Page 1

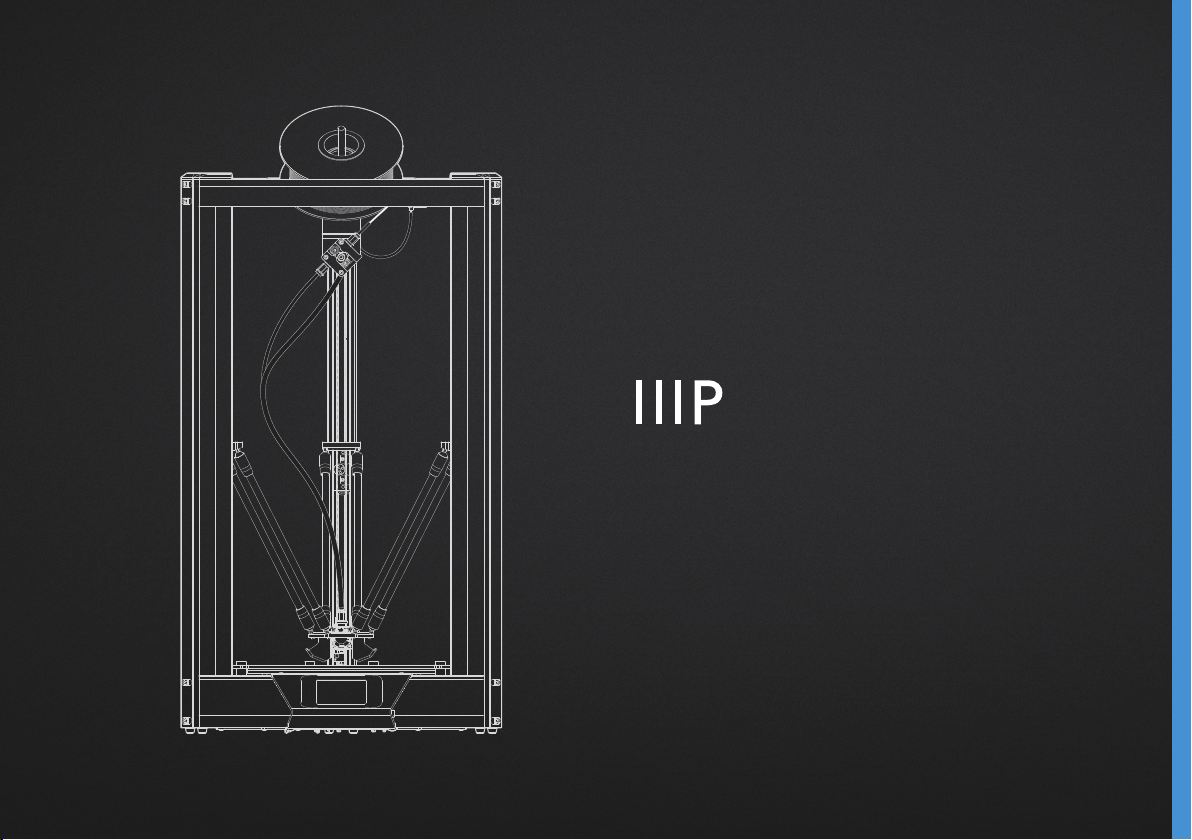

Monoprice Delta Pro 3D Printer

User's Manual

Page 2

Thank you, and congratulations on your purchase of the

Monoprice Delta Pro 3D printer! The Delta Pro is a world-class

desktop machine designed for speed, precision, and reliability.

We know you’ll love printing your designs on the Delta Pro, but

before you do, please read the manual thoroughly.

