Montague RF40, RF240, RD18 User Manual

INSTRUCTION MANUAL

MONTAGUE

Heavy Duty

Gas Fired Fryers

Models:

RF40, RF240, RD18

These instructions should be read thoroughly before attempting installation.

Set up and installation should be performed by qualified installation personnel.

Keep area around appliances free and clear from combustibles.

PLEASE RETAIN THIS MANUAL

FOR FUTURE REFERENCE.

THE MONTAGUE COMPANY

1830 Stearman Avenue P.O. BOX 4954

HAYWARD,CA 94540-4954

TEL: 510/785-8822 FAX: 510/785-3342

CONTENTS

INSTALLATION ………………. 3 MAINTENANCE…………...18

OPERATION……………...…… 15 SERVICE………………….. 25

DRAIN CABINET………….45

IMPORTANT

WARNING:

Improper installation, adjustment,

alteration, service or maintenance

can cause property damage, injury

or death. Read the operating and

maintenance instructions thoroughly before installing or servic-

FOR YOUR SAFETY:

Do not store or use gasoline or

other flammable vapors and

liquids in the vicinity of this or

any other appliance.

ing this equipment.

INSTRUCTIONS TO BE FOLLOWED IN THE EVENT THE USER SMELLS GAS MUST BE

POSTED IN A PROMINENT LOCATION. THIS INFORMATION MAY BE OBTAINED BY

CONSULTING THE LOCAL GAS SUPPLIER.

SHIPPING DAMAGE CLAIM PROCEDURE

For your protection, please note that equipment in this shipment was carefully inspected

and packed by skilled personnel before leaving the factory. The transportation company

assumes full responsibility for safe delivery upon acceptance of this shipment.

If shipment arrives damaged:

1. VISIBLE LOSS OR DAMAGE—Be certain this is noted on freight bill or express receipt,

and signed by person making delivery.

2. FILE CLAIM FOR DAMAGES IMMEDIATELY—Regardless of the extent of damage.

3. CONCEALED LOSS OR DAMAGE—If damage is unnoticed until merchandise is un-

packed, notify transportation company or carrier immediately, and file “concealed damage” claim with them. This should be done within fifteen (15) days of date that delivery

was made to you. Be sure to retain container for inspection.

We cannot assume responsibility for damage incurred in transit. We will, however, be glad

to furnish you with necessary documents to support your claim.

2

INSTALLATION

NOTICE

This appliance is intended for professional use only and is to be operated by qualified

personnel only. A Montague Company Authorized Service Agency or other qualified

professional should perform installation, maintenance, and repairs. Installation, maintenance,

or repairs by unqualified personnel may void the manufacturer’s warranty. See the section

on Installation in this manual for definitions of qualified personnel.

NOTICE

This equipment must be installed in accordance with the appropriate national and local

codes of the country and/or region in which the appliance is installed. See NATIONAL CODE

REQUIREMENTS in the Operation Section of this manual for specifics.

NOTICE TO U.S. CUSTOMERS

This equipment is to be installed in compliance with the basic plumbing code of the Building

Officials and Code Administrators International, Inc. (BOCA) and the Food Service Sanitation

Manual of the U.S. Food and Drug Administration.

NOTICE

Drawings and photos used in this manual are intended to illustrate operational, cleaning and

technical procedures and may not conform to onsite management operational procedures.

DANGER

Improper installation, adjustment, maintenance or service, and unauthorized alterations or

modifications can cause property damage, injury, or death. Read the installation manual and

all markings thoroughly before installing or servicing this equipment. Only qualified service

personnel may convert this appliance to use a gas other than that for which it was originally

configured.

DANGER

No structural material on the fryer should be altered or removed to accommodate placement

of the fryer under a hood. Questions? Call The Montague Co. Service Hotline at

1-888-875-2722.

DANGER

The front ledge of the fryer is not a step! Do not stand on the fryer. Serious injury can result

from slips or contact with the hot oil.

DANGER

Do not store or use gasoline or other flammable liquids or vapors in the vicinity of this or

any other appliance.

DANGER

Instructions to be followed in the event the operator smells gas or otherwise detects a gas

leak must be posted in a prominent location. This information can be obtained from the local

gas company or gas supplier.

3

INSTALLATION INSTALLATION

General Installation Requirements

PROPER INSTALLATION IS ESSENTIAL FOR EFFICIENT, TROUBLE-FREE OPERATION OF

YOUR FRYER. ANY UNAUTHORIZED ALTERATIONS MADE TO THIS EQUIPMENT WILL

VOID THE MONTAGUE COMPANY WARRANTY.

Upon arrival, inspect the fryer carefully for visible or concealed damage.

CLEARANCE AND VENTILATION

The fryer(s) must be installed with a 6" (150 mm) clearance at both sides and back when installed

adjacent to combustible construction; no clearance is required when installed adjacent to

noncombustible construction. A minimum of 24" (600 mm) clearance should be provided at the

front of the fryer.

One of the most important considerations of efficient fryer operation is ventilation. Make sure the

fryer is installed to efficiently remove combustion by-products, and the kitchen ventilation system

does not produce drafts that interfere with proper burner operation.

