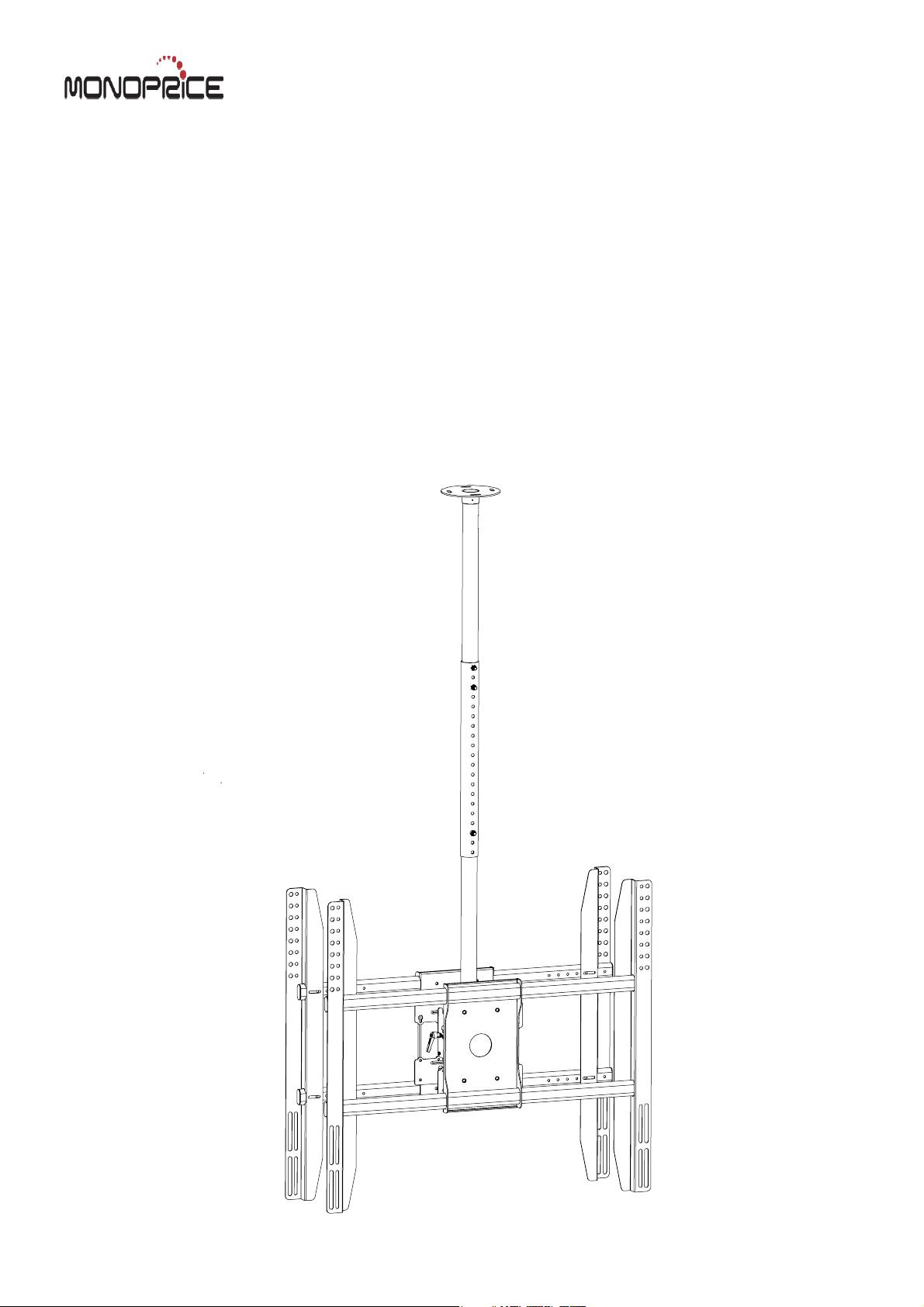

Page 1

INSTALLATION GUIDE

Ceiling TV Mount

MHP-52

Max Load Capacity: 125 lbs (57kg)

Page 2

Note: Read entire instruction sheet before you start installation and assembly.

WARNING

Be sure to read this entire manual thoroughly and you fully understand all the instructions and warning before

attempting to begin your installation.

