Page 1

MP Mini SLA LCD High Resolution Resin 3D Printer

P/N 35435, 38116

User's Manual

Page 2

CONTENTS

SAFETY WARNINGS AND GUIDELINES ....................................................................................................................................... 3

INTRODUCTION ................................................................................................................................................................................................ 5

USEFUL TOOLS ................................................................................................................................................................................................. 6

CUSTOMER SERVICE .................................................................................................................................................................................... 7

PACKAGE CONTENTS ................................................................................................................................................................................. 7

PRODUCT OVERVIEW ................................................................................................................................................................................. 8

CONTROL BUTTONS ..................................................................................................................................................................................... 8

MENU FUNCTIONS ........................................................................................................................................................................................ 9

Main Menu ..................................................................................................................................................................................................... 9

Control Menu .............................................................................................................................................................................................. 9

Print Menu.................................................................................................................................................................................................... 10

Finish Screen ............................................................................................................................................................................................... 11

PREPARING THE PRINTER ....................................................................................................................................................................... 11

QUICK START GUIDE .................................................................................................................................................................................. 12

WI-FI® SETUP .................................................................................................................................................................................................... 13

ACCESSING THE WEB UI ........................................................................................................................................................................ 14

WEB UI DETAILS ............................................................................................................................................................................................ 15

Main UI ............................................................................................................................................................................................................ 15

Web Slicer UI ............................................................................................................................................................................................. 17

USING THE WEB SLICER ......................................................................................................................................................................... 18

AUTO CALIBRATION .................................................................................................................................................................................. 19

ABOUT RESINS ................................................................................................................................................................................................ 19

Resin Storage ............................................................................................................................................................................................. 19

Resin Operation ....................................................................................................................................................................................... 19

2

Page 3

Safety and Resin ..................................................................................................................................................................................... 19

Transferring Resin to Storage .................................................................................................................................................... 20

Discarding Resin ..................................................................................................................................................................................... 20

PRINTING TIPS ................................................................................................................................................................................................ 20

CREATION WORKSHOP ........................................................................................................................................................................... 21

SLICING WITH CREATION WORKSHOP .................................................................................................................................... 25

MODEL CLEANING ..................................................................................................................................................................................... 26

CLEANING THE RESIN VAT .................................................................................................................................................................. 26

TROUBLESHOOTING ................................................................................................................................................................................. 27

TECHNICAL SUPPORT .............................................................................................................................................................................. 28

SPECIFICATIONS ........................................................................................................................................................................................... 28

SAFETY WARNINGS AND GUIDELINES

Please read this entire manual before using this device, paying extra attention to these

safety warnings and guidelines. Please keep this manual in a safe place for future reference.

This device is intended for indoor use only.

Do not expose this device to water or moisture of any kind. Do not place drinks or

other containers with moisture on or near the device. If moisture does get in or on

the device, immediately unplug it from the power outlet and allow it to fully dry

before reapplying power.

Do not touch the device, the power cord, or any other connected cables with wet

hands.

Do not install this device on an unstable surface where it could fall and cause either

personal injury or damage to the device and/or other equipment.

3

Page 4

Do not expose this device to excessively high temperatures. Do not place it in, on,

or near heat sources, such as a fireplace, stove, radiator, etc. Do not leave it in direct

sunlight.

Do not place or install this device in an area where it can be exposed to excessive

amounts of dust, humidity, oil, smoke, or combustible vapors.

Use only in a well-ventilated area. Do not use in close, confined spaces.

Prior to operation, check the unit and power cord for physical damage. Do not use if

physical damage has occurred.

Before plugging the unit into a power outlet, ensure that the outlet provides the

same type and level of power required by the device.

Unplug this device from the power source when not in use.

Take care to prevent damage to the power cord. Do not allow it to become

crimped, pinched, walked on, or become tangled with other cords. Ensure that the

power cord does not present a tripping hazard.

Never unplug the unit by pulling on the power cord. Always grasp the connector

head or adapter body.

This printer has many moving parts. Do not reach inside during printing.

For best results, the ambient/room temperature should be +59 ~ +86°F (+15 ~

+30°C) and the relative humidity should be 20 ~ 50%.

This printer should be placed away from light and should be operated in the dark.

If any resin or liquid gets into the printer, clean it out immediately.

Wear gloves, such as nitrile or neoprene when working with uncured resin. Do not

use latex gloves. If resin gets on your skin, immediately wash it off with soap and

warm water.