The fryer flue opening must not be placed close to the intake of the exhaust fan, and the fryer must

never have its flue extended in a “chimney” fashion. An extended flue will change the combustion

characteristics of the fryer, causing longer recovery time. It also frequently causes delayed ignition.

To provide the airflow necessary for good combustion and burner operation, the areas surrounding

the fryer front, sides, and rear must be kept clear and unobstructed.

Fryers must be installed in an area with an adequate air supply and adequate ventilation. Adequate distances must be maintained from the flue outlet of the fryer to the lower edge of the ventilation filter bank. Filters should be installed at an angle of 45º. Place a drip tray beneath the lowest

edge of the filter. For U.S. installation, NFPA standard No. 96 states, “A minimum distance of 18

in. (450 mm) should be maintained between the flue outlet and the lower edge of the grease filter.”

The Montague Co. recommends that the minimum distance be 24 in. (600 mm) from the flue outlet

to the bottom edge of the filter when the appliance consumes more than 120,000 BTUs per hour.

Information on construction and installation of ventilating hoods can be found in the NFPA standard cited above. A copy of the standard may be obtained from the National Fire Protection Association, Batterymarch Park, Quincy, MA 02269.

DANGER

Do not attach an apron drainboard to a single fryer. The fryer may become unstable, tip

over, and cause injury. The appliance area must be kept free and clear of combustible

material at all times.

4

INSTALLATION

ALL DEEP FAT FRYERS MUST BE INSTALLED WITH AT LEAST A 16 INCH SPACE BETWEEN THE FRYER AND SURFACE FLAMES FROM ANY ADJACENT COOKING EQUIPMENT.

A minimum of 24" should be provided at the front of the unit for servicing and proper operation. Air

for combustion enters the unit from the front of the cabinet. Do not block these openings at any

time.

THE APPLIANCE AREA MUST BE KEPT FREE AND CLEAR OF COMBUSTIBLES.

ASSEMBLY

Uncrate fryer as near to final location as possible. Remove all packing material and accessories

from fryer interior. Then assemble as follows:

1. Screw the adjustable feet of the legs in all the way. Then tightly screw the complete leg

assembly into the mounting holes at each corner of the fryer.

