Montague C36 SHB Installation Manual

INSTRUCTION MANUAL

MONTAGUE

Radiglo Heavy Duty Gas

Fired Over Fired Broilers

MODELS: 36W36, 43W36, 136W36, V136W36, 236W36, 243W36, C36,

C45, C36 SHB, C45 SHB, C36SHBPL, C45SHBPL

These instructions should be read thoroughly before attempting installation.

Set up and installation should be performed by qualified installation personnel.

Keep area around appliances free and clear from combustibles.

PLEASE RETAIN THIS MANUAL

FOR FUTURE REFERENCE.

THE MONTAGUE COMPANY

1830 Stearman Avenue

P.O. BOX 4954

Hayward, CA 94540-4954

TEL: (510) 785-8822 FAX: (510) 785-3342

IMPORTANT

TABLE OF CONTENTS

Important (Cautions and Warnings) .............................................................. Page 1

Introduction .................................................................................................. Page 2 - 3

Installation .................................................................................................... Page 4 - 10

Operation ...................................................................................................... Page 11 - 12

Maintenance ................................................................................................. Page 13 - 15

Maintenance Schedule ................................................................................ Page 16

Service .......................................................................................................... Page 17 - 27

Orifice Size Chart - Drill Size ....................................................................... Page 28

Exploded View and Parts List ..................................................................... Page 29 - 32

SHIPPING DAMAGE CLAIM PROCEDURE

For your protection, please note that equipment in this shipment was carefully inspected and packed

by skilled personnel before leaving the factory. The transportation company assumed full

responsibility for safe delivery upon acceptance of this shipment.

If shipment arrives damaged:

1. VISIBLE LOSS OR DAMAGE - Be certain this is noted on freight bill or express receipt, and

signed by person making delivery.

2. FILE CLAIM FOR DAMAGES IMMEDIATELY - Regardless of the extent of damage.

3. CONCEALED LOSS OR DAMAGE - If damage is unnoticed until merchandise is unpacked,

notify transportation company or carrier immediately, and file “concealed damage” claim with

them. This should be done within fifteen (15) days of date that delivery was made to you. Be sure

to retain container for inspection.

We cannot assume responsibility for damage incurred in transit. We will, however, be glad to furnish you with

the necessary documents to support your claim.

IMPORTANT

FOR YOUR SAFETY

WARNING

Improper installation, adjustment, alteration, service or maintenance can cause property

damage, injury or death. Read the operating and maintenance instructions thoroughly before

installing or servicing this equipment.

WARNING

Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this or

any other appliance.

NOTE: This manual has been prepared for personnel qualified to install commercial

equipment who should perform the initial field start-up and the adjustments of the equipment

covered by this manual.

NOTE: Instructions to be followed in the event the user smells gas must be posted in a

prominent location. This information may be obtained by consulting the local gas supplier.

1

INTRODUCTION

GENERAL

The Gas Broilers covered in this manual are

manufactured for use with the type of gas

indicated on the nameplate. Some models

include a cabinet, conventional oven, or

convection oven.

Montague Gas Broilers are produced with the

best possible material and workmanship.

Proper installation is essential for safe,

efficient, trouble-free operation.

