Montague R2-85A Installation Manual

INSTRUCTION MANUAL

MONTAGUE

Gas

Convection Ovens

MODELS:

70, 115, R85, 2-70,

2-115 & R2-85 Series

These instructions should be read thoroughly before attempting installation.

Set up and installation should be performed by qualified installation personnel.

Keep area around appliances free and clear from combustibles.

PLEASE RETAIN THIS MANUAL

FOR FUTURE REFERENCE.

THE MONTAGUE COMPANY

1830 Stearman Avenue P.O. BOX 4954

HAYWARD,CA 94540-4954

TEL: 510/785-8822 FAX: 510/785-3342

CONTENTS

INSTALLATION ………. 3 MAINTENANCE ……… 21

OPERATION ………….. 11 SERVICE ……………… 26

COOKING HINTS ……. 16

IMPORTANT

WARNING:

Improper installation, adjustment,

alteration, service or maintenance

can cause property damage, injury

or death. Read the operating and

maintenance instructions thoroughly before installing or servicing this

FOR YOUR SAFETY:

Do not store or use gasoline or other

flammable vapors and liquids in the

vicinity of this or any other appliance.

equipment.

INSTRUCTIONS TO BE FOLLOWED IN THE EVENT THE USER SMELLS GAS MUST BE

POSTED IN A PROMINENT LOCATION. THIS INFORMATION MAY BE OBTAINED BY

CONSULTING THE LOCAL GAS SUPPLIER.

SHIPPING DAMAGE CLAIM PROCEDURE

For your protection, please note that equipment in this shipment was carefully inspected and packed

by skilled personnel before leaving the factory. The transportation company assumes full responsibility for safe delivery upon acceptance of this shipment.

If shipment arrives damaged:

1. VISIBLE LOSS OR DAMAGE—Be certain this is noted on freight bill or express receipt, and

signed by person making delivery.

2. FILE CLAIM FOR DAMAGES IMMEDIATELY—Regardless of the extent of damage.

3. CONCEALED LOSS OR DAMAGE—If damage is unnoticed until merchandise is unpacked,

notify transportation company or carrier immediately, and file “concealed damage” claim with

them. This should be done within fifteen (15) days of date that delivery was made to you. Be

sure to retain container for inspection.

We cannot assume responsibility for damage incurred in transit. We will, however, be glad to furnish

you with necessary documents to support your claim.

2

INSTALLATION

Vectaire gas convection ovens are manufactured for use with the type of gas and electric supply indicated

on the nameplate behind the fire box panel.

The Vectaire oven is produced with the best possible material and workmanship. PROPER INSTALLATION

IS ESSENTIAL FOR SAFE AND EFFICIENT TROUBLE-FREE OPERATION.

THE INSTALLATION INSTRUCTIONS CONTAINED HEREIN ARE FOR THE

USE OF QUALIFIED INSTALLATION AND SERVICE PERSONNEL ONLY.

INSTALLATION OR SERVICE BY OTHER THAN QUALIFIED PERSONNEL

MAY RESULT IN DAMAGE TO THE OVEN AND/OR INJURY TO THE

OPERATOR.

Qualified installation personnel are individuals, a firm, corporation or company which either in

person, or through a representative are engaged in, and are responsible for:

A. The installation or replacement of gas piping or the connection, installation, repair or ser-

vicing of equipment, who is experienced in such work, familiar with all precautions required, and has complied with all requirements of state or local authorities having jurisdiction. Reference: National Fuel Gas Code Z223.1-latest addenda, Section 1.4.

B. The installation of electrical wiring from the electric meter, main control box or service out-

let to the electric appliance. Qualified personnel must be experienced in such work, be familiar with all precautions required and have complied with all requirements of state and

local authorities having jurisdiction. Reference: National Electric Code, N.F.P.A. No. 70–

latest addenda.

READ CAREFULY AND FOLLOW THESE INSTRUCTIONS

THE OVEN MUST BE INSTALLED IN ACCORDANCE WITH LOCAL CODES,

OR IN THE ABSENCE OF LOCAL CODES, WITH THE NATIONAL FUEL

CODE, ANSI Z223.1-LATEST ADDENDA, INCLUDING:

1. The appliance and its individual shutoff valve must be disconnected

from the gas supply piping system during any pressure testing of that

system at test pressures in excess of 1/2 psig. (3.45kPa).

2. The appliance must be isolated from the gas supply piping system by

closing its individual manual shutoff valve during any pressure testing of

the gas supply piping system at test pressure equal to or less than 1/2

psig. (3.45kPa).

THIS UNIT WHEN INSTALLED MUST BE ELECTRICALLY GROUNDED

IN ACCORDANCE WITH LOCAL CODES, OR IN ABSENCE OF LOCAL

CODES, WITH THE NATIONAL ELECTRICAL CODE, ANSI/NFPA No.70–

LATEST ADDENDA.

PROVISIONS MUST BE MADE FOR ADEQUATE AIR SUPPLY TO THE UNIT.

3

INSTALLATION

Ventilating Hood

The ideal method of ventilating a convection oven is the use of a properly designed ventilating hood. The hood should extend at least 6‖ beyond all sides of the oven. The hood should

be connected to an adequate mechanical exhaust system.

Information on the construction and installation of ventilating hoods may be obtained from the

―Standard for the Installation of Equipment for the Removal of Smoke and Grease Laden Vapors from Commercial Cooking Equipment‖, NFPA No. 96– latest addenda, available from

the National Fire Protection Association, Batterymarch Park, Quincy, MA 02269.

