Page 1

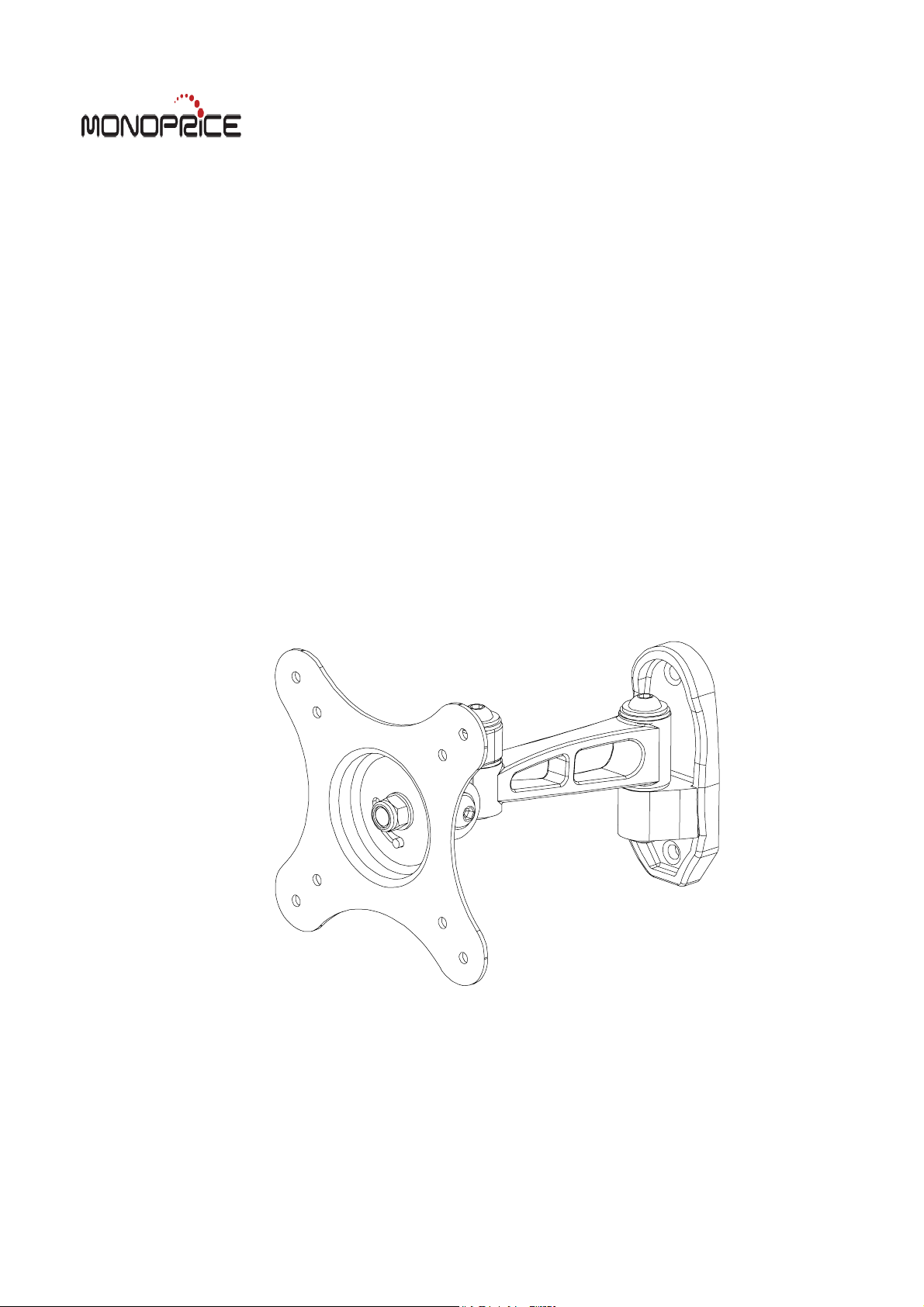

INSTALLATION GUIDE

Flat Panel Arm Mount

MLA100-M

Support 10" to 24" Screens

Max Load Capacity: 30 lbs (15 kg)

VESA 100x100 compatible

Page 2

Note: Read entire instruction sheet before you start installation and assembly.

WARNING

• Be sure to read this entire manual thoroughly and you fully understand all the instructions and warning before

attempting to begin your installation.

• This product should only be installed by someone who has a basic knowledge of buiding construction,in stallations

and fully understands these instructions.

• Make sure that the supporting surface will safely support the combined load of the mount, the display and all

attached hardware and components.

• This wall bracket will only support flat panel displays(LCD,Plasma).The maximum load capacity is 30 pounds.

• If mounting to a wall of wood stud construction, be sure that mounting bolts are anchored to the center of the

studs.

• Always have someone assist you to lift and position your equipment.

• Tighten screws and bolts firmly, but do not over tighten. Over tightening can damage the items and greatly reduce

their ability to hold. Please refer to suggested torque values where applicable in these instructions.

Tools Needed for Assembly

• stud finder ("edge to edge" stud finder is recommended)

• phillips screwdriver

• pencil

• drill

• 3/16"(4mm) drill bit for wood studs, 5/16"(8mm) drill bit for concrete

• level

• tape measure

Table of Contents

Parts List .......................................................................................................................................................................... 3

Installation to Single Wood Stud Wall ................................................................................................................................... 4

Installation to Solid Concrete and Cinder Block ................................................................................