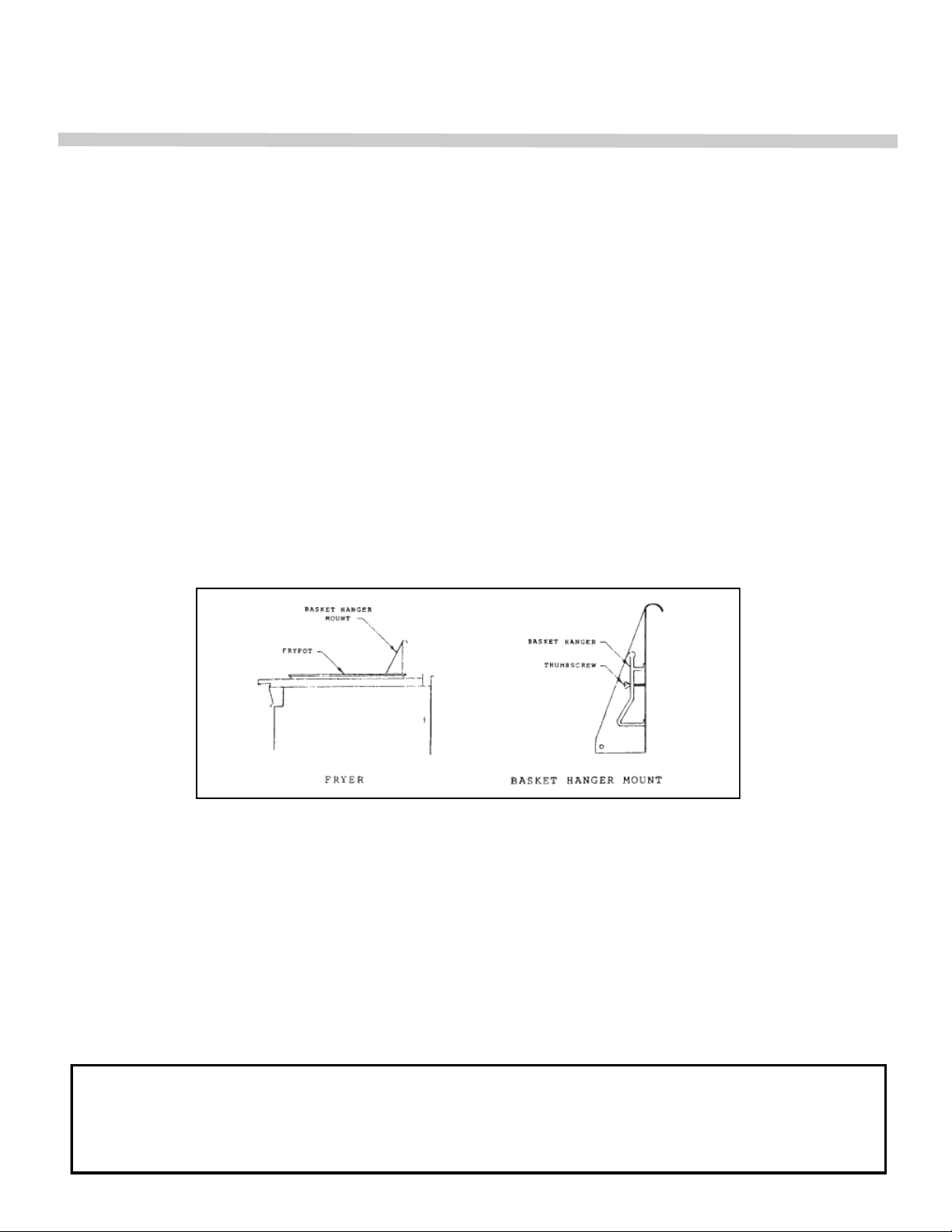

2. Attach basket hanger mount as shown in Figure 1 using bolts that are provided.

SETTING IN PLACE

Battery Arrangement

1. Place the first unit in the exact position it will occupy in the battery.

2. Using a carpenter‟s level, level the unit from front to rear and side to side.

Adjust as follows:

FLOOR INSTALLATION ON LEGS: Adjust by turning foot on adjustable leg.

IMPORTANT

THE UNIT IS EQUIPPED WITH FIXED ORIFICES FOR THE TYPE OF GAS MARKED ON THE

RATING PLATE. THE ORIFICES ARE SIZED FOR THE FOLLOWING MANIFOLD PRESSURE:

NATURAL GAS ..…………. 4.0‖ WC PROPANE GAS ……………….10.0‖ WC

5

INSTALLATION

CURB INSTALLATION: Place shim under the low side. This operation is important since

variation in floor and curbs are common. Unless ranges are level, difficulty will be encountered

in aligning the gas supply manifold and the ranges will not butt together tightly.

3. Remove the upper valve panel from the fryer.

4. Move the next unit into position.

5. Engage union nut on manifold with male fitting on next unit and draw up union nut hand tight.

Be sure appliances butt together both front and rear. If manifolds do not align, then units are not

level. In extreme cases, it may be necessary to loosen manifold bolts and adjust.

6. Continue leveling and connecting gas supply manifolds together until all appliances in battery

are connected.

7. Tighten manifold union gas tight. Use back up wrench to prevent manifold from rotating.

FAILURE TO DO THIS MAY RESULT IN DAMAGE TO PILOTS AND GAS VALVES.

