Monterey Boats 318 SS Super Sport, 318 SC Sport Cruiser, 278 SC Sport Cruiser, 278 SSX Super Sport, 318 SSX Super Sport Owner's Manual

...

BOATSBOATS

SUPER SPORT

OWNER’S MANUAL

278 SS/SSX Super Sport

278 SC Sport Cruiser

318 SS/SSX Super Sport

318 SC Sport Cruiser

Dear Valued Customer,

Welcome to the Monterey Life!

We would like to extend to you our “Thank You” for choosing a Monterey boat!

You have made an investment in our product and we are confident you will enjoy many years of boating

pleasure. Your new boat has been built to the standards set forth by the United States Coast Guard, National

Marine Manufacturers Association and the American Boat and Yacht Council. We are proud to have you in our

“Family!”

At this time, we need you to read your owner’s manual and become familiar with all systems on your boat. Make

certain that you and your dealer have filled out and mailed your warranty registration card back to us here at the

factory. It is very important to us and it is also a U.S. Federal Regulation.

This manual is an important aid in the operation and maintenance of your boat. The information is intended as a

guide and cannot cover every question you may have about your boat and boating in general. We encourage

you to contact your dealership for any additional information you might need. If there is a question about your

boat that can’t be answered by your dealer, please contact our factory direct by calling the Monterey Boats

Customer Service Department, (352) 529-9181 or online if you prefer at: www.info@montereyboats.com.

If you are new to boating, we recommend you participate in a boating class or group to gain more knowledge

and confidence. Contact your dealer, local U.S. Coast Guard or U.S. Power Squadron Organizations for information in your area.

With proper care, routine service and preventive maintenance, your Monterey boat will not only reward you with

enjoyment, but with reliability, dependability and one of the higher resale values in today’s boating industry.

Enjoy your new boat and please respect our environment at all times. Always remember to practice safe boating

procedures for your protection as well as those around you.

Sincerely,

The M.O.S.T. (Monterey Owners Support Team)

Have a safe boating day!

DATE PURCHASED ____________________________________________________________________

DEALER/PHONE NUMBER ______________________________________________________________

BOAT MODEL__________________________________________________________________________

HULL ID NUMBER ______________________________________________________________________

TRAILER ID NUMBER __________________________________________________________________

ENGINE MAKE/MODEL __________________________________________________________________

ENGINE #1 SERIAL NUMBER ____________________________________________________________

ENGINE #2 SERIAL NUMBER ____________________________________________________________

DRIVE MAKE/MODEL __________________________________________________________________

DRIVE #1 SERIAL NUMBER ______________________________________________________________

DRIVE #2 SERIAL NUMBER ______________________________________________________________

To comply with Federal regulations it is important to return the warranty registration card within 15 days.

TABLE OF CONTENTS

Page

M INTRODUCTION ...................................... M-1

New Boat Delivery ..................................... M-2

Parts .......................................................... M-2

Specifications ............................................ M-3

Special Care & Cleaning ........................... M-3

Battery Specifications .............................. M-10

Fire Extinguishing System ........................M-11

Special Gas Precautions ..........................M-12

Generator Set ......................................... M-13

Air Conditioner......................................... M-15

Boat Layouts & Details ........................... M-16

1 BOATING SAFETY ................................... 1-1

Boating Regulations .................................. 1-2

Boater Responsibilities .............................. 1-2

Required Safety Equipment ....................... 1-3

Emergencies .............................................. 1-7

Hazardous Conditions ............................... 1-8

Operation By Minors ................................ 1-10

Passenger Safety .................................... 1-11

Water Sports ............................................ 1-11

General Precautions ................................ 1-12

2 BASIC RULES OF THE ROAD ................ 2-1

Aids to Navigation ...................................... 2-1

Right-of-Way .............................................. 2-4

3 CONTROLS AND INDICATORS ............... 3-1

Shift/Throttle Control .................................. 3-1

Instruments ................................................ 3-2

Switches .................................................... 3-4

Steering System ......................................... 3-8

Page

5 GETTING UNDERWAY ............................ 5-1

Safety Checklist ........................................ 5-1

Safety Equipment ..................................... 5-2

Boarding ................................................... 5-2

6 RUNNING ................................................. 6-1

Maneuvering Techniques .......................... 6-1

Salt Water ................................................. 6-2

Freezing Temperatures ............................. 6-3

Towing Procedure ..................................... 6-3

Anchoring ................................................. 6-4

Performance Boating ................................ 6-5

Propellers ................................................. 6-6

7 CARE AND MAINTENANCE ................... 7-1

Electrical ................................................... 7-1

Fuel System .............................................. 7-3

Steering System ....................................... 7-3

Corrosion Protection ................................. 7-3

General Maintenance ............................... 7-4

8 TROUBLESHOOTING ............................. 8-1

Trouble Check Chart ................................. 8-1

9 STORAGE ................................................ 9-1

10 TRAILERING .......................................... 10-1

Classifications ......................................... 10-1

Trailer Components ................................. 10-2

Safety Chains ......................................... 10-2

Trailering Checklist ................................. 10-3

Backing Up Trailers ................................ 10-4

Launching ............................................... 10-5

Loading ................................................... 10-5

Slinging/Lifting ........................................ 10-6

4 OPERATION ............................................. 4-1

Fueling ....................................................... 4-1

Starting ...................................................... 4-2

Shifting/Running ........................................ 4-4

Warning Alarm ........................................... 4-4

Steering Controls ....................................... 4-5

Stopping .................................................... 4-5

Docking ...................................................... 4-6

Boat Trim ................................................... 4-7

Drive Trim Angle ........................................ 4-7

11 SHIP SYSTEMS ..................................... 11-1

Electrical Systems .................................. 11-1

Water Systems ........................................ 11-8

Hot Water Heater .................................. 11-11

Sanitizing The Fresh Water System ..... 11-12

Sample Float Plan ................................ 11-17

12 GLOSSARY OF TERMS ........................ 12-1

WARRANTY

i-1

This page intentionally left blank

i-2

INTRODUCTION

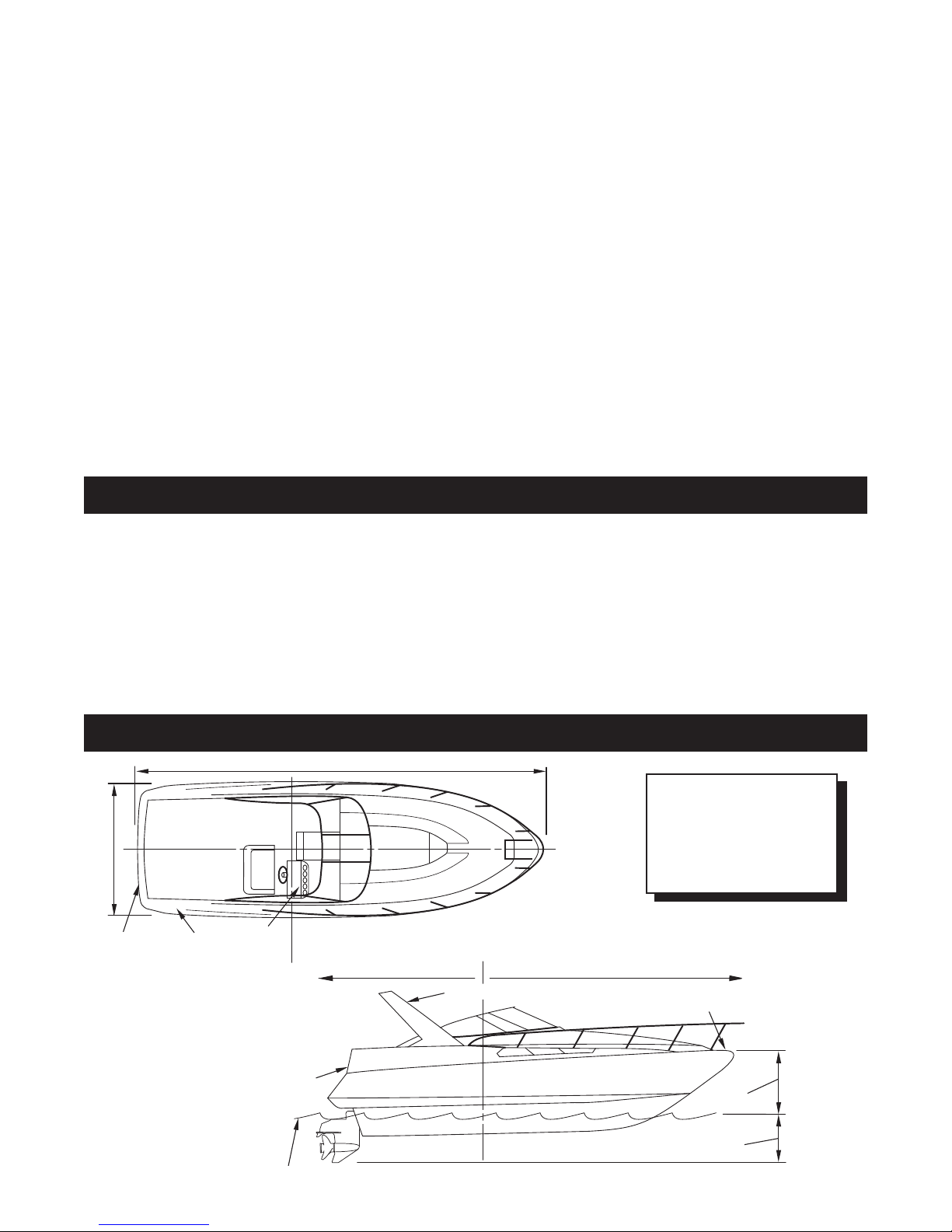

FREEBOARD

BOW

DRAFT

GUNWALE

WATERLINE

AFT

FORWARD

HELM

BEAM

TRANSOM

LENGTH OVERALL (LOA)

PORT SIDE

STARBOARD SIDE

KC-0941A

RADAR ARCH

STERN

Monterey Boats has long been known as a quality boat manufacturer with a commitment to customer

satisfaction. This manual is but one example of that commitment. We have carefully prepared this

information to assist you in the proper operation and care of your new boat, and some of the

responsibilities that go along with owning/operating a boat.

This section contains supplemental information about your Monterey boat that is different or not covered

elsewhere in this manual. If you have questions about your boat not covered in this manual, or in the other

supplied information, your dealer will be glad to assist you. Refer to the Table of Contents on page i-1 to

locate general information.

As part of your warranty responsibilities, you must perform periodic maintenance/inspections as outlined

in this manual, the engine owner’s manual and other information supplied in the owner’s important

papers packet. Please keep this manual onboard for future reference and pass it along to the new owner

if you ever decide to sell the craft.

All information, illustrations, and specifications contained in this manual are based on the latest product

information available at the time of publication. Monterey Boats reserves the right to make changes at any

time, without notice and without incurring obligation, in colors, materials, equipment, specifications and

models.

Once again, thank you for choosing a Monterey boat; we wish you many years of boating enjoyment!

IDENTIFICATION NUMBERS

Safeguard information about your boat by recording the Hull Identification Number (HIN), and model and

serial numbers of major components and accessories. Keep a detailed Data Sheet for emergency

purposes in a safe place off the boat. In case of theft, damage, etc., report these numbers to local

authorities, your insurance agent and your dealer.

NOTICE

By law, the HIN must be clearly visible and may not be removed, altered, or tampered with

in any way. The HIN is attached to the transom on the upper starboard side, above the

waterline.

BOATING TERMINOLOGY

Tip!

PORT side from

An easy way to remember

STARBOARD side

is “PORT” and “LEFT”

both have four letters!