Page 3

MONOPRICE DELTA PRO MANUAL

CONTENTS

SAFETY WARNINGS AND GUIDELINES

CUSTOMER SERVICE

PACKAGE CONTENTS

SOFTWARE INSTALLATION AND SETUP

PREPARING TO PRINT

Auto-leveling

Cleaning the Build Plate

Loading Filament

Unloading Filament

Swapping Hotends

PREPARING TO PRINT

General Slicer Settings

Selecting a file

P. 4

P. 5

P. 5

P. 5

P. 6

P. 7

P. 8

P. 8

P. 8

P. 9

P. 9

CALIBRATING THE PRINTER

Calibrating Dimensional Accuracy

PID Tuning

CONNECTING TO WI-FI

CUSTOMIZING THE UI

UPDATING THE FIRMWARE

CARE AND MAINTENANCE

REGULATORY

P.10

P.10

P. 11

P. 11

P.12

P.13

P.14

Page 4

SAFETY WARNINGS AND GUIDELINES

Safety Warnings and Guidelines

1. Be careful not to damage the glass build plate.

2. Take care to avoid touching hot parts, including heat blocks,

nozzle, extruded filament, and the heated build plate.

3. Keep the printer and all accessories out of reach of small

children.

4. Do not remove or disconnect the USB cable when printing

from a computer.

5. Do not pull or twist the black cable harness at any time.

6. Do not force or tear anything during unpacking and setup.

This may cause damage to the printer and/or its accessories.

7. Do not reach inside the printer during operation. Always allow

the printer and extruded filament to cool before reaching

inside.

8. Ensure that the printer is turned off and unplugged from its

power source before making repairs or performing service.

9. Do not install this device on an unstable surface where it

could fall and cause either personal injury or damage to the

device and/or other equipment.

10. Do not subject the product to extreme force, shock, or

fluctuations in temperature or humidity.

11. This device is intended for indoor use only.

12. Do not expose this device to water or moisture of any kind.

Do not place drinks or other containers with moisture on or

near the device. If moisture does get in or on the device,

immediately unplug it from the power outlet and allow it to

fully dry before reapplying power.

13. Do not touch the device, the power cord, or any other

connected cables with wet hands.

14. Use only in a well-ventilated area. Do not use in confined

spaces.

15. Prior to operation, check the unit and power cord for physical

damage. Do not use if physical damage has occurred.

16. Before plugging the unit into a power outlet, ensure that the

outlet provides the same type and level of power required by

the device.

17. Unplug this device from the power source when not in use.

18. Take care to prevent damage to the power cord. Do not allow

it to become crimped, pinched, walked on, or become tangled

with other cords. Ensure that the power cord does not present

a tripping hazard.

19. Never unplug the unit by pulling on the power cord. Always

grasp the connector head to unlock it from the port.

4

Page 5

CUSTOMER SERVICE / PACKAGE CONTENTS / SOFTWARE INSTALLATION AND SETUP

Customer Service

The Monoprice Customer Service department is dedicated to

ensuring that your ordering, purchasing, and delivery experience

is second to none. If you have any problem with your order,

please give us an opportunity to make it right. You can contact a

Monoprice Customer Service representative through the Live Chat

link on our website www.monoprice.com during normal business

hours (Mon-Fri: 5am-7pm PT, Sat-Sun: 9am-6pm PT) or via email

at support@monoprice.com

Package Contents

Please take an inventory of the package contents to ensure you

have all the items listed below. If anything is missing or damaged,

please contact Monoprice Customer Service for a replacement.

• 1× Monoprice Delta Pro 3D Printer

• 1× MP Select PLA Plus Filament Roll (Black, 1 kg)

• 1× Spare PTFE-lined Nozzle

• 1× Spare All-metal Nozzle

• 1× Auto-level Sensor

• 1× Tool Kit (hex wrenches: 1.5 and 2 mm)

Software Installation and Setup

We recommend using KISSlicer for use with the Delta Pro. Please

visit the Delta Pro page of monoprice.com to download KISSlicer

and for instructions on installation. The installation package

comes with everything you need to get started.

• 1× Touchscreen Stylus

• 4× Bowden Clips

5

Page 6

PREPARING TO PRINT

Auto-Leveling

Before your first print, and anytime you remove the build plate,

you’ll want to run an auto-level to ensure that your parts adhere

well to the glass. Follow the procedure below to run an auto-level

and calibrate the Z-offset of your machine.