Wear safety glasses/goggles when working with uncured resin. If resin gets in your

eye(s), immediately flush with cold, clean water, then consult a doctor.

Clean the resin vat after printing.

Keep out of reach of children.

4

Page 5

INTRODUCTION

This printer uses an LCD screen to mask a cross section of your model, one layer at a time,

using a 405nm UV light array to cure resin held in a vat. The LCD screen is positioned

beneath a vat of resin, with a transparent film separating the resin and screen. Between

layers, the printer will lift (or "Raise") the print and return it one layer higher than

previously. This lifting action allows uncured resin to flow under the print and back into the

vat. This process is repeated layer by layer to shape the object.

Because of how it this style of printing works:

Finer levels of detail are able to be printed than with FFF or filament printers. This

printer is equipped with a 2K screen to print at higher resolutions.

The height of the object is the main determinant on how long it will take to print

the object. Additional models across the build platform will not increase time, as

long as the height does not increase.

Supports should be included in any areas that would be "Islands", or areas that

would not be touching the already printed parts of the model. They should also be

used for heavy pieces that risk falling off of the build plate.

Keeping the build platform, resin vat, and transparent film clean of debris and cured

resin is a must for successful printing.

Cleaning the print and final curing are necessary post processing steps. Natural

sunlight produces all the UV light necessary to cure the final print. Exposure to

sunlight on a well-lit window sill for half an hour or longer will be sufficient for the

final curing process.

5

Page 6

USEFUL TOOLS

There are a few tools that will make life easier when working with a resin printer. Some of

these are more important than others, but this list covers what a good workstation should

contain in ideal conditions.

Disposable Gloves: Always wear gloves when working with uncured resin. Nitrile gloves

are what we use in our lab. Neoprene gloves are also useable. Do not use latex

gloves. If resin gets on your skin, immediately wash it off with soap and warm

water.

Safety Glasses/Goggles: Always wear safety glasses/goggles when working with

uncured resin. If resin gets in your eye(s), immediately flush with cold, clean water,

then consult a doctor.

Metal Scraper: A putty knife or similar instrument can help remove prints from the build

plate when they stick a little too well.

Isopropyl Alcohol: Isopropyl alcohol is used for cleaning the finished print and any tools

that have come in contact with resin.

Spare Containers: Spare containers are always useful with liquid resin. They can be used

to store used resin, which you will recycle, to wash your finished print (be sure that

the container can be used with isopropyl alcohol), or to hold tools after they have

come in contact with the resin.

Plastic Scraper: A plastic scraper, such as an expired credit card, is used in the event

that a print fails and sticks to the FEP liner at the bottom of the resin vat. Refer to

the

CLEANING THE RESIN VAT

Paper Towels: Use paper towels to clean the workstation and prevent dripping on your

workstation.

Aluminum Foil, Plastic Wrap, or Plastic Liner: Use any of these products to protect your

workstation from resin drips.

Storage: You need a place to store everything to make the workflow easier.

section for more information.

6

Page 7

CUSTOMER SERVICE

The Monoprice Customer Service department is dedicated to ensuring that your ordering,

purchasing, and delivery experience is second to none. If you have any problem with your

order, please give us an opportunity to make it right. You can contact a Monoprice

Customer Service representative through the Live Chat link on our website

www.monoprice.com or via email at support@monoprice.com. Check the website for

support times and links.

PACKAGE CONTENTS

Please take an inventory of the package contents to ensure you have all the items listed

below. If anything is missing or damaged, please contact Monoprice Customer Service for a

replacement.