M-1

NEW BOAT DELIVERY

Your Monterey boat is inspected at each step of the manufacturing process. Before leaving the factory,

every Monterey boat undergoes a thorough check for systems operation, fit and finish. Your Monterey

dealer also performs a Pre-Delivery inspection prior to final delivery. When the new boat is delivered to

you, the customer, a final check is performed during orientation. Both the Pre-Delivery and Final Delivery

inspections are documented (New Boat Checklist) to ensure trouble-free operation and returned to

Monterey Boats.

At the time of new boat delivery, your Monterey dealer will ask you to sign the completed Warranty

Registration and New Boat Checklist for the boat and other accessory equipment. By signing these

documents, you acknowledge that you have reviewed and understand all information.

PARTS

Should you require new parts or would like to order an option after your original purchase, please contact

your Monterey Boats dealer to place your orders. Orders may not be placed with the manufacturer.

WARRANTY REGISTRATION AND NEW BOAT CHECKLIST

SUPER SPORT & CRUISER

Boat Number (HIN): RGF Boat Model:

Selling Dealer: Dealer Code:

Engine Brand:

Engine Serial #1:

Engine Serial #2:

Date of Sale:

Owner Name (Last, First):

Address:

City:

E-Mail Address:

Phone:

Indicate Status with the following Key: ¥ or 1 – OK, 2 – Needs Correction, 3- Completed, N/A – Not Applicable

Boat gel coat, striping & graphics

Upholstery fit, clean and free of defects

Sundeck/Sun Island/lounger operation

Canvas fit, clean and free of defects

Cabin Doors, port lights, hatches, cabinet & head doors, latches

All thru-hull fittings, ball valves, head drain, galley drain, anchor

well drain, drain plug-hull, wet bar drain are secure, no leaks

Windshield fit

Ladders

Running Lights (Navigation)

Cabin lights, cockpit lights

Toilet (Head) operation & hoses

Stereo – Radio, CD, remote control

Bilge Pumps – Auto float switch

Air Conditioner/Heater – operation & components secure

Water pressure system (let pressure stand 15 minutes to see if

pump goes on) & heater

Stove, coffee maker, oven, refrigerator, ice maker

Generator – Operation & components secure

Bilge Blower(s)

Wipers

Shore power (AC)

Tables

Plumbing Hose Clamps

Battery – Polarity, Voltage, Tight Connections

Battery Switch(es) - Operation

Engine mounts – tight

Fuel system operation - no leaks

Engine compartment components not missing, disconnected,

loose, kinked, pinched or could chafe

Hose clamps on engine & exhaust

Steering system operation, components secure, steering wheel

straight

Drains cooling system closed (Closed cooling coolant level)

Throttle control, operation & adjustment

Shifter control, operation & adjustment

Stern drive oil level at full mark

Crankcase & power steering oil levels at full mark

Stern drive trim operation

Prop Size:

Prop installed correctly with grease, nut(s), cotter pins

Prop rotation – Forward & Reverse

Neutral start switch, engine will not start in gear

Transom plate seal has no leaks – water, oil

COMMENTS

Distribution: Factory CS – Green, Dealer – Yellow, Owner – Manila Card Rev 1204

PLEASE, INSPECT AND CHECK OFF THE FOLLOWING OPERATIONS

BOAT

EQUIPMENT

ENGINE – BEFORE STARTING

SAMPLE

Engine Model:

Drive Serial #1:

Drive Serial #2:

Warranty Start Date:

State: Zip:

(We respect your privacy and will use for internal puposes only.)

2nd Phone:

Technical Check Performed by

Technician Date

Owner Orientation Performed by

Dealer Personnel Date

I have read and agree with the checklist. I have read and

understand the Monterey Boats Lifetime Limited Warranty

as it appears on the back of this form.

Owner Signature Date

ENGINE - AFTER STARTING: (in water)

Oil pressure

Fuel line connectors – no leaks

Engine has no water or oil leaks

Idle speed per engine specs, in gear

Ignition timi ng check with timing light or scan tool

Gear shift works properly - forward, neutral, reverse

Instruments read correctly

Exhaust system - no leaks

Boat performance

Port engine operation

Starboard engine operation

Steering –operation

Stern drive trim operation

Instruments register normal

Maximum R.P.M.

PRE-DELIVERY FINAL CHECK

All accessory equipment operates (Mech. & Elect.)

Carpets, curtains, cushions & canvas installed

All boat, engine and accessory literature

Boat properly cleaned, interior and exterior

Trailer wiring, wheels, fenders & brakes

Review & familiarize Owner with operation of all features

and options on boat

Sea Trial with Owner

Review of Owners Manual

Review of Warranties

Review of Owner Responsibilities

Review of Service & Maintenance Procedures

Review of Care & Cleaning

OWNER ORIENTATION

SEA TRIAL

1579 S.W. 18

www.montereyboats.com

th

Williston, FL 32696

Fax 888-922-6287

Street

Tel 352-529-9181

M-2

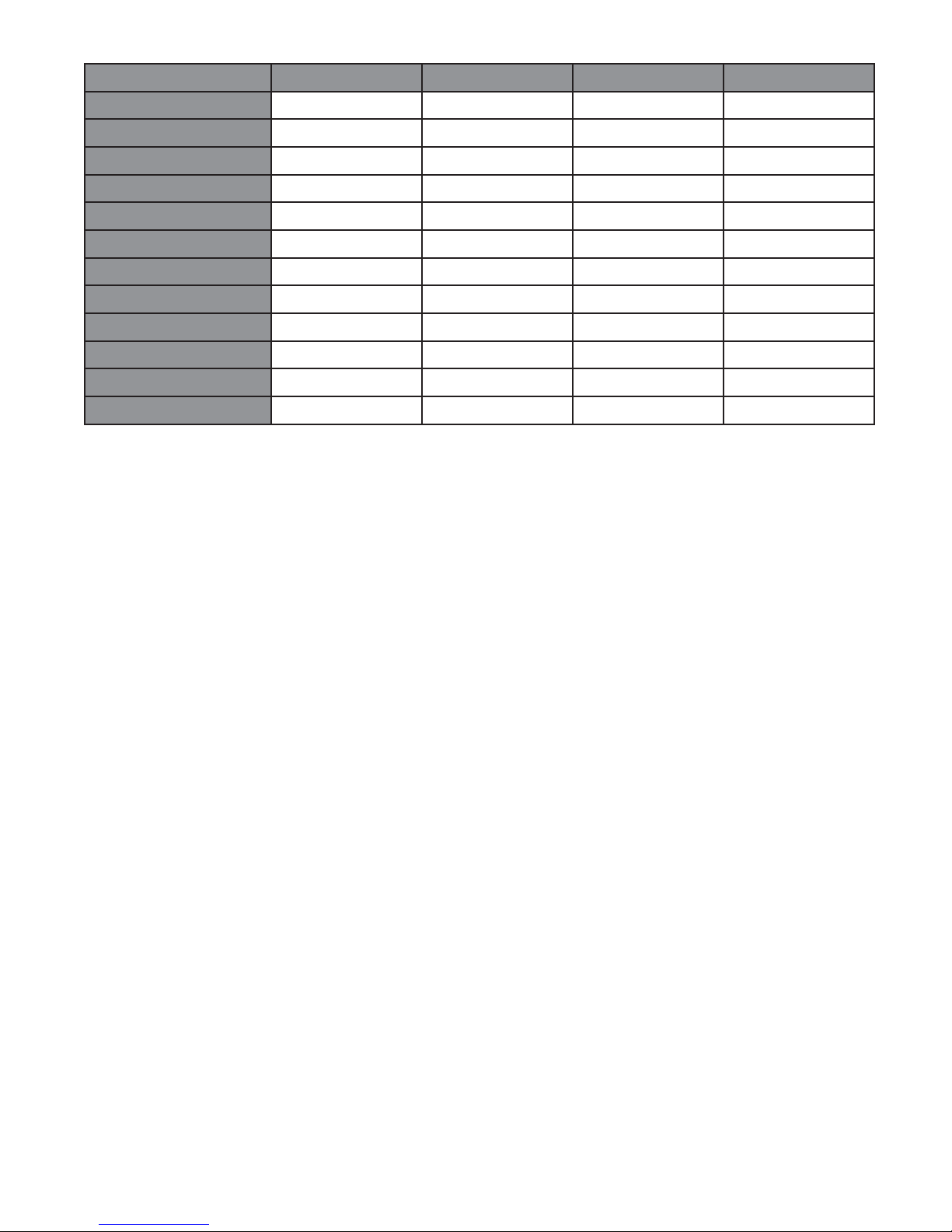

SPECIFICATIONS

MODEL 278 SS/SSX 278 SC 318 SS/SSX 318 SC

LOA W/ SWIM PLATFORM 28’-10” (8.8 m) 28’-10” (8.8 m) 31’-10” (9.7 m) 31’-10” (9.7 m)

MOLDED HULL LENGTH 26’-6” (8.1 m) 26’-6” (8.1 m) 29’-7” (9.0 m) 29’-7” (9.0 m)

BEAM 8’-6” (2.6 m) 8’-6” (2.6 m) 9’-6” (2.9 m) 9’-6” (2.9 m)

BRIDGE CLEAR W/O ARCH 5’-8” (1.5 m) 5’-8” (1.5 m) 6’-0” (1.8 m) 6’-0” (1.8 m)

BRIDGE CLEAR W/ ARCH 8’-0” (2.4 m) 8’-0” (2.4 m) 8’-0” (2.4 m) 8’-0” (2.4 m)

DEAD RISE 21° 21° 22° 22°

DRAFT DRIVE UP 24” (60.9 cm) 24” (60.9 cm) 27” (68.6 cm) 27” (68.6 cm)

DRAFT DRIVE DOWN 37” (94.0 cm) 39” (99.1 cm) 40” (101.6 cm) 40” (101.6 cm)

FUEL CAPACITY 89 gal (337 l) 89 gal (337 l)

WATER CAPACITY 15 gal (57 l) 15 gal (57 l) 15 gal (57 l) 15 gal (57 l)

WASTE CAPACITY N/A N/A 18 gal (68 l) 18 gal (68 l)

STANDARD WEIGHT 5,500 lbs (2,495 kg) 5,500 lbs (2,495 kg) 8,000 lbs (3,629 kg) 8,500 lbs (3,856 kg)

l Draft Up and Draft Down - Minimum shown, will increase based on loading and placement

l Water and Waste Capacity - may differ according to options

l Dry Weight - Average weight of base boat without options, fuel, water, waste, battery(ies) or gear.

142 gal (537 l) 142 gal (537 l)

SPECIAL CARE & CLEANING

The marine environment (sun, salt, pollution and bird droppings) requires special products for proper care

and cleaning. Your dealer is best suited for recommendations on marine care and cleaning products that

work best in your area.

Canvas

The convertible/bimini top is made of acrylic materials. To gain longer life and top performance from your

canvas including windshield connector, side and aft curtains, bow and cockpit covers, we recommend the

following:

l The canvas and clear plastic are not designed to withstand long periods of time exposed to the

elements as a protective cover at dockside or when your boat is in storage. A full, properly fitted, light

colored mooring transportation or storage cover should be used for these purposes.

l If canvas gets wet during use, remove side curtains and open windshield so seams can dry out. The

air circulation will allow all canvas to dry and prevent the growth of mildew. Never store wet or

damp canvas.

l Occasionally set up all canvas and curtains and hose down with fresh water to remove accumulated

soot and dirt. Sweep or brush the underside of the canvas to prevent the accumulation of dirt and

mildew.

M-3

WARNING

!

!