1. Ensure that the hotend is at room temperature.

2. Connect the auto-level sensor to the green wire from the

cable harness, and affix the the sensor’s foam ring to the

nozzle. NOTE: Use the minimum amount of force required

to affix the sensor to the nozzle. If the nozzle is touching

the plastic membrane, it may prematurely trigger the

switch.

3. On the LCD screen, tap

> >

Auto Leveling

4. Once the process is complete, remove the auto-level sensor.

Adjusting the Z-Offset

The Z-offset is the distance between the glass build plate and

the nozzle. The auto-level process ensures that this distance is

consistent across the entire surface of the build plate, but the

distance itself must be manually calibrated. You can do this easily

using a piece of clean, flat copy paper, which are usually about

100 microns thick.

1. Tap

>

2. Place the piece of copy paper on the build plate.

Green Wire

from Effect or

Wire Harness

6

Auto-l evel

Sensor Wire

Page 7

PREPARING TO PRINT

3. Tap the in the center of the circle.

4. Tap

or

to adjust the height of the nozzle up or down.

5. Adjust the height of the nozzle until it pinches the paper,

checking each time whether the paper can be moved. Once

the paper cannot be moved, return to the main menu and tap

testttto home the printer.

Cleaning the Build Plate

To prepare the build plate for printing, use rubbing alcohol or

another ammonia-free solvent and a soft, lint-free cloth to remove

any dust and oil from the surface of the glass while it is at room

temperature.

Loading Filament

1. Place the filament spool

on the holder so that the

working end of the filament

hangs down to the right.

2. Cut the end of the filament

at an angle as illustrated.

3. Gently straighten a

segment about 5 cm

(2”) from the end with

your fingertips to make it

easier to feed the filament

through the sensor and the

extruder.

4. Remove the filament

sensor from its holder and

feed the end of the filament

through the sensor in the

direction as indicated by

the arrow, then into the

tube on the right side of the

extruder.

5. Pinch the extruder idler

lever and push the filament

past the gear and into the

bowden tube just past the

pneumatic connector.

7

Page 8

PREPARING TO PRINT

6. On the LCD screen, preheat the nozzle to the material’s

working temperature e.g. for PLA, ≈200°C.

7. Once the nozzle is up to temperature, tap > > Load

Unloading Filament

1. On the LCD screen, preheat the nozzle to the material’s

working temperature e.g. for PLA, ≈200°C.

2. Once the nozzle is up to temperature, tap > > Unload

3. Hold the filament sensor and carefully rotate the spool while

the filament is unloading to avoid tangles.

4. IMPORTANT: When removing the end of the filament from

the sensor, carefully string the end through the hole in

the spool to avoid overlapping and tangles. These WILL

cause filament jams and failed prints.

Swapping Hotends

The Delta Pro’s hotend is easily swappable so you can print with

different materials at different temperatures. While we always

recommend using the default, PTFE-lined hotend for use with

PLA and many other low-temperature materials, the included allmetal hotend allows you to print with materials which require

temperatures hotter than what PTFE can handle. As always,

please remember to use your printer in a well ventilated area.

Removing and Replacing a Hotend

1. Preheat the hotend and unload the filament.

2. Cool down the hotend, then turn off the machine.

3. Remove the Bowden tube from the effector by removing the

plastic pneumatic connector clips and depressing the top of

the connector while pulling the tube.

4. Disconnect the heater and thermistor connectors from the

cable harness.

5. While holding the hotend, use a 1.5 mm hex wrench (included)

to loosen the two headless hex screws on the side of the

heat sink below the effector, and the hotend should be easily

removable.

6. Replace the hotend in the same orientation and tighten the

screws.

7. Reconnect the heater, thermistor, and Bowden tube, ensuring

that the tube is pushed all the way in.

8

Page 9

SLICING AND PRINTING

General Slicer Settings

If using any other slicer besides KISSlicer, you can follow

these guidelines and the guidelines on the Delta Pro webpage

to configure your preferred slicing software for use with your

machine. For the latest profiles and tips, please check the

product’s webpage and Facebook page regularly.