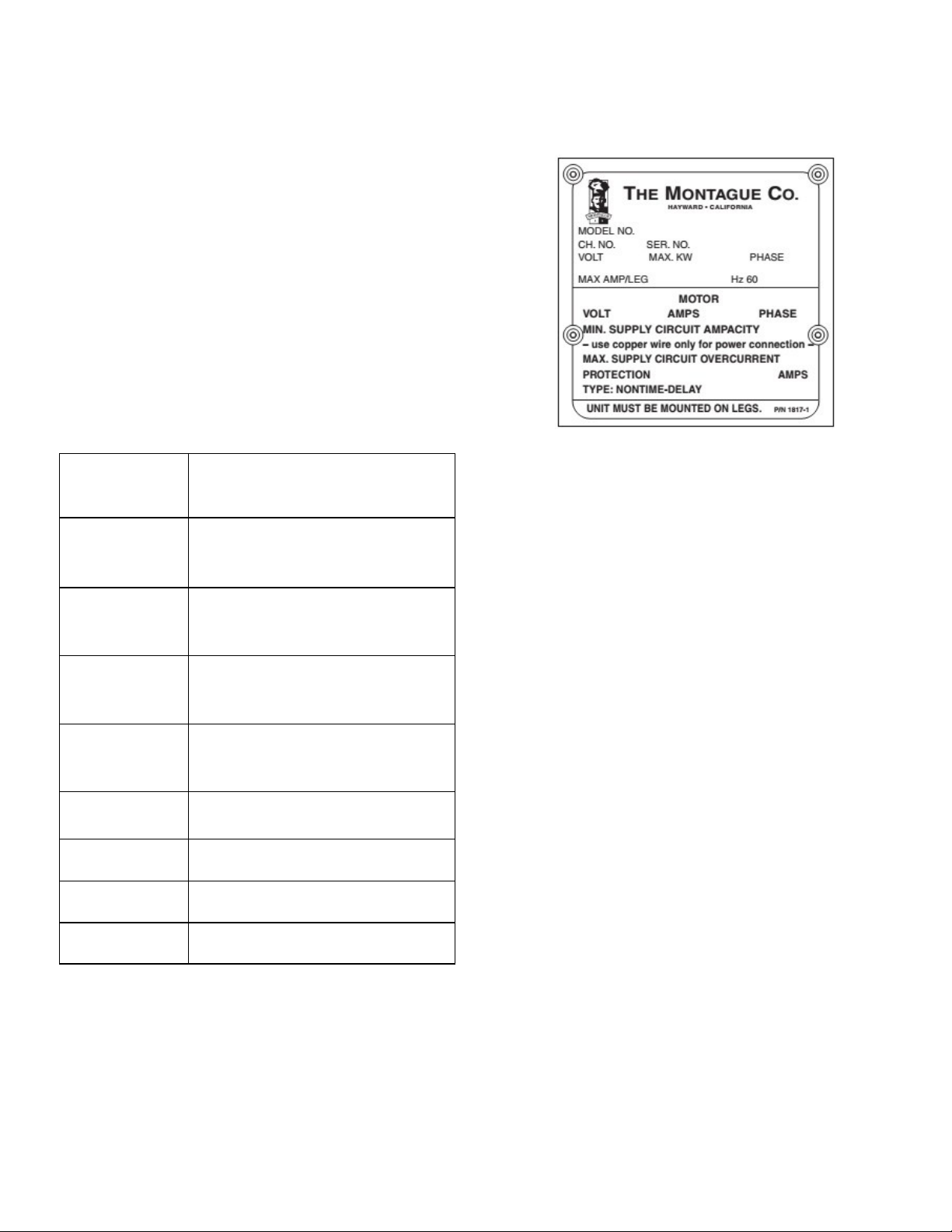

MODELS

Model Features

Typical I.D. Plate

(Figure 1)

36W36

Cabinet Based Broiler with

Warming Oven

Cabinet Based Broiler with

43W36

Warming Oven

Broiler with Conventional

136W36

Oven and Warming Oven

Broiler with Convection

V136W36

Oven

236W36 Double Broiler

243W36 Double Broiler

C36 Broiler Only

C45 Broiler Only

SERIAL NUMBER LOCATION

RECEIVING & INSPECTING THE

EQUIPMENT

Care should be taken during unloading so the

equipment is not damaged while being moved

into the building.

1. Visually inspect the exterior of the package

and skid or container. Any damage should

be noted and reported to the delivering

carrier immediately.

2. If damaged, open and inspect the contents

with the carrier.

3. In the event that the exterior is not

damaged, yet upon opening, there is

concealed damage to the equipment, notify

the carrier. Notification should be made

verbally as well as in written form.

4. Request an inspection by the shipping

company of the damaged equipment. This

should be done within 10 days from receipt

of the equipment.

Always have the serial number of your unit

available when calling for parts and service.

The serial number is on the nameplate that

also includes the model number. A typical

identification plate is shown in Figure 1.

5. Freight carriers can supply the necessary

damage forms upon request.

6. Retain all shipping materials until an

inspection has been made or waived.

