Montague FB-108-SC Service Manual

INSTRUCTION MANUAL

INSTALLATION / OPERATIONS / PARTS & SERVICE

MONTAGUE

REFRIGERATION AND FREEZER

BASES

MODEL(S):

RB36SC—RB108SC

RB36R—RB108R

RB36 FREEZER—RB108 FREEZER

These instructions should be read thoroughly before attempting installation.

Set up and installation should be performed by qualified installation personnel.

PLEASE RETAIN THIS MANUAL

FOR FUTURE REFERENCE.

THE MONTAGUE COMPANY

1830 Stearman Avenue

P.O. BOX 4954

Hayward, CA 94540-4954

TEL: (510) 785-8822 FAX: (510) 785-3342

1

IMPORTANT

WARNING:

Improper installation, adjustment,

alteration, service or maintenance

can cause property damage, injury

or death. Read the operating

and maintenance instructions

Do not store or use gasoline or

other flammable vapors and

liquids in the vicinity of this or

any other appliance.

FOR YOUR SAFETY:

thoroughly before installing or

servicing this equipment.

INSTRUCTIONS TO BE FOLLOWED IN THE EVENT THE USER SMELLS GAS MUST BE

POSTED IN A PROMINENT LOCATION. THIS INFORM ATION MAY BE OBTAINED BY

CONSULTING THE LOCAL GAS SUPPLIER.

SHIPPING DAMAGE CLAIM PROCEDURE

For your protection, please note that equipment in this shipment was carefully inspected

and packed by skilled personnel before leaving the factory. The transportation company

assumes full responsibility for safe delivery upon acceptance of this shipment.

If shipment arrives damaged:

1. VISIBLE LOSS OR DAMAGE—Be certain this is noted on freight bill or express receipt,

and signed by person making delivery.

2. FILE CLAIM FOR DAMAGES IMMEDIATELY—Regardless of the extent of damage.

3. CONCEALED LOSS OR DAMAGE—If damage is unnoticed until merchandise is un-

packed, notify transportation company or carrier immediately, and file “concealed damage” claim with them. This should be done within fifteen (15) days of date that delivery

was made to you. Be sure to retain container for inspection.

We cannot assume responsibility for damage incurred in transit. We will, however, be glad

to furnish you with necessary documents to support your claim.

2

The Refrigeration and Freezer bases are produced with the best possible material and workmanship.

PROPER INSTALLATION IS ESSENTIAL FOR SAFE AND EFFICIENT TROUBLE-FREE OPERATION.

THE INSTALLATION INSTRUCTIONS CONTAINED HEREIN ARE FOR THE

USE OF QUALIFIED INSTALLATION AND SERVICE PERSONNEL ONLY.

INSTALLATION OR SERVICE BY OTHER THAN QUALIFIED PERSONNEL

MAY RESULT IN DAMAGE TO THE EQUIPMENT AND/OR INJURY TO THE

OPERATOR.

Qualified installation personnel are individuals, a firm, corporation or company which either in

person, or through a representative are engaged in, and are responsible for:

A. The installation or replacement of the connection, installation, repair or servicing of equip-

ment, who is experienced in such work, familiar with all precautions required, and has

complied with all requirements of state or local authorities having jurisdiction. Reference:

National Fuel Gas Code Z223.1-latest addenda, Section 1.4.

B. The installation of electrical wiring from the electric meter, main control box or service out-

let to the electric appliance. Qualified personnel must be experienced in such work, be familiar with all precautions required and have complied with all requirements of state and

local authorities having jurisdiction. Reference: National Electric Code, N.F.P.A. No. 70–

latest addenda.

READ CAREFULY AND FOLLOW THESE INSTRUCTIONS

THIS UNIT WHEN INSTALLED MUST BE ELECTRICALLY GROUNDED

IN ACCORDANCE WITH LOCAL CODES, OR IN ABSENCE OF LOCAL

CODES, WITH THE NATIONAL ELECTRICAL CODE, ANSI/NFPA No.70–

LATEST ADDENDA.

PROVISIONS MUST BE MADE FOR ADEQUATE AIR SUPPLY TO THE UNIT.

3

INTRODUCTION

NOTE: Sections of this manual are prepared for the use of Service Technicians and should not be

used by those not properly qualified. This manual is not intended to be all encompassing. You

should read, in its entirety, the repair procedure you wish to perform to determine if you have the

necessary tools, instruments, and skills required to perform the procedure.