Never trailer your boat with the convertible/bimini canvas (including side curtains, aft

curtain, windshield connector, bow cover and cockpit cover) up. Monterey Boats’ canvas is

not designed to withstand the high wind loads of trailering. Severe wind damage can occur

such as torn material, fastener pull-out and frame distortion. Damage caused by trailering

is not covered under the limited warranty.

l The outer canvas surfaces can be cleaned with a soft scrub brush and either automotive convertible

top cleaners or household cleaners suitable for use on acrylic surfaces. The underside of the canvas

may be periodically sprayed with a spray disinfectant to prevent the growth of mildew.

l Do not store or dock your boat under trees. Tree sap is very corrosive to canvas and can also be

harmful to gelcoat and vinyl interiors.

l Adjust top bows to eliminate pockets in which rain water can accumulate. The weight of this

accumulated water can collapse the top or bag the canvas.

l Zippers and snaps should never be forced. Occasionally lubricate with silicone/Teflon grease.

l When trailering, dismantle, roll or fold and securely stow all canvas to prevent damage. Monterey

recommends purchasing a transportation cover to keep your boat clean on the road. Your Monterey

dealer will assist you in finding a suitable cover (not available from Monterey Boats).

l Roll clear plastic (isinglass) curtains (do not fold) and store in a clean, dry place.

l Do not allow petroleum products or bug sprays to come in contact with canvas.

NOTICE

Your Monterey boat is basically an open vehicle. Therefore, in spite of well-designed and

well-fitting canvas enclosures, your boat is not waterproof. We have made every effort to

design these enclosures to conform with the boat, but a certain amount of leakage may

occur, especially at the seam lines. After cleaning with soap and water, allow seams to

thoroughly dry. A sealant can be applied on the seams to somewhat close the needle holes

according to the manufacturer’s instructions.

Acrylic and Plexiglas

Acrylics and Plexiglas have properties that make them ideal for the marine environment. Components

such as cabin doors and deck hatches need special care to prevent scratches and other damage. The

following guidelines will help keep acrylics and Plexiglas looking good for years to come.

DO’S

l Wash your hatches, windshield connector, side curtains and other clear plastic pieces, as well as

other acrylic components on your boat with a mild soap and plenty of lukewarm water.

l Use a clean, soft cloth, applying only light pressure.

l Rinse with clear water and dry by blotting with a damp cloth or chamois.

l Grease, oil or tar may be removed with a good grade of hexane, aliphatic naphtha or kerosene.

These solvents may be obtained at a paint or hardware store and should be used in accordance with

the manufacturer’s recommendations.

l To maintain a high-luster finish on your acrylics, we recommend that after properly cleaning, apply

Meguiar’s™ Mirror Glaze #10 with a soft towel. Note: If slight scratches appear on acrylics, use

Meguiar’s™ Mirror Glaze #17.

®

M-4

NOTICE

Clear plastic (isinglass) is subject to ultraviolet (sunlight) degradation over time. It may turn

yellow-brown (a burnt appearance) and get brittle. Two things that can accelerate this

degradation are:

1. Direct contact with aluminum or stainless steel frames. Use “Standoffs.”

2. In salt water areas, dried salt crystals on the plastic will amplify sunlight. Wash after

each use and/or windy day.

DON’TS

l Do not subject acrylic material to high temperatures when polishing.

l Do not use glass cleaning sprays, scouring compounds or solvents like acetone, gasoline, benzene,

carbon tetrachloride or lacquer thinner.

l Do not use masking tapes, duct tapes or packing tapes on your acrylic materials.

l Do not drill holes in your acrylic materials without proper drill bits (special bits are used in acrylic

material to avoid damage).

Stainless Steel

Marine grade stainless steel components such as hardware, cleats, eyes, and rails offer superior corrosion

resistance. When properly maintained, stainless steel will not rust or stain, even in harsh saltwater

environments. However, if not maintained, stainless steel can rust, discolor or even corrode. The following

guidelines will help keep stainless steel looking good for years to come.

DO’S

l Clean stainless steel frequently (daily in salt or polluted environments) with mild soap and plenty of

water. Any cleaner safe for use on glass is usually safe for stainless steel.

l Remove rust spots (especially around welds) immediately with a brass, silver or chrome cleaner.

Irreversible pitting will develop under rust allowed to remain on stainless steel for any period of time.

l Remove rust stains on gelcoat. See dealer for recommended product.

l Protect stainless steel with waxes or polishes suitable for marine use.

DON’TS

l Do not use coarse abrasives like sandpaper or steel wool which may actually cause rusting.

l Do not use acids or bleaches which may etch the naturally occurring protective coating.

l Do not leave stainless steel in contact with iron, steel, or other metals which cause contamination

leading to rust or corrosion.

M-5

Gemlux Stainless Steel Information and Care Instructions

The GEMLUX Stainless Steel products on your boat are made to the highest quality standards.

Stringent quality control processes such as metallurgical analysis, precision polishing, multiple inspections

and Six Sigma procedures ensure the highest quality possible. In order to ensure that your GEMLUX

Stainless Steel maintains its beautiful finish, it is critical that you care for it properly.

WARNING: Your Stainless Steel can be damaged by exposure to acids and other corrosive agents

found in many cleaning products. A partial list of additives that may cause staining and a weakening of

the finish is provided below. Use of these and other similar solutions to clean your boat can cause your

Stainless Steel to bleed and will void your warranty.

Chlorsulphonic Acid

Ferrous Iodide

Hydrobromic Acid

Iodine

Sodium Chlorite

Sulphur Chloride

Bleach

Comet

EZ-ON, EZ-OFF

Cleaner

Ferric Chloride

Fluorine

Hydrofluosilicic Acid

Silver Chloride

Sodium Hypochlorite

Sulphuric Acid

Muriatic Acid

On & Off Cleaner

Rust StainsAway

Ferrous Chloride

Hydrochloric Acid

Hydrofluoric Acid

Sodium Bifluoride

Stannic Chloride

SnoBol

Soft Scrub

Marine Spray Nine

Cleaning and Cleansers

Frequent cleaning of your stainless steel with soap, water and GEMLUX Cleaning Wax will help maintain

the finish. Always rinse the metal thoroughly with clean water and dry completely. Clean soft cloths or

pads should be used. The use of steel wool pads or other highly abrasive brushes or sponges are not

recommended and will damage the surface.

Contamination of the surface by chemicals, dirt or other material hinders the passivation process and

traps corrosive agents, thus reducing corrosion protection. If your stainless steel is exposed to such

chemicals it should be re-passivated with GEMLUX Passivation solution.

Job Cleaning Agents Method Comments

Once your stainless is

free of discoloration

and/or bleeding, spray

GEMLUX Passivation

Solution directly onto

Routine cleaning Soap and water

Apply with a sponge

or soft cloth. Dry area

completely.

stainless. Allow to cure

for 30-60 seconds.

Stubborn stains,

discoloration or

bleeding

GEMLUX Cleaning

Wax

Apply with soft, dry

cloth. Allow to dry.

Polish and buff using

a clean, dry cloth.

Rinse with fresh water

and dry the area. This

solution will help

re-passivate the stainless

steel.

For purchase information on the GEMLUX Cleaning Wax or GEMLUX Passivation Solution, please

contact us at the numbers listed below.

Tel: 904-264-0173 / 888-GEMLUX-1 (888-436-5891)

Fax: 904-269-5905

www.gemlux.com

M-6

Cockpit Vinyl Upholstery with PreFixx®Coating

Beginning with the 2008 model year, Monterey Boats uses OMNOVA white, smoother and embossed

pleated vinyl material with PreFixx top coating. All other accent embossed white and colored vinyl

requires different care and maintenance. Please refer to page 7-4 for more information.

PreFixx Cleaning Instructions

PreFixx is engineered so that upholstery can be cleaned again and again without showing signs of wear.

With easy cleanability, proven stain and abrasion resistance, PreFixx protective finish can reduce

maintenance costs and frequent reupholstery.

Durability. Creates a barrier that resists stains from penetrating to the surface of the vinyl for proven,

long-lasting protection. With laboratory-tested stain resistance and improved wear properties, BoltaSoft

®

upholstery treated with PreFixx protective finish can retain a “like-new” appearance longer.

Easy Maintenance. Enables most common stains like dirt and smudges to wipe off easily. Many difficult

stains like ballpoint ink also can be cleaned with active solvents, such as nail polish remover, without

damaging the PreFixx protective finish (when recommended cleaning instructions are followed).

Normal Care and Cleaning

Remove ordinary dirt and smudges with a mild soap and water solution and a clean, soft cloth or towel.

Dry with a soft, lint-free cloth or towel. CAUTION: The use of vinyl “conditioners” or “protectants” is not

recommended and should be avoided on vinyl upholstery treated with PreFixx protective finish.

Special Cleaning Problems

Although BoltaSoft upholstery treated with PreFixx protective finish is resistant to most common stains,

the dyes and pigments in some staining agents have the ability to create a permanent stain if not treated

properly. To clean difficult stains from upholstery treated with PreFixx protective finish, locate the staining

agent in the lists below and follow its recommended cleaning method. For best results, treat all stains

immediately.

Cleaning Tip: To determine the method and type of cleaners, the source of the stain should be identified.

Staining Agents: Baby oil, ketchup, chocolate, motor oil, olive oil, grape juice, urine, blood, hair oil tonic,

tea, coffee and betadine. Use Method 1.

Staining Agents: Eye shadow, crayon and grease. Use Method 1. If stains remain, use Method 2.

Staining Agents: Tobacco tar (nicotine), permanent felt tip marker, yellow mustard, lipstick, ballpoint pen

and spray paint. Use Method 1. If stains remain, use Method 2. For stubborn stains still remaining, use

Method 3.

The recommended cleaners used in Cleaning Methods 1, 2 and 3 are progressively more aggressive.

Often, it is better to begin with the least aggressive cleaner and move to the next strongest only if the stain

remains. NEVER EXCEED a staining agent’s recommended cleaner or cleaning method, however.

Method 1: Use one of the following cleaners with a soft cloth or damp sponge. Rinse area with fresh

water, and then dry with a clean, lint-free cloth.

l Formula 409

l Fantastik

®

All-Purpose Spray Cleaner

®

Spray Cleaner

M-7

Method 2: Use a solvent-type cleaner*, such as rubbing alcohol (isopropyl alcohol). Rinse cleaned area

with fresh water, and then dry with a clean, lint-free cloth.

Method 3: Use a strong, active solvent cleaner* diluted in water (70% water/30% solvent cleaner), such

as nail polish remover (acetone/water). Clean with a soft cloth or damp sponge. Stain should be removed

with less than six (6) rubs. If the stain persists after six rubs, the stain has set and probably cannot be

removed. Rinse cleaned area with fresh water, and then dry with a clean, lint-free cloth.

CAUTION

!

Some solvents are highly flammable. Exercise proper care in cleaning and notify personnel

in area of danger. Wear rubber gloves during all cleaning activities. Use caution in cleaning

around buttons, stitching and wooden or decorative trim, since these solvents could

seriously damage such areas.

PREFIXX is a registered trademark of OMNOVA Solutions, Inc.

FORMULA 409 is a registered trademark of The Clorox Company.

FANTASTIK is a registered trademark of Dow Consumer Products, Inc.

Gelcoat

The smooth, beautiful skin of the fiberglass hull is made of gelcoat. Gelcoat is a strong but thin (though

thicker than automotive paint) layer of colored resin. The best way to keep the gelcoat skin on your boat in

top condition is through regular maintenance. The following guidelines will help keep gelcoat looking good

for years to come.

DO’S

l Keep the gelcoat surface out of direct sunlight or covered when not in use.

l Wash gelcoat frequently (daily in salt or polluted environments) with mild detergent and plenty of fresh

water. Remove any stains quickly. Gelcoat is microscopically porous, so long term staining may

become permanent.

l Regularly (monthly in salt or polluted environments) wax gelcoat surfaces with marine grade wax

recommended for fiberglass finishes.