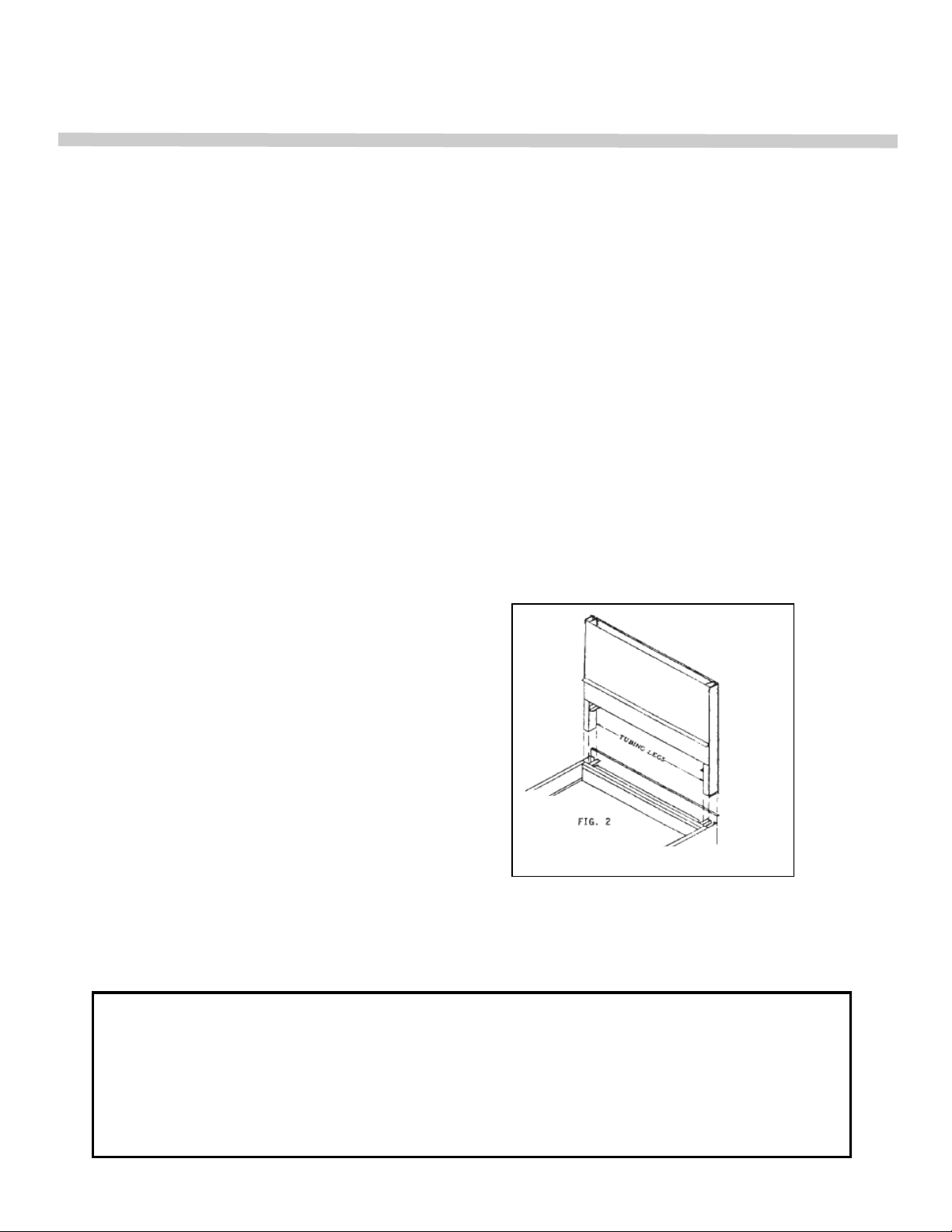

8. Lift the flue riser above the fryer and slide posts into position as shown in Figure 2.

GAS APPLIANCE REGULATOR

Fig. 2

Each deep fat fryer unit is equipped with a gas pressure regulator as a part of the

combination gas control. It is adjusted for the manifold pressure specified on the fryer

nameplate.

WHEN THE FRYER UNIT MANIFOLD IS INTERCONNECTED AS PART OF A

BATTERY, A GAS APPLIANCE PRESSURE REGULATOR SUITABLE FOR THE

BATTERY APPLICATION AND ADJUSTED FOR THE MANIFOLD PRESSURE

SPECIFIED ON THE RANGE. NAMEPLATE MUST BE FURNISHED BY THE

INSTALLER AT THE TIME OF INSTALLATION.

6

INSTALLATION

1. Adequate means must be provided to limit the movement of fryers without depending upon the

gas line connections. If a flexible gas hose is used, a restraining cable must be connected at all

times when the fryer is in use. The restraining cable and installation instructions are packed

with the flexible hose in the accessories box that was shipped with your unit.

2. Single unit fryers must be stabilized by installing restraining chains on fryers equipped with

casters or anchor straps on fryers equipped with legs. Follow the instructions shipped with the

casters/legs to properly install the chains or straps.

3. Level fryers equipped with legs by extending the adjustable portion of the leg out approximately

1 inch, and then further adjust the legs, ensuring the fryer is level and at the proper height in

the exhaust hood. Montague recommends that the minimum distance from the flue outlet to the

bottom edge of the filter be 24 in. (600 mm) when the appliance consumes more than 120,000

BTU per hour.

Refer to the data plate on the inside of the fryer door to determine if the fryer burner is configured

for the proper type of gas before connecting the fryer quick-disconnect device or piping from the

gas supply line.