MONTAGUE MODELS

Montague RB-SC and RB-R models are refrigerated Equipment Stand units available in different

lengths from 36 to 108 inches in width. These units are available as refrigerated or freezer storage

compartments. The condensing systems are designed to be installed with minimal clearance to walls

or other equipment.

These models are available as self-contained or remote. Standard features on these models include:

Electronic temperature control

All stainless steel construction

6” legs for (RB-R) models

Double or single wide drawers

Exterior Top Rail thermometer

MODELS AVAILABLE

SELF-CONTAINED

(RB-SC)

REMOTE

(RB-R)

RB-36-SC RB-36-R FB-36-SC FB-36-R

RB-48-SC RB-48-R FB-48-SC FB-48-R

RB-60-SC RB-60-R FB-60-SC FB-60-R

RB-72-SC RB-72-R FB-72-SC FB-72-R

Display: 3 digit display w/ sign (-199 to 999)

and decimal point.

Six status LED’s

Unique designed evaporator coil (TURBO

COIL). controlled from the outside thermometer

SELF-CONTAINED

(FB-SC)

REMOTE

(FB-R)

RB-84-SC RB-84-R FB-84-SC FB-84-R

RB-96-SC RB-96-R FB-96-SC FB-96-R

RB-108-SC RB-108-R FB-108-SC FB-108-R

* Available options include: Marine edge exterior top in all different models.

