Page 1

http://hespareparts.com

COMPAGNIE RIBOULEAU

Réf. LD2003

PNEUMATIC PLANTER

Operator’s Manual

16-Row 30" Pull type Planter

WING FOLD

Includes Instructions For :

OPERATION, ADJUSTMENT and MAINTENANCE

Page 2

http://hespareparts.com

Introduction 1

Specifications 2

Safety 3

Operation 5

Lubrication 27

Maintenance 30

Parts 37

High output turbofan 38

Hydraulic drive 40

Planting unit – NG plus 2 41

Metering box – NG plus 44

Microsem 46

Fertilizer 48

PVC pipe and hose assembly 50

Frame assembly 51

Hydraulic wing fold 53

Hitch assembly 54

Row marker assembly 56

Marker support 58

Marker – hose – spindle – hub 59

Lift wheel assembly 60

Drive wheel assembly 61

Transmission assembly 64

Hex shaft coupler 66

Hydraulic assembly 67

Lift assist cylinder assembly 69

Wing fold cylinder assembly 70

Slave cylinder assembly 71

Master cylinder assembly 72

Marker cylinder assembly 73

Page 3

Introduction

http://hespareparts.com

2 precautions

for successful

planting :

1- Choose a reasonable working speed

adapted to the field conditions and desired

accuracy.

2- Check proper working of the seed

metering, seed placement, spacing and

density when starting up and from time to

time during planting.

… and don’t forget : accurate planting is

the key to a good stand !

1

Page 4

Specifications

http://hespareparts.com

TYPE - Pull Type - Center-Flex Hydraulic Front Fold, 16 Row

PLANTING UNIT TYPES - NG plus MONOSEM

- Pneumatic metering box

- Double disc opener

- Gauge wheels

- “V” closing wheels

STANDARD ROW SPACING - 16 Row Narrow - 30" Rows

TRANSPORT TIRES - Eight 7.50" x 20" , 6 ply Transport/Ground drive tires

- Adjustable height wheels for ridge planting

TYPE LIFT - Master/Slave hydraulics

16 Row master/slave rephasing with assist cylinders (8

cylinders)

ROW MARKERS - Heavy-duty conventional : Low profile three-fold

HYDRAULICS - Hydraulics for 16 Row dual SCV for independent operation

of lift and markers.

- Hydraulic sequence valve with flow controls for markers.

- Hydraulics for front fold 16 Row.

Dimensions/Weights

PLANTER SIZE 16 Row 30"

Transport Width 23' 2" (7100 mm)

Single Frame Length 24' 6" (7500 mm)

Single Frame Weight* 10489 lbs. (4760 Kg)

* The base machine weight includes planter frame, row markers, drive components, tires and

wheels, hydraulic cylinders and NG plus MONOSEM row unit with seed hopper and lid.

2

Page 5

Safety

http://hespareparts.com

!

! !

Following Operation :

• Following operation, or when unhitching,

stop the tractor or towing vehicle, set the

brakes, disengage the PTO and all

power drives, shut off the engine and

remove the ignition keys.

• Store the planter in an area away from

human activity.

• Do not permit children to play on or

around the stored planter.

• The planter should be stored in a dry and

dust-free location with the hydraulic

cylinders closed.

• Engage all safety devices for storage.

• Wheel chocks may be needed to prevent

the parked planter from rolling.

Performing Maintenance :

• Good maintenance is your responsibility.

• Make repairs in an area with plenty of

ventilation. Never operate the engine of

the towing vehicle in a closed building.

The exhaust fumes may cause

asphyxiation.

• Before working on the planter, stop the

towing vehicle, set the brakes, disengage

the PTO and all power drives, shut off

the engine and remove the ignition keys.

• Be certain all moving parts have come to

a complete stop before attempting to

perform maintenance.

• Always use the proper tools or

equipment for the job at hand.

• Never use your hands to locate a

hydraulic leak. Use a small piece of

cardboard or wood. Hydraulic fluid

escaping under pressure can penetrate

the skin. If injured by escaping

hydraulic fluid, see a doctor at once.

Gangrene can result. Without

immediate medical treatment, serious

infection and reactions can occur.

• Replace all shields and guards after

servicing and before moving.

• After servicing, be sure all tools, parts

and service equipment are removed.

• If the planter has been altered in any way

from the original design, the

manufacturer does not accept any

liability for injury or warranty.

Tire Safety :

• Inflating or servicing tires can be

dangerous. Whenever possible, trained

personnel should be called to service

and / or mount tires.

• Do not attempt to mount a tire unless you

have the proper equipment and

experience to do the job.

• Failure to follow proper procedures when

mounting a tire on a wheel or rim can

produce an explosion which way result in

serious injury or death.

3

Page 6

Safety

http://hespareparts.com

! !

Before Operation :

• Carefully study and understand this

manual.

• Do not wear loose-fitting clothing which

may catch in moving parts.

• It is recommended that suitable

protective hearing and (eye protection)

sight protectors be worn.

• The operator may come in contact with

certain materials witch may require

specific safety equipment, relative to the

handling of such materials (examples :

extremely dusty, molds, fungus, bulk

fertilizers, insecticides, etc.)

• Assure that the planter tires are inflated

evenly.

• Give the planter a visual inspection for

any loose bolts, worn parts or cracked

welds, and make necessary repairs.

• Be sure that there are no tools lying on

or in the planter.

• Don’t hurry the learning process or take

the unit for granted. Ease into it and

become familiar with your new planter.

• Practice operation of your planter and its

attachments. Completely familiarize

yourself and other operators with its

operations before using.

• Do not allow anyone to stand between

the tongue or hitch and the towing

vehicle when backing up the planter.

During Operation :

• Beware of bystanders, particularly

children ! Always look around to make

sure that it is safe to start the engine of

the towing vehicle.

• No passengers allowed anywhere on, or

in the planter during operation.

• Keep hands and clothing clear of moving

parts.

• Do not clean, lubricate or adjust your

equipment while it is moving.

• When halting operation, even

periodically, set the tractor or towing

vehicle brakes, disengage the PTO, shut

of the engine and remove the ignition

key.

• Be especially observant of the operating

area and terrain – watch for holes, rocks

or other hidden hazards. Always inspect

the area prior the operation.

Do not operate near the edge of dropoffs or banks.

Do not operate on steep slopes as

overturn may result.

Be extra careful when working on

inclines.

• As a precaution, always recheck the

hardware on equipment following every

100 hours of operation. Correct all

problems.

4

Page 7

Operation

http://hespareparts.com

PLANTER PREPARATION

For the initial preparation of the planter,

lubricate the planter and row units as

outlined in the lubrication section of this

manual. Make sure all tires are properly

inflated, that all drive chains have the proper

tension, alignment and lubrication.

TRACTOR PREPARATION

Consult your dealer for information on the

minimum tractor horse power requirements

and tractor capability. Tractor requirements

will vary with planter options, tillage and

terrain.

One dual remote hydraulic outlet (SCV) is

required on models equipped with the

standard single valve hydraulic system. Two

dual remote hydraulic outlets (SCV) are

required on models equipped with the

optional dual valve hydraulic system.

PLANTER ATTACHMENT TO TRACTOR

Use the following six steps to attach your

planter to the tractor.

1. Adjust the tractor drawbar so it is 13

to 17 inches above the ground. Adjust the

drawbar so that the hitch pin holes is directly

below the center line of the PTO shaft. Make

sure the drawbar is in a stationary position.

2. Back the tractor to the planter and

connect them with a hitch pin. Make sure the

hitch pin is secured with a locking pin or

cotter pin.

3. Connect the PTO drive shaft to the

tractor. In addition to a standard 540 rpm

PTO, a 1000 rpm shaft is available.

CAUTION – Make sure that you

connect the proper end of the PTO to the

tractor. An arrow on the PTO indicates

the end of the constant velocity (double

clutch) that is attached to the tractor.

The following sticker is placed on your PTO

shaft for your safety...

DANGER – Rotating drive line

contact can cause death – keep away. Do

not operate without all driveline, tractor

and equipment shields in place ; without

drivelines securely attached at both ends,

and without driveline shields that turn

freely on driveline.

4. Connect the hydraulic hoses to tractor

ports in a sequence which is both familiar

and comfortable to the operator.

DANGER – Before applying

pressure to the hydraulic system, make

sure all connections are tight and hoses

and fittings have not been damaged.

Hydraulic fluid escaping under pressure

can have sufficient force to penetrate

skin, causing injury or infection.

CAUTION – Always wipe hose ends

to remove any dirt before connecting

couplers to tractor parts.

5

Page 8

Operation

http://hespareparts.com

5. Raise the jack stand and remount

horizontally on the storage bracket.

6. Lower the planter to the planting position

and check that the planter is level (front to

back and side to side). If the hitch height is

too high or too low, disconnect the planter

and adjust the hitch clevis in an up or down

position as necessary.

LEVELING THE PLANTER

For proper operation of the planter and row

units, it is important that the unit operate

level.

Unless the tractor drawbar is adjustable for

height, the fore and aft level adjustment must

be maintained by the position of the hitch

clevis. Holes in the hitch bracket allow the

clevis to be raised or lowered. When

installing clevis mounting bolt, tighten hex

nut to proper torque setting.

With the planter lowered to proper operating

depth, check to be sure the frame is level

fore and aft (front to back and side to side).

Recheck once the planter is in the field.

It is also important for the planter to operate

level laterally. Tire pressure must be

maintained at pressures specified.

TIRE PRESSURE

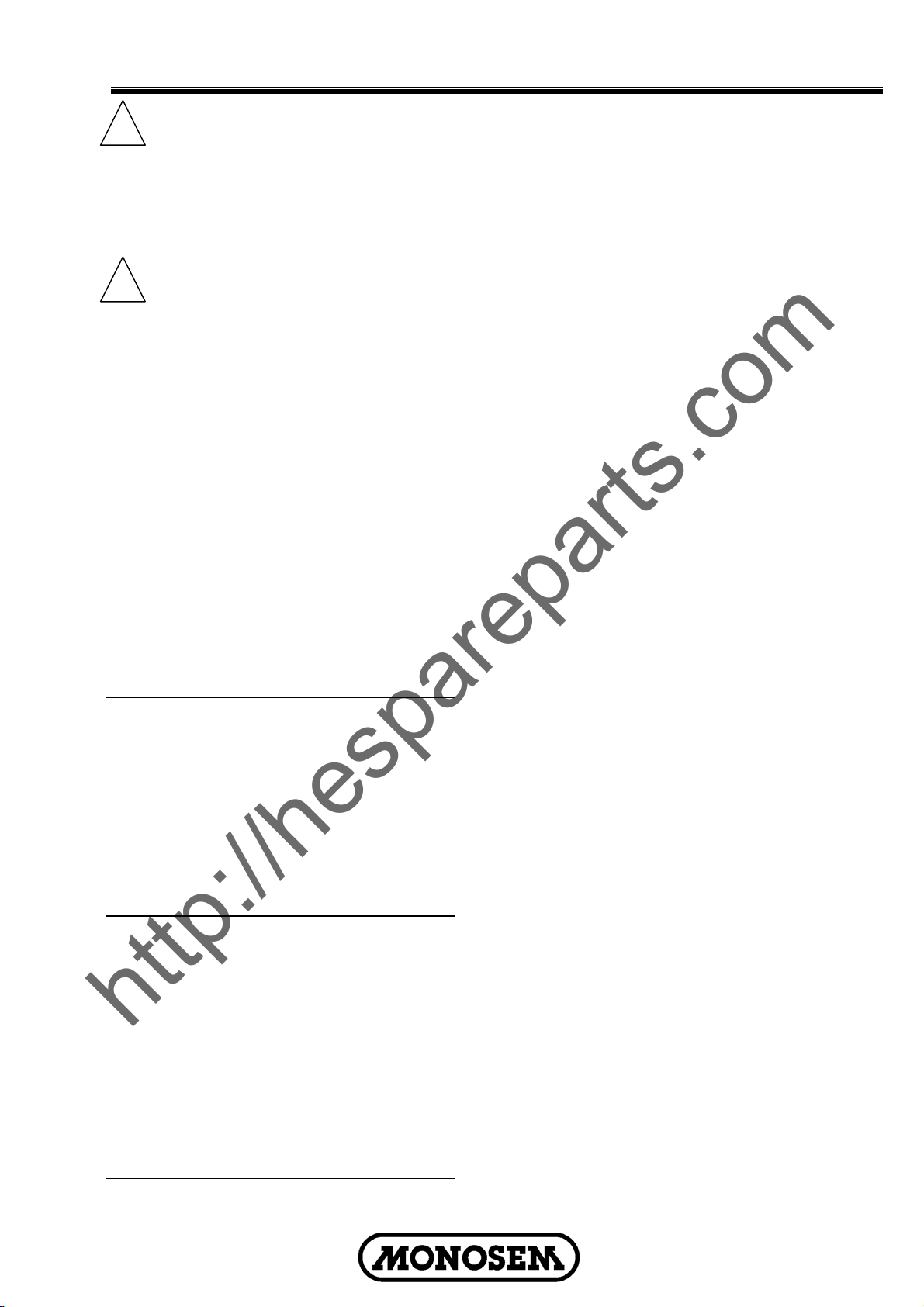

DANGER Rim and tire servicing

can be dangerous. Explosive separation

of a tire and rim parts can cause serious

injury or death.

