Page 1

safet y scr ew

M-J

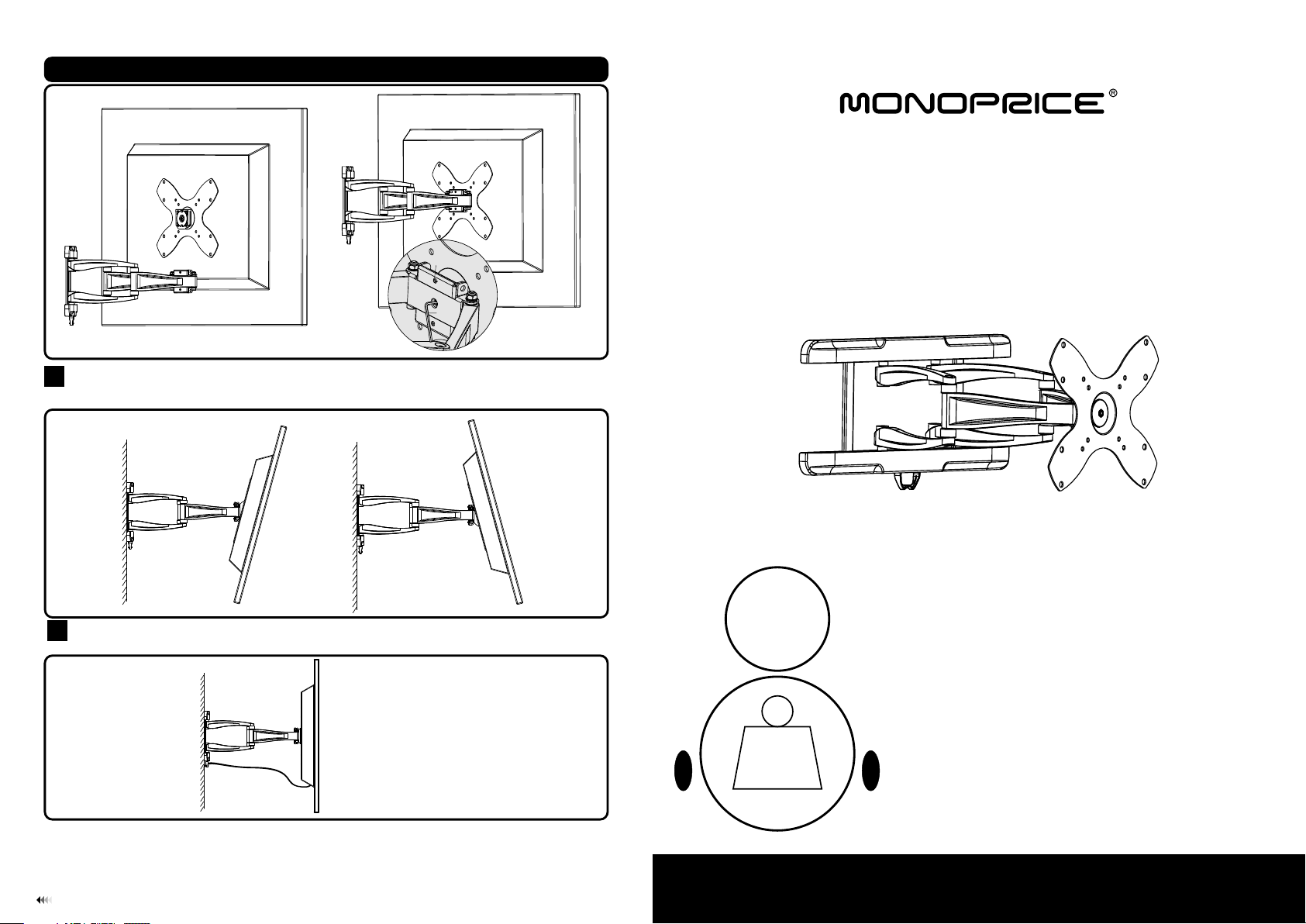

fig. 4.1

Pitching Angle Adjus tment

5

Push or pull from the top or botto m of th e dis pla y to th e des ired angle , the p itc hing angle can be adju ste d

between -15°~ 15° , swivel: 100° as show n in fi g. 5. 1.

INSTALLATION INSTRUCTIONS

fig. 5.1

Cable Management

6

Route the cables thr ough the cable clip as shown in f ig.6.1.

fig. 6.1

Once you have succes sfully mounted the bracke t and flat screen together, ensure it is s ecured safely prior to use.

It is recommended yo u check the mounting screws e very two months for a steady hold. If yo u require additional

information rega rding installation, ple ase contact our Tech nical support team.

7

Pitchin g an gle:

-15° ~ +15°

Swivel: 100°

25kg

(55lbs)

MAX

LCD Wall Mount

Model:MDA03-226 BLACK

Max Loa d Cap aci ty : 25k g(5 5lbs)

Page 2

WARNING

Do not begin installation until you have read and understood the instructions and

•

warnings contained in this manual. If you need further assistance, please contact

Monoprice Technical support team.

