Montague C24-8 Owner’s Manual

INSTRUCTION MANUAL

MONTAGUE EXTREME CUISINE

Custom Refrigerated

Equipment Bases

MODELS:

RB Series

These instructions should be read thoroughly before attempting installation.

Set up and installation should be performed by qualified installation personnel.

Keep area around appliances free and clear from combustibles.

PLEASE RETAIN THIS MANUAL

FOR FUTURE REFERENCE.

THE MONTAGUE COMPANY

1830 Stearman Avenue P.O. BOX 4954

HAYWARD,CA 94540-4954

TEL: 510/785-8822 FAX: 510/785-3342

CONTENTS

INTRODUCTION ……… 4 SERVICE DIAGNOSIS….……….11

SPECIFICATIONS ……..5 WIRING DIAGRAM ……………...14

INSTALLATION…………6 WARRANTY………………………15

OPERATION…………….8 SERVICE RECORD ……………..17

MAINTENANCE………...9

IMPORTANT

WARNING:

Improper installation, adjustment,

alteration, service or maintenance

can cause property damage, injury

or death. Read the operating

and maintenance instructions

thoroughly before installing or

Do not store or use gasoline or

other flammable vapors and

liquids in the vicinity of this or

any other appliance.

FOR YOUR SAFETY:

servicing this equipment.

INSTRUCTIONS TO BE FOLLOWED IN THE EVENT THE USER SMELLS GAS MUST BE

POSTED IN A PROMINENT LOCATION. THIS INFORMATION MAY BE OBTAINED BY

CONSULTING THE LOCAL GAS SUPPLIER.

SHIPPING DAMAGE CLAIM PROCEDURE

For your protection, please note that equipment in this shipment was carefully inspected

and packed by skilled personnel before leaving the factory. The transportation company

assumes full responsibility for safe delivery upon acceptance of this shipment.

If shipment arrives damaged:

1. VISIBLE LOSS OR DAMAGE—Be certain this is noted on freight bill or express receipt,

and signed by person making delivery.

2. FILE CLAIM FOR DAMAGES IMMEDIATELY—Regardless of the extent of damage.

3. CONCEALED LOSS OR DAMAGE—If damage is unnoticed until merchandise is un-

packed, notify transportation company or carrier immediately, and file “concealed damage” claim with them. This should be done within fifteen (15) days of date that delivery

was made to you. Be sure to retain container for inspection.

We cannot assume responsibility for damage incurred in transit. We will, however, be glad

to furnish you with necessary documents to support your claim.

2

TABLE OF CONTENTS

INTRODUCTION

Description of Under Counter Refrigerators 4

Features of Under Counter System 4

Condensing Unit 4

Refrigerant 4

Electrical Characteristics 4

Standard Components 4

Factory Installed Accessories 4

REFRIGERATION SYSTEM SPECIFICATION 5

INSTALLATION 6

Receipt and Inspection of Equipment 6

Location 6

Leveling 6

Plumbing 7

Electrical Connection 7

OPERATION 8

MAINTENANCE 9

Electrical and Piping Connections 9

Care and Cleaning 9

Cleaning the Cabinet 9

Cleaning the Condenser 9

Cleaning the Gaskets 9

Cleaning Drawer Slides 9

Preventing Blower Coil Corrosion 9

Unit Cooler 10

SERVICE DIAGNOSIS 11

Condensing Units 11

WIRING DIAGRAM 14

STANDARD WARRANTY 15

SERVICE RECORD 17

3

INTRODUCTION

DESCRIPTION OF UNDER COUNTER REFRIGERATORS

The E.S.P. Self Contained air cooled Under Counter Refrigeration System utilizes safe CFC’s and

offers tremendous operating efficiency by using an over sized system. This high operating

efficiency is made through effective use of the condenser coil surface area. The condenser coils on

our units are almost 20% bigger than conventional competitive designs. Complete factory assembly

eliminates on-sight construction competitive designs. Complete factory assembly eliminated

on-sight construction costs of built-up systems by refrigeration technicians and electricians in the

field. The Under Counter System is designed primarily for institutional food service operations

including hospitals, universities, schools, hotels, restaurant, coffee shops, and convenience stores.