1x 3D printer

1x microSD™ memory card

1x Hex wrench

1x Bottle sample resin

1x AC power adapter

1x AC power cord

7

Page 8

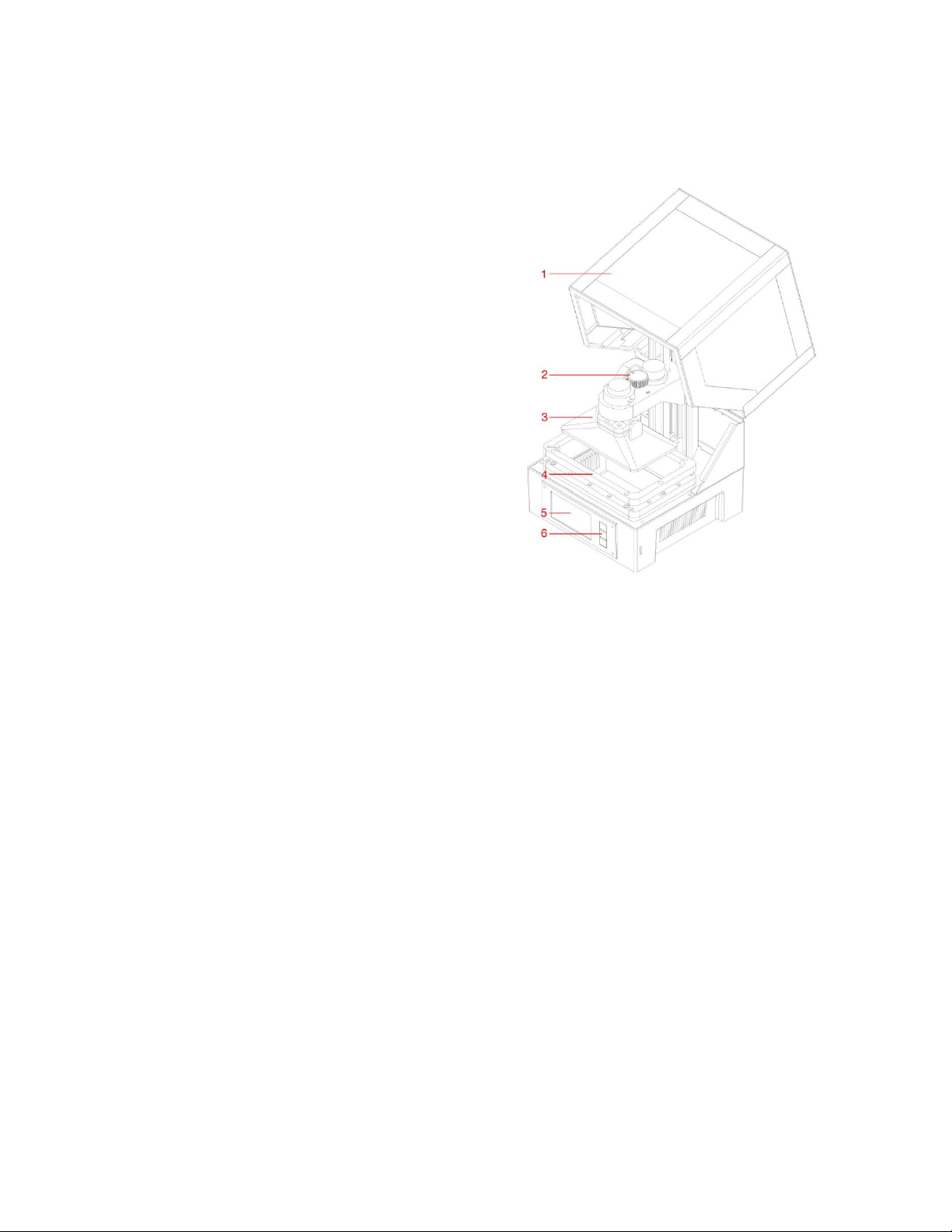

PRODUCT OVERVIEW

1. Acrylic Cover

2. Leveling Knob

3. Printing Platform

4. Resin Vat

5. LCD Display

6. Control Buttons

CONTROL BUTTONS

The control buttons on the front panel perform the following functions.

Press the top button to move the highlight left or up.

Press the top button while editing a value to decrease the value.

Press the bottom button to move the highlight to the right or down.

Press the bottom button while editing a value to increase the value.

Press the center button to select the highlighted menu item or to save an edited

value.

8

Page 9

MENU FUNCTIONS

Main Menu

1. Print: Select this option to print from a microSD™ card.

2. Profile: Select this option to manage the profile file being used.

3. Control: Select this option to display the Control Menu.

Control Menu

1. Z Axis: Select this option to control the movement of the Z axis.

2. Home: Select this option to move the printer to the Home position. The Home

position for this printer is when the printing platform is at its lowest point in the

resin vat.

3. Clear: Select this option to turn the UV lamp on for 10 seconds. This can be used to

clean the resin vat by curing an entire layer and peeling it from the FEP liner.

4. Back: Select this option to return to the Main Menu.

9

Page 10

Print Menu

1. ETA: Displays the estimated remaining print time.

2. Print Phase: Displays either EXPOSURE or LIFT, indicating the action being currently

performed.

