Valve Clearance I I: After the first brake-in period

Engine Oil I R R: After the first brake-in period

Engine Oil Filter R R: After the first brake-in period

Engine Oil Strainer Screen I

Engine Idle Speed I

Transmission Oil R

Radiator Coolant I R

Cooling System I R

Piston I R

Piston Ring I R

Drive Chain I, L

Drive Chain Slider/Tensioner I

Drive/Driven Sprocket I

Brake Fluid I R

Brake Pad Wear I

Brake System I

Clutch Fluid I

Clutch System I

Control Cables I, L

Exhaust Pipe/Muffler I C

Suspension I C Check the spherical bearing damage.

Swingarm/Shock Linkage I C

Fork Oil I R

Wheels/Tires I

Steering Head Bearing I

Nuts, Bolts, Fasteners I

!

WARNING

Service And Maintenance

3-2

Warming-up Inspection

When warming-up the engine, check for the following:

• Do not rev the engine more than necessary or engine

damage may result.

• Check for fuel, oil and water leaks

•Warm up the engine for a few minutes until it is heated

to the operating temperature until the engine

responds to the throttle smoothly.

Ride Inspection

When running the COTA, check for the following:

• Control system

• Brake stopping power

After Ride Inspection

After riding the COTA, check for the following:

• Color condition of piston head and spark plug

• Signs of detonation

• Fuel, oil and water leaks

• Loose or missing bolts and nuts

Replacement Parts

Parts Requiring Periodic Replacement

Item Replacement Interval Cause

Engine

Spark plug/plug cap Every 6 races Contamination or emulsification

Engine oil Every 6 races

Engine oil filter Every 6 races

Transmission oil Every 6 races

Piston Every year Damage or wear at skirt

Piston ring Every half a year Damage at ends or wear

Radiator coolant Every year

Frame

Front fork fluid Every half a year

Fast Wearing/Expendable Parts

Item Cause

Engine

Clutch disc Wear or discoloration

Clutch spring Fatigue

Drive sprocket Wear or damage

Frame

Front/rear tire Wear

Brake pad Wear

Chain slider Wear

Driven sprocket Wear or damage

Drive chain Elongation or wear

Loading...

Loading...