Montague V136LB Specifications

Item No. ___________________________

Heavy-Duty

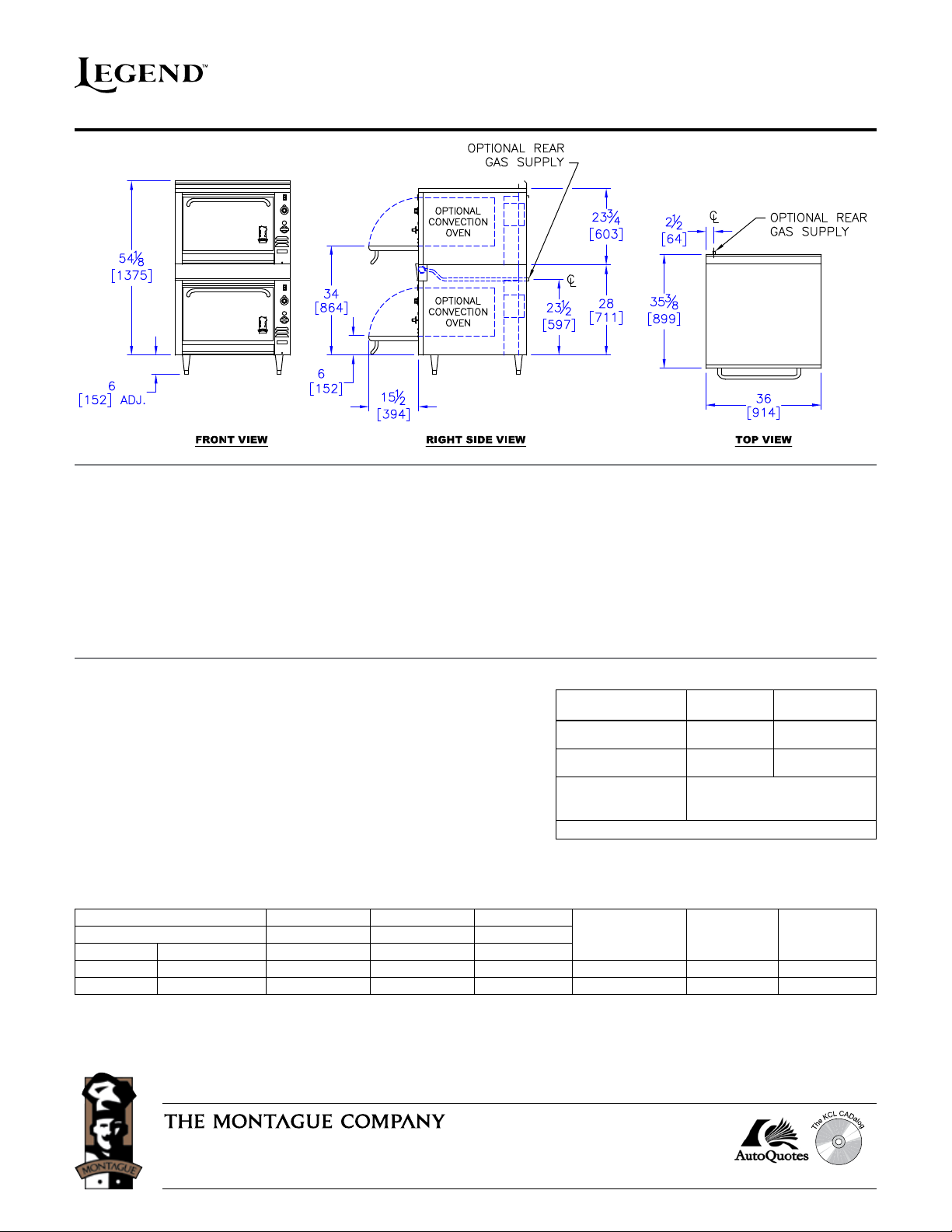

36” (914 mm) Gas Stacked

Bake & Roast Ovens

Model V236

SHORT/BID SPECIFICATION

Ovens shall be a stacked Montague Legend Bake & Roast Oven Model

[Specify one]:

M

236, with two front vented 40,000 BTU/hr conventional ovens, each

with counterweighted door, porcelainized steel interior, four-position

rack guides and one wire pan rack standard

M

V236, with two indirect-fired 45,000 BTU/hr convection ovens, each

with counterweighted door, porcelainized steel interior, five-position

rack guides and three wire pan racks standard

… a 36” (914 mm) wide heavy duty gas-fired unit with stainless steel top

and stainless steel front and exterior bottom, black painted sides and

back, and 1” (25 mm) high flue riser standard; plus all the features listed

and options/accessories checked:

Project ___________________________

Quantity ___________________________

236 or V236

MODEL GUIDE

Model No. Base Style/Type Top

236

V236

STANDARD (236 MODEL) OVEN FEATURES

[EACH OVEN]:

• 26” wide x 28-1/4” deep x 15” high (660 x 718 x 381 mm) cooking

compartment

• Accepts 18” x 26” (457 x 660 mm) pans sideways or lengthwise

• Front venting oven design for more even cooking

• Heavy duty counterweighted oven door — no springs!