3. LAYERS: Displays the number of layers printed and the total number of layers for

the model.

4. BaseCureTime: Select this option to adjust the number of seconds to expose each

of first three layers. Use the top and bottom buttons to change the value. Press the

center button to save the changes.

5. CureTime: Select this option to adjust the number of seconds to expose each layer

other than the three layers. Use the top and bottom buttons to change the value.

Press the center button to save the changes.

6. RaiseDistance: Select this option to adjust the number of millimeters to raise the

platform between each layer. Use the top and bottom buttons to change the value.

Press the center button to save the changes.

7. Pause: Select this option to pause printing. Select it again to resume printing. Note

that the printer will finish exposing the current layer before pausing.

8. Height: Displays the printed height and total height of the model in millimeters.

9. Cancel: Select this option to cancel the current print.

10

Page 11

Finish Screen

1. ONE MORE: Select this option to print the model again.

2. GO HOME: Select this option to return to the Main Menu.

PREPARING THE PRINTER

Before you run your first test print, there are a few steps that you should take to begin

printing.

1. Check the printer for issues:

Verify that the Z axis can move freely and that there is no debris or packaging

material on the Z axis lead screw. Use the Z Axis option on the Control Menu to

raise the build plate to near the top of the printer.

Verify that the FEP liner in the Resin Vat is clean and clear of any packaging

material or cured resin.

Verify that the LCD Display and UV Lamp are functional by selecting the Clear

option on the Control Menu, while observing the bottom of the empty Resin

Vat.

If any issues arise while checking the printer, please contact Technical Support

for assistance.

2. Add resin to the Resin Vat.

a. Move the print bed up to near the top of the Z axis.

b. Twist to remove the magnetic Printing Platform.

11

Page 12

c. Shake the resin prior to filling the Resin Vat. Pigments can settle to the bottom

of the bottle, so make sure they are mixed properly prior to pouring.

d. Pour resin to fill the vat about half way. If recycling used resin, be sure to filter it

to prevent cured resin from entering the vat and causing complications with the

auto leveling system.

QUICK START GUIDE

To get started quickly, follow these steps to make a test print:

1. Remove the packaging materials from the box. Check the printer's Z axis for debris

from the packaging material.

2. Insert the microSD™ card into the card slot on the printer, then power the printer

on.

3. Select the Control option on the Main Menu to open the Control Menu.

4. Verify that the printing LCD Display turns on by selecting the Clear option on the

Control Menu. The display will turn on for about 10 seconds.

5. Ensure that the Resin Vat and build plate are clean and free of packaging material

and debris. Refer to the

6. Shake the resin bottle to ensure it is properly mixed.

7. Fill the Resin Vat about half way using the included sample resin.

8. Select the Back option on the Control Menu to return to the Main Menu.

9. Select the Print option on the Main Menu.

10. Select a model file from the list. You will be prompted to select a profile to use.

Select Okay to print using the default print profile. The printer will go to its Home

position, perform its leveling process, then start printing.

11. Once the print is finished, twist the build plate to remove it. We recommend

twisting to release the magnets, as they have a relatively strong force and pulling

CLEANING THE RESIN VAT

section for details.

directly may drive the Printing Platform and the print into the Resin Vat.

12

Page 13

12. Scrape the print from the build plate into a small container. Fill the container with

Isopropyl Alcohol (91% or greater can be found at your local drugstore).

13. Cover the container, then shake vigorously for about 30-60 seconds. Refer to the

MODEL CLEANING

14. Place the finished print in sunlight to perform the final cure.

section for more detail.

WI-FI® SETUP

Perform the following steps to configure the printer to connect with your home's Wi-Fi®

network. Use of Wi-Fi is not required, you can print from the microSD™ card if you do not

wish to use a Wi-Fi connection. Note that the printer can only connect to a 2.4GHz Wi-Fi

network. The Web UI can only be accessed using a Wi-Fi connection.

1. Plug in and power on the printer. The first time it is powered on, the following

screen will be displayed.

2. Open your web browser on your computer, then navigate to http://bit.ly/linksla

3. Enter your Wi-Fi® SSID and password into the fields in your web browser, then click

the Generate button. The website will generate and download a file to the

Downloads directory on your PC that contains your Wi-Fi login information.

13

Page 14

4. Locate the wifi.conf file in the Download directory, then copy it to the included

microSD™ card.