It is also necessary that sufficient room air ingress be allowed to compensate for the amount

of air removed by the ventilating system. Otherwise, a subnormal atmospheric pressure will

occur which may interfere with burner performance or may extinguish the pilot flame. In case

of unsatisfactory oven performance, check with the exhaust fan in the ―OFF‖ position.

Direct Flue Connection

If the oven is connected directly to an outside flue, a draft hood P/N 04391-5 or 04392-3 for

Model 70, 115, SE70 and SE115 series and P/N 03109-7 or 03099-6 for Model 2-70, 2-115,

SE2-70 and SE2-115 series must be used. (See Fig. 2 & 5) The flue should rise at least 10

feet above the roof or any surrounding structure. The flue must be terminated with an U.L.

listed vent cap or spinner.

Clearances

Adequate clearance must be provided in the aisle and at the side and back to allow the doors

to open sufficiently to permit the removal of the racks and for serviceability. Adequate clearance for air openings into the combustion chamber must be provided.

CLEARANCES

MODEL 70, 115, SE70 & SE115 SERIES WITH ENCLOSED BASE & MODULAR STAND:

COMBUSTIBLE CONSTRUCTION NONCOMBUSTIBLE CONSTRUCTION

Back: 6” 5”

Left & Right Side: 6” 0

WITH 4” OR 6” LEGS: SUITABLE FOR INSTALLATION ON COMBUSTIBLE FLOORS.

MODEL 2-70, 2-115, SE2-70 & SE2-115 SERIES:

COMBUSTIBLE CONSTRUCTION NONCOMBUSTIBLE CONSTRUCTION

Back: 6” 5”

Left & Right Side: 6” 0

WITH 4” OR 6” LEGS: SUITABLE FOR INSTALLATION ON COMBUSTIBLE FLOORS.

CURB MOUNT WITH 1” TOE BASE (P/N: 555): FOR USE ONLY WITH NONCOMBUSTIBLE

FLOORS.

4

INSTALLATION

CAUTION

DO NOT OBSTRUCT THE FLOW OF COMBUSTION AND VENTILATION

AIR TO THE OVEN. KEEP THE APPLIANCE AREA FREE AND CLEAR

FROM COMBUSTIBLES

Solid state components have a very short life span when exposed to temperatures

above 185°F (85° C), therefore, certain installation precautions are necessary. The

―SE‖ ovens have been designed to operate below this temperature when properly

installed. The following precautions must be observed:

1. Do not obstruct the flow of air through the vent openings at the top of the oven, or

the flow of room air to the oven bottom or lower front portion of the burner access

panel.

2. Do not mount the oven on a curb unless it has been equipped with the No.555 Toe

Base (P/N:06024-0) for this type of installation.

3. When stacking ovens, never reverse the top and bottom oven sections.

4. Never stack an ―SE‖ series convection oven with a standard Vectaire or another

bra brand of oven without first consulting the factory. Certain ovens are not

compatible, or a stacking kit may be required.

SPECIAL CAUTION

DO NOT PLACE HIGH HEAT PRODUCING EQUIPMENT ADJACENT TO THE

RIGHT SIDE OF AN ―SE‖ VECTAIRE CONVECTION OVEN, OR ANY OVEN

EQUIPPED WITH THE IFO FAN CONTROL. SURFACE TEMPERATURES EXCEEDING 185°F (85°C) CAN CAUSE PREMATURE COMPONENT FAILURE

NOT COVERED UNDER MANUFACTURER’S WARRANTY.

