Montague DG Installation Manual

Part # 464044

®

**WARNING**

Disconnect and secure all electrical power to the

“OFF” position prior to inspection or servicing.

Failure to comply with this safety precaution

could result in serious injury or death.

**IMPORTANT**

All factory provided lifting lugs must be used when lifting any unit. Failure to comply with this safety

precaution could result in property damage, serious injury or death.

FOR YOUR SAFETY

If you smell gas

1. Open windows

2. Don’t touch electrical switches

3. Extinguish any open flames

4. Immediately call your gas supplier

Report any damaged equipment to the shipper immediately!

All units are shipped on a skid or packaged to minimize damage during shipment. The transporting carrier has

the responsibility of delivering all items in their original condition as received from Greenheck. The individual

receiving the equipment is responsible for inspecting the unit for obvious or hidden damage, recording any

damage on the bill of lading before acceptance and filing a claim (if required) with the final carrier. Some

accessory items are stored inside the unit during shipping. Care must be taken during installation to prevent

damage to units.

FOR YOUR SAFETY

The use and storage of gasoline or other

flammable vapors and liquids in open

containers in the vicinity of this appliance

is hazardous.

**WARNING**

Improper installation, adjustment, alteration,

service or maintenance can cause property

damage, injury or death. Read the installation,

operating and maintenance instructions

thoroughly before installing or servicing this

equipment.

MaintenanceTroubleshooting

OperationStart-UpInstallation

Reference

GREENHEAT™ SYSTEM for INDUSTRIAL

SPACE HEATING -

MODEL DG / DGX

Installation, Operation and Maintenance Manual

TABLE OF CONTENTS

Installation

Unit - Indoor . . . . . . . . . . . . . . . . . . . . . .I-1

Unit - Arrangement DB/HZ . . . . . . . . . . .I-2

Diffuser . . . . . . . . . . . . . . . . . . . . . . . . . . .I-3

Remote Panel (TSCP) . . . . . . . . . . . . . . .I-3

Electrical Wiring . . . . . . . . . . . . . . . . . . . .I-4

Direct Gas Piping . . . . . . . . . . . . . . . . . . .I-5

I

Start-Up

Blower . . . . . . . . . . . . . . . . . . . . . . . . . .S-1

Direct Gas . . . . . . . . . . . . . . . . . . . . . . . .S-3

S

Operation

Electrical without 7 Day Timer . . . . . . .O-1

Electrical with 7 Day Timer . . . . . . . . . .O-2

O

Troubleshooting

Blower . . . . . . . . . . . . . . . . . . . . . . . . . . .T-1

Heater . . . . . . . . . . . . . . . . . . . . . . . . . . .T-2

Vibration . . . . . . . . . . . . . . . . . . . . . . . . .T-5

T

Reference

Gas Train Layout 400-800 MBH . . . . . .R-1

Gas Train Layout > 800 MBH . . . . . . . .R-2

Control Center Layout . . . . . . . . . . . . . .R-3

Maintenance

Routine . . . . . . . . . . . . . . . . . . . . . . . . .M-1

Fall . . . . . . . . . . . . . . . . . . . . . . . . . .M-3

Log . . . . . . . . . . . . . . . . . . . . . . . . . .M-4

M

R

STORAGE

When a unit is not going to be in service for an extended period of time, certain procedures should be followed

to keep the unit in proper operating condition:

• Plug all piping

• Rotate fan wheel monthly and purge bearings once every one to three months (depending on environment).

• Energize fan motor once every three months

• Store belts flat to keep them from warping and stretching

• Store unit in location without vibration

• Cover unit with tarp to protect from dirt and moisture

• After storage period, purge grease before putting fan into service

NOTE!

Do not cover unit with a black tarp, as this will

promote condensation.

NOTE!

Improper storage which results in damage to the

unit will void the warranty.