Do not attempt to mount a tire unless you

have the proper equipment and

experience to perform the job. This

should only be done by properly trained

and equipped to do the job.

Maintain the correct tire pressure. Do not

inflate the tires above the recommended

pressure.

When inflating tires, use a clip-on air

chuck and extension hose long enough

to allow you to stand to one side, and not

in front of or over the tire assembly. Use

a safety cage to enclose the tire and

assembly when inflating.

Inspect tires and wheels daily. Do not

operate with low pressure, cuts, bubbles,

damaged rims or missing lug bolts and

nuts.

Tire pressure should be checked regularly

and maintained as follows :

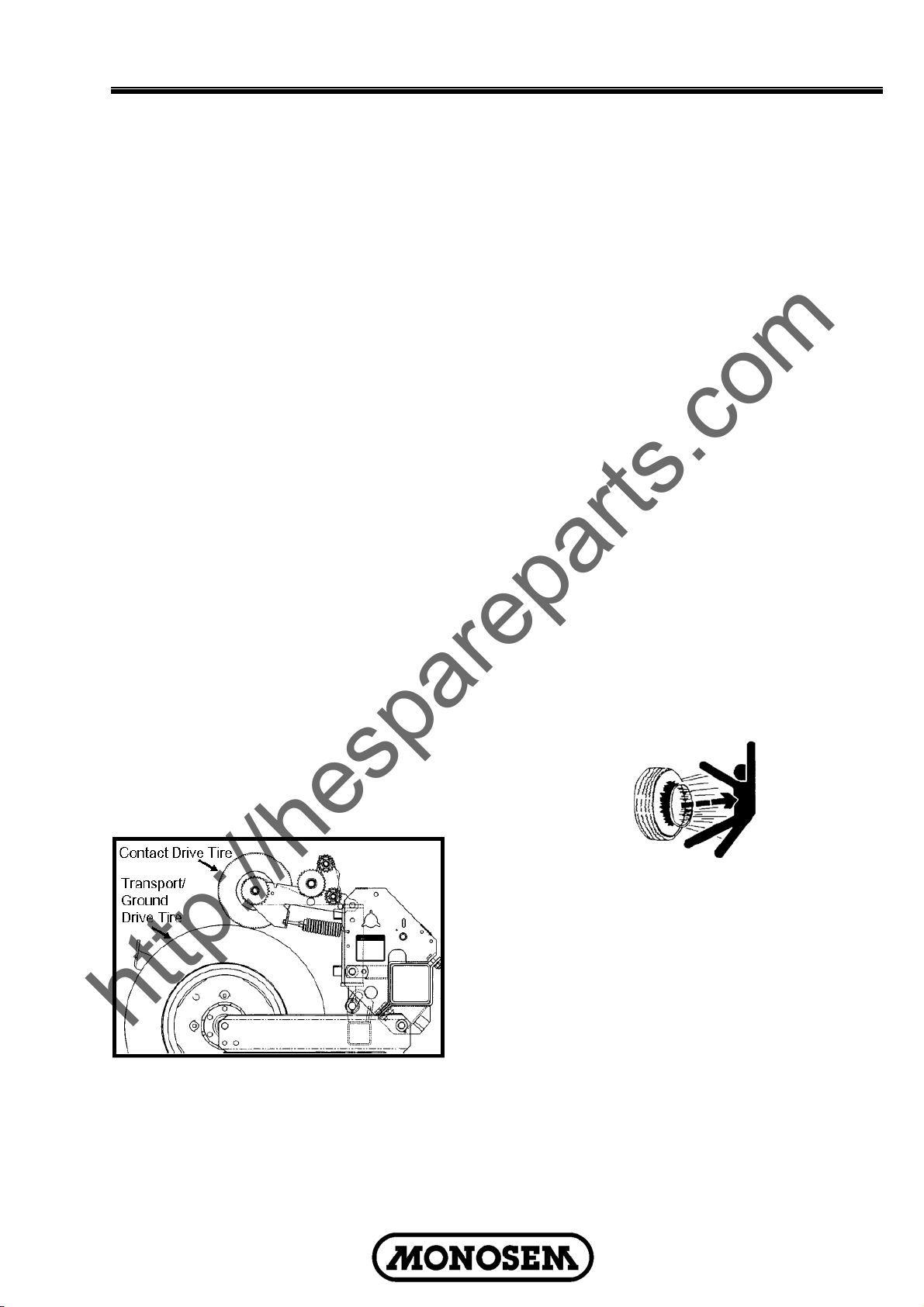

Transport Ground Drive : 7.50" x 20" - 40 psi

(2,7 bars)

Contact Drive : 4.10" x 8"- 60 psi (4 bars)

6

Page 9

Operation

http://hespareparts.com

OPERATING SPEED

The operating speed needs to be selected

as a function of :

- The desired consistency in the row

- The ground conditions

- The density of the seed

A high speed is not conducive to accuracy,

especially in rough or rocky conditions which

causes the unit to bounce.

Likewise, a high seed density may cause the

disc to rotate fast, burdening the metering.

It should also be noted, and especially for

corn, the misshapen and angular seeds are

difficult to sow regularly, especially at high

working speeds.

A base speed of 3 ½ to 4 ½ mph (5/7 km/h)

assures good results for most seeds in the

majority of conditions. However when

planting corn at lighter population more than

6” (15 cm) between the seed, 5/6 mph (8/10

km/h) is quite possible.

For planting of high seed population such as

peanuts, edible beans, and kidney beans,

best results can be obtained by not going

faster than ¾ mph (4,5/6 km/h).

STANDARD RATE DRIVE

Seed planting rate charts are based on the

standard rate drive. The standard rate drive

uses a 30 tooth sprocket on each contact

drive tire.

IMPORTANT : After each sprocket

combination adjustment, make a field

check to be sure you planting at the

desired rate.

7

Page 10

Operation

http://hespareparts.com

CONTACT DRIVE WHEEL SPRING

ADJUSTMENT

There are two down pressure springs on

each contact drive wheel. The down

pressure is factory pre-set and should need

no further adjustment.

The spring tension is set leaving 2 ¼"

between the spring plug and the bolt head.

TIRE SCRAPER

Due to the clearance between the wheel

assembly and the transport tire when a

planter is equipped with the 20" transport

tire, a tire scrapper should always be used.

This will help prevent a build-up of dirt/mud

between the wheel arm assembly and the

tire. Adjust the scrapper so it does not

contact the tire.

Standard 20" tire

RIDGE PLANTING

For ridge planting mount the 20" tires in the

lower rear holes in the ground drive wheel

arm to raise the bar height 3". Mount the

contact drive wheel arm and springs in the

lower set of mounting holes in the wheel

module mount and raise the hitch height to

maintain fore and aft levelness.

installation

For ridge planting

To raise bar height

Tire scraper

TRANSMISSION ADJUSTMENT

Planting population rate changes are made

at the end mounted transmission. The

planter is designed to allow simple, rapid

changes in sprockets to obtain the desired

planting population. By removing the lynch

pins on the hexagon shafts, sprockets can

be interchanged with those from the sprocket

storage rod bolted to the transmission.

Chain tension is controlled by a springloaded dual sprocket idler. The idler

assembly is adjusted with a ratchet arm. This

arm has a release position to remove spring

tension for replacing sprockets. The amount

of spring tension on the chain can be

controlled by the ratchet arm.

The planting rate chart on the following

pages of this section will aid you in selecting

the correct sprocket combinations.

Drive

Driven

8

Page 11

Operation

http://hespareparts.com

!

WARNING: Always make sure

safety/warning lights, reflectors and SMV

emblem are in place and visible prior to

transporting the machine on public

roads. In this regard, check federal,

state/provincial and local regulations.

!

WARNING: Always install safety

lockups on lift cylinders and make sure

wing lockup pins are in place to secure

wings at hitch.

TRACTOR PLANTING SEED

Planters are designed to operate within a

speed range of 2 to 8 mph. See “planting

and application rate charts”. Variations in

ground speed will produce variations in

rates.

NOTE : Due to a multitude of variables,

seed spacing can be adversely affected at

speeds above 5,5 mph.

METRIC CONVERSION TABLE

Multiply By To Get

Inches (in.) x 2.54 = centimeters (cm)

Inches (in.) x 25.4 = millimeters (mm)

Feet (ft.) x 30.48 = centimeters (cm)

Acres x 0.405 = hectares (ha)

Miles per hour x 1.609 = kilometers per

(mph) hour (Km/h)

Pounds (lbs.) x 0.453 = kilograms (kg)

Bushels (bu.) x 35.238 = liters (l)

Gallons (gal.) x 3.785 = liters (l)

Pounds per x 6.894 = kilopascals (kPa)

square inch (psi) (100 kPa = 1 bar)

Inch pounds x 0.113 = newtons-meters

(in. lbs.) (N•m)

Foot pounds x 1.356 = newtons-meters

(ft. lbs.) (N•m)

Centimeters x .394 = inches (in.)

(cm)

Millimeters x .0394 = inches (in.)

(mm)

Centimeters x .0328 = feet (ft.)

(cm)

Hectares (ha) x 2.469 = acres

Kilometers per x 0.621 = miles per hour

hour (Km/h) (mph)

Kilograms (kg) x 2.208 = pounds (lbs.)

Liters (l) x 0.028 = bushels (bu.)

Liters (l) x 0.264 = gallons (gal.)

Kilopascals x 0.145 = pounds per

(kPa) (100 kPa = 1 bar) square inch (psi)

Newtons-meters x 8.85 = inch pounds

(N•m) (in. lbs.)

Newtons-meters x 0.738 = foot pounds

(N•m) (ft. lbs.)

FIELD TEST

With any change of field and/or planting

conditions, seed size or planter adjustment,

we recommend a field test be made to

ensure proper seed placement and operation

of row units. See “Rate Charts”, “Checking

Seed Population”, and “Checking Granular

Chemical Application Rate” at end of this

section :

Check the planter for fore to aft and

lateral level operation. See “Leveling The

Planter”.

Check all row units to be certain they are

running level. When planting, the row

unit parallel arms should be

approximately parallel to the ground.

Check row markers for proper operation

and adjustment. See “Marker

Adjustment” and “Marker Speed

Adjustment”.

Check for proper application rates and

placement of granular chemicals on all

rows. See “Checking Granular Chemical

Application Rate”.

Check for desired depth placement and

seed population on all rows. See

“Checking Seed Population”.

After the planter has been field tested,

reinspect the machine :

Hoses and fittings

Bolts and nuts

Cotter pins and spring pins

Drive chain alignment

9

Page 12

Operation

http://hespareparts.com

TRANSPORT TO FIELD OPERATION

Hydraulic Wing Fold

WARNING : Be sure the planter is

on a level surface, fore and aft and side to

side. Avoid standing between the wing

and main frame when folding the planter.

Wing may swing suddenly.

SUMMARIZED TRANSPORT TO FIELD SEQUENCE

. With center lift cylinders retracted and lock ups in place

remove wing lock pins.

. Move selector valve to "fold" position.

. Hydraulically fold wings out.

. Swing wing locking bolts into place.

. Extend lift cylinders.

. Remove center section lift cylinder lockups.

. Lower planter.

. Tighten wing locking bolts.

. Release turnbuckle at center of planter.

. Move selector valve to "marker" position.

NOTE : Read the following information for more detailed

instructions.

1. If the wing lift tires are not retracted,

with the cylinder lockups in place on the four

center section lift cylinders, move the tractor

hydraulic lever to the lowering position until

the cylinders are fully retracted thus raising

the wing tires.

2. With the planter raised and the

cylinder lockups in place, remove the wing

lock pins at the marker support and hitch.

4. Move the tractor hydraulic lever and

fold the wings out to operating position.

5. Swing the wing locking bolts into

position to lock each wing.

6. Operate the hydraulic lever to extend

all the lift cylinders.

7. Remove the cylinder lockups from the

four center section lift cylinders and place

them in the storage position on the wheel

modules.

8. Lower the planter.

9. Using the special wrench which is

stored on the hitch of the planter, tighten the

¼" hex nuts to secure the wing locking bolts.

3. Position the selector handle on the

manual selector valve in the "fold" position.

10

10. Release the turnbuckle

located in the center of the planter frame,

using the special wrench, and fold it to one

side. Return wrench to the storage position

on the longue.

11. Move the selector handle on

the manual selector valve to the "marker"

position. (Remove pressure from the

hydraulic system before moving the selector

handle).

Page 13

Operation

http://hespareparts.com

MARKER SPEED ADJUSMENT

The marker hydraulic system includes two

flow control valves. One flow control valve

controls the lowering speed of both markers

and one controls the raising speed of both

markers. To adjust marker speed, loosen the

jam nut and turn the control(s) clockwise or

IN to slow the travel speed and counter

clockwise or OUT to increase the travel

speed. The flow controls determine the

amount of oil flow restriction through the

valves, therefore determining travel speed of

the markers.