4

TABLE OF CONTENTS

THE SERIAL TAG …………………………………. PAGE 6

RECEIVING & INSPECTING …………………….. PAGE 7

A. UNPACKING AND CHECKING

INSTALLATION ……………………………………. PAGE 7 & 8

A. UNPACK LOOSE COMPONENTS

B. REFRIGERATION LINES

C. ELECTRIC CONNECTION

OPERATION ……………………………………….. PAGE 8

A. TEMPERATURE SETTING

B. FREEZER SETTING

C. THERMOSTAT

D. DEFROST

E. SHUTTING OFF

DRAWER CONFIGURATION ……………………. PAGE 9 & 10

MAINTENANCE PROCEDURES ……………….. PAGE 11

A. CLEANING STORAGE CABINET

B. STORAGE CABINET

C. CONDENSING UNIT

TROUBLESHOOTING GUIDE …………………… PAGE 12

WIRING DIAGRAM (RB-SELF CONTAINED) … PAGE 13

WIRING DIAGRAM (RB-REMOTE) …………….. PAGE 14

WIRING DIAGRAM (FB-SELF CONTAINED) …. PAGE 15

WIRING DIAGRAM (FB-REMOTE)……………… PAGE 16

EXPLODED VIEWS & PARTS LISTS……………. PAGE 17-25

5

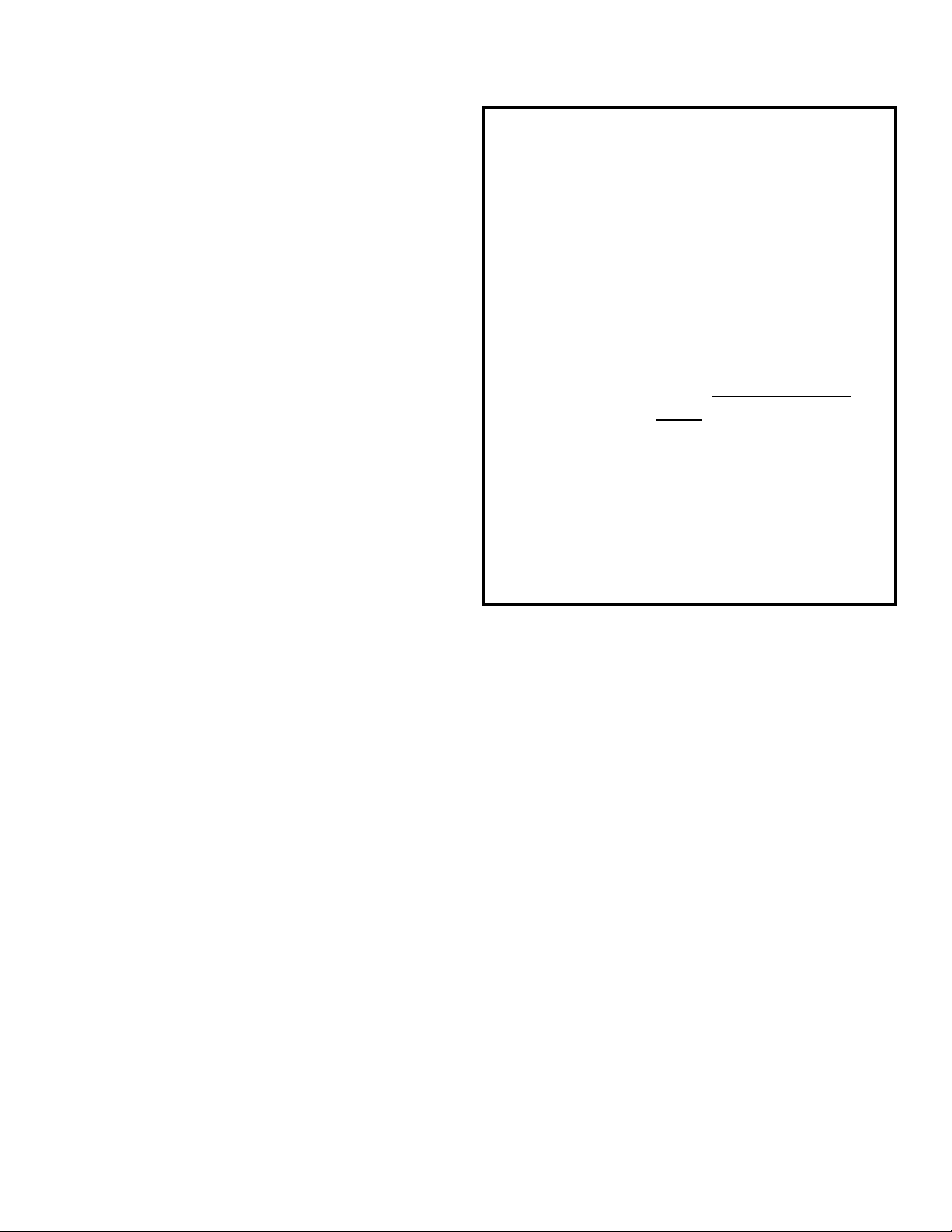

THE SERIAL TAG

The serial tag is a label permanently affixed to

EXAMPLE:

every unit on which vital electrical and

refrigeration data about your Montague product,

is recorded as well as model and serial

number. This tag is located inside the storage

cabinet on all standard Self-contained (RB-SC)

or Remote (RB-R) model refrigerated equipment

stand units. Prior to installation, test the

electrical service to assure that it agrees with

VOLTS: HZ: PH:

TOTAL AMPS:

MIN CIRCUIT AMPACITY:

the specifications of the equipment marked on

the serial tag.

READING THE SERIAL MODEL:

HIGH SIDE: LOW SIDE:

Serial = The permanent ID# of your

REFRIGERANT: LBS: OZ:

Montague unit

A TYPE II DISPLAY REFRIGERATOR OR FREEZER

Model = The model # of your Montague unit

Volts = Voltage

Hz = Cycle

INTENDED FOR OTHER THAN HOUSEHOLD USE.

THE MONTAGUE CO.

HAYWARD – CALIFORNIA

MOD:

SER:

DESIGN PRESSURE

(PSIG)

(DESTINE A UN USAGE AUTRE QUE

DOMESTIQUE.)

P/N:59935-2

Heaters (freezers only) = Number of Heaters

Total Amps = Maximum Amp draw

Minimum Circuit = Minimum Circuit Ampacity

Maximum Amps Protection = Breaker size

Refrigerant = Refrigerant type and amount

used

Design Pressure = Maximum operating

pressures

Figure 1.

SERIAL NUMBER LOCATION

Always have the serial number of your unit

available when calling Parts & Service.

The serial number is on the nameplate that also

includes the model number. A typical

identification plate is shown in Figure 1.

6

RECEIVING & INSPECTING

SHIPPING DAMAGE CLAIM PROCEDURE

NOTE: For your protection, please note that

equipment in this shipment was carefully

inspected and packed by skilled personnel

before leaving the factory. The transportation

company assumed full responsibility for safe

delivery upon acceptance of this shipment.

* We cannot assume responsibility for

damage incurred in transit. We will, however,

be glad to furnish you with the necessary

documents to support your claim.

All Montague products are factory tested for

performance and are free from defects when

shipped. The utmost care has been taken in

crating this product to protect against damage in

transit.

You should carefully inspect your Montague unit

for damage during delivery. If damage is detected, you should save all the crating materials and make note on the carriers Bill of Lading

describing the damage. A freight claim should be

filed immediately. There is a fifteen (15) day limit

to file freight damage with the carrier. (to

verify)

Care should be taken during unloading so the

equipment is not damaged while being moved

into the building.