5. Ensure the printer is powered off.

6. Insert the microSD card into the card slot, then turn the printer on. The printer will

automatically read the generated file and will connect to your Wi-Fi network. After

it connects, the printer will automatically delete the file from the microSD card.

If you need to change the Wi-Fi login information, repeat steps 2-6 above.

ACCESSING THE WEB UI

Once you have established a Wi-Fi® connection, you can access and control the printer

using your web browser. Perform the following steps to access the Web UI.

1. If you have not already, perform the steps in the

2. Power the printer on. The Wi-Fi IP is displayed in the upper left corner of the Main

Menu.

3. Type the IP address into your browser's address window, then press the ENTER key.

4. The first time you access the Web UI, the printer will display an Access Code.

WI-FI SETUP

section above.

14

Page 15

5. Enter the Access Code into the field on your web browser, then click the Submit

button.

WEB UI DETAILS

Main UI

1. Displays an image of the current layer being printed.

2. The printer management window allows you to Start, Pause, or Cancel prints. You

can also review the status of the current print.

3. Upload the print files by dragging and dropping sliced print files from your PC into

this window. The file will be copied to the microSD™ card using the Wi-Fi®

connection. Sliced files are generated using the Web Slicer, Creation Workshop, or

Print Studio.

4. This window displays a list of print files on the microSD card. Select a print file, click

Print, then select a profile to begin printing. If files have been added or removed,

click Refresh to refresh the print file list.

15

Page 16

5. You can create and review profiles in this window by selecting the value, then

typing in the new parameters.

Resin: Displays or changes the name of the profile file.

Burn in second: Displays or changes the cure time for the base three layers.

Different manufacturers have different cure times for their resins. Monoprice

resin has a nominal cure time of 60 seconds for the three base layers.

Exposure second: Displays or changes the cure time for the layers other than the

base three layers. Different manufacturers have different cure times for their

resins. Monoprice resin has a nominal cure time of 8 seconds for layers other

than the first three layers.

Separation: Displays or changes the raise distance, which is the number of

millimeters that the printing platform lifts between layers to allow the uncured

resin to flow back into the Resin Vat. Different manufacturers have different

viscosities for their resin. For more viscous resins, a higher lift height may be

necessary.

6. Web slicer: Click the button to display the Web Slicer.

16

Page 17

Web Slicer UI

1. Upload an STL 3D model file by dragging and dropping the file onto the Web Slicer

screen.

2. Adjust the Layer Height, Exposure Time, Lift Height, and Lift Speed parameters.

a. Layer Height: The vertical size in millimeters of each printed layer. Smaller values

will result in a smoother surface on the finished print model, but will take longer

to print. On the other hand, larger values will result in a coarser surface, but will

take less time to print.

b. Exposure Time: The amount of time that the UV light will expose each layer

during printing. Different manufacturers have different cure times for their

resins. Monoprice resin has a cure time of 8 seconds for layers other than the

base three layers.

c. Lift Height: The number of millimeters that the Printing Platform is lifted out of

the Resin Vat between layers. Different manufacturers have different viscosities

for their resin. For more viscous resins, a higher lift height may be necessary.

d. Lift Speed: The speed at which the Printing Platform is lifted from the Resin Vat

between layers.

17

Page 18

USING THE WEB SLICER

1. Turn the printer on. Type the IP address in the upper left corner of the Main Menu

into your web browser's address bar, then press the Enter key.

2. Click the Slicer entry in the upper left corner of the Main UI.

3. Load an STL model file using the file browser. Alternatively, you can drag and drop

an STL file directly onto the interface.

4. Use the controls in the Build Volume section to

change the size of the build area. This defaults to the

maximum print size for the printer and should rarely

need to be changed.

5. Use the controls in the Transformations section to

rotate, mirror, or scale the model.

6. Click the Slice button to begin slicing the model

7. After slicing is finished, click the Download button to

download the finished GIF file to your computer.

Alternatively, click the Print button to send the file

directly to the printer.

8. Copy the downloaded GIF file to the included microSD™ card. Alternatively, you can

upload the print file using the Web UI to save it to the microSD card inserted in the

printer using Wi-Fi®.

18

Page 19

9. With the printer powered off, insert the microSD™ card into the card slot.

AUTO CALIBRATION

Whenever the printer is sent to the Home position or whenever a print is started, the

printer will automatically calibrate the Printing Platform. This requires the Resin Vat to be

free of cured resin particles or print failures can occur.