Machine Settings:

• Build Plate / Bed Diameter: 270 mm

• Build Envelope Height: 340 mm

• Firmware: 5D Absolute E

• File Extension: .gcode

• Fan On: M106 / Off: M107 (Fan can do PWM or blip to speed)

• Maximum Recommended Speed Settings:

• Bottom, Top, and Perimeter: 30 mm/s

• Loops and Infill: 60 mm/s

• Travel: 100 mm/s

• Z-speed: 50 mm/s

• Max Acceleration: 1000 mm/s

• For G-code pre-, and postfixes, visit the Delta Pro webpage

General Settings

(Note: These are general settings guidelines and fine

adjustments WILL need to be made for different materials):

• Extrusion Width: 0.4 mm

• Min. Flow Rate: 1 mm3/s

• Max. Flow Rate: 4 mm3/s

• Destring/Retraction Distance: 3-6 mm

• Destring/Retraction Speed: 100 mm/s

Selecting a File

To select a file, tap , then use the arrows to highlight your file,

ten tap OK and then tap Yes to begin printing.

9

Page 10

CALIBRATING THE PRINTER

Calibrating the Printer

Your Monoprice Delta Pro was calibrated before leaving the

factory to ensure great prints out of the box. However, sometimes

it may be necessary re-calibrate certain functions of the printer

over the natural course of use.

Calibrating Dimensional Accuracy

If you find that the dimensions of your prints differ from the

dimensions of your CAD model beyond 10 microns or so, you

may want to adjust the firmware to correct the discrepancy. Follow

the steps below to analyze the error and calibrate your machine

settings.

1. Go to the Delta Pro page at Monoprice.com and download the

calibration box G-code.

2. Print the calibration box G-code.

3. Carefully measure the part with calipers, aligning the jaws

with the layer lines and record the dimensions.

4. On the LCD screen, tap > Structure. Note the “Push Rod

Length.” Compute the new “Push Rod Length” value using

the following formula: New Value = Old Value × (Measured

Printed Dimension / 3D Model Dimension)

5. Tap Push Rod Length, erase the old value, and enter the

new value.

PID Tuning

If you find that your nozzle fails to maintain a stable temperature

or fails to reach the target temperature, you may run an autoPID tuning procedure to attempt to correct the issue. If nozzle

temperature issues persist after running an auto-PID tune, you

may need to replace your thermistor or heater. Follow the steps

below to run an auto-PID tune.

Note: The tuning process will vary slightly depending on the

nozzle hotend type and target temperature of the material you are

trying to print. For the PTFE-lined nozzle, turn the part cooling

fans (side fans) on 100% power before proceeding to tune the

PID. Leave the fans off for the all-metal nozzle and materials with

target temperatures higher than 260°C. You can turn on the fans

by tapping > . 100% is the default input. Then tap .

Turn to the next page.

10

Page 11

CONNECTING TO WI-FI

1. On the LCD screen, tap > Temperature > Hotend1

Settings > PID Settings > Auto PID Tuning

2. Wait for the process to complete.

3. Try preheating to your desired target temperature.

Connecting to Wi-Fi

The Delta Pro is equipped with Wi-Fi capabilities that allow you

to start and stop a print, and use other functions remotely from

its mobile app. For details and a link to download the mobile app,

please visit the Delta Pro webpage.

To connect the Delta Pro to Wi-Fi, place the machine in a room

with or nearby a Wi-Fi router. On the LCD screen, tap > >

ro utr, then use the arrow keys to select the nearest router and

tap .

Enter the password of the router and tap the . The LCD

screen will notify you whether the attempt to connect to the router

was successful.

Note: For the mobile app to work, it must be connected to the

same Wi-Fi network as the machine.

11

Page 12

CUSTOMIZING THE UI

Customizing the UI

The Delta Pro’s touchscreen LCD UI can be customized to your

preferences in the following categories.

Changing the Color

Change the color scheme of the LCD screen by tapping tete >

System > .