ASSEMBLY

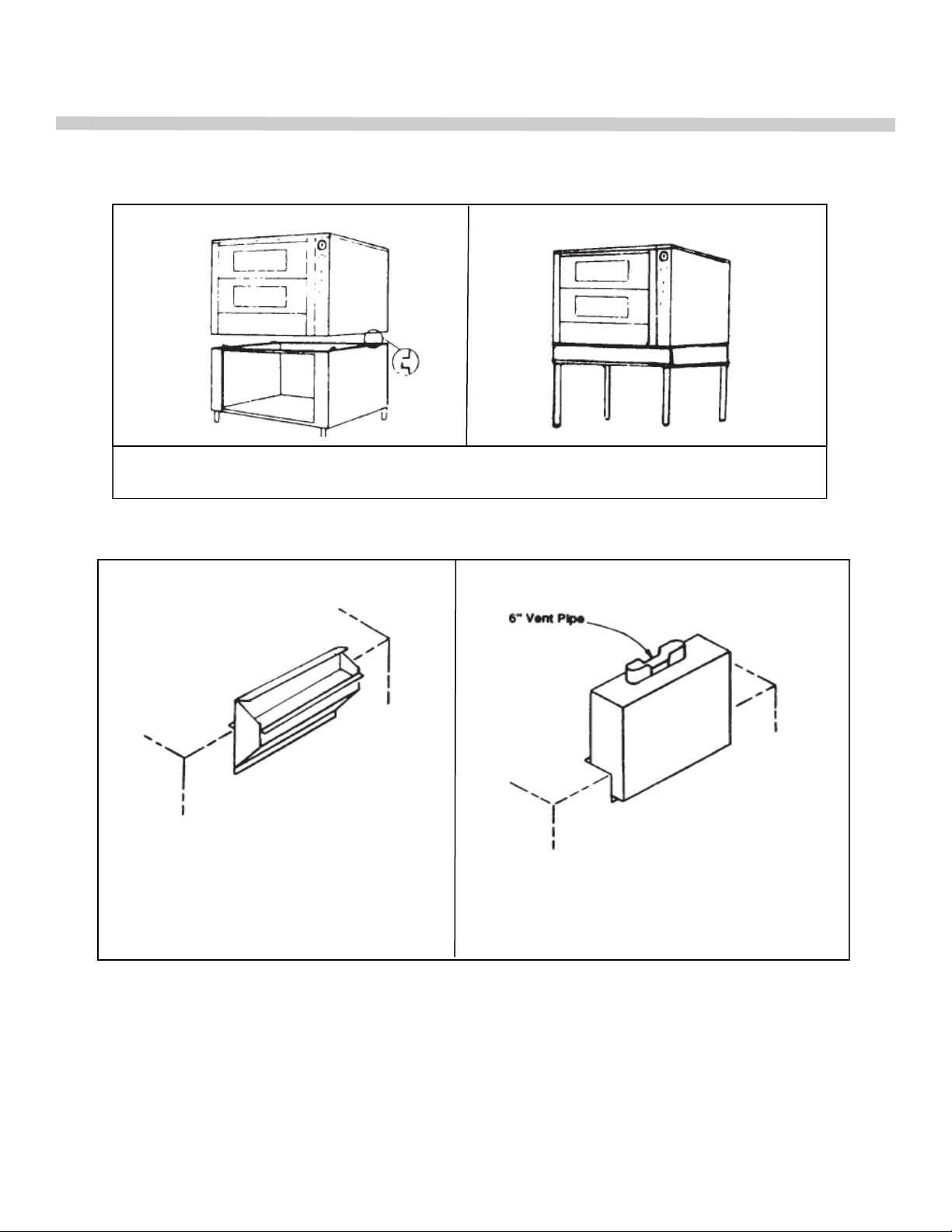

Model 70, 115, SE70 & SE115 Series (Fig. 1 & 2)

Uncrate oven and base as near to final location as possible. Remove all packing

material and accessories from oven interior. Install rack guides (if provided) in base.

Place oven on stand as shown in Figure 1. Install flue deflector (P/N 16522-0 or 16532

-8) or draft hood (P/N 04391-5 or 04392-3). Either a flue deflector or a draft hood is

shipped with every unit. The flue deflector is intended for use when the oven is installed under a properly designed hood.

When oven is directly connected to vent system, the draft hood must be used. (See

Figure 2 & 6). When oven is in permanent position, level entire unit by placing carpenter’s level on oven rack and adjusting the foot of the bottom of each leg so that oven is

level from front to back and side to side.

5

INSTALLATION

Enclosed Base

P/N 16522-0 (Painted) or P/N 16532-8 (S/S)

Flue Deflector

Figure 1

Modular Stand

P/N 4391-5 (Painted) or 4392-3 (S/S)