MARKER ADJUSTMENT

To determine the correct length at which to

set the marker assemblies, multiply the

number of rows by the average row spacing

in inches. This provides the total planting

width. Adjust the marker extension so the

distance from the marker blade to the center

line of the planter is equal to the total

planting width previously obtained. Both the

planter and marker assembly should be

lowered to the ground when measurements

are being taken. The measurement should

be taken from the point where the blade

contacts the ground. Adjust right and left

marker assemblies equally and securely

tighten clamping bolts. An example of

marker length adjustment follows:

Number of rows x Row spacing inches = Dimension between

planter center line and marker blade.

16 Rows x 30" Spacing = 480" Marker Dimension

DANGER: The flow controls should be

properly adjusted before the marker

assembly is first put into use. Excessive

travel speed of the markers can be

dangerous and/or damage the marker

assembly.

NOTE: When oil is cold, hydraulics

operate slowly. Make sure all adjustments

are made with warm oil.

NOTE: On a tractor where the oil flow can

not be controlled, the rate of flow of oil

from the tractor may be greater than the

rate at which the marker cylinder can

accept it. The tractor hydraulic control

lever will have to be held until the

cylinder reaches the end of its stroke.

This occurs most often on tractors with

an open center hydraulic system.

On tractors with a closed center hydraulic

system, the tractor's hydraulic flow

control can be set so the tractor's detent

will function properly.

The marker blade is installed so the concave

side of the blade is outward to throw dirt

away from the grease seals. The spindle

bracket is slotted so the hub and blade can

be angled to throw more or less dirt. To

adjust the hub and spindle, loosen the 1/2"

mounting hardware and move the bracket as

required. Tighten bolts to the specified

torque.

IMPORTANT: A marker blade assembly

that is set at a sharper angle than

necessary will add unnecessary stress to

the complete marker assembly and

shorten the life of bearings and blades.

Set the blade angle only as needed to

leave a clear mark.

A field test is recommended to ensure the

markers are properly adjusted. After the field

test is made, make any minor adjustments

as necessary.

11

Page 14

Operation

http://hespareparts.com

PLANTER METERING UNIT NG PLUS 2

The NG Plus 2 metering unit in fig. 40 is

shown with standard features. Other options

are available for specific conditions or uses.

The drive chain is mounted as per fig. 41.

The individual disengaging of a metering unit

is possible by removing the lynch pin (rep.1)

of by disconnecting the vacuum hose.

The seed depth is adjusted by the

handwheel (rep.2) which changes the height

of the 2 depth wheels (rep.3) in relation to

the furrow disc openers (rep.4). A sticker

close to the handwheel, provided with a

gradual scale, ensures the uniformity of the

depth control on all row units of the planter.

The furrow opener and ground adjustment

system guarantees an accurate and regular

seed depth in all types of soil and conditions

because the depth wheels are positioned

perpendicular to the falling point of seeds.

The two rear press wheels (rep.5) affect only

the closing of the seed furrow. They float

independently and therefore do not have any

effect on the ground engaging. Their soil

pressure is regulated by the handwheel

(rep.6). This pressure has to be chosen

carefully in order to assure proper seed to

soil contact. Soil should be pressed over the

complete length of the row. This setting

depends on the type and humidity of the soil.

In order for the furrow disc opener to remain

properly cleaned, the 2 gauge wheels (rep.3)

have to touch (without pinching their outside

circumference). After starting up the planter,

the factory assembly may need

readjustment.

Adjust gauge wheel spacing by putting the

washers (rep.7) from one side of the

articulating arms to the other.

Adjust the pressure of the scrapers of discs

by tightening or loosening the bolts (rep.8).

Before and during each new planting

season, check if the seed tubes (rep.9) are

in good condition as consistent and regular

seeding will depend on this. Do not hesitate

to replace them if they are worn or damaged.

To replace them, remove pin (rep.10) after

removing the gauge wheel and furrow disc

opener on one side (Fig.42).

The function of clod removers (rep.11) is to

clear the surface of the soil but not to plow a

furrow. One use of the front brace of the clod

remover is to slice open hard soil and move

stones away from the track of the disc

opener. They need to be adjusted

accordingly. Using them in stony soils may

be a problem because they can cause

clogging and blocking. In this case it is better

to choose an assembly with a flexible

support bracket (fig. 43) which is efficient in

difficult soil conditions.

Fig.43

12

Page 15

Operation

http://hespareparts.com

2

7

6

4

35

11

Fig.40

10

8

9

Fig.41 Fig.42

13

Page 16

Operation

http://hespareparts.com

METERING BOX

7

6

5

The plastic wear gasket 5 on which the seed

disc rotates should be smooth and in good

condition. Under normal operating

conditions, it should be replaced only after

500 to 1000 ha (1250 to 2500 acres). The

metal brace 7 should be positioned with its

tab notched in the hole of the housing. The

outer edge of the plastic wear gasket is then

rotating , and is then held in position by cup

6 and 3 bolts. (Fig.33)

NOTE : Thoroughly clean the metering

box housing, before installing a new wear

gasket. Any residue left from previous

use will not allow the gasket to fit in the

proper position.

Fig.33

SUGGESTED SEED DISC USE

Crop Seed disc

Corn DC1850-Low population

DC2450-Medium population

DC3050-High population

Sunflower DC1225-Low population

(Oils & confection)

DC1825-High population

(Oils & confection)

14

Page 17

Operation

http://hespareparts.com

A

A sheet metal shutter 1 is mounted inside

the cover B. This shutter regulate the flow of

seeds coming from the hopper and provide a

constant and sufficient level in front of the

disc. According to the seed used, the shutter

as to be checked and adjusted at 2 different

positions before planting:

1. High position : For large seeds such as

corn , soybean, edible beans, peanuts,

cotton, etc.

2.Low position (fig.35) : For small seeds

such as sunflower, beet, sorghum, etc.

This position should also be used for large

seeds when the planter has to work for

several hundred meters (1000 or more) on

slopes of more than 20%.

The shutter is adjusted by lowering it after

loosening the two bolts 2. A small plastic

sheet 3 located under the shutter is also

used to limit the level of seeds in front of the

disc .

Before beginning your season, make sure

that it is in good condition.

B

3

2

2

4

A special metering box cover with a larger

opening (to improve the seed flow into the

seed chamber), a large discharge channel

(to avoid blockage) , and a special less

aggressive seed scraper (to avoid skips) are

available for the planting of large seeds such

as peanuts, kidney beans and large squash.

1

Fig.35

A special metal shutter is available for

planting small seeds such as cabbage ,

rape seed, etc. to reduce the seed flow into

the seed chamber.

A special ejector block maybe needed to

eliminate bridging in the discharger channel

in the cover for large peanuts and large

squash seed.

The ejector block 4 enables the seeds to fall

regularly. For this purpose, it is

recommended to check its conditions

periodically.

15

Page 18

Operation

http://hespareparts.com

METERING ADJUSTMENT

Two factors influence the degree of seed:

1.The position of the seed scraper in relation

to the holes of the disc. It is therefore

necessary to adjust the eight of the scraper

as needed for each seed type.

2.The degree of suction (depression) at the

seed disc. It is therefore necessary to adjust

the degree of suction to the weight of the

seed to be planted;

1

Fig.36

The (patented) MONOSEM system allows a

unique adjustment (fig. 36-37).

• To adjust the height of the scraper

and at the same time

• To adapt the degree of suction to the

weight and size of the seed.

1

2

Fig.37

When the indicator 1 is positioned to the “+”

(fig 36) it raises the scraper over the holes of

the disc and increases the degree of suction

(closing the size of the hole 2) . This may

cause doubles if raised too high.

When the indicator 1 is positioned to (fig 37).

It lower the scraper over the holes and

reduces the degree of suction (opening the

size of the hole 2) . This may cause skipping

if too low.

A control window in the cover allows you to

monitor the results.

16

Page 19

Operation

http://hespareparts.com

TRANSMISSION ADJUSTMENT

Planting population rate changes are made

at the end mounted transmission. The

planter is designed to allow simple, rapid

changes in sprockets to obtain the desired

planting population. By removing the lynch

pins on the hexagon shafts, sprockets can

be interchanged with those from the sprocket

storage rod bolted to the transmission.

Chain tension is controlled by a springloaded dual sprocket idler. The idler

assembly is adjusted with a ratchet arm. This

arm has a release position to remove spring

tension for replacing sprockets. The amount

of spring tension on the chain can be

controlled by the ratchet arm.

The planting rate chart on the following

pages of this section will aid you in selecting

the correct sprocket combinations.

OPTIONAL EQUIPMENT

An optional hydraulic drive for the turbofan is

available. You must then double check that

there is adequate oil flow for the turbofan to

run at 500 rpm. Use an rpm gauge to check,

placing it at the center of the lower pulley.

A vacuum gauge may also be mounted to

the turbofan. (The vacuum gauge is standard

equipment when ordering the hydraulic

drive).

17

Page 20

Operation

http://hespareparts.com

SOWING DISTANCES

Planting distances obtained with standard

assembly and sprocket system.

IMPORTANT : Make sure the chains are

tight and properly lubricated, and tires

are properly inflated.

The above indicated spacings are

theoretical and may vary from 5-10 %

depending on soil conditions.

Check proper working of the seed

metering, seed placement, spacing and

density when starting up and from time to

time during planting.

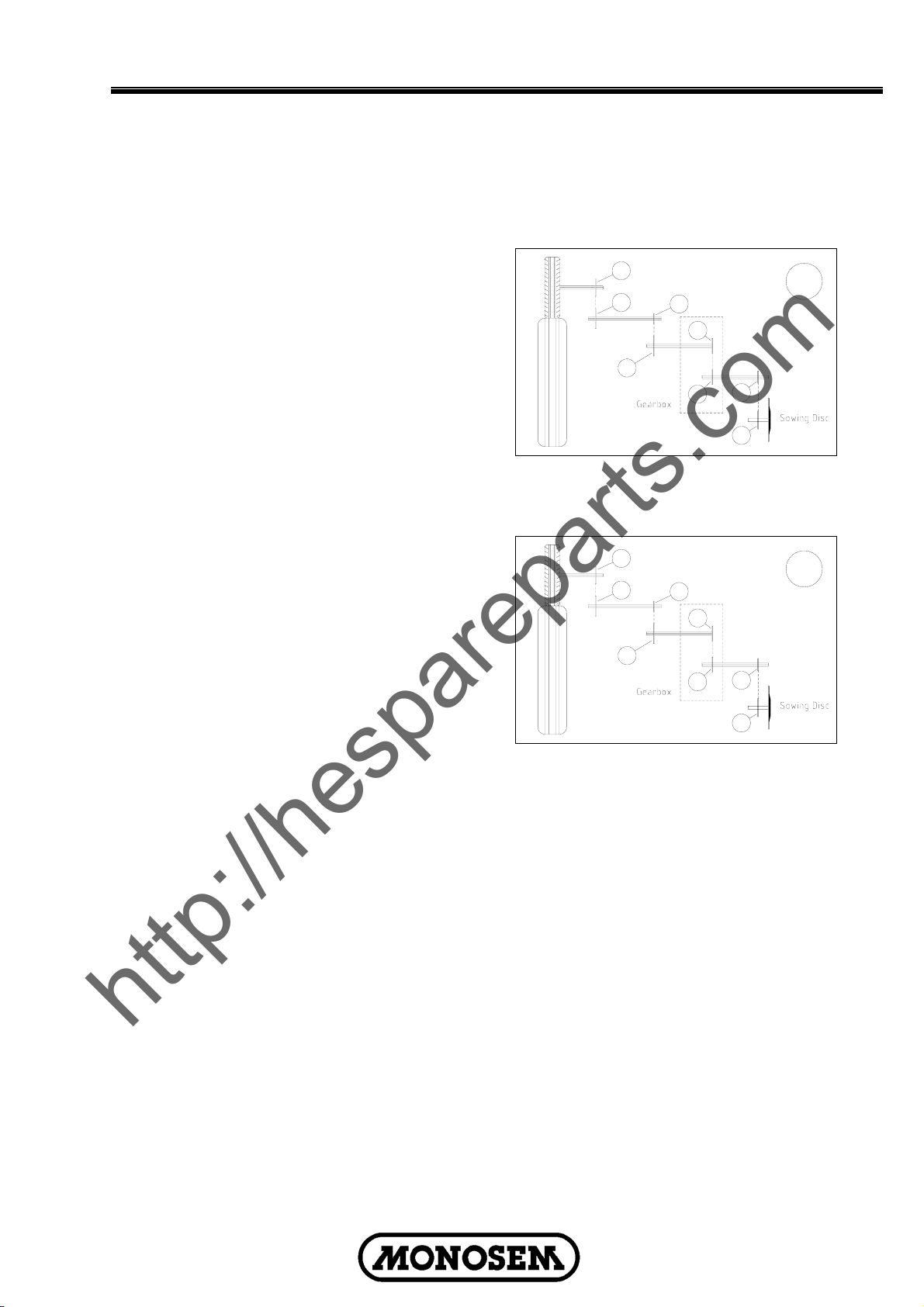

The following drawings show the two

possibilities of wheel unit mounting.

