Montague 136W36 Installation Manual

INST ALLA TION &

OPERA TION MANUAL

G

AS FIRE

D

BR

O

E36W36 EV136W36 EC36

E43W36 E236W36 EC45

E136W36 E243W36

ILERS

G

I

S

N

E

D

THE M

ONTAGUE CO.

C

E

D

R

E

I

T

F

I

Please read this manual completely before attempting to

install or operate this equipment! Notify carrier of damage.

Inspect all components immediately . See page 4.

RETAIN THIS MANUAL FOR FUTURE REFERENCE.

The MONTAGUE Company

1830 Stearman A ve. • P.O. Box 4954 • Hayward, CA 94540-4954 • Tel: 510/785-8822 • Fax: 510/785-3342

IMPORTANT FOR YOUR SAFETY

THE INSTALLATION INSTRUCTIONS CONTAINED HEREIN ARE FOR THE USE OF QUALIFIED

INSTALLATION AND SERVICE PERSONNEL ONLY. INSTALLATION OR SERVICE BY OTHER THAN

QUALIFIED PERSONNEL MAY RESULT IN DAMAGE TO THE UNIT AND/OR INJURY TO THE OPERATOR.

IF YOU SMELL GAS

1. TURN OFF THE APPLIANCE AT THE GAS INLET COCK AND OPEN ALL DOORS

AND WINDOWS.

2. DO NOT OPERATE ANY ELECTRICAL SWITCHES AND EXTINGUISH ALL

NAKED FLAMES.

3. CONTACT THE LOCAL GAS AUTHORITY IMMEDIATELY.

THE FOLLOWING INSTRUCTIONS SHOULD BE READ CAREFULLY AS THE

MANUFACTURER CANNOT BE HELD RESPONSIBLE FOR ANY DAMAGE

TO PROPERTY, PERSONS OR ANIMALS CAUSED BY INCORRECT

INSTALLATION OR OPERATION OF THE APPLIANCE.

POST IN A PROMINENT LOCATION THE INSTRUCTIONS TO BE FOLLOWED

IN THE EVENT THE SMELL OF GAS IS DETECTED. THIS INFORMATION CAN

BE OBTAINED FROM THE LOCAL GAS SUPPLIER.

IN THE EVENT OF A POWER FAILURE, DO NOT ATTEMPT TO OPERATE THIS DEVICE.

IMPORTANT

IN THE EVENT A GAS ODOR IS DETECTED, SHUT DOWN UNITS AT MAIN

SHUTOFF VALVE AND CONTACT THE LOCAL GAS COMPANY OR GAS

SUPPLIER FOR SERVICE.

FOR YOUR SAFETY

DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE VAPORS

OR LIQUIDS IN THE VICINITY OF THIS OR ANY OTHER APPLIANCE.

Improper installation, adjustment, alteration, service or

maintenance can cause property damage, injury or death. Read the

INSTALLATION, OPERATING AND MAINTENANCE INSTRUCTIONS

thoroughly before installing, servicing or operating this equipment.

I&O-2

SAVE THESE INSTRUCTIONS FOR FUTURE USE.

The MONTAGUE Company

TABLE OF CONTENTS

IMPORTANT FOR YOUR SAFETY ..................................................................................................................2

INTRODUCTION ................................................................................................................................................ 4

GENERAL...................................................................................................................................................4

MODELS ....................................................................................................................................................4

DATA PLATE LOCATION...........................................................................................................................4

SERIAL NUMBER LOCATION ...................................................................................................................4

RECEIVING AND INSPECTING THE EQUIPMENT................................................................................... 4

SPECIFICATIONS ...................................................................................................................................... 5

INSTALLATION .................................................................................................................................................6

STATUTORY REGULATIONS ..........................................................................................................................6

CLEARANCES ...........................................................................................................................................6

VENTILATING HOOD .................................................................................................................................6

VENTILATION AIR......................................................................................................................................6

ASSEMBLY................................................................................................................................................6

