Montague 2EK8(N) Installation Manual

INSTRUCTION MANUAL

MONTAGUE

Electric

Convection Ovens

MODELS:

EK-12A, 2EK-12A,

EK-15A, 2EK-15A

These instructions should be read thoroughly before attempting installation.

Set up and installation should be performed by qualified installation personnel.

Keep area around appliances free and clear from combustibles.

PLEASE RETAIN THIS MANUAL

FOR FUTURE REFERENCE.

THE MONTAGUE COMPANY

1830 Stearman Avenue P.O. BOX 4954

HAYWARD,CA 94540-4954

TEL: 510/785-8822 FAX: 510/785-3342

CONTENTS

INSTALLATION ………. 3 MAINTENANCE ………12

OPERATION ………….. 7 SERVICE ………………15

COOKING HINTS …….. 8

IMPORTANT

WARNING:

Improper installation, adjustment,

alteration, service or maintenance

can cause property damage, injury

or death. Read the operating and

maintenance instructions thoroughly

before installing or servicing this

FOR YOUR SAFETY:

Do not store or use gasoline or other

flammable vapors and liquids in the

vicinity of this or any other

appliance.

equipment.

INSTRUCTIONS TO BE FOLLOWED IN THE EVENT THE USER SMELLS GAS MUST BE POSTED

IN A PROMINENT LOCATION. THIS INFORMATION MAY BE OBTAINED BY CONSULTING THE

LOCAL GAS SUPPLIER.

SHIPPING DAMAGE CLAIM PROCEDURE

For your protection, please note that equipment in this shipment was carefully inspected and packed by

skilled personnel before leaving the factory. The transportation company assumed full responsibility

for safe delivery upon acceptance of this shipment.

If shipment arrives damaged:

1. VISIBLE LOSS OR DAMAGE—Be certain this is noted on freight bill or express receipt, and

signed by person making delivery.

2. FILE CLAIM FOR DAMAGES IMMEDIATELY—Regardless of the extent of damage.

3. CONCEALED LOSS OR DAMAGE—If damage is unnoticed until merchandise is unpacked,

notify transportation company or carrier immediately, and file “concealed damage” claim with

them. This should be done within fifteen (15) days of date that delivery was made to you. Be sure

to retain container for inspection.

We cannot assume responsibility for damage incurred in transit. We will, however, be glad to furnish

you with necessary documents to support your claim.

2

INSTALLATION

INSTALLATION

Vectaire electric convection ovens are manufactured for use on the electric supply indicated on the rating

plate located on the front of the hinged panel. Units wired for three (3) phase service CANNOT be changed

to single phase nor single phase units changed to three (3) phase.

Units designated for 208 VAC will operate satisfactorily within the voltage range of 197 to 219 VAC. Units

designated 230 VAC will operate satisfactorily within the voltage range of 220 to 240 VAC.

The Vectaire oven is produced with the best possible material and workmanship. PROPER INSTALLATION

IS ESSENTIAL FOR SAFE AND EFFICIENT TROUBLE-FREE OPERATION.

THE INSTALLATION INSTRUCTIONS CONTAINED HEREIN ARE FOR THE

USE OF QUALIFIED INSTALLATION AND SERVICE PERSONNEL ONLY.

INSTALLATION OR SERVICE BY OTHER THAN QUALIFIED PERSONNEL

MAY RESULT IN DAMAGE TO THE OVEN AND/OR INJURY TO THE

OPERATOR.

READ CAREFULY AND FOLLOW THESE INSTRUCTIONS

THIS UNIT WHEN INSTALLED MUST BE ELECTRICALLY GROUNDED

IN ACCORDANCE WITH LOCAL CODES, OR IN ABSENCE OF LOCAL

CODES, WITH THE NATIONAL ELECTRICAL CODE, ANSI/NFPA No.70–

LATEST ADDENDA.

CHECK FOR SHIPPING DAMAGE

Check carton for handling damage. After carefully uncrating oven, check for “concealed”

damage. Notify transportation company or carrier immediately and file “Concealed Damage”

claim with them. Be sure to retain container for their inspection.

3

INSTALLATION

INSTALLATION

ASSEMBLY

Uncrate oven and base as near to final location as possible. Remove all packing material and

accessories from oven interior.