DON’TS

l Do not use plastic or other nonporous (non-breathable) materials to cover gelcoat surfaces. Trapped

moisture from condensation can cause gelcoat damage. Shrink wrap storage covers must be

properly ventilated, including hullsides.

l Do not use abrasives, bleaches, ammonias, acids or harsh detergents. See your dealer for special

marine formulations.

l NEVER wax a gelcoat surface in direct sunlight.

l Do not attempt to remove stains and scratches. Chalking, stains, and minor scratches can be

removed in most cases with careful rubbing and polishing with appropriate chemicals and is best

done by a professional – see your dealer.

CAUTION

!

Apply No-Slip tape or step plates on surfaces which are walked on. Waxed gelcoat surfaces

are extremely slippery, especially when wet.

M-8

Exterior Carpet

Exterior carpet manufactured by Syntec Industries is produced with a special blend of resilient fibers to

withstand traffic and retain its beauty.

Carpets manufactured by Syntec are inherently stain-resistant. To keep your carpet at its best, we

recommend regular vacuuming for general cleaning, soap and water for hard-to-remove spots and an

approved cleaner for deep cleansing and to revitalize the carpet.

Stain Removal

If a spill does occur, it can easily be removed by following the stain removal chart. All stains should be

removed as soon as possible, as this enhances the ability to remove the stain.

Miscellaneous Stains Removal Process

Coffee, Tea, Coke, Dye, Fruit Juice, Ice Cream,

Motor Oil, Clay, Grease, Blood, Catsup,

Chocolate, Milk, Rust, Latex Paint, Water

Colors, Berry Stains, Egg, Salad Dressing,

Wine, Furniture Polish, Fish Formula,

Mayonnaise or Urine

Persistent Stains Removal Process

Chewing Gum, Crayon, Ink, Wax, Lipstick,

Tar, Polish or Oil Paint

Apply warm water and household detergent in

minimal amounts to the stained area. Sponge

or scrape until stain is removed and wash

thoroughly with clean water.

Apply warm water and household detergent.

Work well into the stained area, then flush with

warm water.

NOTICE

Most stains should be removed easily from olefin fibers. If the stain persists, the cleaning

procedure should be repeated to ensure stain removal. Remember, the sooner the stain

removal process begins, the easier the stain will be to remove. Under no circumstances

should any solvents normally associated with the dry cleaning of apparel

(perchlorethylene, carbon tetrachloride, etc.) be utilized, as permanent damage to the

fiber will result.

MARPOL Treaty

The International Convention for the Prevention of Pollution from ships, commonly referred to

as the MARPOL Treaty (MARine POLlution) prohibits the overboard dumping of all shipgenerated plastics, chemicals, garbage and oil.

M-9

BATTERY SPECIFICATIONS

ATTENTION

MINIMUM BATTERY SIZE REQUIRE D:

Group 24

750 CCA@ 0°F/-18°C or 950 MCA

MINIMUM BATTERY SIZE REQUIRE D:

800 CCA@ 0°F/-18°C or 1000 MCA

ATTENTION

Group 31

Group 24 is for: V6 & V8 Small Block Engines up to 6.2 Liters.

Group 31 is for: Volvo 8.1L, Merc 496 Mag Big Block Engines and Merc DTS Models

NOTICE:

Do not use a battery with wing nut connectors; use hex nuts. Battery cables should

always be tightened with a wrench.

CAUTION

!

Do not use deep cycle batteries on EFI engines. A deep cycle battery, while it may have

enough cold cranking amps (CCA), will cause problems with EFI engines. The correct

battery for EFI engines is a standard marine starting battery.

NOTE: Batteries are not provided by Monterey Boats. The above battery information was obtained

from installation and owners manuals published by Mercury Marine and Volvo Penta of the

Americas. For sourcing and additional battery information, contact your local Monterey dealer.

Typical labels used to identify battery cables and fuel lines are shown below.

PORT BATTERY

POSITIVE (+)

STBD BATTERY

POSITIVE (+)

ENGINE

GROUND (-)

PORT ENGINE FUEL

SUPPLY

STBD ENGINE FUEL

SUPPLY

TANK FUEL

SUPPLY

Positive battery cables are red. Negative battery cables are yellow or occasionally black.

M-10

FIRE EXTINGUISHING SYSTEM

a

Some stern drive boats are equipped with an optional Automatic Fire Extinguishing

System for an engine compartment fire. The system is automatically actuated when

temperatures reach or exceed a preset limit.

SYSTEM

CHARGED

When actuation occurs, a loud popping sound may be heard followed by “rushing”

air sound. When a discharge occurs, immediately shut down all electrical and

mechanical systems including engine and powered ventilation (blowers).

Do not open the engine hatch at this time! This feeds oxygen to the fire and

flashback can occur. Allow the extinguishing agent to “soak” the compartment for at

least fifteen (15) minutes, and wait for hot metals and fuels to cool before inspecting

for cause or damage.

WARNING

!

Fire extinguishing agents and fire by-product fumes are toxic; do not breath fire fumes.

Accidental discharge can be dangerous and may cause serious injury. Do not attempt to

service the system unless qualified to do so.

WARNING

!

If fire is still active after system discharges: All occupants should immediately put on PFDs

(Personal Flotation Devices) and get off the boat.

!

!

DISCHARGED

AUTOMATIC

FIRE

EXTINGUISHING

SYSTEM

SYSTEM

KC-0084

CAUTION

!

Extinguishing agent cylinders must be accurately weighed periodically according to the

manufacturer’s specifications to ensure that they are adequately charged.

M-11

SPECIAL GAS PRECAUTIONS

KC-0463

KC-0464

KC-0468

KC-0465

KC-0469.1

KC-0466

KC-0467

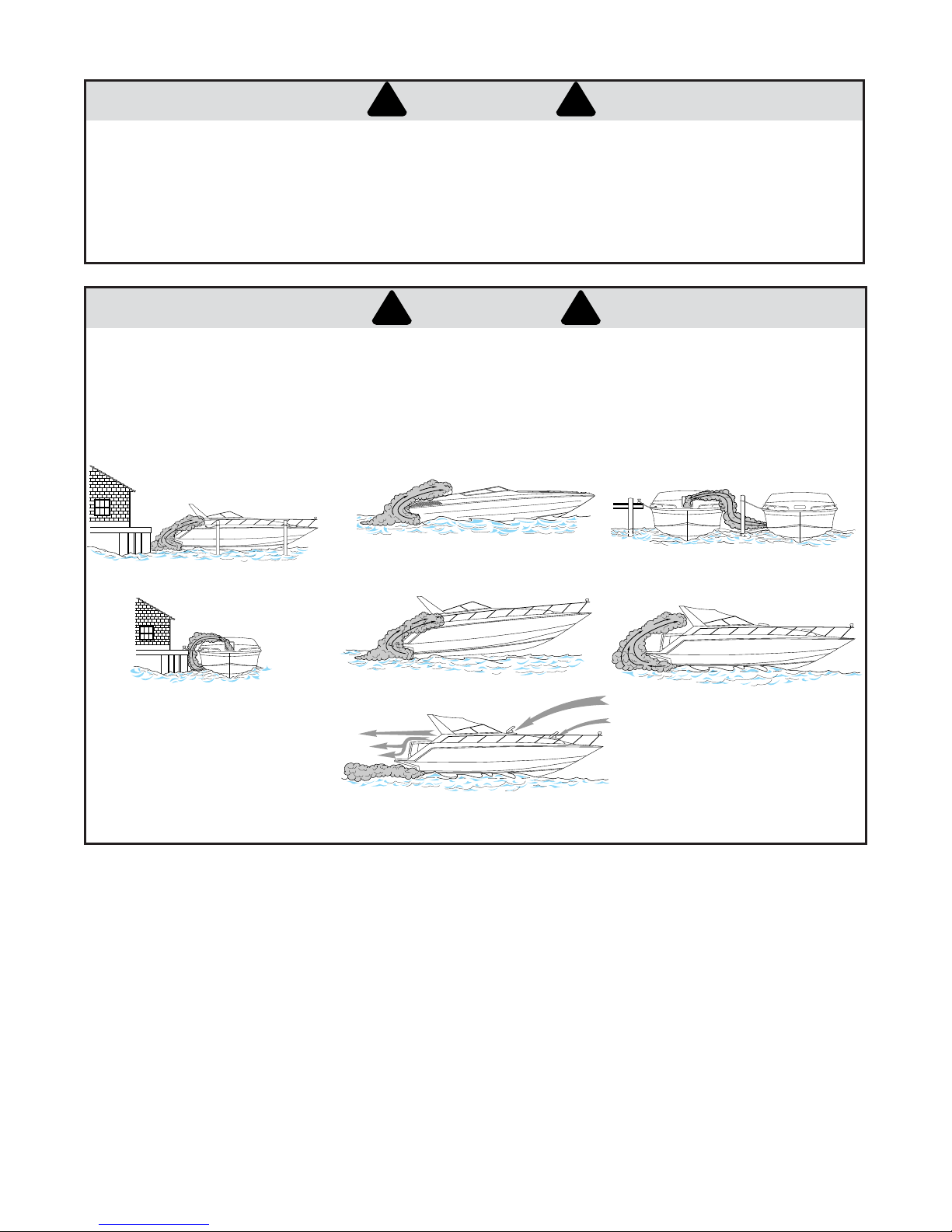

DANGER

!

Holding tank systems on boats produce odorless Methane gas which is extremely lethal in

enclosed spaces. Follow these precautions when working on your boat's holding tank

system to prevent injury:

l Before work, open all doors and hatches wide, and rig a good fan to disperse gas.

l During work, have another person frequently check on you.

l Before and during work, DON’T SMOKE.

DANGER

!

EXTREME HAZARD – Carbon monoxide gas (CO) is colorless, odorless and extremely

dangerous. All engines and fuel burning appliances produce CO as exhaust. Direct and

prolonged exposure to CO will cause BRAIN DAMAGE or DEATH. Signs of exposure to

CO include nausea, dizziness and drowsiness. Sources of CO include:

!

!

Blockage of boat exhausts by

obstruction.

Exhausts traveling along obstruction.

ENSURE ADEQUATE VENTILATION FOR CORRECT AIR MOVEMENT THROUGH BOAT!

Operating at slow speed or while dead

in the water.

Operating with high bow angle.

Exhausts from other vessels in

confined areas.

Operating with canvas tops and side

curtains in place without ventilation.