Fix the AA on the display screen with VESA mounting pattern

Tilting

........................................................................................

®

.................................................................................... 6

.................................................................................... 6

2 of 8

.................................... 5

Page 3

Before you begin, mak e sure all parts shown are included

with your product.

Parts may appear slightly different than illustrated.

Parts List

M4x12(x4)

philips pan head screw

M6x40(x2)

concrete anchor

mount(AA)

M4x20(x4) M5(x1)

philips pan head screw

M6x60(x2)

corss slotted head screw

allen wrench

¢8.0x¢5.0x8(x4) L=200

spacer

line

3 of 6

Page 4

Installation to Single Wood Stud Wall

WARNING

• Installer must verify that the supporting surface will safely support the combined load of the equipment and all attached

hardware and components.

• Tighten wood screws so that wall plate is firmly attached, but do not overtighten. Overtightening can damage the

screws, greatly reducing their holding power.

• Make sure that mounting screws are anchored into the center of the stud. The use of an "edge to edge" stud finder is

highly recommended.

• Hardware provided is for attachment of mount through standard thickness drywall or plaster into wood studs. Installers

are responsible to provide hardware for other types of mounting situations.

A

Using a stud finder, locate and mark the edges of the wood stud. Use of an edge to edge stud finder is highly

recommended. Use a level to draw a vertical line down the center of the stud. Use AA as template to

mark center of holes along the vertical line.

to wall using

two M6 X 60 corss slotted head screws

STUD

Drill two 1/8" (4 mm) dia. pilot holes 2" (50 mm) deep. Attach AA

as shown in fig. A.2. Level plate, then tighten all fasteners.

STUD

AA

corss slotted head screw

fig. A.1

AA

fig. A.2

4 of 6

Page 5

Installation to Solid Concrete or Cinder Block

WARNING

• When installing the wall mounts on cinder block, verify that you have a minimum of 1-3/8" of actual concrete

thickness in the hole to be used for the concrete anchors. Do not drill into mortar joints! Be sure to mount in a solid

part of the block, generally 1" minimum from the side of the block. Cinder block must meet ASTM C-90 specifications.

It is suggested that a standard electric drill on slow setting is used to drill the hole instead of a hammer drill to avoid

breaking out the back of the hole when entering a void or cavity.

• Concrete must be 2000 psi density minimum. Lighter density concrete may not hold concrete anchor.

• Make sure that the supporting surface will safely support the combined load of the equipment and all attached hard-

ware and components.

B

Use wall plate (AA) as template to mark mounting

holes.

Drill two 5/16" (8 mm) dia. holes 1.5" (40 mm) deep as

shown in fig. B.1. Insert concerte anchor

in holes flush with

wall as shown (right). Place wall plate over anchors and

secure with M6x 60 cross slotted head screw

fasteners.

WARNING

• Tighten hex head bolts

is firmly attached,but do not overtighten. Overtightening

can damage the screws, greatly reducing their holding

power.

so that wall arm assembly

WARNING

• Always attach concrete anchors directl to loadbearing concrete.

• Never attach concrete anchors to concrete covered

with plaster, drywall, or other finishing material. If

mounting to concrete surfaces covered with a finishing

surface is unavoidable, the finishing surface must be

counterbored as shown below. Be sure concrete

anchors do not pull away from concrete when tightening screws. If plaster/drywall is thicker than 5/8",

custom fasteners must be supplied by installer.

y

1

Drill holes and insert anchors

2

corss slotted head screw

3

Tighten all fasteners.

corss slotted head screw

concrete

anchor

solid concrete

concrete

surface

concrete

anchor

concrete

anchor

cinder

block

CUTAWAY VIEW

wall plate

plaster/

dry wall

INCORRECT

concrete

wall plate

CORRECT

concrete

AA

fig. B.1

plaster/

dry wall

5 of 6

Page 6

Fix the AA on the display screen w ith VES A mounting Pattern

Choose hole pattern as shown in detail 3 for VESA mounting pattern. Begin with the shortest length screw, hand thread

C

through adapter plate into screen as shown in detail 4. Screw must make at least three full turns into the mounting hole

and fit snug into place. Do not over tighten. If screw cannot make three full turns into the screen, select a longer length

screw from the fastener pack. Repeat for remaining mounting holes. Securely tighten screws.

NOTE: Spacers may not be used, depending upon the type of screen.

®

VESA® 100 x 100

SCREEN

ADAPTER

PLATE

NOTE: For screens with a hole

pattern in a pocket,

spacers go between

adapter plate and

screen.

VESA

®

75 x 75

ADAPTER

PLATE

DETAIL 3

SCREEN

DETAIL 4

Tilting

D

The rotation angle of head is 180° as shown in fig.D.1.

The rotation angle of adapter is 90° as shown in fig.D.2.

The tilt angle of adapter is 45

shown in fig.D.3.

CAUTION

• Be careful not to pinch fingers when

opening and

wall.

closing mount from the

• Do not remove or loosen screw while the mount is in use. Doing so may cause the

° up and 90°down as

WARNING

90°

6 of 6

180°

fig. D.1

-45°--90°

fig. D. 2

fig. D.3

screen to fall.

Loading...

Loading...