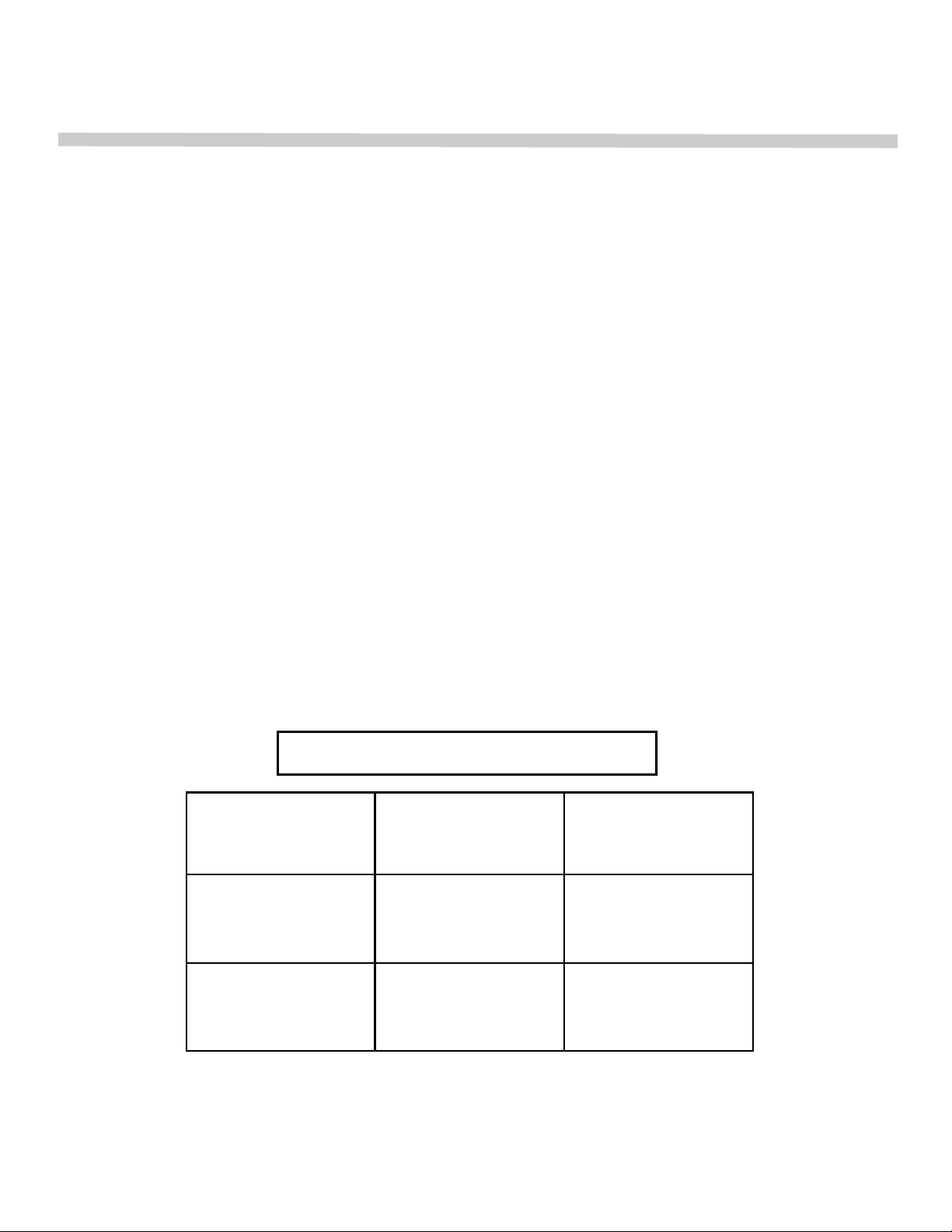

Verify that the minimum and maximum gas supply pressures for the type of gas to be used are in

accordance with the following tables.

Incoming Gas Pressure

Gas Minimum Maximum

Natural

LP

6” WC

1.49kPa

14.93 mbar

11” WC

2.74 kPa

27.37 mbar

7

14” WC

3.48 kPa

34.84 mbar

14” WC

3.48 kPa

34.84 mbar

INSTALLATION

Connection to Gas Line

The size of the gas line used for installation is very important. If the line is too small, the gas

pressure at the burner manifold will be low. This may cause pilot outage, slow recovery and

delayed ignition. The incoming gas supply line should be a minimum of 1½” (38 mm) in diameter.