ABOUT RESINS

Resin Storage

Resins should be kept in a dark and ventilated place. The storage location should be kept in

the +68 ~ +86°F (+20 ~ +30°C) temperature range. Lower temperatures can extend the

shelf life. The official shelf life is one year.

Resin Operation

Wear gloves when working with resin to prevent direct skin exposure. If resin does get on

your skin, wash the exposed area immediately with soap and warm water.

Cured resin is safe to handle without gloves. Printed models should not be used for food

applications.

Safety and Resin

There are many types of resins and resin manufacturers. This section contains general

safety guidelines for handling resin.

Wear gloves when working with uncured resin.

Wear safety glass/goggles when working with resin.

Do not eat or drink resin.

Refer to the Material Safety Data Sheet (MSDS).

19

Page 20

Transferring Resin to Storage

When you use resin, small portions can be unintentionally cured. For this reason, it is

recommended to not mix used resin and unused resin. The used resin can be filtered using

a fine mesh to remove any cured bits. For best results, store the resin in a black container

with a lid. The container should be stored in a dark, ventilated place to prevent curing

during storage.

Discarding Resin

Before discarding resin, it should be fully cured. The easiest way to cure the resin is to pour

it into a clear, disposable cup, then placing the cup in direct sunlight until the resin is fully

cured.

PRINTING TIPS

Check the Resin Vat and Printing Platform before printing to ensure they are clean.

After removing the model, cover the lid to prevent the remaining resin curing.

After printing is finished, store the remaining resin in another container or leave it in

the Resin Vat. The shelf life will be significantly shorter for used resin. Adding fresh

resin can increase the shelf life.

20

Page 21

CREATION WORKSHOP

The following screen is displayed when the Creation Workshop program is executed.

Click the button to load an STL or OBJ model file.

Click the button to save the loaded model file in Creation Workshop format.

Click the button to slice the loaded model file.

21

Page 22

After a model file has been loaded, the following screen is displayed.

After the model has been loaded, you can add supports, as needed.

Click to open the Support Generation menu.

Click , then click on the model to manually add a support to that location.

Click to add bottom supports.

Click to automatically add necessary supports to the model.

You can control the size and shape of supports using the Support

Shape portion of the screen. Note that the top of the support must

not be less than 0.25mm and the base must not be less than 0.6mm.

Note that if you model using PRO/E or CREO, the FRONT face is the

bottom of the model instead of the TOP.

22

Page 23

The imported model may differ in size and location from the print

area. You can adjust the model using the controls on the Property

Bar on the right side of the screen.

The Move (mm) button allows you to easily and quickly locate the

model file. Clicking the button reveals the following options:

Click to "fit the base". This should be done prior to

each cut.

Click to move the XYZ axis absolute to the middle.

Click to move the model to the middle of the build platform.

Click the Configure button, then click Configure Slicing Profile to display the following

screen.

23

Page 24

Special note should be made of the following options:

Enable Slice Outlines: This is the feather value option. The larger the value, the

smoother the printed model will be. This can reduce the model pixel pattern. The

general value of 3 or more can effectively alleviate.

Slice Thickness (mm): The setting range is 0.02 - 0.1 mm, with a default value of

0.05mm. The smaller the thickness is, the higher the accuracy and the more time it

takes to print. Exposure time can be reduced if the layer thickness is smaller.

Exposure Time (ms): This value can be set according to the actual situation. The

default is 15 seconds. Smaller and simpler models can reach up to 3 seconds. If the

details of the print cannot be shown during printing, the single exposure time

should be increased. For models with holes, a shorter curing time is better. For

models with smaller columns, the longer the curing time, the better the effect.

Bottom Exposure (ms): The default exposure time for the bottom layers is 60

seconds. When printing smaller and simpler models, the exposure time can be as

short as 5 seconds. Increase the exposure time if the model won't stick to the build

platform. The longer the exposure time is, the more tightly the model will stick to

the build platform.

Z-axis Lift Distance (mm): This value can be set according to the model size. If the

area is too large but the lifting height is low, the resin cannot be returned to the

middle of the model, resulting in a bubble in the middle, a defect, or print failure.

Z-axis Lift Speed (mm/m): The default value is 100mm/m. It is recommended to use

a value between 50-150 mm/m.

Z-axis Retraction Speed (mm/m): The default value is 100mm/m. It is recommended

to use a value between 100-150 mm/m.