30 toothed drive sprocket with 23 toothed

driven sprocket:

8"

30

1

23

30

23 toothed drive sprocket with 30 toothed

driven sprocket:

8"

23

15

A

18

B

26

2

30

30

15

A

18

B

26

18

Page 21

Operation

http://hespareparts.com

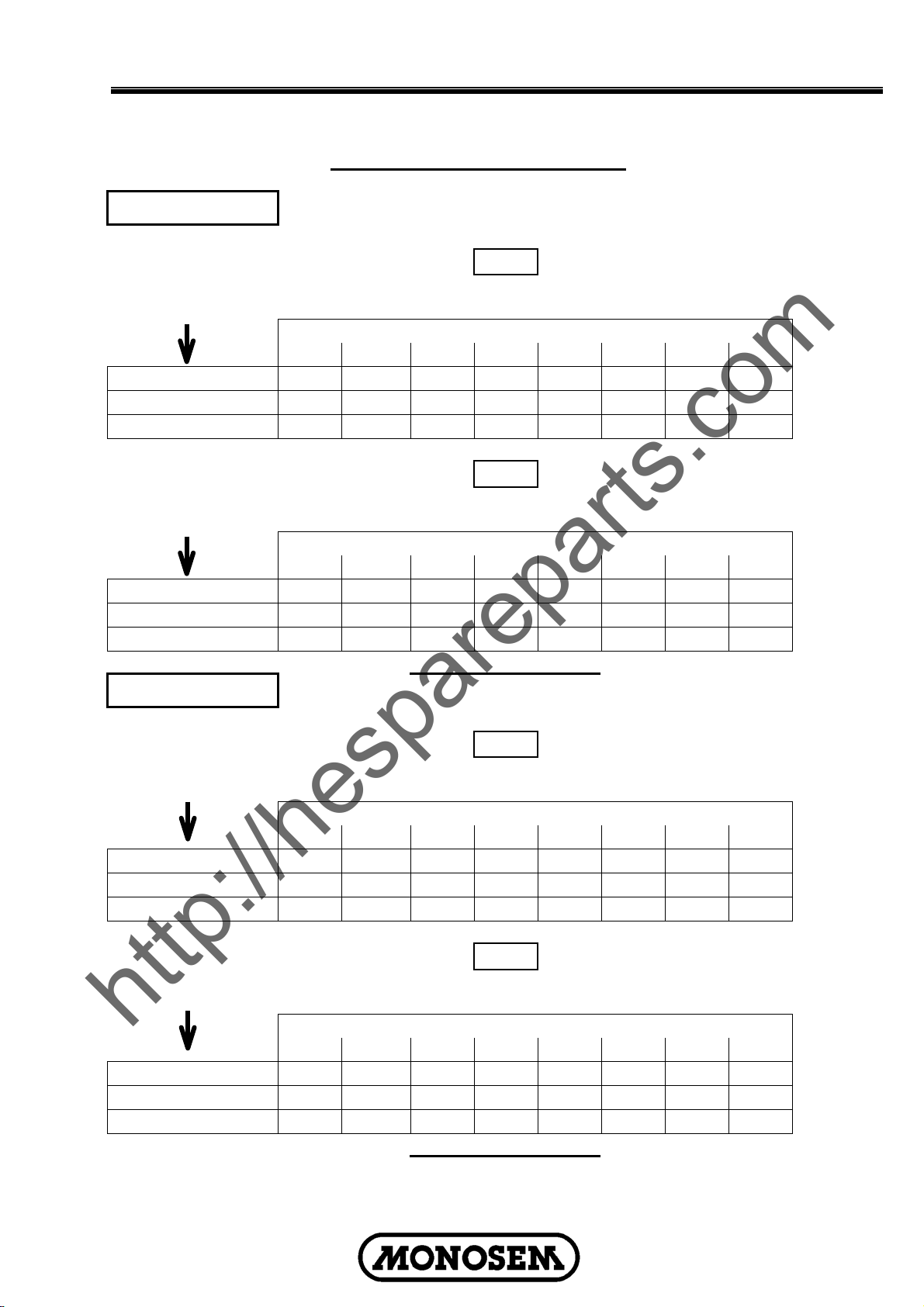

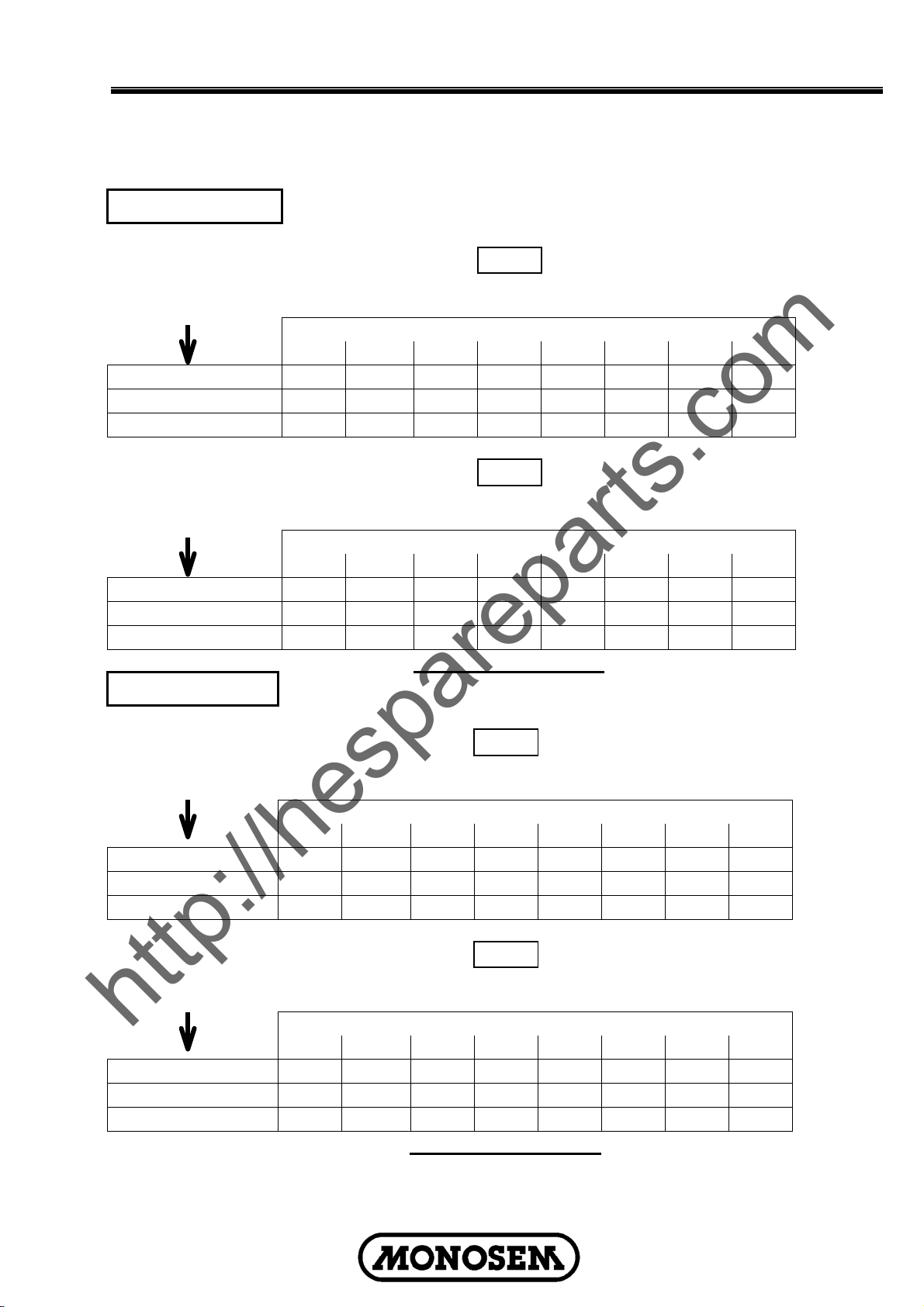

TRANSMISSION SELECTION

The seed spacing is shown in cm

B=28

Number of holes in

the seed disc

24 Sunflower

30 Corn

60 Soybean

Number of holes in

the seed disc

24 Sunflower

30 Corn

60 Soybean

Drawing N°1 30/23

A

27 25 24 23 21 19 17 15

28 28 28 28 28 28 28 28

B

12,7 13,7 14,3 14,9 16,4 18,1 20,2 22,9

10,2 11,0 11,5 12,0 13,1 14,5 16,2 18,3

5,1 5,5 5,7 6,0 6,5 7,2 8,1 9,2

Drawing N°2 23/30

27 25 24 23 21 19 17 15

A

28 28 28 28 28 28 28 28

B

21,7 23,4 24,4 25,4 27,8 30,8 34,4 39,0

17,3 18,7 19,5 20,3 22,3 24,6 27,5 31,2

8,7 9,4 9,7 10,2 11,1 12,3 13,8 15,6

B=27

Number of holes in

the seed disc

24 Sunflower

30 Corn

60 Soybean

Number of holes in

the seed disc

24 Sunflower

30 Corn

60 Soybean

Drawing N°1 30/23

A

28 25 24 23 21 19 17 15

27 27 27 27 27 27 27 27

B

11,8 13,3 13,8 14,4 15,8 17,4 19,5 22,1

9,5 10,6 11,0 11,5 12,6 14,0 15,6 17,7

4,7 5,3 5,5 5,8 6,3 7,0 7,8 8,8

Drawing N°2 23/30

A

28 25 24 23 21 19 17 15

27 27 27 27 27 27 27 27

B

20,1 22,6 23,5 24,5 26,8 29,7 33,2 37,6

16,1 18,0 18,8 19,6 21,5 23,7 26,5 30,1

8,1 9,0 9,4 9,8 10,7 11,9 13,3 15,0

19

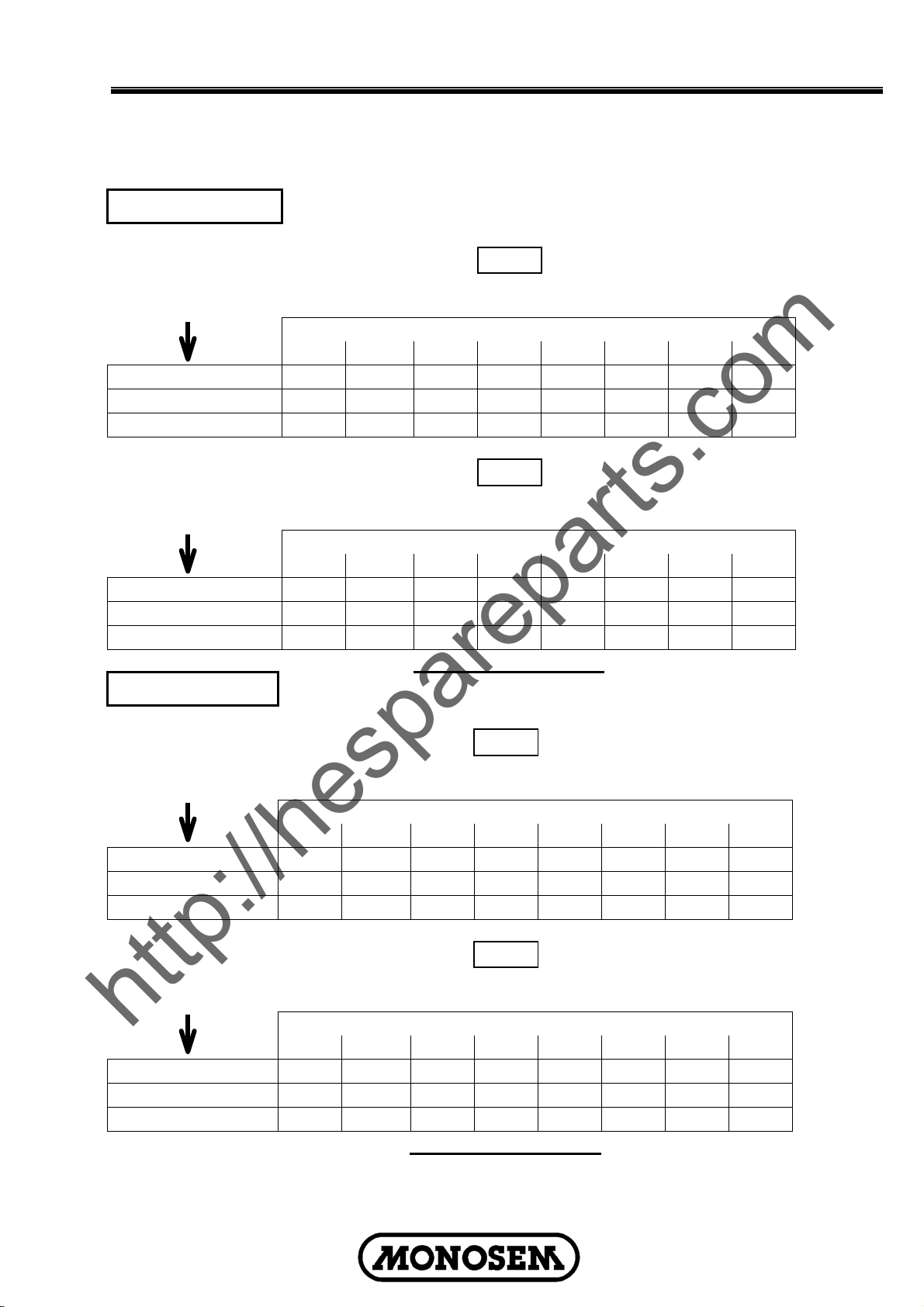

Page 22

Operation

http://hespareparts.com

B=25

Number of holes in

the seed disc

24 Sunflower

30 Corn

60 Soybean

Number of holes in

the seed disc

24 Sunflower

30 Corn

60 Soybean

Drawing N°1 30/23

A

28 27 24 23 21 19 17 15

25 25 25 25 25 25 25 25

B

11,0 11,4 12,8 13,3 14,6 16,1 18,0 20,5

8,8 9,1 10,2 10,7 11,7 12,9 14,4 16,4

4,4 4,5 5,1 5,3 5,8 6,5 7,2 8,2

Drawing N°2 23/30

28 27 24 23 21 19 17 15

A

25 25 25 25 25 25 25 25

B

18,6 19,3 21,8 22,7 24,9 27,5 30,7 34,8

14,9 15,5 17,4 18,2 19,9 22,0 24,6 27,8

7,5 7,7 8,7 9,1 9,9 11,0 12,3 13,9

B=24

Number of holes in

the seed disc

24 Sunflower

30 Corn

60 Soybean

Number of holes in

the seed disc

24 Sunflower

30 Corn

60 Soybean

Drawing N°1 30/23

A

28 27 25 23 21 19 17 15

24 24 24 24 24 24 24 24

B

10,5 10,9 11,8 12,8 14,0 15,5 17,3 19,6

8,4 8,7 9,4 10,2 11,2 12,4 13,9 15,7

4,2 4,4 4,7 5,1 5,6 6,2 6,9 7,9

Drawing N°2 23/30

28 27 25 23 21 19 17 15

A

24 24 24 24 24 24 24 24

B

17,9 18,6 20,0 21,8 23,9 26,4 29,5 33,4

14,3 14,8 16,0 17,4 19,1 21,1 23,6 26,7

7,2 7,4 8,0 8,7 9,5 10,6 11,8 13,4

20

Page 23

Operation

http://hespareparts.com

B=23

Number of holes in

the seed disc

24 Sunflower

30 Corn

60 Soybean

Number of holes in

the seed disc

24 Sunflower

30 Corn

60 Soybean

Drawing N°1 30/23

A

28 27 25 24 21 19 17 15

23 23 23 23 23 23 23 23

B

10,1 10,5 11,3 11,8 13,4 14,9 16,6 18,8

8,1 8,4 9,0 9,4 10,8 11,9 13,3 15,1

4,0 4,2 4,5 4,7 5,4 5,9 6,6 7,5

Drawing N°2 23/30

28 27 25 24 21 19 17 15

A

23 23 23 23 23 23 23 23

B

17,2 17,8 19,2 20,0 22,9 25,3 28,3 32,0

13,7 14,2 15,4 16,0 18,3 20,2 22,6 25,6

6,9 7,1 7,7 8,0 9,1 10,1 11,3 12,8

B=21

Number of holes in

the seed disc

24 Sunflower

30 Corn

60 Soybean

Number of holes in

the seed disc

24 Sunflower

30 Corn

60 Soybean

Drawing N°1 30/23

A

28 27 25 24 23 19 17 15

21 21 21 21 21 21 21 21

B

9,2 9,5 10,3 10,7 11,2 13,6 15,2 17,2

7,4 7,6 8,2 8,6 9,0 10,9 12,1 13,7

3,7 3,8 4,1 4,3 4,5 5,4 6,1 6,9

Drawing N°2 23/30

28 27 25 24 23 19 17 15

A

21 21 21 21 21 21 21 21

B

15,7 16,2 17,5 18,3 19,1 23,1 25,8 29,2

12,5 13,0 14,0 14,6 15,3 18,5 20,6 23,4

6,3 6,5 7,0 7,3 7,6 9,2 10,3 11,7

21

Page 24

Operation

http://hespareparts.com

Densities - Seed Population Chart

AVERAGE

SEED

SPACING (cm)

5

6

7

8

9

10

11

12

13

14

15

16

ROW SPACING (cm)

45 50 70 75 76,2 80

(30")

444444 400000 285714 266667 262467 250000

370370 333333 238095 222222 218723 208333

317460 285714 204082 190476 187477 178571

277778 250000 178571 166667 164042 156250

246914 222222 158730 148148 145815 138889

222222 200000 142857 133333 131234 125000

202020 181818 129870 121212 119303 113636

185185 166667 119048 111111 109361 104167

170940 153846 109890 102564 100949 96154

158730 142857 102041 95238 93738 89286

148148 133333 95238 88889 87489 83333

138889 125000 89286 83333 82021 78125

17

18

19

20

21

Seed population per ha :

D = Seed population per ha (Seed/ha)

I = Row spacing (m)

E = Seed spacing (m)

D = 10.000

I x E

Example : D = 10.000

0,75 x 0,13

130719 117647 84034 78431 77196 73529

123457 111111 79365 74074 72908 69444

116959 105263 75188 70175 69070 65789

111111 100000 71429 66667 65617 62500

105820 95238 68027 63492 62492 59524

= 102.564 Seed/ha

Seed spacing :

D = Seed population per ha (Seed/ha)

I = Row spacing (m)

E = Seed spacing (m)

E = 10.000

I x D

Example : D = 10.000

90.000 x 0,75

= 0,148 m (14,8 cm)

22

Page 25

Operation

http://hespareparts.com

FERTILIZER

Gearbox for fertilizer low adjustment. See

following page for adjustments.

Linking tube to be disconnected for the

folding of the planter.

175 litres hopper for 2 rows.

Double discs for fertilizer. To be

positionned at 6 – 8 cms from the sowing

line.

23

Page 26

Operation

http://hespareparts.com

FERTILIZER

I Set on A1 adjustment.

II Make 100 m

III Use the following formula :

10000

inter-row spacing (cm)

You obtain the weight/ha. And then you determine the column

on the chart corresponding to the ratio used.

Example

- weight calculated = 533 gr. On ratio 1

10000

76,2

The column

350 kg/ha according to the adjustment.

40 50 60

A1

45 60 70

B1

60 80 95

C1

70 90 110

D1

75 100 120

A2

80 105 130

E1

100 120 140

B2

110 140 165

F1

120 160 180

C2

140 180 210

D2

160 200 250

E2

200 250 300

F2