Installation - Indoor

I - 1

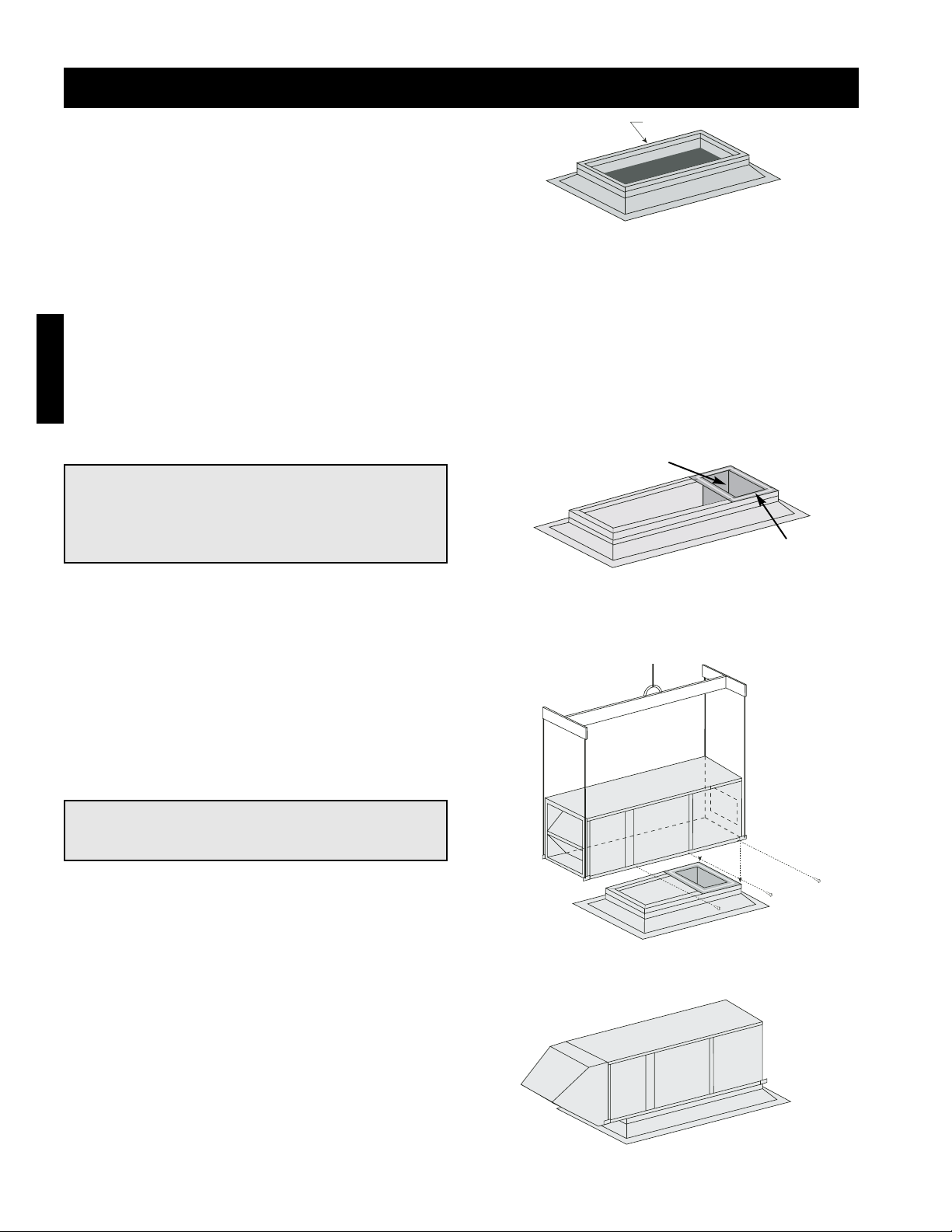

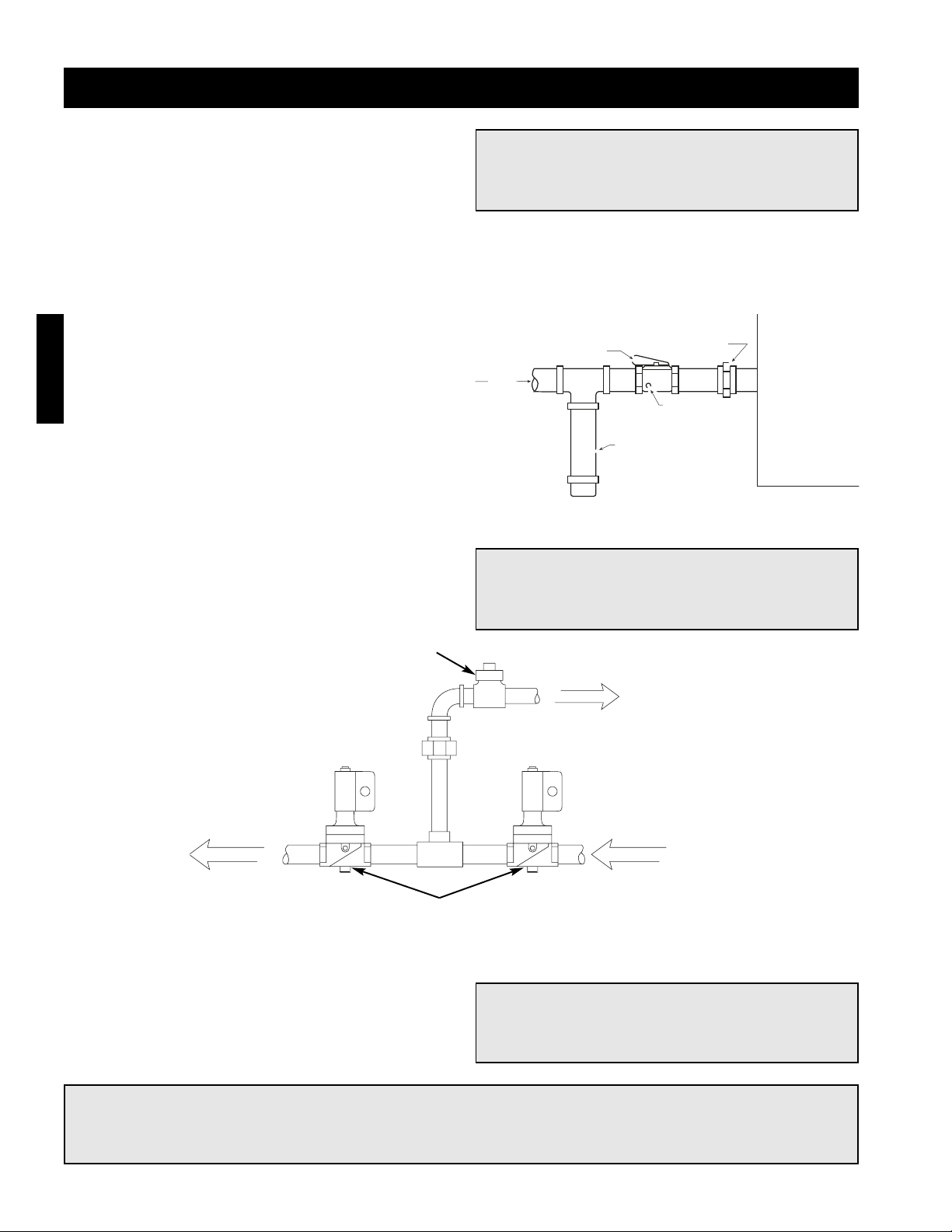

Step 1 Install Hangers

Install threaded hangers from ceiling supports. When locating hangers, allow enough room to open access

panel(s). Be sure to allow for the recommended diffuser height outlined in the diffuser installation instructions.

Two nuts must be used on the end of each threaded hanger. Ceiling supports are supplied by others. Refer to

figure #1.

Step 2 Install Unit

Using sheet metal screws, attach the

weatherhood/thru-wall/filter section to the

blower/burner section. The flange on the

weatherhood/thru-wall/filter section should overlap

the flange on the blower/burner section.

Raise the assembled unit into place.

Using two nuts per hanger, fasten the unit supports to

the hangers under the unit. Appropriate unit supports,

such as the optional Greenheck hanging bracket kit

or c-channel and angle iron (supplied by others)

should be used. Refer to figure #1.

In order to prevent the unit from swinging and to

provide a safe environment for service and

maintenance, additional measures must be taken to

secure the unit in all directions.

Step 3 Seal Wall Opening

Apply sealant around the perimeter of the

weatherhood to prevent water penetration and drafts

into the building. Refer to figure #2.

NOTE!

Two nuts must be used on each end of each threaded hanging rod for proper support.

NOTE!

Good duct practices should be followed for all ductwork. Ductwork should be installed in accordance

with SMACNA and AMCA guidelines, NFPA 96 and any local codes. Reference the CAPS submittal for

duct sizes.

Sealant

Unit

Supports

Ceiling

Supports

Hangers

Diffuser

Figure 1. Indoor Mounting

Figure 2. Sealing Wall Opening

Step 1 Install Curb

Position curb on the roof (reference the CAPS

submittal for placement of curb in relation to the unit).

Verify that the curb is level, shim if necessary. Attach

