Montague GC-12 Installation Manual

INSTALLATION AND OPERATION

MANUAL

GAS FIRED TILTING KETTLE

MODEL GC-12

CROWN FOOD SERVICE EQUIPMENT LTD.

70 OAKDALE ROAD, DOWNSVIEW, (TORONTO), ONTARIO, CANADA, M3N 1V9

TELEPHONE: (416) 746-2358, FAX: (416) 746-8324

PART NUMBER 10105R5 1 2007-01-03

PRINTED IN CANADA

INSTALLATION AND OPERATION MANUAL, GAS FIRED TILTING KETTLE, MODEL GC-12

1.0 IMPORTANT NOTES FOR INSTALLATION AND OPERATION

This is the safety alert symbol. It is used to alert you to potential

personal injury hazards. Obey all safety messages that follow this

symbol to avoid possible injury or death.

WARNING: Improper installation, operation, adjustment, alteration,

service or maintenance can cause property damage, injury or death.

Read the installation, operating and maintenance instructions

thoroughly before installing, operating or servicing this equipment.

FOR YOUR SAFETY: Do not store or use gasoline or other flammable

vapours or liquids in the vicinity of this or any other appliance.

This manual should be retained for future reference.

PURCHASER: Instructions to be followed in te event that the operator of this

appliance smells gas must be posted in a prominent location. This information

shall be obtained by consulting the local gas supplier.

Keep the appliance area free and clear from combustibles.

Do not obstruct the flow of combustion and ventilation air.

Adequate clearances must be maintained for servicing and proper operation.

Intended for commercial use only. Not for household use.

PART NUMBER 10105R5 2 2007-01-03

INSTALLATION AND OPERATION MANUAL, GAS FIRED TILTING KETTLE, MODEL GC-12

TABLE OF CONTENTS

DESCRIPTION PAGE

1.0 Important Notes For Installation and Operation ..................................2

2.0 Service Connections ......................................................4

3.0 Introduction .............................................................5

4.0 Installation Instructions ....................................................6

5.0 Operating Instructions .................................................... 9

6.0 Periodic Maintenance ....................................................11

7.0 Troubleshooting ........................................................16

Appendix “A”, Material Safety Data Sheet .........................................17