Draft Hood

Figure 2

6

INSTALLATION

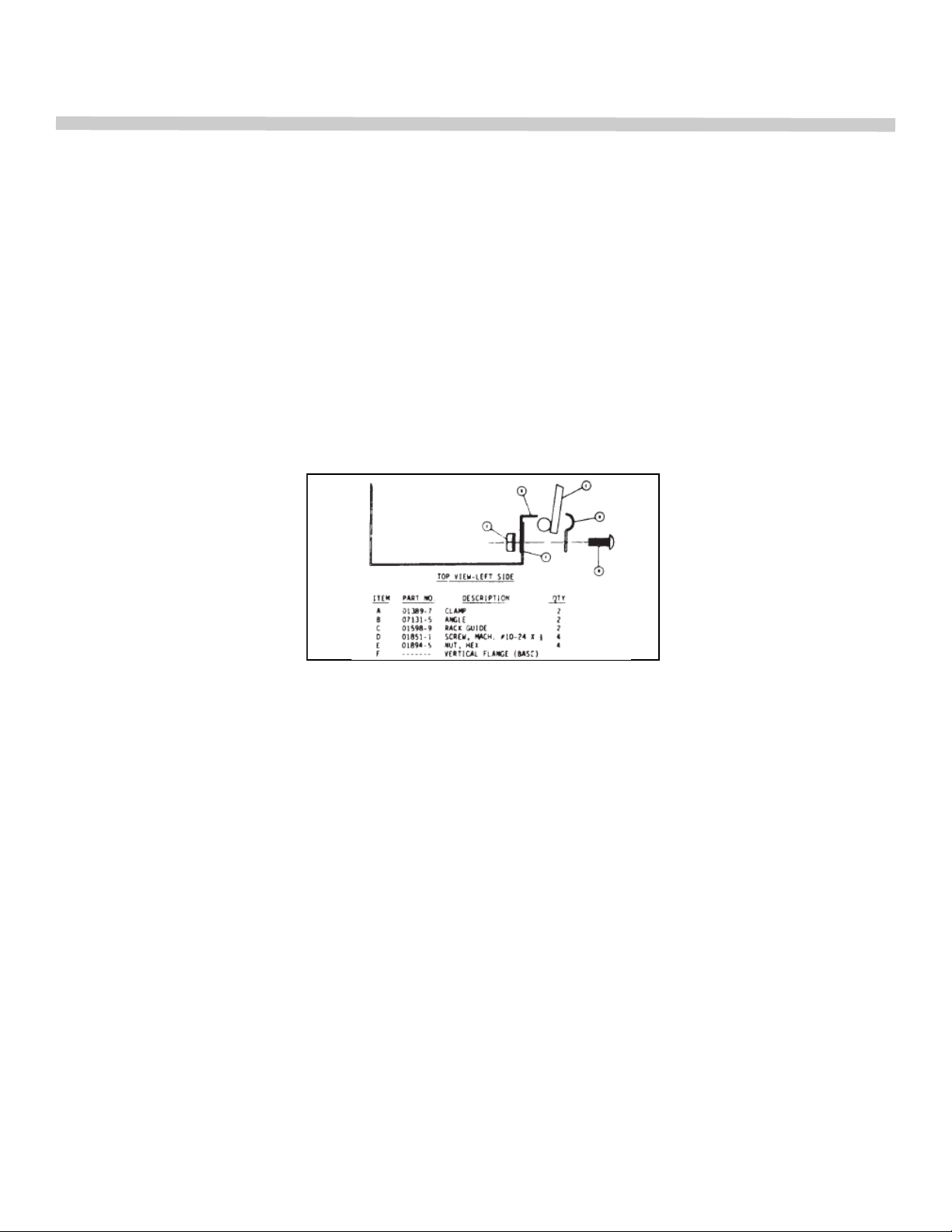

Installation of Rack Guides in Base -Kit No. 04651-5

(If provided See Fig. 3)

1. Set base upright and place on rack guide in position with rod extensions toward rear

and through holes in back.

2. Install stop (B) behind vertical flange forming base opening.

3. Place screw through clamp (A), upper hole of base flange (B) and stop. Install nut.

4. Repeat step 3 with lower hole of flange and stop. Tighten both nuts.

5. Repeat step 2, 3, and 4 for installation of other rack guide on opposite side.

Figure 3

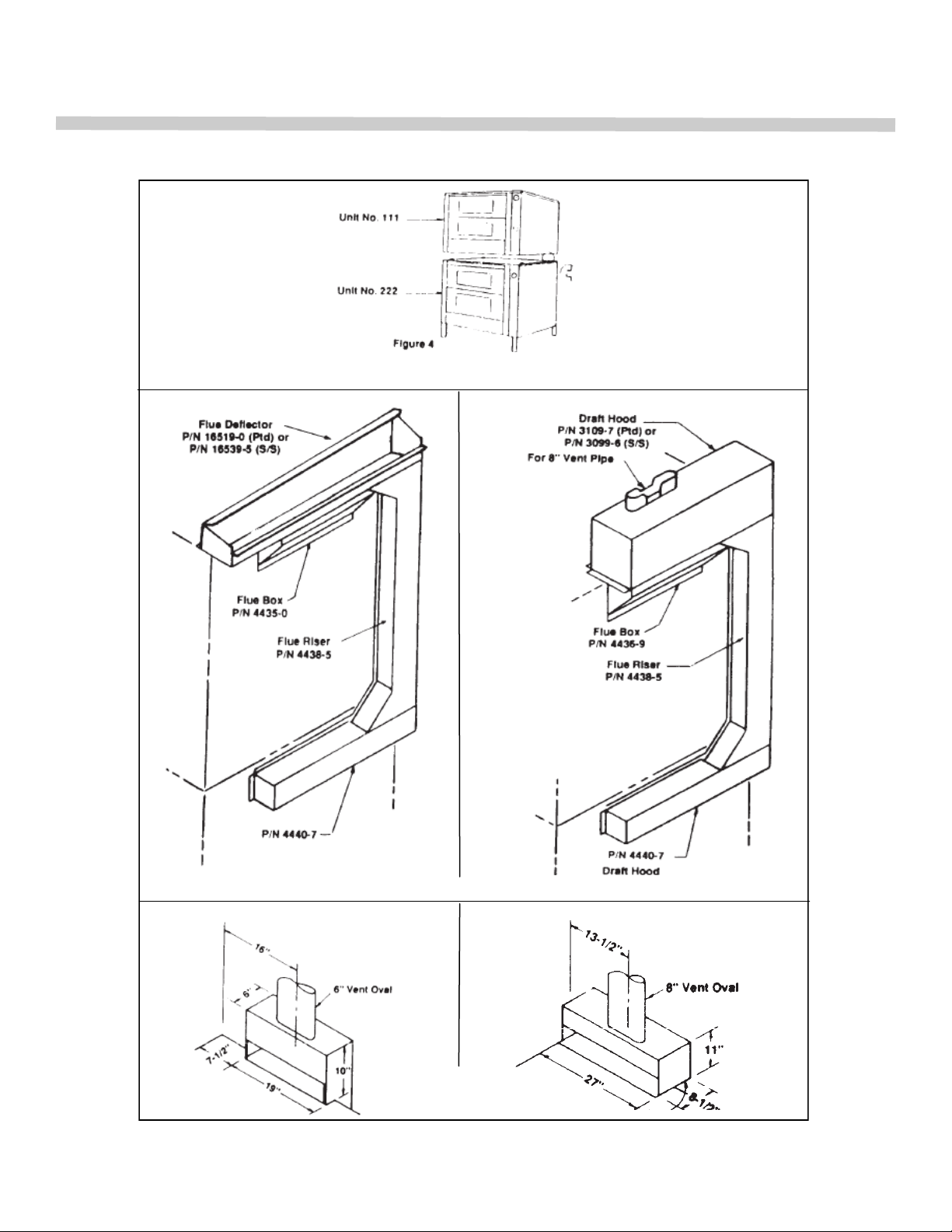

Vectaire Models 2-70, 2-115, SE2-70 & SE2-115 Series (Fig. 4 & 5)

1. Screw the adjustable feet of the legs in all the way. Then tightly screw the complete

leg assembly into the mounting holes at each corner of the lower dock (note logs on

top of lower deck). If unit is intended for curb mounting, Toe Base (P/N:6024-0)

must be used. The Toe Base is factory installed when curb mount is specified.