This product should only be installed by someone who has a basic knowledge of buiding construction,in stallations

and fully understands these instructions.

Make sure that the supporting surface will safely support the combined load of the mount, the display and all

attached hardware and components.

The maximum load capacity is 125 pounds.

If mounting to a wall of wood stud construction, be sure that mounting bolts are anchored to the center of the

studs.

Always have someone assist you to lift and position your equipment.

Tighten screws and bolts firmly, but do not over tighten. Over tightening can damage the items and greatly reduce

their ability to hold. Please refer to suggested torque values where applicable in these instructions.

Tools Needed for Assembly

stud finder ("edge to edge" stud finder is recommended)

phillips screwdriver

drill with 1/4", 3/8", and 5/32" drill bits

Table of Contents

Parts List .............................................................................................................................................................................. 3

Installation to Wood Joist Ceiling .......................................................................................................................................... 4

Installation to Concrete Ceiling ............................................................................................................................................. 5

Installation of Extension Column ........................................................................................................................................... 6

Mounting the Assembly Adapter plate to screen ........................................................................................ ......................... 7

Attach Assembly Adapter plate to Assembly Arm ...................................................................................... ......................... 8

Tilt Adjustment and cord Cord Coves and Wire Managment .............................................................................................8

2 of 8

Page 3

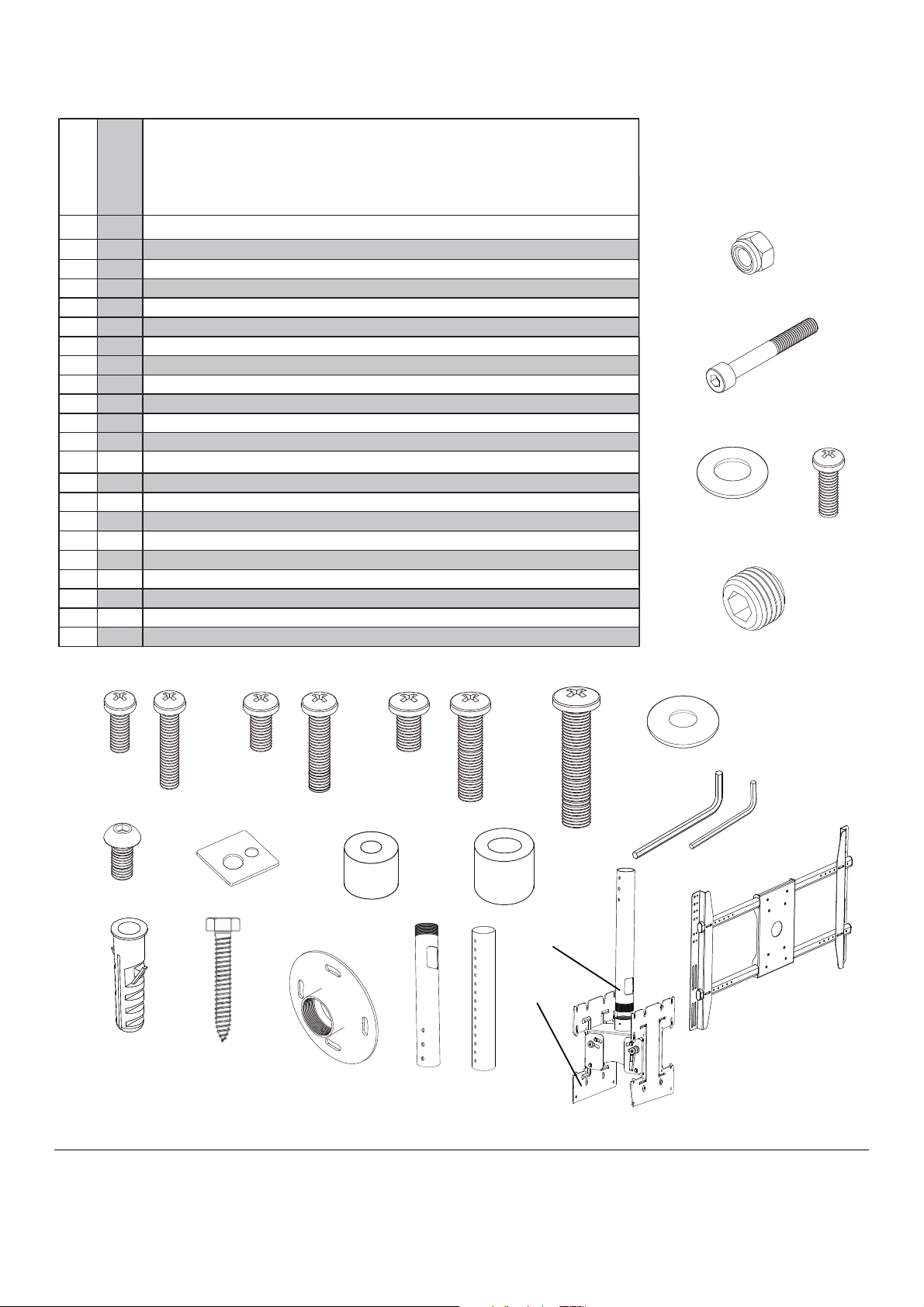

Before you begin, make sure all parts shown are included

with your product.

Parts may appear slightly different than illus trated.

Parts List

Description

A

A

B

B

C

D

D

H

H

J

K

L

L

M

N

N

nonskid nut

Hexagon fillister head screw

philips pan head screw

washer

allen cap screw

philips pan head screw

philips pan head screw

philips pan head screw

E

philips pan head screw

E

philips pan head screw

F

philips pan head screw

F