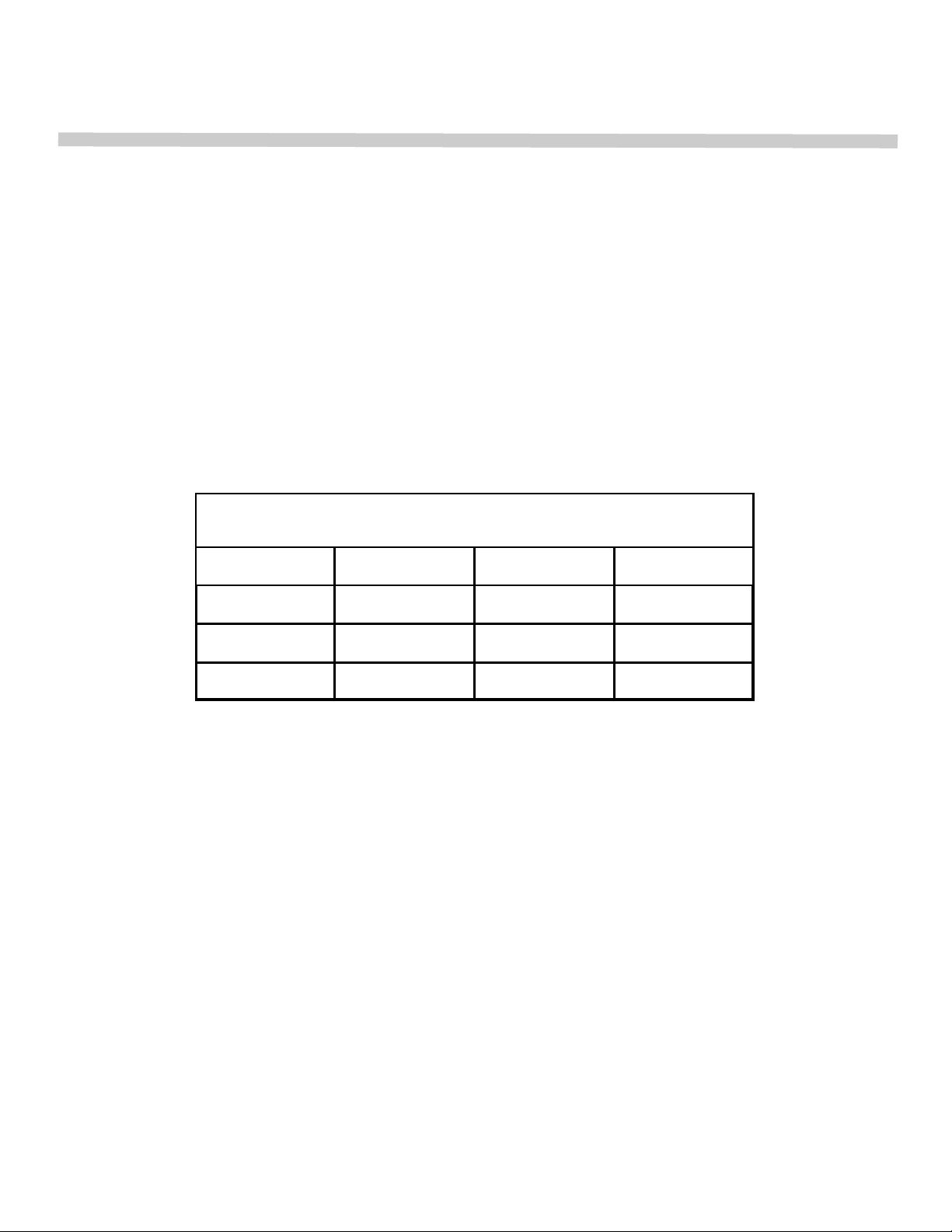

Refer to the chart below for the minimum sizes of connection piping.

Gas Single Unit 2-3 Units 4 or more Units*

Natural 1/2” (13 mm) 1” (25mm) 1-1/4” (33 mm)

Propane 1/2” (13 mm) 1” (25 mm) 1” (25 mm)

Manufactured 1” (25 mm) 1-1/4” (33 mm) 1-1/2” (38 mm)

Gas Connection Pipe Sizes

(Minimum incoming pipe size should be 1-1/2‖ (38mm)

NOTE: For distances of more than 20

feet (6m) and/or more than 4 fittings or

elbows, increase the connection by one

pipe size.

8

INSTALLATION

Before connecting new pipe to your unit, the pipe must be thoroughly blown out to remove any

foreign particles. If these foreign particles get into the burner and controls, they will cause

improper and sometimes dangerous operation.

1. Connect the quick-disconnect hose to the fryer quick-disconnect fitting under the front of the

fryer and to the building gas line.

NOTE: Some fryers are configured for a rigid connection to the gas supply line. These units

are connected to the gas supply line at the rear of the unit.

When using thread compound, use very small amounts on male threads only. Use a pipe

thread compound that is not affected by the chemical action of LP gases (Loctite™ PST56765

Sealant is one such compound). DO NOT apply compound to the first two threads. This will

ensure that the burner orifices and control valve do not become clogged.

2. Open the gas supply to the fryer and check all piping, fittings, and gas connections for leaks.

A soap and water solution should be used for this purpose.

DANGER

Never use matches, candles, or any other ignition source to check for leaks. If gas odors

are detected, shut off the gas supply to the fryer at the main shut-off valve and contact

the local gas company or an authorized service agency for service.

3. Close the fryer drain valve and fill the frypot with water or boil-out solution to the bottom

OIL-LEVEL line at the rear of the frypot. Light the fryer and perform the boil-out procedures

that are described in the “Lighting Instructions” and “Boiling Out the Frypot” topics found in

the OPERATION section of this manual.

WARNING

―Dry-firing‖ your unit will cause damage to the frypot. Always ensure that melted

shortening, cooking oil, or water and boil-out solution is in the frypot before firing your

unit.

9

INSTALLATION

INSTALLATION

4. It is suggested that the burner manifold pressure be checked at this time by a local gas com-

pany or an authorized service agent. Refer to “Check Burner Manifold Pressure” in

MAINTENANCE section of this manual for the proper procedure.

Converting to Another Gas Type

Your fryer is configured at the factory for either natural gas or Propane (LP) gas.

If you desire to switch form one type of gas to another, a gas conversion kit must be

installed by a Montague Company Authorized Service technician.

Burner Manifold Gas Pressure

Gas Pressure

Natural 4” WC

0.87 kPa

LP 9” WC

2.24 kPa

DANGER

Switching to a different type of gas without installing the proper conversion kit may

result in fire or explosion!

NEVER ATTACH YOUR FRYER TO A GAS SUPPLY FOR WHICH IT IS NOT

CONFIGURED!

10

INSTALLATION

INSTALLATION

GAS CONNECTION

Before connecting the range and fryer battery to the gas supply line, be sure that all new piping

has been cleaned and purged to prevent any foreign matter from being carried into the controls

by the gas. In some cases, filters or drops are recommended. A separate Gas Shut Off Valve

must be installed upstream from the range and fryer battery and located in an accessible area.

WARNING

CAP ALL UNUSED OPEN ENDS OF THE GAS SUPPLY MANIFOLD

PIPE JOINT COMPOUND OR THREAD SEALANT THAT IS USED

SHOULD BE RESISTANT TO ACTION OF LIQUEFIED PETROLEUM

GASES. USE SPARINGLY AND ONLY ON MALE THREADS.

It is important that adequately sized piping be run directly to the point of connection at range

and fryer battery with as few elbows and tees as possible. Consult local gas company for proper

piping size and gas pressure.