Under Counter System pulls fresh air over the compressor bodies to reduce their operating

temperature. Compressor ventilation has become increasingly important because of regulations

effecting the use of R-22 refrigerant.

FEATURES OF UNDER COUNTER SYSTEM

Condensing Unit

A refrigeration condensing unit is a highly sophisticated apparatus. It is with the anticipation that it

will provide many years of trouble-free operation with minimal maintenance. Usually the length of

service life realized from a particular condensing unit is directly proportional to the care with which

the original installation was performed. The correct electrical supply must be provided to the

condensing unit. The voltage at the motor-compressor terminals should be checked during start-up

and units operation under full load to insure a tolerance of plus or minus 10 percent of the nameplate rating.

Refrigerant

R-22 is used for the Under Counter System.

Electrical Characteristics

Each unit is equipped with 120 Volts. 1 Phase. 60 Hertz power supply.

Standard Components

Each unit consists of hermetic compressors, condenser with heavy duty fan motors, oversized

receivers, factory installed accessories, unit coolers with T-stat solenoid valve, TX valve and

suction line P-Trap.

Factory Installed Accessories

Drier, sight glass, and pressure control.

The E.S.P. Under Counter Systems are tested and assembled under strict quality assurance

procedures. Each unit is tested and charged with R-22 before shipment.