2

INTRODUCTION

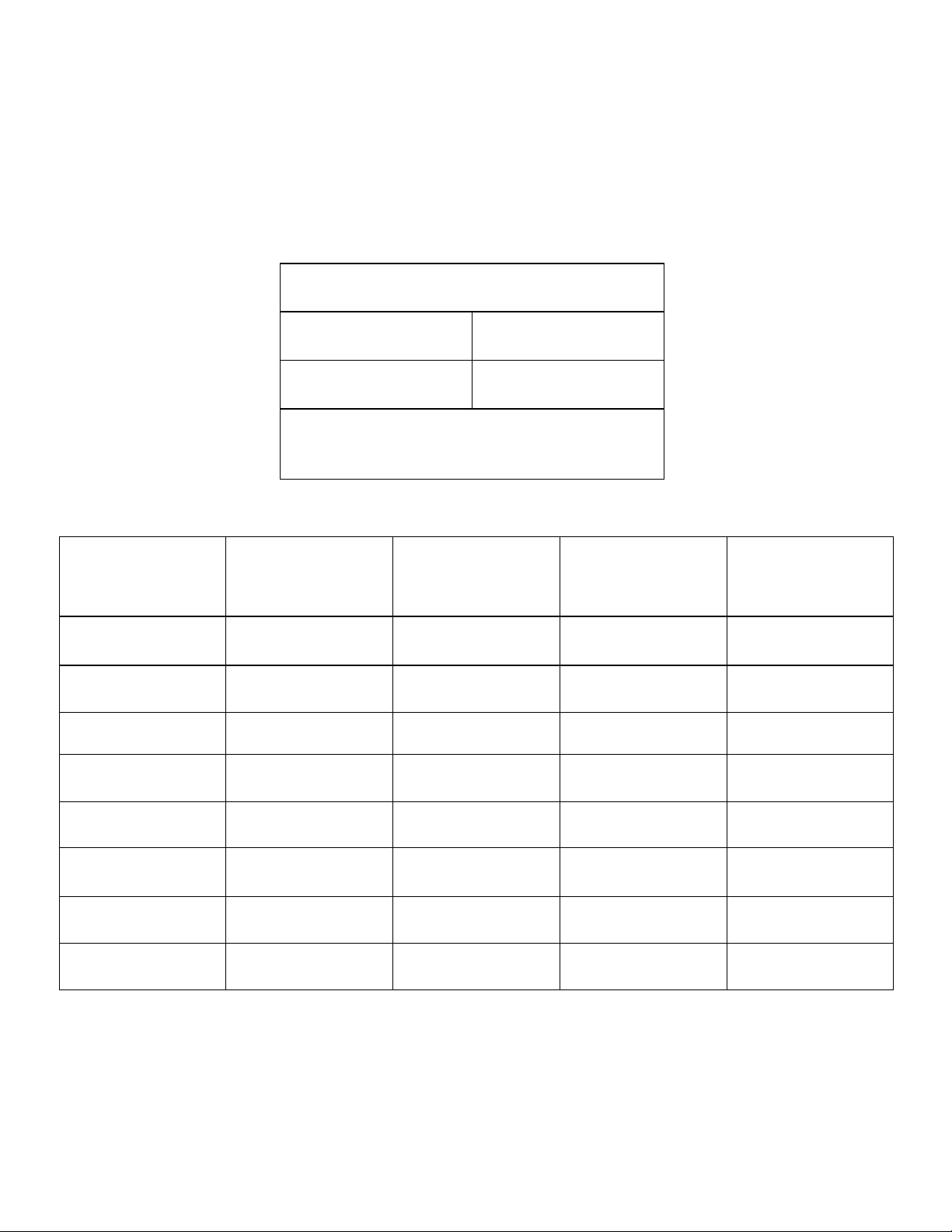

ORIFICES

Fixed for specified Gas type:

Gas Inlet Size: 3/4” NPT at lower left rear (all

models).

# Burners

Model

(Broilers Only)

Natural Gas: #33 DMS

Propan Gas: #48 DMS

Manifold Pressure

Natural Gas Propane Gas

6” W.C. 10” W.C.

Natural BTU/h Propone BTU/h Total BTU/h

36W36 2 42,000 ea. 42,000 ea. 84,000

43W36 3 42,000 ea. 42,000 ea. 126,000

136W36 2 42,000 ea. 42,000 ea. 124,000

V136W36 2 42,000 ea. 42,000 ea. 129,000

236W36 4 42,000 ea. 42,000 ea. 168,000

243W36 6 42,000 ea. 42,000 ea. 252,000

C36 2 42,000 ea. 42,000 ea. 84,000

C45 3 42,000 ea. 42,000 ea. 126,000

3

INSTALLATION

This manual has been prepared for personnel

qualified to install gas equipment, who should

perform the initial field start-up and

adjustments of the equipment covered by this

manual.

Qualified installation personnel are individuals,

a firm, corporation, or company which either in

person or through a representative are

engaged in and are responsible for:

1. The installation or replacement of gas

piping or the connection, installation, repair

or servicing of equipment, who is

experienced in such work familiar with all

precautions required, and have complied

with all requirements of state or local

authorities having jurisdiction. reference:

National Fuel Gas Code, ANSI Z223.1,

section 1.4, latest addenda.

2. The installation of electrical wiring from the

electric meter, main control box or service

outlet to the electric appliance. Qualified

installation personnel must be experienced

in such work, be familiar with all

precautions required and have complied

with all requirements of state and local

authorities having jurisdiction. Reference:

National Electric Code, ANSI / NFPA No.