TEST ALL PIPE JOINTS FOR LEAKS BEFORE OPERATING BROILER(S) OR ANY

OTHER APPLIANCE. THIS INCLUDES ALL GAS CONNECTIONS THAT MAY HAVE

LOOSENED DURING SHIPMENT. USE A RICH SOAP SOLUTION (OR OTHER

ACCEPTED LEAK TESTER) AROUND ALL PIPE CONENCTIONS AND ALL OTHER

JOINTS. DO NOT USE AN OPEN FLAME. ABSOLUTELY NO LEAKAGE SHOULD

OCCUR, OTHERWISE, THERE IS A DANGER OF FIRE OR EXPLOSION

DEPENDING UPON CONDITIONS. NEVER USE IF LEAKAGE IS DETECTED.

Turn Gas Shut Off Valve “ON” and immediately check carefully for gas leaks. Do this before

attempting to operate the range and fryer battery.

NEVER OPERATE THE BURNER WITH AN EMPTY FRYPOT. IT ONLY TAKES A

FEW MINUTES TO COMPLETELY RUIN A FRYPOT THIS WAY, AND THE FRYPOT THIS WAY, AND THE FRYTOP WARRANTY WILL BE VOID.

ADJUSTMENTS

The burner used on the fryer is a patented design which does not require primary air

adjustment.

11

INSTALLATION

INSTALLATION

OPERATING INFORMATION FOR THIS FRYER HAS BEEN PREPARED FOR USE BY

QUALIFIED AND/OR PROFESSIONAL OPERATION PERSONNEL.

IN THE EVENT A GAS ODOR IS DETECTED, SHUT DOWN UNITS AT MAIN SHUT OFF

VALVE AND CONTACT THE LOCAL GAS COMPANY OR GAS SUPLIER FOR SERVICE.

Start-Up Procedure

CAUTION

If this is the first time the fryer is being used after installation, refer to Boil-Out

Procedure.

CAUTION

The cooking oil/shortening capacity of the RF40 Series fryer is 40lbs (20 liters) at 70°F

(21°C).

Before lighting the fryer, make sure the fryer is OFF and the frypot drain valve is

closed. Remove the basket support rack, if installed, and fill the frypot to the bottom

OIL-LEVEL line.

To prevent scorching, if solid shortening is being used, make sure it is tightly packed

down into the bottom of the frypot.

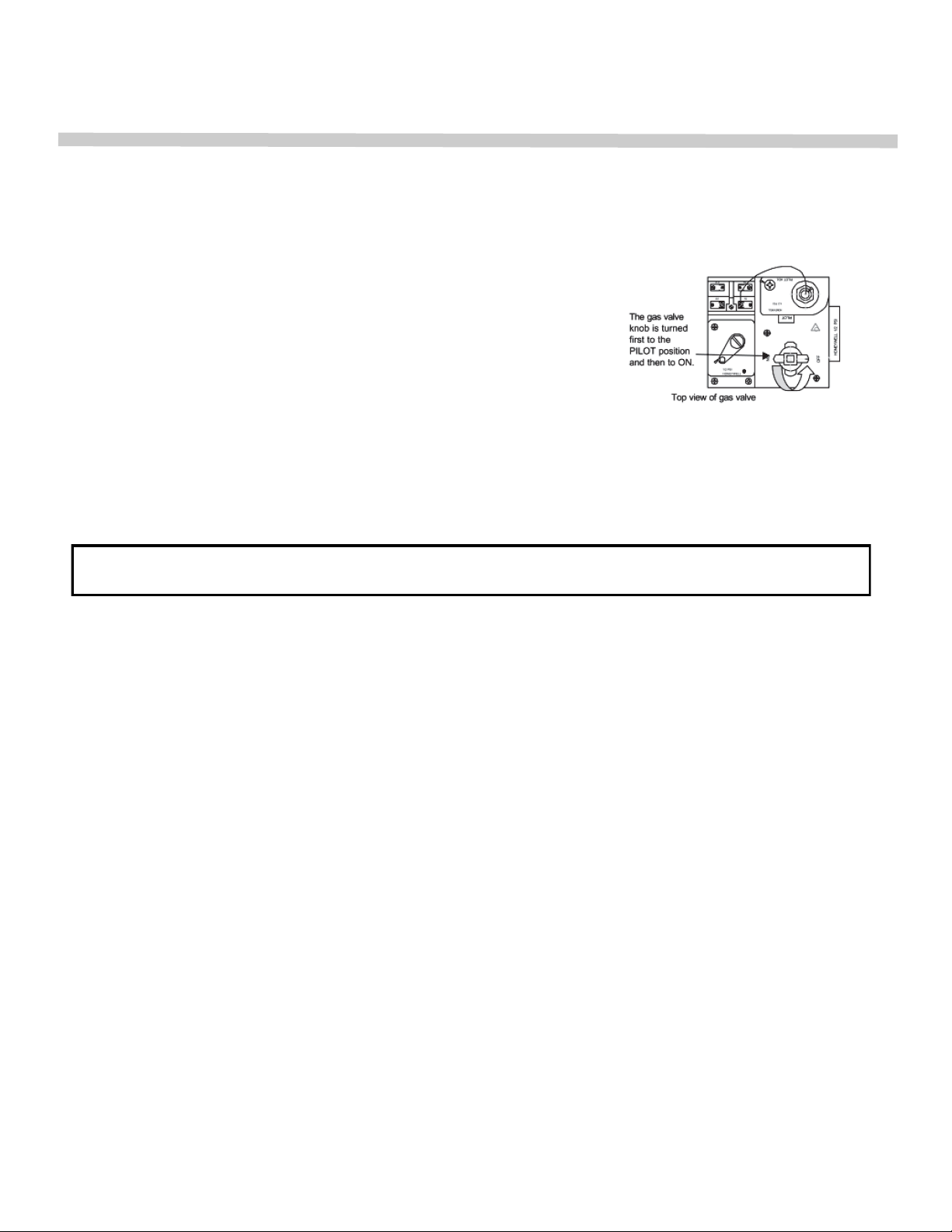

Lighting the Pilot on Honeywell Valves:

WARNING: Frypot must be filled with water or shortening before lighting.