curb to roof and flash into place. Refer to figure #3.

Step 2 Install Ductwork

Good duct practices should be followed for all ductwork. All ductwork should be installed in accordance with

SMACNA and AMCA guidelines, NFPA 96 and all local codes. Reference the CAPS submittal for ductwork sizes.

Be sure to allow for the recommended diffuser height outlined in the diffuser installation instructions.

Apply an appropriate sealant around the perimeter of the curb and duct adapter to isolate fan vibration and

prevent water penetration. Refer to figure #4.

Step 3 Install Unit

Use a crane and a set of spreader bars hooked to the

factory lifting lugs to lift and center the unit on the

curb. Use self-tapping sheet metal screws to fasten

the unit to the curb. See figure #5.

Step 4 Assemble and Install

Weatherhood

The weatherhood can now be assembled and

attached to the unit. Detailed assembly instructions

can be found with the weatherhood. Once the

weatherhood is installed, use an appropriate sealant

to seal the seam between the weatherhood and the

unit.

Supply Air Duct Work

(Arrangement DB only)

Sealant

Installation - Arrangement DB / HZ

I - 2

NOTE!

The use of all lifting lugs and a set of spreader

bars is mandatory when lifting the unit.

NOTE!

The use of a duct adapter is recommended on a

downblast (DB) arrangement to align the

ductwork with the supply unit and is only a guide

and is not to be used to support the ductwork.

er

Equipment

Support

Roof Curb

Figure 3. Roof Curb

Figure 4. Ductwork

Figure 5. Placing Unit

Figure 6. Complete Rooftop Installation

Installation - Diffuser and Remote Panel (TSCP)

I - 3

IMPORTANT!

The location of the discharge diffuser and the TSCP are critical for optimum performance of the

Greenheat space heat system.

IMPORTANT!

DO NOT install the TSCP in the blast area of the space heater or near any other source of heat.

