Montague SB36-C Installation Manual

INSTRUCTION MANUAL

Destination Country: United Kingdom, Ireland

MONTAGUE

Gas Fired

Salamander

MODELS:

SBE3418 & SBE3618

It is required by law that all gas appliances are installed by competent persons in accordance with

the LOCAL GAS SAFETY REGULATIONS. Failure to install appliance correctly can lead to

prosecution. It is in your own interests and that of safety to insure that there is compliance with the

law.

IF YOU SMELL GAS

1. TURN OFF THE APPLIANCE AT THE

GAS INLET COCK AND OPEN ALL

DOORS AND WINDOWS.

2. DO NOT OPERATE ANY ELECTRICAL

SWITCHES AND EXTINGUISH ALL

NAKED FLAMES.

3. CONTACT THE LOCAL GAS

AUTHORITY IMMEDIATELY.

THE FOLLOWING INSTRUCTIONS

SHOULD BE READ CAREFULLY AS

THE MANUFACTURER CANNOT BE

HELD RESPONSIBLE FOR ANY

DAMAGE TO PROPERTY, PERSONS

OR ANIMALS CAUSED BY

INCORRECT INSTALLATION OR

OPERATION OF THE APPLIANCE.

PLEASE RETAIN THIS MANUAL

FOR FUTURE REFERENCE.

THE MONTAGUE COMPANY

1830 Stearman Avenue P.O. BOX 4954

HAYWARD,CA 94540-4954

TEL: 510/785-8822 FAX: 510/785-3342

IMPORTANT

WARNING:

Improper installation, adjustment,

alteration, service, or maintenance

can cause property damage, injury

or death. Read the operating

and maintenance instructions

thoroughly before installing or

Do not store or use gasoline or

other flammable vapors and

liquids in the vicinity of this or

any other appliance.

FOR YOUR SAFETY:

servicing this equipment.

SHIPPING DAMAGE CLAIM PROCEDURE

For your protection, please note that equipment in this shipment was carefully inspected

and packed by skilled personnel before leaving the factory. The transportation company

assumes full responsibility for safe delivery upon acceptance of this shipment.

If shipment arrives damaged:

1. VISIBLE LOSS OR DAMAGE—Be certain this is noted on freight bill or express receipt,

and signed by person making delivery.

2. FILE CLAIM FOR DAMAGES IMMEDIATELY—Regardless of the extent of damage.

3. CONCEALED LOSS OR DAMAGE—If damage is unnoticed until merchandise is

unpacked, notify transportation company or carrier immediately, and file “concealed

damage” claim with them. This should be done within fifteen (15) days of date that

delivery was made to you. Be sure to retain container for inspection.

We cannot assume responsibility for damage incurred in transit. We will, however, be glad

to furnish you with necessary documents to support your claim.

2

INSTALLATION

STATUTORY REGULATIONS

The installation of this appliance must be carried out by a competent person and in accordance

with the relevant regulations, standards, codes of practice, and the related publications of the

country of destination.

MODEL DESIGNATIONS

SBE3418 ………………………………….. 34” (864mm) wide

SBE3618 ………………………………….. 36” (914mm) wide

GENERAL INFORMATION

1. Check carton or crate for possible damage sustained during transit. Carefully remove unit from

carton or crate and again check for damage. Any damage to the appliance must be reported to

the carrier immediately.

2. All other packing material must be removed from unit. Any protective material covering

stainless steel parts must also be removed.

3. The type of gas and supply pressure that the equipment was set up for at the factory is noted

on the data plate and on the packaging. This type of gas supply must be used.

4. Do not remove permanently affixed labels, warnings, or data plates from the appliance, for this

may invalidate the manufacturer’s warranty.

TECHNICAL SPECIFICATIONS

GAS SUPPLY

The gas pipe connection is made at the top right hand side of the equipment. The size of the pipe

work supplying the appliance must not be less than the inlet connection which is 1/2” pipe. An

isolating cock is recommended to be close to the appliance to allow shut down during an

emergency or routine servicing. After installation, the complete pipe work must be checked for

soundness.

DATA PLATE LOCATION

The data plate is readily accessible, located on left hand side of inner liner. It contains all of the

pertinent information required by the installer.