M-12

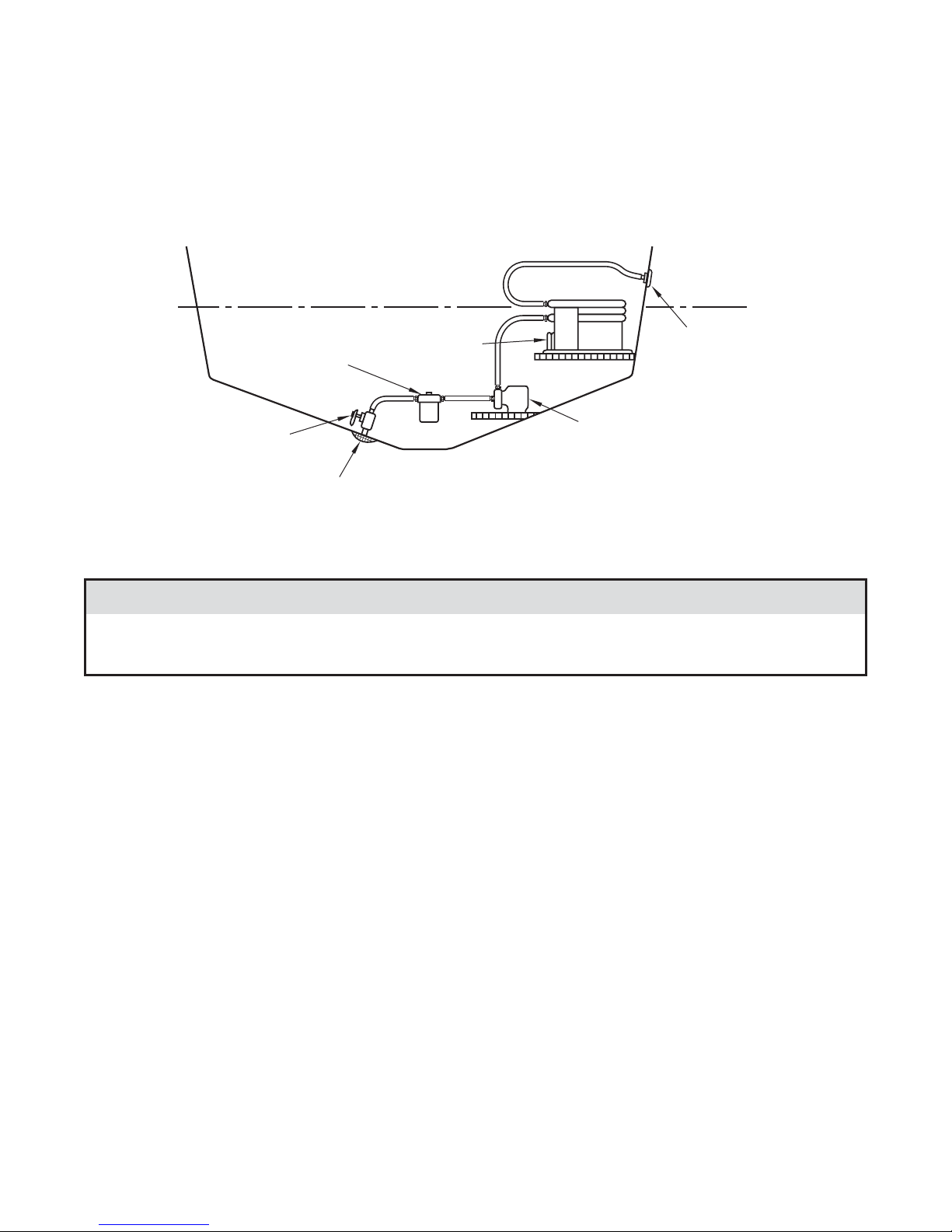

GENERATOR SET

KOHLER

HEAT

EXCHANGER

EXHAUST

MIXER

ENGINE-DRIVEN

SEAWATER PUMP

SEAWATER

STRAINER

INTAKE

STRAINER

SEACOCK

HANDLE

SEACOCK

COOLANT

RECOVERY

TAN K

KC-2058

The following procedure summarizes the operation of, and safety precautions for, the optional marine

generator available for your boat. Before operating your generator, read the owner's manual which

accompanies your generator.

Prestart

1. Check that the air cleaner is clean and properly installed.

2. Check the battery connections and electrolyte level (if battery has filler caps).

3. Check that the fuel tanks are full and that the fuel system is primed for operation.

4. Check that the oil level is at or near FULL mark.

WARNING

!

!

Hot coolant can cause severe burns. Do not remove the pressure cap when engine is hot.

4. Check that coolant level in coolant recovery tank is between the MIN and MAX marks. Periodically

remove the pressure cap and check on the fluid level when engine is cool. Do not rely solely on

level in the coolant recovery tank.

5. For initial startup only, prime the seawater pump by closing seacock, removing hose from water filter

outlet, filling hose and pump with clean water, replacing hose and opening seacock.

CAUTION

Failure to have seacock open when generator is running will result in serious engine

damage due to overheating.

6. Check that generator seacock is open.

7. Check that marine ship-to-shore transfer switch is in the proper position and that all breakers are in

the OFF position.

8. Open the manual fuel shut-off valve (if equipped).

M-13

Starting

WARNING

!

The blowers must be operated for a minimum of four minutes before each time the engine

is started. Failure to operate the blower can cause an explosion.

1. Operate the ventilation blowers for a minimum of four minutes and check the engine compartment for

gasoline vapors.

!

CAUTION

Do not crank the engine for more than seven seconds at a time. Allow a five-second cool

down period between cranking attempts if the engine fails to start. If the engine fails to start

after three attempts, contact an authorized dealer for repairs. Failure to do so may result in

serious damage to the starter motor.

2. Press the controller master switch, or the remote start switch on the AC control panel, to the START

position and release switch when the unit has started.

CAUTION

Allow at least 30 seconds after shutdown before starting a hot engine. If the engine fails to

start after the first attempt, close the seacock before continuing. This will prevent seawater

from entering the engine cylinders through the exhaust valve.

CAUTION

After generator has started, check to be sure that water is flowing overboard from the

generator discharge. If there is no discharge, stop and check for leaks or obstructions.

Stopping

1. Run generator set at no load for five minutes to allow engine to cool down.

2. Switch the controller master switch, or the remote start switch on the AC control panel, to the STOP

position and wait until the generator set comes to a complete stop.

Circuit Protection

The AC circuit breaker on the generator controller will trip if a fault is detected in the AC output circuit. In

case of fault, refer to your generator owner's manual for troubleshooting information.

CAUTION

Only replace fuses with fuses of the same type (ABC or #AB (ceramic)) and ampere rating.

Do not use clear glass fuses.

Engine Shutdown Switches

The generator set engine is protected by three shutdown switches which automatically reset after the

engine cools down; or in the case of low oil pressure, if the problem is corrected.

Low Oil Pressure (LOP) – will shut down unit if pressure is 20 psi or less.

High Water Temperature (HWT) – will shut down unit if temperature is greater than 248°266°.

High Exhaust Temperature (HET) – will shut down unit if temperature is greater than

M-14

215° ± 5°.

AIR CONDITIONER

The following describes the optional air conditioning unit available for your boat. Before operating your air

conditioner, read the accompanying owner's manual for more information.

The rated capacity of the air conditioning unit for the 318 CU is 5,000 BTU/hr.

The optional air conditioning unit is supplied with seawater through a seawater pump. The seacock must

be open to operate the heating/cooling unit.

WATER LINE

SEACOCK

CONDITIONING

STRAINER

SCOOP TYPE

THRU HULL INLET

AIR

UNIT

SEAWATER

PUMP

SEAWATER

OUTLET

KC-2088

CAUTION

After air conditioner has started, check to be sure that water is flowing overboard from the

air conditioner discharge. If there is no discharge, stop and check for leaks or obstructions.

M-15

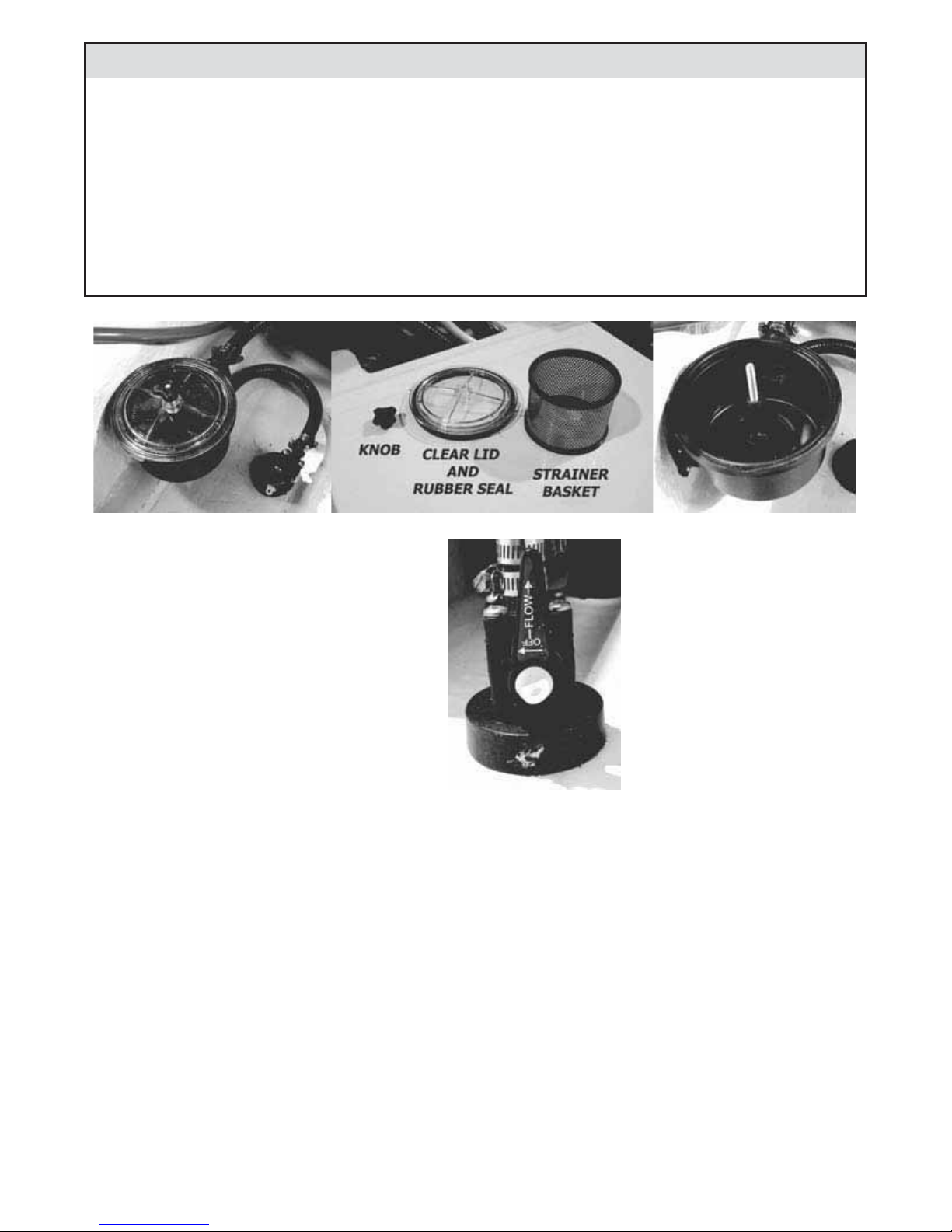

CAUTION

The sea strainers for the generator and/or air conditioning must be checked regularly for

obstructions. If the strainer gets clogged it can prevent adequate water flow to the units

causing severe damage. The strainers are equipped with a clear top for easy visual

inspection. In order to clean the filter basket, first make sure the seacock is in the CLOSED/

OFF position. Verify the genset and or AC systems are turned off. Remove the knob located

on the top of the strainer basket. Gently apply upward pressure on the clear lid. Do not use

any tool to force or pry the lid up. This may result in damage to the strainer. Remove the

clear lid and rubber seal. Remove the strainer basket assembly, remove all debris, and

rinse clean. Reinstall the strainer basket. Apply a small amount of lubricant to the rubber

seal. Reinstall the lid and tighten the knob snugly. Do not overtighten! Open the seacock

and activate the unit to check for leaks.

When the seacock handle is in the vertical

position to the base, it is open and seawater

can flow into the system it supplies. When

the handle is in the horizontal position, the

seacock is closed and no water can flow

into the unit. Always keep the seacock

closed when not in use. Also verify it is

open before starting any equipment it

supplies water to. Periodically check

seacock seals for leaks and that all hose

clamps on fittings are tight. Lubricate

moving parts at least annually.