2. Set upper deck unit in place on top of lower deck.

3. Install flue riser (P/N:25128-3) over outlet of the horizontal flue collector (P/N:25135-

6) of the lower deck. Secure in place with the screws that are provided. Install flue

deflector (P/N:25328-6) over flue outlet of top oven section.

4. Install low profile deflector trim (P/N:26604-3) or draft hood (P/N:24678-6). Either a

flue deflector or a draft hood is shipped with every unit. The flue deflector is intended for use when the oven is installed under a properly designed hood. When the

oven is directly connected to the vent system, the draft hood must be used.

5. When oven is in permanent location, level entire unit by placing a carpenter’s level

on the oven rack and adjusting the foot on the bottom of each leg, so that the oven

is level from front to back and side to side. Level a curb mounted unit by placing a

shim under the slow side.

7

INSTALLATION

Figure 4

Figure 5

Figure 6

8

INSTALLATION

GAS CONNECTION

Before connecting oven to the gas supply line, be sure that all new piping has been cleaned

and purged to prevent any foreign matter from being carried into the controls by the gas. In

some cases, filters or drops are recommended. A separate gas shutoff valve must be installed

upstream from the gas pressure regulator adjacent to the oven and be located in an accessible area.

It is important that adequately sized piping be run directly to the point of connection at the

oven, with as few elbows and tees as possible. Consult local gas company for proper piping

size and gas pressure.

Each oven is equipped with an appliance gas pressure regulator. This gas pressure regulator

is factory adjusted for the manifold pressure specified on the name plate.

THIS OVEN IS DESIGNED FOR USE WITH A GAS PRESSURE REGULATOR. THE

REGULATOR SUPPLIES WITH THIS UNIT MAY BE USED.

For Natural Gas: This pressure regulator is factory adjusted for 3.5‖- W.C. manifold

pressure. The maximum inlet pressure to the regulator should not exceed 10.5‖ water column.

For Propane Gas: This gas pressure regulator is factory adjusted for 10‖ W.C. manifold

pressure. The maximum inlet pressure to the regulator should not exceed 21‖ water column.

Connect the gas supply line from the service gas shutoff valve to the inlet side of the gas

pressure regulator using 3/4‖ pipe. If flexible or semi-flexible connectors are used, an AGA

Listed flexible connector with an I.D. equal to 3/4‖ pipe must be used. DO NOT USE A

DOMESTIC APPLIANCE TYPE GAS FLEXIBLE CONNECTOR. Avoid kinks or sharp bends

that could restrict gas flow.

PIPE JOINT COMPOUND OR THREAD SEALANT THAT IS USED SHOULD BE

RESISTANT TO ACTION OF LIQUEFIED PETROLEUM GASES.

Turn gas shutoff valve ―ON‖ and immediately check carefully for gas leaks. Do this before

attempting to operate the oven.

TEST ALL PIPE JOINTS FOR LEAKS BEFORE OPERATING OVEN. THIS INCLUDES ALL

GAS CONNECTIONS THAT MAY HAVE LOOSENED DURING SHIPMENT. USE A RICH

SOAP SOLUTION (OR OTHER ACCEPTED LEAK TESTER) AROUND ALL PIPE CONNEC-

TIONS AND ALL OTHER JOINTS. DO NOT USE AN OPEN FLAME. ABSOLUTELY NO

LEAKAGE SHOULD OCCUR, OTHERWISE THERE IS A DANGER OF FIRE OR

EXPLOSION DEPENDING UPON CONDITIONS. NEVER USE IF LEAKAGE IS DETECTED.

9

INSTALLATION

Model R85 (Refer to Fig. 2, p. 4)

Uncrate oven and base as near to final location as possible. Remove all packing material

and accessories from oven interior. With help from at least two other people, tip the oven slowly

on its side. With the oven lying on its side, hold the front leg securely and align the threaded

stud on the leg with the nut located at the front corner of the accessible side. Insert the leg into

the nut and turn the leg clockwise. Tighten the leg to the oven securely. Rotate the leg counterclockwise slightly to align the two leg plate holes with the holes on the bottom of the oven.

Secure the leg using the provided 3/8‖ bolts and washers. Repeat the procedure for the rear

corner of the side off the ground. Tip the oven up on the secured legs and lean the oven

against a wall so that the legs on the remaining side can be attached. Install the remaining two

legs using the aforesaid procedure. Tip the oven back down on the newly installed legs and

re-tighten all the bolts securely.

A flue detector is supplied in Kit RS1 with the gusset legs. A Draft Hood is also available

as Kit RS2, and replaces the flue deflector. Either a flue deflector or a draft hood must be

installed on the unit. The flue detector is intended for use when the oven in installed under a

properly designed hood. When the oven is directly connected to a vent system, the draft hood

must be used.

When the oven is in permanent position, level entire unit by placing a carpenter’s level

on the oven rack and adjusting the foot on the bottom of each leg so that the oven is level from

front to back and side to side.