1. Turn the thermostat knob to the required frying tempera-

ture.

2. Push down on the gas valve knob and turn to the PILOT

position.

3. Push the knob and light the pilot. Continue to hold the knob

in for about 60 seconds after the flame appears on the pilot.

Release the knob. The pilot should remain lit.

12

INSTALLATION

CAUTION: If the pilot fails to remain lit, wait five minutes before attempting to re-light.

4. With the pilot lit, push down and slowly turn the knob to the ON position.

5. The burner will now light and is controllable by the

thermostat.

CAUTION: If the pilot and main burner go out, the fryer(s) must be completely shut down at least

five minutes before re-lighting.

6. Set the thermostat knob to the desired cooking temperature. The U-shaped burner should light

THE APPLIANCE AREA MUST BE KEPT FREE AND CLEAR OF COMBUSTIBLES.

HOW TO USE YOUR FRYER

One of the most important considerations in the profitable use of a fryer is the choice of the frying

compound used. The best you can buy is actually the least expensive, because it lasts longer

than the lower grades and produces fried foods with superior taste and appearance. There are

numerous high-grade products available and you are highly urged to use them.

Boiling Out the Frypot

To ensure that the frypot is free of any contamination resulting from its manufacture, shipping,

and handling during installation, the frypot must be boiled out before first use. Frymaster recommends boiling out the frypot each time the oil or shortening is changed.

13

INSTALLATION

DANGER

Never leave the fryer unattended during the boil-out process. If the boil-out solution

boils over, turn the fryer off immediately and let the solution cool for a few minutes

before resuming the process.

1. Before operating the burner, close fryer drain valve and fill empty frypot with a mixture of

cold water and boil-out solution. Fill to the frypot oil-level line.

2. To light fryer, follow lighting instructions in Startup procedure.

3. Set thermostat knob to 275°F (135°C) and turn the fryer gas valve knob to the on position.

4. Simmer the solution for one hour. Caution: NEVER leave the fryer unattended during the

boil-out procedure. The solution may foam up and overflow. To lessen the chance for

overflowing, turn the fryer’s gas valve knob to the Pilot position occasionally.

5. After the solution has simmered for one hour, turn the fryer‟s gas valve knob to the Pilot po-

sition and allow the solution to cool.

6. Add one gallon (3.8 liters) of cold water and stir. Drain out the solution into a suitable con-

tainer and clean the frypot thoroughly.

7. Rinse the frypot at least twice by filling with clean water and draining. Dry the frypot

thoroughly with a clean, dry towel.

8. Refill with shortening.

WARNING

Do not drain boil-out solution into the built-in filtration system. Doing so may cause

damage to the filtration pump.

DANGER

Remove all drops of water from the frypot before filling with cooking oil/shortening.

Failure to do so may cause spattering of hot liquid when the oil/shortening. Failure to

do so may cause spattering of hot liquid when the oil/shortening is heated to cooking

temperature.

Filling with Shortening

The RF40 series fryer has a minimum 30lbs (14.5 liters)/maximum 40lbs (19.5 liters) shortening

capacity.

1. Ensure the fryer‟s gas valve is off or in the pilot position.

2. Close the frypot drain valve; remove basket support rack if required.

3. Fill empty frypot to the oil-level line. When solid shortening is used, it must be

thoroughly packed down into the frypot’s cold zone.

14

INSTALLATION

INSTALLATION

4. To melt solid shortening without scorching, the burner should be turned ON for about three

seconds and OFF for about 10 seconds; alternate until melted. If any smoke is seen during

this process, the oil is heating too quickly and scorching. This melting process is not necessary with liquid shortening.

Shutting the Fryer Down

For short-term shut down during the workday, place the fryer‟s gas valve in the Pilot position

and put the frypot covers in place (if the fryer is so equipped).

When shutting the fryers down at closing time, place the fryer power switch in the OFF position,

place the gas valve in the OFF position, and put the frypot covers in place (if the fryer is so

equipped).

Thermostats

The centerline thermostat on a RF40 is connected to a temperature knob. On the standard

model, the knob is attached directly to the thermostat (see photo above). Rotating the knob to

the desired cooking temperature (setpoint) directly adjusts the thermostat control to that temperature.

The Thermostat Controller required no programming, but it may require calibration from time to

time. To determine if it required calibration, refer to Check Thermostat Controller Thermostat

Calibration.

15

Loading...

Loading...