70, latest addenda.

individual manual shutoff valve during any

pressure testing of the gas supply piping

system at test pressures equal to or less

than 1/2 psig (3.45 kpa).

Post in a prominent location the instructions to

be followed in the event the smell of gas is

detected. This information can be obtained

from the local gas supplier.

In the event of a power failure, do not attempt

to operate this device.

IMPORTANT

IN THE EVENT A GAS ODOR IS

DETECTED, SHUT DOWN UNITS AT MAIN

SHUTOFF VALVE AND CONTACT THE

LOCAL GAS COMPANY OR GAS

SUPPLIER FOR SERVICE.

CAUTION

PROVISIONS MUST BE MADE TO ASSURE

ADEQUATE AIR SUPPLY TO UNIT FOR

PROPER BURNER OPERATION.

CLEARANCES

The following are minimum clearances from

combustible and noncombustible materials.

READ CAREFULLY AND FOLLOW THESE

INSTRUCTIONS

The broiler(s) must be installed in accordance

with local codes, or in the absence of local

codes, with the national fuel gas code, ANSI

Z223.1 latest addenda, including:

1. The appliance and its individual shutoff

valve must be disconnected from the gas

supply piping system during any pressure

testing of that system at test pressures in

excess of 1/2 psig (3.45 kpa).

2. The appliance must be isolated from the

gas supply piping system by closing its

Combustible

Noncombustible

Location

Construction

Construction

Back Wall 6” 0”

Left Side 6” 0”

Right Side 6” 0”

With 6” Legs: Suitable for installation on

combustible floors.

Without Legs: For use with special insulated

base on noncombustible floors only.

4

INSTALLATION

VENTILATING HOOD

The broiler(s) must be installed under a

properly designed ventilating hood. The hood

should extend at least 6” beyond all sides of

the unit. The hood should be connected to an

adequate mechanical exhaust system.

Information on construction and installation of

ventilating hoods may be obtained from the

“Standard for the Installation of Equipment for

the Removal of Smoke and Grease Laden

Vap ors f ro m Com merc ial Co okin g

Equipment”, NFPA No. 96-1987, available

from the National Fire Protection Association,

Batterymarch Park, Quincy, MA. 02269.

It is also necessary that sufficient room air

ingress be allowed to compensate for the

amount of air removed by the ventilating

system. Otherwise, a subnormal atmospheric

pressure will occur which may interfere with

burner performance or may extinguish the

pilot flame. In case of unsatisfactory broiler

performance, check with the exhaust in the

“OFF” position.

ASSEMBLY

Ceramic radiants, Figure 1 & 2, are located on

each side of the burners. Ceramic end pieces

are installed at both ends of each burner

assembly. Five (5) ceramic radiants are

installed on each side of each burner with the

pointed side facing down and the holes facing

up (See Figure 3).

4 2 3 1

1 Frame

2 Ceramic Radiants

3 Burner

4 Ceramic Ends

Uncrate broiler as near to final location as

possible. For easier and lighter handling of

broiler, remove grids, grid frame, drip tray and

grease container. Remove all packing

materials and accessories from broiler interior.

Legs

Some broilers are mounted on legs.

Screw the legs into the modular stand.

Tightly screw the complete leg assembly into

the mounting holes in the bottom of the broiler

at each corner. If the unit is intended for curb

installation, no legs are provided. The curb

must be noncombustible material.

Ceramic Radiants

Burner Assembly and Ceramic Radiants,

Top View

(Figure 1)

Burner Assembly and Ceramic Radiants,

Front View

(Figure 2)

5

INSTALLATION

Ceramic Radiant

(Figure 3)

1. Insert ceramic end pieces at front and rear

of the burner frame. Four (4) are required

for each burner.

2. Tilt ceramic radiants sideways to clear

burner and frame assembly, then lower

radiant into position with one flange resting

on burner ledge and one flange resting on

frame edge.

Floor Mounted Ranges

1. Place the first unit in the exact position it

will occupy in the battery.

2. Using a carpenter’s level, level the unit

front to rear and side to side. An

unleveled unit will adversely affect

performance. Adjust as follows:

FLOOR INSTALLATION ON LEGS

Level by turning foot on leg.

CURB INSTALLATION

Place shim under the low side. This operation

is important since variations in floors and

curbs are common. Unless units are level,

aligning the gas supply manifold will be

difficult and the units will not fit together tightly.

3. Remove the valve panel from the broiler.

4. Move the unit into position.

3. Install the remaining ceramic radiants so

that five (5) ceramic radiants are located

on each side of the burner.

LOCATION

Adequate clearance for service and proper

operation must be provided at the front, top,

sides, and back. The combustion air openings

are provided in the front of the unit and must

not be obstructed.