Model R2-85 Series (Refer to Figs. 4, 5 & 6, p. 6)

Screw the adjustable feet of the legs in all the way. Then tightly screw the complete leg

assembly into the mounting holes at each corner of the lower R85 unit. Mount lugs on top of the

lower R85 unit, as to center the top unit on the lower one.

Set upper deck unit in place on top of lower deck.

From Kit RD1, locate the flue riser, the flue collector, and the flue deflector. Install the

flue collector over the flue outlet on the lower R85 unit. Install the flue riser over the outlet of the

horizontal flue collector. Secure in place with self-drilling sheet-metal screws. Install the flue

deflector over the flue outlet of the upper R85 unit. This setup is intended for use when the

oven is installed under a properly designed hood. Note: When the oven is to be directly connected to a vent system, Kit RD2 must be used in conjunction with Kit RD1. Replace the flue

deflector with the Draft Hood ensuring that it covers the flue outlet of the upper R85 unit. It must

cover the top of the flue riser as well.

When the oven is in permanent position, level entire unit by placing a carpenter’s level

on the oven rack and adjusting the foot on the bottom of each leg, so that the oven is level from

front to back and side to side.

10

OPERATION

GAS CONTROL SYSTEM—All Models Except with Suffix ―EI‖

Lighting

Turn on main gas shutoff valve and electrical service.

IN THE EVENT A GAS ODOR IS DETECTED, SHUT DOWN UNITS AT MAIN SHUTOFF

VALVE AND CONTACT THE LOCAL GAS COMPLANY OR GAS SUPPLIER FOR SERVICE.

1. Turn oven burner valve clockwise to ―OFF‖ position.

2. Remove burner compartment access panel below oven doors by pulling bottom panel

outward to disengage panel catches.

3. Press and hold red safety pilot in and apply lighted match to pilot burner. After pilot burner

ignites, continue to hold red button depressed for 30-45 seconds or until pilot remains

burning when button is released.

4. Replace burner compartment access panel.

5. Set thermostat to desired temperature.

6. Turn oven burner valve counterclockwise to ―ON‖ position.

7. Turn on fan. Fan should be on at all times during cooking operation.

Shut Down

1. Stand By

a. Turn oven burner valve to ―OFF‖ position.

b. Turn off fan.

2. Complete

a. Turn all gas valves to ―OFF‖ position

b. Turn fan off.

c. Turn electrical service off of disconnect electrical supply cord from wall receptacle.

Relighting

1. Turn oven burner valve to ―OFF‖ position.

2. Wait five (5) minutes then follow ―Lighting‖ instructions.

11

OPERATION

GAS CONTROL SYSTEM—Models With Suffix ―EI‖

(Equipped with electronic ignition system)

Operation

1. Turn manual valve to ―ON‖ position.

2. Set thermostat to desired temperature.

3. Push toggle of Start/Reset switch to ―UP‖ position and release. The electronic pilot ignition control

will automatically light the pilot and burner each time the thermostat calls for heat.

4. If pilot fails to ignite within 30 seconds, a complete shut down of the ignition system will occur. To

initiate a re-ignition, wait at least 30 seconds, push toggle of Start/Reset switch up, then release.

Shut Down

1. Turn manual valve to ―OFF‖ position.

2. Turn thermostat to lowest setting.

CAUTION

DO NOT ATTEMPT TO LIGHT THE PILOT MANUALLY WITH A MATCH. THIS COULD RESULT IN THE

MAIN VALVE BEING ENERGIZED IMMEDIATELY.

CONTROLS

Standard Models—Models With Suffix ―AE, AG, ZE, ZG‖

1. ―LIGHT-OFF‖ switch controls the oven interior lights.

2. ―FAN-OFF-COOL‖ switch controls the fan operation. It must be on to obtain satisfactory

performance.

a. The center position is ―OFF‖

b. Depressing ―FAN‖ side of switch causes the motor to run continuously when doors are

closed. When doors are opened, fan will stop. This position is for cooking.

c. Depressing ―COOL‖ side of switch will result in continuous blower operation even with

doors open. This position is intended for cooling the oven at the end of work period or

lowering oven temperature.

NOTE: When cooling oven down, the burner valve should be turned off to prevent burner

operation.

3. The thermostat controls the oven temperature. The ―BURNER‖ indicator light remains lit until

desired oven temperature is reached.

4. The timer is only a time reminder. It has no control over the oven.

12

OPERATION

Models With Suffix ―EI‖

Same as ―Standard Models‖ above except for ―START/RESET‖ switch for the electronic ignition

system. Depress switch momentarily at the start of the work period.