• Please refer to manufacture’s installation guide for recommended distance from wall

to avoid risk of property damage.

This product should only be installed by someone of good mechanical aptitude and

•

basic building experience to avoid malfunction.

• Make sure that the supporting surface will safely support the combined load of the

equipment and all attached hardware and components.

NOTE: Pleas e re ad Inst ructi on M anual p rior to i ns talla tion.

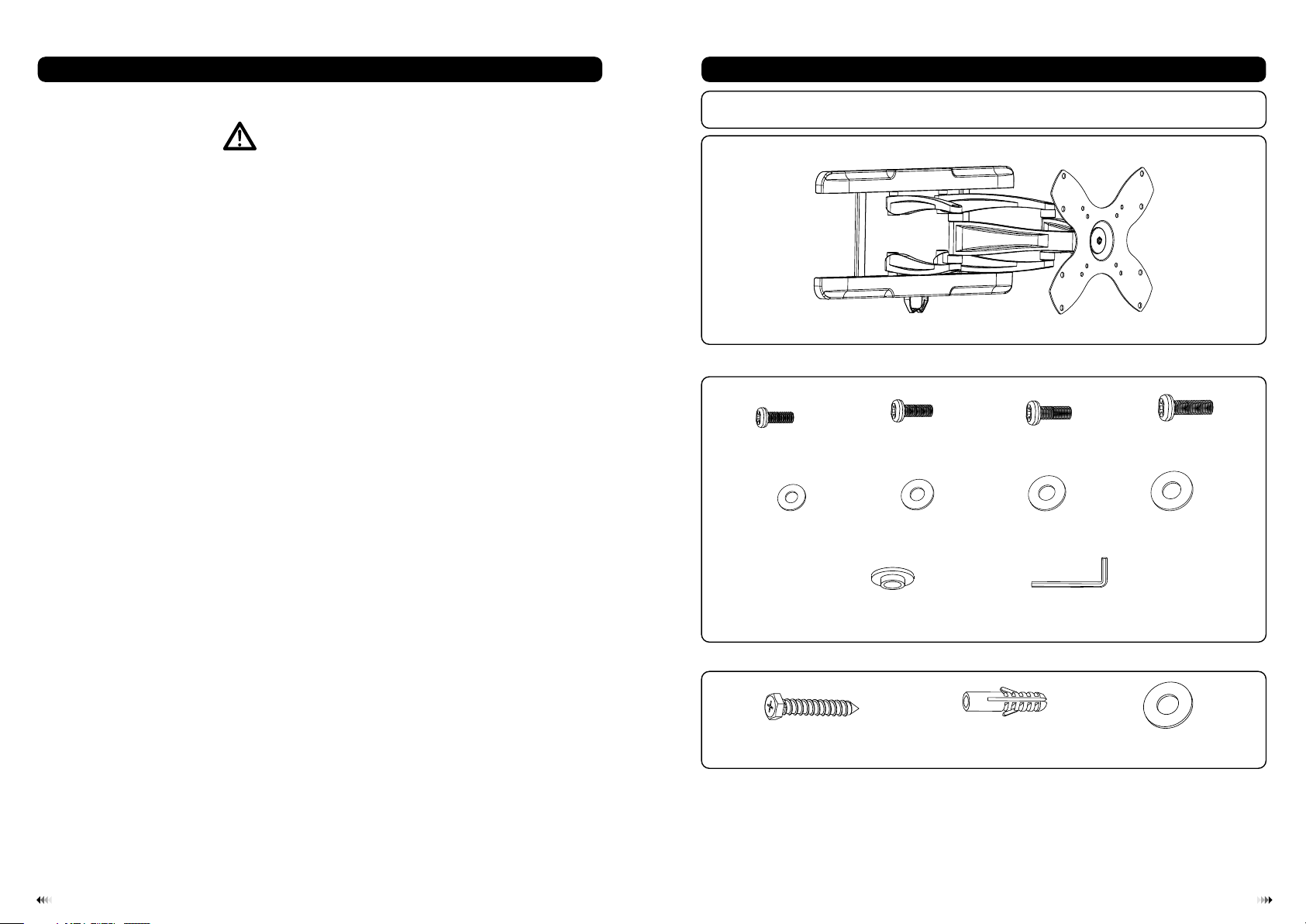

Package M

• Never exceed the maximum load capacity.

• If mounting to wood wall studs, make sure that mounting screws are anchored into

the center of the studs. Use of an “edge to edge” stud finder is highly recommended.

• Always use an assistant or mechanical lifting equipment to safely lift and position

equipment.

• Tighten screws firmly, but do not over tighten. Over tightening can damage the items,

greatly reducing their holding power.

• This product intended for indoor use only. Using this product outdoors could lead to

product failure and personal injury.