Legs......................................................................................................................................................6

Ceramic Radiants ................................................................................................................................7

LOCATION ..................................................................................................................................................7

SITING ........................................................................................................................................................7

BATTERY ARRANGEMENT ......................................................................................................................7

Setting In Place ................................................................................................................................... 7

Floor Mounted Ranges.........................................................................................................................8

GAS SUPPLY ............................................................................................................................................8

GAS CONNECTION....................................................................................................................................8

GAS PRESSURE REGULATOR................................................................................................................9

Adjustment Procedure ....................................................................................................................... 10

PILOT INITIAL ADJUSTMENT ..................................................................................................................11

BURNER ADJUSTMENT .......................................................................................................................... 11

OPERATION ................................................................................................................................................... 12

GENERAL................................................................................................................................................. 12

OPERATING CONTROLS ........................................................................................................................ 12

Gas Control ........................................................................................................................................ 12

Lighting/Relighting Pilot and Main Burner ..................................................................................12

Shutdown .....................................................................................................................................13

Grid Height Adjustment ..................................................................................................................... 13

GENERAL MAINTENANCE............................................................................................................................14

GENERAL CLEANING ............................................................................................................................. 14

Daily ................................................................................................................................................... 14

PAINTED SURFACES.............................................................................................................................. 14

Exterior............................................................................................................................................... 14

Interior ................................................................................................................................................14

STAINLESS STEEL SURFACES............................................................................................................. 14

VENTILATION ........................................................................................................................................... 15

SAFETY .................................................................................................................................................... 15

SERVICING .............................................................................................................................................. 15

C36 & C45 EXPLODED VIEW........................................................................................................................ 16

C36 & C45 PARTS LIST ................................................................................................................................. 17

36W36 & 43W36 EXPLODED VIEW.............................................................................................................. 18

36W36 & 43W36 PARTS LIST ....................................................................................................................... 19

GAS FIRED BROILERS

I&O-3

INTRODUCTION

GENERAL

The gas broilers covered in this manual are

manufactured for use with the type of gas

indicated on the nameplate. Some models

include a cabinet, conventional oven or

convection oven. Ovens are covered in separate

manuals. This manual only covers the broiler.

Montague gas broilers are produced with the

best possible material and workmanship.

Proper installation is essential for safe,

efficient, trouble-free operation.