4

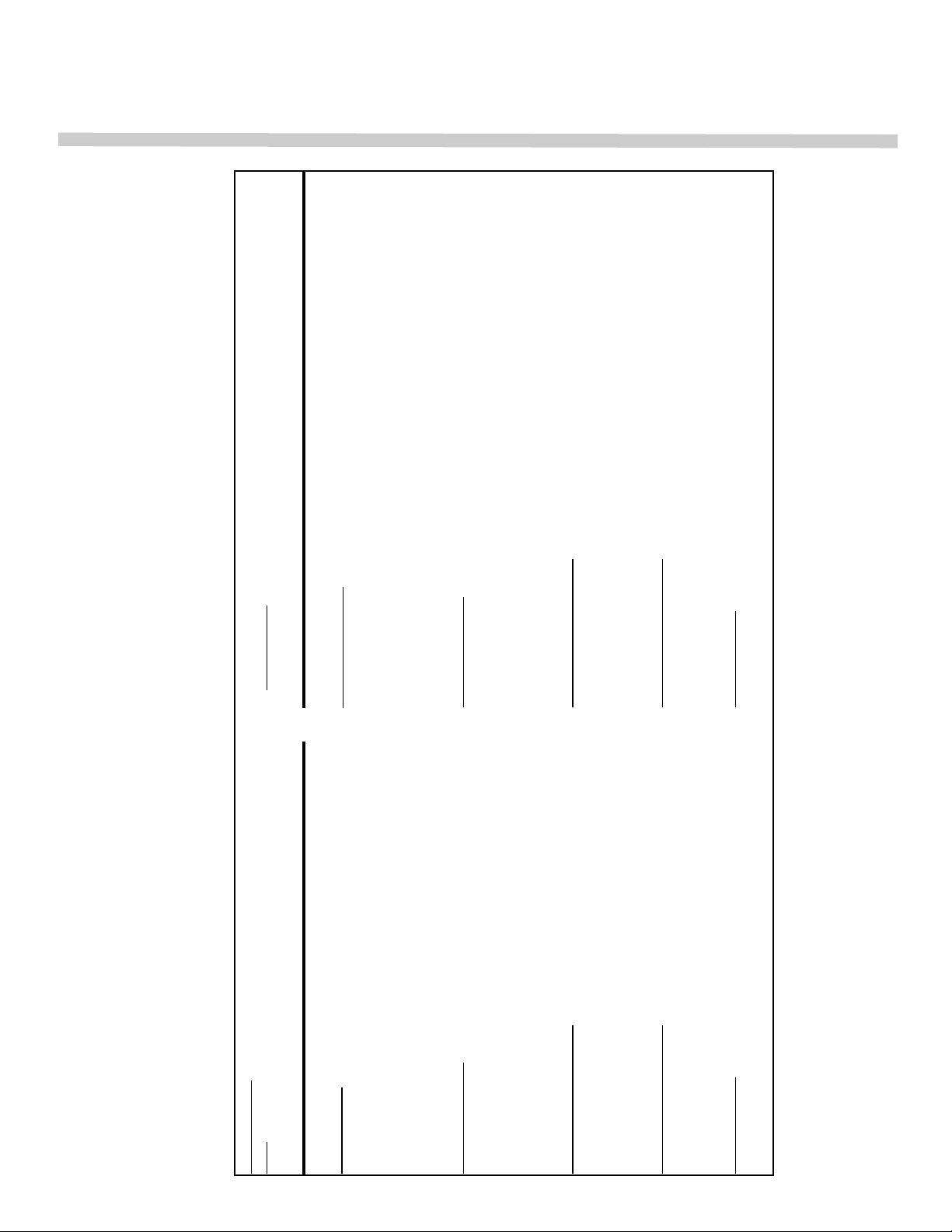

REFRIGERATION SYSTEM SPECIFICATIONS

1/4* 160 484-1020 3.0

Length H.P. EVAP BTU BTU LOAD COIL AMPS

24" to 54"

Salad Tables:

Pizza/Sandwich Tables:

Pizza/Sandwich Tables:

Baker's Tables:

PLUG

R-22 NEMA

Length R-22 H.P. R-22 AMPS

All units are 115 volts, 60 hertz, single phase

Self-Contained

Units Remote Units

Salad Tables:

36" to 66" 1/4 8.0 5-15P

72" to 84" 1/3 12.0 5-15P 60" to 84" 1/3* 320 1111-1478 6.0

96" to 102" 1/3 12.0 5-15P 90" to 96" 1/2* 320 1570-1661 6.0

108" to 114" 1/2 14.0 5-20P

Work Top Tables: Work Top Tables:

36" to 66" 1/4 8.0 5-15P 24" to 54" 1/4* 160 367-825 3.0

72" to 84" 1/3 12.0 5-15P 60" to 84" 1/3* 320 917-1183 6.0

96" to 102" 1/3 12.0 5-15P 90" to 96" 1/2* 320 1375-1466 6.0

108" to 114" 1/2 14.0 5-20P

Pizza/Sandwich Tables:

60" to 66" 1/4 8.0 5-15P 48" 1/4* 160 1424 3.0

84" to 90" 1/2 14.0 5-15P 72" 1/2* 320 2135 6.0

114" to 120" 3/4 16.0 5-20P 96" 3/4* 320 2705 6.0

Pizza/Sandwich Tables:

66" to 72" 1/3 12.0 5-15P 54" 1/3* 160 1716 3.0

93" to 99" 1/2 14.0 5-20P 81" 1/2* 320 2574 6.0

Baker's Tables:

66" to 72" 1/4 8.0 5-15P 54" 1/3* 160 1053 3.0

93" to 99" 1/3 12.0 5-15P 81" 1/3* 320 1580 6.0

5

INSTALLATION

RECEIPT AND INSPECTION OF EQUIPMENT

Inspect Under Counter unit and all accessories shipped for any damage or shortages. Any

damage or shortages should be reported immediately to the delivering carrier. Damaged material

becomes the delivering carrier’s responsibility and it should not be returned to the manufacturer

without prior approval. Do not remove any shipping material until the unit is installed in its

permanent location.

LOCATION

Be sure the location chosen has a floor strong enough to support the total weight of the cabinet

and contents. A fully loaded 72” long model may weight as much as 3000 pounds! Reinforce the

floor as necessary to provide for maximum loading.

For the most efficient refrigeration, be sure to provide good air circulation inside and out.

Inside cabinet: Do not pack refrigerator so full that air cannot circulate.

Outside cabinet: Be sure that the unit has access to ample air. Avoid hot corners and locations

near stoves and ovens.

It is recommended that the unit be installed no closer than 1 inch from any wall. Do not install the

unit near any combustible material or object affected by heat or moisture.

LEVELING

A level cabinet looks better and will perform better because:

1. The drain pan will drain properly.

2. The doors will line up with the frames properly.

3. The cabinet will not be subject to undue strain.

Some models have casters for your convenience, for ease of cleaning underneath and for mobility.

It is important that the unit be installed in a stable condition with the front casters locked before

operating, however.

6

Loading...

Loading...