By means of an initial adjustment (A1) for a known surface area, calculate the minimum requirement

per hectare for the fertilizer used : 80-90-100-110 etc … kilo/ha. The table will then give the setting

(A1-B1-C1…) suitable for the required amount per hectare.

IMPORTANT

to different brands, temperature, humidity, etc… check your manual for procedure to measure your

fertilizer to the above chart.

WARNING

animals and soil. Handle with care and follow instructions of chemical manufacturer.

x weight calculated on one outlet (gr)

: - Inter-row spacing = 30" = 76,2 cm

x 533 = 70.000 gr/ha = 70 kg/ha

4 is used = 70 kg/ha, with a choice from 70 to

Requirement per Hectare for different fertilizers

– Fertilizer application rates can vary from the weight calculated in the above chart due

- Agricultural chemicals can be dangerous. Improper use can result in injury to persons,

4

70

80

110

125

135

145

160

190

210

240

280

350

80 90 100 110 120 130

90 105 115 125 140 150

120 140 160 175 190 205

140 160 180 195 215 230

150 175 190 210 230 250

160 185 205 230 250 270

180 205 230 250 275 300

215 245 270 300 325 350

235 270 300 330 360 390

270 310 340 380 410 445

315 360 400 440 480 520

390 450 500 550 600 650

24

Page 27

Operation

http://hespareparts.com

MICROSEM

The Microsem is ground driven, and the

output set by means of a transmission which

is unaffected by a change in planting speed.

The Microsem system is mounted to the

toolbar frame to reduce weight on the planter

unit. Each Microsem hopper has an 18 lt.

capacity

Setting of the output = the output is a

function of the number of rotations of the

spindle of the metering boxes. The drive

system is a central drive system which is set

primarily with the double sprocket and the

interchangeable sprockets the Microsem

setting chart will assist with the setting and

also indicates the sprockets to be used.

Gearbox assembly

Microsem hopper assembly

Microsem hopper assembly

Microsem tube assembly

ATTENTION : Avoid moisture

contamination. This unit should be used

only with microgranulars and not with

powders or granulates. Agricultural

chemicals can be dangerous. Improper

use can result in injury to persons,

animals and soil. Handle with care and

follow instructions of chemical

manufacturer.

25

Page 28

Operation

http://hespareparts.com

MICROSEM ADJUSTMENT

1. Put the product in a 2 outlet microgranulator.

2. Position in smallest ration : A = 12

B = 30 (ratio = 0.24- see here under)

C = 12

3. Make 100 m.

4. Weigh the product recuperated on the two outlets.

5. Use the following formula :

Output = 10 x quantity weighed (g.)

Inter-row (cm) x 2

Example : Inter-rows = 60 cm Output = 10 x 60

Quantity weighed = 60 g 60 x 2

If you require 10 Kg/ha, choose the ratio

2 x 0.24 = 0.48

i.e. : A = 12

If you require 15 Kg/ha, choose the ratio

3 x 0.24 = 0.72

i.e. : A = 12

B = 15

C = 12

Note : Checking when starting up remains essential.

Possible combinations of the sprockets A-B-C Obtained ratios

12-35-12 teeth 0.21

12-32-12 teeth 0.22

12-30-12 teeth 0.24

12-25-12 teeth 0.29

12-22-12 teeth 0.33

12-20-12 teeth 0.36

12-18-12 teeth 0.40

12-16-12 teeth 0.45

12-15-12 teeth or 12-25-20 0.48

12-23-20 teeth 0.51

12-22-20 teeth 0.54

12-21-20 teeth 0.57

12-12-12 teeth 0.60

25-24-12 teeth 0.63

12-18-20 teeth 0.66

25-22-12 teeth 0.68

12-10-12 teeth 0.72

25-20-12 teeth 0.75

12-15-20 teeth 0.80

25-18-12 teeth 0.83

25-16-12 teeth 0.94

25-15-12 teeth or 12-12-20 1

25-22-20 teeth 1.13

12-10-20 teeth 1.2

25-12-12 teeth 1.25

25-18-20 teeth 1.4

25-10-12 teeth 1.5

25-15-20 teeth 1.66

25-12-20 teeth 2.08

25-10-20 teeth 2.5

The interchangeable sprockets B in bold characters are delivered as standard (12-15-18-22-

25-30 teeth), those in ordinary characters are delivered on request (10-11-13-14-16-17-19-20-2123-24-26-27-32-35 teeth).

(N° Microsem shaft rotations for 1 leading shaft rotation)

= 5 Kg/ha

B = 15

The nearest standard

C = 20

Less product

More product

26

Page 29

Lubrication

http://hespareparts.com

WHEEL BEARINGS

All wheel bearings should be repacked

annually and checked for wear. This applies

to all drive wheels, transport wheels and

marker hubs. To check for wear, lift the

wheel off the ground. Check for endplay in

the bearings by moving the tire in and out.

Rotate the tire to check for roughness in the

bearings. If bearings sound rough, the hub

should be removed and the bearings

inspected and replaced if necessary. See

“Wheel Bearing Lubrication or

Replacement”. To repack wheel hubs, follow

the procedure outlined for wheel bearing

replacement with the exception that bearings

and bearing cups are reused.

!

DANGER: Always install safety

lockups or lower to the ground before

working under or around the machine.

NOTE: Numbers on below illustration

correspond to photos on following pages

showing lubrication frequencies.

GREASE FITTINGS

Those parts equipped with grease fittings

should be lubricated at the frequency

indicated with an SAE multipurpose type

grease. Be sure to clean the fitting

thoroughly before using grease gun. The

frequency of lubrication recommended is

based on normal operating conditions.

Severe or unusual conditions may require

more frequent attention.

1

7 7

3

6 4

5

1

3

2

2 2 2

2 2 2 2

27

Page 30

Lubrication

http://hespareparts.com

The following pages show the locations of all

lubrication points. Proper lubrication of all

moving parts will help ensure efficient

operation of your MONOSEM planter and

prolong the life of friction producing parts.

!

lockups or lower to the ground before

working under the machine.

LUBRICATION SYMBOLS

Lubricate at frequency indicated with an SAE

multipurpose type grease.

Lubricate at frequency indicated with a high

quality SAE 10 weight oil or a quality spray

lubricant.