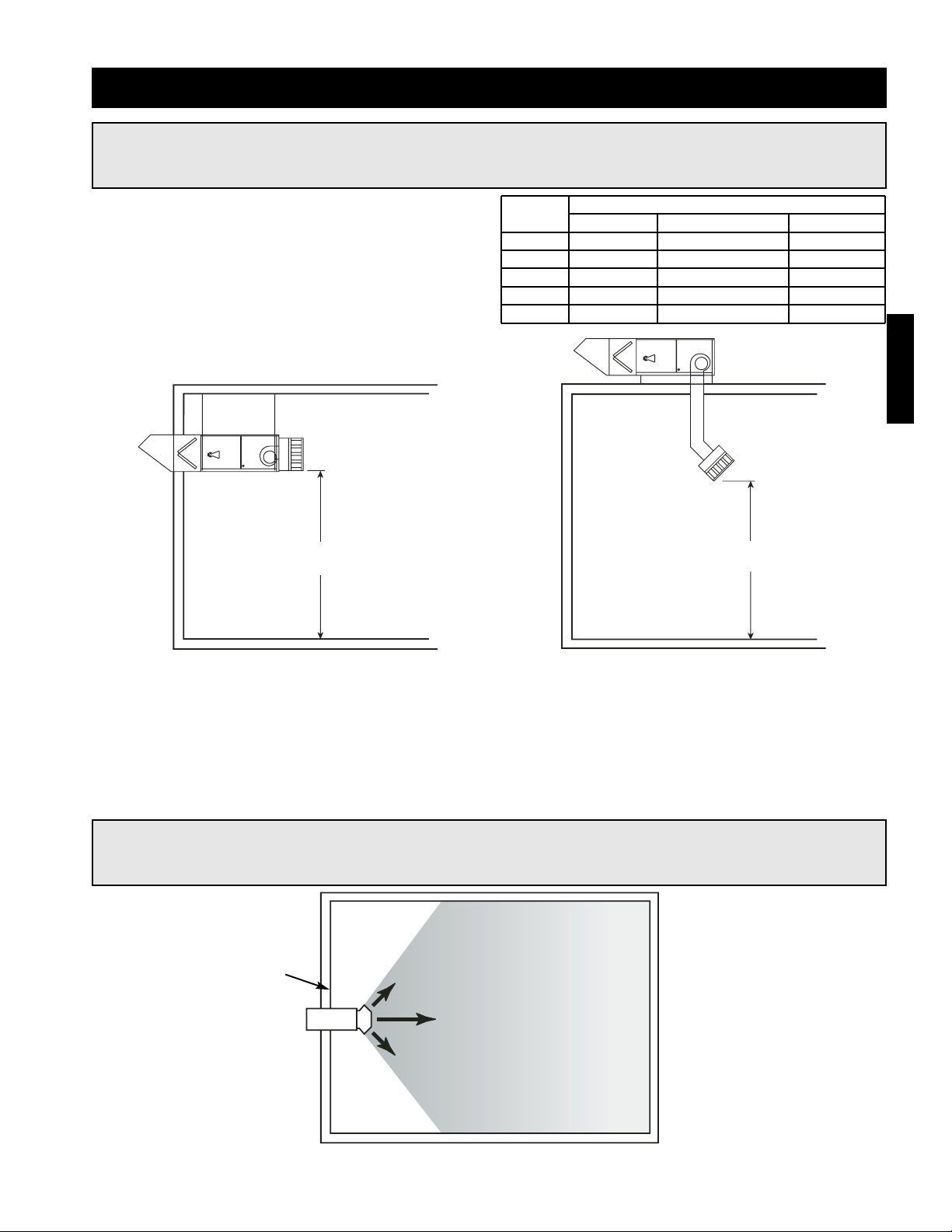

Airflow Diffuser Height (ft.)

(cfm) Minimum Recommended Maximum

4,000 15 20 25

6,000 15 20 25

8,000 20 20-25 30

10,000 20 25-30 35

13,000 25 30-35 40

Step 1 Install Diffuser

Using self-tapping screws, attach diffuser to the

ductwork or unit. Be sure to maintain the

recommended floor to diffuser height. Refer to the

chart to the right for the recommended diffuser

height. See figures #7 and #8.

Step 2 Install TSCP

When installing the TSCP, the locataion is critical to performance of the Greenheat space heat system. The

TSCP should be installed 5-6 feet above the floor. It is recommended that the TSCP be installed on an outside

wall, in the space, and close to any source of infiltration such as dock doors. DO NOT install the TSCP in the

blast area of the heater or near any other source of heat. Refer to figure #9.

h

h

Blast Area

Recommended

TSCP Location

Indoor Mounted

Unit

Rooftop Unit

Figure 7. Thru-wall Diffuser Height Figure 8. Rooftop Diffuser Height

Figure 9. TSCP Location

I - 4

Step 4 Wire the Optional Convenience Outlet

The convenience outlet requires a separate 115V power supply circuit. The circuit must include short circuit

protection which may need to be supplied by others.

Step 3 Connect the Main Power

Connect the main power lines to the disconnect

switch and main grounding lug(s). Torque field

connections to 20 in-lbs. See the control center layout

in the reference section for main disconnect and

grounding lug(s) locations.

Installation - Electrical Wiring

CAUTION!

If replacement wire is required, it must have a

temperature rating of at least 105°C, except for

energy cut-off or sensor lead wire which must be

rated to 150°C.

CAUTION!

Any wiring deviations may result in personal injury or property damage. Greenheck is not responsible

for any damage to, or failure of the unit caused by incorrect final wiring.

DANGER!

High voltage electrical input is needed for this

equipment. This work should be performed by a

qualified electrician.

IMPORTANT!

All wiring should be done in accordance with the

latest edition of the National Electrical Code

ANSI/NFPA-70 and any local codes that may

apply. In Canada, wiring should be done in

accordance with the Canadian Electrical Code.

