Montague RCH-2 Installation Manual

Post in a prominent location the

instructions to be followed in the

event the operator smells gas.

Consult the local gas supplier for

this instructions.

FOR YOUR SAFETY

Do not store or use gasoline or other

flammable vapors and liquids in the

vicinity of this or any other appliance

This manual describes procedure for the

installation, minor repairs and servicing,

operation, cleaning and ordering of extra parts

for all models of Montague equipment listed

herein.

It is suggested that the Model No., Change

No. and Serial No. as they appear on your

Montague Nameplate be written in on

the last page of this manual, in the spaces

provided, upon receipt of equipment.

For extra copies of this manual please write

to: The Montague Company, 1830 Stearman Ave.,

Hayward, Calif. 94545.

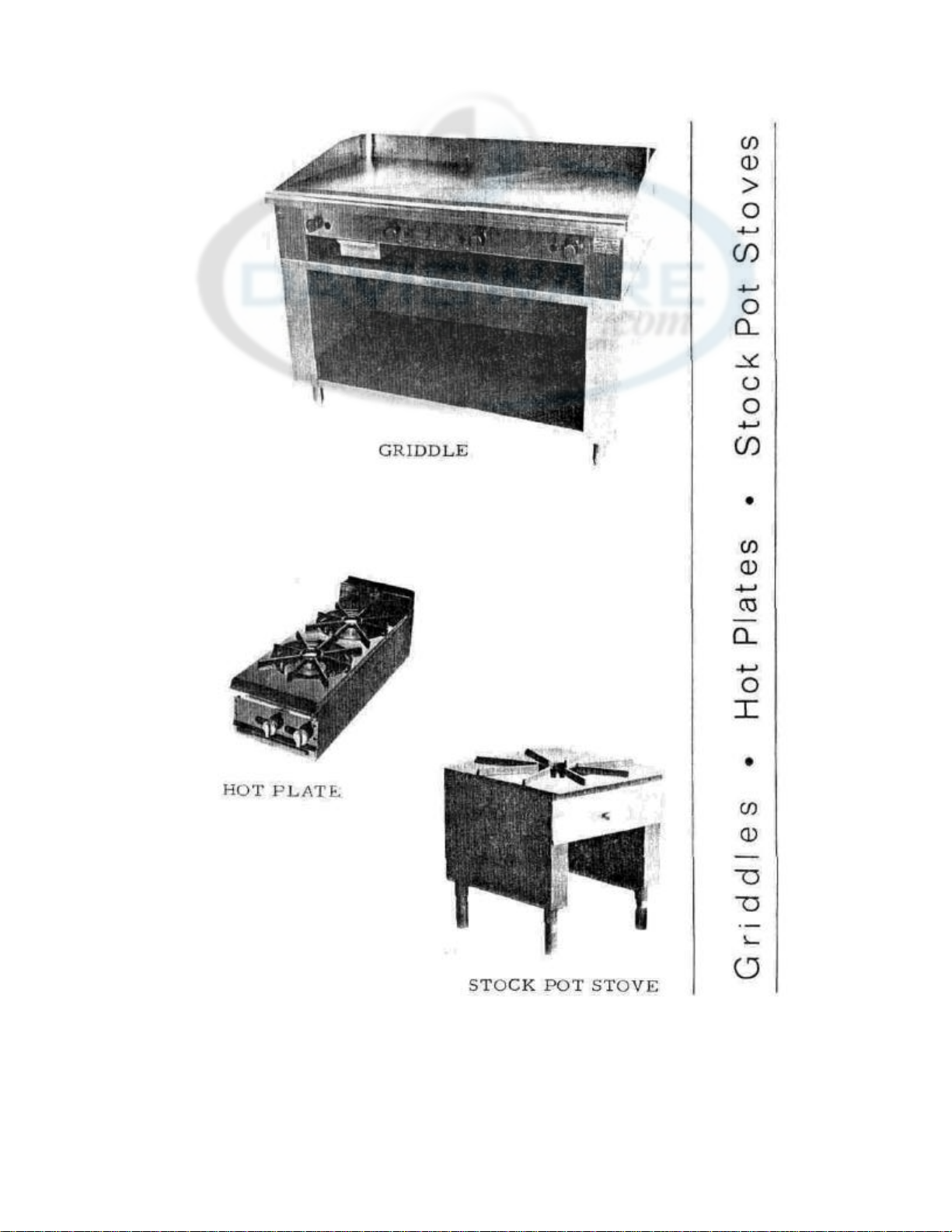

INSTRUCTIONS

GRIDDLES • HOTPLATES STOCK POT

STOVES

INSTALLATION

The Montague griddles, hot plates and stock pot stoves

are manufactured for use with the type of gas indicated

on the nameplate located on the front right side of unit.

The appliance must be installed in accordance with

local codes, or in the absence of local codes, with the

National Fuel Gas Code, ANSI Z223. 1-1974.

The appliances are produced with the best possible

materials and workmanship. Proper installation is

vital if safe operation and best performance are to be

achieved.

CAREFULLY READ AND FOLLOW THESE

INSTRUCTIONS.