3

INSTALLATION

INSTALLATION

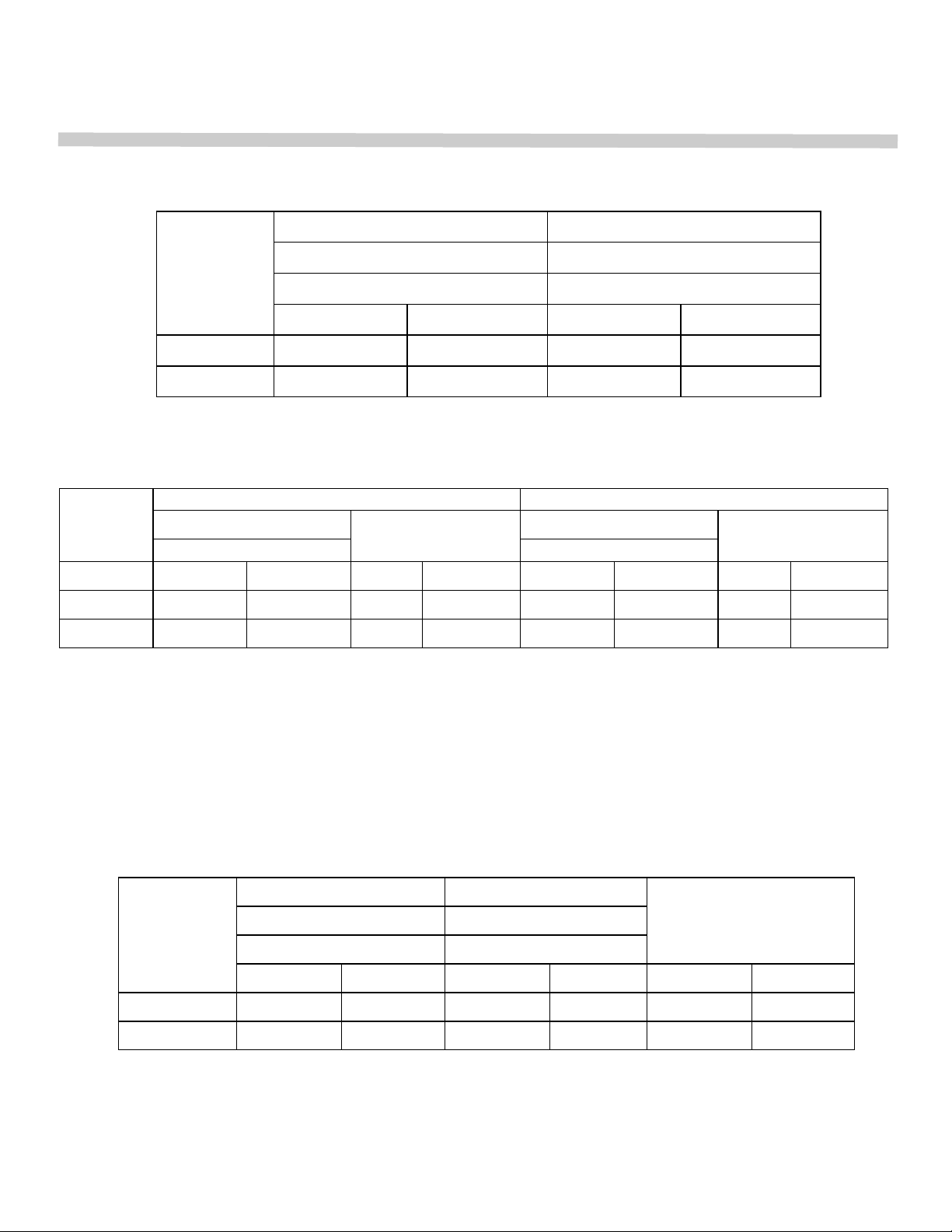

TABLE A: HEAT INPUT (GROSS) PER BURNER

2nd FAMILY, GROUP H 3rd FAMILY, GROUP 3P

MODEL

SBE3418 12.3 42,000 12.3 42,000

SBE3618 12.3 42,000 12.3 42,000

(G20 @ 20 mbar) NATURAL GAS (G31 @ 37 mbar) PROPANE

Per burner / section Per burner / section

kW BTU/HR kW BTU/HR

TABLE B: SETTING PRESSURE INJECTOR SIZE

MODEL

mbar "W.C." I.D.# mm mbar "W.C." I.D. # mm

SBE3418 15 6.00 31 3.05 25 10.00 47 1.99

SBE3618 15 6.00 31 3.05 25 10.00 47 1.99

Setting Pressure

2nd FAMILY, GROUP H 3rd FAMILY, GROUP 3P

Setting Pressure

Injector Size

Injector Size (G20 @ 20 mbar) G31 @ 37 mbar

NOTE: The pressure must be measured at the pressure test nipple located on the

manifold pipe with the burner lit.

TABLE C: AERATION SHUTTER SETTING / PILOT FLAME LENGTH

2nd FAMILY, GROUP H 3rd FAMILY, GROUP 3P

MODEL

SBE3418 25 1.0 32 1.25 12.5 0.5

SBE3618 25 1.0 32 1.25 12.5 0.5

(G20 @ 20 mbar) (G31 @37 mbar)

NATURAL GAS PROPANE

mm Ins. mm Ins. mm Ins.

4

PILOT FLAME LENGTH

INSTALLATION

GENERAL INSTALLATION

SITING

The floor on which the range and salamander broiler are to be sited must be capable of

adequately supporting the weight of the appliance and any ancillary equipment. Once in position,

check that the unit is level, both front to back and side to side. Adjust, if necessary, using the

adjusting foot on each leg of range.

VENTILATION AIR

The following notes are intended to give general guidance. For detailed recommendations, refer to

the applicable codes(s) in the country of destination.

Note 1: The room containing the appliance is required to have a permanent air vent. The

minimum effective area of the vent is related to the maximum rated heat input of the

appliance and shall be 4.5cm² per kW in excess of 7 kW.

Note 2: Air vents should be of such a size to compensate for the effects of any extract fan in

the premises.

GAS SUPPLY

The local gas region should be consulted at the installation planning stage in order to establish the

availability of an adequate supply of gas and to ensure that the meter is adequate for the required

flow rate. The pipe work from the meter to the appliances must be of an appropriate size. Where a

number of appliances are installed in a battery, no more than five should be served by any one

supply pipe.

All fixed (non-mobile) appliances MUST be fitted with a manual gas cock upstream of the

appliance to provide a means of isolation for servicing or cleaning purposes. A union or similar

means of disconnection must be provided between the gas cock and the appliance. A manually

operable valve must be fitted to the gas supply to the kitchen to enable it to be isolated in an

emergency. Wherever practical, this shall be located either outside the kitchen or near to an exit in

a readily accessible position.

Where it is not practical to do this, an automatic isolation valve system shall be fitted which can be

operated from a readily accessible position near to the exit.

At locations where the manual isolation valve is fitted or the automatic system can be reset, a

notice must be fitted stating:

“ALL DOWNSTREAM BURNER AND PILOT VALVES MUST BE TURNED OFF PRIOR TO

ATTEMPING TO RESTORE THE SUPPLY. AFTER EXTENDED SHUT OFF, PURGE BEFORE

RESTORING GAS.”

5

Loading...

Loading...