IMPORTANT!

The equipment must be properly grounded.

Any wiring running through the unit in the

airstream must be protected by metal conduit,

metal clad cable or raceways.

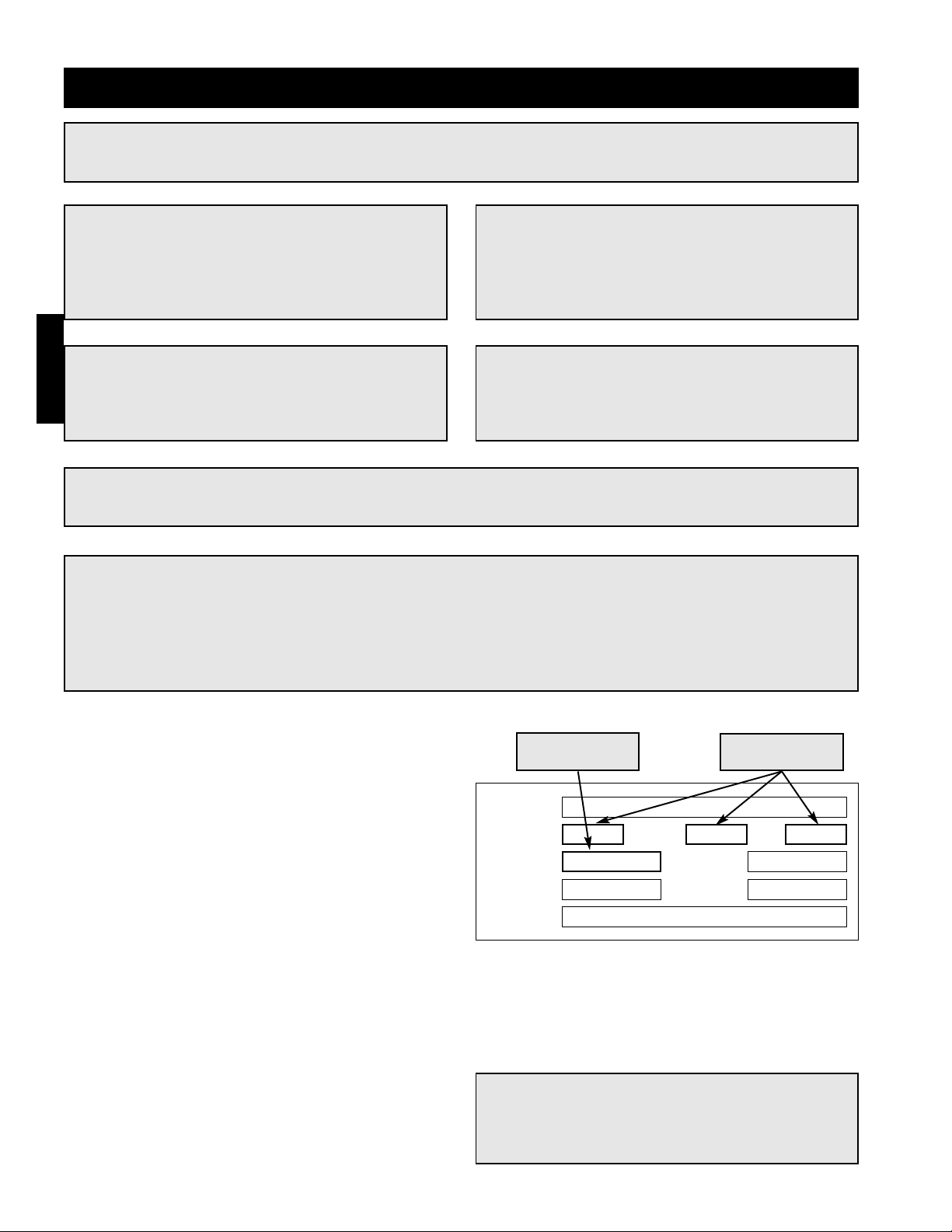

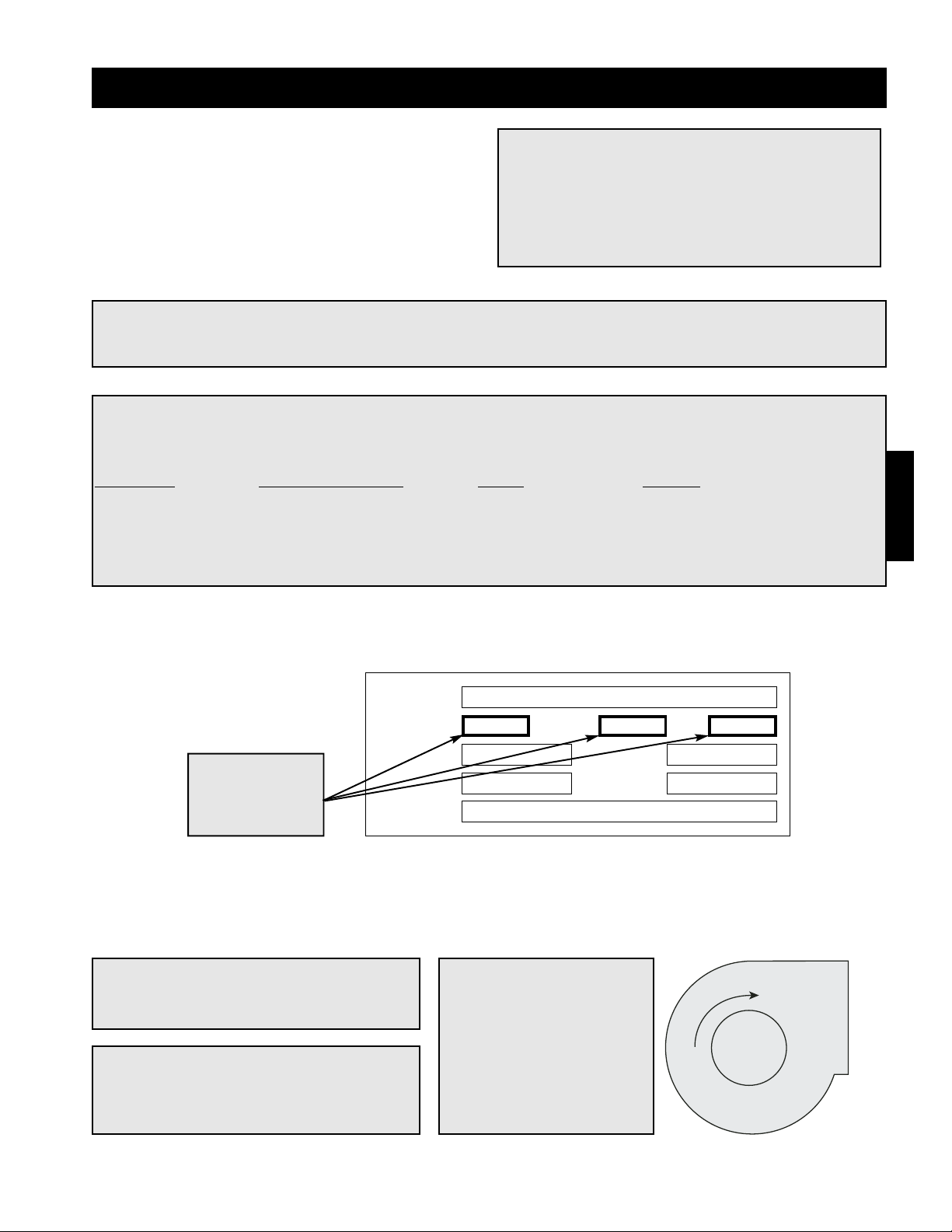

Step 1 Determine the Size of the Main

Power Lines

The unit’s nameplate states the voltage and the unit’s

total amps. The main power lines to the unit should

be sized accordingly. See figure #10.

Step 2 Provide the Opening(s) for the

Electrical Connections

Electrical openings vary by unit size and arrangement

and are field supplied.

MODEL

VOLTS

SUP HP

MARK

AMPS

HTZ PH

S/N

EXH HP

Voltage, Hertz,

and Phase

Unit’s Total

Amps

IMPORTANT!

Before connecting power to the unit, read and understand the following instructions and wiring

diagrams. Complete wiring diagrams are attached on the inside of the control center door(s).

IMPORTANT!

Greenheck’s standard control voltage is 24 VAC.

Control wire resistance should not exceed 0.75 ohms (approximately 285 feet total length for 14 gauge

wire; 455 feet total length for 12 gauge wire). If the resistance exceeds 0.75 ohms, an industrial-style,

plug-in relay should be wired in place of the remote switch. The relay must be rated for at least

5 amps and have a 24 VAC coil. Failure to comply with these guidelines may cause motor starters to

chatter or not pull in, resulting in contactor failures and/or motor failures.

Step 5 Wire the Remote Panel (TSCP)

Reference the ladder diagram on the inside of the