DANGER : Always install safety

Weekly

Weekly

Daily

Daily

DRIVE CHAINS

All transmission and drive chains should be

lubricated daily with a high quality SAE 10

weight oil or a quality spray lubricant.

Extreme operating conditions such as dirt,

temperature or speed may require more

frequent lubrication. If a chain become stiff, it

should be removed, soaked and washed in

solvent to loosen and remove dirt from the

joints. Then soak the chain in oil so the

lubricant can penetrate between the rollers

and bushings.

Contact drive chain

Jack shaft chain

28

Page 31

Lubrication

http://hespareparts.com

1.Marker Assemblies : 3 Greasers per

assembly.

4. Center frame flex pin : 4 Greasers.

2. Wheel pivots : 2 Greasers per wheel

module.

3. Wing hinges : 2 Greasers per wing.

5. Hitch flex pin : 3 Greasers.

6. Turnbuckle : 1 Greaser.

7. Transmission Assemblies: 1 Greaser

(Idler).

29

Page 32

Maintenance

http://hespareparts.com

MARKER SEQUENCING/FLOW CONTROL

VALVE INSPECTION

The valve block assembly consists of the

marker sequencing and flow control valves in

one assembly. The sequencing valve portion

consists of a chambered body containing a

spool and series of check valves to direct

hydraulic oil flow. Should the valve

malfunction, the components may be

removed for inspection.

1. Remove valve block assembly from

planter.

2. Remove detent assembly and port

adapter assemblies from rear of valve

block.

IMPORTANT: Damage to the spool may

occur if the detent assembly and port

adapter assemblies are not removed prior

to removal of the spool.

3. Remove plug from both sides of valve

block and remove spool.

4. Inspect all parts for pitting, contamination

or foreign material. Also check seating

surfaces inside the valve. Replace any

parts found to be defective.

5. Lubricate spool with a light oil and re-

install. Check to be sure spool moves

freely in valve body.

IMPORTANT: Make sure correct check

ball(s) and spring are installed in each

valve bore upon reassembly.

A flow control valve is located on each side

of the block assembly. The flow control

valves should be adjusted for raise and

lower speed as part of the assembly

procedure or upon initial operation. If the

valve fails to function properly or requires

frequent adjustment, the needle valve should

be removed for inspection. Check for foreign

material and contamination. Be sure needle

moves freely in adjustment screw. Replace

any components found to be defective.

NOTE: When oil is cold, hydraulics

operate slowly. Make sure all adjustments

are made with warm oil.

30

Page 33

Maintenance

http://hespareparts.com

TROUBLE SHOOTING AND CAUSES

Excessive skipping :

• Transfer scraper too low (incorrect

setting on indicator).

• Transfer scraper is bent (no flat).

• Seed disc is bend or worn.

• Transfer scraper is dirty with chemical

product.

• Plastic wear surface of metering box

warped or used up.

• Holes of seed disc too small (do not

match).

• Holes of seed clogged (sugarbeets,

rapeseed, cabbage). To be double

checked from time to time.

• Excessive working speed.

• Defective vacuum hoses.

• Insufficient vacuum suction.

• PTO speed is to low.

• Foreign material mixed with seed.

• Seed blockage in the hopper (seed

treatment product too moist).

• Fan belt is too loose.

Excessive Doubling :

• Transfer scraper too high (bad setting on

indicator).

• Transfer scraper worn.

• Holes seed disc too large (do not fit).

• Excessive PTO speed.

• Excessive working speed.

• Seed level too high in the metering box.

Irregular Seeding (skipping-doubles) :

• Excessive working speed.

• Holes of seed disc too large (cut off

seeds).

• Field are too steep.

• Shutter adjusted incorrectly.

• Ejector is damaged.

Irregular spacing :

• Excessive working speed.

• Soil too wet and stricking to drive wheel

tires.

• Incorrect tire pressure

• Shutter adjusted incorrectly.

Safety slipcluch is actived :

• Seizing of metering box

• Foreign material in the seed.

• Blockage in transmission units.

Fertilizer :

• Foreign material in fertilizer.

• Clods/clumps in fertilizer.

• Clogging of outlet or chute caused by

moisture.

• Auger is defective (warped).

Microsem (Output varies between chutes

and cases) :

• Foreign material mixed with product.

• Attention : moisture in product.

• Improper assembly of metering unit

(auger reversed).

• Outlet chute unit warped.

• Hose clogged because too long or bent.

31

Page 34

Maintenance

http://hespareparts.com

32

Page 35

Maintenance

http://hespareparts.com

* Operate hydraulics slowly to accentuate the problem . Rephase after each lowering cycle.

33

Page 36

Maintenance

http://hespareparts.com

MARKER BEARING LUBRICATION OR

REPLACEMENT

1. Remove marker blade.

2. Remove dust cap from hub.

3. Remove cotter pin, nut and washer.

4. Slide hub from spindle.

5. Remove bearings and cups and discard

if bearings are being replaced. Clean hub

and dry. Remove bearings only and not

cups if repacking.

6. Press in new bearing cups with thickest

edge facing in. (Bearing replacement

procedure only.)

7. Pack bearings with heavy duty wheel

bearing grease thoroughly forcing grease

between roller cone and bearing cage.

Also fill the space between the bearing

cups in the hub with grease.

8. Install rubber seal into grease seal. Place

inner bearing in place and press in new

rubber seal/grease seal.

9. Clean spindle and install hub.

10. Install outer bearing, washer and slotted

hex nut. Tighten slotted hex nut while

rotating hub until there is some drag.

This assures that all bearing surfaces are

in contact. Back off slotted nut to nearest

locking slot and install cotter pin.

11. Fill dust caps approximately 3/4 full of

wheel bearing grease and install on hub.

12. Install blade and dust cap retainer on

hub and tighten evenly and securely.

WHEEL BEARING LUBRICATION OR

REPLACEMENT

1. Raise tire clear of ground and remove

wheel.

2. Remove double jam nuts and slide hub

from spindle.

3. Remove bearings and cups and discard

if bearings are being replaced. Clean hub

and dry. Remove bearings only and not

cups if repacking.

4. Press in new bearing cups with thickest

edge facing in. (Bearing replacement

procedure only.)

5. Pack bearings with heavy duty wheel

bearing grease thoroughly forcing grease

between roller cone and bearing cage.

Also fill the space between the bearing

cups in the hub with grease.

6. Place inner bearing in place.

7. Clean spindle and install hub.

8. Install outer bearing and jam nut. Tighten

jam nut while rotating hub until there is

some drag. This assures that all bearing

surfaces are in contact. Back off jam nut

1/4 turn or until there is only slight drag

when rotating the hub. Install second jam

nut to lock against first.

9. Install wheel on hub and tighten evenly

and securely.

34

Page 37

Maintenance

http://hespareparts.com

HYDRAULIC SYSTEM SCHEMATIC Planter Raising

HYDRAULIC SYSTEM SCHEMATIC Planter Lowering

35

Page 38

http://hespareparts.com

Page 39

http://hespareparts.com

SPARE PARTS

Page 40

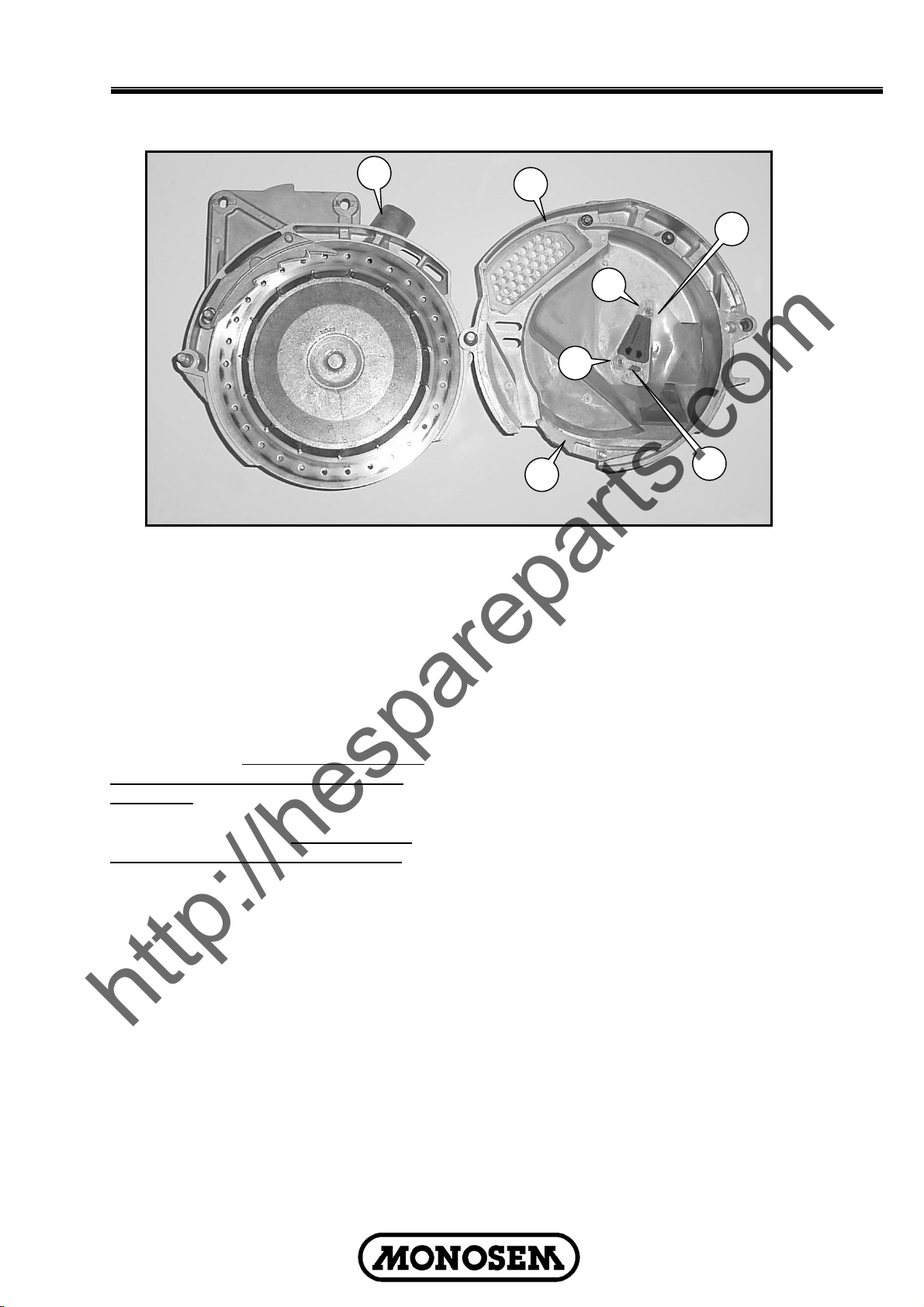

EXTRA HIGHT OUTPUT TURBOFAN

http://hespareparts.com

38

FR

Page 41

EXTRA HIGHT OUTPUT TURBOFAN

http://hespareparts.com

PART NO. DESCRIPTION

4240 SUPPORT FRAME EXTRA HI-OUTPUT TURBOFAN

4241 TURBOFAN HOUSING DRIVE BELT SIDE

4242 TURBOFAN HOUSING MANIFOLD SIDE

4243 FRAME BAND, EXTRA HI-OUTPUT TURBOFAN

4244 TURBOFAN BLADE, EXTRA HI-OUTPUT TURBOFAN

4245 SUPPORT DISC, EXTRA HI-OUTPUT TURBOFAN

4246 SNAPRING

4247 BUSHING

4248 SPINDLE

4249 PULLEY BELT, 540 RPM

4249.1 PULLEY BELT, 1000 RPM

4250 COVER SHIELD

4251 BEARING, UPPER SPINDLE (62072RS)

4252 BEARING, UPPER SPINDLE (63072RS)

4404.A EXTRA HI-OUTPUT TURBOFAN SUPPORT BRACKET

4405.A SPINDLE WITH ADAPTOR

4407 BEARING 62 MM (62062RS)

4408 BEARING 72 MM (63062RS)

4409 SNAPRING (LARGE)

4411 BUSHING

4412.A PULLEY 500 RPM 11 ⅜” DIA.

4412.1A PULLEY 1000 RPM 5 ⅞” DIA.