LEVELING

After broiler is positioned, check that

appliance is level both side-to side and front-to

back.

BATTERY ARRANGEMENT

Setting In Place

Model No”s 36W36, 43W36, 136W36, and

V136W36.

5. Engage union nut on manifold with male

fitting on next unit and draw up union nut

hand tight. Be sure appliances meet

together both front and rear. If manifolds

do not align, then units are not level. In

extreme cases it may be necessary to

loosen manifold bolts and adjust.

6. Continue leveling and connecting gas

supply manifolds together until all

appliances in battery are connected.

7. Tighten manifold gas union. Use backup

wrench to prevent manifold from rotating.

Failure to do this may result in damage

to the pilots and gas valves.

GAS CONNECTION

Before connecting the broiler(s) to the gas

supply line, be sure that all new piping has

been cleaned and purged to prevent any

foreign matter from being carried into the

controls by the gas. In some cases, filters

6

INSTALLATION

or drops are recommended. A separate gas

shutoff valve must be installed upstream from

the gas pressure regulator adjacent to the

broiler and located in an accessible are.

It is important that adequately sized piping be

run directly to the point of connection at the

broiler with as few elbows and tees as

possible. Consult your local gas company for

proper piping size and gas pressure. Each

broiler has a 3/4” NPT manifold input located

at the lower left rear of the broiler, Figure 4.

On dual broilers, each broiler must have a

separate regulator.

NOTE: Pipe joint compound or thread sealant

that is used should be resistant to action of

liquefied petroleum gases.

3/4” NPT Gas Inlet

Gas Inlet

(Figure 4)

Install the gas pressure regulator with gas

flowing as indicated by the arrow on the

regulator. The arrow must be pointing in

toward the unit. Use pipe compound or thread

sealant and carefully thread regulator to pipe

so that there is no cross threading, etc., which

could cause leakage.

1. Apply wrench only to the flat areas around

the pipe tapping at the end being threaded

to the pipe to avoid possible damage to the

regulator body which could result in

leakage.

2. Connect the gas supply line from the

service gas shutoff valve to the inlet side of

the gas pressure regulator using 3/4” pipe.

Avoid kinks or sharp bends that could

restrict gas flow.

NOTE: If flexible or semi-flexible connectors

are used, an AGA listed flexible connector

with an I.D. equal to 3/4” pipe must be used.

WARNING

DO NOT USE A DOMESTIC TYPE

FLEXIBLE GAS CONNECTOR.

3. Turn gas shutoff valve on and carefully

check for gas leaks immediately. Do this

before attempting to operate the broiler.

WARNING

TEST ALL PIPE JOINTS FOR LEAKS

BEFORE OPERATING BROILER. THIS

INCLUDES ALL GAS CONNECTIONS THAT

MAY HAVE LOOSE NE D DURIN G

SHIPMENT. USE A RICH SOAP SOLUTION

(OR OTHER ACCEPTED LEAK TESTER)

AROUND ALL PIPE JOINTS. DO NOT USE

AN OPEN FLAME. ABSOLUTELY NO

LEAKAGE SHOULD OCCUR, OTHERWISE

THERE IS A DANGER OF FIRE OR

E XPL O S IO N D EP E N D IN G U PO N

CONDITIONS. DO NOT USE UNIT IF

LEAKAGE IS DETECTED.

After piping has been checked for leaks, all

piping receiving gas should be fully purged to

remove air.

GAS PRESSURE REGULATOR

WARNING

DO NOT INSTALL UNIT WITHOUT AN

APPLIANCE REGULATOR.

7

INSTALLATION

THE BROILER IS DESIGNED FOR USE

WITH A PRESSURE REGULATOR. THE

REGULATOR(S) SUPPLIED WITH THIS

UNIT MUST BE USED.

For Natural Gas

This gas pressure regulator is factory adjusted

for 6.0” W.C. manifold pressure. The rated

inlet pressure to the regulators should not

exceed 1/2 psig (3.45 kPa).

For Propane Gas

This gas pressure regulator is factory adjusted

for 10.0” W.C. manifold pressure. The rated

inlet pressure to the regulator should not

exceed 1/2 psig (3.45 kPa).

The broiler is equipped with fixed orifices for

use with a manifold pressure of 6.0” W.C. for

natural gas and 10.0” W.C. for propane gas.

Position the gas pressure regulator outside

the broiler as near to the unit as possible.

CAUTION

3. Make sure that the regulator is mounted in

the horizontal position with the arrow going

in the direction of the gas flow.