control center door for correct wiring of the TSCP.

NOTE!

TSCP has number-to-number wiring to the

control center in the unit.

Figure 10. Electrical Nameplate

Installation - Direct Gas Piping

Step 1 Determine the Supply Gas Requirements

The unit’s direct gas nameplate states the requirements for the gas being supplied to the unit. See figure #11.

IMPORTANT!

All gas piping must be installed in accordance with the latest edition of the National Fuel Gas Code

ANSI/Z223.1 and any local codes that may apply. In Canada, the equipment shall be installed in

accordance with the Installation Code for Gas Burning Appliances and Equipment (CGA B149) and

Provincial Regulations for the class. Authorities having jurisdiction should be consulted before

installations are made.

WARNING!

All components of this or any other gas fired heating unit must be leak tested prior to placing the unit

into operation. A soap and water solution should be used to perform this test. NEVER test for gas

leaks with an open flame.

WARNING!

If pressure testing in excess of 1/2 psig

(3.5 kPa), the heater and manual shutoff valve

must be disconnected from the supply gas line.

WARNING!

If pressure testing at or below 1/2 psig (3.5 kPa),

the heater must be isolated from the supply gas

line by closing its manual shutoff valve.

IMPORTANT!

All piping should be clean and free of any foreign

matter. Foreign material entering the gas train

can damage the valves, regulators and burner.

“W.C.

“W.C.

“W.C.

F

PSI

“W.C.

“W.C.