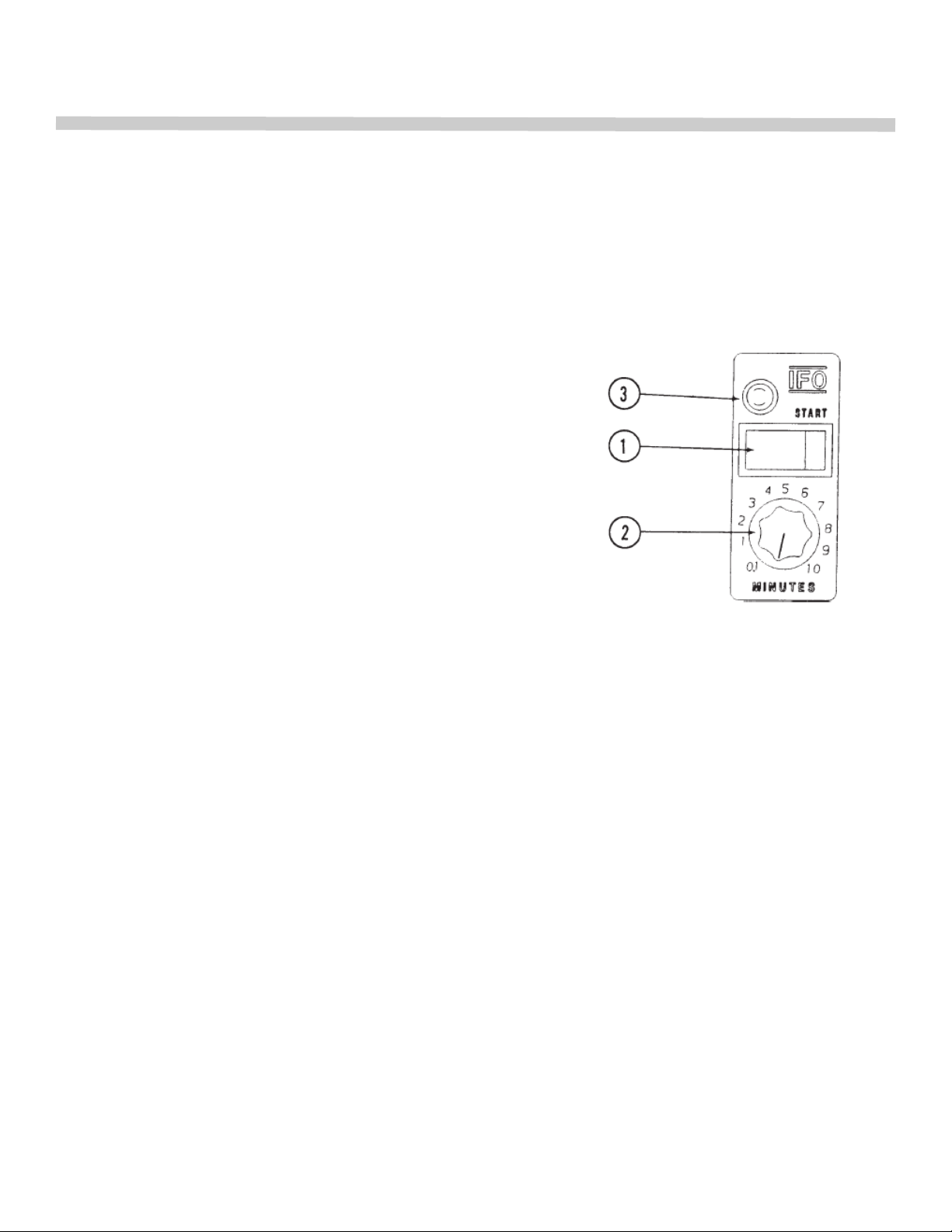

INTERMITTENT FAN OPERATION (IFO) CONTROLS (Optional)

The IFO fan control cycles the fan ON for 30 seconds and OFF for 30 seconds during a variable

time of 0.1 to 10 minutes of the cook period.

IFO Control

1. START SWITCH (MOMENTARY)

Activated the IFO cycle.

2. CYCLE TIMER (0.1 TO 10 MIN.)

Controls the duration of the IFO cycle.

3. INDICATOR LIGHT (AMBER)

When lighted, indicates the oven is in the IFO cycle.

IFO Operation

To set the IFO controls, first set the ―Cycle Timer‖ knob for the desired IFO time period. Once the

oven has reached temperature, load the product to be baked and close the door. Immediately set

and start the standard timer for the overall cook cycle. Next, push the ―Start‖ switch on the IFO

control. The amber indicator light will come on, the fan will stop, and then cycle on and off every

30 seconds until the set time has expired. The amber light will remain on continuously until the set

time has expired.

Once the amber light is on, additional pushing of the ―Start‖ switch will have no effect. Also the

―Cycle Timer‖ knob does not count down during the IFO cycle, but remains at its setting for

repeat cycle if desired.

To cancel the IFO cycle once started, simply rotate the ―Cycle Timer‖ knob counterclockwise until

it stops.

Once started, the IFO time period can be readjusted by simply repositioning the ―Cycle Timer‖

knob. If the knob is turned counterclockwise to a setting that is less than the current time expired

during the cycle, the cycle will be terminated. To restart a cycle, simply push the ―Start‖ switch.

If it is necessary to open the door during the IFO cycle, the fan will shut off if it is running. The IFO

timed cycle will continue uninterrupted, however, until the set time has expired. If there is a loss of

power during the cycle, it will be terminated.