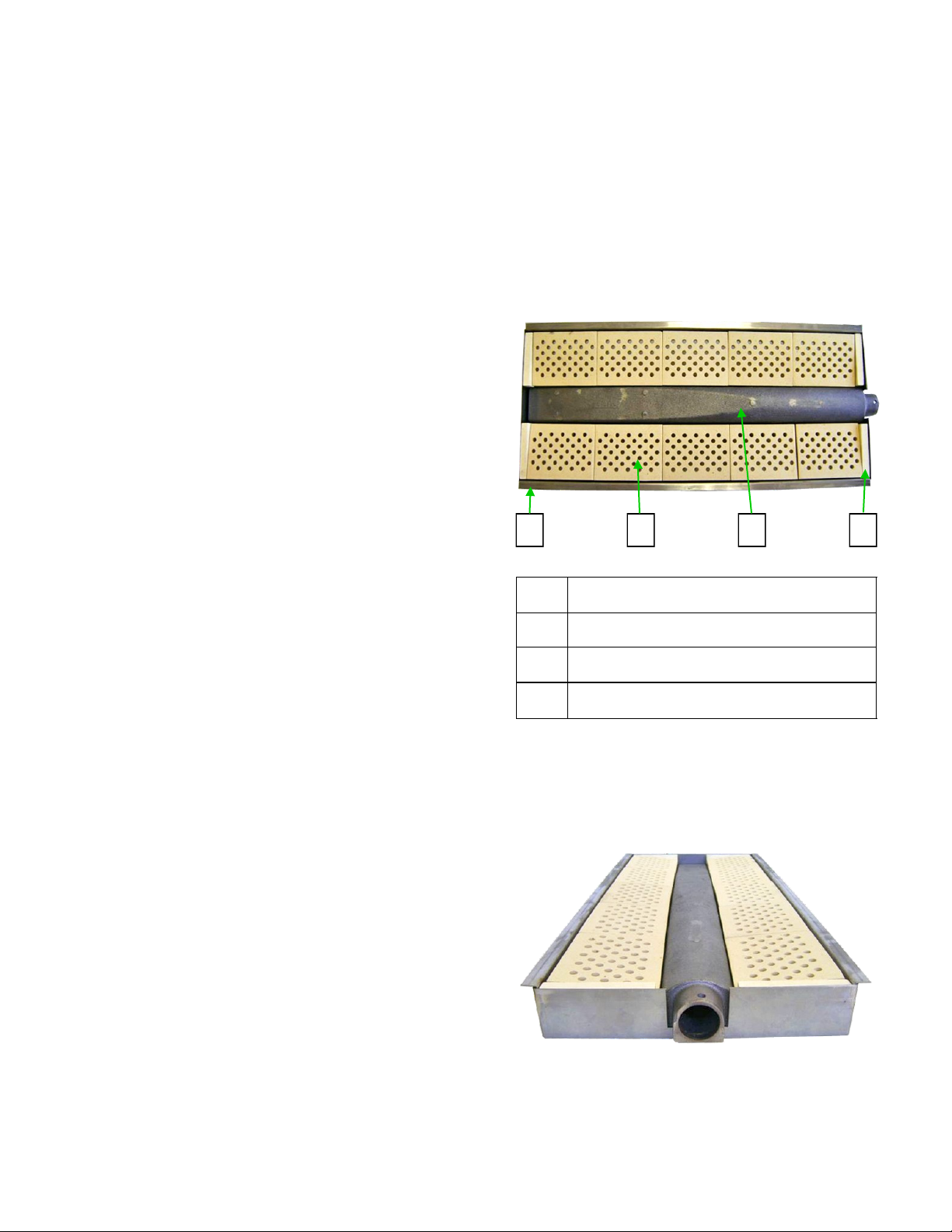

4. Remove the main burner control valve

knobs, Figure 5.

Burner Valve Knobs Screws

Control Valve Knobs

(Figure 5)

5. Remove the control valve panel by

removing two screws.

THE GAS PRESSURE REGULATOR MUST

BE LOCATED OUT OF THE HEAT ZONE TO

PREVENT DAMAGE TO THE REGULATOR.

ADJUSTMENT PROCEDURE

WARNING

DO NOT ALLOW UNTRAINED PERSONNEL

TO MAINTAIN OR SERVICE THE GAS

PRESSURE REGULATOR.

1. Before adjusting the regulator, check the

incoming gas line pressure into the

regulator. Incoming pressure must be 8.0”

W.C. for natural gas, or 14” W.C. for

propane gas.

2. If incoming pressure is not correct, have

the gas source checked and adjusted.