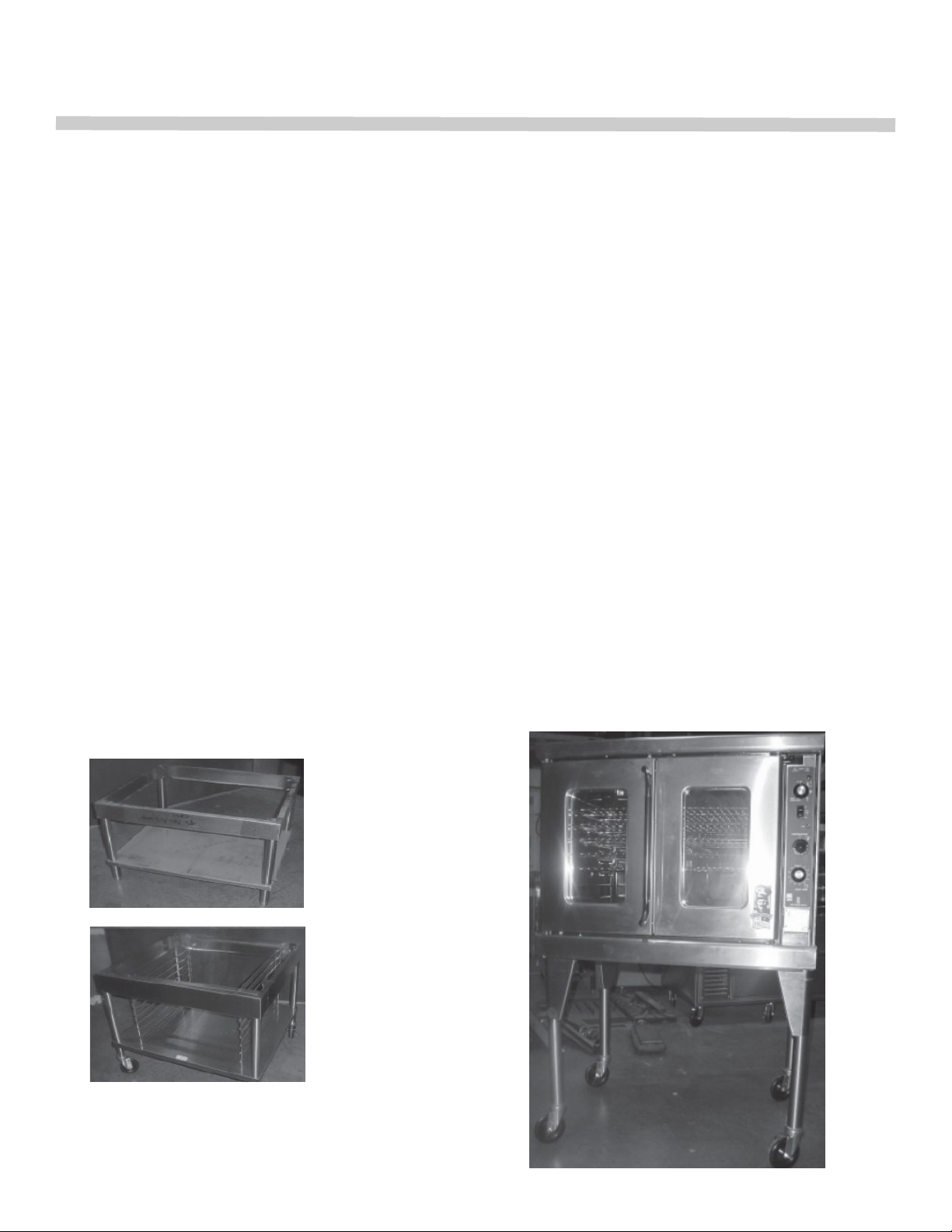

MODULAR STAND

MODEL EK-12A, EK-15A: Turn modular stand frame upside down. Insert a leg or caster into

each socket (4). Set modular stand in desired location of oven. Place oven section on stand

and position oven so that locator tabs on stand engage oven bottom frame.

MODEL 2EK-12A, 2EK-15A

Turn modular stand frame upside down. Insert a leg or caster into each socket (4). Set modular

stand in desired location of oven. Place bottom oven section on stand and position oven so that

locator tabs on stand engage oven bottom frame. Place top oven section on lower unit and

position so that locator tabs on lower unit engage oven bottom frame. (See Fig. 4)

Remove screws from side of moisture vent outlet on back of each oven section. Place duct over

outlets and attach with these same screws.

LEGS

MODEL 2EK-12A, 2EK-15A: Lift oven off of shipping pallet. Screw legs into each threaded hole

on the oven base

4

INSTALLATION

INSTALLATION

LEVELING

When the oven is in permanent position, level entire unit by placing a carpenters level on

the oven rack and adjusting the foot on the bottom of each leg, so that the oven is level from front

to back and side to side.

ELECTRICAL CONNECTION

Before making any electrical connections to the unit, check the rating plate which is

located on the hinged panel to make sure that the oven is being connected to the proper electrical supply. Units marked "208V" will operate satisfactorily from 197 - 219 VAC. Units marked

"230V" will operate satisfactorily from 220 - 240 VAC.