• Four position adjustable nickel-plated rack supports, with one rack standard

• Interior panels and door porcelain lined for long life & easy cleaning

• Low-to-500°F (260°C) thermostat mounted in insulated cool zone

• 40,000 BTU/hr cast iron burner with automatic ignition safety pilot

CONVECTION (V236 MODEL) OVEN FEATURES

[EACH OVEN]:

• 26-5/8” wide x 22-1/4” deep x 15” high (676 x 565 x 381 mm) cooking

compartment

• Muffled, indirect fired design with blower, for fast-even cooking

• Heavy-duty counterweighted oven door — no springs!

• Five position adjustable nickel-plated rack supports, with three racks

standard

• Interior panels and door porcelain lined for long life & easy cleaning

• Low-to-500°F (260°C) thermostat mounted in insulated cool zone

• 45,000 BTU/hr cast iron burner with automatic ignition safety pilot

STANDARD CONSTRUCTION FEATURES:

• Satin finish stainless steel front

• Stainless steel top

• Other surfaces painted black with electrolytic zinc undercoating

• Stainless steel 1” (25 mm) rear flue riser standard

• 6” (152 mm) stainless steel legs with adjustable bullet feet

• 1-1/4” NPT front gas manifold with 1/2 union on each end

STANDARD WARRANTY:

• One Year, Parts & Labor

• Lifetime Warranty on Oven Door

AGENCY APPROVALS

• NSF Listed

• ETL Design Certified to ANSI Z83.11

With Two Standard Ovens Stainless steel

With Two Convection Oven Stainless steel

HDS-40 [Rev. 10/10]

THE MONTAGUE COMPANY • 1830 Stearman Avenue, Hayward, CA 94545 • 800 345-1830 • Fax: 510 785-3342 • montaguecompany.com

Item No. ___________________________

Heavy-Duty 36” (914 mm)

Gas Stacked Bake & Roast Ovens

236 or V236

OPTIONS GUIDE:

Finish:

M

Stainless steel left side panels

M

Stainless steel right side panels

M

Stainless steel back panel

M

Stainless steel exterior bottom

Electrical (V136):

M

120 V, 1-phase, 60 Hz, 3.4 A

(standard, with 6’ (1.8m) NEMA 5-15P power cord)

M

208-240 V, 1-phase, 60 Hz, 1.7 A

General:

M

Casters — set of four 5” (127 mm) casters

Flex Connector Kit [1”]: NPT

M

3’ (914 mm) M 4’ (1219 mm)

M

Curb mounting:

Security Options/Prison Package

[Consult Factory]

Project ___________________________

Quantity ___________________________

Dimensions in brackets are millimeters

Oven:

M

Cast iron oven bottoms [236 Model only]

M

Extra oven racks: ____ea.

Manifolds: [Left rear with pressure regulator]:

M

1” NPT up to 250,000 BTU/hr

Manifold Cap:

M

left side M right side

Stainless Manifold Cover:

M

left side M right side

INSTALLATION REQUIREMENTS & SHIPPING INFORMATION

1. Ovens must be installed in accordance with local codes or in their absence with the

National Fuel Gas Code: ANSI Z223.1; Natural Fuel Gas Code: CAN/CGA-B149.1 or Propane

Installation Code: CAN/CGA-B149.2, as applicable. Compliance with codes is the

responsibility of the Owner and Installer.

2. An adequate ventilation system is required. Refer to National Fire Protection Association

Standard No. 96, “Vapor Removal from Cooking Equipment.”

3. This appliance is intended for commercial use by professionally trained personnel.

NOT intended for Residential Use.

4. Specify installation elevation: _____________ if above 2,000 ft (610m).

5. GAS INLET SIZE (All Models): 1-1/4 NPT front manifold with 1/2 union on each end

provided for battery connection. A properly sized gas pressure regulator must be furnished

by the Installer.

6. The incoming gas line pressure into the regulator should be 8”-14” w.c. for natural gas,

and 12”-14” w.c. for propane gas.

Specify Type of Gas: M Natural M Propane Electrical

Manifold Pressure: 6.0” WC 10.0” WC 120V

Models: Burners BTU/hr (kW) BTU/hr (kW) Amperage

236 2 80,000 (23.4) 80,000 (23.4) ---

V236 2 90,000 (26.4) 90,000 (26.4) 3.4

Minimum

Clearances

Combustible

Construction

Noncombustible

Construction

From Back Wall* 2” (51 mm) 0”

Left & Right Side 6” (152 mm) 0”

With 6” (152 mm) legs Suitable for installation

on combustible floors

*V136 models require 2” (51 mm) for motor clearance at rear

Shipping

Weight

646 lbs (293 kg)

796 lbs (361 kg)

Entry Clearance: 30” (762 mm) uncrated, with legs removed [All Models]

Shipping

Class

85 48/1.4

85 51/1.4

Cube

(Crated)

ft

Due to continuous product improvements,

specifications are subject to change without notice.

3/m3

1830 Stearman Avenue, Hayward, CA 94545

800 345-1830 • Fax: 510 785-3342

www.montaguecompany.com

HDS-40 [Rev. 10/10]

Loading...

Loading...