PART NUMBER 10105R5 3 2007-01-03

INSTALLATION AND OPERATION MANUAL, GAS FIRED TILTING KETTLE, MODEL GC-12

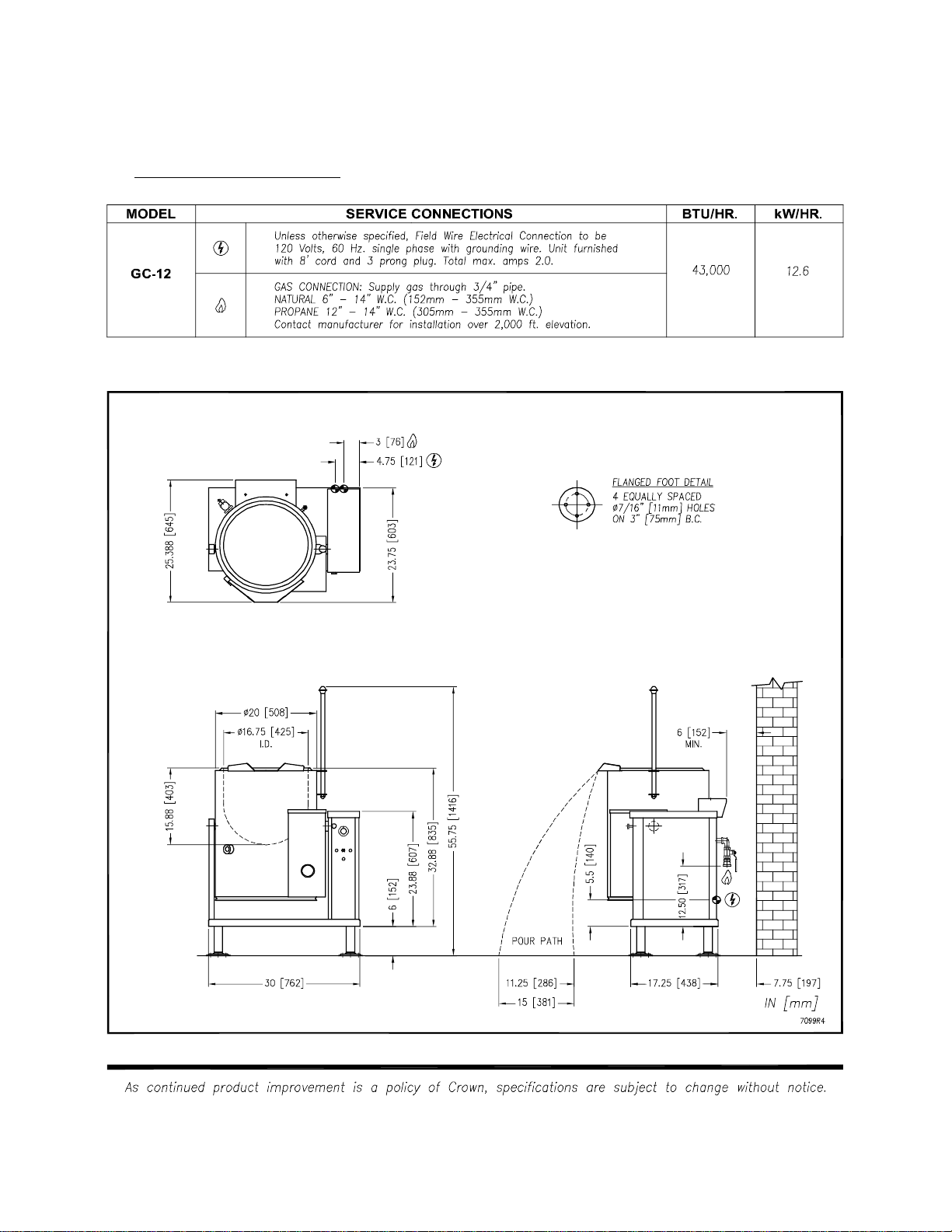

2.0 SERVICE CONNECTIONS

PART NUMBER 10105R5 4 2007-01-03

INSTALLATION AND OPERATION MANUAL, GAS FIRED TILTING KETTLE, MODEL GC-12

3.0 INTRODUCTION

DESCRIPTION

Model GC-12 (12 gallon capacity) gas fired, self-contained, tilting kettle. The kettle has a jacket of

double-wall construction forming a sealed reservoir around the lower two-thirds of the kettle. The

reservoir is charged with distilled water. The kettle is equipped with a “clean lock” to hold kettle in

cooking position or tilted 105 degrees for ease of cleaning. The kettle is also equipped with

automatic ignition, low water cut off and tilt switch, which, when activated, shuts down the burner.

BASIC FUNCTION

The kettle operates by generating steam in the kettle reservoir. The sequence of operation is as

follows:

1. Operator turns the power switch to the on position and sets the temperature control dial to the

desired setting.

2. The red light comes on indicating the kettle is heating. The green “IGNITION” light comes on

indicating that the ignition and burner are active.

3. Once the kettle reaches the set temperature, the red “TEMPERATURE” light and the green

“IGNITION” light extinguish.

4. All kettles are supplied with sufficient water in the jacket. If for any reason the water level falls

below the required amount to operate the kettle, the burner shuts down and the amber light

comes on. See Adding Water in Service section.

5. The sight glass indicates the water level within the kettle jacket.

6. The relief valve is a safety feature which prevents the internal kettle pressure from exceeding

50 PSI. It should never be tampered with.

PART NUMBER 10105R5 5 2007-01-03

INSTALLATION AND OPERATION MANUAL, GAS FIRED TILTING KETTLE, MODEL GC-12

4.0 INSTALLATION INSTRUCTIONS

INSTALLATION CODES AND STANDARDS

Installation must conform with local codes, or in the absence of local codes, with the National Fuel

Gas Code, ANSI Z223.1/NFPA 54, or the Natural Gas and Propane Installation Code, CSA

B149.1, as applicable.

1. The appliance and its individual shut off valve must be disconnected from the gas supply piping

system during any pressure testing of that system at pressures in excess of ½ psi (3.5 kPa).

2. The appliance must be isolated from the gas supply piping system by closing its individual

manual shut off valve during any pressure testing of the gas supply piping system at test

pressures equal to or less than ½ psi (3.5 kPa).