4429.A OUTPUT SHIELD

4434.3 SAFETY SHIELD

4437 LOCK KEY 8X7X40

4439.A LOCK KEY 6X6

4440 BOLT TO ADJUST BELT TENSION

4450 MANIFOLD, 12 HOLE

4453 HOSE CLAMP

4454 VACUUM HOSE, SPECIFY LENGTH

9525 END CAP, SUPPORT FRAME

31X412 WASHER

31X413 WASHER

FR

39

Page 42

HYDRAULIC DRIVE

http://hespareparts.com

PART NO. QTY. DESCRIPTION

4988 2 PUSH PULL CMC ½

4989 1 MGCYL FITTING – ½ X FJ ⅞

4990 1 COUPLING SLEEVE

4991 2 BLOCK FOR STANDARD TURBOFAN

4992 1 HYDRAULIC MOTOR BRACKET

4994 1 HYDRAULIC MOTOR WITH VALVE 59 CC – FTA0027

4995 1 UNIDIRECTION CHOKE ½

4996 2 HOSE ½ LG.4 M

4997 2 UNION MSAE ¾ X MLIC ⅞

4998 1 UNION MGCYL ½ X MJ ⅞

4999 2 UNION UM 15L X ½ GCYL NU

5000 2 BUSHING BS ½

40

FR

Page 43

PLANTING UNIT – NG PLUS 2

http://hespareparts.com

FR

41

Page 44

PLANTING UNIT – NG PLUS 2

http://hespareparts.com

PART NO. DESCRIPTION

4502.S U BOLT, 7X7

5021 BUSHING (B25)

5681.B SCRAPER SPRING, TENSION

6090 SNAPRING 6 MM

6202 COLLAR BRACE FOR COVER

6463 PIN, 6 MM DIA. X 65 MM LENGTH

6779 BUSHING SELF-LUBRICATING

6795 WING NUT, 8 MM

6915 SNAPRING, 30 MM

6963 PIVOT PIN REAR, LOWER

PARALLEL LINKAGE

6965 PIVOT PIN FRONT, UPPER

PARALLEL LINKAGE

6967.7 CLAMP FACING, 7X7

6972.1 SAFETY CLUTCH

6998 SPRING

7012.DA REMOVAL RIGHT-HAND SPINDLE

7012.GA REMOVAL LEFT-HAND SPINDLE

7014.A BEARING

7048.A BUSHING, SHOULDERED

7049 SPRING

7064.C MAIN FRAME, NG PLUS 2

7065 INTERCHANGEABLE CAST POINT

7065.A V-SLICE INSERT

7065.S V SHOE INSERT, SMALL SEED

7067 SPACERS FOR UNIT LOCK UP

7068.CO OPENING DISC COMPLETE

7068 OPENING DISC Ø380 MM

7010.A DISC HUB, USES 6X22 RIVETS

7014.A DISC BEARING (3204-2RS)

7015.A WASHER (6204ID)

7069.A ADJUSTABLE BLOCK FOR DEPTH

CONTROL

7070 SWING BRACKET

7076 ROD FOR PRESSURE

ADJUSTMENT

7077.2 PLASTIC HOPPER, 60 L

7078 WIRESTOP DEPTH ROD

7079 BLANK TUBE

7079.2 STANDARD TUBE WITH SENSOR

7079.1 STANDARD TUBE ONLY

D1700270S1 STANDARD SENSOR ONLY

7079.2S STANDARD TUBE WITH SENSITIVE

SENSOR

7079.4 TUBE FOR SMALL SEED ONLY

D2440891S1 SENSITIVE SENSOR ONLY

7079.3S PEANUT TUBE WITH SENSOR

7079.3 PEANUT TUBE ONLY

D1700270S1 STANDARD SENSOR ONLY

7083 HANDWHEEL DEPTH CONTROL

7084.1 RIGHT OUTSIDE SCRAPER

7084.2 LEFT OUTSIDE SCRAPER

7085.DA INSECTICIDE DROP TUBE, RIGHT

7085.GA INSECTICIDE DROP TUBE, LEFT

7086 PIN SEED TUBE

7087.A PIN FOR ADJ. BLOCK DEPTH

CONTROL, USES TWO 5X40 SPLIT

PINS

7089 SMALL CHAIN SHIELD

7090.A CHAIN GUARD

7091 HAIR PIN

7094 BUSHING

7095 PIVOT PIN

7096 CHAIN ROLLER

7097 UPPER PARALLEL LINKAGE ARM

7098 LOWER PARALLEL LINKAGE ARM

7099 PIVOT PIN REAR, UPPER

7100 SELF-LUBRICATING BUSHING

7101 FRONT BRACE CLOD REMOVER

7102.A CLOD REMOVER BRACKET

PART NO. DESCRIPTION

7103.A CLOD REMOVER

7104.CO LID PLASTIC HOPPER, WITH

7104.2 SPRING CLIP

7105 SPACERS FOR UNIT

7106 METAL HANDLE FOR UNIT LOCK

7106.ASY HANDLE FOR UNIT LOCK UP

7107 PLASTIC HANDLE FOR UNIT LOCK

7108 BUSHING

7109 CHAIN TIGHTENER

7114 DRIVE CHAIN METERING UNIT

(124 LINKS)

7124 UNIT STOP

7125 SEED CHUTE

7127 THREADED ROD

7130.BASY UNIT LOCK UP ASSEMBLY

7130.A UNIT LOCK UP

7066 BUSHING

7136 SPRING

7262.A REAR SPACER

7269 INTERMEDIATE PRESS WHEEL, SS

7271 BRACKET, INTERMEDIATE PRESS

7272 BRACKET, SCRAPER PIVOTING

7273 BRACKET, SCRAPER MOUNTING

7274 SCRAPER GREENFLEX

7275 SHOULDERED BOLT, BRACKET

7276 LOCKUP STOP

7278 RETAINING RING, BEARING

11579 BEARING (30X55X13)

11580 SNAPRING (I55)

PARALLEL LINKAGE ARM

SPRING CLIP

UP

UP

W/HANDLE

WHEEL

PIVOTING

42

FR

Page 45

PLANTING UNIT – NG PLUS 2

http://hespareparts.com

HARDWARE :

F38664 HEX METRIC 10X70

F40166 HEX NUT, 10 MM

10170015 2,5X5 COTTER PIN

10502012 10X15 BOLT

10502016 10X25 BOLT

10511007 6X100 BOLT

10511064 8X70 BOLT

10512018 10X35 BOLT

10512019 10X40 BOLT

10512027 10X100 BOLT

10512029 10X120 BOLT

10512054 12X70 BOLT

10512059 12X120 BOLT

10530094 6X20 BOLT

10170065 5X30 COTTER PIN

10170067 5X40 COTTER PIN

10172090 6X25 ROLL PIN

10172091 6X30 ROLL PIN

10176004 6X22 RIVET

10620095 10X27X2 WASHER

10621026 13X18X2 (12X18X2) WASHER

10622024 16.5X26X1 (16X26X1) WASHER

10622026 16.5X20X2 (16X26X2) WASHER

10622052 17X50X1 (16X50X1) WASHER

20016010 7X41 WASHER

GAUGE WHEEL :

7072.DF GAUGE WHEEL ARM, RIGHTHAND

7072.GF GAUGE WHEEL ARM, LEFTHAND

7073.N NYLON GAUGE WHEEL

COMPLETE

7073.2 TIRE ONLY

7122.D GAUGE WHEEL SCRAPER,

RIGHT HAND

7122.G GAUGE WHEEL SCRAPER,

LEFT HAND

900125 BEARING, 40 MM

30513015 RIGHT-HAND 16X80 BOLT

30513115 LEFT-HAND 16X80 BOLT

ADJUSTABLE CLOSING WHEEL :

7071.A TENSION ROD

7074.NASY COMPLETE ADJ. CLOSING

WHEEL W/BRACKET

7074.N COMPLETE ADJ. CLOSING

WHEEL

7074.1B HALF ADJ. CLOSING WHEEL

7074.2 TIRE, CLOSING WHEEL, 1X12

7080.B BRACKET ADJ. CLOSING

WHEEL

7082 HANDWHEEL PRESSURE

CONTROL

7259 SPRING

7260 STOP WASHER

7261 NUT

F38709 12X45 BRACKET MOUNTING

BOLT

F40165 12 MM HEX NUT

F13005 HSC ¼ - 20X1Z5

10621046 13X27X2 WASHER

900125 BEARING, 40 MM

900159 BUSHING

30513015 RIGHT-HAND MOUNTING

BOLT

30513115 LEFT-HAND MOUNTING BOLT

FR

43

Page 46

METERING BOX – NG PLUS

http://hespareparts.com

44

FR

Page 47

METERING BOX – NG PLUS

http://hespareparts.com

PART NO. DESCRIPTION

4329.A SNAPRING

5692 WING NUT, 10 MM

6077 LYNCH PIN

6089 RUBBER RING

6090 SNAPRING 6 MM

6092 SPRING (R132)

6200.A HOUSING FOR METERING BOX

ONLY

6201 COVER

6202 COLLAR BRACE FOR COVER

6203.A PLASTIC INSERT

6204.A BRONZE INJECTOR BLOCK

ASSEMBLY WITH 6X10 SCREW

6205 CONTROL WINDOW

6206 TIGHTENING CAP

6207 SHAFT METERING BOX

6208 TIGHTENING ROD COVER

6209.A BRACE FOR PLASTIC INSERT

6210 PRESSURE PIN SCRAPER

6211 STANDARD SCRAPER

6211.2A SCRAPER USE WITH PEANUTS,

LARGE SEED

6212.A AGITATOR, BRASS (STANDARD)

6213 SNAPRING (E20)

6214 TRAP DOOR

6215 SPRING FOR TRAP DOOR

6216 FIXED PIN SCRAPER

6217 ADJUSTABLE PIN SCRAPER

6218 PRESSURE SPRING

6219 PIN CONTROL WINDOW

6221 BEARING

6222 HARDWARE FOR 6212.A

AGITATOR

6225 CASING FOR EJECTOR BLOCK

SPRING

6227 SPRING, SELECTOR HANDLE

6228 SELECTOR HANDLE

6230.A REMOVABLE PLUG

6232 GASKET INSIDE METERING BOX

COVER

6233 GATE INSIDE METERING BOX

COVER

6233.1 SPECIAL PLATE FOR SMALL

SEED

6235 COMPLETE COVER, STANDARD

6235.M PEANUT COVER, COMPLETE

6238 EJECTOR, PEANUT

7110 SPROCKETS, 27 TOOTH

7115 SPROCKET, 26 TOOTH

7117 DUAL SPROCKET, 26-12 TOOTH

9999.NG METERING BOX COMPLETE, NG

9999.NG+ METERING BOX COMPLETE,

NG+

10072094 SCREW, FOR METERING BOX

BRACE, 6209.A

10530060 SCREW, PHILLIPS HEAD, 5X10

10172043 ROLL PIN, 4X35

10172099 ROLL PIN, 6X70

10173022 ROLL PIN, 8X50

Standard seed discs, complete with agitator :

DC0325 3 hole, 2.5 mm, melons, low population

DC3x2x2.5 3 hole, 2.5 mm, melons, double seed drop

DC0335 3 hole, 3.5 mm, pumpkin, low population

DC0625 6 hole, 2.5 mm, melons, medium population

DC0635 6 hole, 3.5 mm, pumpkin, low population

DC0925 9 hole, 2.5 mm, melons, high population

DC0930D 9 hole, 3.0 mm, hilldrop cotton, double seed

drop

DC0930T 9 hole, 3.0 mm, hilldrop cotton, triple seed drop

DC0935 9 hole, 3.5 mm, pumpkin, high population

DC1225 12 hole, 2.5 mm, sunflower, low population (oils

& confection)

DC1230D 12 hole, 3.0 mm, hilldrop cotton, double seed

drop

DC1230T 12 hole, 3.0 mm, hilldrop cotton, triple seed

drop

DC1820 18 hole, 2.0 mm, cucumber, hand harvest

DC1825 18 hole, 2.5 mm, sunflower, high population

(oils & confection)

DC1850 18 hole, 5.0 mm, corn, low population

DC2437 24 hole, 3.7 mm, sweetcorn, small seed

DC2445 24 hole, 4.5 mm, sweetcorn, large seed

DC2450 24 hole, 5.0 mm, corn, medium population

DC3016 30 hole, 1.6 mm, sugarbeets, small-medium

DC3020 30 hole, 2.0 mm, pickles, machine harvest

DC3050 30 hole, 5.0 mm, corn, high population

DC3065 30 hole, 6.5 mm, kidney beans, large peanuts

DC3610 36 hole, 1.0 mm, onion, low population

DC3612 36 hole, 1.2 mm,

cabbage/cauliflower/pepper/tomato, low

population

DC3622 36 hole, 2.2 mm, sorghum, low population

DC3635 36 hole, 3.5 mm, cotton, low population

DC3660 36 hole, 6.0 mm, peanut/beans, large

DC3665 36 hole, 6.5 mm, peanut (large, jumbo)

Beans (large kidney)

DC4016 40 hole, 1.6 mm, sugarbeets, small, medium,

large

DC4020 40 hole, 2.0 mm, sugarbeets, medium, large

pellets

DC4060 40 hole, 6.0 mm, peanut, small to medium

DC4850 48 hole, 5.0 mm, beans, large (pinto)

DC6035 60 hole, 3.5 mm, beans, small (navy)

DC6045 60 hole, 4.5 mm, beans medium, (snap) &

soybeans (pinto)