MAX BTU/HR

BTU/H MAX

NORMAL MANIFOLD

PRESSURE

PRESSION D’ADMISSION

NORMALE

MIN GAS

PRESSURE

PRESSION DE GAZ

MIN BURNER

PRESSURE DROP

PERTE MIN DE PRESSION

DANS LE BRULEUR

TYPE OF GAS

NATURE DU GAZ

MIN BTU/HR

BTU/H MIN

MIN GAS PRESSURE

FOR MAX OUTPUT

PRESSION DE GAZ MIN

POUR PUISSANCE MAX

MAX BURNER

PRESSURE DROP

PERTE MAX DE PRESSION

DANS LE BRULEUR

MAX GAS

PRESSURE

PRESSION DE GAZ

MAX

DESIGN ∆T

∆T NORMALE

EQUIPPED FOR

CONCU POUR

SCFM

“W.C.

EXTERNAL STATIC PRESSURE

PRESSION STATIQUE EXTERIEURE

AGAINST

CONTE

Minimum and

maximum gas

pressures

Minimum gas

pressure for

maximum output

Type of Gas

IMPORTANT!

Do NOT connect the unit to gas types other than

what is specified and do NOT connect the unit

to gas pressures that are outside of the pressure

range shown on the label.

I - 5

Figure 11. Direct Gas Nameplate

Installation - Direct Gas Piping

I - 6

From

Gas

Supply

Gas Cock

1/8 in. Plugged Tap

6 in. Trap

Ground Joint Union

Step 3 Connect the Supply Gas Line

A manual shut off valve (gas cock), 1/8 inch plugged

test port and 6 inch drip leg must be installed prior to

the gas train (see figure #12). The valve and the test

port must be accessible for the connection of a test

gauge. Supply gas connections must be made by a

qualified installer and are not furnished by Greenheck

Step 2 Install Additional Regulator if

Required

When the supply gas pressure exceeds the maximum

gas pressure shown on the direct gas nameplate (see

figure #11), an additional regulator (by others) is

required to reduce the pressure. The regulator must

have a listed leak limiting device or it must be vented

to the outdoors.

Step 4 Pipe the Optional Vent Line

If an optional vent line is located between the safety

shutoff valves it must be piped to the outdoors. Refer

to figure #13.

Step 5 Test the System for Leaks

Check both the supply lines and the factory piping for

leaks. Apply a soap and water solution to all piping

and watch for bubbling which indicates a leak.

WARNING!

The factory piping has been checked for leaks, but should be rechecked due to shipping and

installation.

WARNING!

NEVER test for a gas leak with an open flame.

NOTE!

The regulator located inside the unit is used to

adjust the unit’s maximum output temperature.

NOTE!

Reference the National Fuel Gas Code for

additional vent line requirements.