13

OPERATION

OPERATION

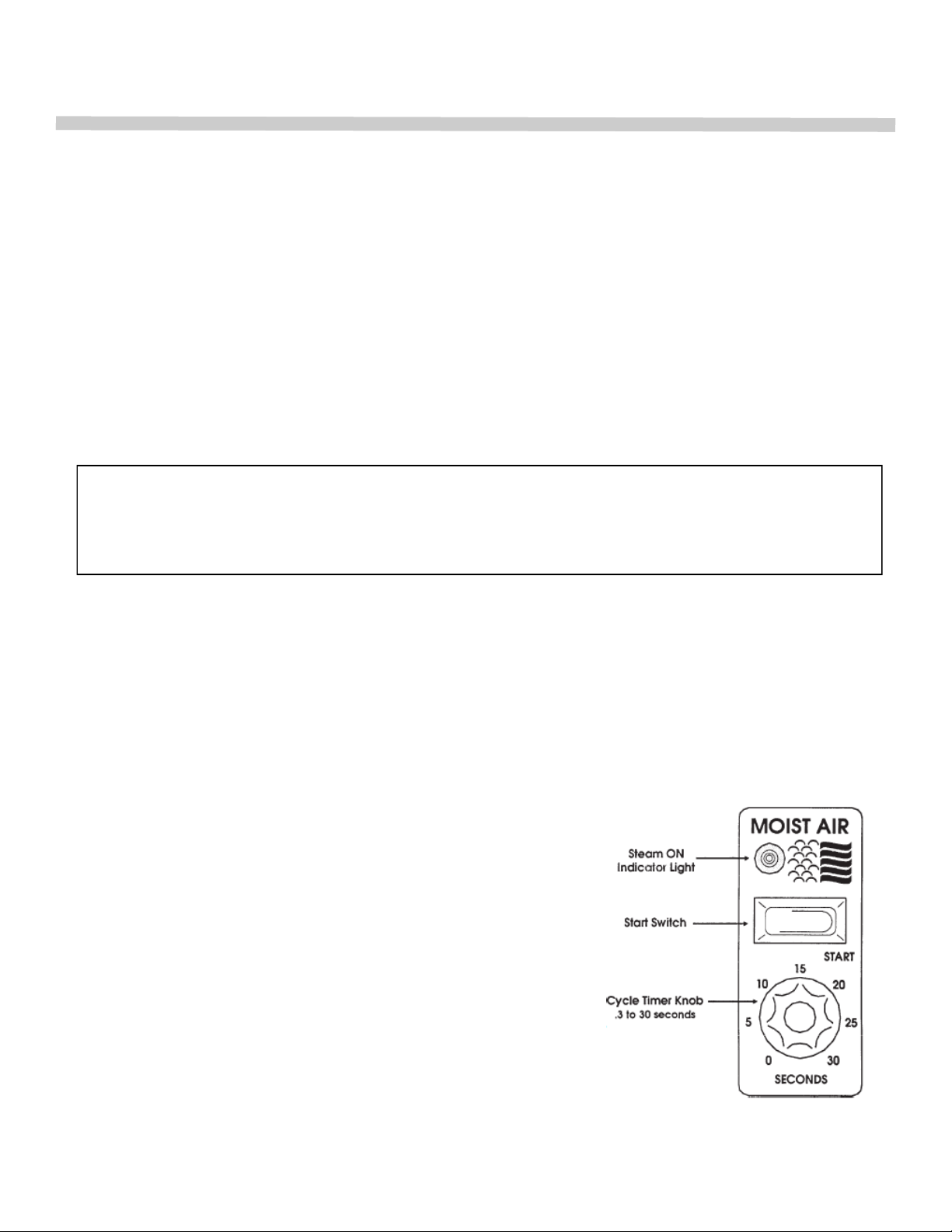

MOIST AIR CONTROLS & OPERATION (optional)

Moist Air (Steam) Option

The Moist Air option permits the operator to add steam to the oven chamber during the cooking cycle.

This is desirable during baking operations for crusting purposes or to maximize growth during the initial

bake period. It can also be useful for products requiring more moisture during the cook cycle.

Moist Air Components

The Moist Air option includes a water shut-off valve, water regulator/filter assembly, solenoid valve,

steel piping, spray nozzle, steam pan and Moist Air control cluster. During operation, activating controls

causes the solenoid valve to open and heated water to be sprayed into the hot oven chamber where it

is turned into steam. The steam pan converts any excess spray to steam and controls residue accumulation.

INSTALLATION

ATTENTION!

The Moist Air option requires a connection to good quality water that is low in total dissolved

solids and free of particulate matter. A water purification/treatment system must be installed if

harsh water conditions exist. If in doubt, have your water supply checked by a water treatment

company.

The water regulator filter assembly with shut-off valve (supplied with the Moist Air option) should be

wall mounted near the oven so that the four foot removable hose will reach the water connection on

the back of the oven. A permanent 1/2‖ cold water connection should be made at the shut-off valve.

This filter is meant to remove final traces of taint, odor, rust, and scale when used with good quality

water or a water purification/treatment system. It is not a substitute for a water treatment if harsh water conditions exist.

All other normal installation requirements for a Vectaire convection oven, as described in the

―Installation‖ section of the main Vectaire manual, should be followed.

OPERATION

The Moist Air control regulates the spray of water that created

steam in the oven chamber. The duration of the water spray can

be varied from .3 to 30 MOIST AIR seconds. The spray is initiated

by depressing the start switch.

To set the Moist Air controls, first set the ―Cycle Timer‖ knob for

the desired time period. Once the oven has reached temperature,

load the product to be baked and close the door. Immediately set

and start the standard timer for the overall cook cycle. Next, push

the ―Start‖ switch on the Moist Air control. The blue indicator light

will come on, and remain on continuously until the set time has

expired. Steam is being generated in the oven when the light is

on.

Once the blue light is on, additional pushing of the ―Start‖ switch

will have no effect. The ―Cycle Timer‖ knob does not count down, but remains at its setting for repeat

cycle if desired.

14

Loading...

Loading...