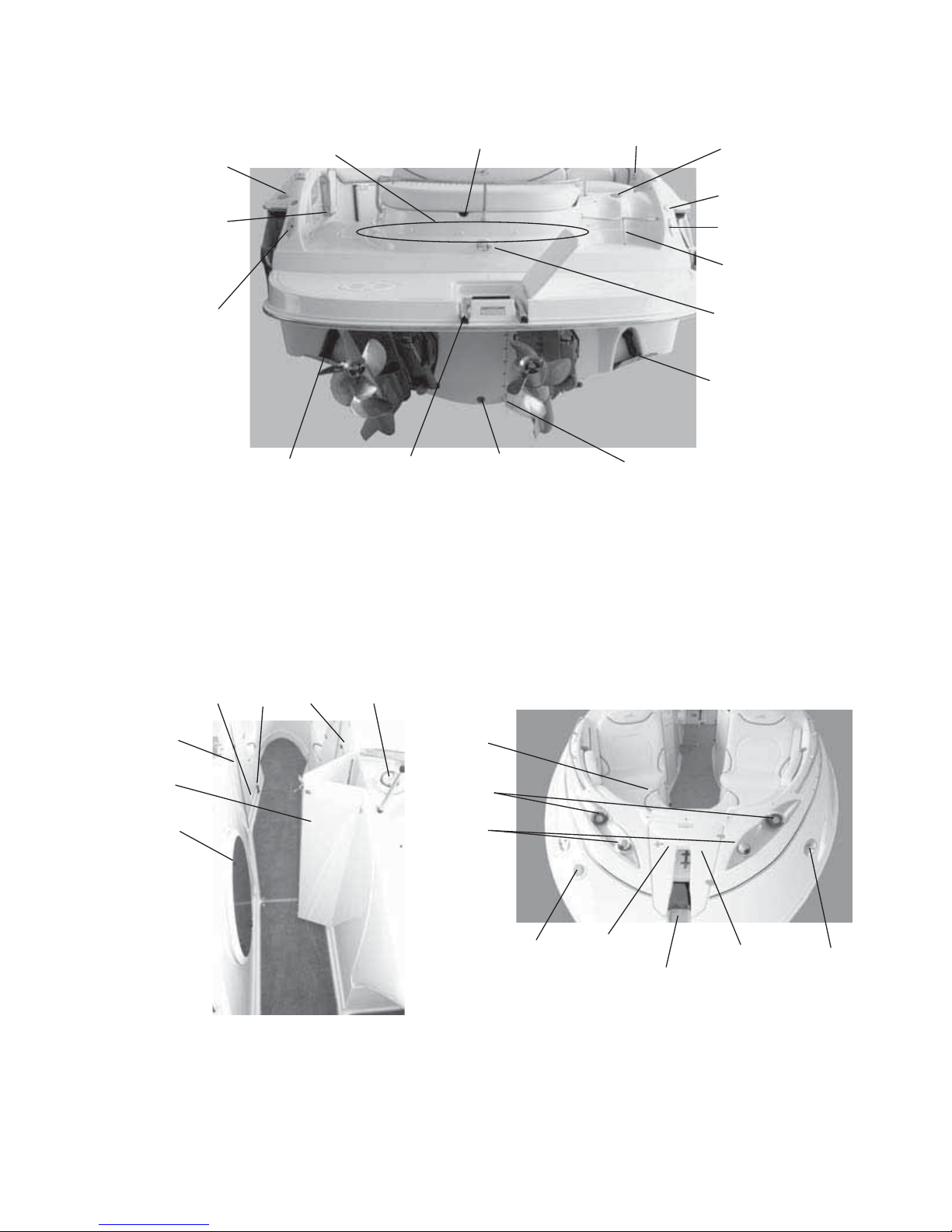

BOAT LAYOUTS & DETAILS

The following illustrations are intended to give you, the boat owner, a brief overview of your new boat.

These illustrations are a representation and may not reflect all options or layouts. Your Monterey dealer or

their representative can give you a detailed demonstration of your boat and operation of its many features.

M-16

VECTOR SERIES AIR CONDITIONER SELF CONTAINED UNIT WIRING DIAGRAM

M-17

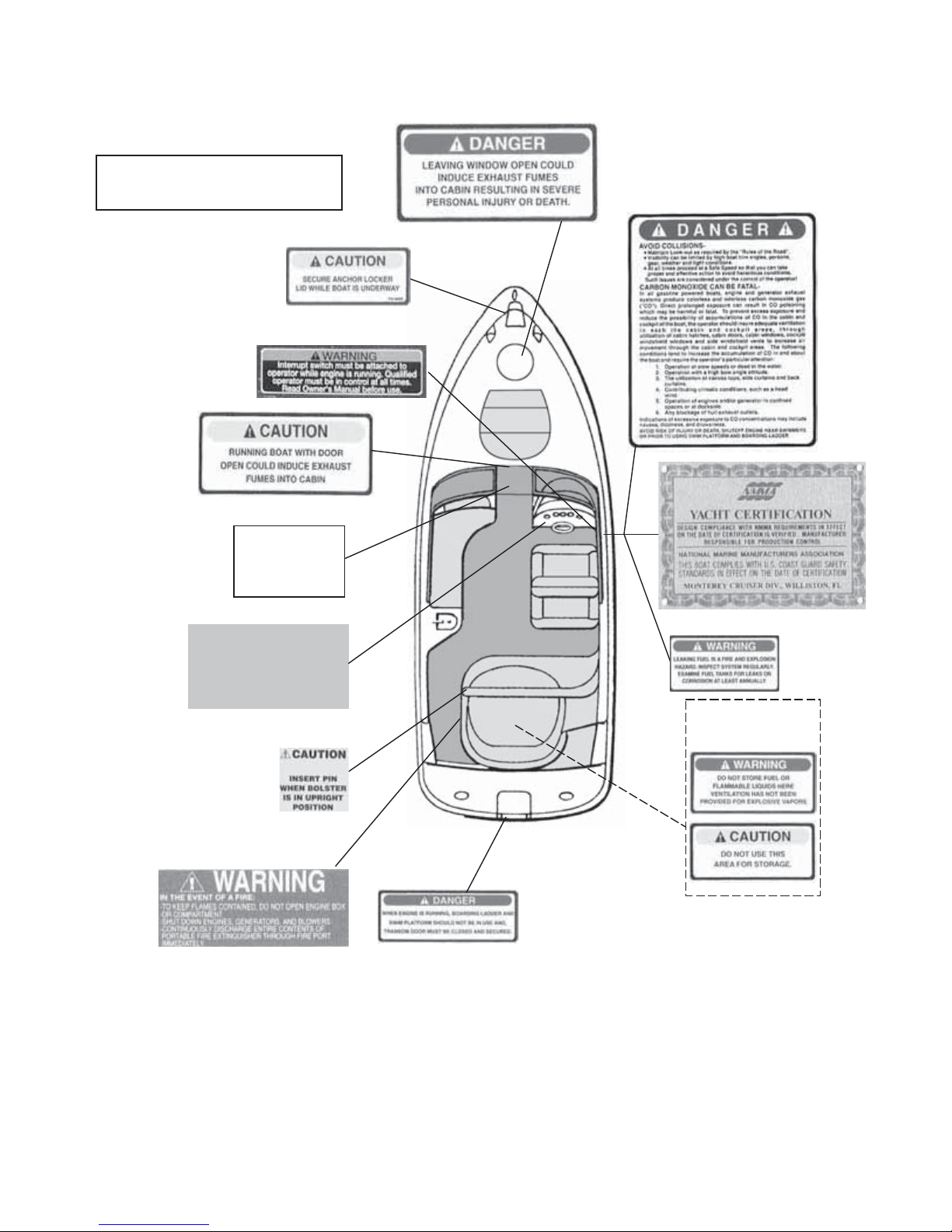

Warning and Safety Labels

The labels on this page are a sample of the warning

and safety labels on your boat. There may be

additional or differently worded labels. Please be

aware and use appropriate caution.

Volvo Engine

WARNING

GASOLINE VAP ORS CAN EXPLODE

BEFORE STARTING ENGINE:

CHECK ENGI NE COMPARTMEN T FOR

GASOLINE OR VAPORS.

OPERATE BL OWER FOR 4 MINUT ES.

RUN BLOWER BE LOW CRUISING SPEED.

CAUTION

TO AVOID INJU RY, GLASS

DOOR MUST B E S ECU R ED IN A

CLOSE D A ND LOC KED

POSITION WHEN BOAT IS

UNDER WAY. USE BOTH TURN

LOCKS TO SECUR E DOOR.

WARNING & SAFETY LABELS

Label placement shown is

approximate.

ENGINE AREA

LABELS

M-18

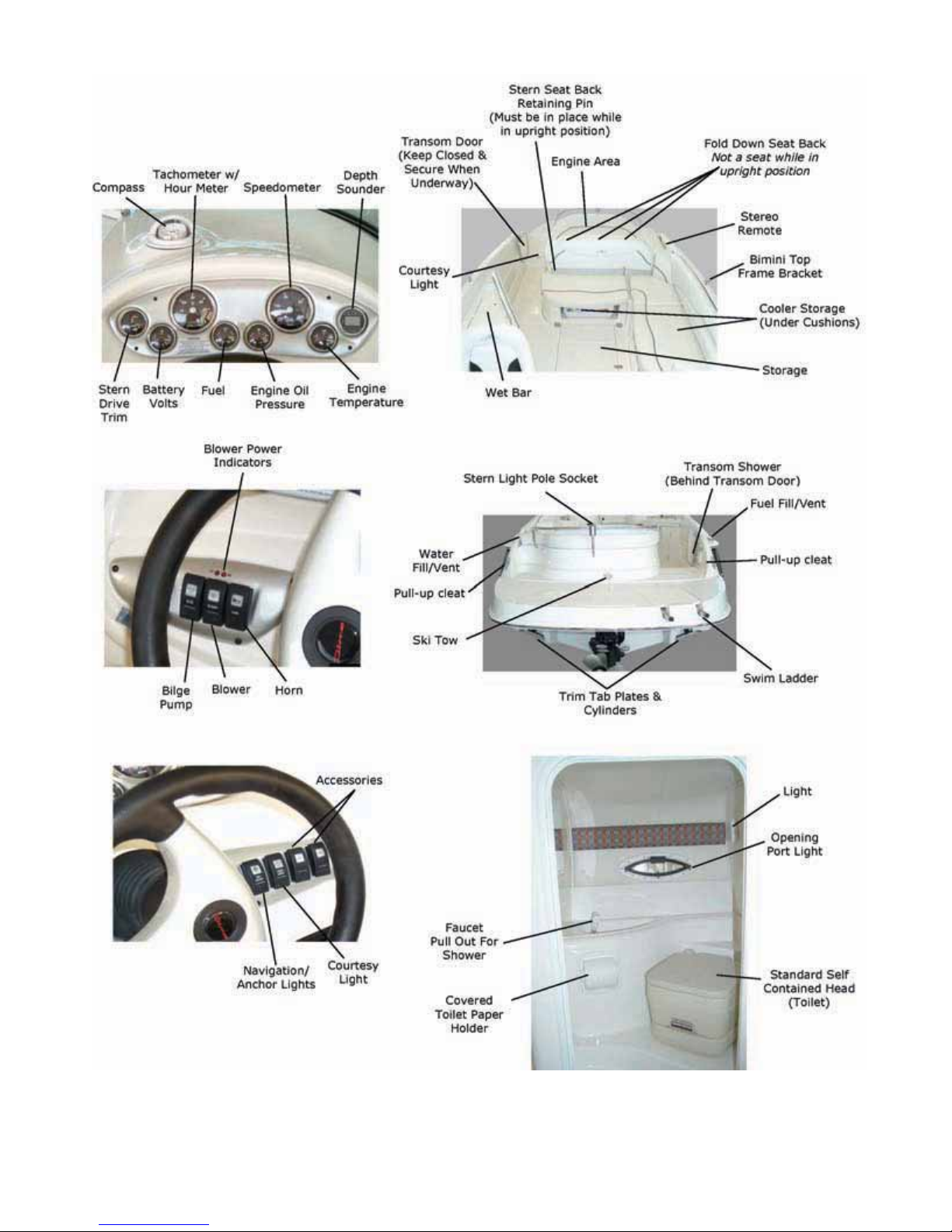

278 SS/SSX/SC General Features

M-19

278 SC Features

(CO)