M4x14 ( x4 )

M-A

D4 wash er ( x4)

Package W

ST6.3 x5 5 (x6)

M-E

W-A

M5x14 ( x4 )

M-B

D5 wash er ( x4)

M-F

ø13.5 xø 5.5x3 .2 (x4)

M-I

concr et e ancho r (x6)

M6x14 ( x4 )

D6 wash er ( x4)

allen key 4mm (x1)

W-B

M-C

M-G

Tools required

Phillips Head Screw driver(200mm length exclude the handle)

·

M6 Socket and Wrench

·

·

Electric drill and 10mm masonry bit for concrete wall installation

·

Marking Pen

·

Hammer

M-J

M8x14 ( x4 )

M-D

D8 wash er ( x4)

M-H

washe r( ø6.5x ø24) (x 6)

W-C

21

Page 3

Disassemble the wa ll mount as shown below.

Loosen the safety sc rews with a proper screwdriver to di sassemble the adapter bracket fo r easy

installation.

Woo d Stud Wall Mounting:

1a

WARNING

• Make sure that the supporting surface will safely support the combined load of the

equipment and all attached hardware and components.

W-A

Solid Bri ck And Concrete Block Mounting:

1b

W-C

Make su re t he wall p late is

corre ct ly plac ed

WARNING

•

When installing to a cinder block wall, please verify you have a minimum of

concrete thickness. Do not drill directly into mortar joints, be sure to mount to a

solid part of the block generally 1” minimum from the side of the block. It is

suggested to use an electric drill with a slow setting instead of a hammer to avoid

breaking the wall.

•

Please verify the supporting surface will safely support the capacity of hardware

and equipment prior to installing.

fig. 1.1

• Tighten wood screws firmly, but do not over tighten. Over tightening can damage

the screws, greatly reducing their holding power.

• Make sure that mounting screws are anchored into the center of the studs. Use of

an “edge to edge” stud finder is highly recommended.

• Hardware provided is for attachment of mount through standard thickness drywall

or plaster into studs. Installers are responsible to provide hardware for other types

of mounting situations.

• Use a st ud finder to locate th e edges of the stud s. Use of an edge-to-e dge stud finde r is highly r ecommended.

Based on th eir edges , draw a vert ical line down each st ud’s cent er.

• Place wal l plate on wa ll as a template. An d mark the center of the fo ur mounting ho les . Make sure that

the mount ing holes are on the stu d centerline .

• Drill fou r 1/8” (3mm ) dia. Hole s 1.2” (30m m) deep. Ma ke sure tha t the wall pl ate is leve l, secure it using

four scre ws (W- A) as shown in fig. 1.1.

• Use the wall p lat e to ma rk six holes l oca tions on the wall . as sh own in fig.1 .2.

• Pre-drill the se ho les with a 10m m mas onry bit to at leas t 60m m in depth. In ser t a con crete anch or (W -B)

into each of thes e hol es. Attach the wal l pla te to the wall u sin g six s crews (W-A) and six wa she rs (W-C) ,

as shown in fig.1 .3.

fig. 1.2

43

Page 4

W-B

W-C

W-A

Make su re t he wall p late is

corre ct ly plac ed

fig. 1.3

Top of disp la y

Mounting The Plastic Covers and The Cable Clip

2

• Snap the plastic cov ers to top and bottom of wall pla te rails and then insert the cable cli p from the bottom of the

plastic cover as sho wn in fig. 2.1.

fig. 2.1

Installing Adapte r Brack et:

3

• To prevent s cra tching the scre en, s et a cl oth o n a fla t, le vel s urface tha t wil l sup por t the weight of the

scr een.

• Pla ce sc reen face side do wn. P lac e adapter on the back of scre en, a lig n to ho les, and center o n bac k of

scr een, as shown in fig.3 .1.

• Att ach the adapter brac ket t o the b ack o f the s creen using the appr opr iate combi nat ion of screws,

was hers, and space rs, a s sho wn in f ig.3.2 and fig. 3.3 .

fig.3.1

• Beg in with the prope r scr ew, ha nd th rea d through washe r and a dap ter bracke t int o scr een a s sho wn in fig.3.2

and f ig. 3.3.

• Scr ew mu st make at least three f ull t urn s int o mounting h ole a nd fi t snu g int o place. Do not over tighte n.

• Rep eat for remaini ng mo unt ing holes, l eve l bra cket and tighte n scr ews .

M-G/M -H

M-C/M -D

fig. 3.2

Installing the Display

4

Hang the bracket mou nted display onto the plate o f articulated arm assembly, and then tighten safety screws

securely with a prop er screwdriver as shown in fi g.4.1.

Important: Make su re the bracket mounted display is co rrectly mounted and the saf ety screws are tightened

securely before lo osening the display.

You can adjust tighter or looser u sing a 4mm allen key according to the we ight of the display you will be installing.

M-I

M-A/M -B

M-E/M -F

fig. 3.3

65

Loading...

Loading...