Safety Shut-off

Valves

Vent Line

Solenoid

To Burner

Vent Line

To Outdoors

From Supply

Space Heat Unit

Figure 12. Supply Gas Line

Figure 13. Vent Line

Start-Up - Blower

S - 1

MODEL

VOLTS

SUP HP

MARK

AMPS

Hz PH

S/N

EXH HP

Voltage, Hertz,

and Phase

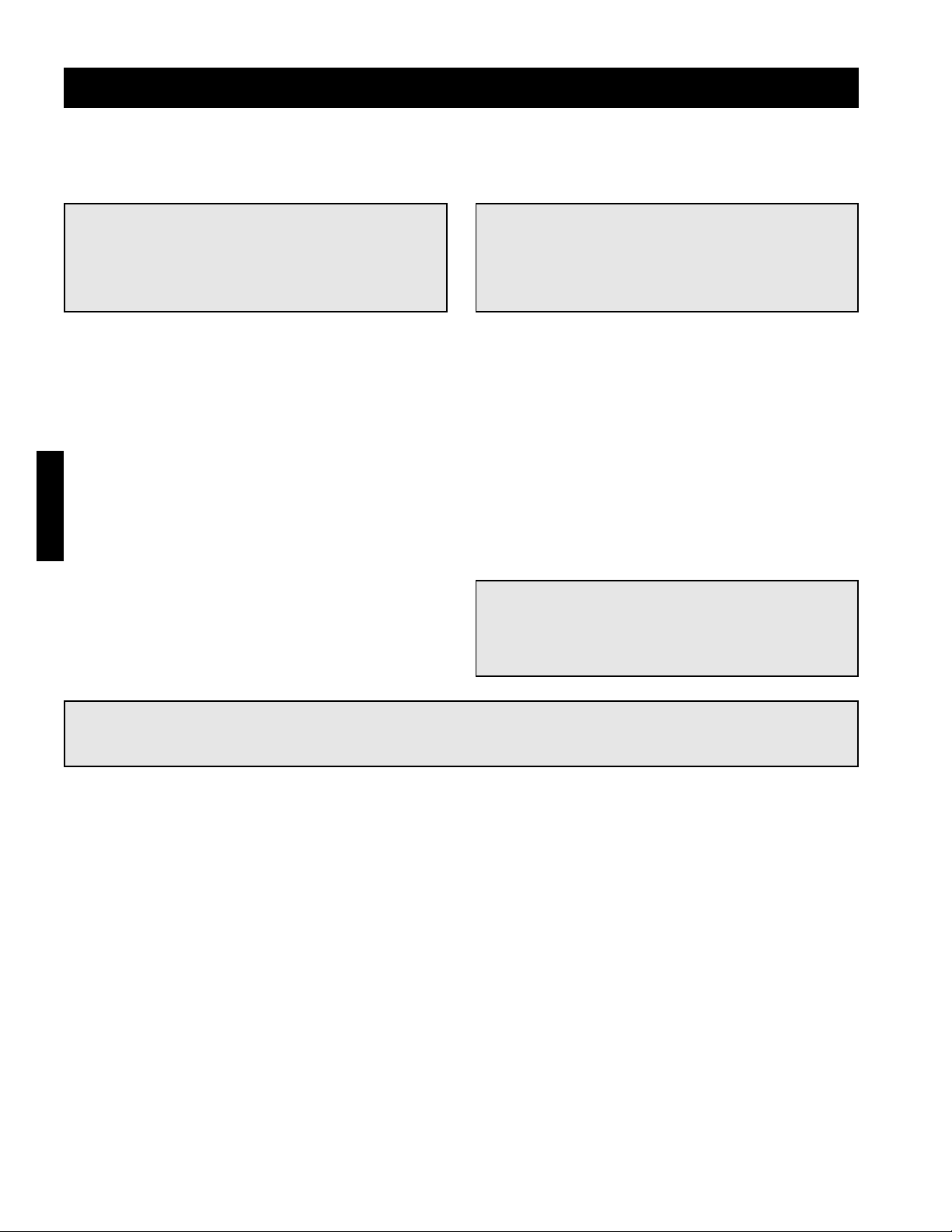

Step 1 Check the Voltage

Before starting the unit, compare the supplied voltage, hertz, and phase with the unit and motor’s nameplate

information. See figure #14.

Step 2 Check the Blower Rotation

Open the blower access door and run the blower momentarily to determine the rotation. Arrows are placed on

the blower scroll to indicate the proper direction or reference figure #15.

IMPORTANT!

If the blower is rotating in

the wrong direction, the

unit will move some air,

but will not perform as

designed. Be sure to

perform a visual inspection

to guarantee the correct

blower rotation.

SPECIAL EQUIPMENT REQUIRED

Below is a list of special tools that are required. A recommended model is shown, but equivalent

products may be used.

Description

Manufacturer-Model Phone Website

Voltage Meter Fluke-23 1-800-44-FLUKE www.fluke.com

Amperage Meter Fluke-23 1-800-44-FLUKE www.fluke.com

Thermometer Fluke-50 1-800-44-FLUKE www.fluke.com

U-Tube manometer Dwyer-Slack Tube 1-219-897-8000 www.dwyer-inst.com

Tachometer Monarch-Pocket Tach 100 1-800-999-3390 www.monarchinstruments.com

WARNING!

Disconnect and lock-out all power and gas

before performing any maintenance or service to

the unit. Failure to due so could result in serious

injury or death and damage to equipment.

WARNING!

Check the housing, blower, weatherhood, filter section and ductwork for foreign objects and debris

before the blower is run.

Pre Start-Up Check

Rotate the fan wheel by hand and make sure no parts

are rubbing. Check the V-belt drive for proper

alignment and tension (a guide for proper belt tension

and alignment is provided in the belt maintenance

section). Check fasteners, set screws and locking

collars on the fan, bearings, drive, motor base and

accessories for tightness. Remove any shipping

fasteners from the blower’s vibration isolators.

NOTE!

To reverse the rotation on three phase

units, disconnect and lock-out the power,

then interchange any two power leads.

NOTE!

To reverse the rotation on single phase

units, disconnect and lock-out the power,

then rewire the motor per the

manufacturer’s instructions.

Figure 14. Electrical Nameplate

Figure 15. Blower Rotation

Rotation

Blower

Housing

Start-Up - Blower

S - 2

Step 4 Motor Check

Measure the motor voltage, amps and RPM, and compare to the specifications on the motor’s nameplate.

Step 5 Air Volume Measurement and

Check

Measure the unit’s air volume (CFM) and compare it

with its rated air volume. If the air volume is off, adjust

the fan RPM by changing the drive.

Step 6 Set-up Optional Components

Adjust the settings on the optional components. See the control center layout in the reference section for

location of optional components.

• Building Freeze Protection (typical setting: 5 min at 45ºF)

• Dirty Filter Gauge (typical setting: settings vary greatly for each unit)

NOTE!

The most accurate way to measure the air

volume is by using a pilot traverse method

downstream of the blower. Other methods can

be used but should be proven and accurate.

IMPORTANT!

Changing the air volume can significantly increase the motor’s amps. If the air volume is changed, the

motor’s amps must be checked to prevent overloading the motor.

Step 3 Check for Vibration

Check for unusual noise, vibration or overheating of the bearings. Reference the troubleshooting section for

corrective actions.

IMPORTANT!

Excessive vibration may be experienced during

the initial start-up. Left unchecked, it can cause

a multitude of problems including structural

and/or component failure.

IMPORTANT!

Generally, fan vibration and noise is transmitted

to other parts of the building by the ductwork.

To minimize this undesirable effect, the use of

heavy canvas duct connectors is recommended.

Loading...

Loading...