Window Hatch/

Pass Thru

Refrigerator

(Optional)

Overhead

Lights

Portable

Stove

Light

Switch

Swivel

Light

Storage

Stove

Storage

Opening

Port Light

Deck Hatch

Speakers

Swivel

Light

Swivel

Light

Mirror

(Storage Area

Behind Mirror)

V Berth

Filler

Cushions

Deck Hatch

Carbon Monoxide

Detector

Access Hatch Below Companionway

Shower Sump

with Auto Pump

Speaker

Bilge Pump

Float Switch

Courtesy

Light

Head Door

Bilge Pump

(Not Shown)

Docking

Lights

Navigation

Ladder/Line

Storage

Locker

Telescoping

Ladder

Glove

Box

Drink

Holder

Window Hatch/

Pass Thru

Flip-up

Bolster

Companionway Door/

Bow Access Steps

Lights

Pull-up

Cleats

Horn

Storage

Locker

Drain

Pedestal Seat Bottom with

Swivel Brake & Fore/Aft Brake

(Secure before boat operation)

M-20

278 SS/SSX Features

Head

Walk-Thru

Door

Walk –Thru

Door Latch

Cockpit Table

Base

Storage Area

Compass

Storage

(Under Cushion)

Navigation Lights

Horn

Locker Lid

Latch

Anchor

Roller/Frame

Docking Lights

Pull-Up

Cleat

Anchor

Rope

Locker

M-21

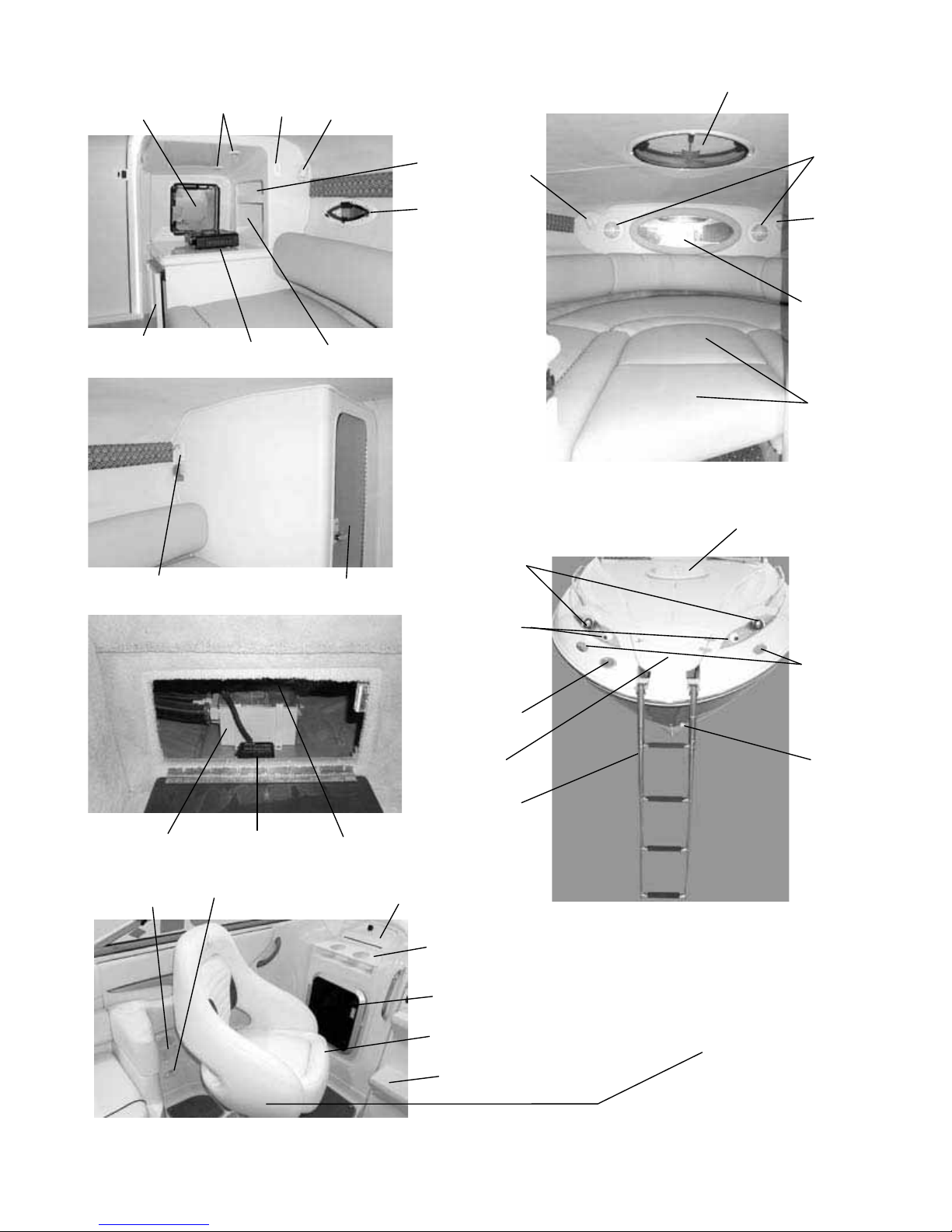

278 Engine

Automatic

Float Switch

Bilge Pump

Battery Trays

(Batteries not

provided by

Monterey Boats)

Engine

Blowers

Trim Tab

Pump

Blower

Hoses

Stern Drive

Trim Pump

Sea Water Intake for

Porcelain Head

Option

(Seacock shown in

parallel open

position)

Waste Out

(Seacock shown

in perpendicular

closed position)

Macerator

(Option)

Main DC Accessory

Breaker (40 Amp)

Circuit Breakers

(Remove Cover to Access)

• Aft Bilge Pump

•

Fwd Bilge Pump

• Shower Sump Pump

• CO Monitor

Automatic

Fire

Light

Fresh Water Tank, Pump & Strainer

Not Shown - Recessed und e r ste p a re a

Yellow Battery Cable (Ground)

(Trim Pump Ground – Black)

Red Battery

Cable (Positive)

Light

(Not Shown)

BATTERY

POSITIVE (+)

M-22

ENGINE

GROUND (-)

Stereo

Remote

(optional)

Not a seat

while in upright

position

Stern Seat Back

Retaining Pin

(Must be in place while

in upright position)

Engine Hatch Switch

(Bow Rider Only, Switch

for Cuddy Engine hatch

located at helm)

Faucet

Pull Out For

Shower

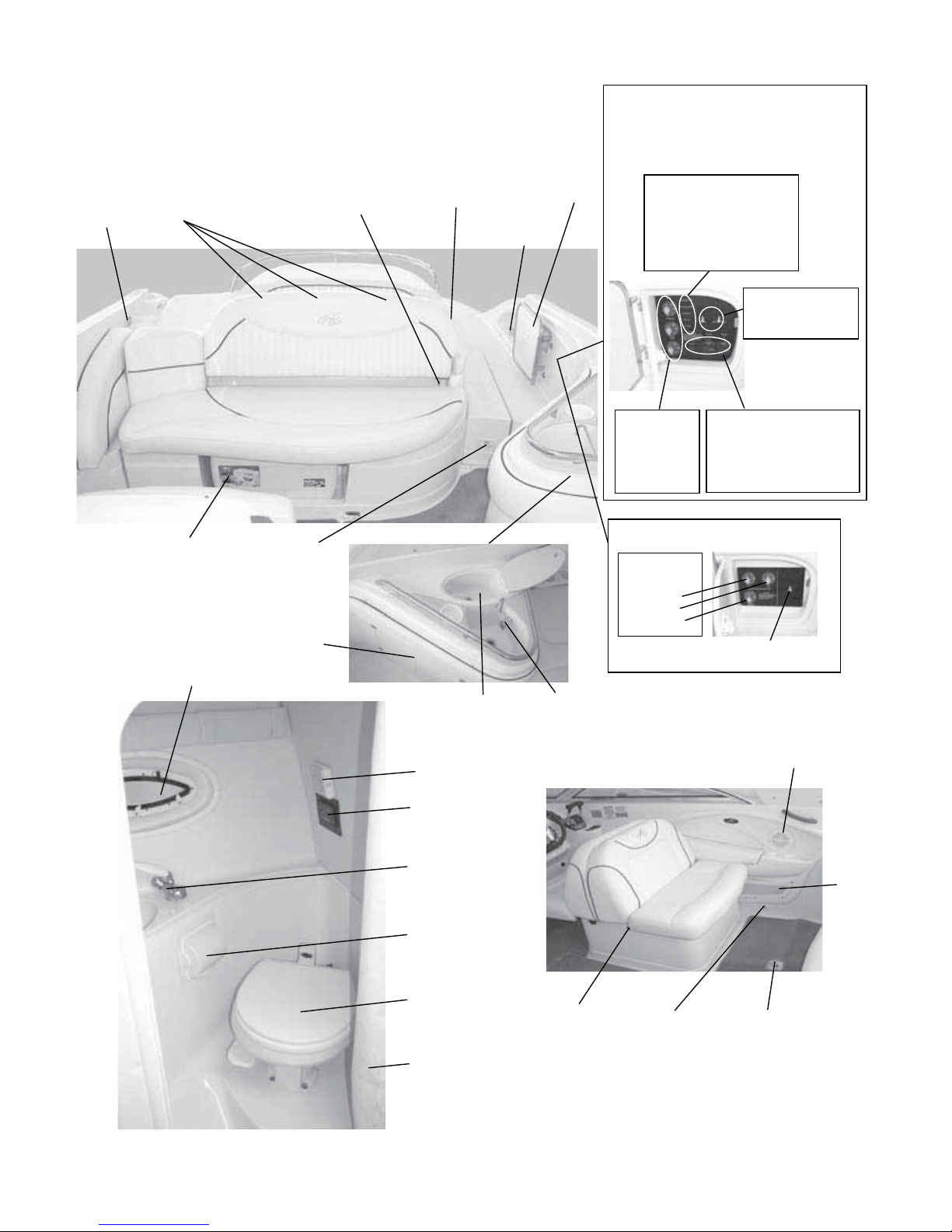

318 SS/SSX/SC General Features

Cuddy Panel

NOTE: Original version pictures -

See electrical schematics

for later info.

Transom

Door

Circuit Breakers

Fwd Emergency Pump

Emergency Bilge Pump

Stereo Memory

Sump Pump

Electronics

Circuit Breakers

AC (Alt Crnt) Main

Air Conditioner

Cooler Storage

(Space not available

with Generator Option)

Refrigerator Option

Opening

Port Light

Courtesy

Light

Storage or

(not shown)

Ice Area

w/ drain

Cabin Light

Waste Tank

Level Indicator

Faucet

Pull Out For

Shower

Faucet

Battery

Switches

Port

Parallel

Stbd.

Battery

Switches

Port

Stbd.