MODELS

MODEL CONSISTS OF

E36W36 Cabinet Base Broiler with

Warming Oven

E43W36 Cabinet Base Broiler with

Warming Oven

E136W36 Broiler with Conventional

Oven and Warming Oven

EV136W36 Broiler with Convection Oven

E236W36 Double Broiler

E243W36 Double Broiler

EC36 Broiler Only

EC45 Broiler Only

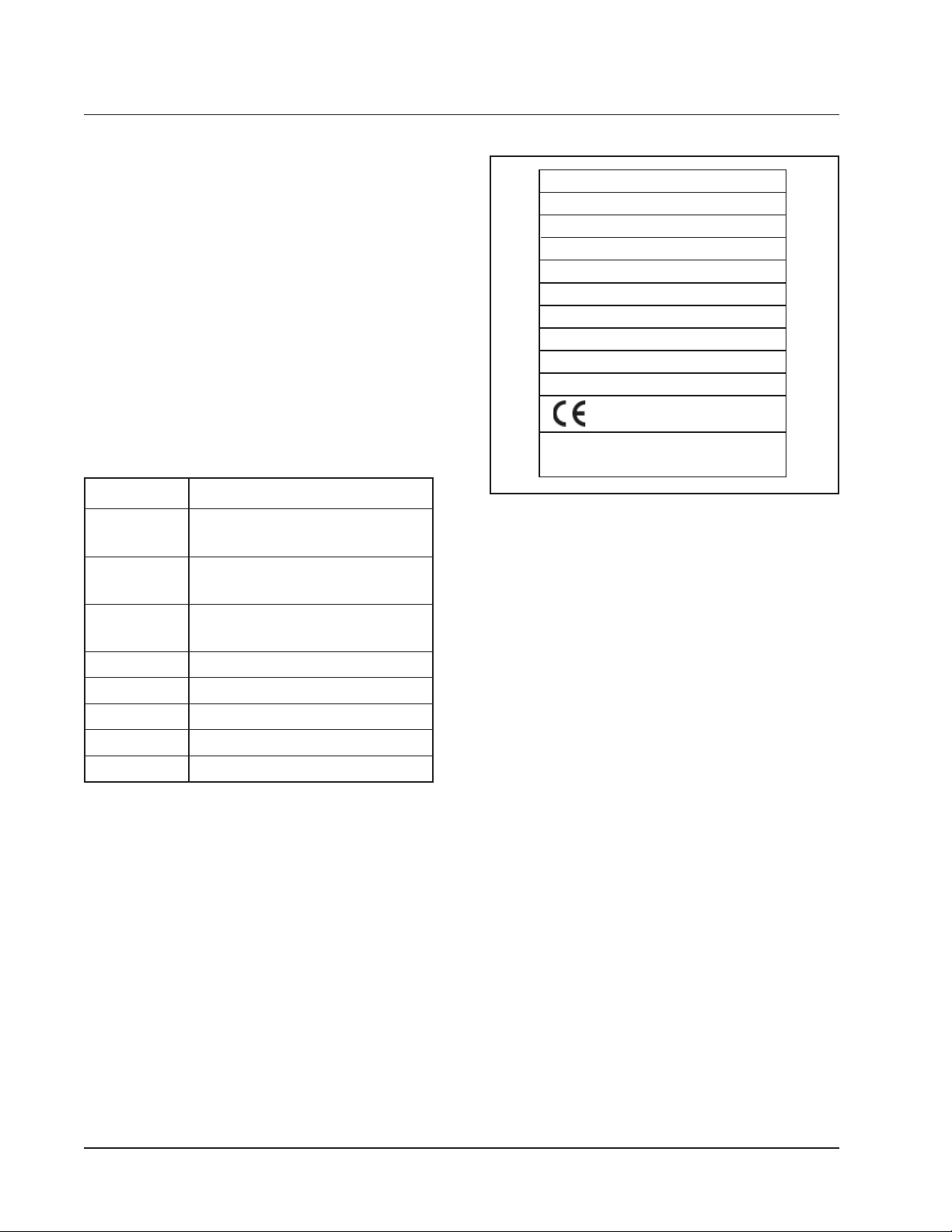

MODEL:

SERIAL NO.:

I TA

PN

EH

CATEGORY:

SUPPLY PRESSURE: mbar

GAS: SET PRESS: mbar

ELECTRICAL

VHzPh W

COUNTRY:

P.I.N.:

GAS CATERING EQUIPMENT

SALAMANDER - TYPE A

Wk:TU

THE MONTAGUE COMPANY

HAYWARD, CALIFORNIA USA

Figure 1. Typical Nameplate

RECEIVING AND INSPECTING

THE EQUIPMENT

Care should be taken during unloading so the

equipment is not damaged while being moved

into the building.

1. Visually inspect the exterior of the package

and skid or container. Any damage should

be noted and reported to the delivering

carrier immediately.

DATA PLATE LOCATION

The Data Plate is located on the front left of the

unit, at the level of the Control Valve panel.

SERIAL NUMBER LOCATION

Always have the serial number of your unit

available when calling for parts or service.

The serial number is on the nameplate that

also includes the model number. A typical

identification plate is shown in Figure 1.

I&O-4

2. If damaged, open and inspect the contents

with the carrier.

3. In the event that the exterior is not

damaged, yet upon opening, there is

concealed damage to the equipment, notify

the carrier. Notification should be made

verbally as well as in written form.

4. Request an inspection by the shipping

company of the damaged equipment. This

should be done within 10 days from receipt

of the equipment.