1. Visually inspect the exterior of the package

and skid or container. Any damage should be

noted and reported to the delivery carrier

immediately.

2. If damaged, open and inspect the contents

with the carrier.

3. In the event the exterior is not damaged, yet

upon opening, there is concealed damage to

4. Request an inspection by the shipping

5. Freight carriers can supply the necessary

6. Retain all shipping materials until an

A. Uncrate unit as near to final location as

Some components are packed and shipped

inside the storage cabinet to avoid damage

during shipment. Remove these items from the

cabinet and remove packing materials.

(CASTERS, LEGS, ETC.)

B. FOR CORD CONNECTED UNITS

C. WARNING: THIS UNIT IS PROVIDED

D. PERMANENTLY WIRED UNITS (Remote

the equipment, notify the carrier. Notification

should be made verbally as well as in written

form.

company of the damaged equipment. This

should be done within 10 days from receipt

of equipment.

damage form upon request.

inspection has been made or waived.

INSTALLATION

possible for easier and lighter handling of the

unit and remove all packing materials from

interior.

(Self-contained models): Plug the unit into a

properly sized outlet. See data plate location

inside storage cabinet for circuit sizing.

WITH A THREE PRONGED GROUNDING

PLUG. THE OUTLET TO WHICH THIS

PLUG IS CONNECTED MUST BE

PROPERLY GROUNDED. IF

RECEPTACLE IS NOT THE PROPER

GROUNDING TYPE, CONSULT ELECTRICIAN FOR PROPER INSTALLATION.

Models): A junction box located on the back

of the unit is provided for electrical field

7

INSTALLATION(CONTINUED) OPERATION

connections. See wiring diagram shipped

with the unit on the compressor compartment

behind the louver panel for electrical rating.

E. REFRIGERATION LINES (Remote units

only)

WARNING: REFRIGERATION LINES ARE

SHIPPED UNDER PRESSURE. USE CAUTION

WHEN OPENING LINES.

F. ON REMOTE UNITS. Refrigeration lines for

suction and supply are located on the back

of the unit. The suction line is marked

“suction” and 3/8 copper tubing. The liquid

supply line is 1/4” copper. If upon opening

lines, no release of charge is evident, contact

your local authorized service agent immediately.

Cut refrigeration tubing with appropriate tool

and de-burr end of the tube. Clean tubing prior

brazing connection. Use Silfos 5% refrigerant

line brazing or better.

A. TEMPERATURE CONTROL SETTINGS:

On both Self-Contained and Remote

Refrigerated units, temperature Control

should be set 35°F with a 5°F dierenal. This

display should read between 35°F to 40°F . The

temperature control seng is “locked” to avoid

unauthorized adjustments. Therefore,

adjustments to the set point must be made by an

authorized service technician.

B. ON FREEZER BASE UNITS: The temperature

control should be set at 0°F with 5°F dierenal.

Temperature display should read between 0°F

and 5°F

C. The temperature control is the actual

thermometer of the unit, it does display the

actual temperature of the storage cabinet.

Allow cabinet to reach normal operang

temperature before loading (approximately) 20

minutes for refrigerator and 45 minutes for

freezer. If the storage cabinet is overloaded with

warm food products, a certain amount of me is

required to remove heat from items before

operang temperatures can be maintained.

The system is designed for storage of

refrigerated or frozen products.

D. DEFROST TIME SETTINGS: All models are

provided with an electronic temperature control

which have a built-in defrost system, which is

factory set as well as the temperature sengs.

Any change made to the seng must be made

by a qualied or authorized service technician.

E. SHUTDOWN FOR EXTENDED PERIODS: If the

units are not to be used for an extended period

of me, disconnect the electrical power supply

and remove the drawers from the storage

cabinet. As soon as cabinet has warmed to room

temperature, wipe out the base interior.