philips pan head screw

G

washer

allen cap screw

square spacer

I

spacer

spacer

allen wrench

allen wrench

concrete anchor

washer

hex bolt screw

4

4

8

8

2

8

8

8

8

8

8

8

8

8

8

8

8

1

1

4

4

4

M8x60

M6x12

Ø6xØ13x1.2

M4x3

M4x16

M4x30

M5x16

M5x30

M6x16

M6x30

M8x45

Ø8.2xØ1.5x16

M8x15

25.65x25.65x2.5

Ø12.7xØ6.0x12.7

Ø19xØ8.2x19.6

M6

M5

M8x50

Ø8.2xØ16x2.0

M8x50

B

A

A

B

C

DE F

GH

HI J K L

M N plate (x1)

CC (x1)

DD (x1)

adapter plate

AA (x1)

BB (x1)

EE (x2)

3 of 8

Page 4

Installation to Wood Joist Finished Ceilings,

Exposed Wood Joists, or Wood Beam Ceilings

Drill four 1/4" (6 mm) dia. holes to a minimum

depth of 1.57" (40 mm). Attach ceiling plate

with four hex bolt screws M8x50 ( N ) as shown

using 1/2" (13mm) socket wrench.Tighten wood

screws ( N ). so ceiling plate

is firmly attached.

WARNING

Tighten wood screws so that ceiling plate is firmly

attached, but do not overtighten. Overtightening can

damage the screws, greatly reducing their holding

power.

Make sure that mounting screws are anchored into the

center of the joist. The use of an "edge to edge" stud

finder is highly recommended.

N

4 of 8

Page 5

Installation to Concrete Ceilings

Drill four 3/8" (10 mm) dia. holes to a minimum depth of

1.57" (40 mm). Attach ceiling plate using four concrete

anchors (MM) and M8x50 hex bolt screws ( N

in Illustration A

Tighten all fasteners.

and 1, 2, and 3 (below).

) as shown

WARNING

Tighten wood screws firmly, but do not overtighten.

Overtightening can damage the bolt, greatly reducing

its holding power.

WARNING

Concrete anchors are not intended for attachment to

concrete wall covered with a layer of plaster, drywall,

or other finishing material. If mounting to concrete wall

covered with plaster/drywall is unavoidable, plaster/

drywall (up to 5/8" thick) must be counterbored as

shown below. If plaster/drywall is thicker than 5/8",

custom fasteners must be supplied by installer.

metal

bracket

INCORRECT

concrete

metal

bracket

CORRECT

concrete

N

Illustration A

1

concrete

ceiling

M

Drill hole and insert anchor

2

N

Place ceiling plate over anchor and secure with screw

3

M

CUTAWAY VIEW

plaster/

dry wall

plaster/

dry wall

5 of 8

N

After repeating step one tighten all fasteners

M

Page 6

Installation of Extension Column

Attach threaded end of adjuster tube (AA) to threaded

fitting in ceiling plate

slot in end of adjuster tube (AA ) with one of the holes

in the side of threaded fitting. Insert and tighten one

M4 x 3 mm allen cap screw ( C) to lock adjuster

tube (AA) to threaded fitting.