5. Freight carriers can supply the necessary

damage forms upon request.

6. Retain all shipping materials until an

inspection has been made or waived.

The MONTAGUE Company

SPECIFICATIONS

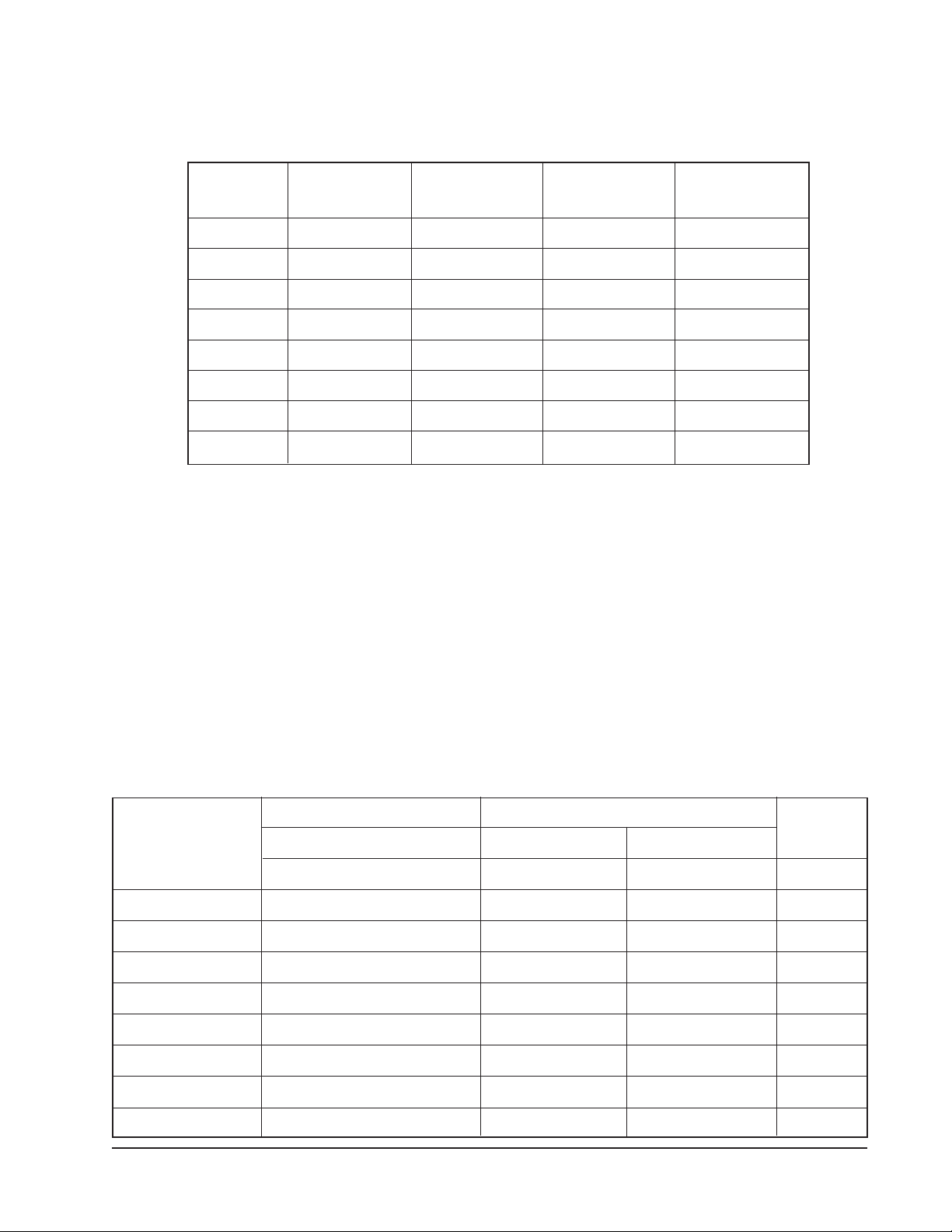

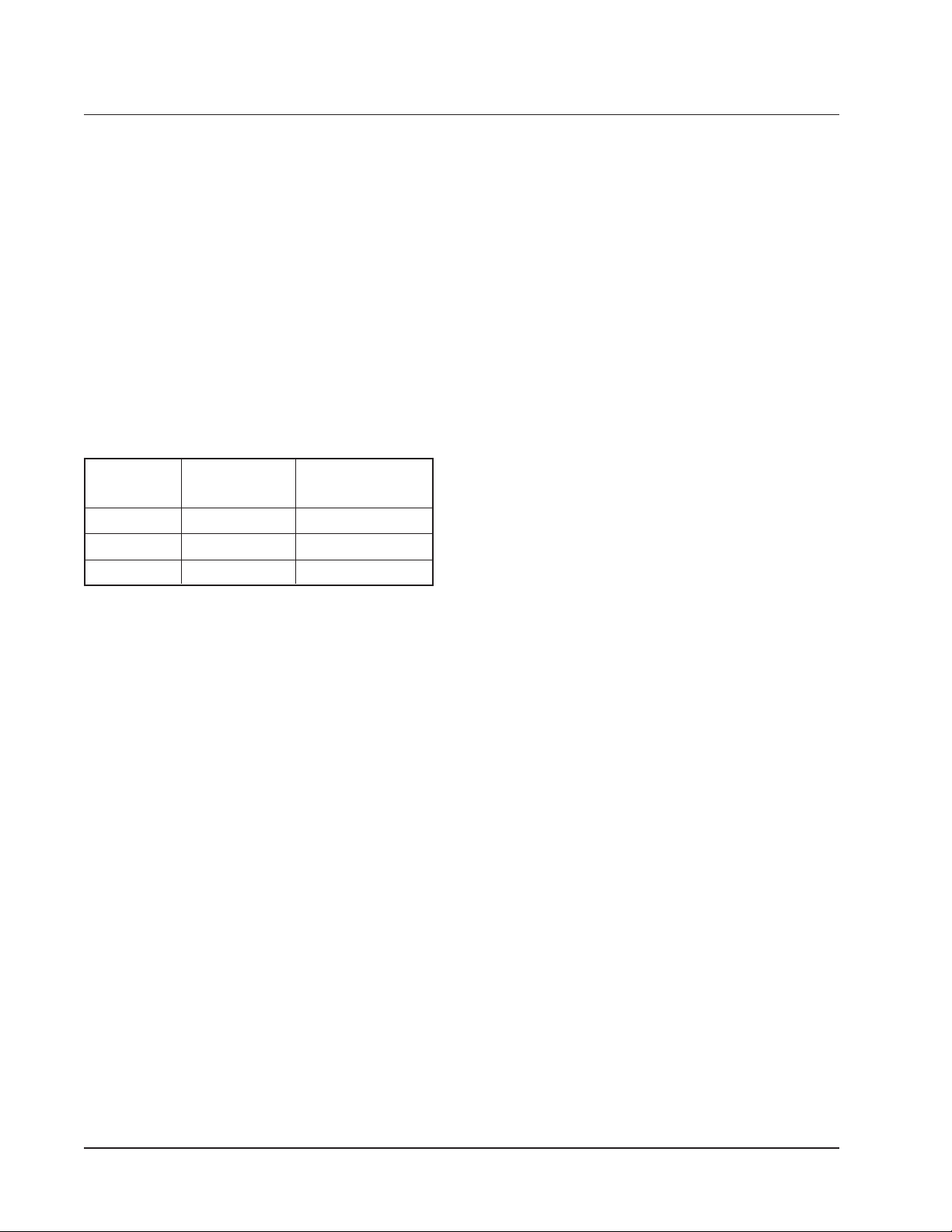

Table A: Heat Input

MODEL

E36W36 2 123,000 ea. 123,000 ea. 24.6

E43W36 3 123,000 ea. 123,000 ea. 36.9

E136W36 2 123,000 ea. 123,000 ea. 36.3

EV136W36 2 123,000 ea. 123,000 ea. 36.3

E236W36 4 123,000 ea. 123,000 ea. 49.2

E243W36 6 123,000 ea. 123,000 ea. 73.8

EC36 2 123,000 ea. 123,000 ea. 24.6

EC45 3 123,000 ea. 123,000 ea. 36.9

NO. BURNERS G20 @ 20 mbar G31 @ 37 mbar TOT AL

(broiler only) kW kW kW

Table B: Setting Pressure/Injector Size

Manifold Pressure

G20: 15 mbar

G31: 25 mbar

G30: 25 mbar

Orifices

Fixed for specified gas type

G20: mm (#32 DMS)

G31: mm (#47 DMS)

Gas Inlet Size:

3/4" NPT at lower left rear (all

models)

NOTE: The pressure must be measured at the pressure test nipple located on

the manifold pipe with the burner lit.

Table C: Aeration Shutter/Pilot Flame Settings

MODEL 2nd FAMIL Y , GROUP H 3rd FAMIL Y , GROUP 3+

G20 @ 20 mbar G30 @ 30 mbar G31 @ 37 mbar

mm mm mm mm

E36W36 25 32 32 12.5

E43W36 25 32 32 12.5

E136W36 25 32 32 12.5

EV136W36 25 32 32 12.5

E236W36 25 32 32 12.5

E243W36 25 32 32 12.5

EC36 25 32 32 12.5

PILOT