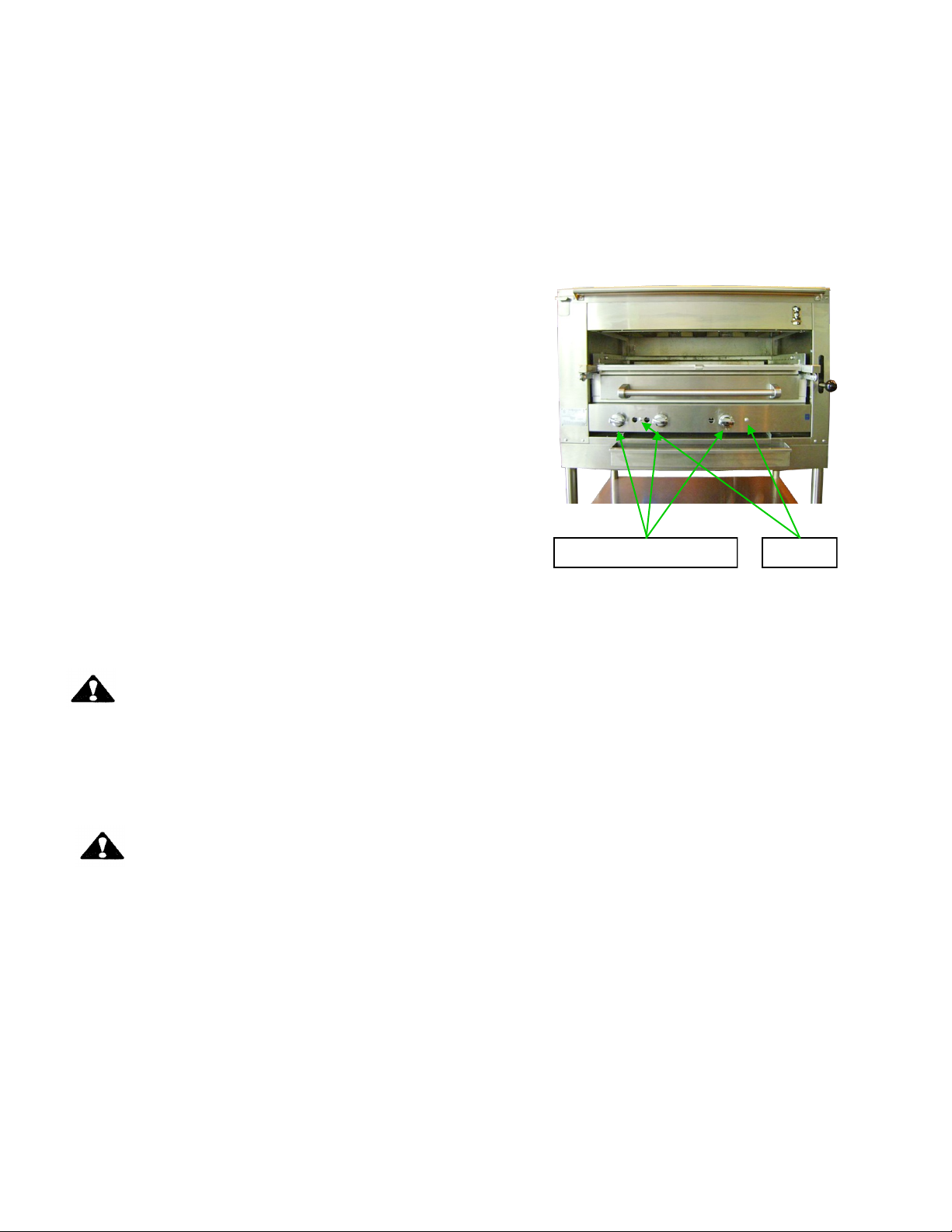

6. Connect a manometer to the pressure tap

provided on the broiler unit gas piping

manifold, Figure 6.

7. Check the manometer reading. The

reading must be 6.0” W.C. for natural gas,

or 10.0” W.C. for propane gas. (DYNAMIC)

8. If incoming line pressure is not correct,

adjust the regulator. Remove the seal cap

on the top of the regulator.

9. Insert a slot screwdriver into the top of the

regulator.

10. Turn the adjust screw clockwise to

increase the pressure, or counter

clockwise to decrease the pressure.

While watching the manometer, turn the

adjustment screw to set proper regulator outlet

pressure to the manifold.

8

INSTALLATION

Manifold

Manometer

Connection Pressure

Tap

Gas Pressure Tap

(Figure 6)

PILOT INITIAL ADJUSTMENT

Each burner has a separate pilot burner. The

pilot flame is adjusted through access holes in

the valve control panel, Figure 7. Pilot access

is through the broiler panel opening.