UNITS WIRED FOR THREE (3) PHASE SERVICE CAN NOT BE CHANGED TO SINGLE

PHASE, OR SINGLE PHASE UNITS CHANGED TO THREE (3) PHASE.

USE COPPER WIRE ONLY FOR POWER CONNECTION(S)

The electrical supply connection to the unit is made at the lower terminals of the circuit

breaker. The electrical supply conduit is fed through the 4" diameter opening in back of oven and

through the hole in the electrical enclosure to the circuit breaker.

Picture A

4” opening in back of oven

For access to electrical supply connection terminals, open control panel by removing the

screw at the top. (Remove the thermostat dial first). This will allow the control panel to pull

forward. For access to conduit connection, remove the front portion of the right side panel.

The models 2EK-12A, 2EK-15A (double deck ovens) requires a separate electrical supply

to each oven section.

THE OVEN(S) MUST BE WIRED TO GROUND. USE GREEN COLORED SCREW THAT IS

PROVIDED INSIDE ELECTRICAL ENCLOSURE FOR THIS PURPOSE.

Picture B

Electrical enclosure

5

OPERATION

THIS APPLIANCE HAS BEEN CLASSIFIED AS COMMERCIAL COOKING EQUIPMENT

AND MUST BE OPERATED BY PROFESSIONAL PERSONNEL.

OPERATION INSTRUCTIONS - MODEL EK-12A, EK-15A, MODEL 2EK-12A, 2EK-15A

Be sure power is "ON" at the main panel box. Open the hinged "Panel" at lower right front

of oven. Turn breaker switch to "ON" to energize controls. Rotate fan switch to "HI". Set the

thermostat to the desired temperature. The heating elements are controlled by the thermostat,

and will not operate unless the fan is running. Until the temperature setting is reached, the

"Amber" indicator light will glow. When temperature setting is reached, the "Amber" indicator light

turns off. The indicator light will change back on when the oven cools and the thermostat calls for

more heat.

Opening the oven doors will cause the fan and heating elements to shut off. They will automatically resume operation when the doors are closed. Do not attempt to cook until the "Amber"

indicator light has turned off.

To load the oven: Open doors and load quickly and evenly, leaving space around each item

for air circulation. Close doors immediately. Set the mechanical timer to desired cooking time. (If

less than 10 minutes, turn the dial past 10, then back to proper setting). Never turn past 60 as this

will damage the timer mechanism. When time has elapsed bell will ring, but it will not shut off the

oven. The oven lights may be turned "ON" or "OFF" at any time by pressing the light switch.

6

OPERATION

OPERATION

USING A CONVECTION OVEN

The convection oven is a different type of oven which offers many features and advantages to the

food service operation. The operation of the oven is not difficult to understand or control.

The convection oven is the sealed type whereby the combustion products are separated from the

air inside the oven. The heat is transferred through the oven surface into the cavity. The air inside

the oven is continuously recirculated over the heat source and the product.

The moving air strips away the insulating layer of moisture on the products allowing heat to

penetrate faster for quicker baking and roasting. Due to these differences in the methods of cooking in a convection oven, procedures and techniques may require some modification for successful results. A general rule, which will assist in better operation, is cooking time will be less and

temperatures should be 25 to 75 degrees lower than those called for in standard recipes.

For convection oven cooking, reduce temperature 25 to 75 degrees from those given in

standard recipes.

Type of FoodBaked Products Reduction in Temperature Reduction in Time

Cookies 25° 1/4 to 1/3

Cakes & Quick Bread 50° 1/4 to 1/3

Yeast Products 75° 1/4 to 1/3

Casseroles 25° 1/4 to 1/2

GUIDE TO BAKING TIMES AND TEMPERATURES

These times and temperatures were especially prepared and tested for use in a Vectaire

convection oven. Times, temperatures, and moisture contents may vary in other convection

ovens. The suggested times and temperatures may vary considerably from those shown. They

are affected by weight of load, recipe, type of pan, size of portion, and calibration of thermostat.

Differences in quality and age of meats and fowl and quantities of shortening, milk, fat and other

ingredients in baked goods affect both cooking times and temperatures.

These charts have been compiled carefully. However, they are only guides. You may want to cook

certain foods a little more or a little less according to your preference and your recipe. Also, types

and sizes of pans influence baking time and temperatures.

It is absolutely necessary to use lower temperatures. As a guide, set oven temperatures 25-75

degrees lower than called for in your recipes using non-convection ovens.

Use this chart as a guide to develop your own cooking techniques.

7

Loading...

Loading...