FLAME

LENGTH

EC45 25 32 32 12.5

GAS FIRED BROILERS

I&O-5

INSTALLATION

CAUTION: Provision must be made to

assure adequate air supply to unit for

proper burner operation.

STATUTORY REGULATIONS

The installation of this appliance must be carried

out by a competent person and in accordance

with the relevant regulations, standards, codes

of practice and the related publications of the

country of destination.

CLEARANCES

The following are minimum clearances from

combustible and noncombustible materials.

Location Combustible Noncombustible

Construction Construction

Back Wall 152 mm 0 mm

Left Side 152 mm 0 mm

Right Side 152 mm 0 mm

With 152 mm legs: Suitable for installation on

combustible floors.

NOTE 1: The room containing the appliance

is required to have a permanent air vent. The

minimum effective area of the vent is related

to the maximum rated heat input of the

appliance and shall be 4.5 cm2 per kW in

excess of 7 kW.

NOTE 2: Air vents should be of such a size

to compensate for the effects of any extract

fan in the premises.

It is also necessary that sufficient room air

ingress be allowed to compensate for the amount

of air removed by the ventilating system.

Otherwise, a subnormal atmospheric pressure

will occur which may interfere with burner

performance or may extinguish the pilot flame.

In case of unsatisfactory broiler performance

check with the exhaust fan in the “OFF” position.

This appliance is to be installed with sufficient

ventilation to prevent the occurance of

unacceptable concentrations of substances

harmful to health in the room in which it is

installed.

Without legs: For use with special insulated

base on noncombustible floors only.

VENTILATING HOOD

The broiler(s) must be installed under a properly

designed ventilating hood. The hood should

extend at least 152 mm beyond all sides of the

unit. The hood should be connected to an

adequate mechanical exhaust system.

VENTALIATION AIR

The following notes are intended to give general

guidance. For detailed recommendations, refer

to the applicable code(s) in the country of

destination.

ASSEMBLY

Uncrate broiler as near to final location as

possible. For easier and lighter handling of broiler,

remove grids, grid frame, drip tray and grease

container. Remove all packing materials and

accessories from broiler interior.

Legs

Some broilers are mounted on legs.

1. Screws the legs into the modular stand.

2. Tightly screw the complete leg assembly

into the mounting holes in the bottom of the

broiler at each corner. If the unit is intended

for curb installation, no legs are provided.

The curb must be noncombustible material.

I&O-6

The MONTAGUE Company

Loading...

Loading...