Parallel

Circuit Breakers

Windlass (opt)–80A

Helm Main–50A

Cabin Main-50A

Bowrider Panel

AC (Alt Crnt) Main

Circuit Breaker

Speakers

Storage

Net

Covered

Toilet Paper

Holder

Vacu-Flush Toilet

(Head)

Shower Curtain

(Cuddy Only)

Seat Slide

Tension Knob

Courtesy Light

Access Hatch to

Storage and

Fuel Sender

M-23

318 SS/SSX/SC General Features

Anchor

Roller/Frame

Anchor

Locker

Windlass Under Lid

(Optional)

Pull-up

Cleat

Navigation

Lights

Docking

Lights

Storage

(Under Cushion)

Water

Fill/Vent

Transom Door/Gate

Ensure door is

secured in closed

position when

underway

Pull-up

Cleat

Cockpit Cover or Aft

Curtain Bungee Clips

Trim Tab

Swim Ladder

Ensure ladder is

stowed when

engine(s) running

Shore Power Cord/

City Water

Routing Notch

Garboard Drain

Plug

Aft Stereo

Remote

Speedometer Pitot & Hose

(Volvo Ocean Series

Drive/Composite Only,

Built-in drive on MerCruiser,

Volvo SX-1 & Volvo DP)

Waste Withdrawal

Gas Fill/Vent

Pull-up

Not to be used for tying

boat or towing anything

other than skiers

Trim Tab

Cleat

Fender

Holder

Ski Tow

318 SS/SSX Bow Area

Cabin

Entry

Folding Door

Bomar

Opening Cabin

Window

Courtesy

Light

Cabin

Door

Strap

Head

Entry

Compass

Horn

M-24

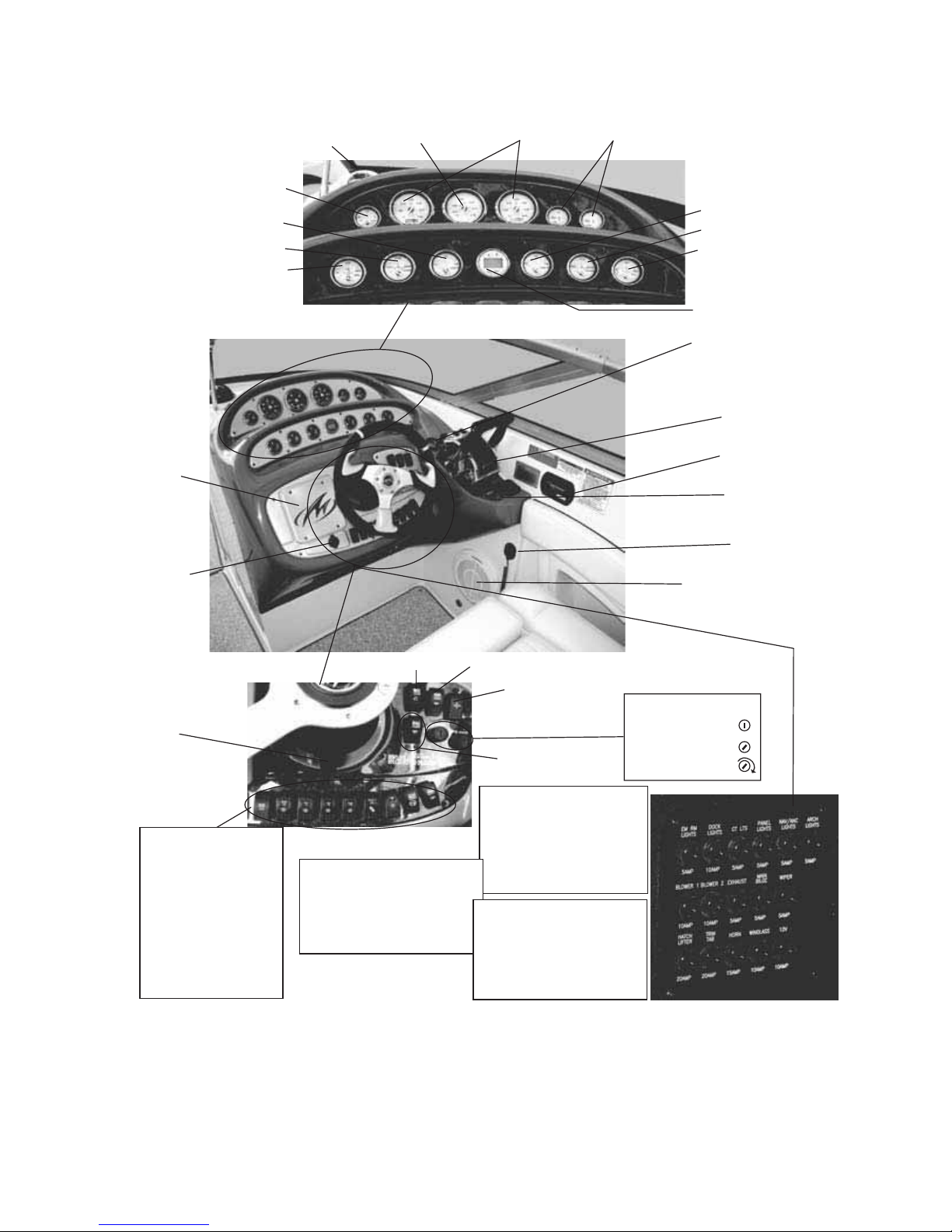

318 SS/SSX Helm

g

p

p

p

Port Eng. Oil Pressure

Port Eng. Temperature

GPS/

Chartplotter

Location

(Option)

Fuel

Port Volts

Compass

Speedometer

Tachometer with

Hour Meter

Stern Drive

Trim Indicators

Stbd Volts

Stbd Eng. Oil Pressure

Stbd Eng. Temperature

Depth Sounder

Trim Tab

Indicators

Drive Trim

Switches/

Throttle/Shift

Levers

Stereo Remote

Fixed Fire

Extinguisher

Indicator Light

Engine Stop Switch

w/ Lanyard

12-Volt

Receptacle

(15A Max)

Steer Tilt

Release

Lever

Switches

(In order Left to Right)

Engine Hatch

Bilge

Wiper

Eng. Rm. Lights

Docking Lights

Courtesy Lights

Panel Lights

Nav/Anchor

Exhaust

Accessory

Horn

Wiper

Circuit Breakers - Center Row

(In order Left to Right)

Blower 1 – 10 Amp

Blower 2 – 10 Amp

Exhaust – 5 Amp

Main Bilge – 5 Amp

Wi

er – 5 Am

Push Circuit Breakers to Reset

Horn

Windlass

(Option)

Blower Switch & Power

Indicator Lights

Circuit Breakers - Top Row

(In order Left to Right)

Engine Room Lights – 5 Amp

Dock Lights – 10 Amp

Courtesy Lights – 5 Amp

Panel Lights – 5 Amp

Nav/Anchor Lights – 5 Amp

Arch Li

hts – 5 Am

Circuit Breakers- Bottom Row

(In order Left to Right)

Hatch Lifter – 20 Amp

Trim Tabs – 20 Amp

Horn. – 15 Amp

Windlass – 10 Amp

12-V Receptacle – 15 Amp

Stereo Subwoofer

(Optional)

Ignition Switches

Off

On

Crank to Start

M-25

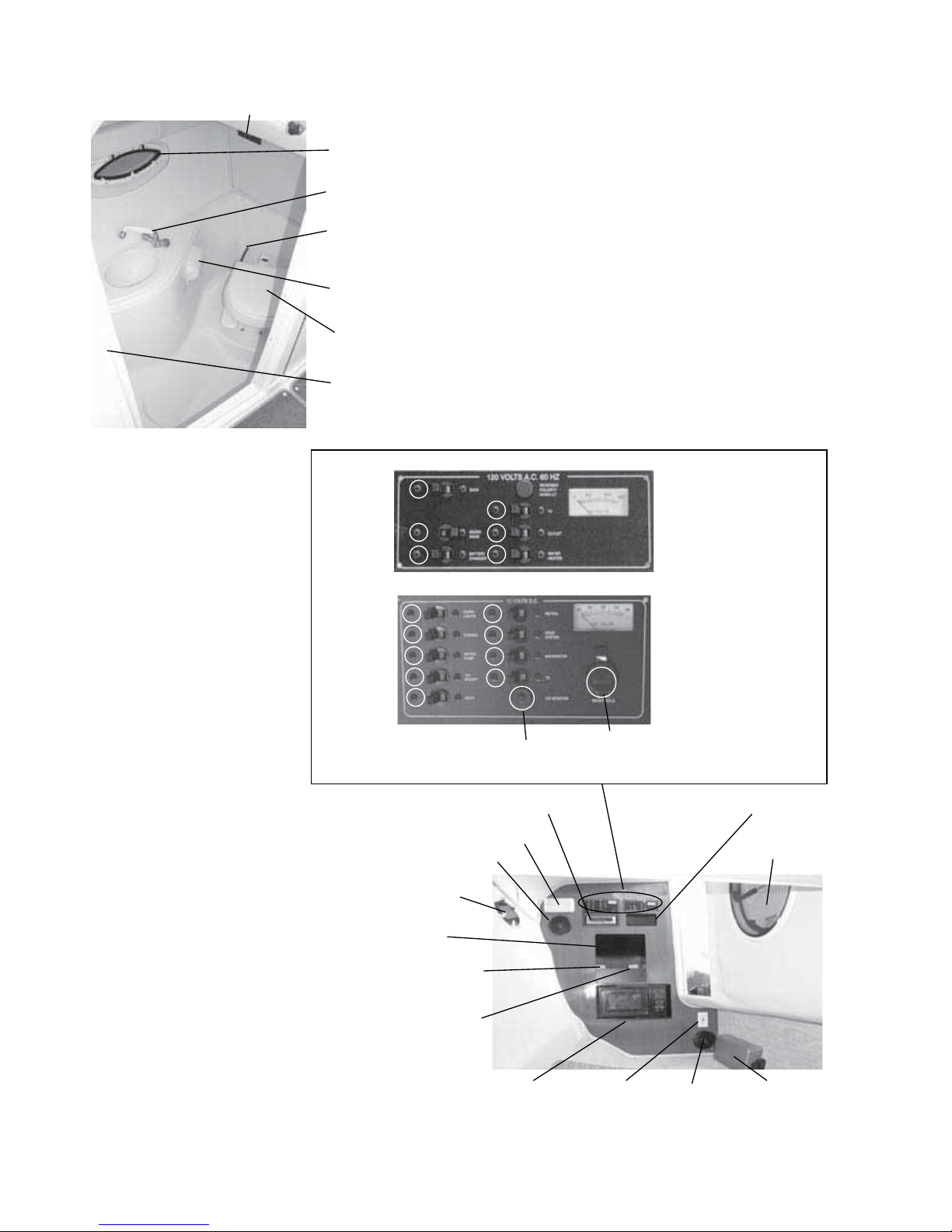

318 SS/SSX Cabin/Head

(

)

p

p

Waste Tank

Level Indicator

Opening Port

Light

Faucet (Pull out

for shower)

Water Intake

Hose

Toilet Paper

Holder w/ Cover

Vacu-Flush

Toilet (Head)

Vanity Mirror

& Cabinet

(Not Shown)

NOTE: Original version pictures -

See electrical schematics

for later info.

Electrical

Switch

Panel (AC)

Electrical

Switch

Panel (DC)

Optional LCD Flat

Panel TV

not shown

1

2

3

A

B

C

D

E

Opening

Port Light

Telephone

TV/

S

eaker

4

5

6

F

G

H

I

CO Monitor

Reset Breaker

(3A)

Stereo

Cabin

Light

1. Main (30A)

2. Microwave (15A)

3. Battery Charger (10A)

4. TV (10A)

5. Outlet (15A)

6. Water Heater (15A)

A. Cabin Lights (15A)

B. Stereo (15A)

C. Water Pump (10A)

D. 12 Volt Receptacle (5A)

E. Accessory (15A)

F. Refrigerator (15A)

G. Head System (7.5A)

H. Macerator (7.5A)

I. TV (10A)

12 Volt

Receptacle

(15A Max)

Optional DVD Player

(not shown)

Opening

Hatch

M-26

120 Volt

Electrical

Outlet

Microwave

120 Volt

Electrical

Outlet

S

eaker

Optional

CD Changer

Loading...

Loading...