Electrical grounding must be provided in accordance with local codes, or in the absence of local

codes, with the National Electrical Code, ANSI/NFPA 70, or the Canadian Electrical Code, CSA

C22.2, as applicable.

Ventilation must be provided in accordance with local codes, or in the absence of local codes, with

ANSI/NFPA 96 Standard for Ventilation and Fire Protection of Commercial Cooking Operations.

WARNING: ELECTRICAL GROUNDING INSTRUCTIONS

This appliance is equipped with a three-prong (grounding) plug for

your protection against shock hazard and should be plugged directly

into a properly grounded three-prong receptacle. Do not cut or

remove the grounding prong from this plug. (120V units only).

The electrical wiring diagram is located inside the right hand console of the appliance.

PART NUMBER 10105R5 6 2007-01-03

INSTALLATION AND OPERATION MANUAL, GAS FIRED TILTING KETTLE, MODEL GC-12

GAS CONNECTION

WARNING: Do not connect the appliance to the electrical supply until

after the gas connection has been made.

CAUTION: The pipe thread compound used when installing pipes

must be a type that is resistant to the action of liquified petroleum or

propane gases.

1. The Serial and Rating Plate on the unit indicates the type of gas your unit is equipped to burn.

DO NOT connect to any other gas type.

2. A 3/4" NPT line is provided at rear for the connection. The unit is equipped with an internal

pressure regulator which is set at 4" W.C. manifold pressure for Natural Gas and 10" W.C. for

Propane Gas. Use 1/8" pipe tap on the union elbow assembly located in the console for

checking pressure.

An adequate gas supply is imperative. Undersized or low pressure lines will restrict the volume of

gas required for satisfactory performance. A steady supply pressure, minimum 6 inch W.C. for

natural gas and minimum 12 inch W.C. for propane gas is recommended. With all units operating

simultaneously, the manifold pressure on all units should not show any appreciable drop.

Fluctuations of more than 25% on natural gas and 10% on propane gas will create problems,

affecting burner operation. Contact you gas company for correct supply line sizes.

Purge the supply line to clean out any dust, dirt or other foreign matter before connecting the line

to the unit. Use pipe joint compound which is suitable for use with L.P. on all threaded

connections.

Test pipe connections thoroughly for gas leaks.

WARNING: Never use an open flame to check for gas leaks. Check all

connections for leaks using soapy water before use.

NOTICE: If this equipment is being installed at over 2,000 feet altitude and was

not so specified on order, contact service department. Failure to install with

proper orifice sizing may void the warranty.

PART NUMBER 10105R5 7 2007-01-03

INSTALLATION AND OPERATION MANUAL, GAS FIRED TILTING KETTLE, MODEL GC-12

INSTALLATION

1. Uncrate carefully. Report any hidden freight damage to the freight company immediately.

2. Ideally an exhaust system should be directly above the appliance to exhaust combustion

gases generated by the unit.

3. The appliance is intended for use on noncombustible floors. The minimum clearance from

combustible and noncombustible floor construction is 0" on right side, 0" on left side and 6"

(152 mm) from the back of the flue chimney.

4. Appliance location must allow air supply to unit and obstruction free clearance for air opening

into the combustion chamber.

5. Set the appliance in place and level using spirit level. Level left to right and front to back.

6. Mark hole locations on the floor through the anchoring holes provided in the flanged

adjustable feet.

7. Remove the appliance from installation position and drill holes in locations marked on the

floor. (See installation diagram on Page 4). Insert proper anchoring devices. (Not supplied).

8. Place appliance back in the installation position and Re-level left to right and front to back.

9. Bolt and anchor appliance securely to the floor.

10. Seal bolts and flanged feet with silastic or equivalent compound.

11. Make service connections as indicated.

12. The pressure relief valve is located at the left rear of the unit. This area should be kept clear

and should not be in an area where operators will normally stand. The elbow on the relief

valve should be turned toward the floor. 3/4" diameter pipe may be used to extend to the

floor, but must not be piped directly to a drain. It must be vented to the atmosphere.

13. Check the pressure gauge on the front panel before operating. The reading should be in the

green vacuum zone (below 0 PSI). See “Re-establishing Vacuum” section under Service

Instructions.

PART NUMBER 10105R5 8 2007-01-03

Loading...

Loading...