. Tighten securely aligning

WARNING

Installer must verify that the ceiling will safely support

the combined weight of all attached equipment and

hardware.

Slide extension pipe (BB) over adjuster tube (AA)

to the desired height. Attach with two M8 x 60 mm

hexagon fillister head screws (

Slide extension pipe (CC ) over adjuster tube (BB)

to the desired height. Attach with two M8 x 60 mm

hexagon fillister head screws(A) and lock nut ( A).

Attach threaded end of adjuster tube (DD

fitting in ( ) and lock nut ( ).

DD

) and lock nut (

A

C

) to threaded

WARNING

Adjuster tube must be fully threaded (six or seven

full turns) onto threaded fitting in ceiling plate and then

locked with screw (C).

C

AA

A

A ).

BB

A

CC

DD

6 of 8

C

Page 7

Mounting the Assembly Adapter Plate to screen

Modify the Adapter Plate

Adaptor Modify the Assembled Adapter Plate

Slide the adapter brackets into Assembled adapter plate slightly.

Place the Assembled Adapter Plate on the back of the display with

one Adapter Bracket aligned with a set of vertical mounting

holes.Then,slide the other Adapter Bracket in or out until it aligns

y.

with the second set of vertical mounting holes.The Adapter should

be horizontally centered on the back of the flat panel displa

Adapter

Bracket

Back of Screen

Adaptor and hooks

Adaptor and hooks

and tighten it with

Phillips Head Screw Driver.

Use four M6x12 screws and four washers

Mounting

Screw

M6&M8

Hole

M5 Hole

Top of

Display

Square

spacer

*For screen with a hole

pattern in a pocket,spacers

go between Assembly

Adapter Plate and screen.

Spacers

washers

(13x6x1.2)

M6x12

Adaptor and hooks

Screw

Note:

Recessed Mounting Holes.

If the mounting holes are recessed

into the back of the display, use the

supplied spacers to pack the

recessed hole. If the mounting

screw is M5&M6,use the

Spacers1.(K.1.)If the mounting screw

is M8,use the Spacers 2.(K.2.)

Ensure that the brackets are

securely fixed to the display.

For Flat Back Screen

SCREEN

EE(adapter plate)

Select the small,medium,large or extra large screws from the baffled .Fastener pack then attach

screen brackets(AA) to screen following figure C.1 or C.2 on page 7.

fig C.1 fig C.2

SCREW

SCREEN

SPACER

SCREW

OR

7 of 8

Page 8

Attach Assembly Adapter Plate to Assembly Arm

1. Insert two M8x15mm screws

and two metal washers into swivel box

on Assembly Adapter Plate as above

shown.

Leave approx. 1/4" of exposed thread.

2. Lift the display and hook it

over the mounting head by lowering

the exposed portion of the top screws

down the open key slots.

3. Once in position, attach the bottom

two M8x15mm screws and two

washers to secure the display to the

mounting head using M5mm Allen

Wrench.

Iron spacer

M8x15mm

screw bolt

.25"

NOTE:This procedure will require

two persons.Ensure that the arm is

set to its maximum negative tilt prior

to attaching the display

top screw

washers

M8x15mm

screw

Tilt Adjustment and cord Coves

WARNING:

Before removing

1.Loosen Tiltlevers(Only enough to

allow controlled adjustment)

2. Adjust Tilt

3. Lock Tilt Levers(Tighten)

4. Once Tilt Levers are locked,the

position of the levers can be adjusted

without loosening ortightening the unit

by pulling the levers outwards and then

repositioning them to a vertical,less

obtrusive position.

Tiltl

ever

your

display,ensure

the display has a

negative Tilt and

Tilt Lever is

LOCKED!

Tighten

Loosen

Wire Management

pull cables up and through conduit .

8 of 8

Loading...

Loading...