8

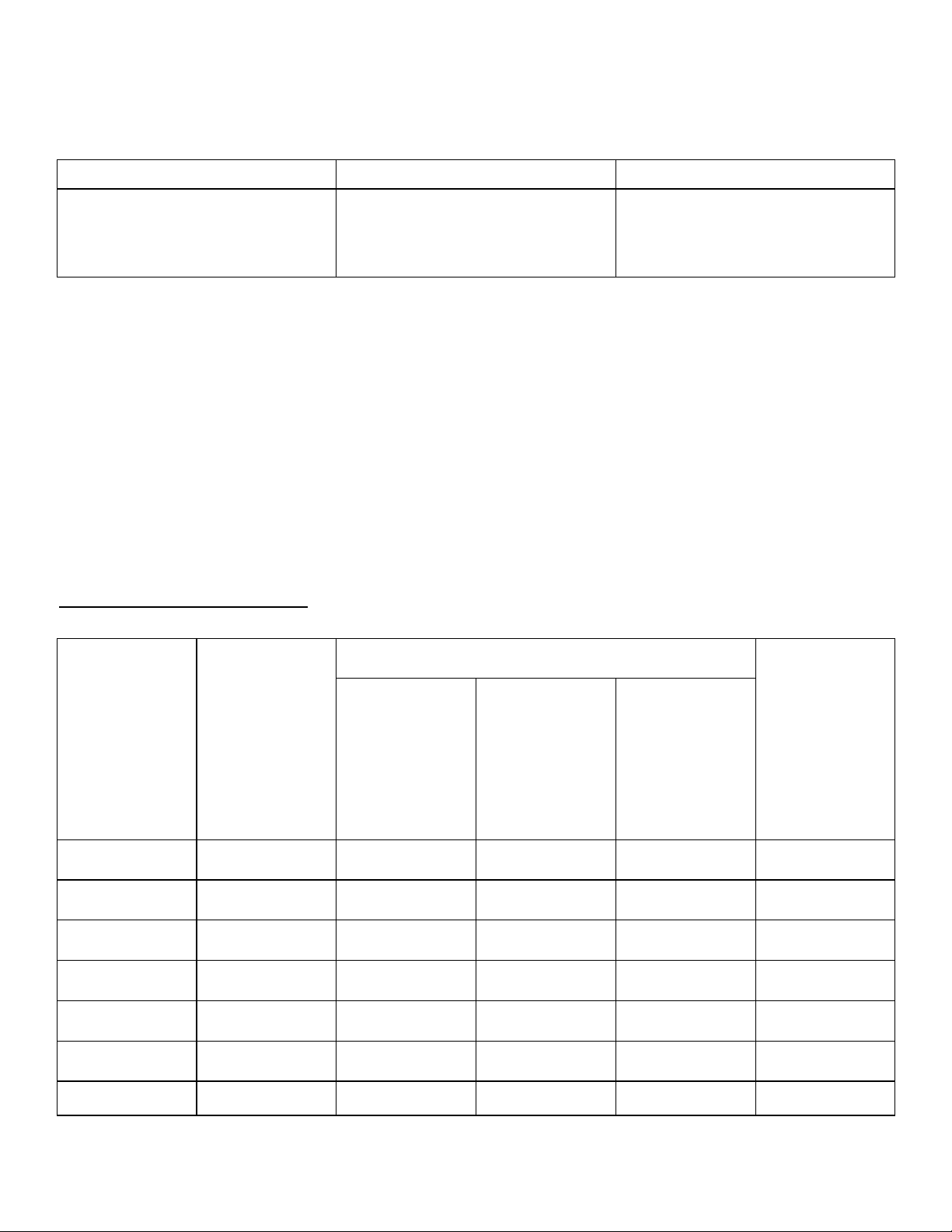

AVAILABLE DRAWER CONFIGURATION

DRAWER CONFIGURATION (A) DRAWER CONFIGURATION (B) DRAWER CONFIGURATION (C)

Can accommodate up to one

6” (152mm) deep, 12” x 20” (305 x

508mm)

Heavy 14-gauge stainless steel track system

Recessed drawer handles

Drawers are easily removed for cleaning

300lbs (136 kg) individual drawer weight

Can accommodate up to two pans

6” (152mm) deep, 12” x 20” (305 x

508mm) *(from left to right)

capacity

Tandem 2” (51mm) diameter stainless steel

wheel

Self-Contained Model Guide

Drawers: Width & Configuration

Can accommodate up to two pans

6” (152mm) deep, 12” x 20” (305 x

508mm) *(from front to back)

Unit Width

Model

Inches

Number

(mm)

RB-36-SC 36” (914) A 2

RB-48-SC 48” (1219) C 4

RB-60-SC 60” (1524) A B 6

RB-72-SC 72” (1829) B C 8

RB-84-SC 84” (2134) C 8

RB-96-SC 96” (2438) B - (2) C 12

RB-108-SC 108” (2743) C - (3) 12

14-3/8”

(356mm)

22-3/8”

(566mm)

27-1/4”

(692mm)

Total

Pans

9

Loading...

Loading...