1Tap Preheat

You can change the 1Tap preheat target temperature by tapping

tete > Temperature > Preheat Setting > 1Tap Preheat and then

entering a target temperature value.

Maximum Temperatures

By default, the maximum temperatures allowed by the firmware

are set to the maximum safe operating temperature of the PTFE-

lined hotend, 260°C. If you would like to increase this while using

the all-metal hotend, tap > Temperature > Hotend 1 Setting

> Max Temperature and enter a value at least 5°C beyond your

desired target temperature to allow the PID to function properly.

12

Page 13

UPDATING THE FIRMWARE / CARE AND MAINTENANCE

Updating the Firmware

We recommend updating your machine to the latest firmware

before printing for the first time to ensure you have the latest

version. Monoprice will release updates to the Delta Pro’s

firmware from time to time on the Delta Pro’s webpage. Once

you’ve downloaded the latest firmware, unzip the files to a USB

drive and follow the steps below to perform the update.

1. On the LCD screen, tap > System >

2. Select the folder containing the .bin firmware file, then tap

Update.

3. Repeat steps 1 and 2 to update the .ui user interface file.

Care and Maintenance

Regular care and maintenance will keep your Delta Pro looking

and working like new for years. Please follow these care and

maintenance guidelines for each component of your machine.

• Clean the machine’s frame with a damp, lint-free cloth.

• Clean the glass build plate with rubbing alcohol or another

ammonia-free solvent and a soft, lint-free cloth such as

microfiber.

• Lubricate the magnetic control arms with PTFE or lithium

grease on at least a monthly basis. This can be done by

applying a small amount of grease onto the magnets of the

control arms which function as a lubricant reservoir. After a

few prints, wipe away any excess grease from the ball joints

with a lint-free cloth.

• The carriages have been factory calibrated to ensure many

thousands of hours of consistent, precision movement. If

after an extended period of time they seem loose or noisy,

they may require adjustment or lubrication.

• To adjust the wheel spacing,

• USE ONLY silicone lubricant on the wheels when they

seem noisy

• Use a dry brush to clean the extruder gear’s teeth when they

become clogged or when the gear starts to slip.

• Clean the LCD touchscreen display while the machine is

powered off using a soft cloth. DO NOT use any solvents or

cleaning fluids on the display.

13

Page 14

REGULATORY

Notice for FCC

This device complies with part 15 of the FCC Rules. Operation is

subject to the following two conditions:

1. This device may not cause harmful interference.

2. This device must accept any interference received, including

interference that may cause undesired operation.

Changes or modifications not expressly approved by the party

responsible for compliance could void the user's authority to

operate the equipment.

This equipment has been tested and found to comply with the

limits for a Class B digital device, pursuant to Part 15 of the

FCC Rules. These limits are designed to provide reasonable

protection against harmful interference in a residential

installation. This equipment generates uses and can radiate radio

frequency energy and, if not installed and used in accordance

with the instructions, may cause harmful interference to radio

communications. However, there is no guarantee that interference

will not occur in a particular installation. If this equipment does

cause harmful interference to radio or television reception, which

can be determined by turning the equipment off and on, the user

is encouraged to try to correct the interference by one or more of

the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different

from that to which the receiver is connected.

• Consult the dealer or an experienced radio/TV technician for

help.

Radio Notice for FCC

CAUTION: This FCC Part 15 radio device operates on a non-

interference basis with other devices operating at this frequency.

Any changes or modification to said product not expressly

approved by Monoprice, including the use of non-approved

antennas, could void the user’s authority to operate this device.

This device complies with Part 15 of the FCC Rules. Operation

is subject to the following two conditions: (1) this device may

not cause harmful interference, and (2) this device must accept

any interference received, including interference that may cause

undesired operation.

14

Page 15

Page 16

Address

11701 6th Street

Rancho Cucamonga, CA 91730, USA

Customer Service

support@monoprice.com

tech@monoprice.com

Call Us

Tel: 877.271.2592 Fax: 909.989.0078

Legal

legal@monoprice.com

Loading...

Loading...