DC7210 72 hole, 1.0 mm, onion, high population

DC7212 72 hole, 1.2 mm,

cabbage/cauliflower/pepper/tomato, high population

DC7222 72 hole, 2.2 mm, sorghum, high population

DC7235 72 hole, 3.5 mm, cotton, high population

DN….. Seed disc only (stainless portion with holes)

less agitator, order seed disc number preceded by DN

FR

45

Page 48

MICROSEM

http://hespareparts.com

46

FR

Page 49

MICROSEM

http://hespareparts.com

PART NO. DESCRIPTION

4329.A SNAPRING

4478 V BOLT Ø16, 7 X 7

4821 PART FOR HYDRAULIC TUBE HOLDING

5021 BUSHING (B25)

5516 HAIR PIN

6090 SNAPRING, 6MM

7085.DA INSECTICIDE DROP TUBE, RIGHT

7085.GA INSECTICIDE DROP TUBE, LEFT

7088 HOPPER LID, 25 LT.

7088.2 CLIP FOR HOPPER LID

7108 SPACER BUSHING

7109 NG PLUS UNIT IDLER

7158 MICROSEM DRIVE CHAIN 7X7, LOWER 70

LINKS

9158 SPRING (R57)

9174 TENSION SPRING

9280 BUSHING

9500.A LEFT & RIGHT SIDE HOUSING

9502.1A HELICID HOPPER

9502.C MICROSEM HOPPER

9504 STEEL BASE, HOPPER

9505.A RUBBER FLAP

9506 MAIN SPINDLE

9507 LEFT WORM GEAR (V75G)

9508 RIGHT WORM GEAR (F75G)

9509 CENTRAL GEAR

9512 TRAP DOOR

9513.B SEAL TRAP DOOR

9514 LEVER STOPPER

9516 SPRING (R139)

9517 BOLT (A117)

9518 PART FOR MICROSEM HOSE HOLDING

9519 UNIT CAP

9520 DOUBLE OUTLET, INSECTICIDE

9520.A DOUBLE OUTLET, HERBICIDE

9521 PLUG

9522 MICROSEM HOSE, SPECIFY LENGTH

9523 CLAMP

9525 END CAP

9548.D SUPPORT BAR, 7 X 7 STD

9549 CARRIER BAR, SPECIFY LENGTH

9552 BUSHING, USES 2 4X25RP AND 2 6X30RP

9553.B MICROSEM DRIVE CHAIN 7X7, UPPER 110

LINKS

9554.3 12 TOOTH SPROCKET

9554.6 15 TOOTH SPROCKET

9554.9 18 TOOTH SPROCKET

9554.13 22 TOOTH SPROCKET

9554.16 25 TOOTH SPROCKET

9554.21 30 TOOTH SPROCKET

9555.A SPROCKET 12-25 TOOTH

9557 SMALL LYNCH PIN

9559 BUSHING

9562 ROLLER FOR CHAIN TIGHTNER

9565 RUBBER O RING

9568 MICROSEM HOSE CLAMP

9574 PLATE FOR HOPPER, 1 OUTLET

9606.A UPPER DRIVE SPROCKET, 20 TOOTH

9612 INTERMEDIATE SPINDLE

9613 SPRING CHAIN TIGHTNER

9638.A ADJUSTABLE MICRO BRACKET DOUBLE

PILLOW BLOCK

9645 RUBBER SLEEVE

9650.2T INTERIOR MICROSEM ROD, 2 HOLES

9651.2T EXTERIOR MICROSEM ROD, 2

HOLES

9653 CHAIN TIGHTNER

9654 DBLE INTERMEDIATE SPROCKET

9656.1 REINFORCEMENT PLATE, 7X7 STD

9658 ROLLER SPACER TUBE

9661 FEMALE SHOE DROP TUBE

9662 MALE SLIDING TUBE

9720 SUPPORT BRACKET, 7X7 STD

9721 OPENING SAFETY SHIELD, DRIVE

CHAIN

9723 CLOSING PIN, SAFETY SHIELD

9724.1 CLOSING CLIPS

9726 SNAP RING

10118 GREASER

FR

47

Page 50

FERTILIZER

http://hespareparts.com

48

FR

Page 51

FERTILIZER

http://hespareparts.com

PART NO. DESCRIPTION

4329.A SNAPRING

4478 V CLAMP Ø16

4479 U CLAMP Ø16

4515 BEARING

4523 BUSHING STOP

4786.C 7X7 GEARBOX IDLER (96)

4787 7X7 WHEEL UNIT IDLER HANDLE

4827 CHAIN IDLER ROLLER

4841 BALANCING SPRING

5021 BUSHING (B25)

7009 DISK ONLY

7010.A DISK HUB

7012.DA REMOVABLE RH SPINDLE

7012.GA REMOVABLE LH SPINDLE

7014.A DISK BEARING (32042RS, 52042RS)

7015.A WASHER (6204ID)

7016.D SCRAPER, INSIDE RIGHT

7016.G SCRAPER, INSIDE LEFT

7017.B BRACKET SCRAPERS

7018.A SCARPER, OUTSIDE

7158 LATERAL CHAIN ON NG

METERING UNIT

9159.A FERTILIZER HOSE COMPLETE 24"

9171.B SPROCKET CLUSTER, FERTILIZER

DRIVE

9173 BEARING HOLDER

9242 FERTILIZER DISK BRACKET

SLEEVE TUBE

9244 SPRING BUSHING

9246.2 ARTICULATION TUBE

9247.D RIGHT FERTILIZER DISK BRACKET

9247.G LEFT FERTILIZER DISK BRACKET

9248 FERTILIZER DISK ARM

9249 FERTLIZER DEPTH CONTROL

THREADRED ROD

9250 FERTILIZER FIXING SHAFT

9251 FERTILIZER FIXING FORK

9252 FERTILIZER DEPTH CONTROL

ARTIC. SHAFT

9253.D FERTILIZER BRACKET FORK

9254.2A PLASTIC FERTILIZER HOPPER, 2

OUTLET

9255 ALUMINIUM HOUSING

9256 SPRING, TRAP DOOR

9257.2 METAL LID FOR HOPPER, 2

OUTLET

9258 FERTILIZER HOSE CLAMP

9261 INSIDE HOPPER REINFORCEMENT

9262.1A STANDARD FERTILIZER AUGER

9263.1 TRAP DOOR, 1 OUTLET

9264.B SPINDLE FOR FERTILIZER

METERING UNIT 95

9265.C INSIDE CAP FOR FERTILIZER 93

9266.A DRIVE SHAFT BETWEEN HOPPERS,

FOR 4-ROW

9267 PIN FOR TRAP DOOR

9268 REINFORCEMENT BRACKET

9269.2A FERTILIZER SLEVE FOR 2 OUTLET

HOPPER

9279 DRIVE FORK

9280 BUSHING

9281 FERTILIZER DISK OFF-SET

9282 FERTILIZER DISK OFF-SET CLAMP

9288 FERTILIZER HOPPER SUPPORT

9289.2 SUPPORT BAR FERTILIZER 2

OUTLET HOPPER

9290 FERTILIZER DRIVE BRACKET

9292 FERTILIZER BRACKET SIMPLE

FOOT

9293 FERTILIZER BRACKET COMBINED

FOOT

9525 END CAP MICROSEM BAR

9549 MICROSEM BRACKET BAR

9555.A SPROCKET, 12-25 TOOTH

9557 SMALL LYNCH PIN

9565 O RING

9613 SPRING CHAIN TIGHTNER (R81)

9650.052 INTERIOR DRIVE CONNECTOR

ROD, 52 CM

9651.035 EXTERIOR DRIVE CONNECTOR

ROD, 31,5 CM

10118 GREASER

FR

49

Page 52

PVC PIPE AND HOSE ASSEMBLY

http://hespareparts.com

50

US

Page 53

FRAME ASSEMBLY

http://hespareparts.com

US

51

Page 54

FRAME ASSEMBLY

http://hespareparts.com

ITEM PART NO. QTY. DESCRIPTION

1. 1-298-010001-1 10 FITTING, GREASE ¼-28

2. 1-512-010005-01 2 NUT, HEX 1/4-20 GRB

3. 1-512010007-16 2 NUT, HEX 1-1/4-7 GRB

4. 1-654-010047-04 2 SCREW, HEX HEAD CAP ¼-20 X ¾ GR5

5. 1-654-010059-03 2 SCREW, HEX HEAD CAP ⅝ -11 X 1- ½ GR5

6. 1-861-010032-29 4 WASHER, FLAT 1- ¼ W

7. 1-861-010034-15 2 WASHER, SPLIT LOCK ⅝

8. 101406 3 PIN, COTTER ⅜ X 3

9. 104033 12 PIN, COTTER 5/32 X 1-½

10. 116076 2 SPRING LEVELING ARM WELDMENT

11. 116237 1 TURNBUCKLE, CONNECTOR WING TO MAIN FRAME

12. 116238 1 HOOK WELDMENT

13. 116248 10 BUSHING, MACHINERY, 10GA

14. 116260 1 CENTER SPRING WELDMENT

15. 116051 3 EYEBOLT

16. 116358 1 PIN, 2-⅛ X 20

17. 116359 4 PIN, ⅞ X 3-⅛

18. 116363 2 PIN, ⅞ X 6-9/16

19. 116365 2 WING HINGE WELDMENT

20. 116241 1 MAIN FRAME WELDMENT, RH (1230 REAR VAC)

21. 116212 1 MAIN FRAME WELDMENT, LH (1230 REAR VAC)

22. 116186 1 WING WELDMENT, RH (1230 REAR VAC)

23. 116187 1 WING WELDMENT, LH (1230 REAR VAC)

24. 116367 2 RUBBER SPACER, WING HINGE, MAIN FRAME

25. 103817 2 HOSE CLAMP

26. 1-512-01005-05 2 NUT, HEX LOCK ⅜

27. 100825 2 WASHER, SLOTTED LOCK 1-¼

28. 1-512-010005-03 8 NUT, HEX LOCK 5/16 - 18

29. 1-557-010362-63 REF PIN, COTTER ¼ X 2

30. 1-654-010049-07 8 SCREW, HEX HEAD CAP 5/16 -18 X 1- ½ GR5

31 1-654-010051-09 REF SCREW, HEX HEAD CAP ⅜ -16 X 2 GR5

32 1-654-010125-10 2 SCREW, HEX HEAD CAP ⅛ X 3- ¼

33 1-861-010032-09 16 WASHER, FLAT 5/16

34 -1861-010032-09 2 WASHER, SPLIT LOCK 1"

35 70260977 1 SMV EMBLEM

36 116034 REF PIN, DBL HOLE ROW MARKER PIVOT

37 116070 2 ROW MARKER PIVOT WELDMENT

38 116514 1 DECAL, WARNING MONOSEM

39 1-512-010005-13 REF NUT, HEX LOCK ⅝ -11

40 112120 REF SCREW, HEX HEAD CAP ⅝ -11 X 2-1/4 GR8

41 116100 REF WASHER, FLAT 1 – ¼ N

42 1-512-010005-15 4 NUT, HEX LOCK ¾ -10

43 1-654-010061-05 2 SCREW, HEX HEAD CAP ¾ -10 X 2 GR5

52

US

Page 55

HYDRAULIC WING FOLD ASSEMBLY

http://hespareparts.com

ITEM PART NO. QTY. DESCRIPTION

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

1/4 X 1-1/2 24 PIN, COTTER 1/4 X 1-1/2

116037 2 BAR, WING HINGE, PIVOT

116256 2 ARM WELDMENT, WING HINGE

116258 4 SPACER WING HINGE

116341 2 CYLINDER BASE, 3 X 16

116429 2 HOSE ASSEMBLY 3/8 X 25

116440 2 PIN, 1 X 7-3/16

116441 2 PIN, 1 X 5-3/4

116442 4 PIN, 1 X 3-1/8

118-2680-010 4 CONNECTOR

2062-8-6S 4 ELBOW 90

620-0859 4 ADAPTER

1-512-010007-05 4 NUT, HEX 1/4-20

1-654-010047-06 2 SREW, HEX HEAD CAP 1/4-20 X 1

1-654-010047-14 2 SREW, HEX HEAD CAP 1/4-20 X 3

1-681-010034-09 4 WASHER, SPLIT LOCK 1/4

116259 1 ANGLE W/ HOLES

102-1123 2 SWIVEL (12/16 ROW REAR & TOP VAC)

HOSE ASSEMBLY 3/8 X 158 (16 ROW REAR & TOP

116430 2

112158 2

116350 1 VALVE ASSEMBLY

VAC)

HOSE ASSEMBLY 3/8 X 136 (16 ROW REAR & TOP

VAC)

US

53

Page 56

HICTH ASSEMBLY

http://hespareparts.com

ITEM PART NO. QTY. DESCRIPTION

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

1-298-010001-1 3 ZERK, FITTING 1/4

1-512-010005-01 1 NUT, HEX LOCK 1/4-20

1-512-010005-05 3 NUT, HEX LOCK 3/8-16

1-512-010005-13 3 NUT, HEX LOCK 5/8-11 GRB

1-512-010005-15 2 NUT, HEX LOCK 3/4-10 GRB

1-512-010005-19 3 NUT, HEX LOCK 1-8 GRB

1-512-010007-06 2 NUT, HEX LOCK 5/16-18

1-512-010007-11 2 NUT, HEX LOCK 5/8-11 GRB

1-512-010007-12 12 NUT, HEX 3/4-10 GRB