CHECK FOR SHIPPING DAMAGE

Check carton for handling damage. After carefully

uncrating appliance, check for "concealed" damage.

Notify transportation company or carrier immediately,

and file "Concealed Damage" claim with them. Be

sure to retain container for inspection.

THIS APPLIANCE IS CLASSIFIED AS

COMMERCIAL COOKING EQUIPMENT AND

IS NOT INTENDED FOR RESIDENTIAL USE.

SETTING IN PLACE

GRIDDLE

Counter Installation: Must be installed on fireresistive counter only. Level unit by placing shim

under low side.

1

2

Floor Mounted Installation:

Enclosed Base: Screw the adjustable feet of the legs

in all the way. Then tightly screw the complete leg

assembly or casters into mounting holes provided in

bottom of base. Set griddle unit in position on base.

Modular Stand: Insert legs into socket on bottom of

stand. Secure legs with thumb screws that are

provided. Set griddle unit in position on stand.

Leveling Adjustments:

When griddle unit is in permanent position, adjust

leveling bolts so that the griddle plate is pitched to

the front to provide grease runoff. The leveling bolts

are located at the rear of the unit under the griddle

plate.

HOT PLATE

Counter Installation: Must be installed on fire-resistive

counter only. Level unit by placing shim under low

side. Remove shipping wires from burners. Unpack

and install open top sections. Install burner bowls

and grates.

STOCK POT STOVE

Level stove by adjusting foot on the leg assembly.

ALL UNITS

Install top burner valve handle(s) and/or thermostat

knob(s). If top burner valve handle is loose on valve

shaft, spread slot on end of shaft slightly with screwdriver blade so that handle will fit snug.

GAS CONNECTION

Before connecting appliance to the gas supply line, be

sure that all new piping has been cleaned and purged

to prevent any foreign matter from being carried into

the controls by the gas. In some cases, filters or

drops are recommended. A separate Gas Shut-Off

Valve must be installed upstream from the gas

pressure regulator adjacent to the appliance and be

located in an accessible area.

It is important that adequately sized piping be run

directly to the point of connection at appliance, with

as few elbows and tees as possible. Consult local gas

company for proper piping size and gas pressure.

Locate the gas pressure regulator external to the

appliance as near unit as possible. The gas pressure

regulator must be located out of the heat zone to

prevent damage to the regulator.

This Appliance Is Designed For Use With a Gas

Pressure Regulator. The Regulator Supplied

With This Unit Must Be Used.

For Natural Gas: This gas pressure regulator

is factory adjusted for 5.0" W. C. manifold

pressure. The maximum inlet pressure to the

regulator should not exceed 10.5" water column.

For Propane Gas: This gas pressure regulator

is factory adjusted for 10" W. C. manifold

pressure. The maximum inlet pressure to the

regulator should not exceed 21" water column.

Install the gas pressure regulator with gas flowing as

indicated by the arrow on the regulator. Use pipe

compound or thread sealant and carefully thread

regulator to pipe so that there is no cross threading,

etc., which could cause breakage. Apply wrench only

to the flat areas around the pipe tapping at the end

being threaded to the pipe to avoid possible damage.

PIPE JOINT COMPOUND OR THREAD

SEALANT THAT IS USED SHOULD BE

RESISTANT TO ACTION OF LIQUEFIED

PETROLEUM GASES.

Connect the gas supply line from the service gas shutoff valve to the inlet side of the gas pressure regulator.

If flexible or semi-flexible connectors are used, an

AGA listed flexible connector must be used. DO NOT

USE A DOMESTIC APPLIANCE TYPE GAS FLEXIBLE

CONNECTOR. Avoid kinks or sharp bends that could

restrict gas flow.

3

Turn Gas Shut-Off Valve on and immediately check

carefully for gas leaks. Do this before attempting to

operate the appliance.

TEST ALL PIPE JOINTS FOR LEAKS BEFORE

OPERATING APPLIANCE. THIS INCLUDES

ALL GAS CONNECTIONS THAT MAY HAVE

LOOSENED DURING SHIPMENT. USE A RICH

SOAP SOLUTION (OR OTHER ACCEPTED LEAK

TESTER) AROUND ALL PIPE CONNECTIONS

AND ALL OTHER JOINTS. DO NOT USE AN

OPEN FLAME. ABSOLUTELY NO LEAKAGE

SHOULD OCCUR, OTHERWISE THERE IS A

DANGER OF FIRE OR EXPLOSION DEPENDING

UPON CONDITIONS. NEVER USE IF LEAKAGE

IS DETECTED.

VENTILATION

A properly designed and installed hood will act as the

heart of the ventilating system for the room or area

in which the appliance is installed. It will leave the

appliance independent of changing draft conditions.

It is necessary that sufficient room air ingress be

allowed to compensate for the amount of air removed

by the ventilating system. Otherwise, subormal

atmospheric pressure will occur, affecting appliance

operation adversely.

The flow of combustion and ventilation air to the

appliance must not be obstructed. Adequate clearance

for air openings into the combustion chamber and for

servicing must be maintained.

4

Loading...

Loading...