Note: Click Apply Changes to save your custom settings.

24

Page 25

Click the Configure button, then click Configure Machine to display the following screen.

If the print size is different from the actual size, you can change the display size. Correct

the print size by adjusting the XY values in the Build Size (mm) section. Click Apply

Changes to save your settings.

SLICING WITH CREATION WORKSHOP

Perform the following steps to slice a model using Creation Workshop.

1. Run the Creation Workshop software program on the included microSD™ card.

2. Click the button to load a model file (STL or OBJ).

3. Click the button to save the loaded model file in Creation Workshop format.

4. Click the button to slice the loaded model file.

25

Page 26

5. Copy the resulting CWS file to the microSD™ card or send it over the network to

the printer.

MODEL CLEANING

Perform the following steps to clean your finished print/model.

1. Once the print has completed, twist to remove the build platform, then use a metal

putty knife or spatula to remove the print from the platform.

2. Place the model in a container filled with isopropyl alcohol. Cover the container,

then shake it vigorously for about 30-60 seconds.

Note that the cleaning time should not be more than 5 minutes. If it is cleaned for too long,

the details on the model will soften and the model surface will begin to whiten. The

cleaning time should be shorter if the finished print has a lot of small/fine details.

3. Once cleaning is finished, place the model in a sunny location or under a UV light.

The curing time will depend on the type of resin used.

CLEANING THE RESIN VAT

It is not uncommon for cured resin to stick to the FEP lining in the bottom of the resin vat.

Perform the following steps while wearing gloves to clean this type of obstruction.

1. Use the included hex wrench to remove the protruding screw on the left side and

the protruding screw on the right side of the resin vat.

2. Pour the resin from the vat into a separate container. Do not pour it back into the

original resin bottle. A mesh strainer can help remove small pieces of free floating,

cured resin.

3. Using a plastic spatula, an expired bank/credit card, or other plastic tool that does

not have sharp edges, gently peel the resin from the FEP lining. The FEP lining is

extremely thin and can be torn or punctured if approached too aggressively or with

a sharp tool. Remove any remaining pieces of cured resin.

26

Page 27

4. Use isopropyl alcohol and paper towels, clean the vat of any remaining resin. The

FEP liner should be as clean as possible.

5. Reinstall the vat into the printer.

TROUBLESHOOTING

1. If the print finishes and there is nothing on the build platform, there can be three

potential reasons:

The first layers did not cure enough and the print has fallen off the Printing

Platform. Increase the base cure time. For Monoprice resins, the base cure time

should be 60 seconds. Other resins may require different amounts of time.

The Printing Platform did not level correctly. Verify that there are no small

particles from previous prints in the resin vat, as this will disrupt the leveling

process. Keeping the resin vat clear of small pieces of cured resin in an absolute

necessity.

Run the "Clear" function on the Control Menu to verify that the LCD screen is

turning on and off.

2. If the first layers are present, but the rest of the model is missing, there can be two

reasons:

The cure time for the resin in not long enough. The model likely fell into the vat

and it will be necessary to remove it before attempting to print again. The

default exposure time for Monoprice resins is 8 seconds for layers other than the

first three layers.

The model has insufficient supports. Add additional supports to compensate for

the weight of the model during printing.

27

Page 28

TECHNICAL SUPPORT

Model

35435

Maximum Print Size

4.6" x 2.6" x 4.3" (118 x 65 x 110 mm)

Resolution

0.05mm

UV Wavelength

405nm

Interface

Wi-Fi®, microSD™ card

File Format

STL, OBJ

Software

Creation Workshop, Web Slicer, Print

Studio

Input Power

12 VDC, 5A

AC Adapter Input Power

100 ~ 240 VAC, 50/60 Hz

Dimensions

10.2" x 10.2" x 15.2" (260 x 260 x 385 mm)

Weight

6.6 lbs. (3.0 kg)

Monoprice is pleased to provide free, live, online technical support to assist you with any

questions you may have about installation, setup, troubleshooting, or product

recommendations. If you ever need assistance with your new product, please come online

to talk to one of our friendly and knowledgeable Tech Support Associates. Technical

support is available through the online chat button on our website www.monoprice.com

or through email by sending a message to tech@monoprice.com. Check the website for

support times and links.

SPECIFICATIONS

microSD™ is a trademark of SD-3C, LLC.

Wi-Fi® is a registered trademark of Wi-Fi Alliance.

28

Loading...

Loading...