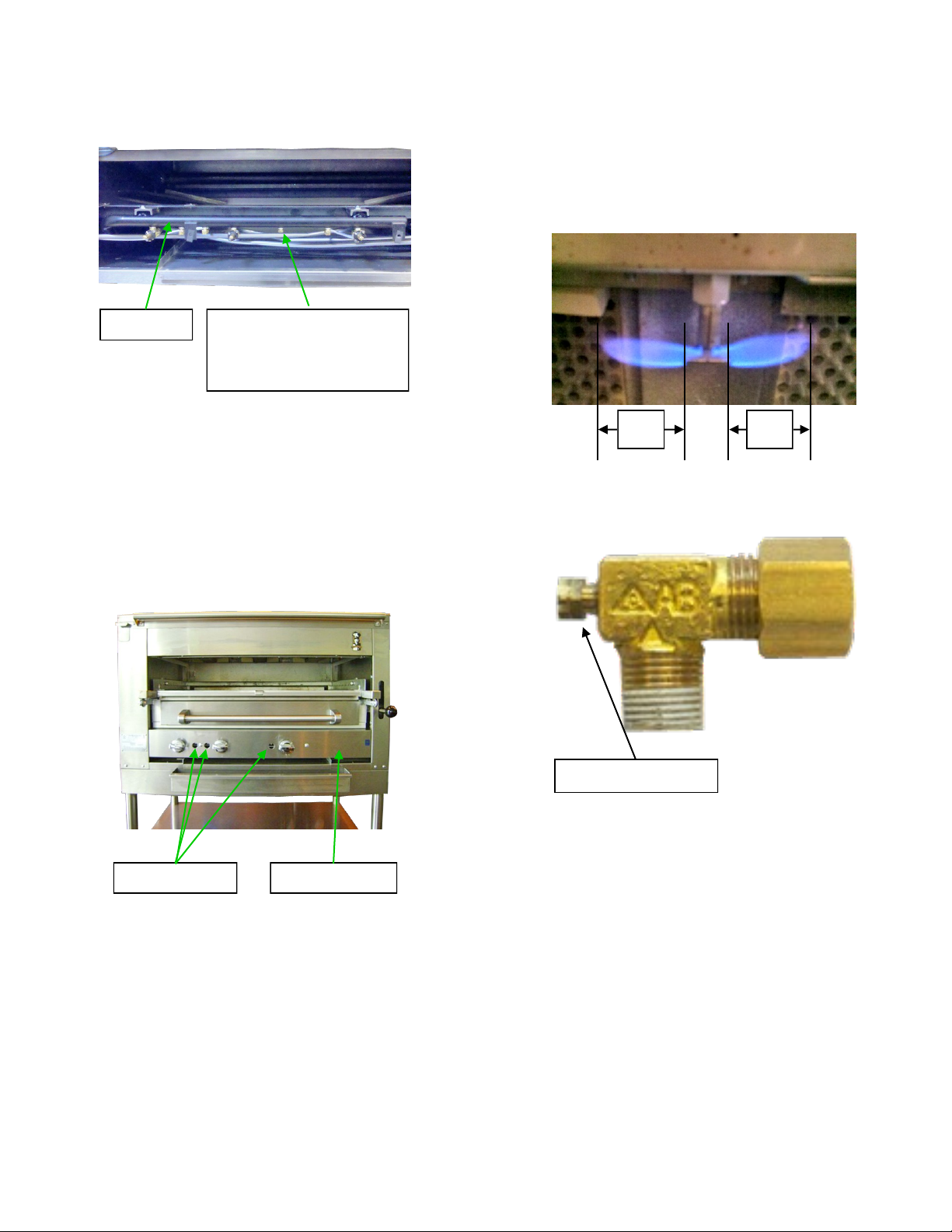

3. Adjust pilot valve adjustment screw so that

each pilot burner has a steady blue flame,

Figure 8.

1/2” 1/2”

Pilot Burner

(Figure 8)

Adjustment Screw

Pilot Value

(Figure 9)

Pilot Valves Valve Panel

Pilot Valves

(Figure 7)

1. Turn the main gas shutoff valve to the on

position.

NOTE: Pilots are on at all times if main shutoff

valve is in the on position and pilot adjustment

valves are open.

2. Light each pilot.

BURNER ADJUSTMENT

The efficiency of the broiler depends on a

delicate balance between the supply of air and

the volume of gas at each main burner

resulting in complete combustion. Whenever

this balance is disturbed, poor operating

characteristics occur. An air shutter, Figure 9,

on the front of each main burner controls the

air supply.

9

Loading...

Loading...